Metabolic Energy Consumption during Green Area Management

Abstract

:1. Introduction

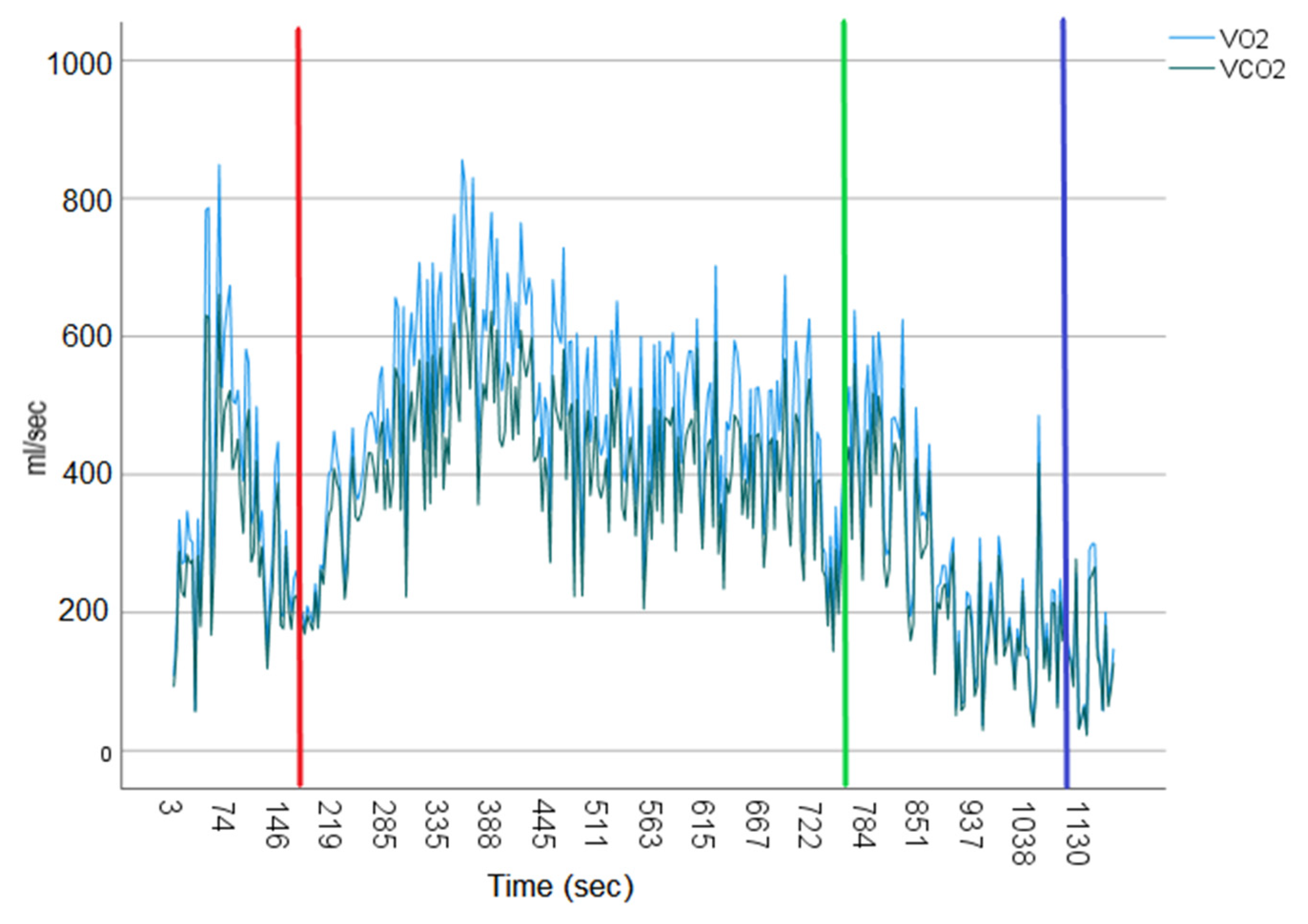

2. Materials and Methods

2.1. Field Sampling and Employed Equipment

2.2. Determination of Metabolic Rate from Oxygen Consumption Rate

2.3. Statistical Analysis

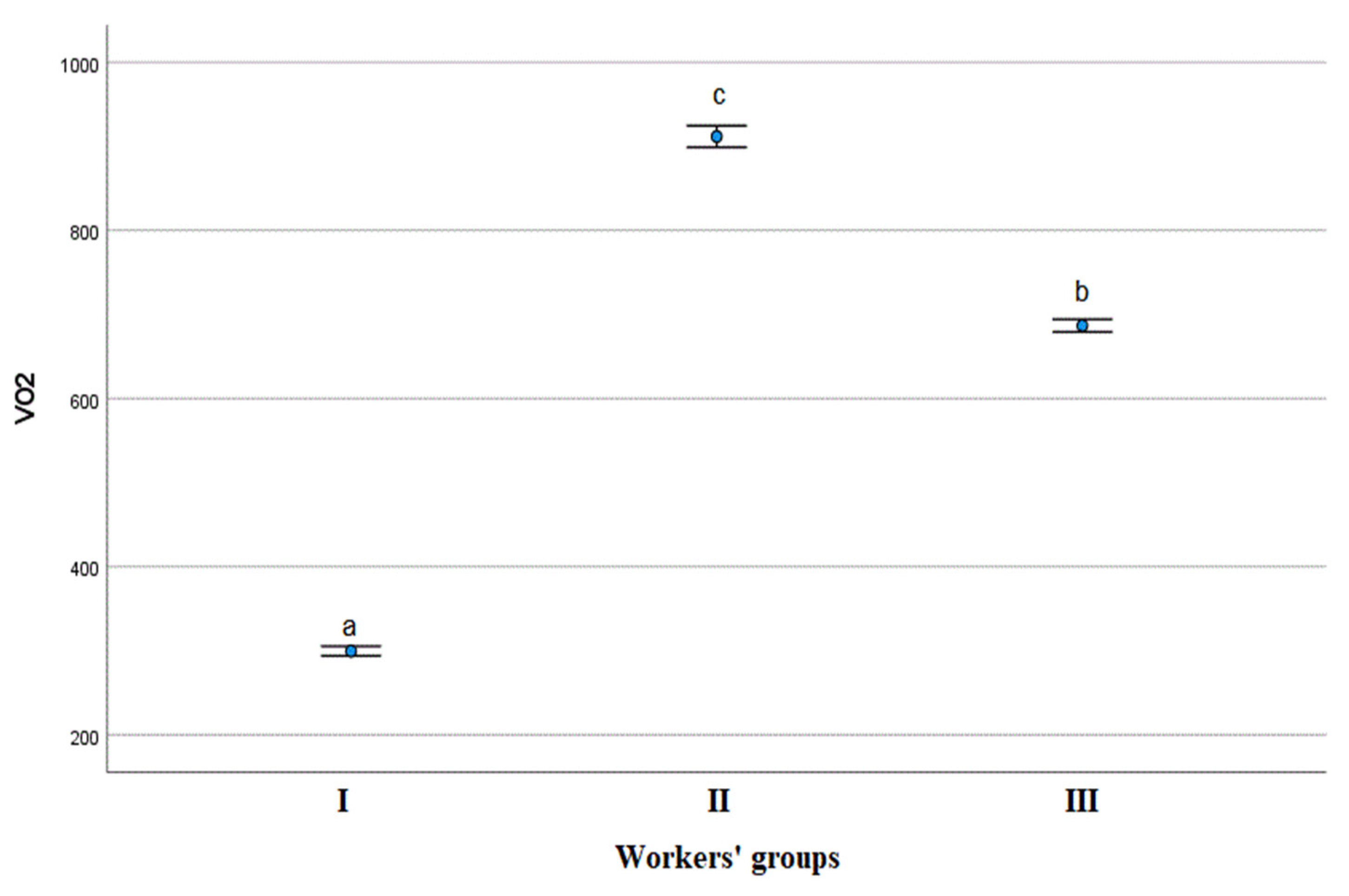

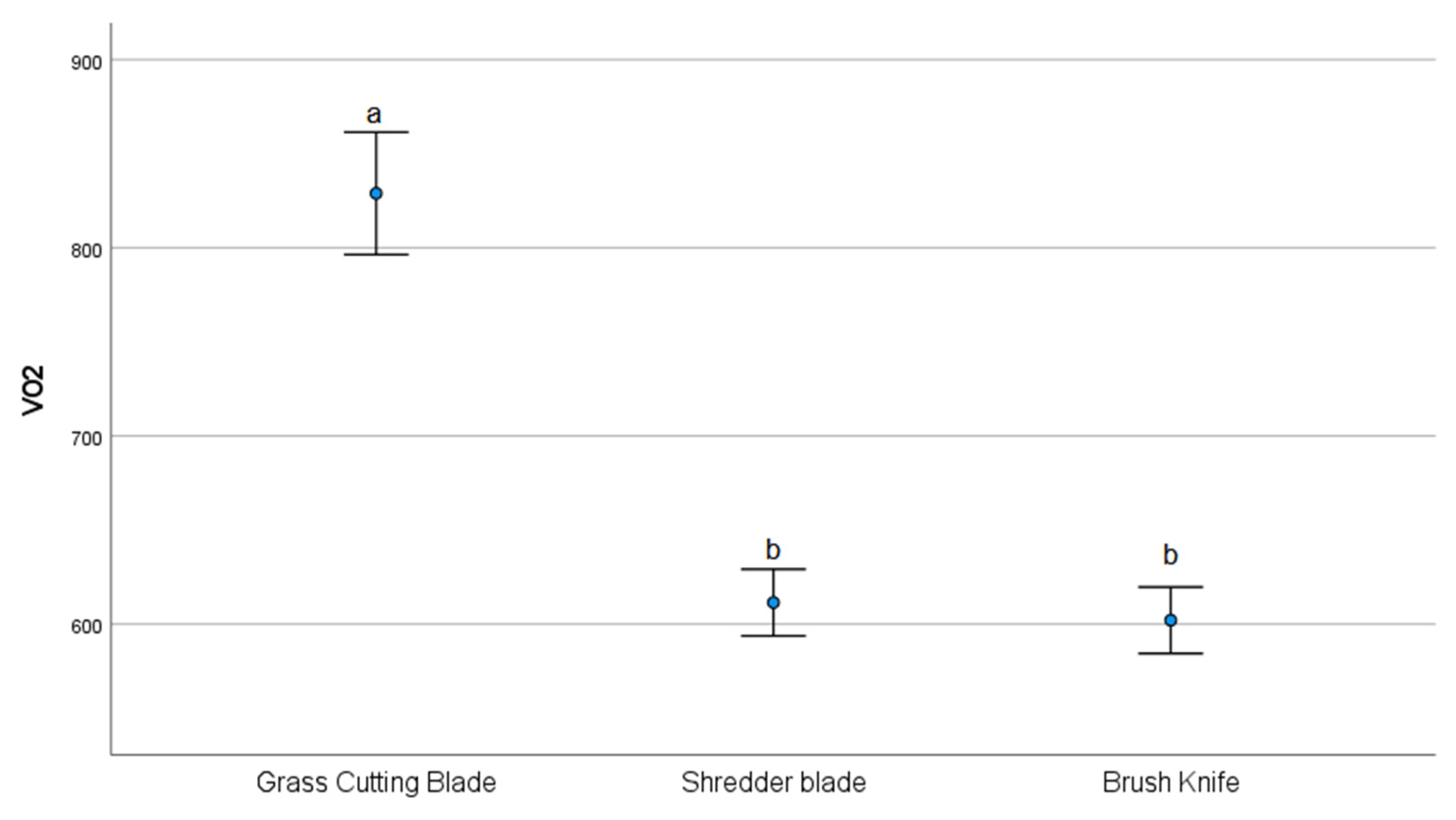

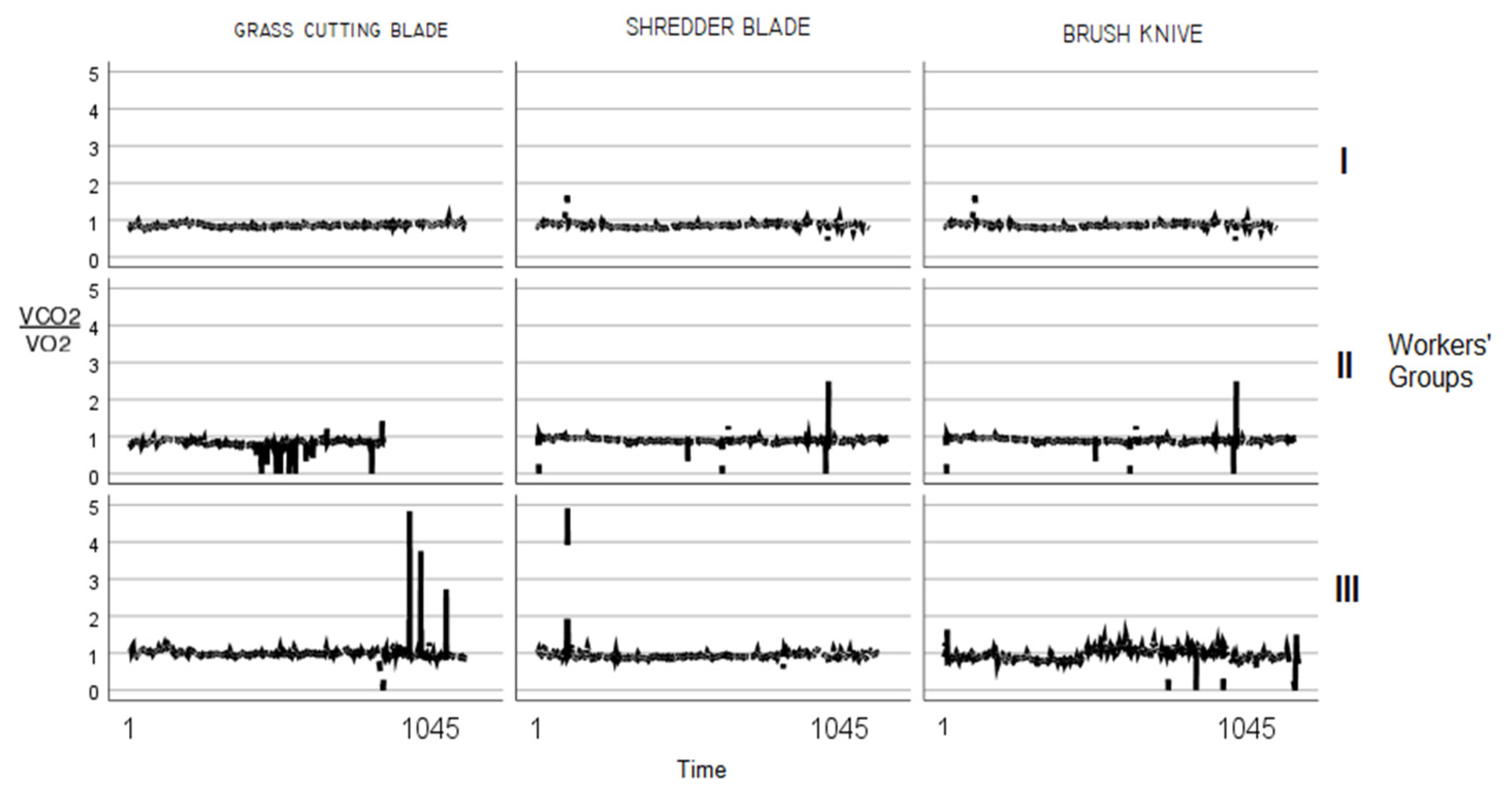

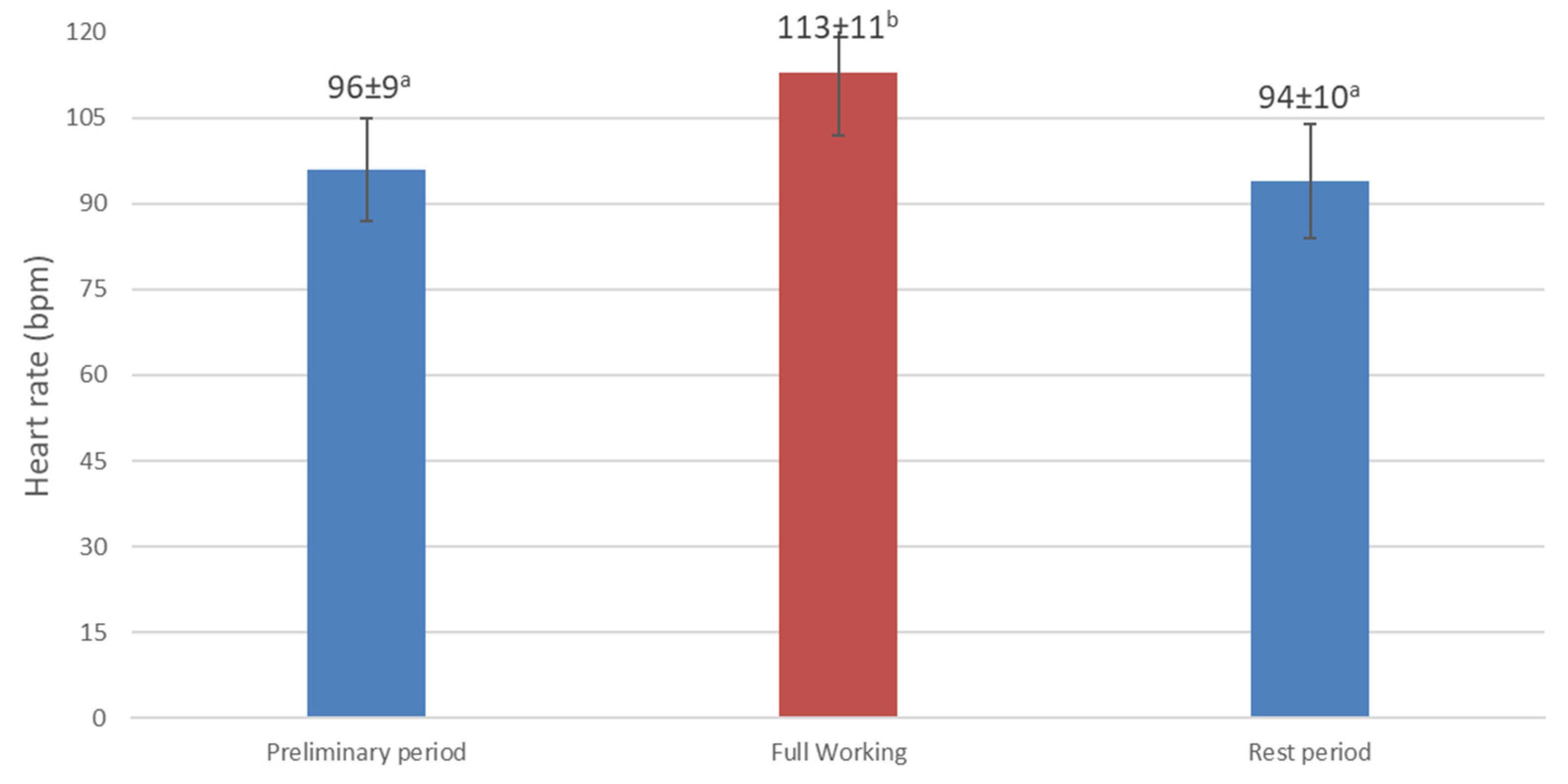

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Campagnaro, T.; Sitzia, T.; Cambria, V.E.; Semenzato, P. Indicators for the Planning and Management of Urban Green Spaces: A Focus on Public Areas in Padua, Italy. Sustainability 2019, 11, 7071. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M.; Haber, N.; Puri, D. The Impact of Human Error in the Use of Agricultural Tractors: A Case Study Research in Vineyard Cultivation in Italy. Agriculture 2018, 8, 82. [Google Scholar] [CrossRef]

- Iofrida, N.; De Luca, A.I.; Silveri, F.; Falcone, G.; Stillitano, T.; Gulisano, G.; Strano, A. Psychosocial risk factors’ impact pathway for social life cycle assessment: An application to citrus life cycles in South Italy. Int. J. Life Cycle Ass. 2018, 24, 767–780. [Google Scholar] [CrossRef]

- Bernardi, B.; Quendler, E.; Benalia, S.; Mantella, A.; Zimbalatti, G. Occupational risks related to vibrations using a brush cutter for green area management. Ann. Agric. Environ. Med. 2018, 25, 255–258. [Google Scholar] [CrossRef]

- Aiello, G.; La Scalia, G.; Vallone, M.; Catania, P.; Venticinque, M. Real time assessment of hand-arm vibration system based on capacitive MEMS accelerometers. Comput. Electron. Agric. 2012, 85, 45–52. [Google Scholar] [CrossRef]

- Gómez-Galán, M.; Pérez-Alonso, J.; Callejón-Ferre, Á.-J.; López-Martínez, J. Musculoskeletal disorders: OWAS review. Ind. Health 2017, 55, 314–337. [Google Scholar]

- Gómez-Galán, M.; Pérez-Alonso, J.; Callejón-Ferre, Á.-J.; Sánchez-Hermosilla-López, J. Assessment of Postural Load during Melon Cultivation in Mediterranean Greenhouses. Sustainability 2018, 10, 2729. [Google Scholar] [CrossRef]

- EN ISO 8996:2021. Ergonomics of the Thermal Environment-Determination of Metabolic Rate. International Organization for Standardization: Geneva, Switzerland, 2021.

- Sunkpal, M.; Roghanchi, P.; Kocsis, K.C. A method to protect mine workers in hot and humid environments. Saf. Health Work 2018, 9, 149–158. [Google Scholar] [CrossRef]

- Ventura, F.; D’Auria, R. Prevenzione e Sicurezza Sul Lavoro in Agricoltura: Conoscenze e Costi Per le Aziende Agricole; Rete Rurale Nazionale—MiPAAF—DISRII: Rome, Italy, 2014. [Google Scholar]

- Del Ferraro, S.; Molinaro, V. Lo studio dell’attività metabolica per una corretta valutazione del rischio da esposizione ad ambienti termici. La Med. Del Lav. 2010, 101, 38–48. [Google Scholar]

- Marucci, A.; Monarca, D.; Cecchini, M.; Colantoni, A.; Di Giacinto, S.; Cappuccini, A. The heat stress for workers employed in a dairy farm. J. Agric. Eng. 2014, 44, 170. [Google Scholar] [CrossRef]

- Lucena, A.; Guedes, J.; Vaz, M.; Silva, L.; Bustos, D.; Souza, E. Modeling Energy Expenditure Estimation in Occupational Context by Actigraphy: A Multi Regression Mixed-Effects Model. Int. J. Environ. Res. Public Health 2021, 18, 10419. [Google Scholar] [CrossRef] [PubMed]

- Guidetti, L.; Meucci, M.; Bolletta, F.; Emerenziani, G.P.; Gallotta, M.C.; Baldari, C. Validity, reliability and minimum detectable change of COSMED K5 portable gas exchange system in breath-by-breath mode. PLoS ONE 2018, 13, e0209925. [Google Scholar] [CrossRef]

- DeBlois, J.P.; White, L.E.; Barreira, T.V. Reliability and validity of the COSMED K5 portable metabolic system during walking. Eur. J. Appl. Physiol. 2021, 121, 209–217. [Google Scholar] [CrossRef] [PubMed]

- Mtaweh, H.; Tuira, L.; Floh, A.A.; Parshuram, C.S. Indirect Calorimetry: History, Technology, and Application. Front. Pediatr. 2018, 6, 257. [Google Scholar] [CrossRef] [PubMed]

- Ainsworth, B.E.; Haskell, W.L.; Herrmann, S.D.; Meckes, N.; Bassett, D.R., Jr.; Tudor-Locke, C.; Greer, J.L.; Vezina, J.; Whitt-Glover, M.C.; Leon, A.S. Compendium of Physical Activities: A Second Update of Codes and MET Values. Med. Sci. Sports Exerc. 2011, 43, 1575–1581. [Google Scholar] [CrossRef]

- Poulianiti, K.P.; Havenith, G.; Flouris, A.D. Metabolic energy cost of workers in agriculture, construction, manufacturing, tourism, and transportation industries. Ind. Health 2019, 57, 283–305. [Google Scholar] [CrossRef]

- Callea, P.; Zimbalatti, G.; Quendler, E.; Nimmerichter, A.; Bachl, N.; Bernardi, B.; Smorto, D.; Benalia, S. Occupational illnesses related to physical strains in apple harvesting. Ann. Agric. Environ. Med. 2014, 21, 407–411. [Google Scholar] [CrossRef]

- Tamilselvi, P.; Anantha, K.D. Ergonomic evaluation of conventional agricultural sprayers with respect to human performance. Agric. Sci. Dig. 2016, 36, 179–184. [Google Scholar] [CrossRef]

- Chethan, C.R.; Krishnan, D.A. Dynamic push-pull strength data generation for agricultural workers to develop manual dryland weeders. Curr. Sci. 2017, 113, 1601–1605. [Google Scholar] [CrossRef]

- Araie, T.; Nishizawa, U.; Ikeda, T.; Kakimoto, A.; Toyama, S. Evaluation of Labor Burden Reduction Achieved through Wearing an Agricultural Power Assist Suit. Int. J. Model. Optim. 2017, 7, 202–206. [Google Scholar] [CrossRef]

- Okubo, N.; Nakagawa, H.; Furuya, K.; Toi, T. Vibration Reduction of Brush Cutter. In Topics in Modal Analysis, Proceedings of the 31st IMAC, A Conference on Structural Dynamics, Garden Grove, CA, USA, 11–14 February 2013; Allemang, R., De Clerck, J., Niezrecki, C., Wicks, A., Eds.; Conference Proceedings of the Society for Experimental Mechanics Series 45; Springer: New York, NY, USA, 2013; Volume 7, pp. 377–387. [Google Scholar]

- Lstiburek, J. Relative humidity. In Proceedings of the Healthy Indoor Environments, Austin, TX, USA; 2003. [Google Scholar]

- COSMED, Suite Software Manuale Utente, V Edizione, 272; COSMED: Rome, Italy, 2013.

- Parr, B.B.; Strath, S.J.; Bassett, D.R., Jr.; Howley, E.T. Validation of the Cosmed K4b2 portable metabolic measurement system. Med. Sci. Sport Exerc. 2001, 33, 300. [Google Scholar] [CrossRef]

- Bernardi, B.; Abenavoli, L.M.; Franco, G.; Fazari, A.; Zimbalatti, G.; Benalia, S. Worker’s metabolic rate assessment during weeding. Qual. Access Success 2020, 21, 139–141. [Google Scholar]

- Yadav, R.; Pund, S.; Gite, L.P. Ergonomic evaluation of male and female operators during weeding operation. Agric. Mech. Asia Afr. Lat. Am. 2010, 41, 26–29. [Google Scholar]

- Ocan, H.; Kinabo, J.; Mamiro, P.; Nyaruhucha, C. Basal metabolic rate and energy expenditure or rural farmers in Magubike village, Kilosa district, Tanzania. Afr. J. Food Agric. Nutr. Dev. 2013, 13, 8128–8138. [Google Scholar] [CrossRef]

- Toupin, D.; LeBel, L.; Dubeau, D.; Imbeau, D.; Bouthillier, L. Measuring the productivity and physical workload of brushcutters within the context of a production-based pay system. For. Policy Econ. 2007, 9, 1046–1055. [Google Scholar] [CrossRef]

- Brun, T. The assessment of total energy expenditure of female farmers under field conditions. J. Biosoc. Sci. 1992, 24, 325–333. [Google Scholar] [CrossRef]

| Worker Groups | Age (Years) | Mass (kg) | Height (cm) |

|---|---|---|---|

| I | 20–30 | 70–75 | 160–170 |

| II | 31–40 | 75–80 | 160–175 |

| III | 41–50 | 70–75 | 165–170 |

| CLASS | Average Metabolic Rate Wm−2 |

|---|---|

| 0 Resting | 65 (55 to 70) |

| 1 Low metabolic rate | 100 (70 to 130) |

| 2 Moderate metabolic rate | 165 (130 to 200) |

| 3 High metabolic rate | 230 (200 to 260) |

| 4 Very high metabolic rate | 290 (>260) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bernardi, B.; Franco, G.; Messina, G.; Fazari, A.; Benalia, S.; Zimbalatti, G.; Abenavoli, L.M.M. Metabolic Energy Consumption during Green Area Management. Appl. Sci. 2023, 13, 9671. https://doi.org/10.3390/app13179671

Bernardi B, Franco G, Messina G, Fazari A, Benalia S, Zimbalatti G, Abenavoli LMM. Metabolic Energy Consumption during Green Area Management. Applied Sciences. 2023; 13(17):9671. https://doi.org/10.3390/app13179671

Chicago/Turabian StyleBernardi, Bruno, Giovanni Franco, Gaetano Messina, Antonio Fazari, Souraya Benalia, Giuseppe Zimbalatti, and Lorenzo M. M. Abenavoli. 2023. "Metabolic Energy Consumption during Green Area Management" Applied Sciences 13, no. 17: 9671. https://doi.org/10.3390/app13179671

APA StyleBernardi, B., Franco, G., Messina, G., Fazari, A., Benalia, S., Zimbalatti, G., & Abenavoli, L. M. M. (2023). Metabolic Energy Consumption during Green Area Management. Applied Sciences, 13(17), 9671. https://doi.org/10.3390/app13179671