Use of Carbon and Basalt Fibers with Adhesives to Improve Physical and Mechanical Properties of Laminated Veneer Lumber

Abstract

:1. Introduction

2. Materials and Methods

2.1. LVL Panels

2.2. Reinforcement Fibers

2.3. Adhesives

2.4. Characterization of Adhesives

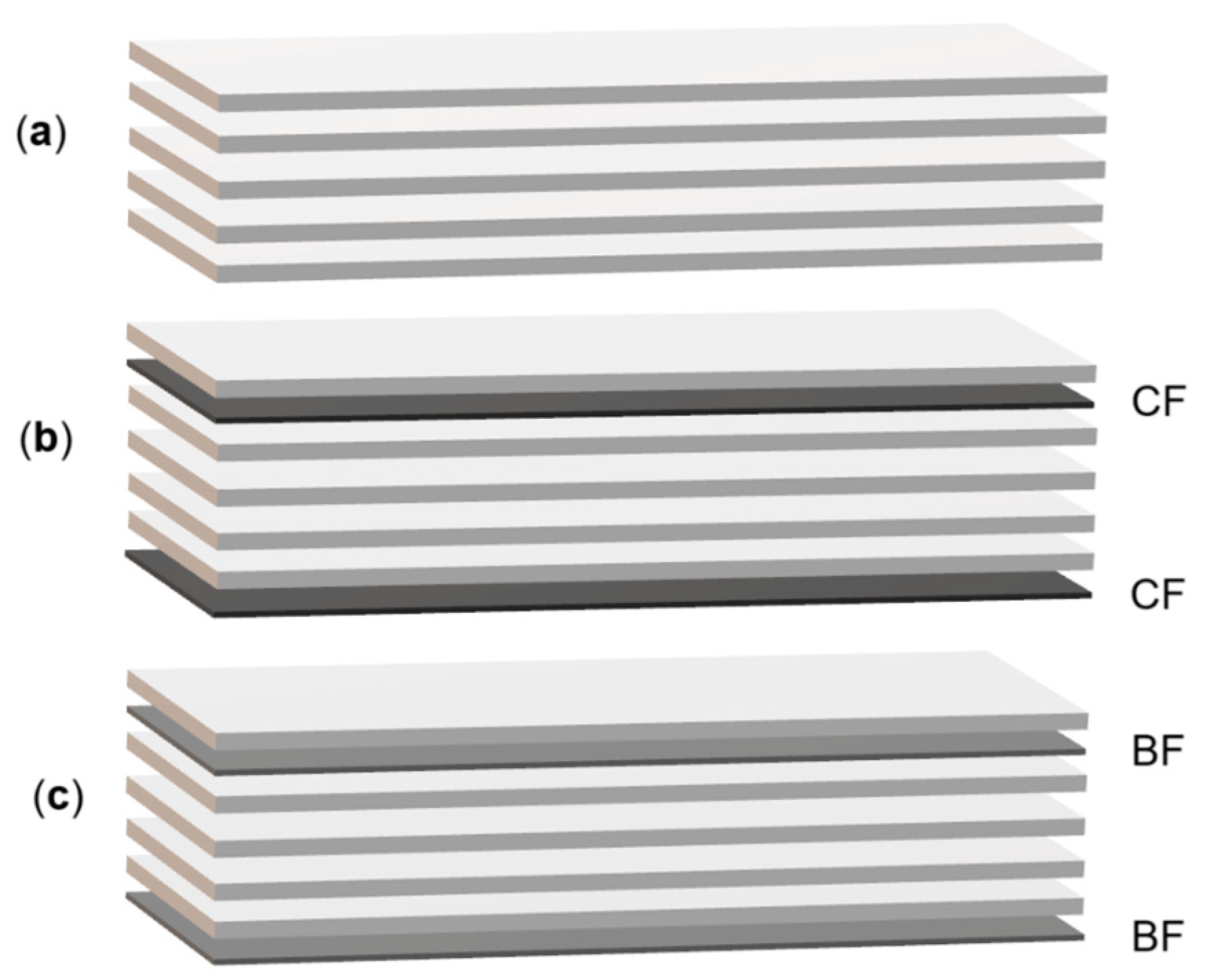

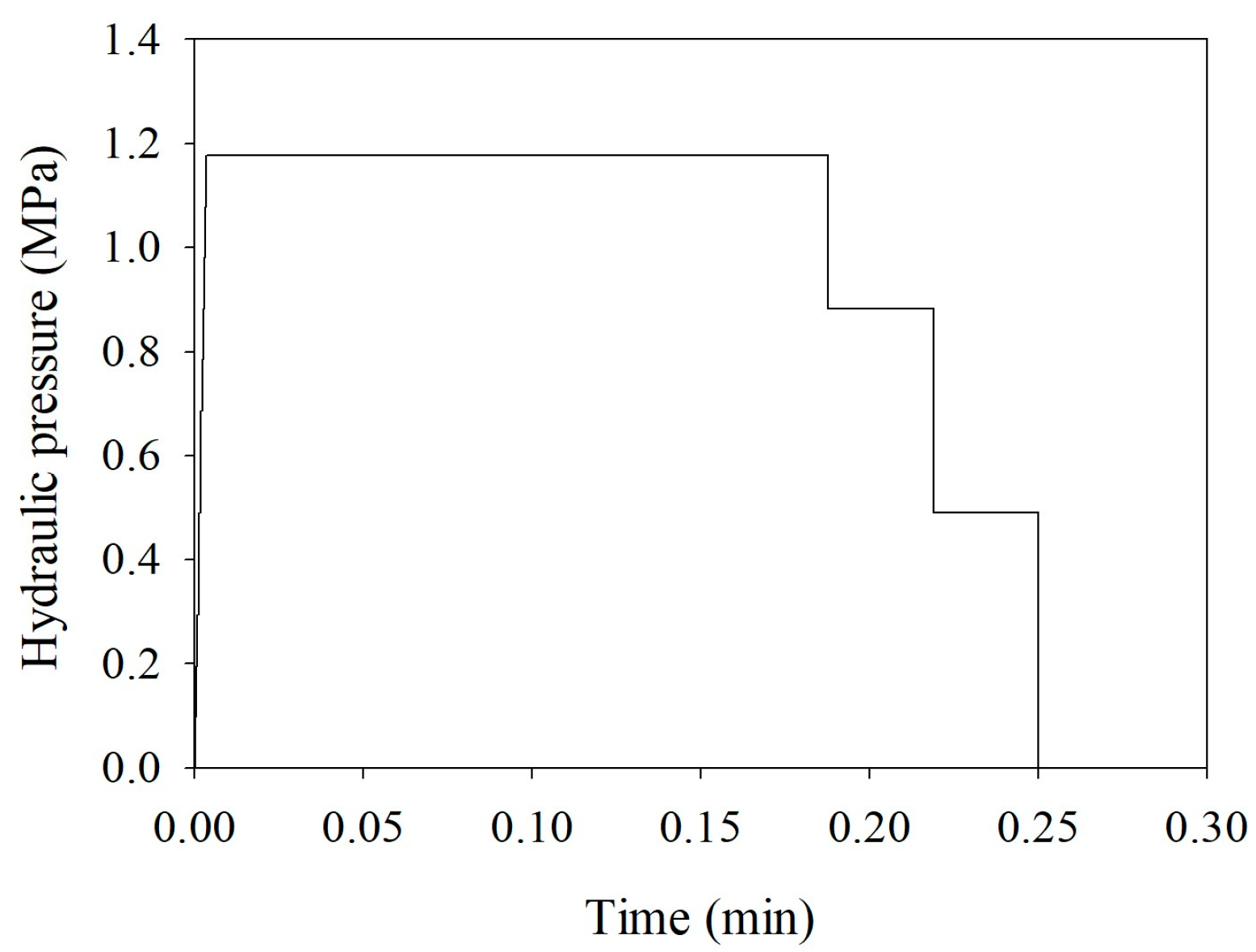

2.5. Reinforcement of LVL Panels

2.6. Physical Properties

2.7. Mechanical Properties

2.7.1. Static Bending Tests

2.7.2. Tensile Strength

2.7.3. Hardness Test

2.7.4. Thermal Properties

2.7.5. Analysis of Data

3. Results and Discussion

3.1. Characterization of Adhesives

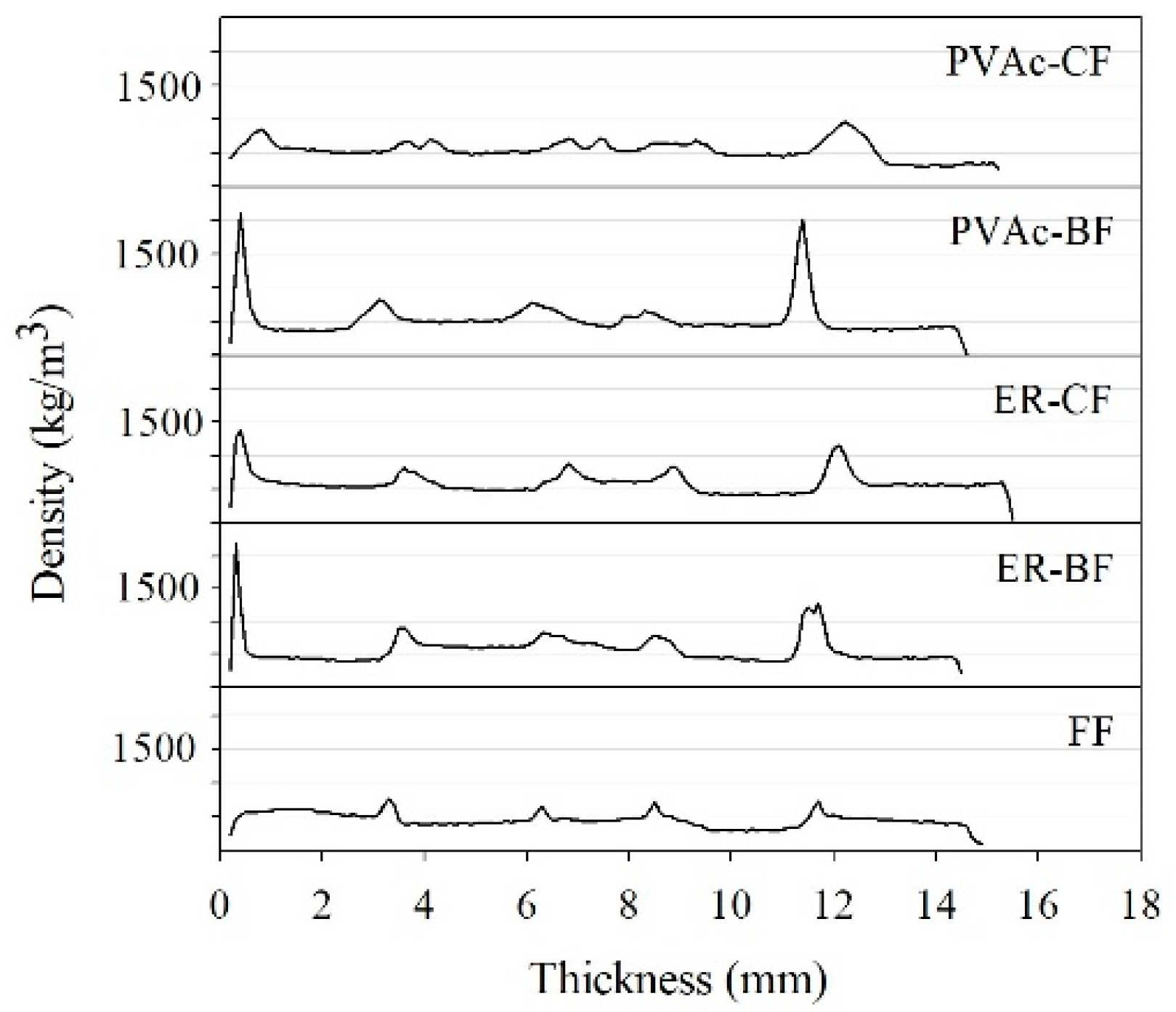

3.2. Physical Properties

3.3. Mechanical Properties

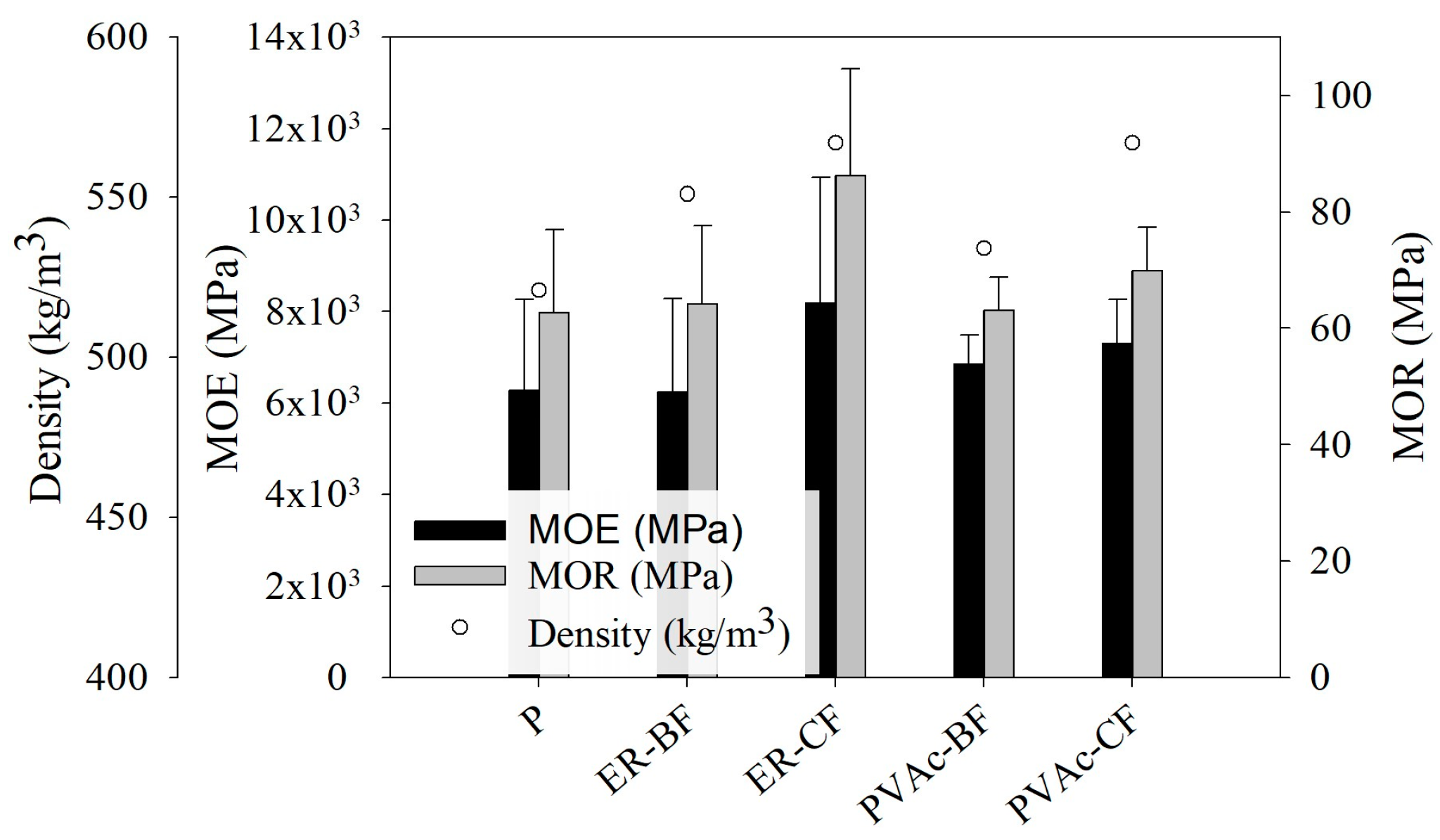

3.3.1. Strength and Stiffness Bending Properties

3.3.2. Tensile Strength

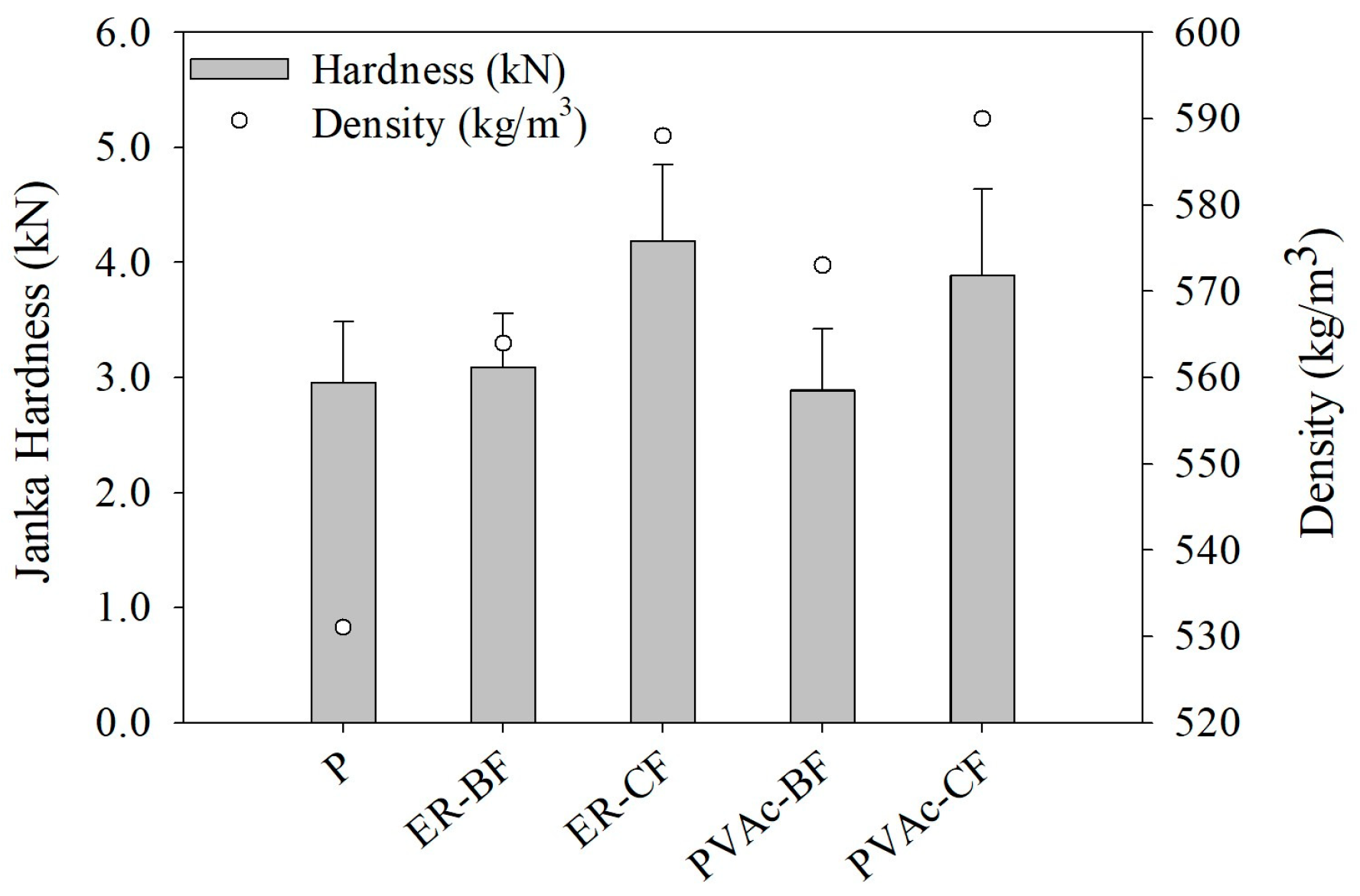

3.3.3. Janka Hardness

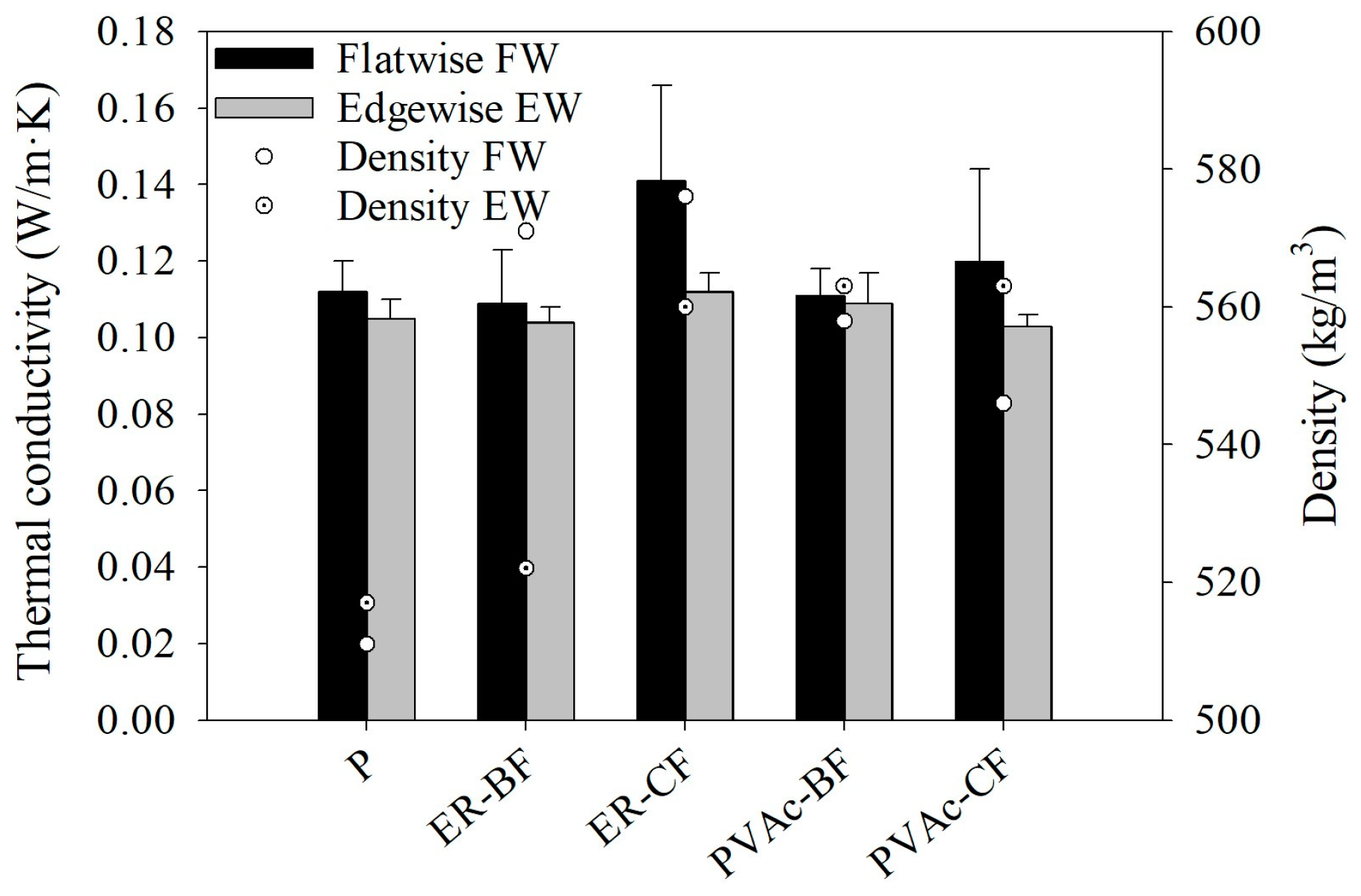

3.4. Thermal Properties

4. Conclusions

- In general, FRP-LVL increases their physical properties in 48 h water immersion when glued with PVAc adhesive. The sample PVAc-CF had the best performance, with a decrease in thickness swelling by 19%. These results introduce a good option for reinforced-LVL panels, as PVAc is a more environmentally friendly adhesive than epoxy resin and, in its case, evidenced good dimensional stability;

- FRP-LVL increase their flexural stiffness and strength properties when glued with ER adhesive; the samples ER-CF and ER-BF increased the MOE by 31% (FW), 36% (EW), and the MOR by 38% (FW) and 29% (EW), respectively;

- LVL panels, when reinforced with ER-CF, increase their tensile strength by 56% and their hardness by 41% in comparison to the control panel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- CEI-Bois. La reducción de la huella de carbono y el impacto ambiental de edificios nuevos. In “Reportes ambientales para materiales constructivos”. 1998–2001.

- Lippke, B.; Wilson, J.; Perez-Garcia, J.; Bowyer, J.; Meil, J. CORRIM: Life-Cycle Environmental Performance of Renewable Building Materials. For. Prod. J. 2004, 54, 8–19. [Google Scholar]

- IAAC. Why Er Need a New Generation of Wood Buildings and Professionals? By Michael Salka. Institute for advanced architecture of Catalonia. Available online: https://iaac.net/why-we-need-a-new-generation-of-wood-buildings-and-professionals/ (accessed on 27 August 2023).

- Bal, B.C. Some physical and mechanical properties of reinforced laminated veneer lumber. Constr. Build. Mater. 2014, 68, 120–126. [Google Scholar] [CrossRef]

- Ribeiro, A.S.; de Jesus, A.M.P.; Lima, A.M.; Lousada, J.L.C. Study of strengthening solutions for glued-laminated wood beams of maritime pine wood. Constr. Build. Mater. 2009, 23, 2738–2745. [Google Scholar] [CrossRef]

- Çolak, S.; Çolakoğlu, G.; Aydin, I. Effects of logs steaming, veneer drying and aging on the mechanical properties of laminated veneer lumber (LVL). Build. Environ. 2007, 42, 93–98. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Ross, P.; Downes, G.; Lawrence, A.; Technology, T. Timber in Contemporary Architecture: A Designer’s Guide; TRADA Technology: London, UK, 2009. [Google Scholar]

- Zhang, Y.; Yu, C.; Chu, P.K.; Lv, F.; Zhang, C.; Ji, J.; Zhang, R.; Wang, H. Mechanical and thermal properties of basalt fiber reinforced poly(butylene succinate) composites. Mater. Chem. Phys. 2012, 133, 845–849. [Google Scholar] [CrossRef]

- Deans, M. Inorganic and Composite Fibers; Woodhead Publishing: Sawston, UK, 2018; p. iv. [Google Scholar] [CrossRef]

- Núñez-Decap, M.; Barra-Rodríguez, Y.; Opazo-Carlsson, C.; Moya-Rojas, B.; Vidal-Vega, M.; Opazo-Vega, A. Use of Carbon and Basalt Fibers with Adhesives to Improve Physical and Mechanical Properties of Plywood. Appl. Sci. 2022, 12, 5114. [Google Scholar] [CrossRef]

- Rafique, I.; Kausar, A.; Muhammad, B. Epoxy Resin Composite Reinforced with Carbon Fiber and Inorganic Filler: Overview on Preparation and Properties. Polym. Plast. Technol. Eng. 2016, 55, 1653–1672. [Google Scholar] [CrossRef]

- Kramár, S.; Trcala, M.; Chitbanyong, K.; Král, P.; Puangsin, B. Basalt-Fiber-Reinforced Polyvinyl Acetate Resin: A Coating for Ductile Plywood Panels. Materials 2019, 13, 49. [Google Scholar] [CrossRef]

- Weichand, P.; Gadow, R. Basalt fibre reinforced SiOC-matrix composites: Manufacturing technologies and characterisation. J. Eur. Ceram. Soc. 2015, 35, 4025–4030. [Google Scholar] [CrossRef]

- Fořt, J.; Kočí, J.; Černý, R. Environmental Efficiency Aspects of Basalt Fibers Reinforcement in Concrete Mixtures. Energies 2021, 14, 7736. [Google Scholar] [CrossRef]

- Qin, Y.; Xu, D.; Zhang, S.; Fan, X. Dynamic behavior of carbon nanotubes and basalt fiber reinforced coral sand cement mortar at high strain rates. Constr. Build. Mater. 2022, 340, 127396. [Google Scholar] [CrossRef]

- Asil, M.B.; Ranjbar, M.M. Hybrid effect of carbon nanotubes and basalt fibers on mechanical, durability, and microstructure properties of lightweight geopolymer concretes. Constr. Build. Mater. 2022, 357, 129352. [Google Scholar] [CrossRef]

- Łach, M.; Kluska, B.; Janus, D.; Kabat, D.; Pławecka, K.; Korniejenko, K.; Guigou, M.D.; Choińska, M. Effect of Fiber Reinforcement on the Compression and Flexural Strength of Fiber-Reinforced Geopolymers. Appl. Sci. 2021, 11, 10443. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Y.; Liu, B. Hybrid effect of basalt fiber and carbon fiber on the mechanical properties and microstructure of oil well cement. Constr. Build. Mater. 2021, 286, 122696. [Google Scholar] [CrossRef]

- de la Rosa, P.; González, M.d.l.N.; Prieto, M.I.; Gómez, E. Compressive Behavior of Pieces of Wood Reinforced with Fabrics Composed of Carbon Fiber and Basalt Fiber. Appl. Sci. 2021, 11, 2460. [Google Scholar] [CrossRef]

- Zhou, A.; Qin, R.; Chow, C.L.; Lau, D. Bond integrity of aramid, basalt and carbon fiber reinforced polymer bonded wood composites at elevated temperature. Compos. Struct. 2020, 245, 112342. [Google Scholar] [CrossRef]

- Wdowiak-Postulak, A. Natural Fibre as Reinforcement for Vintage Wood. Materials 2020, 13, 4799. [Google Scholar] [CrossRef]

- Wang, B.; Bachtiar, E.V.; Yan, L.; Kasal, B.; Fiore, V. Flax, Basalt, E-Glass FRP and Their Hybrid FRP Strengthened Wood Beams: An Experimental Study. Polymers 2019, 11, 1255. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y.; Xie, X. Experimental and analytical investigation of the flexural behaviour of stiffened hollow glulam beams reinforced with fibre reinforced polymer. Structures 2023, 50, 810–822. [Google Scholar] [CrossRef]

- Rescalvo, F.J.; Duriot, R.; Pot, G.; Gallego, A. Mechanical behaviour of poplar laminated veneer lumber with fiber reinforced polymer under shear and compression stresses. Wood Mater. Sci. Eng. 2022, 18, 893–901. [Google Scholar] [CrossRef]

- Gallego, A.; Rescalvo, F.; Suarez, E. Madera microlaminada estructural de chopo reforzada con tejidos de carbono o basalto. Alzada 2020, 120, 32–43. [Google Scholar]

- Wdowiak-Postulak, A.; Świt, G. Behavior of glulam beams strengthened in bending with BFRP fabrics. Civ. Environ. Eng. Rep. 2021, 31, 1–14. [Google Scholar] [CrossRef]

- Wdowiak-Postulak, A. Basalt Fibre Reinforcement of Bent Heterogeneous Glued Laminated Beams. Materials 2021, 14, 51. [Google Scholar] [CrossRef] [PubMed]

- Globa, A.; Subhani, M.; Moloney, C.; Al-Ameri, R. Carbon Fiber and Structural Timber Composites for Engineering and Construction. J. Archit. Eng. 2018, 24, 1–14. [Google Scholar] [CrossRef]

- Subhani, M.; Globa, A.; Al-Ameri, R.; Moloney, J. Effect of grain orientation on the CFRP-to-LVL bond. Compos. Part B Eng. 2017, 129, 187–197. [Google Scholar] [CrossRef]

- Núñez, M. Adhesivo de extractos de proteínas de levadura de riles cerveceros y panificadora, nanolignina y entrecruzante. Chile Patent Appl. 2022, 202203793. [Google Scholar]

- ASTM D1084-16R21; Standard Test Methods for Viscosity of Adhesives. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM E0070-19; Standard Test Method for pH of Aqueous Solutions with the Glass Electrode. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D1490-01R18; Standard Test Method for Nonvolatile Content of Urea-Formaldehyde Resin Solutions. ASTM International: West Conshohocken, PA, USA, 2018.

- UNE-EN 323; Wood-Based Panels—Determination of Density. Fernández de la Hoz: Madrid, Spain, 1994.

- UNE-EN 322; Wood-Based Panels. Determination of Moisture Content; Fernández de la Hoz: Madrid, Spain, 1994.

- UNE-EN 317; Particleboards and Fibreboards. Determination of Swelling in Thickness after Immersion in Water; Fernández de la Hoz: Madrid, Spain, 1994.

- UNE-EN 408; Timber Structures. Structural Timber and Glued Laminated Timber. Determination of Some Physical and Mechanical Properties; Fernández de la Hoz: Madrid, Spain, 2012.

- UNE-EN 310; Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength; Fernández de la Hoz: Madrid, Spain, 1994.

- ASTM D3500-20; Standard Test Methods for Wood Structural Panels in Tension. ASTM International: West Conshohocken, PA, USA, 2020; p. 6.

- ASTM D1037-12; Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D5334-22; Standard Test Method for Determination of Thermal Conductivity of Soil and Rock by Thermal Needle Probe Procedure. ASTM International: West Conshohocken, PA, USA, 2000.

- de Melo, R.R.; del Menezzi, C.H.S. Influence of Adhesive Type on the Properties of LVL Made from Paricá (Schizolobium amazonicum Huber ex. Ducke) Plantation Trees. Drv. Ind. 2015, 66, 205–212. [Google Scholar] [CrossRef]

- Fu, Q.; Yan, L.; Ning, T.; Wang, B.; Kasal, B. Interfacial bond behavior between wood chip concrete and engineered timber glued by various adhesives. Constr. Build. Mater. 2020, 238, 117743. [Google Scholar] [CrossRef]

- Yusoh, A.; Tahir, P.; Uyup, M.; Lee, S.; Husain, H.; Khaidzir, M. Effect of wood species, clamping pressure and glue spread rate on the bonding properties of cross-laminated timber (CLT) manufactured from tropical hardwoods. Constr. Build. Mater. 2020, 273, 121721. [Google Scholar] [CrossRef]

- Wang, X.-M.; Casilla, R.; Zhang, Y.; Cooper, P.; Huang, Z. Effect of extreme pH on bond durability of selected structural wood adhesives. Wood Fiber Sci. 2016, 48, 245–259. [Google Scholar]

- Hýsek, S.; Premysl, S.; Böhm, M.; Schönfelder, O.; Beran, R. Influence of Using Recycled Polyurethane Particles as a Filler on Properties of Polyurethane Adhesives for Gluing of Wood. BioResources 2018, 13, 2592–2601. [Google Scholar] [CrossRef]

- Sanghvi, M.R.; Tambare, O.H.; More, A.P. Performance of various fillers in adhesives applications: A review. Polym. Bull. 2022, 79, 10491–10553. [Google Scholar] [CrossRef]

- Lengowski, E.C.; Júnior, E.A.B.; Nishidate Kumode, M.M.; Carneiro, M.E.; Satyanarayana, G. Nanocellulose-Reinforced Adhesives for Wood-Based Panels. Sustain. Polym. Compos. Nanocompos. 2019, 35, 1001–1025. [Google Scholar] [CrossRef]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.-J.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. Part B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Wang, J.; Guo, X.; Zhong, W.; Wang, H.; Cao, P. Evaluation of Mechanical Properties of Reinforced Poplar Laminated Veneer Lumber. BioResources 2015, 10, 7455–7465. [Google Scholar] [CrossRef]

- Wei, P.; Wang, B.J.; Zhou, D.; Dai, C.; Wang, Q.; Huang, S. Mechanical Properties of Poplar Laminated Veneer Lumber Modified by Carbon Fiber Reinforced Polymer. BioResources 2013, 8, 4883–4898. [Google Scholar] [CrossRef]

- Frihart, C.R.; Hunt, C.G. Adhesives with Wood Materials Bond Formation and Performance. In Wood Handbook: Wood as an Engineering Material; Forest Products Laboratory, United States Department of Agriculture Forest Service: Madison, WI, USA, 1910-2010.

- Bakalarz, M.M.; Kossakowski, P.G. Strengthening of Full-Scale Laminated Veneer Lumber Beams with CFRP Sheets. Materials 2022, 15, 6526. [Google Scholar] [CrossRef]

- Subagia, I.D.G.A.; Kim, Y.; Tijing, L.D.; Kim, C.S.; Shon, H.K. Effect of stacking sequence on the flexural properties of hybrid composites reinforced with carbon and basalt fibers. Compos. Part B Eng. 2014, 58, 251–258. [Google Scholar] [CrossRef]

- de Souza, J.B.; de Azevedo, T.K.B.; Sousa, T.B.; da Silva, G.G.C.; Guimaraes, J.B.; Pimenta, A.S. Plywood bonding with an adhesive based on tannins from Acacia mangium Wild. bark from trees grown in Northeastern Brazil. Rev. Bras. Cienc. Agrar. Agrar. 2020, 15, 1–7. [Google Scholar] [CrossRef]

- Yang, G.; Park, M.; Park, S.-J. Recent Progresses of fabrication and characterization of fibers-reinforced composites: A review. Compos. Commun. 2019, 14, 34–42. [Google Scholar] [CrossRef]

- Studiengemeinschaft Holzeimbau e.V.; Finnish Woodworking Industries. Laminated Veneer Lumber (LVL) Bulletin, 3rd ed.; Studiengemeinschaft Holzeimbau e.V.: Wuppertal, Germany; Finnish Woodworking Industries: Helsinki, Finland, 2020; pp. 1–8. Available online: https://timberdevelopment.uk/resources/laminated-veneer-lumber-lvl-bulletin/ (accessed on 27 August 2023).

| Properties | Carbon Fiber | Basalt Fiber |

|---|---|---|

| Fabric | Bidirectional weaving | Bidirectional weaving |

| Thickness (mm) | 0.28 | 0.18 |

| Grammage (g/m2) | 200 | 200 |

| Tensile Strength (MPa) | ≥3500 | ≥1000 |

| ID | N° LVL | Adhesive Grammage (g/m2) |

|---|---|---|

| P | 4 | 200 |

| ER-CF | 4 | 250 |

| ER-BF | 4 | 250 |

| PVAc-CF | 4 | 400 |

| PVAc-BF | 4 | 400 |

| ID | Viscosity (cP) | pH | Electrical Conductivity (mS) | Solid Content (%) |

|---|---|---|---|---|

| PF | 4827 | 12.53 | 24.23 | 42.27 |

| ER | 1200 | 7.50 | - | 93.88 |

| PVAc | 1240 | 2.76 | 13.89 | 52.06 |

| ID | Density (kg/m3) | Moisture Content (%) | Thickness (mm) | Thickness Swelling (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 24 h | 48 h | |||||||||

| Mean | St. Dev. | Mean | St. Dev. | Mean | St. Dev. | Mean | St. Dev. | Mean | St. Dev. | |

| P | 530 a | 27.29 | 8 a | 0.64 | 14.33 a | 0.31 | 1.26 a | 1.81 | 5.13 ab | 0.93 |

| ER-CF | 563 ab | 43.13 | 10 b | 0.82 | 14.97 b | 0.44 | 0.74 a | 1.22 | 4.43 bc | 0.45 |

| ER-BF | 570 b | 31.81 | 11 c | 0.28 | 14.41 a | 0.20 | 0.66 a | 1.88 | 5.32 a | 0.41 |

| PVAc-CF | 585 b | 14.14 | 12 d | 0.14 | 15.03 b | 0.23 | 0.60 a | 1.70 | 4.16 c | 0.64 |

| PVAc-BF | 568 b | 41.92 | 12 cd | 0.40 | 14.20 a | 0.24 | 0.00 a | 0.00 | 4.83 abc | 1.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Núñez-Decap, M.; Sandoval-Valderrama, B.; Opazo-Carlsson, C.; Moya-Rojas, B.; Vidal-Vega, M.; Opazo-Vega, A. Use of Carbon and Basalt Fibers with Adhesives to Improve Physical and Mechanical Properties of Laminated Veneer Lumber. Appl. Sci. 2023, 13, 10032. https://doi.org/10.3390/app131810032

Núñez-Decap M, Sandoval-Valderrama B, Opazo-Carlsson C, Moya-Rojas B, Vidal-Vega M, Opazo-Vega A. Use of Carbon and Basalt Fibers with Adhesives to Improve Physical and Mechanical Properties of Laminated Veneer Lumber. Applied Sciences. 2023; 13(18):10032. https://doi.org/10.3390/app131810032

Chicago/Turabian StyleNúñez-Decap, Mario, Bárbara Sandoval-Valderrama, Camila Opazo-Carlsson, Boris Moya-Rojas, Marcela Vidal-Vega, and Alexander Opazo-Vega. 2023. "Use of Carbon and Basalt Fibers with Adhesives to Improve Physical and Mechanical Properties of Laminated Veneer Lumber" Applied Sciences 13, no. 18: 10032. https://doi.org/10.3390/app131810032

APA StyleNúñez-Decap, M., Sandoval-Valderrama, B., Opazo-Carlsson, C., Moya-Rojas, B., Vidal-Vega, M., & Opazo-Vega, A. (2023). Use of Carbon and Basalt Fibers with Adhesives to Improve Physical and Mechanical Properties of Laminated Veneer Lumber. Applied Sciences, 13(18), 10032. https://doi.org/10.3390/app131810032