WASPAS Based Multi Response Optimization in Hard Turning of AISI 52100 Steel under ZnO Nanofluid Assisted Dual Nozzle Pulse-MQL Environment

Abstract

:1. Introduction

Research Gap, Novelty, and Objectives

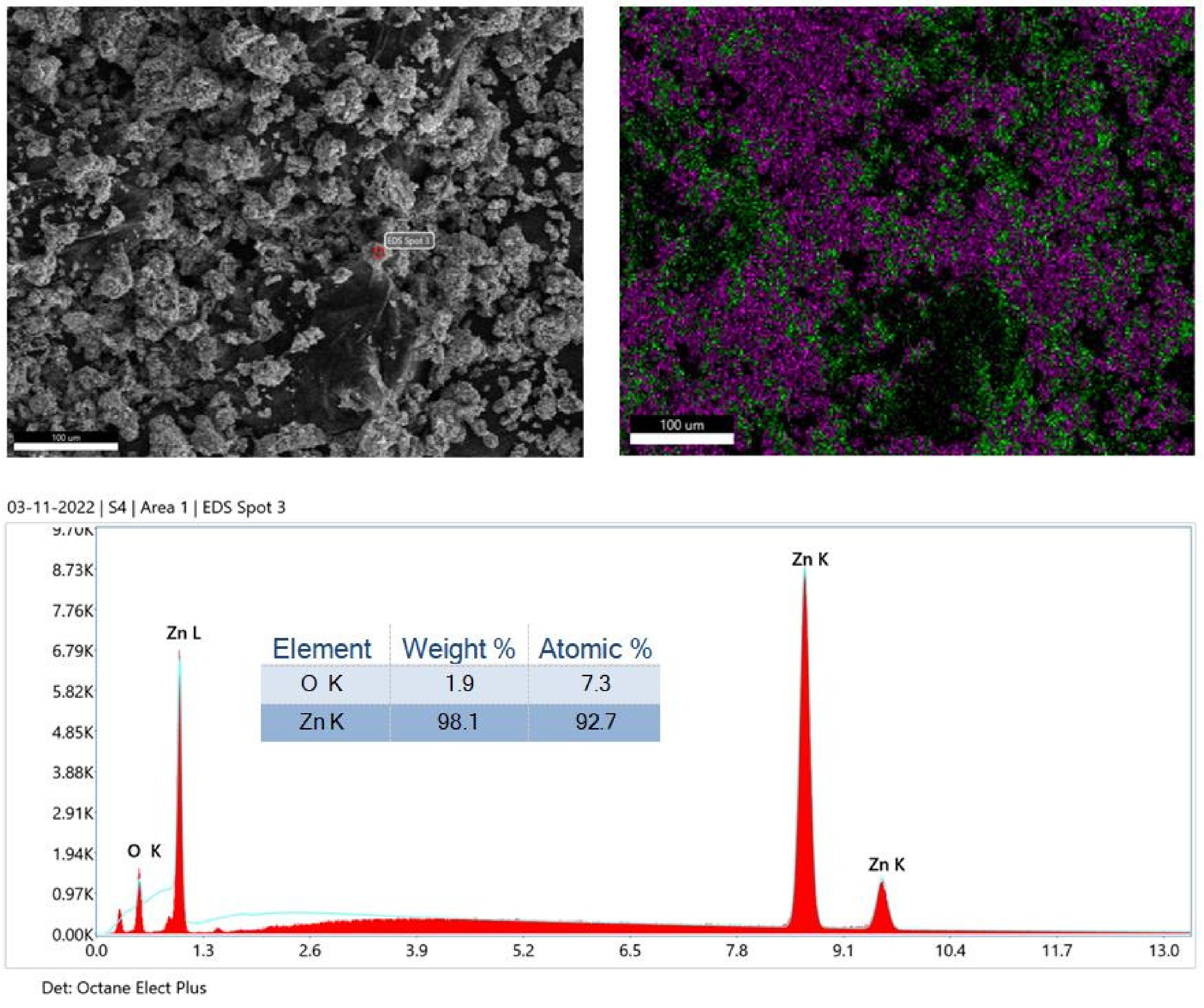

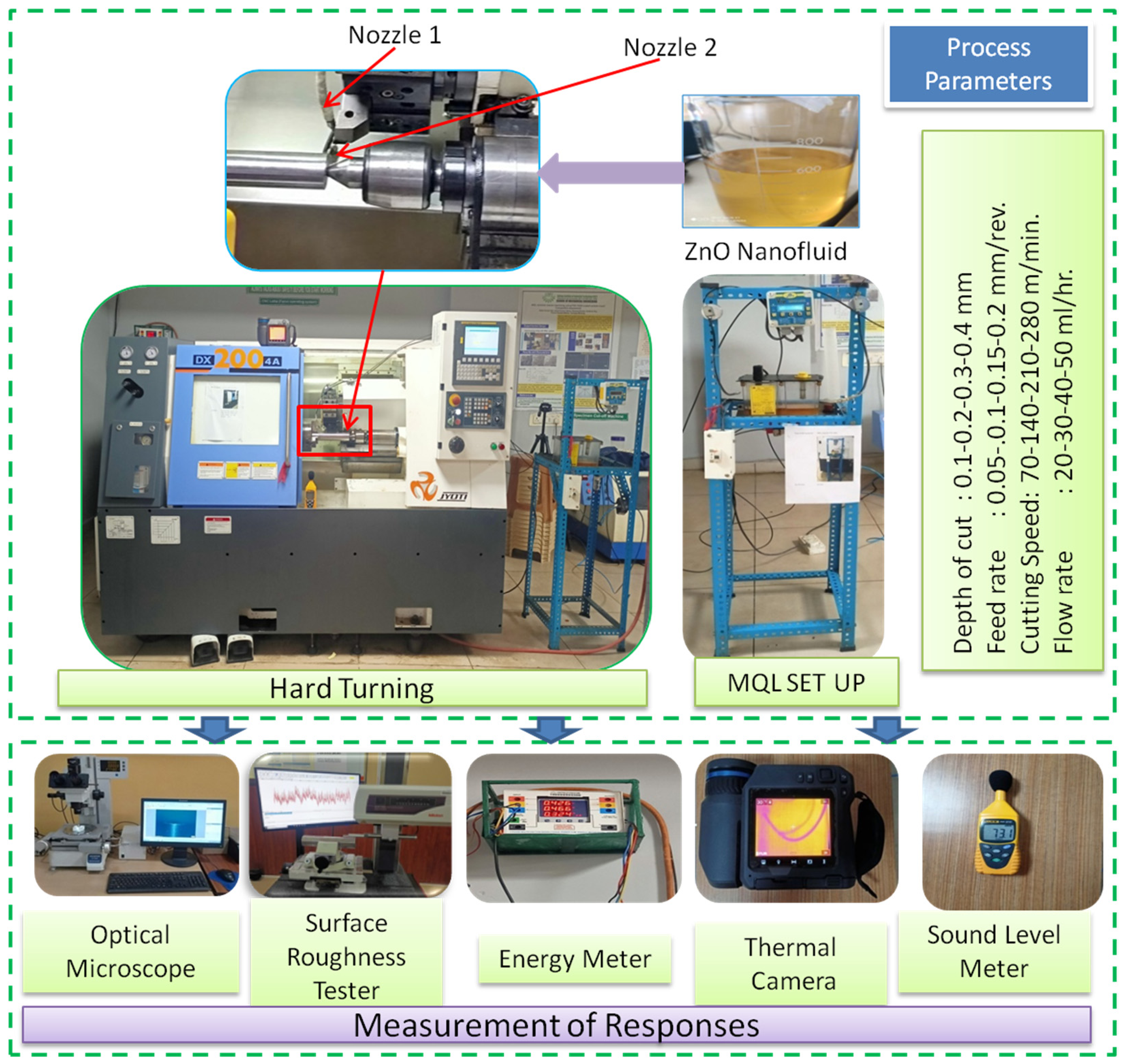

2. Implementation Details

3. Results and Discussion

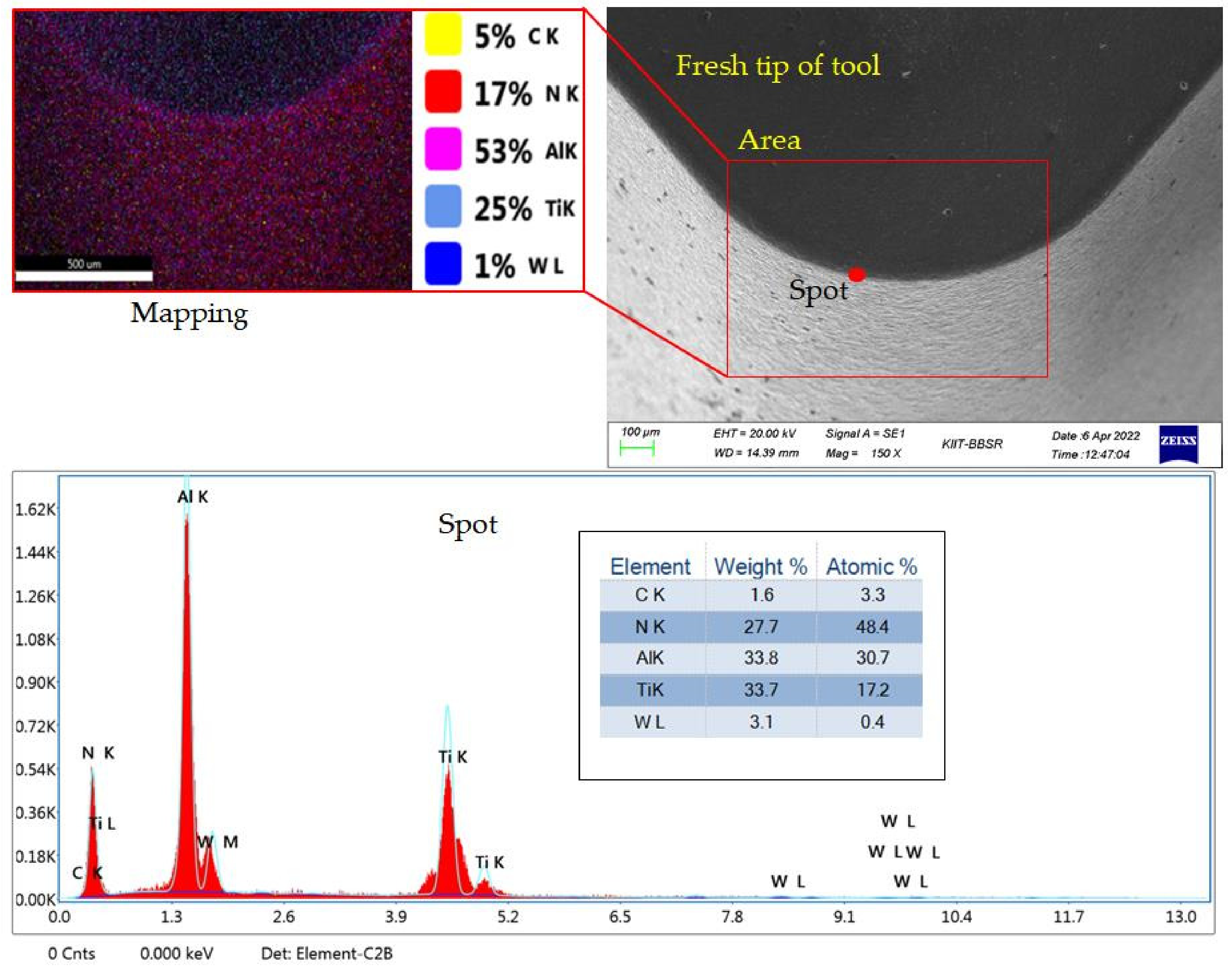

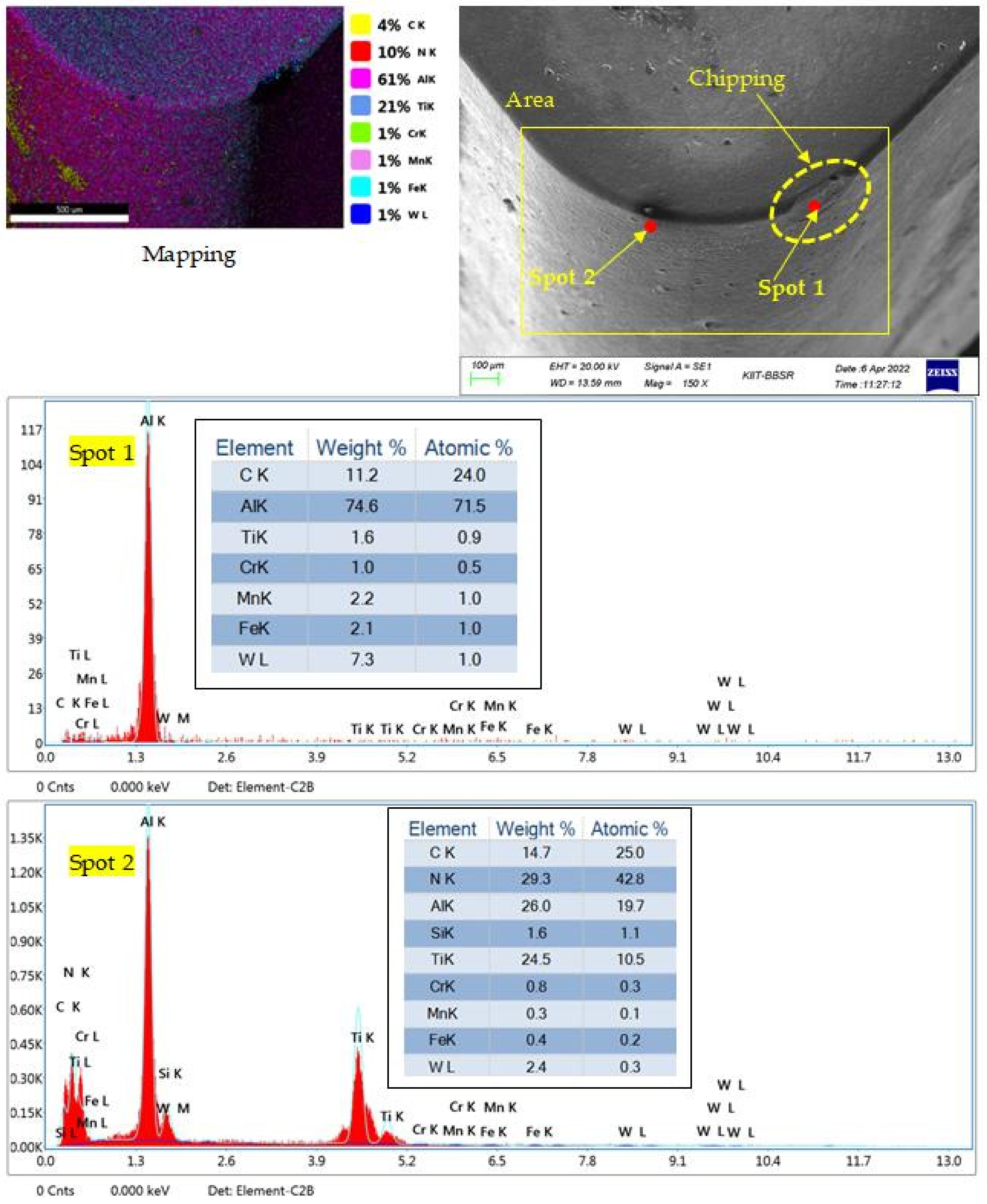

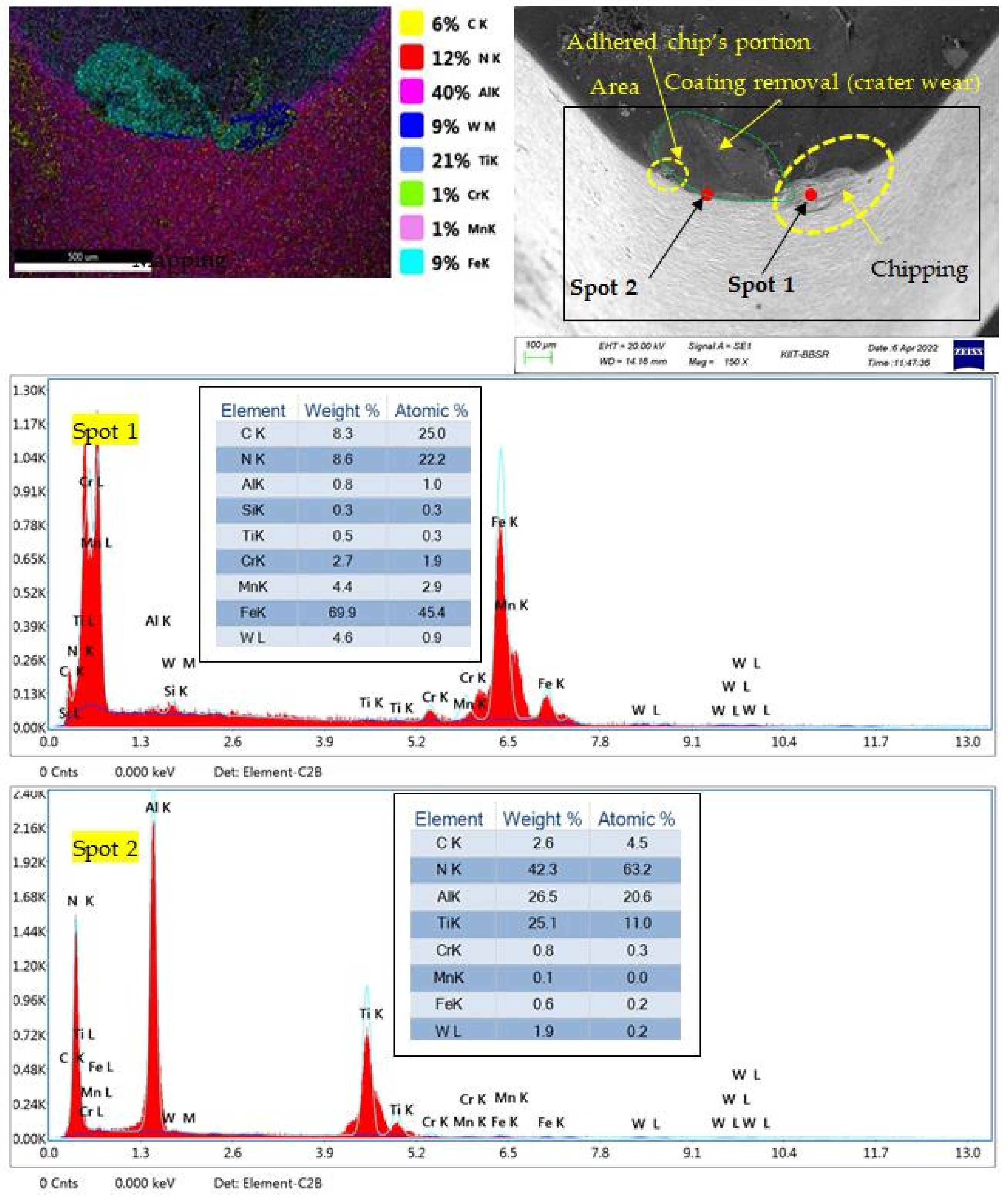

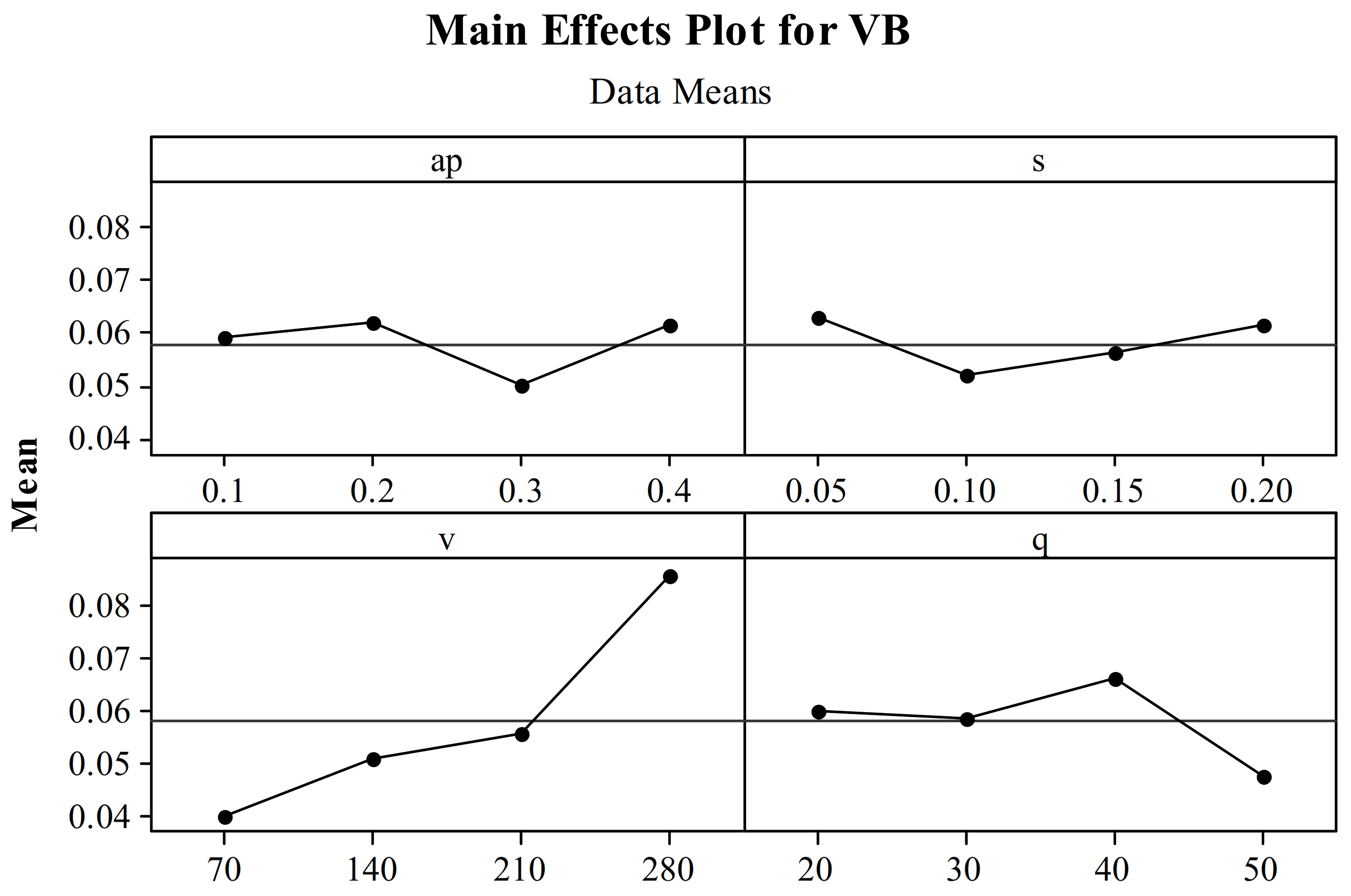

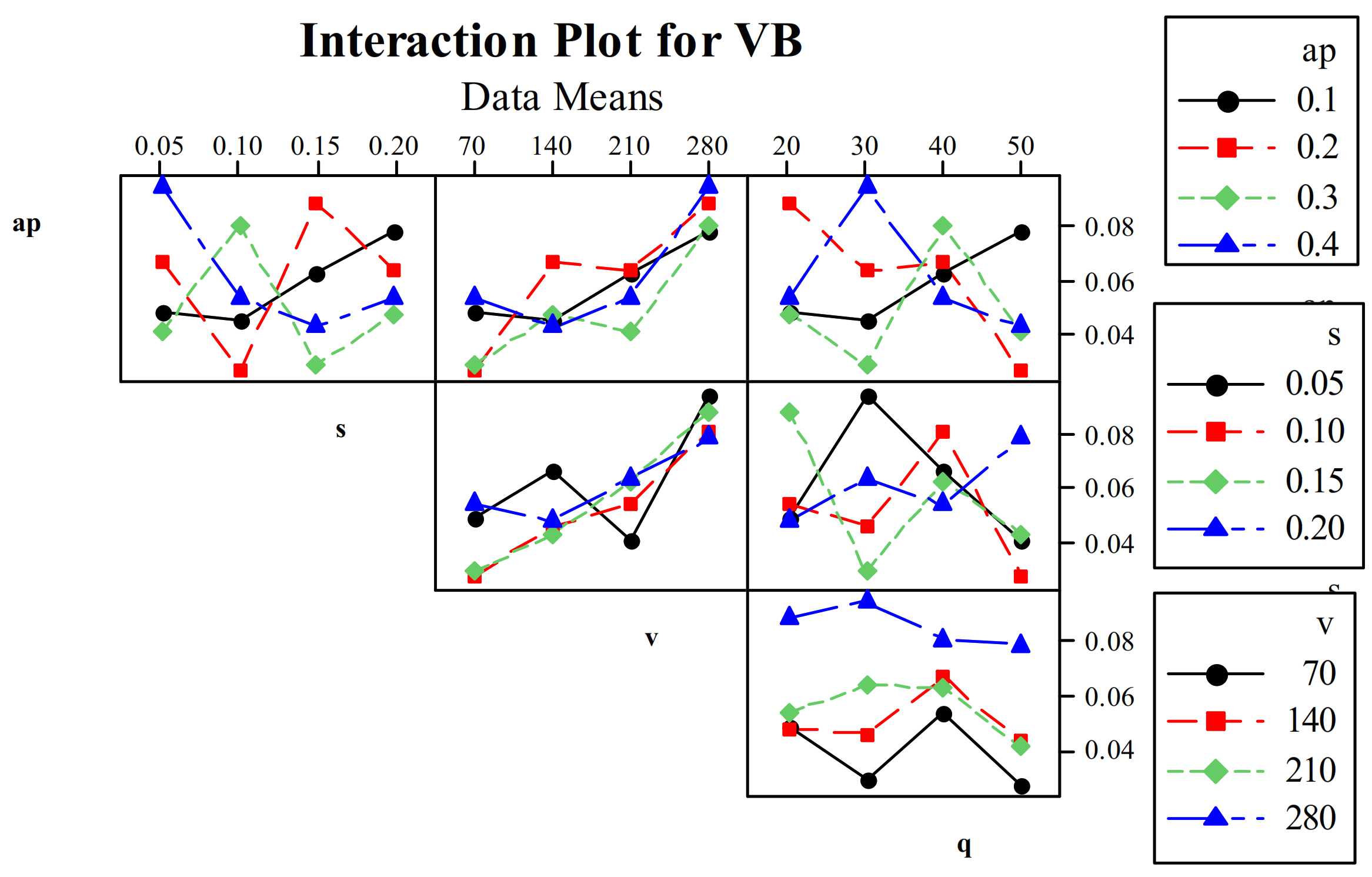

3.1. Assessment of Tool Wear

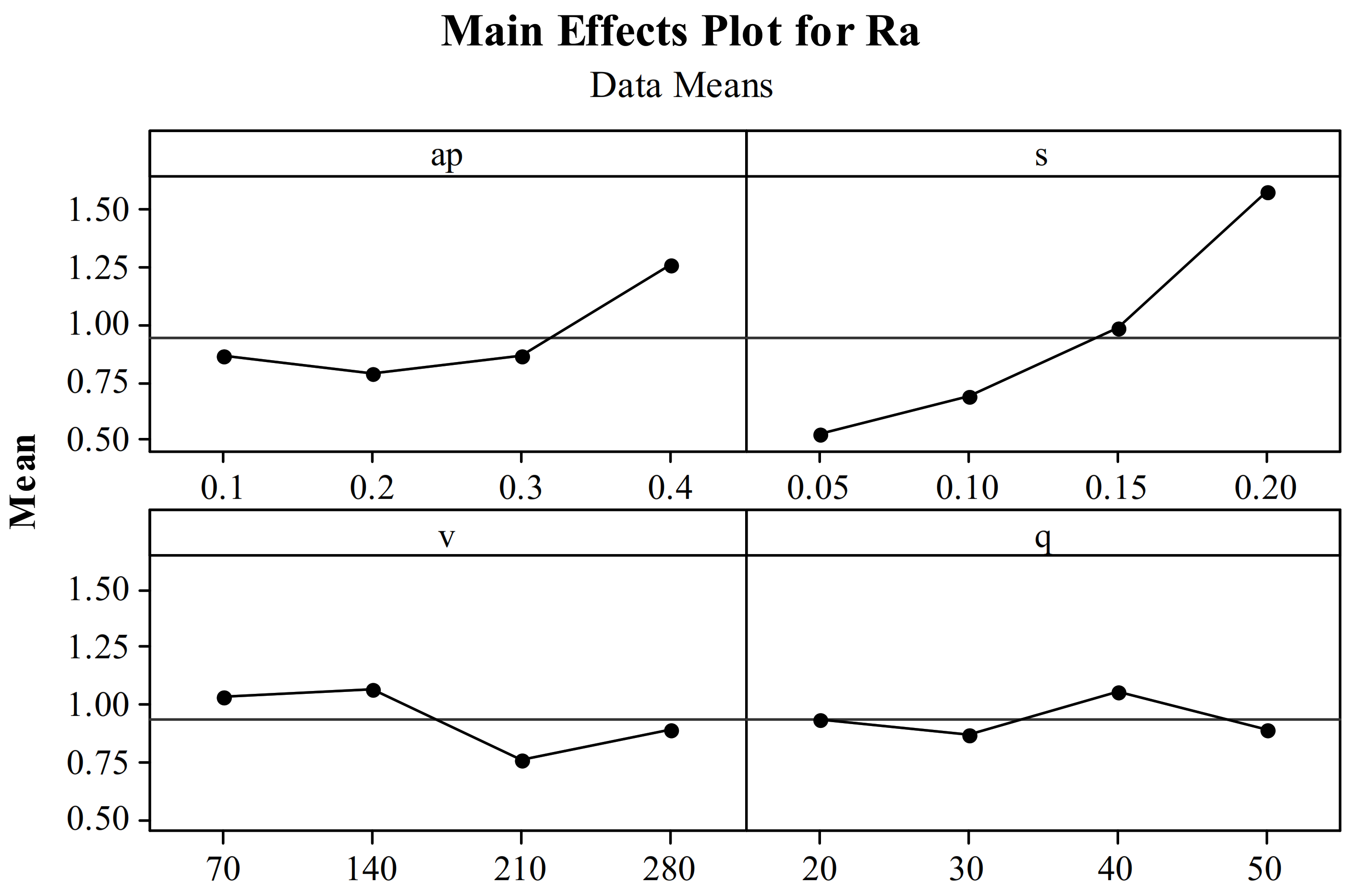

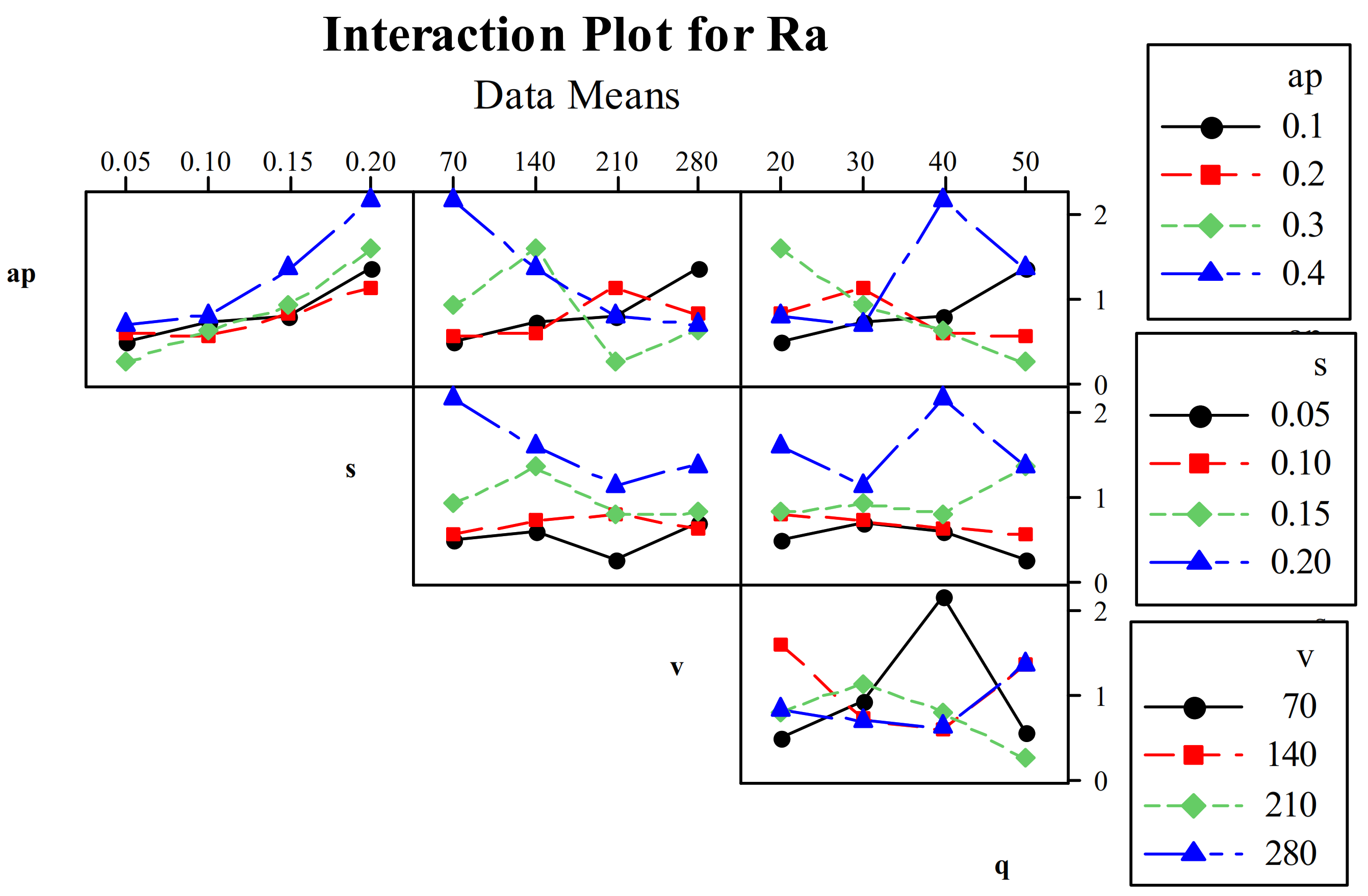

3.2. Assessment of Surface Roughness

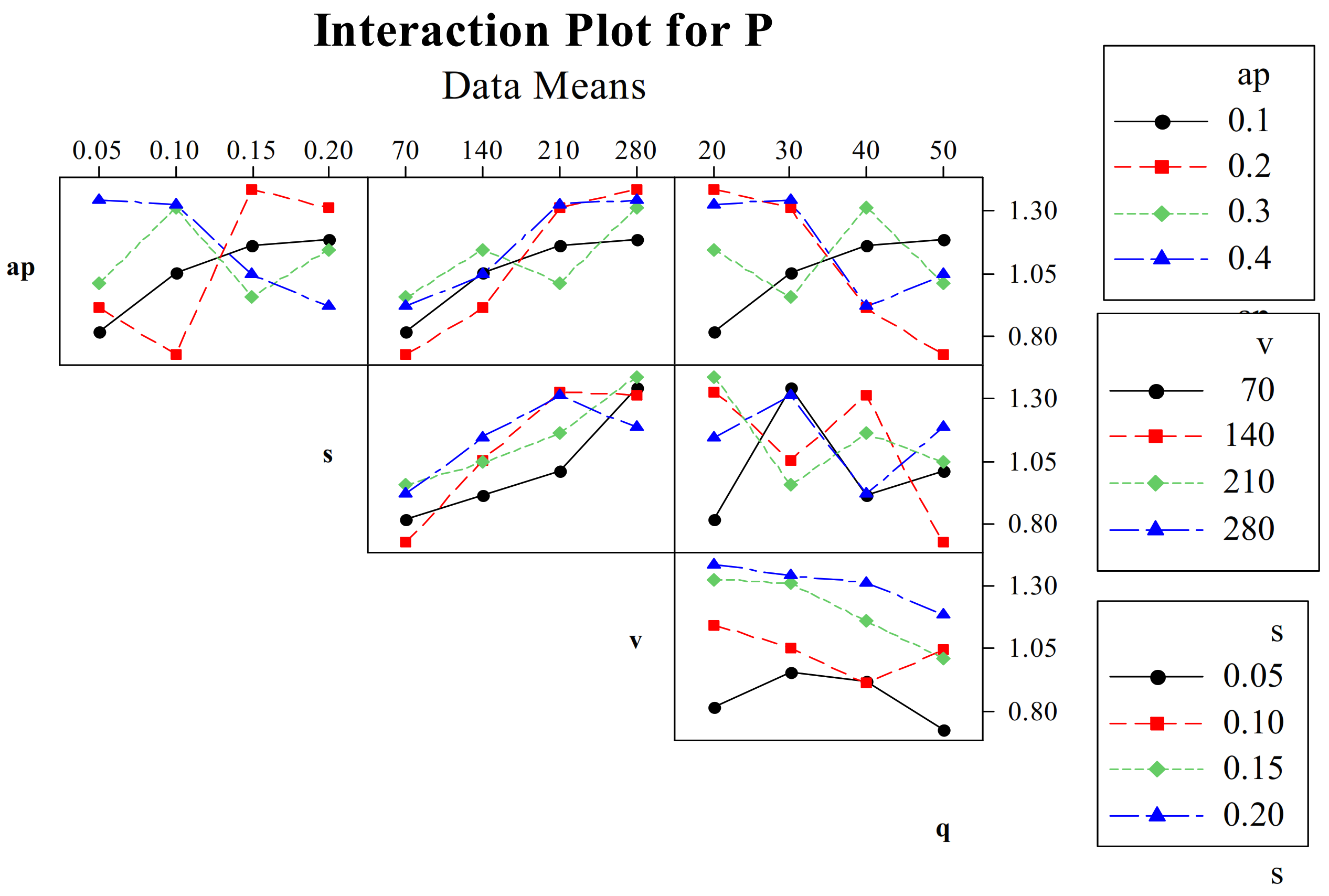

3.3. Assessment of Power Consumption

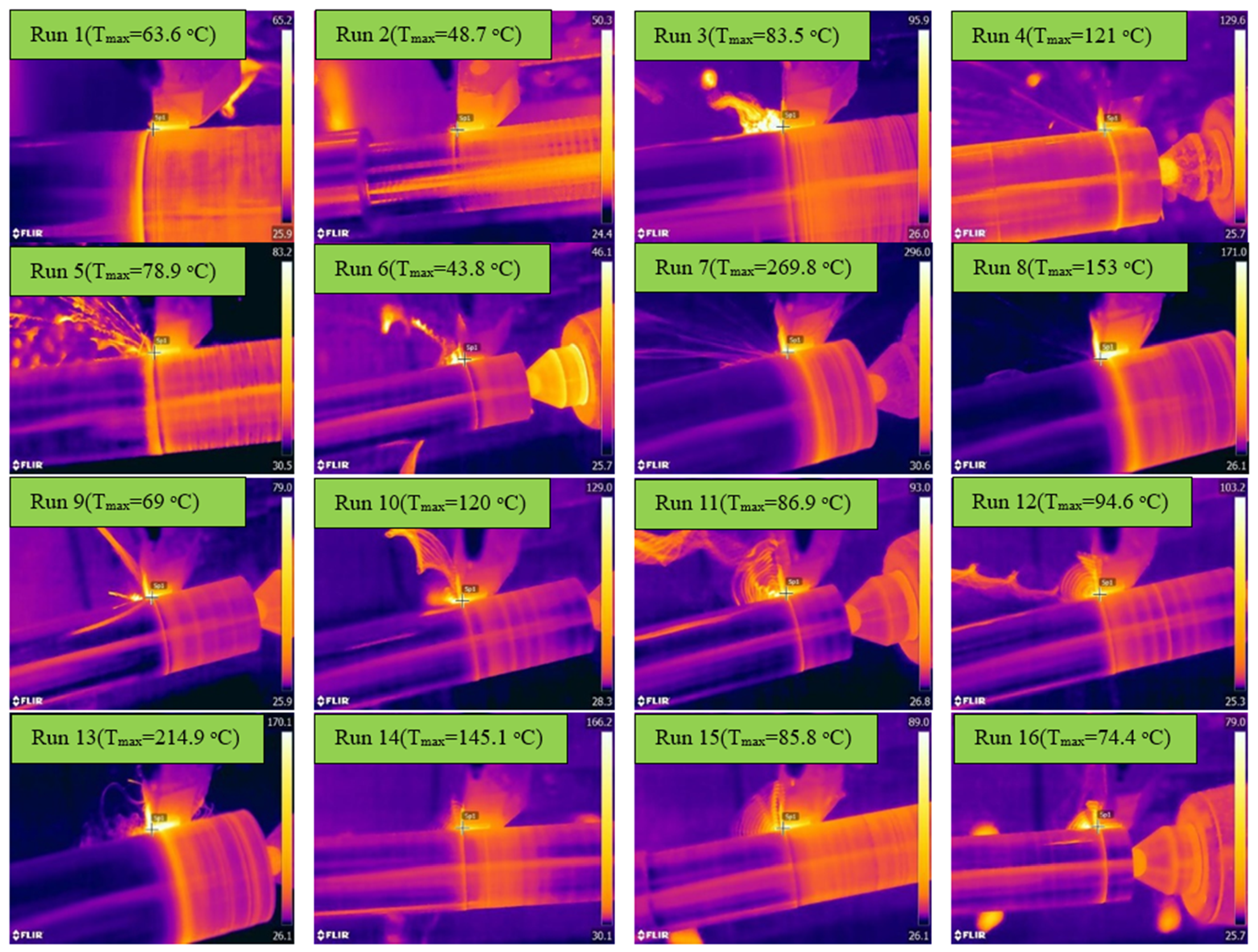

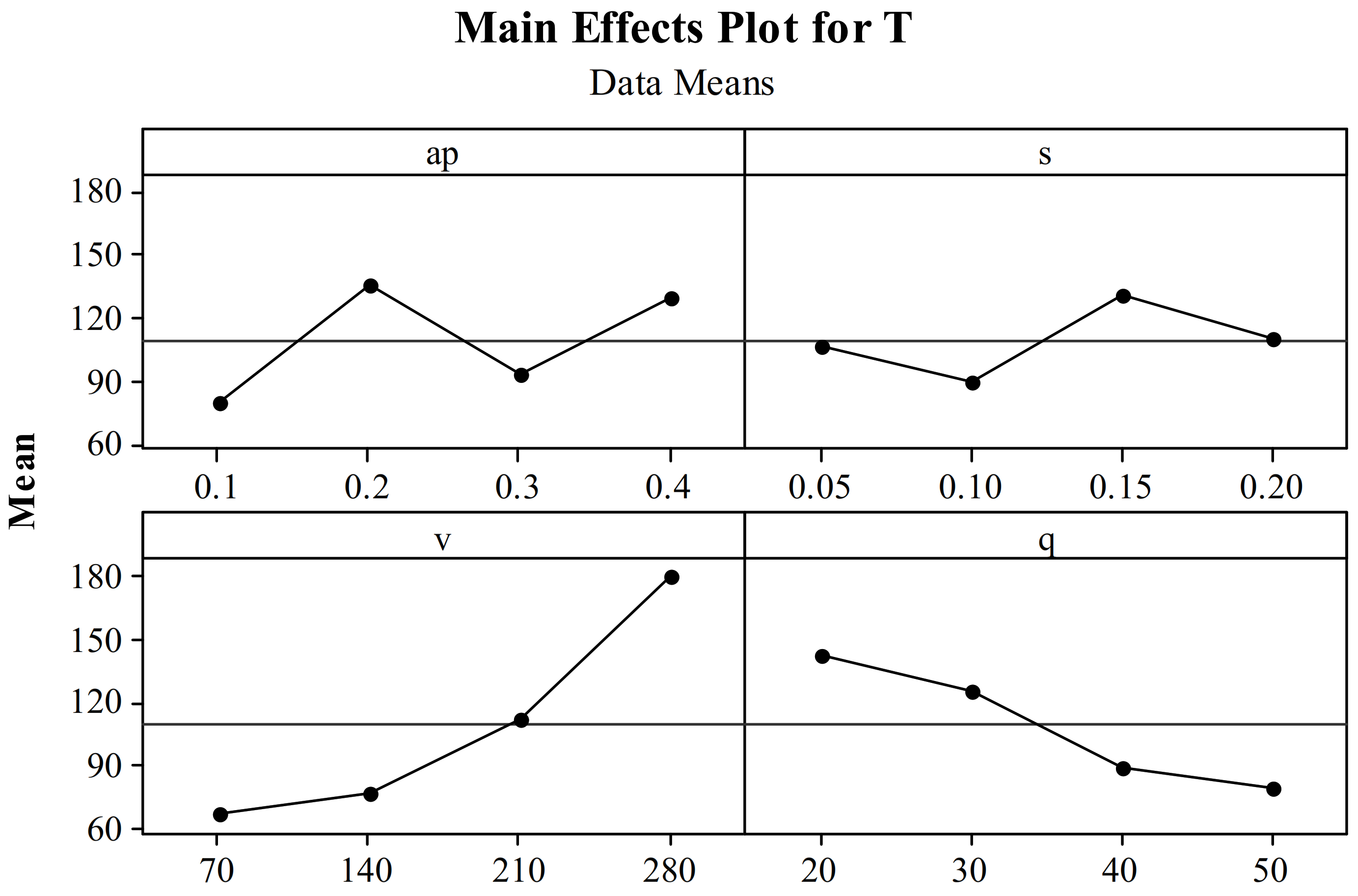

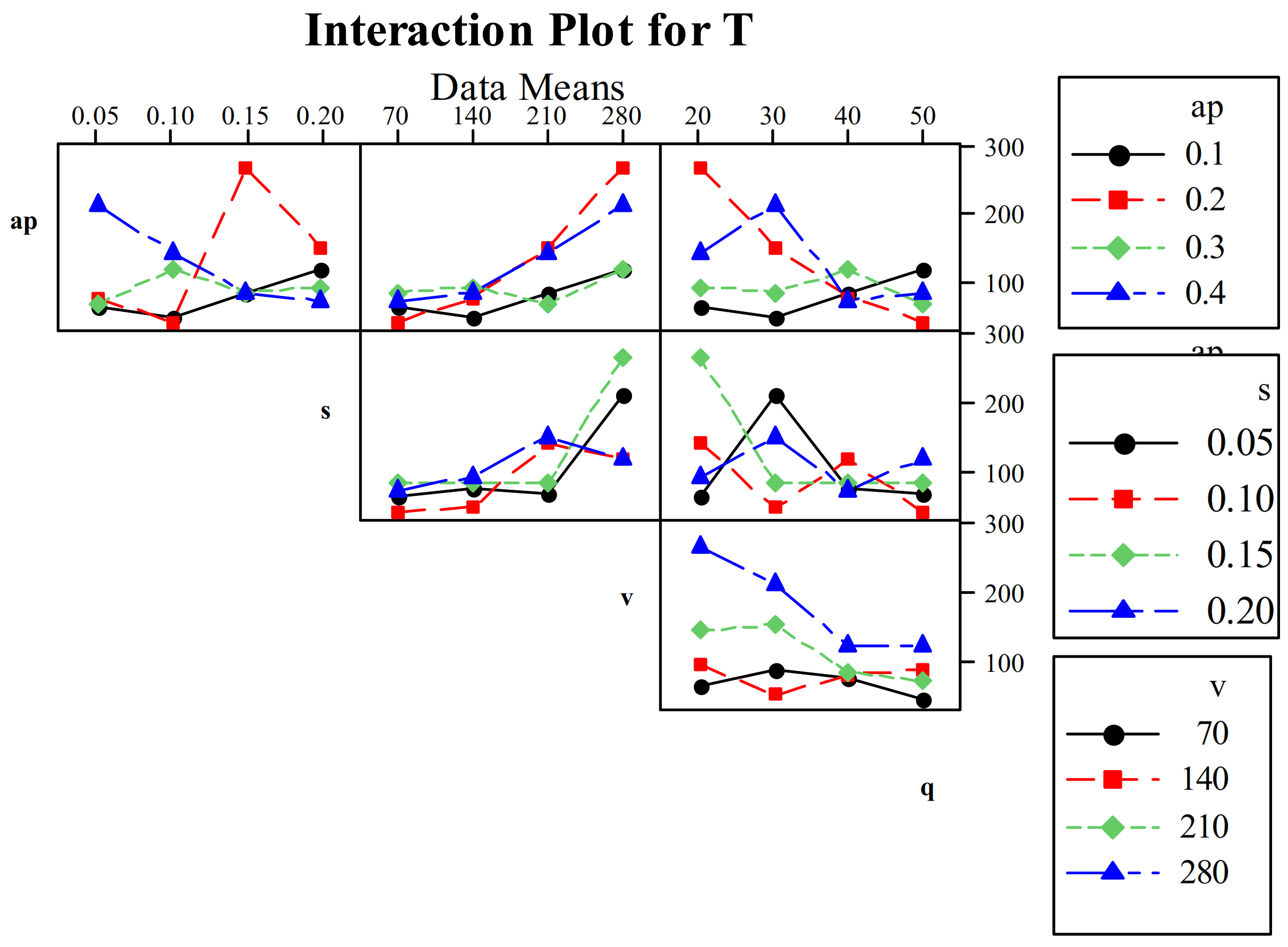

3.4. Assessment of Cutting Temperature

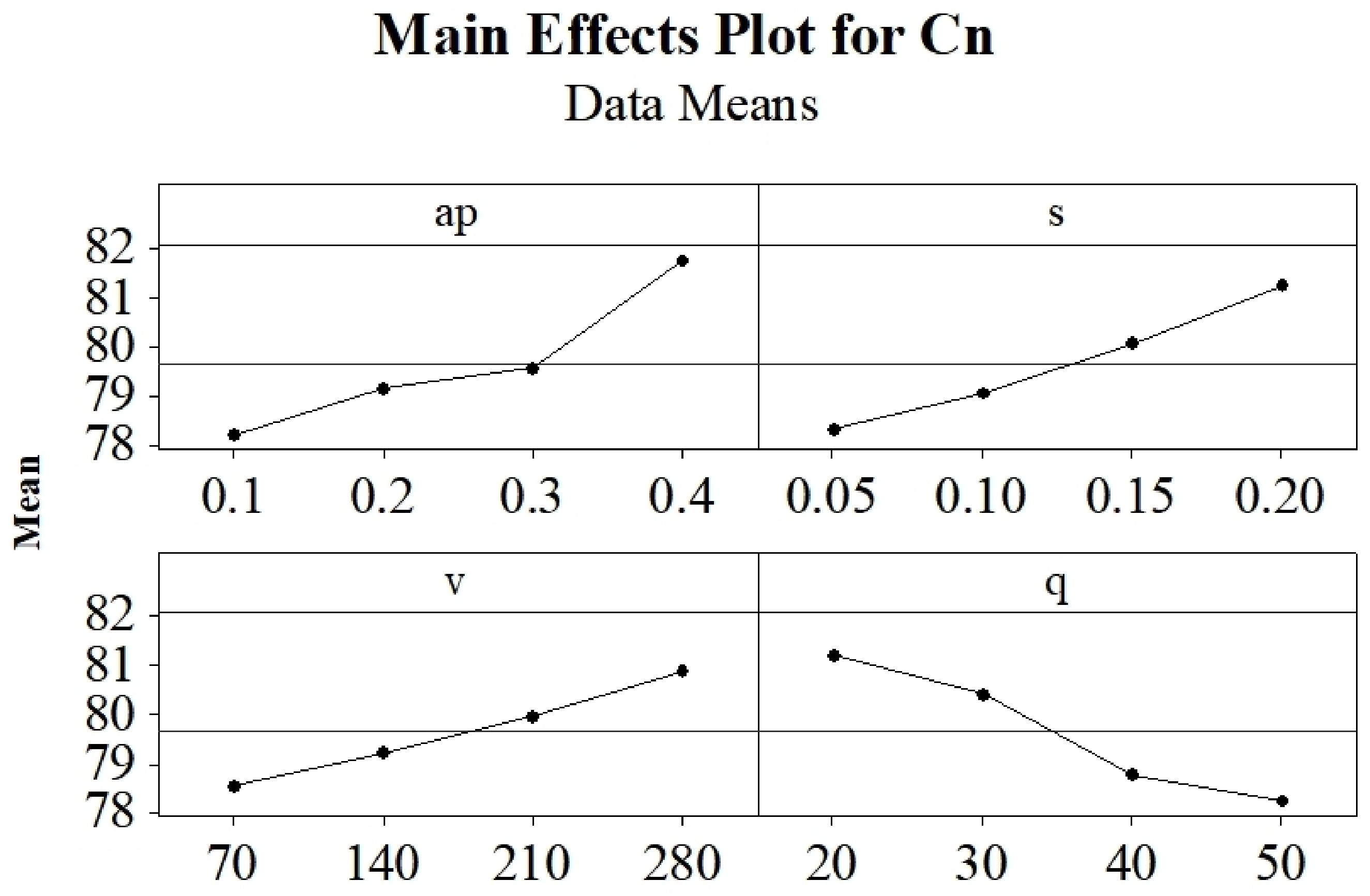

3.5. Assessment of Cutting Noise

4. WASPAS Multi-Objective Assessment

4.1. Weight Calculation Using Entropy Method

4.2. Implementation of WASPAS Optimization

5. Conclusions

- ▪

- The tool-wear was greatly controlled using ZnO nano-cutting lubricant due to the better lubricating characteristics of the synthesized fluid. The effects of cutting speed were traced to be the largest (76.68%), followed by flow rate (11.94%), depth of cut (6.27%), and feed (4.94%). The mechanisms like abrasion, chipping, and diffusion were found to be dominant.

- ▪

- The surface roughness (Ra) was extensively influenced by feed (74.26%) and depth of cut (15.88%). The impact of flow rate over Ra was traced to be insignificant.

- ▪

- The power consumption observed throughout the machining process showed an increase in conjunction with elevated cutting speeds and flow rates. Significant impacts of the feed-depth of cut, feed-flow rate, and depth of cut-flow rate interactions were also found for power consumption.

- ▪

- The cutting temperature was greatly reduced with use of dual-nozzle nano-cutting lubricant. All the input variables had a significant impact on cutting temperature. The cutting speed was the largest consequence (57.25%) on cutting temperature, followed by flow rate (19.22%), depth of cut (16.73%), and feed (6.4%).

- ▪

- The cutting noise in the entire experiment was found to be in the range of 76.08 to 83.31 dB, which is relatively lower than the human hearing capability (85 dB). The effects of the depth of cut were determined to be the largest (33%) while other inputs were also significant.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Davim, J.P. Machining of Hard Materials; Springer: New York, NY, USA, 2011. [Google Scholar]

- Chinchanikar, S.; Choudhury, S.K. Machining of hardened steel—Experimental investigations, performance modelling and cooling techniques: A review. Int. J. Mach. Tools Manuf. 2015, 89, 95–109. [Google Scholar] [CrossRef]

- Choudhury, S.K.; Chinchanikar, S. 1.3 Finish Machining of Hardened Steel. Compr. Mater. Finish. 2017, 1, 47–92. [Google Scholar]

- Karim, M.R.; Tariq, J.B.; Morshed, S.M.; Shawon, S.H.; Hasan, A.; Prakash, C.; Pruncu, C.I. Environmental, economical and technological analysis of MQL-assisted machining of Al-Mg-Zr alloy using PCD tool. Sustainability 2021, 13, 7321. [Google Scholar] [CrossRef]

- Kursus, M.; Liew, P.J.; Che Sidik, N.A.; Wang, J. Recent progress on the application of nanofluids and hybrid nanofluids in machining: A comprehensive review. Int. J. Adv. Manuf. Technol. 2022, 121, 1455–1481. [Google Scholar] [CrossRef]

- Sarikaya, M.; Gupta, M.K.; Tomaz, I.; Danish, M.; Mia, M.; Rubaiee, S.; Jamil, M.; Pimenov, D.Y.; Khanna, N. Cooling techniques to improve the machinability and sustainability of light-weight alloys: A state-of-the-art review. J. Manuf. Process. 2021, 62, 179–201. [Google Scholar] [CrossRef]

- Duc, T.M.; Tuan, N.M.; Long, T.T.; Ngoc, T.B. Machining feasibility and Sustainability study associated with air pressure, air flow rate, and nanoparticle concentration in Nanofluid minimum quantity lubrication-assisted hard milling process of 60Si2Mn steel. Proc. Inst. Mech. Eng. Part C J. Mechan. Eng. Sci. 2022, 23, 11256–11269. [Google Scholar] [CrossRef]

- Usha, M.; Rao, G.S. Machining Aspects of Al2O3 Nano Cutting Fluids–A Comparative Study. Tribol. Ind. 2022, 44, 1. [Google Scholar] [CrossRef]

- Khatai, S.; Sahoo, A.K.; Kumar, R.; Panda, A. Recent research progress on various cooling and lubrication techniques used in sustainable hard machining: A comprehensive review. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023, 09544089231169655. [Google Scholar] [CrossRef]

- Junankar, A.A.; Parate, S.R.; Dethe, P.K.; Dhote, N.R.; Gadkar, D.G.; Gadkar, D.D.; Gajbhiye, S.A. Optimization of bearing steel turning parameters under CuO and ZnO nanofluid-MQL using MCDM hybrid approach. Mater. Today Proc. 2021, 47, 4292–4297. [Google Scholar] [CrossRef]

- Khan, A.M.; Gupta, M.K.; Hegab, H.; Jamil, M.; Mia, M.; He, N.; Pruncu, C.I. Energy-based cost integrated modelling and sustainability assessment of Al-GnP hybrid nanofluid assisted turning of AISI52100 steel. J. Clean. Prod. 2020, 257, 120502. [Google Scholar] [CrossRef]

- Khandekar, S.; Sankar, M.R.; Agnihotri, V.; Ramkumar, J. Nano-cutting fluid for enhancement of metal cutting performance. Mater. Manuf. Process 2012, 27, 963–967. [Google Scholar] [CrossRef]

- Sertsöz, Ş. Nano mos2 application in turning process with minimum quantity lubrication technique (Mql). Teh. Vjesn. 2021, 28, 70–76. [Google Scholar]

- Ngoc, T.B.; Duc, T.M.; Tuan, N.M.; Hoang, V.L.; Long, T.T. Machinability Assessment of Hybrid Nano Cutting Oil for Minimum Quantity Lubrication (MQL) in Hard Turning of 90CrSi Steel. Lubricants 2023, 11, 54. [Google Scholar] [CrossRef]

- Usluer, E.; Emiroğlu, U.; Yapan, Y.F.; Kshitij, G.; Khanna, N.; Sarıkaya, M.; Uysal, A. Investigation on the effect of hybrid nanofluid in MQL condition in orthogonal turning and a sustainability assessment. Sustain. Mater. Technol. 2023, 36, e00618. [Google Scholar] [CrossRef]

- Tuan, N.M.; Duc, T.M.; Long, T.T.; Hoang, V.L.; Ngoc, T.B. Investigation of Machining Performance of MQL and MQCL Hard Turning Using Nano Cutting Fluids. Fluids 2022, 7, 143. [Google Scholar] [CrossRef]

- Duc, T.M.; Long, T.T.; Chien, T.Q. Performance evaluation of MQL parameters using Al2O3 and MoS2 nanofluids in hard turning 90CrSi steel. Lubricants 2019, 7, 40. [Google Scholar] [CrossRef]

- Wickramasinghe, K.C.; Sasahara, H.; Abd Rahim, E.; Perera, G.I.P. Green Metalworking Fluids for sustainable machining applications: A review. J. Clean. Prod. 2020, 257, 120552. [Google Scholar] [CrossRef]

- Abbas, A.T.; El Rayes, M.M.; Luqman, M.; Naeim, N.; Hegab, H.; Elkaseer, A. On the Assessment of Surface Quality and Productivity Aspects in Precision HardTurning of AISI 4340 Steel Alloy: Relative Performance of Wiper vs. Conventional Inserts. Materials 2020, 13, 2036. [Google Scholar] [CrossRef]

- Mondal, K.; Chatterjee, S.; Das, S.; Mandal, B. An Investigation on Turning of AISI 4340 Steel Using Innovative Eco-Friendly Cutting Fluids. In Recent Advances in Thermofluids and Manufacturing Engineering: Select Proceedings of ICTMS; Springer Nature: Singapore, 2022; pp. 429–445. [Google Scholar]

- Junankar, A.A.; Yashpal, Y.; Purohit, J.K. Experimental investigation to study the effect of synthesized and characterized monotype and hybrid nanofluids in minimum quantity lubrication assisted turning of bearing steel. Proc. Inst. Mech. Eng. J. Eng. 2022, 236, 1794–1813. [Google Scholar] [CrossRef]

- Naresh Babu, M.; Anandan, V.; Muthukrishnan, N.; Arivalagar, A.A.; Dinesh Babu, M. Evaluation of graphene based nano fluids with minimum quantity lubrication in turning of AISI D3 steel. SN Appl. Sci. 2019, 1, 1–15. [Google Scholar] [CrossRef]

- Javid, H.; Jahanzaib, M.; Jawad, M.; Ali, M.A.; Farooq, M.U.; Pruncu, C.I.; Hussain, S. Parametric analysis of turning HSLA steel under minimum quantity lubrication (MQL) and nanofluids-based minimum quantity lubrication (NF-MQL): A concept of one-step sustainable machining. Int. J. Adv. Manuf. Technol. 2021, 117, 1915–1934. [Google Scholar] [CrossRef]

- Thakur, A.; Manna, A.; Samir, S. Multi-response optimization of turning parameters during machining of EN-24 steel with SiC nanofluids based minimum quantity lubrication. Silicon 2020, 12, 71–85. [Google Scholar] [CrossRef]

- Ramoliya, P.; Vora, B.; Vaghasiya, N.; Prajapati, H.; Vaghasiya, H. Effect of Various Heat Treatment On The Mechanical Properties of Steel Alloy EN31. Int. J. Innov. Res. Sci. Technol. 2017, 3, 2349–6010. [Google Scholar]

- Yıldırım, Ç.V. Investigation of hard turning performance of eco-friendly cooling strategies: Cryogenic cooling and nanofluid based MQL. Tribo. Int. 2020, 144, 106127. [Google Scholar] [CrossRef]

- Anurag, K.R.; Sahoo, A.K.; Panda, A. Comparative performance analysis of coated carbide insert in turning of Ti-6Al-4V ELI grade alloy under dry, minimum quantity lubrication and spray impingement cooling environments. J. Mater. Eng. Perform. 2022, 31, 709–732. [Google Scholar] [CrossRef]

- Das, A.; Pradhan, O.; Patel, S.K.; Das, S.R.; Biswal, B.B. Performance appraisal of various nanofluids during hard machining of AISI 4340 steel. J. Manuf. Process 2019, 46, 248–270. [Google Scholar] [CrossRef]

- Tuan, N.M.; Ngoc, T.B.; Thu, T.L.; Long, T.T. Investigation of the Effects of Nanoparticle Concentration and Cutting Parameters on Surface Roughness in MQL Hard Turning Using MoS2 Nanofluid. Fluids 2021, 6, 398. [Google Scholar] [CrossRef]

- Bilga, P.S.; Singh, S.; Kumar, R. Optimization of energy consumption response parameters for turning operation using Taguchi method. J. Clean. Prod. 2016, 137, 1406–1417. [Google Scholar] [CrossRef]

- Rajemi, M.F.; Mativenga, P.T.; Aramcharoen, A. Sustainable machining: Selection of optimum turningconditions based on minimum energy considerations. J. Clean Prod. 2010, 18, 1059–1065. [Google Scholar] [CrossRef]

- Nur, R.; Noordin, M.; Izman, S.; Kurniawan, D. Machining parameters effect in dry turning of AISI 316L stainless steel using coated carbide tools. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2015, 231, 676–683. [Google Scholar] [CrossRef]

- Ochengo, D.; Liang, L.; Zhao, W.; He, N. Optimization of Surface Quality and Power Consumption in Machining Hardened AISI 4340 Steel. Adv. Mater. Sci. Eng. 2022, 2022, 2675003. [Google Scholar] [CrossRef]

- Şahinoğlu, A.; Rafighi, M.; Kumar, R. An investigation on cutting sound effect on power consumption and surface roughness in CBN tool-assisted hard turning. Proc. Inst. Mech. Eng. Part E J. Process Mecha. Eng. 2022, 236, 1096–1108. [Google Scholar] [CrossRef]

- Senthilkumar, N.; Tamizharasan, T. Effect of tool geometry in turning AISI 1045 Steel: Experimental investigation and FEM Analysis. Arab. J. Sci. Eng. 2014, 39, 4963–4975. [Google Scholar] [CrossRef]

- Zaw, A.K.; Myat, A.M.; Thandar, M.; Htun, Y.M.; Aung, T.H.; Tun, K.M.; Han, Z.M. Assessment of Noise Exposure and Hearing Loss among Workers in Textile Mill (Thamine), Myanmar: A Cross-sectional Study. Saf. Health Work 2020, 11, 199–206. [Google Scholar] [CrossRef] [PubMed]

- Goelzer, B.; Hansen, C.H.; Sehrndt, G. Occupational Exposure to Noise: Evaluation, Prevention and Control; World Health Organisation: Geneva, Switzerland, 2001. [Google Scholar]

- Bouacha, K.; Yallese, M.A.; Mabrouki, T.; Rigal, J.F. Statistical analysis of surface roughness and cutting forces using response surface methodology in hard turning of AISI 52100 bearing steel with CBN tool. Int. J. Ref. Met. Hard Mate. 2010, 28, 349–361. [Google Scholar] [CrossRef]

- Perec, A.; Radomska-Zalas, A. WASPAS Optimization in Advanced Manufacturing. Procedia Comput. Sci. 2022, 207, 1193–1200. [Google Scholar] [CrossRef]

- Reddy, P.V.; Kumar, G.S.; Kumar, V.S. Multi-response optimization in machining Inconel-625 by abrasive water jet machining process using WASPAS and MOORA. Arab. J. Sci. Eng. 2020, 45, 9843–9857. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, S.; Bilga, P.S.; Singh, J.; Singh, S.; Scutaru, M.L.; Pruncu, C.I. Revealing the benefits of entropy weights method for multi-objective optimization in machining operations: A critical review. J. Mater. Res. Technol. 2021, 10, 1471–1492. [Google Scholar] [CrossRef]

- Kumar, R.; Bilga, P.S.; Singh, S. Multi objective optimization using different methods of assigning weights to energy consumption responses, surface roughness and material removal rate during rough turning operation. J. Clean. Prod. 2017, 164, 45–57. [Google Scholar] [CrossRef]

| Test No. | Input Variables | Response Measured | |||||||

|---|---|---|---|---|---|---|---|---|---|

| ap (mm) | s (mm/rev) | v (m/min) | q (mL/hr) | VB (mm) | Ra (μm) | P (kW) | T (°C) | Cn (dB) | |

| 1 | 0.1 | 0.05 | 70 | 20 | 0.049 | 0.498 | 0.817 | 63.6 | 77.13 |

| 2 | 0.1 | 0.1 | 140 | 30 | 0.046 | 0.722 | 1.053 | 48.7 | 77.86 |

| 3 | 0.1 | 0.15 | 210 | 40 | 0.063 | 0.815 | 1.161 | 83.5 | 78.08 |

| 4 | 0.1 | 0.2 | 280 | 50 | 0.079 | 1.395 | 1.184 | 121 | 79.71 |

| 5 | 0.2 | 0.05 | 140 | 40 | 0.067 | 0.603 | 0.913 | 78.9 | 76.62 |

| 6 | 0.2 | 0.1 | 70 | 50 | 0.027 | 0.567 | 0.726 | 43.8 | 76.08 |

| 7 | 0.2 | 0.15 | 280 | 20 | 0.089 | 0.823 | 1.388 | 269.8 | 82.31 |

| 8 | 0.2 | 0.2 | 210 | 30 | 0.064 | 1.153 | 1.312 | 153 | 81.62 |

| 9 | 0.3 | 0.05 | 210 | 50 | 0.041 | 0.252 | 1.012 | 69 | 77.03 |

| 10 | 0.3 | 0.1 | 280 | 40 | 0.081 | 0.636 | 1.314 | 120 | 79.18 |

| 11 | 0.3 | 0.15 | 70 | 30 | 0.029 | 0.924 | 0.956 | 86.9 | 79.74 |

| 12 | 0.3 | 0.2 | 140 | 20 | 0.048 | 1.604 | 1.147 | 94.6 | 82.34 |

| 13 | 0.4 | 0.05 | 280 | 30 | 0.095 | 0.697 | 1.342 | 214.9 | 82.42 |

| 14 | 0.4 | 0.1 | 210 | 20 | 0.054 | 0.814 | 1.328 | 145.1 | 83.11 |

| 15 | 0.4 | 0.15 | 140 | 50 | 0.043 | 1.363 | 1.045 | 85.8 | 80.14 |

| 16 | 0.4 | 0.2 | 70 | 40 | 0.054 | 2.174 | 0.919 | 74.4 | 81.31 |

| Source | DF | Seq-SS | Adj-MS | F | P | % Impact | Significant |

|---|---|---|---|---|---|---|---|

| ap | 3 | 0.0003837 | 0.0001279 | 39.61 | 0.007 | 6.27 | Yes |

| s | 3 | 0.0003022 | 0.0001007 | 31.19 | 0.009 | 4.94 | Yes |

| v | 3 | 0.0046892 | 0.0015631 | 484.05 | 0.000 | 76.68 | Yes |

| q | 3 | 0.0007302 | 0.0002434 | 75.37 | 0.003 | 11.94 | Yes |

| Error | 3 | 0.0000097 | 0.0000032 | ||||

| Total | 15 | 0.0061149 |

| Source | DF | Seq-SS | Adj-MS | F | P | % Impact | Significant |

|---|---|---|---|---|---|---|---|

| ap | 3 | 0.56579 | 0.18860 | 35.85 | 0.008 | 15.88 | Yes |

| s | 3 | 2.64453 | 0.88151 | 167.57 | 0.001 | 74.26 | Yes |

| v | 3 | 0.25405 | 0.08468 | 16.10 | 0.024 | 7.13 | Yes |

| q | 3 | 0.08066 | 0.02689 | 5.11 | 0.107 | 2.26 | No |

| Error | 3 | 0.01578 | 0.00526 | ||||

| Total | 15 | 3.56082 |

| Source | DF | Seq-SS | Adj-MS | F | P | % Impact | Significant |

|---|---|---|---|---|---|---|---|

| ap | 3 | 0.023368 | 0.007789 | 9.95 | 0.046 | 3.78 | Yes |

| s | 3 | 0.037242 | 0.012414 | 15.86 | 0.024 | 6.02 | Yes |

| v | 3 | 0.469742 | 0.156581 | 200.04 | 0.001 | 75.94 | Yes |

| q | 3 | 0.085909 | 0.028636 | 36.59 | 0.007 | 13.89 | Yes |

| Error | 3 | 0.002348 | 0.000783 | ||||

| Total | 15 | 0.618609 |

| Source | DF | Seq-SS | Adj-MS | F | P | % Impact | Significant |

|---|---|---|---|---|---|---|---|

| ap | 3 | 9389.6 | 3129.9 | 44.03 | 0.006 | 16.73 | Yes |

| s | 3 | 3591.9 | 1197.3 | 16.84 | 0.022 | 6.40 | Yes |

| v | 3 | 32123.1 | 10707.7 | 150.64 | 0.001 | 57.25 | Yes |

| q | 3 | 10788.5 | 3596.2 | 50.59 | 0.005 | 19.22 | Yes |

| Error | 3 | 213.2 | 71.1 | ||||

| Total | 15 | 56106.3 |

| Source | DF | Seq-SS | Adj-MS | F | p | % Impact | Significant |

|---|---|---|---|---|---|---|---|

| ap | 3 | 27.0136 | 9.0045 | 152.58 | 0.001 | 33.00 | Yes |

| s | 3 | 19.5626 | 6.5209 | 110.49 | 0.001 | 23.89 | Yes |

| v | 3 | 12.0609 | 4.0203 | 68.12 | 0.003 | 14.73 | Yes |

| q | 3 | 23.0560 | 7.6853 | 130.22 | 0.001 | 28.16 | Yes |

| Error | 3 | 0.1770 | 0.0590 | ||||

| Total | 15 | 81.8701 |

| Experiment No. | Cumulative Relative Relevance Index | Rank |

|---|---|---|

| 1 | 0.603162 | 4 |

| 2 | 0.605453 | 3 |

| 3 | 0.427278 | 7 |

| 4 | 0.295346 | 13 |

| 5 | 0.485798 | 5 |

| 6 | 0.768964 | 2 |

| 7 | 0.25192 | 16 |

| 8 | 0.293974 | 14 |

| 9 | 0.769163 | 1 |

| 10 | 0.37983 | 9 |

| 11 | 0.483902 | 6 |

| 12 | 0.352656 | 11 |

| 13 | 0.287809 | 15 |

| 14 | 0.348862 | 12 |

| 15 | 0.396269 | 8 |

| 16 | 0.364621 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khatai, S.; Kumar, R.; Panda, A.; Sahoo, A.K. WASPAS Based Multi Response Optimization in Hard Turning of AISI 52100 Steel under ZnO Nanofluid Assisted Dual Nozzle Pulse-MQL Environment. Appl. Sci. 2023, 13, 10062. https://doi.org/10.3390/app131810062

Khatai S, Kumar R, Panda A, Sahoo AK. WASPAS Based Multi Response Optimization in Hard Turning of AISI 52100 Steel under ZnO Nanofluid Assisted Dual Nozzle Pulse-MQL Environment. Applied Sciences. 2023; 13(18):10062. https://doi.org/10.3390/app131810062

Chicago/Turabian StyleKhatai, Saswat, Ramanuj Kumar, Amlana Panda, and Ashok Kumar Sahoo. 2023. "WASPAS Based Multi Response Optimization in Hard Turning of AISI 52100 Steel under ZnO Nanofluid Assisted Dual Nozzle Pulse-MQL Environment" Applied Sciences 13, no. 18: 10062. https://doi.org/10.3390/app131810062