Thermal Stability of Oxidation-Resistant Ta-Zr-Si-B-N and Ta-Zr-Si-B-C Coatings under In Situ TEM Heating and Vacuum Annealing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coating Deposition

2.2. Structural Characteristics

2.3. Mechanical Characteristics

2.4. Thermal Stability

3. Results and Discussion

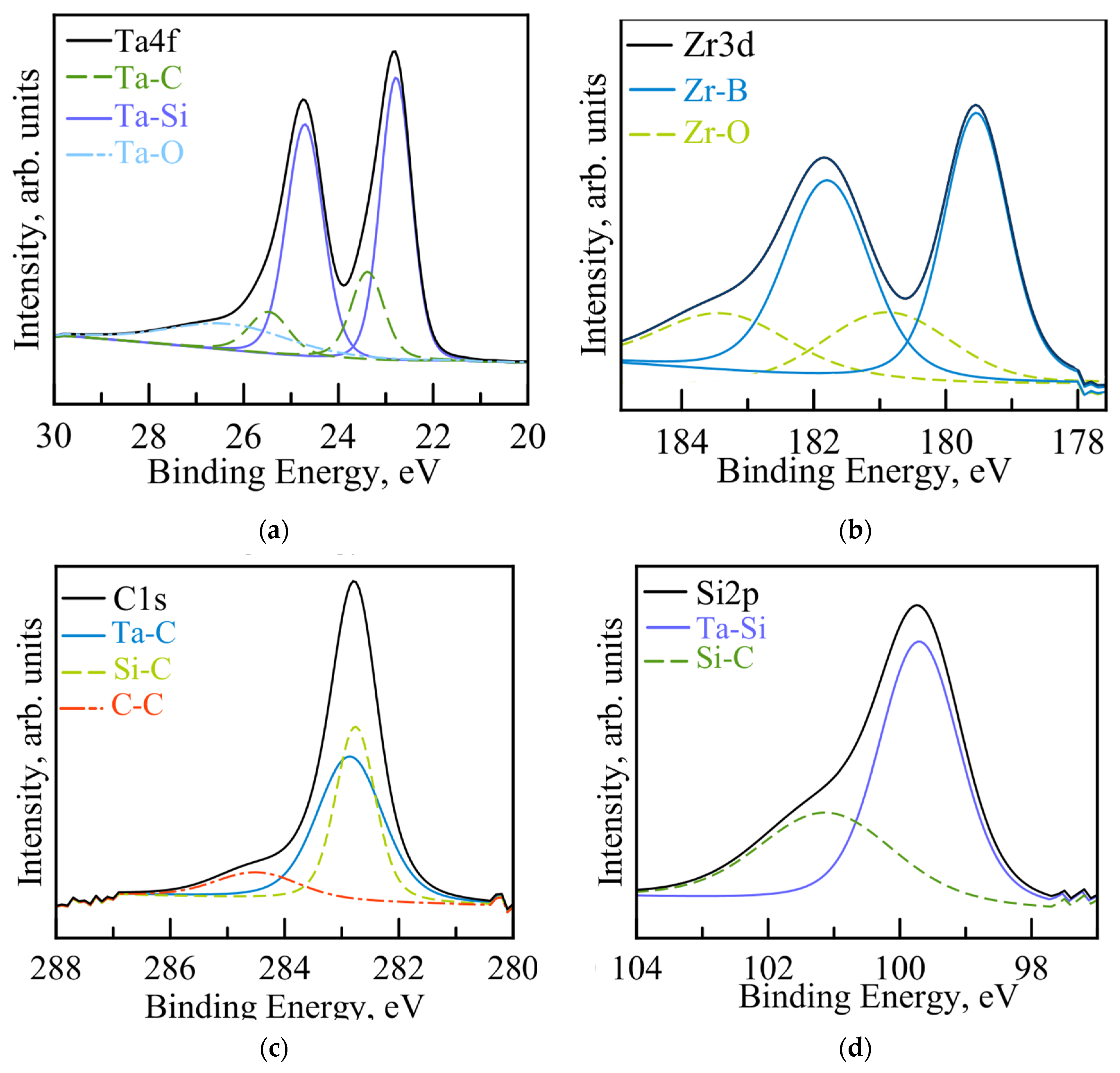

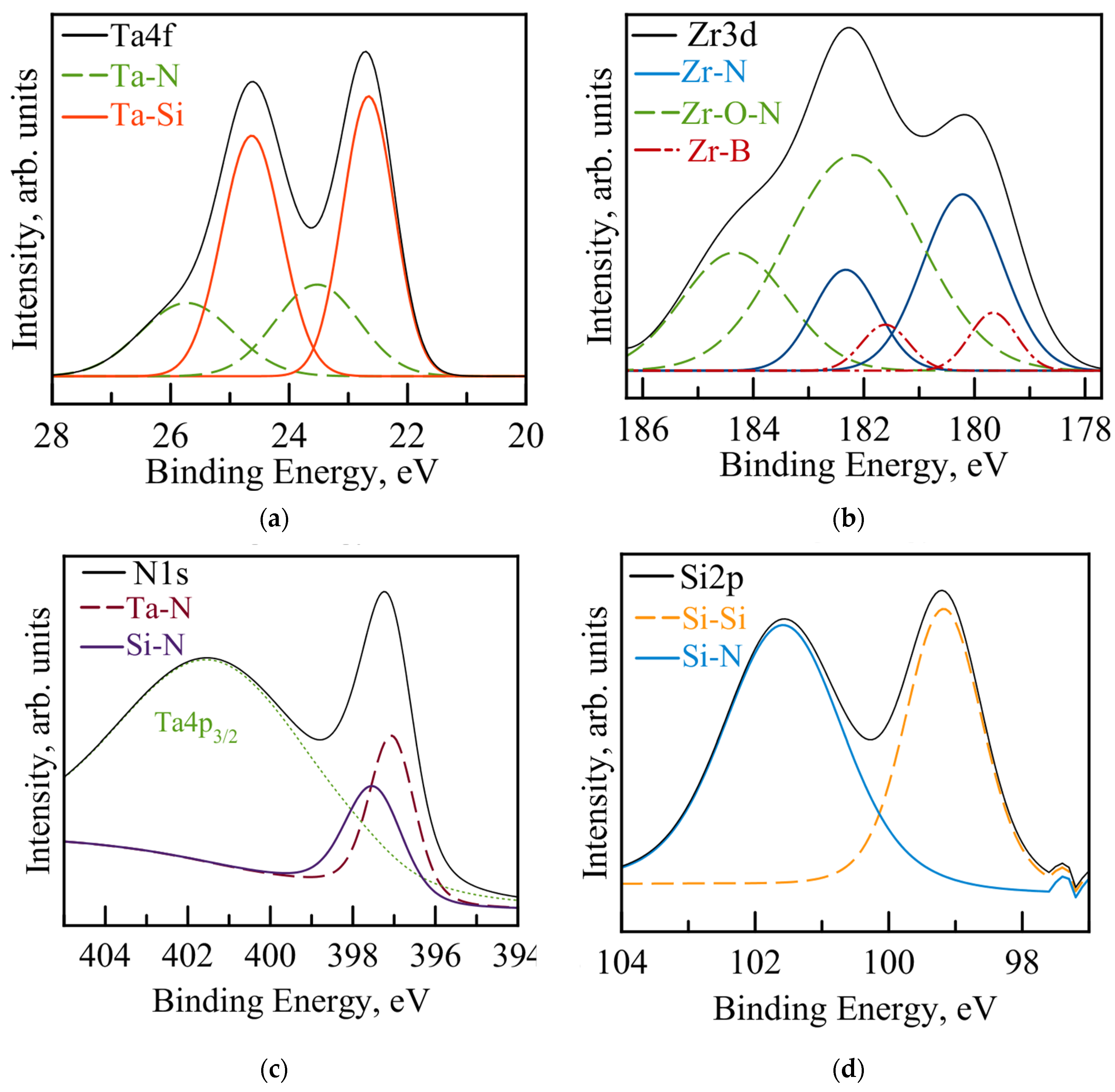

3.1. Structure and Mechanical Characteristics of As-Deposited Coatings

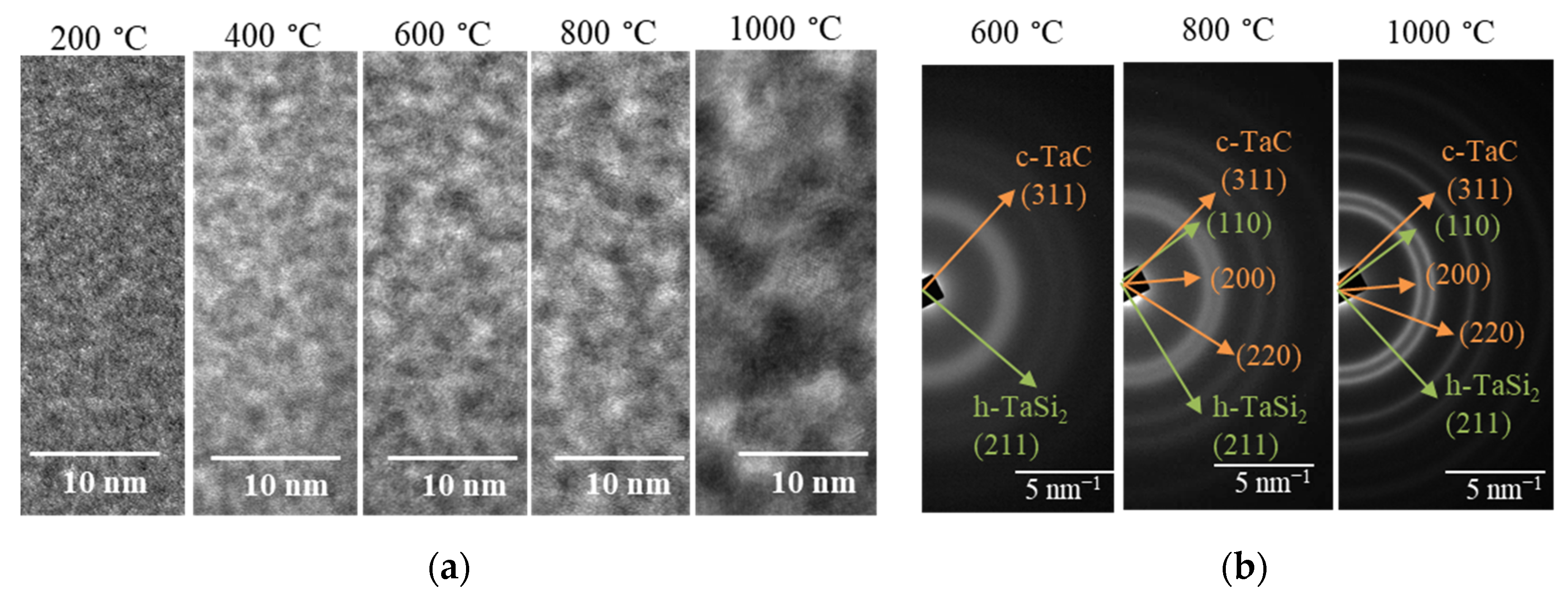

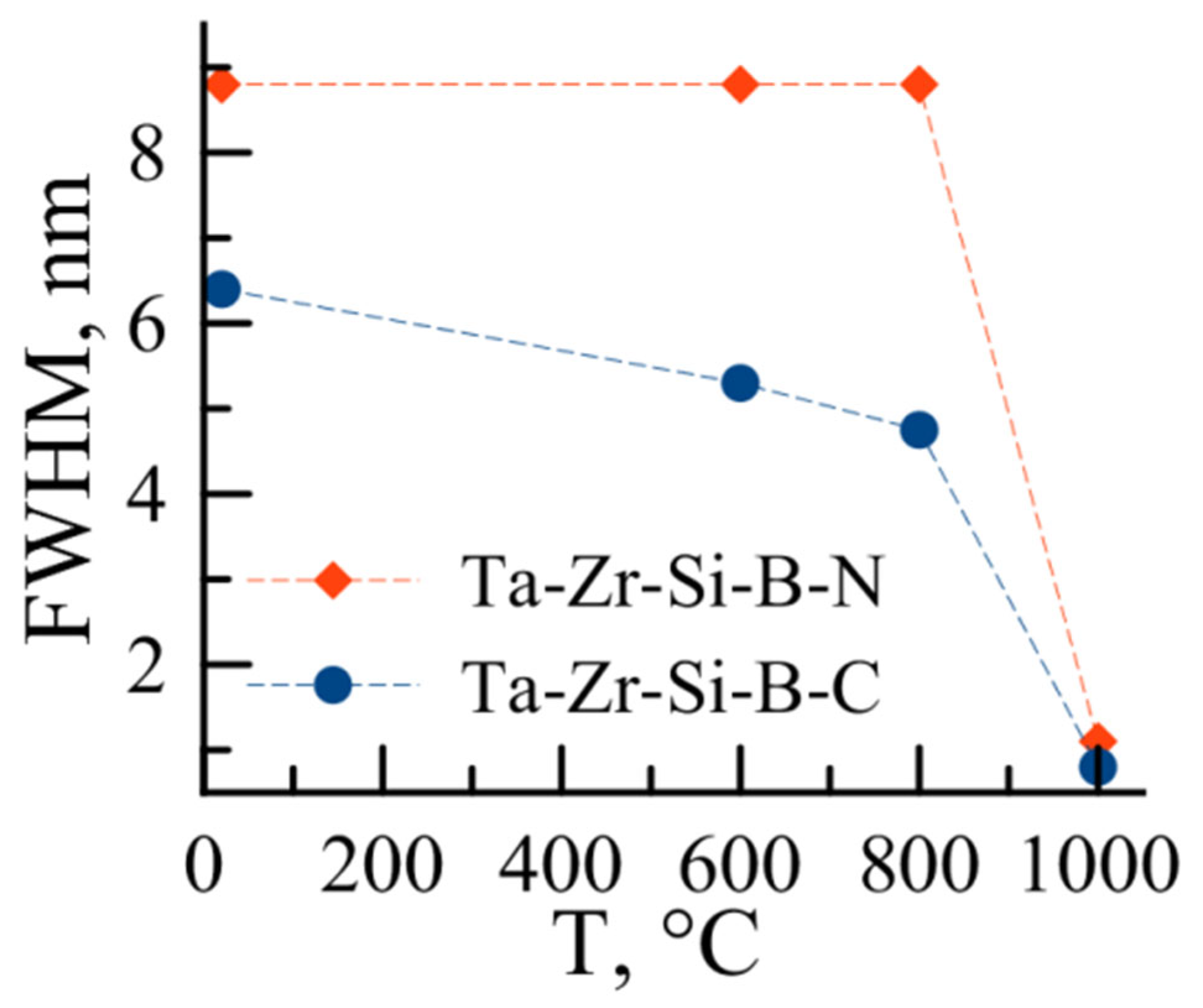

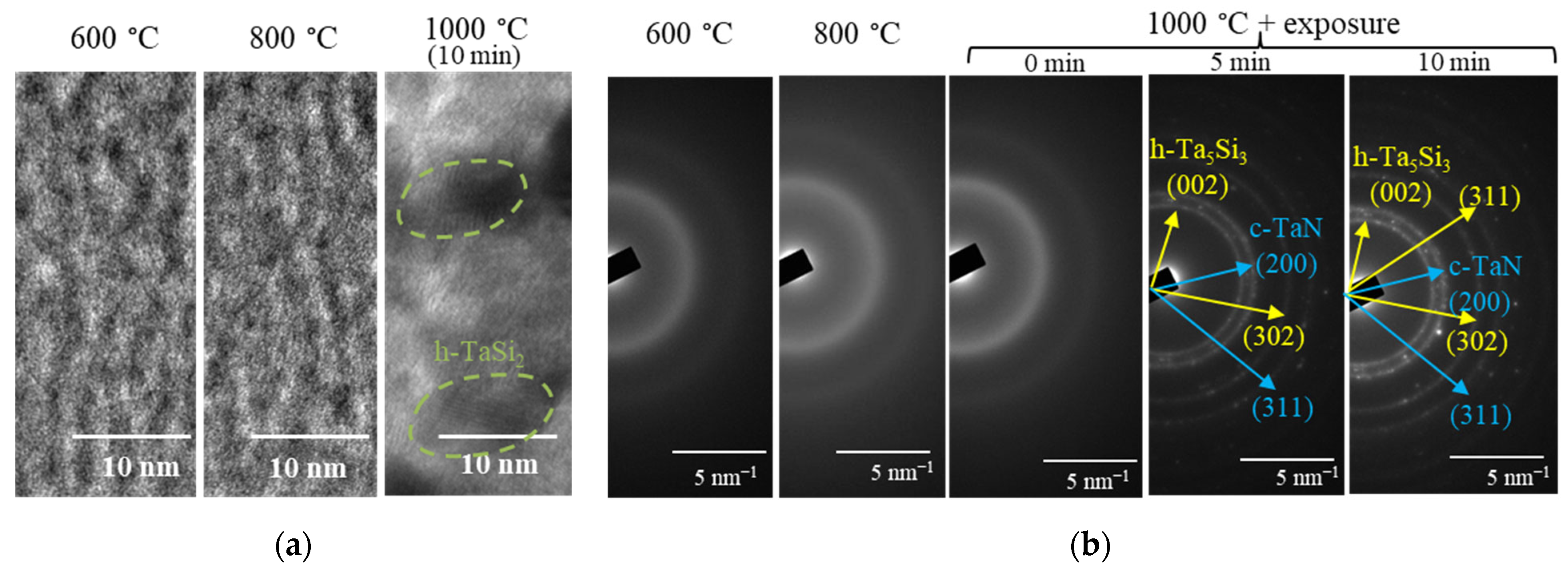

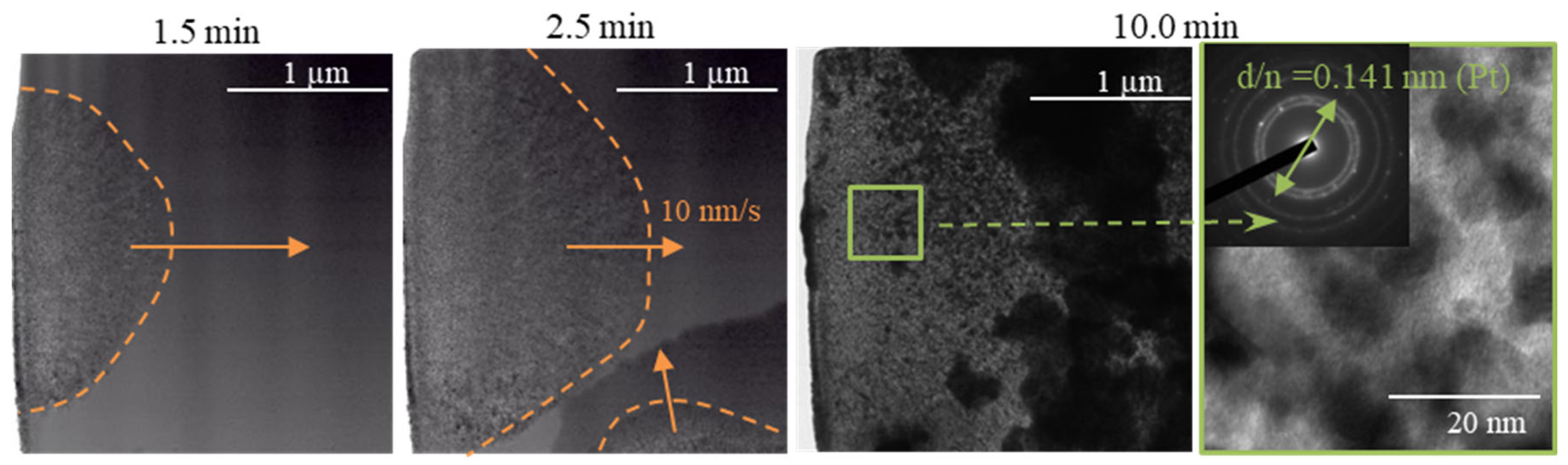

3.2. Thermal Stability under In Situ TEM Heating

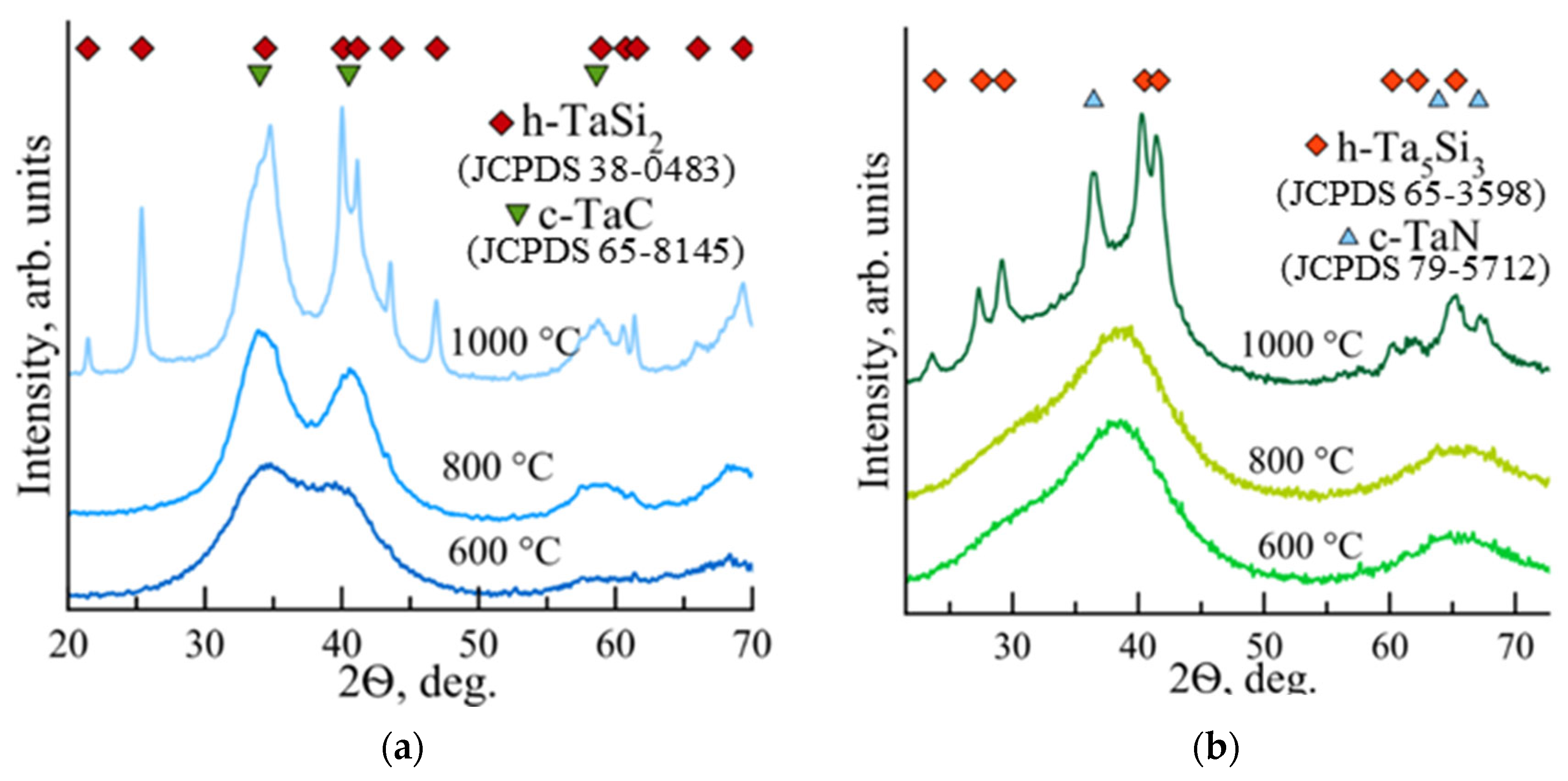

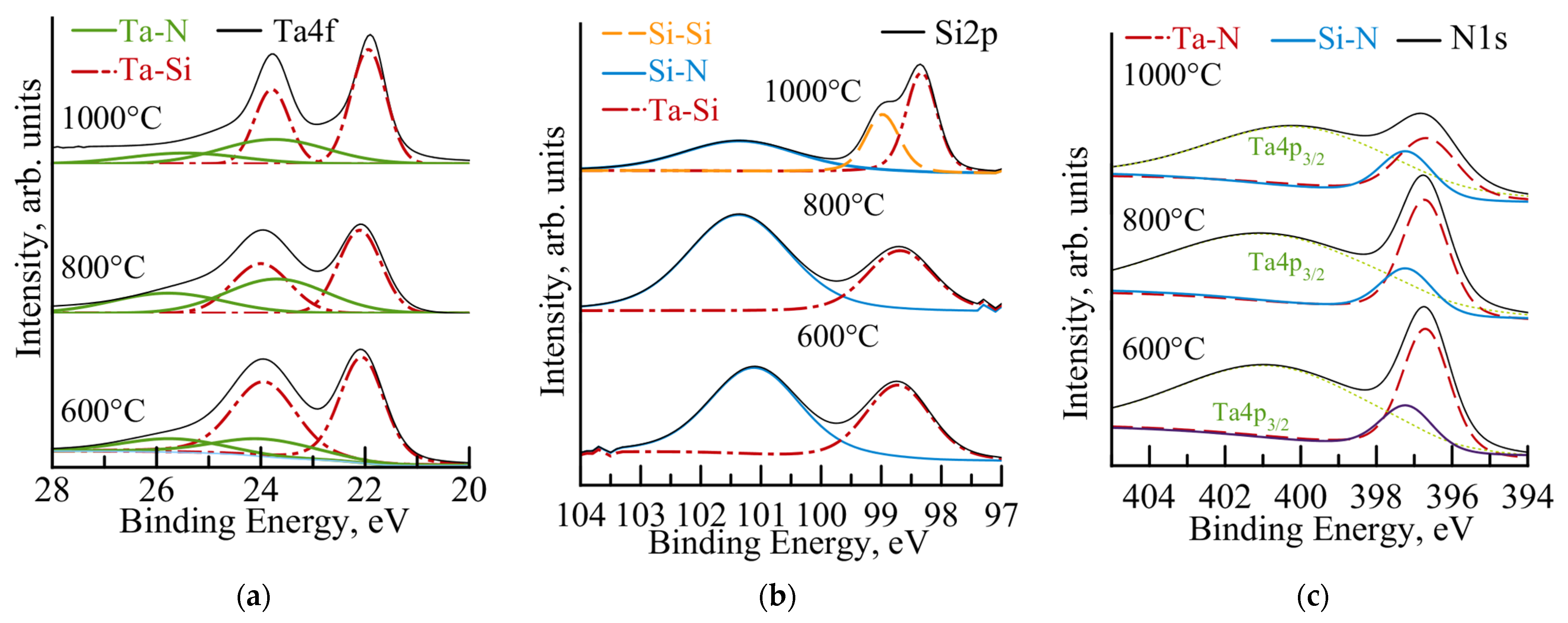

3.3. Thermal Stability under Vacuum Annealing

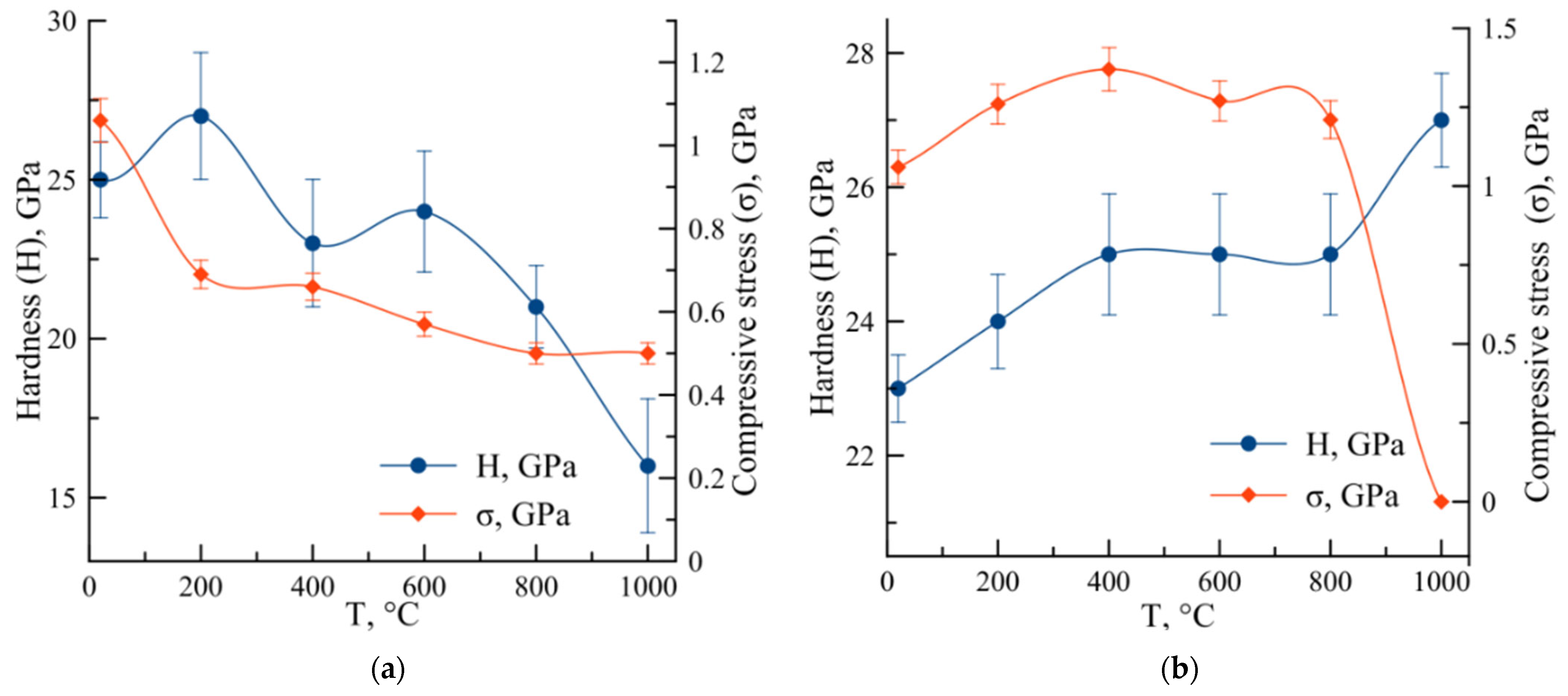

3.4. Thermal Stability under Nanoindentation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bahr, A.; Richter, S.; Hahn, R.; Wojcik, T.; Podsednik, M.; Limbeck, A.; Ramm, J.; Hunold, O.; Kolozsvári, S.; Riedl, H. Oxidation Behaviour and Mechanical Properties of Sputter-Deposited TMSi2 Coatings (TM = Mo, Ta, Nb). J. Alloys Compd. 2023, 931, 167532. [Google Scholar] [CrossRef]

- Shon, I.-J.; Ko, I.-Y.; Chae, S.-M.; Na, K. Rapid consolidation of nanostructured TaSi2 from mechanochemically synthesized powder by high frequency induction heated sintering. Ceram. Int. 2011, 37, 679–682. [Google Scholar] [CrossRef]

- Niu, Y.; Huang, L.; Zhai, C.; Zeng, Y.; Zheng, X.; Ding, C. Microstructure and Thermal Stability of TaSi2 Coating Fabricated by Vacuum Plasma Spray. Surf. Coat. Technol. 2015, 279, 1–8. [Google Scholar] [CrossRef]

- Sytchenko, A.D.; Kozlova, N.S.; Zabelina, E.V.; Loginov, P.A.; Levashov, E.A.; Kiryukhantsev-Korneev, P.V. The Effect of the Ar/N2 Gas Ratio on the Structure and Properties of Ta-Si-N Coatings Produced by Magnetron Sputtering of TaSi2 Target. Surf. Interfaces 2023, 37, 102654. [Google Scholar] [CrossRef]

- Sytchenko, A.D.; Levashov, E.A.; Kiryukhantsev-Korneev, P.V. Structure and Properties of Ta–Si–N Coatings Produced by Pulsed Magnetron Sputtering. Russ. J. Non-Ferrous Met. 2021, 62, 611–617. [Google Scholar] [CrossRef]

- Zeman, P.; Musil, J.; Daniel, R. High-Temperature Oxidation Resistance of Ta–Si–N Films with a High Si Content. Surf. Coat. Technol. 2006, 200, 4091–4096. [Google Scholar] [CrossRef]

- Du, S.; Zhang, K.; Wen, M.; Ren, P.; Meng, Q.; Hu, C.; Zheng, W. Tribochemistry Dependent Tribological Behavior of Superhard TaC/SiC Multilayer Films. Surf. Coat. Technol. 2018, 337, 492–500. [Google Scholar] [CrossRef]

- Bondarev, A.V.; Vorotilo, S.; Shchetinin, I.V.; Levashov, E.A.; Shtansky, D.V. Fabrication of Ta-Si-C Targets and Their Utilization for Deposition of Low Friction Wear Resistant Nanocomposite Si-Ta-C-(N) Coatings Intended for Wide Temperature Range Tribological Applications. Surf. Coat. Technol. 2019, 359, 342–353. [Google Scholar] [CrossRef]

- Ren, X.; Li, H.; Fu, Q.; Li, K. Ultra-High Temperature Ceramic TaB2–TaC–SiC Coating for Oxidation Protection of SiC-Coated Carbon/Carbon Composites. Ceram. Int. 2014, 40, 9419–9425. [Google Scholar] [CrossRef]

- Korotaev, A.D.; Borisov, D.P.; Moshkov, V.Y.; Ovchinnikov, S.V.; Oskomov, K.V.; Pinzhin, Y.P.; Savostikov, V.M.; Tymentsev, A.N. Nanocomposite and Nanostructured Superhard Ti-Si-B-N Coatings. Russ. Phys. J. 2007, 50, 969–979. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Kozlova, N.S.; Levashov, E.A. Optical Characteristics of NUV-VIS-NIR Transparent Zr-Si-B-N Hard Films for Protection of Optical and Laser Devices. J. Phys. Conf. Ser. 2020, 1692, 012022. [Google Scholar] [CrossRef]

- Wang, Z.; Niu, Y.; Hu, C.; Li, H.; Zeng, Y.; Zheng, X.; Ren, M.; Sun, J. High Temperature Oxidation Resistance of Metal Silicide Incorporated ZrB2 Composite Coatings Prepared by Vacuum Plasma Spray. Ceram. Int. 2015, 41, 14868–14875. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, X.; Cheng, H.; Geng, Z.; Li, W. Fabrication and Oxidation Resistance of a Novel MoSi2-ZrB2-Based Coating on Mo-Based Alloy. Materials 2023, 16, 5634. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Qian, Y.; Xu, J.; Jiang, Y.; Zuo, J.; Li, M. Oxidation and Cracking/Spallation Resistance of ZrB2–SiC–TaSi2–Si Coating on Siliconized Graphite at 1500 °C in Air. Ceram. Int. 2020, 46, 6254–6261. [Google Scholar] [CrossRef]

- Wang, R.-q.; Wang, N.; Zhu, S.-z.; Liu, Y.-b.; Ma, Z. Study on the Mechanism of Ultra-High Temperature Ablation of ZrB2–SiC–TaSi2 Coatings by Low-Pressure Plasma Spraying on the C/C Composites. Ceram. Int. 2022, 49, 11344–11354. [Google Scholar] [CrossRef]

- Farhadizadeh, A.; Vlček, J.; Houška, J.; Haviar, S.; Čerstvý, R.; Červená, M.; Zeman, P.; Matas, M. Effect of Nitrogen Content on High-Temperature Stability of Hard and Optically Transparent Amorphous Hf-Y-Si-B-C-N Coatings. Ceram. Int. 2023, 49, 6086–6093. [Google Scholar] [CrossRef]

- Houska, J.; Mares, P.; Simova, V.; Zuzjakova, S.; Cerstvy, R.; Vlcek, J. Dependence of Characteristics of MSiBCN (M = Ti, Zr, Hf) on the Choice of Metal Element: Experimental and Ab-Initio Study. Thin Solid Films 2016, 616, 359–365. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.; Sytchenko, A.; Pogozhev, Y.; Vorotilo, S.; Orekhov, A.; Loginov, P.; Levashov, E. Structure and Properties of Zr-Mo-Si-B-(N) Hard Coatings Obtained by D.C. Magnetron Sputtering of ZrB2-MoSi2 Target. Materials 2021, 14, 1932. [Google Scholar] [CrossRef] [PubMed]

- Kiryukhantsev-Korneev, P.V.; Sytchenko, A.D.; Vorotilo, S.A.; Klechkovskaya, V.V.; Lopatin, V.Y.; Levashov, E.A. Structure, Oxidation Resistance, Mechanical, and Tribological Properties of N- and C-Doped Ta-Zr-Si-B Hard Protective Coatings Obtained by Reactive D.C. Magnetron Sputtering of TaZrSiB Ceramic Cathode. Coatings 2020, 10, 946. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Sytchenko, A.D.; Levashov, E.A.; Lobova, T.A. Mechanical Properties and Heat Resistance of Ta–Zr–Si–B–C–N Coatings Obtained upon the Magnetron Sputtering of the TaZrSiB Target in Ar, N2, and C2H4 Atmosphere. Russ. J. Non-Ferr. Met. 2020, 61, 732–738. [Google Scholar] [CrossRef]

- Sytchenko, A.D.; Vakhrushev, R.A.; Kiryukhantsev-Korneev, P.V. Investigation of the Tribological Characteristics of Ta–Zr–Si–B–C–N Coatings. Powder Metall. Funct. Coat. 2023, 17, 62–70. [Google Scholar] [CrossRef]

- Morgiel, J.; Poliarus, O.; Pomorska, M.; Maj, Ł.; Szlezynger, M. Thermal Stability of Plasma-Sprayed NiAl/CrB2 Composite Coatings Investigated through in-Situ TEM Heating Experiment. Mater. Charact. 2020, 159, 110068. [Google Scholar] [CrossRef]

- Falqui, A.; Loche, D.; Casu, A. In Situ TEM Crystallization of Amorphous Iron Particles. Crystals 2020, 10, 41. [Google Scholar] [CrossRef]

- Jin, H.W.; Park, C.G.; Kim, M.C. In Situ TEM Heating Studies on the Phase Transformation of Metastable Phases in Fe–Cr–B Alloy Spray Coatings. Mater. Sci. Eng. A 2001, 304–306, 321–326. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Shpak, A.P.; Beresnev, V.M.; Kolesnikov, D.A.; Kunitskii, Y.A.; Sobol, O.V.; Uglov, V.V.; Komarov, F.F.; Shypylenko, A.P.; Makhmudov, N.A.; et al. Effect of Thermal Annealing in Vacuum and in Air on Nanograin Sizes in Hard and Superhard Coatings Zr-Ti-Si-N. J. Nanosci. Nanotechnol. 2012, 12, 9213–9219. [Google Scholar] [CrossRef] [PubMed]

- Koller, C.M.; Hollerweger, R.; Sabitzer, C.; Rachbauer, R.; Kolozsvári, S.; Paulitsch, J.; Mayrhofer, P.H. Thermal Stability and Oxidation Resistance of Arc Evaporated TiAlN, TaAlN, TiAlTaN, and TiAlN/TaAlN Coatings. Surf. Coat. Technol. 2014, 259, 599–607. [Google Scholar] [CrossRef]

- Rao, J.C.; Diao, H.Y.; Ocelík, V.; Vainchtein, D.; Zhang, C.; Kuo, C.; Tang, Z.; Guo, W.; Poplawsky, J.D.; Zhou, Y.; et al. Secondary Phases in AlxCoCrFeNi High-Entropy Alloys: An in-Situ TEM Heating Study and Thermodynamic Appraisal. Acta Mater. 2017, 131, 206–220. [Google Scholar] [CrossRef]

- Zhu, Q.; Liu, Y.; Cong, W.; Chang, D.; Fan, Q.; Cao, F.; Wang, T.G. The Effect of Vacuum Annealing Temperature on the Properties of AlCrTiSiN Coating Prepared by Arc Ion Plating. Coatings 2022, 12, 316, Retracted. [Google Scholar] [CrossRef]

- Penkov, O.V.; Kopylets, I.A.; Khadem, M.; Kondratenko, V.V.; Malykhin, S.V.; Surovitskiy, S.V.; Fedchenko, A.V. Evaluation of Structure and Mechanical Properties of TiZrNi Coatings under Annealing. Thin Solid Films 2022, 748, 139149. [Google Scholar] [CrossRef]

- Vorotilo, S.; Levashov, E.A.; Kurbatkina, V.V.; Patsera, E.I.; Loginov, P.A.; Lopatin, V.Y.; Orekhov, A.S. Theoretical and Experimental Study of Combustion Synthesis of Microgradient ULTRA High-Temperature Ceramics in Zr-Ta-Si-B System. J. Eur. Ceram. Soc. 2021, 41, 4728–4746. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Sytchenko, A.D.; Sviridova, T.A.; Sidorenko, D.A.; Andreev, N.V.; Klechkovskaya, V.V.; Polčak, J.; Levashov, E.A. Effects of Doping with Zr and Hf on the Structure and Properties of Mo-Si-B Coatings Obtained by Magnetron Sputtering of Composite Targets. Surf. Coat. Technol. 2022, 442, 128141. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of Hardness and Elastic Modulus by Instrumented Indentation: Advances in Understanding and Refinements to Methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Chen, P.Y.; Wang, W.C.; Wu, Y.T. Experimental Investigation of Thin Film Stress by Stoney’s Formula. Measurement 2019, 143, 39–50. [Google Scholar] [CrossRef]

- Du, S.; Wen, M.; Yang, L.; Ren, P.; Meng, Q.; Zhang, K.; Zheng, W. Structural, Hardness and Toughness Evolution in Si-Incorporated TaC Films. Ceram. Int. 2018, 44, 9318–9325. [Google Scholar] [CrossRef]

- Zhang, M.; Li, M.; Yan, Z.; Zhang, L.; Yin, J.; Ma, X.; Li, W.; Deng, L. Multifunctional Ag-ZrB2 Composite Film with Low Infrared Emissivity, Low Visible Light Reflectance and Hydrophobicity. Appl. Surf. Sci. 2022, 604, 154626. [Google Scholar] [CrossRef]

- Kaur, A.; Chahal, P.; Hogan, T. Selective Fabrication of SiC/Si Diodes by Excimer Laser under Ambient Conditions. IEEE Electron Device Lett. 2016, 37, 142–145. [Google Scholar] [CrossRef]

- Liu, X.; Ma, G.J.; Sun, G.; Duan, Y.P.; Liu, S.H. Effect of Deposition and Annealing Temperature on Mechanical Properties of TaN Film. Appl. Surf. Sci. 2011, 258, 1033–1037. [Google Scholar] [CrossRef]

- Muneshwar, T.; Cadien, K. Comparing XPS on Bare and Capped ZrN Films Grown by Plasma Enhanced ALD: Effect of Ambient Oxidation. Appl. Surf. Sci. 2018, 435, 367–376. [Google Scholar] [CrossRef]

- Zaman, A.; Meletis, E.I. Microstructure and Mechanical Properties of TaN Thin Films Prepared by Reactive Magnetron Sputtering. Coatings 2017, 7, 209. [Google Scholar] [CrossRef]

- Yamamoto, K.; Koga, Y.; Fujiwara, S. XPS Studies of Amorphous SiCN Thin Films Prepared by Nitrogen Ion-Assisted Pulsed-Laser Deposition of SiC Target. Diam. Relat. Mater. 2001, 10, 1921–1926. [Google Scholar] [CrossRef]

- Prakash, A.; Sundaram, K.B. Optical and XPS Studies of BCN Thin Films by Co-Sputtering of B4C and BN Targets. Appl. Surf. Sci. 2017, 396, 484–491. [Google Scholar] [CrossRef]

- Hu, J.; Li, H.; Li, J.; Huang, J.; Kong, J.; Zhu, H.; Xiong, D. Structure, Mechanical and Tribological Properties of TaCx Composite Films with Different Graphite Powers. J. Alloys Compd. 2020, 832, 153769. [Google Scholar] [CrossRef]

- Koller, C.M.; Marihart, H.; Bolvardi, H.; Kolozsvári, S.; Mayrhofer, P.H. Structure, Phase Evolution, and Mechanical Properties of DC, Pulsed DC, and High Power Impulse Magnetron Sputtered Ta–N Films. Surf. Coat. Technol. 2018, 347, 304–312. [Google Scholar] [CrossRef]

- Li, X.; Yin, X.; Zhang, L.; Pan, T. Comparison in Microstructure and Mechanical Properties of Porous Si3N4 Ceramics with SiC and Si3N4 Coatings. Mater. Sci. Eng. A 2009, 527, 103–109. [Google Scholar] [CrossRef]

- Hirata, A. Local Structure Analysis of Amorphous Materials by Angstrom-Beam Electron Diffraction. Microscopy 2021, 70, 171. [Google Scholar] [CrossRef] [PubMed]

- Cao, Z.H.; Hu, K.; Meng, X.K. Diffusion Barrier Properties of Amorphous and Nanocrystalline Ta Films for Cu Interconnects. J. Appl. Phys. 2009, 106, 113513. [Google Scholar] [CrossRef]

- Kuo, Y.L.; Lee, C.; Lin, J.C.; Yen, Y.W.; Lee, W.H. Evaluation of the Thermal Stability of Reactively Sputtered (Ti, Zr)Nx Nano-Thin Films as Diffusion Barriers between Cu and Silicon. Thin Solid Films 2005, 484, 265–271. [Google Scholar] [CrossRef]

- Lin, C.; Al-Muhtaseb, S.A.; Ritter, J.A. Thermal Treatment of Sol-Gel Derived Nickel Oxide Xerogels. J. Sol-Gel Sci. Technol. 2003, 28, 133–141. [Google Scholar] [CrossRef]

- Zier, M.; Oswald, S.; Reiche, R.; Wetzig, K. XPS Investigations of Thin Tantalum Films on a Silicon Surface. Anal. Bioanal. Chem. 2003, 375, 902–905. [Google Scholar] [CrossRef] [PubMed]

- Solov’ev, A.A.; Sochugov, N.S.; Oskomov, K.V. Effect of Residual Internal Stresses in TiN Coatings On Specific Losses in Anisotropic Electrical Steel. Phys. Met. Metallogr. 2010, 109, 111–119. [Google Scholar] [CrossRef]

- Shugurov, A.R.; Panin, A.V. Mechanisms of Stress Generation in Thin Films and Coatings. Tech. Phys. 2020, 65, 1881–1904. [Google Scholar] [CrossRef]

- Chen, Y.I.; Cheng, Y.R.; Chang, L.C.; Lu, T.S. Chemical Inertness of Ta-Si-N Coatings in Glass Molding. Thin Solid Films 2015, 584, 66–71. [Google Scholar] [CrossRef]

- Chung, C.K.; Chen, T.S.; Chang, N.W.; Chang, S.C.; Liao, M.W. Oxidation Resistance and Mechanical Property of Cosputtered Quasi-Amorphous Ta–Si–N Films under Vacuum Rapid Thermal Annealing. Surf. Coat. Technol. 2010, 205, 1268–1272. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Hörling, A.; Karlsson, L.; Sjölén, J.; Larsson, T.; Mitterer, C.; Hultman, L. Self-Organized Nanostructures in the Ti–Al–N System. Appl. Phys. Lett. 2003, 83, 2049–2051. [Google Scholar] [CrossRef]

- Wang, C.; Shi, K.; Gross, C.; Pureza, J.M.; de Mesquita Lacerda, M.; Chung, Y.W. Toughness Enhancement of Nanostructured Hard Coatings: Design Strategies and Toughness Measurement Techniques. Surf. Coat. Technol. 2014, 257, 206–212. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Beresnev, V.M.; Pogrebnjak, A.D.; Beresnev, V.M. Hard Nanocomposite Coatings, Their Structure and Properties. In Nanocomposites-New Trends Development; InTech: Houston, TX, USA, 2012. [Google Scholar] [CrossRef]

- Chung, C.K.; Chen, T.S.; Peng, C.C.; Wu, B.H. Thermal Stability of Ta–Si–N Nanocomposite Thin Films at Different Nitrogen Flow Ratios. Surf. Coat. Technol. 2006, 201, 3947–3952. [Google Scholar] [CrossRef]

| T, °C | Coating Ta-Zr-Si-B-C | Coating Ta-Zr-Si-B-N | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H, GPa | E, GPa | W, % | σ, GPa | H/E | H3/E2, GPa | H, GPa | E, GPa | W, % | σ, GPa | H/E | H3/E2, GPa | |

| 20 | 25 | 259 | 71 | −1.1 | 0.096 | 0.233 | 23 | 229 | 74 | −1.1 | 0.100 | 0.232 |

| 200 | 27 | 277 | 80 | −0.7 | 0.097 | 0.256 | 24 | 241 | 75 | −1.3 | 0.099 | 0.238 |

| 400 | 23 | 250 | 70 | −0.6 | 0.092 | 0.195 | 25 | 245 | 78 | −1.4 | 0.102 | 0.260 |

| 600 | 24 | 281 | 72 | −0.6 | 0.085 | 0.175 | 25 | 252 | 74 | −1.3 | 0.099 | 0.246 |

| 800 | 21 | 273 | 67 | 0 | 0.077 | 0.124 | 25 | 259 | 72 | −1.2 | 0.096 | 0.233 |

| 1000 | 16 | 239 | 53 | 0 | 0.067 | 0.072 | 27 | 275 | 77 | 0 | 0.098 | 0.260 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sytchenko, A.D.; Loginov, P.A.; Levashov, E.A.; Kiryukhantsev-Korneev, P.V. Thermal Stability of Oxidation-Resistant Ta-Zr-Si-B-N and Ta-Zr-Si-B-C Coatings under In Situ TEM Heating and Vacuum Annealing. Appl. Sci. 2023, 13, 10440. https://doi.org/10.3390/app131810440

Sytchenko AD, Loginov PA, Levashov EA, Kiryukhantsev-Korneev PV. Thermal Stability of Oxidation-Resistant Ta-Zr-Si-B-N and Ta-Zr-Si-B-C Coatings under In Situ TEM Heating and Vacuum Annealing. Applied Sciences. 2023; 13(18):10440. https://doi.org/10.3390/app131810440

Chicago/Turabian StyleSytchenko, Alina D., Pavel A. Loginov, Evgeny A. Levashov, and Philipp V. Kiryukhantsev-Korneev. 2023. "Thermal Stability of Oxidation-Resistant Ta-Zr-Si-B-N and Ta-Zr-Si-B-C Coatings under In Situ TEM Heating and Vacuum Annealing" Applied Sciences 13, no. 18: 10440. https://doi.org/10.3390/app131810440

APA StyleSytchenko, A. D., Loginov, P. A., Levashov, E. A., & Kiryukhantsev-Korneev, P. V. (2023). Thermal Stability of Oxidation-Resistant Ta-Zr-Si-B-N and Ta-Zr-Si-B-C Coatings under In Situ TEM Heating and Vacuum Annealing. Applied Sciences, 13(18), 10440. https://doi.org/10.3390/app131810440