Structure and Electrical Properties of AlFe Matrix Composites with Graphene

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

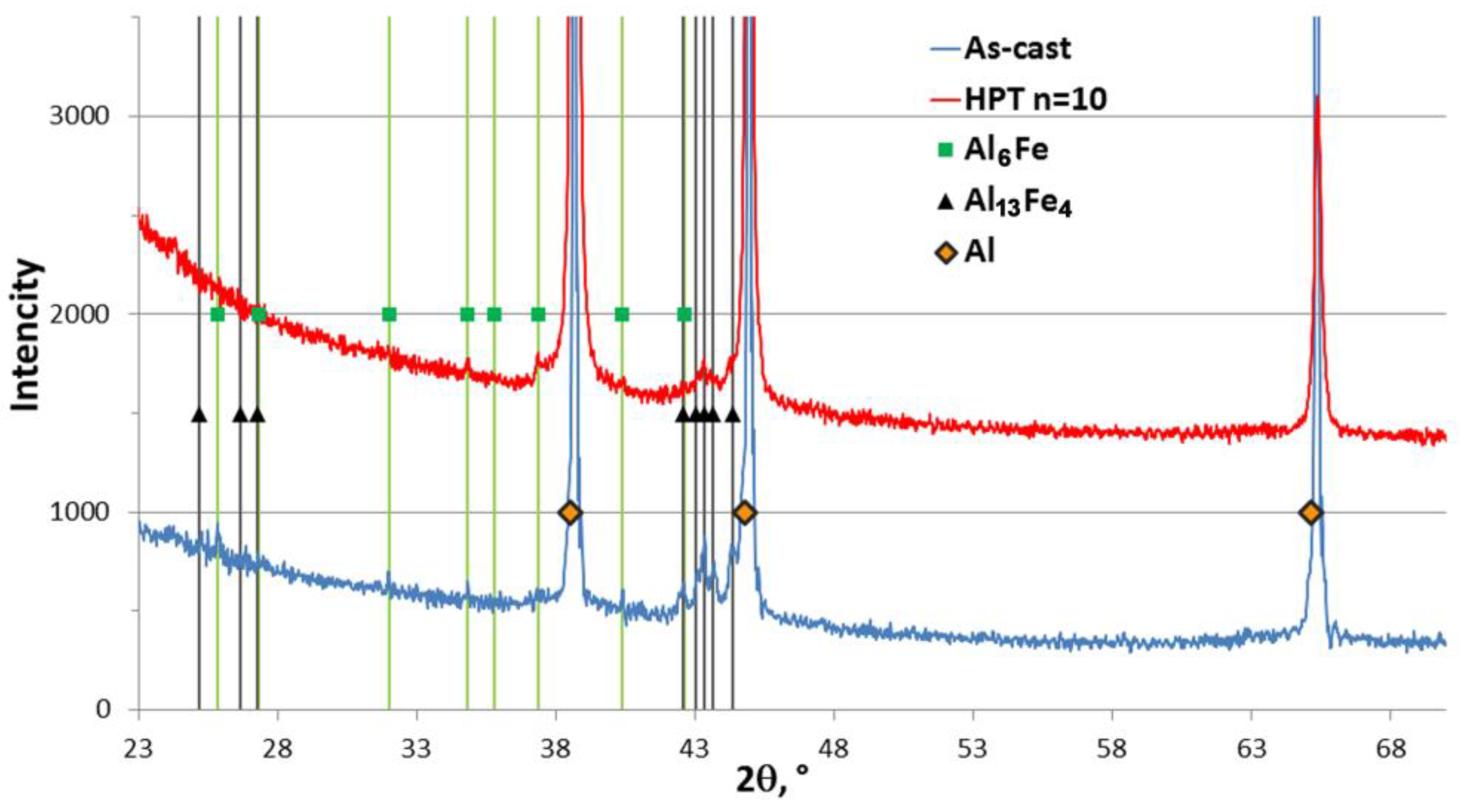

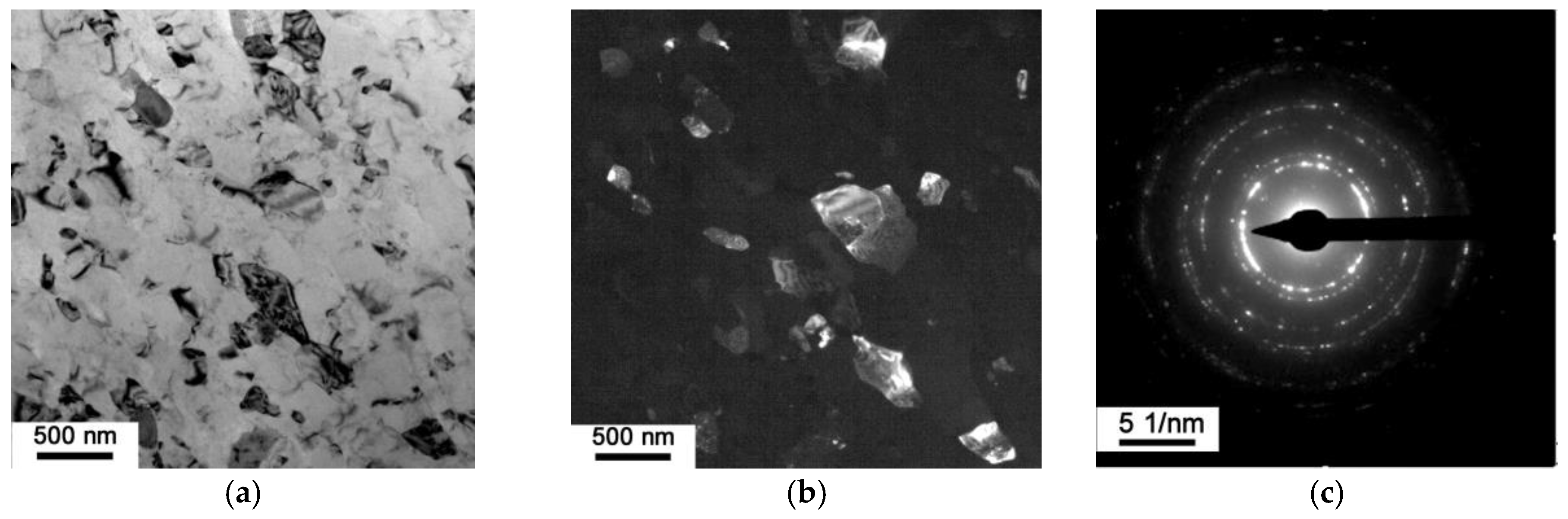

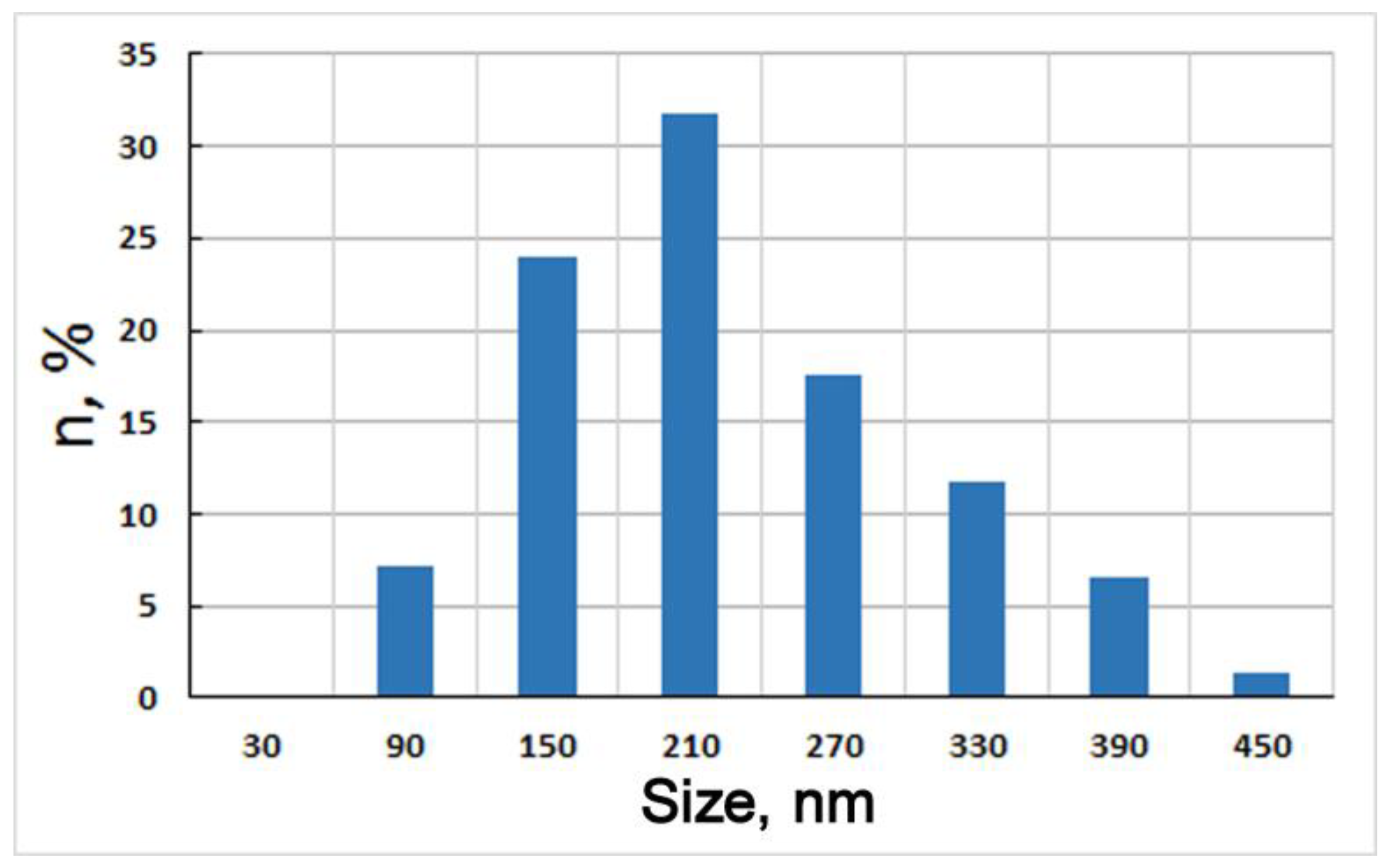

3.1. Structure and Hardness

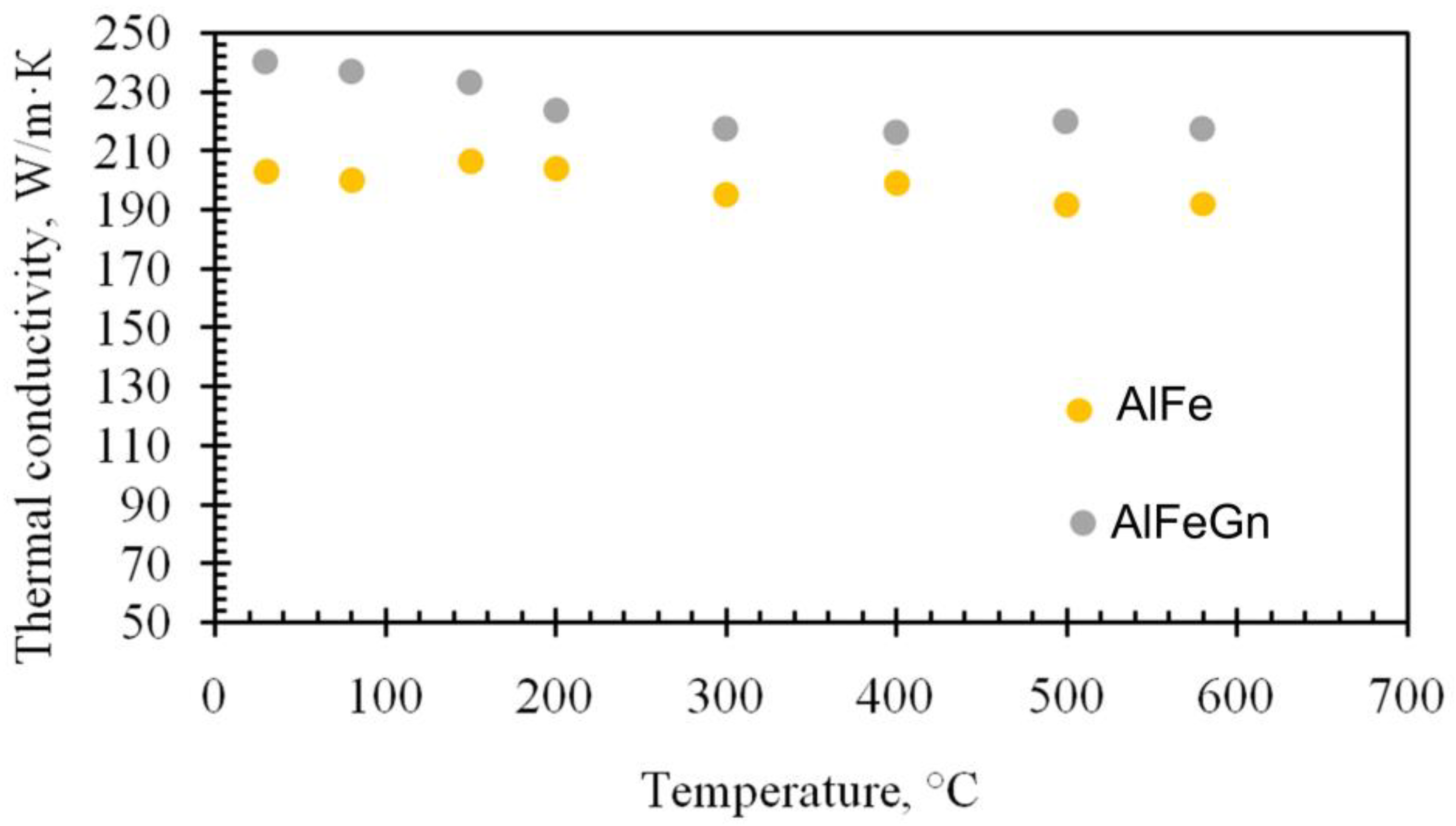

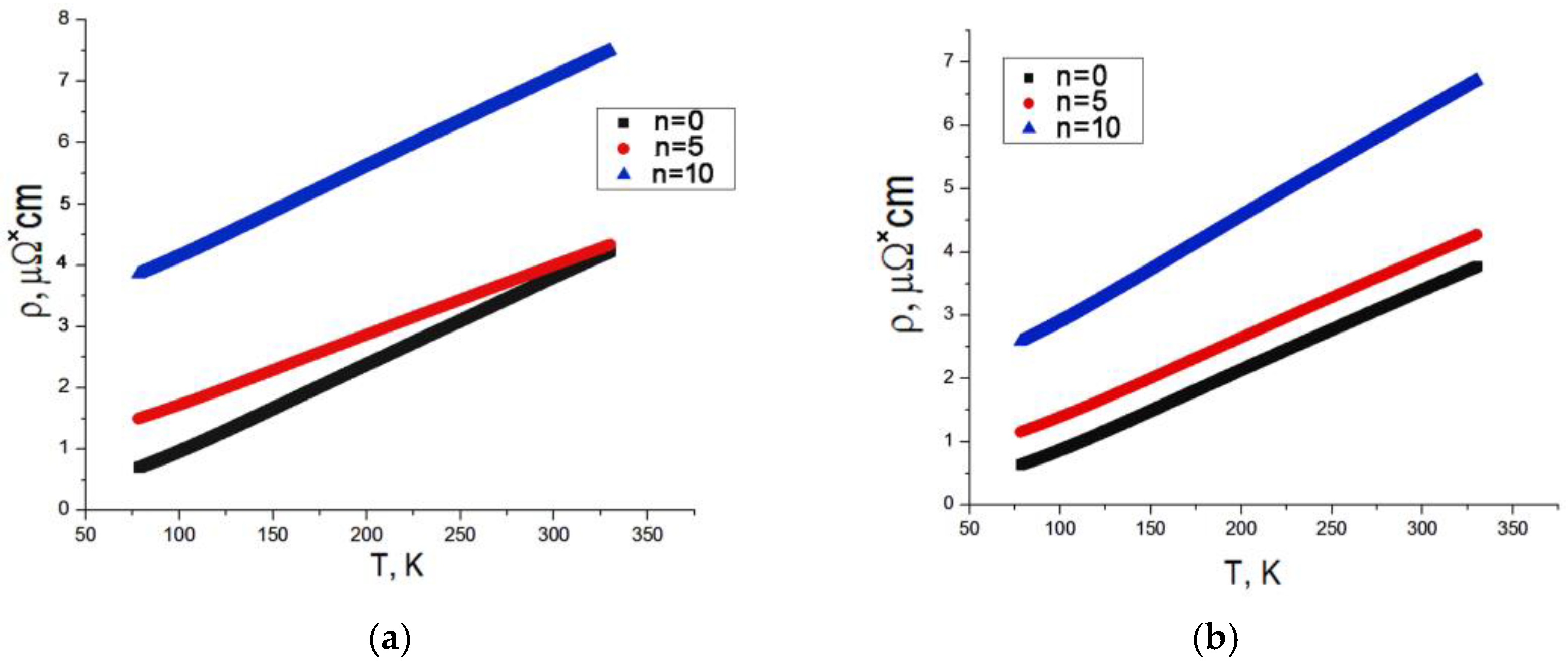

3.2. Electrical Properties

4. Conclusions

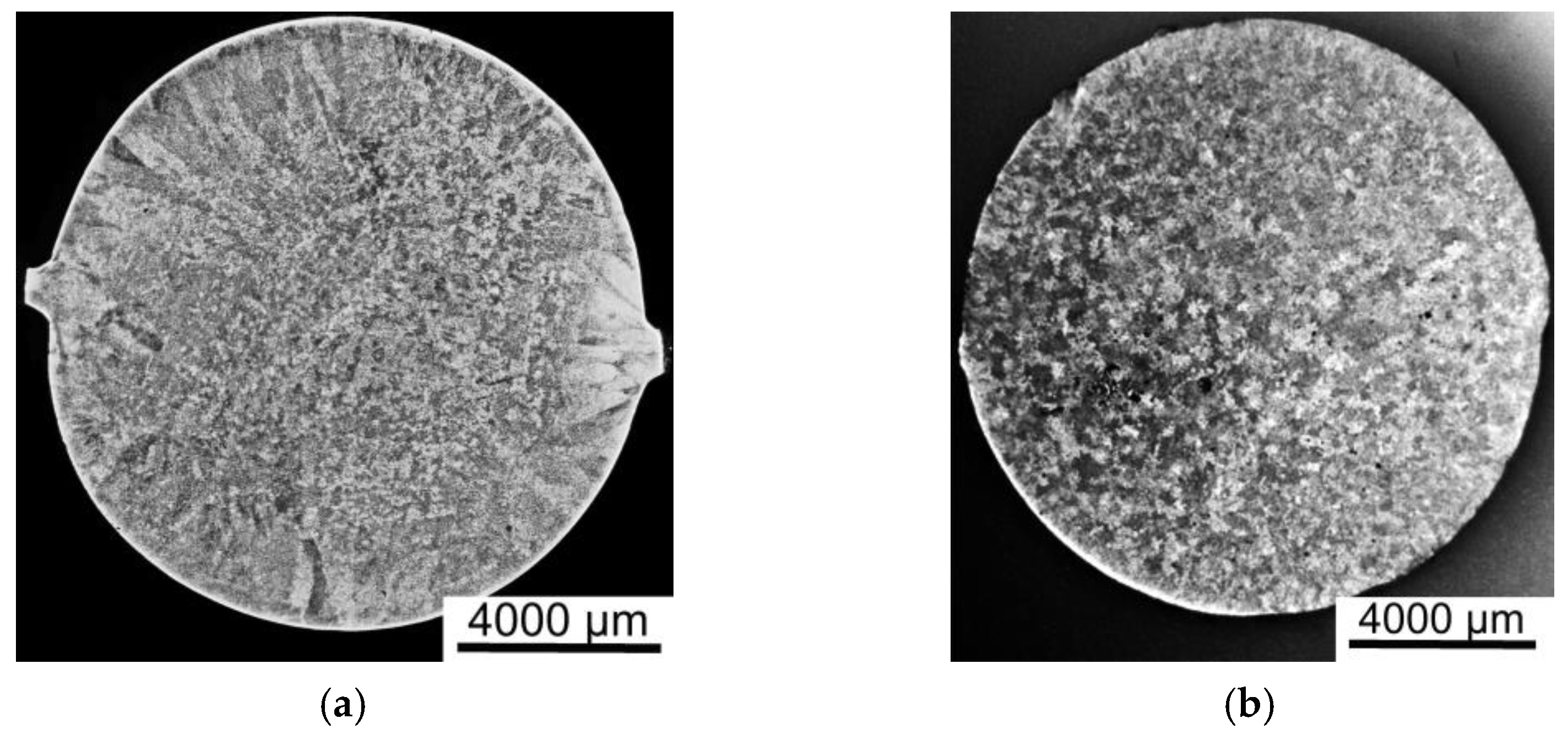

- Comparison of the macrostructure of the matrix alloy with the structure of the composite, in which there was no zone of columnar crystals, suggests that the reason for the different solid phase growth pattern is the higher thermal conductivity of the composite due to the addition of graphene.

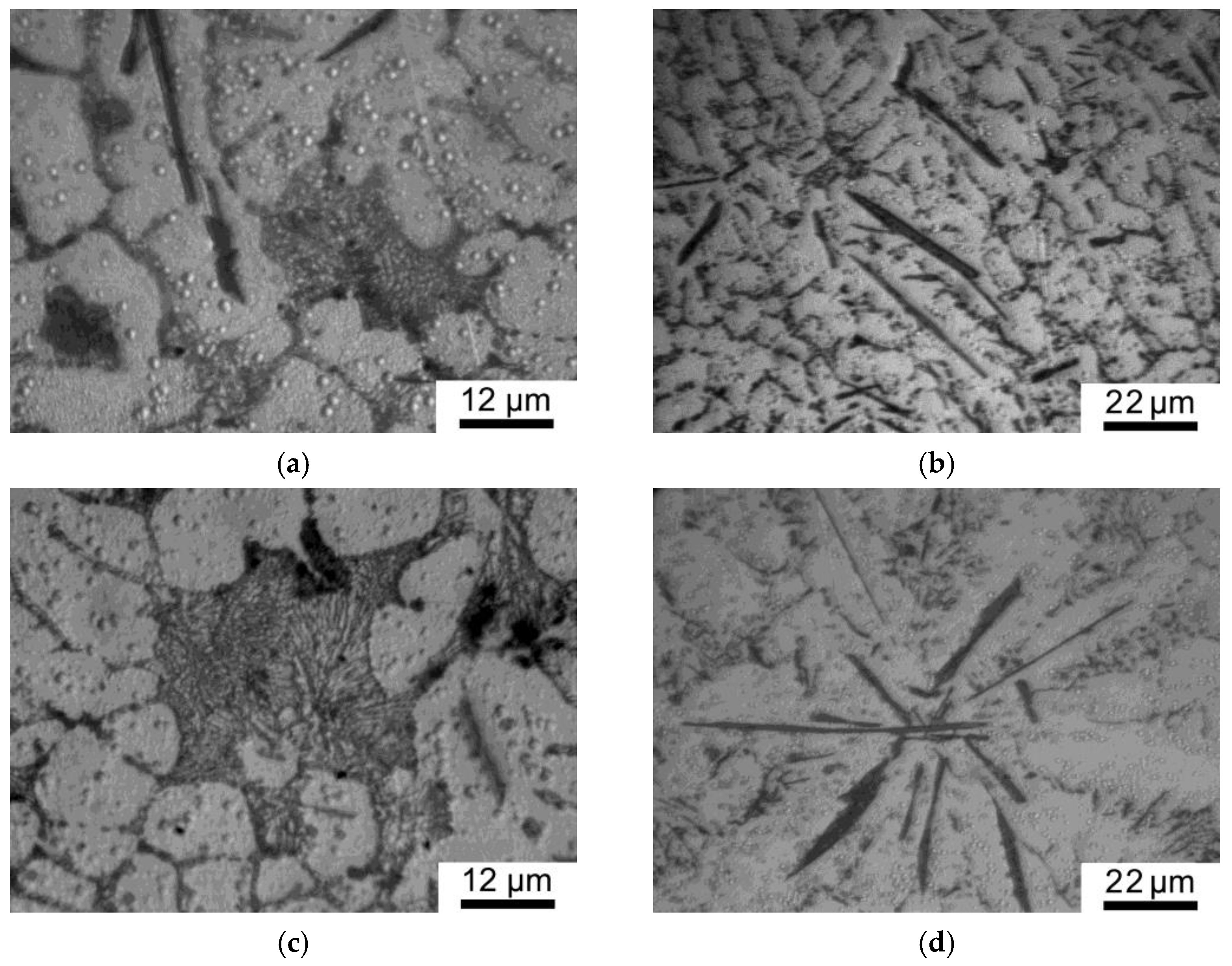

- Metallographic techniques were employed to establish that graphene used as reinforcement did not have modifying properties and did not affect the size and morphology of the structural constituents in the as-cast composites. Nonequilibrium crystallization of the AlFe alloy and the AlFeGn composites led to the formation of dendrites of Al solid solution 15–20 µm in size with degenerate eutectic along the grain boundaries and primary needle-like Al13Fe4 crystals of 10–40 µm long and 1–3 µm wide.

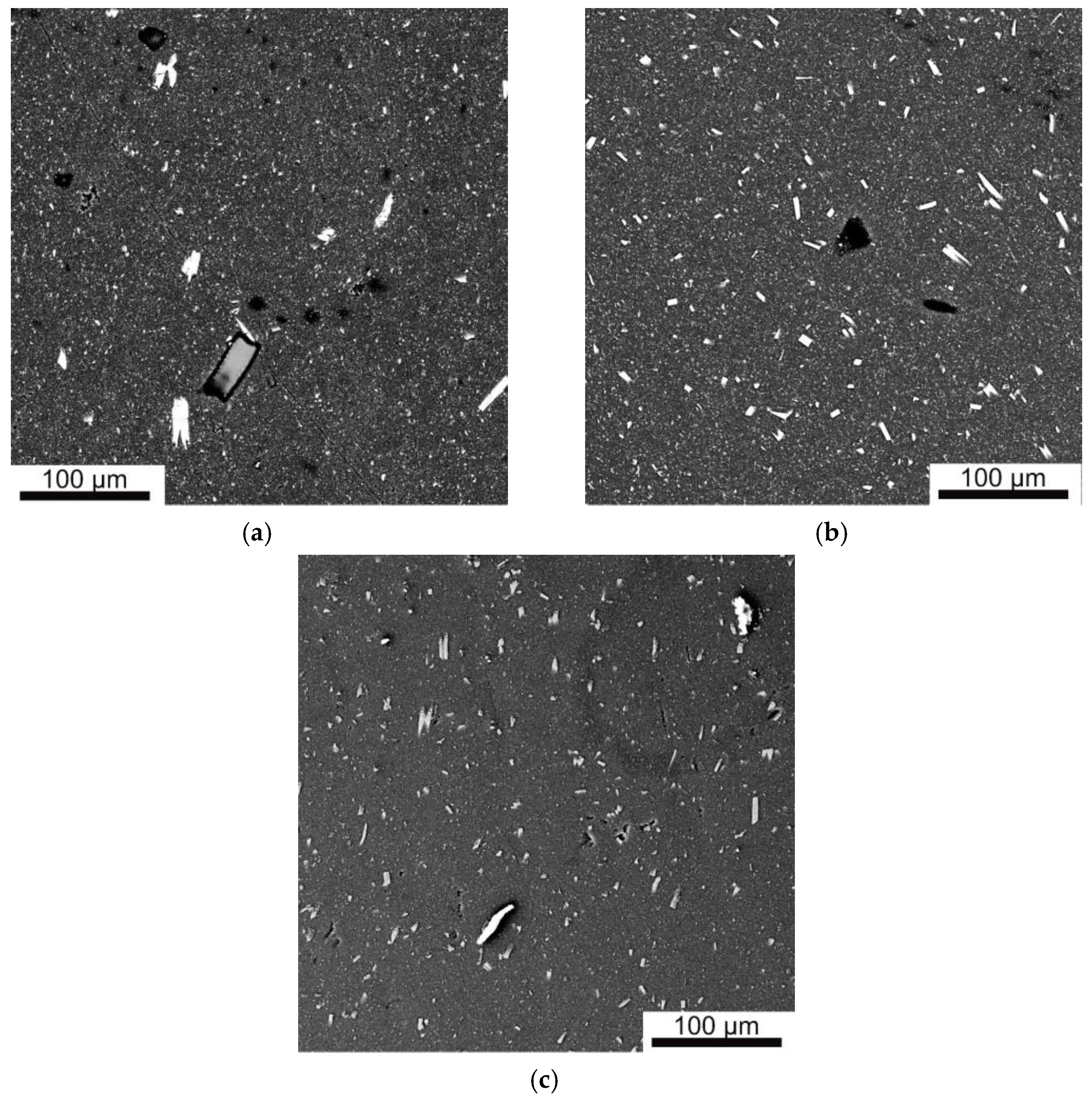

- HPT produces an UFG structure with an average grain size of 200 nm and induces the breakage and fragmentation of the eutectic and primary crystals of iron aluminides and their partial deformation-induced dissolution with the formation of a supersaturated solid solution of Fe in Al.

- The hardness of the deformed composite is four times higher than the hardness of the composite in the as-cast state, and its electrical resistance is two times less. This strengthening was achieved via the sum of contributions from various structural mechanisms, i.e., grain– boundary (the Hall–Petch relationship), dispersion (the Orowan mechanism), dislocation (proportional to density of dislocftion), and solid-solution mechanisms (proportional to the content of the alloying element in the Al solid solution).

- The micro-addition of graphene increases the specific electrical conductivity of the composite both in the as-cast and in the deformed states compared to the matrix alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shikagawa, T.; Itoh, G.; Suzuki, S.; Kuroda, H.; Horikoshi, T. Effect of small additions of Fe on the tensile properties and electrical conductivity of aluminium wires. Mater. Sci. Forum 2016, 519, 515–518. [Google Scholar]

- Medvedev, A.E.; Murashkin, M.Y.; Enikeev, N.A.; Ovid’ko, I.A.; Valiev, R.Z. Optimization of strength-electrical conductivity properties in Al-2Fe alloy by severe plastic deformation and heat treatment. Adv. Eng. Mater. 2018, 20, 1700867. (In Russian) [Google Scholar] [CrossRef]

- Cubero-Sesin, J.M.; Horita, Z. Age Hardening in Ultrafine-Grained Al-2PctFe Alloy Processed by High-Pressure Torsion. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2015, 46, 2614–2624. [Google Scholar] [CrossRef]

- Murashkin, M.Y.; Enikeev, N.A.; Ovid’ko, I.A.; Valiev, R.Z. Strength and electrical conductivity of ultra—Fine grained aluminum alloy Al-2Fe subjected to annealing and straining. Mater. Phys. Mech. 2015, 24, 297–307. (In Russian) [Google Scholar]

- Belov, N.A.; Alabin, A.N.; Matveeva, I.A.; Eskin, D.G. Effect of Zr additions and annealing temperature on electrical conductivity and hardness of hot rolled Al sheets. Trans. Nonferrous Met. Soc. China Engl. Ed. 2015, 25, 2817–2826. [Google Scholar] [CrossRef]

- Zhang, Y.-Z.; Gao, H.-Y.; Wang, Y.-F.; Wang, J.; Sun, B.-D.; Gu, S.-W. Effects of addition on microstructure and properties of Al-Zr alloys. Trans. Nonferrous Met. Soc. China Engl. Ed. 2014, 24, 2239–2243. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, W.; Gao, H.; Han, Y.; Wang, K.; Wang, J. Precipitation evolution of Al-Zr-Yb alloys during isochronal aging. Scr. Mater. 2013, 69, 477–480. [Google Scholar] [CrossRef]

- Wen, S.P.; Gao, K.Y.; Li, Y.; Huang, H.; Nie, Z.R. Synergetic effect of Er and Zr on the precipitation hardening of Al-Er-Zr alloy. Scr. Mater. 2011, 65, 592–595. [Google Scholar] [CrossRef]

- Medvedev, A.E.; Hodgson, P.D.; Lapovok, R.; Murashkin, M.Y.; Enikeev, N.A.; Valiev, R.Z. Enhancement of mechanical and electrical properties of Al-Re alloys by optimizing rare-earth concentration and thermos-mechanical treatment. J. Alloys Compd. 2018, 745, 696–704. [Google Scholar] [CrossRef]

- Eliezer, D.; John, G.; Froes, F.H. Mossbauer study of rapidly solidified Al-rare-earth alloys. J. Mater. Sci. Lett. 1986, 5, 781–782. [Google Scholar] [CrossRef]

- Yu, X.W.; Cao, C.A.; Yan, C.W.; Yao, Z.M. Rare earth application in sealing anodized Al-based metal matrix composites. J. Mater. Sci. Technol. 2001, 17, 283–284. [Google Scholar]

- Murashkin, M.Y.; Medvedev, A.E.; Enikeev, N.A.; Valiev, R.Z.; Sabirov, I.; Lefebvre, W.; Sauvage, X. Mechanical and electrical properties of an ultrafine grained Al-8.5% RE (RE=5.4Ce, 3.1wt.% La) alloy processed by severe plastic deformation. Mater. Des. 2016, 90, 433–442. [Google Scholar] [CrossRef]

- Kim, D.H.; Cantor, B. Structure and decomposition behaviour of rapidly solidified Al-Fe alloys. J. Mater. Sci. 1994, 29, 2884–2892. [Google Scholar] [CrossRef]

- Cubero-Sesin, J.M.; Watanabe, M.; Arita, M.; Horita, Z.J. Aging and precipitation behavior in supersaturated Al-2%Fe alloy produced by high-pressure torsion. In Proceedings of the 14th International Conference on Aluminium Alloys, Trondheim, Norway, 15–19 June 2014; Trans Tech Publications Ltd.: Zurich, Switzerland, 2014; pp. 766–771. [Google Scholar]

- Llurma, J.A.; Benito, A.; Rosa, A.; Cabrera, J.M.; Prado, J.M. Study of the nanometric grain size distribution in iron compacts jbtained by mechanical milling. Mater. Sci. Forum 2006, 503–504, 1007–1012. [Google Scholar] [CrossRef]

- Sasaki, T.T.; Ohkubo, T.; Hono, K. Microstructure and mechanical properties of bulk nanocrystalline AlFe alloy processed by mechanical alloying and spark plasma sintering. Acta Mater. 2009, 57, 3529–3538. [Google Scholar] [CrossRef]

- Senkov, O.N.; Froes, F.H.; Stolyarov, V.V.; Valiev, R.Z.; Liu, J. Microstructure of aluminum-iron alloys subjected to severe plastic deformation. Scr. Mater. 1998, 38, 1511–1516. [Google Scholar] [CrossRef]

- Medvedev, A.E.; Zhukova, O.O.; Kazykhanov, V.U.; Shaikhulova, A.F.; Enikeev, N.A.; Timofeev, V.N.; Murashkin, M.Y. On the effect of ECAP and subsequent cold rolling on the microstructure and properties of electromagnetically cast Al-Fe alloys. Int. J. Lightweight Mater. Manuf. 2022, 5, 484–495. [Google Scholar] [CrossRef]

- Uesugi, T.; Takigawa, Y.; Higashi, K. Deformation mechanism of nanocrustalline Al-Fe alloys by analysis from Al-Initio calculation. Mater. Sci. Forum 2006, 503–504, 209–214. [Google Scholar] [CrossRef]

- Tcherdyntsev, V.V.; Kaloshkin, S.D.; Afonina, E.A.; Tomilin, I.A.; Baldokhin, Y.V.; Shelekhov, E.V. Effect of deformation by high pressure torsion on the phase composition and microhardness of mechanically alloyed and rapidly quenched Al-Fe. Defect Diffus. Forum 2003, 216–217, 313–322. [Google Scholar] [CrossRef]

- Das, D.K.; Mishra, P.C.; Singh, S.; Thakur, R.K. Properties of ceramic-reinforced aluminium matrix composites—A review. Int. J. Mech. Mater. Eng. 2014, 9, 12. [Google Scholar] [CrossRef]

- Khrustalev, A.P.; Kozulin, A.A.; Zhukov, I.A.; Khmeleva, M.G.; Vorozhtsov, A.B.; Eskin, D.G.; Chankitmunkong, S.; Platov, V.V.; Vasilev, S.V. Influence of Titanium Diboride Particle Size on Structure and Mechanical Properties of an Al-Mg Alloy. Metals 2019, 9, 1030. [Google Scholar] [CrossRef]

- Karabay, S. Influence of AlB2 compound on elimination of incoherent precipitation in artificial aging of wires drawn from redraw rod extruded from billets cast of alloy AA-6101 by vertical direct chill casting. Mater. Des. 2008, 29, 1364–1375. [Google Scholar] [CrossRef]

- Cui, X.; Wu, Y.; Liu, X.; Zhao, Q.; Zhang, G. Effects of grain refinement and boron treatment on electrical conductivity and mechanical properties of AA1070 aluminum. Mater. Des. 2015, 86, 397–403. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Lahiri, D.; Agarwal, A. Carbon nanotube reinforced metal matrix composites—A review. Int. Mater. Rev. 2010, 55, 41–64. [Google Scholar] [CrossRef]

- Sheinerman, A.G. Mechanical properties of metal matrix composites with graphen and carbon nanotubes. Phys. Met. Metallogr. 2022, 123, 57–84. [Google Scholar] [CrossRef]

- Hu, Z.; Tong, G.; Lin, D.; Chen, C.; Guo, H.; Xu, J.; Zhou, L. Graphene-reinforced metal matrix nanocomposites—A review. Mater. Sci. Technol. 2016, 32, 930–953. [Google Scholar] [CrossRef]

- Pérez-Bustamante, R.; Bolaños-Morales, D.; Bonilla-Martínez, J.; Estrada-Guel, I.; Martínez-Sánchez, R. Microstructural and hardness behavior of graphene-nanoplatelets/aluminum composites synthesized by mechanical alloying. J. Alloys Compd. 2014, 615 (Suppl. 1), S578–S582. [Google Scholar] [CrossRef]

- Shirinkina, I.G.; Brodova, I.G.; Rasposienko, D.Y.; Muradymov, R.V.; Yolshina, L.A.; Shorokhov, E.V.; Razorenov, S.V.; Gorkushin, G.V. Influence graphene additions on aluminum structure and properties. Phys. Met. Metallogr. 2020, 121, 1193–1202. [Google Scholar] [CrossRef]

- Brodova, I.; Yolshina, L.; Razorenov, S.; Rasposienko, D.; Petrova, A.; Shirinkina, I.; Shorokhov, E.; Muradymov, R.; Garkushin, G.; Savinykh, A. Effect of Grain Size on the Properties of Aluminum Matrix Composites with Graphene. Metals 2022, 12, 1054. [Google Scholar] [CrossRef]

- Brodova, I.G.; Petrova, A.N.; Shirinkina, I.G.; Rasposienko, D.Y.; Yolshina, L.A.; Muradymov, R.V.; Razorenov, S.V.; Shorokhov, E.V. Mechanical properties of submicrocrystalline aluminium matrix composites reinforced by “in situ” graphene through severe plastic deformation processes. J. Alloys Compd. 2021, 859, 158387–158395. [Google Scholar] [CrossRef]

- Brodova, I.G.; Yolshina, L.A.; Rasposienko, D.Y.; Muradymov, R.V.; Shirinkina, I.G.; Razorenov, S.V.; Petrova, A.N.; Shorokhov, E.V. Structure formation and physical-mechanical properties of Al-Mg alloy with microadditions of graphene. Lett. Mater. 2022, 12, 269–275. [Google Scholar] [CrossRef]

- Vanin, M.; Mortensen, J.J.; Kelkkanen, A.K.; Garcia-Lastra, J.M.; Thygesen, K.S.; Jacobsen, K.W. Graphene on metals: A van der Waals density functions study. Phys. Rev. B 2010, 87, 081408. [Google Scholar] [CrossRef]

- Sharma, R.; Chadha, N.; Saini, P. Determination of defect density, crystallite size and number of graphene layers in graphene analogues using X-ray diffraction and Raman spectroscopy. Indian J. Pure Appl. Phys. 2017, 55, 625–629. [Google Scholar]

- Winegard, W.C. An Introduction to the Solidification of Metals; Department of Metallurgy University of Toronto: Toronto, ON, Canada; The Institute of Metals: London, UK, 1964. [Google Scholar]

- Mondolfo, L.F. Aluminum Alloys: Structure and Properties; Butterworth & Co: London, UK, 1976. [Google Scholar]

| Fe | C | |

|---|---|---|

| AlFe | 2.5 | 0 |

| AlFeGn | 2.4 | 0.12 |

| Graphene Content, wt.% | Number of Revolutions, n | Δa, Å | Fe Content, wt.% | ||

|---|---|---|---|---|---|

| 0 | 5 | 10 | |||

| a, Å | |||||

| 0 | 4.0490 ± 0.0002 | 4.0478 ± 0.0001 | 4.0466 ± 0.0001 | 0.0024 | 0.48 |

| 0.12 | 4.0491 ± 0.0002 | 4.0470 ± 0.0002 | 4.0454 ± 0.0002 | 0.0037 | 0.74 |

| Number of Revolutions n | ρ, Oh·m·cm | σ, MS/m | IACS, % | |||

|---|---|---|---|---|---|---|

| AlFe | AlFeGn | AlFe | AlFeGn | AlFe | AlFeGn | |

| 0 | 3.7184 ± 0.0027 | 3.3255 ± 0.0073 | 26.8933 | 30.0704 | 46 | 52 |

| 5 | 3.9662 ± 0.0026 | 3.8235 ± 0.0026 | 25.2129 | 26.1541 | 43 | 45 |

| 10 | 6.9797 ± 0.0029 | 6.1212 ± 0.0034 | 14.3273 | 16.3367 | 24 | 28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrova, A.N.; Rasposienko, D.Y.; Brodova, I.G.; Yolshina, L.A.; Muradymov, R.V.; Markin, A.A.; Marchenkov, V.V.; Fominykh, B.M. Structure and Electrical Properties of AlFe Matrix Composites with Graphene. Appl. Sci. 2023, 13, 10501. https://doi.org/10.3390/app131810501

Petrova AN, Rasposienko DY, Brodova IG, Yolshina LA, Muradymov RV, Markin AA, Marchenkov VV, Fominykh BM. Structure and Electrical Properties of AlFe Matrix Composites with Graphene. Applied Sciences. 2023; 13(18):10501. https://doi.org/10.3390/app131810501

Chicago/Turabian StylePetrova, Anastasiia N., Dmitry Y. Rasposienko, Irina G. Brodova, Liudmila A. Yolshina, Roman V. Muradymov, Artem A. Markin, Vyacheslav V. Marchenkov, and Bogdan M. Fominykh. 2023. "Structure and Electrical Properties of AlFe Matrix Composites with Graphene" Applied Sciences 13, no. 18: 10501. https://doi.org/10.3390/app131810501

APA StylePetrova, A. N., Rasposienko, D. Y., Brodova, I. G., Yolshina, L. A., Muradymov, R. V., Markin, A. A., Marchenkov, V. V., & Fominykh, B. M. (2023). Structure and Electrical Properties of AlFe Matrix Composites with Graphene. Applied Sciences, 13(18), 10501. https://doi.org/10.3390/app131810501