Application of High-Pressure Gas Expansion Rock-Cracking Technology in Hard Rock Tunnel near Historic Sites

Abstract

:1. Introduction

2. High-Pressure Gas Expansion Rock-Cracking Technology

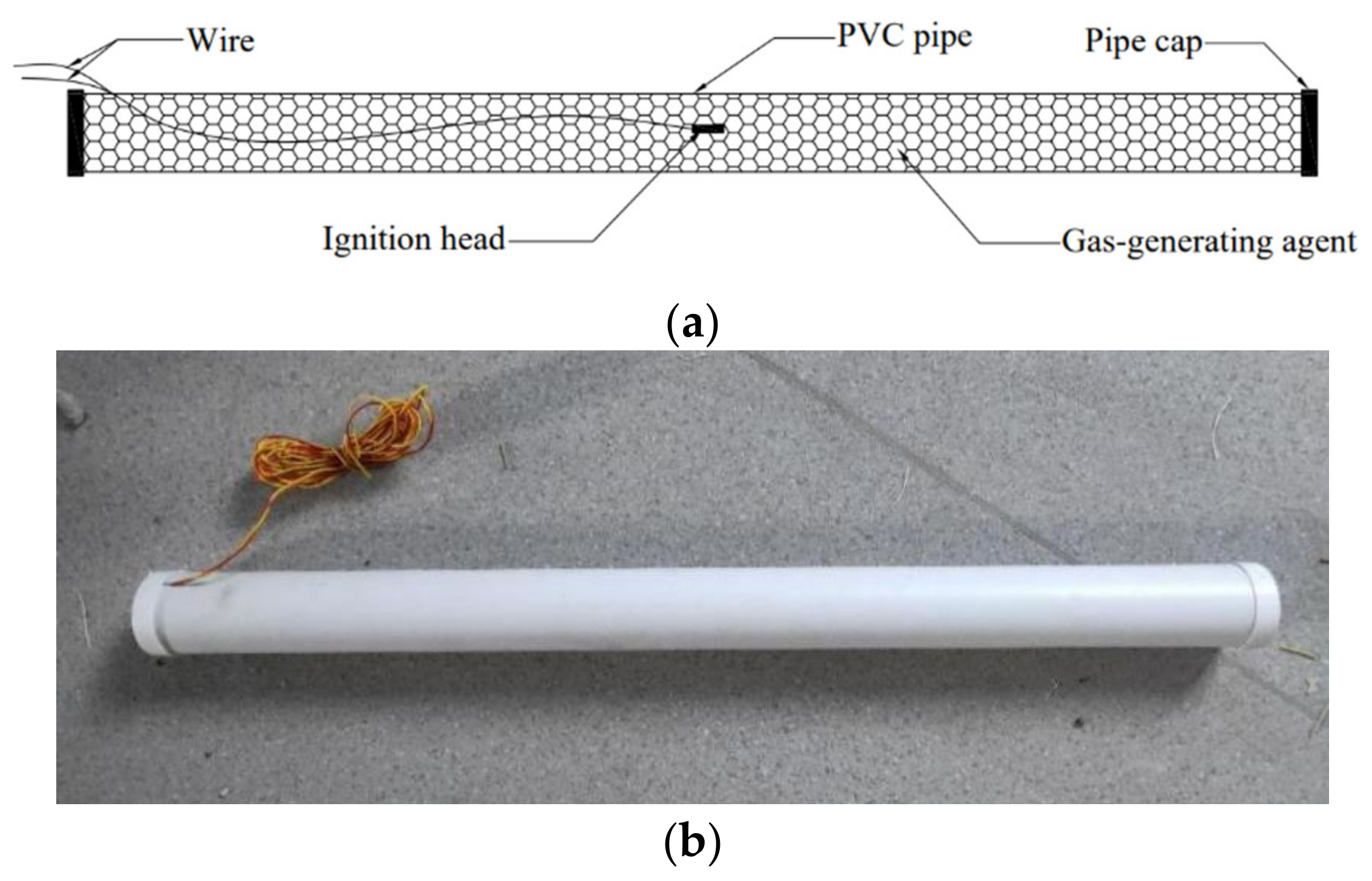

2.1. Rock-Cracking Equipment

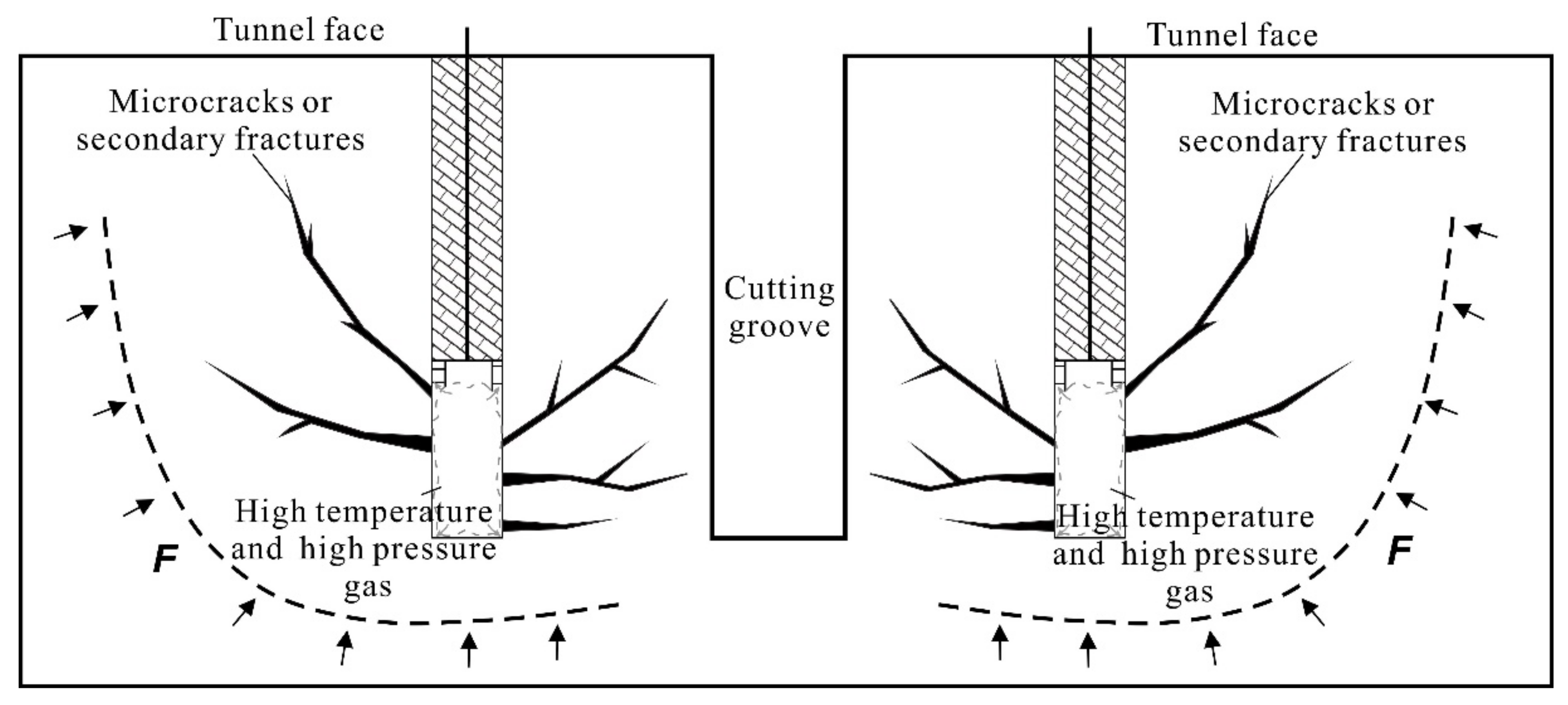

2.2. Technology Principle

2.3. Technology Advantages

3. Field Excavation Tests

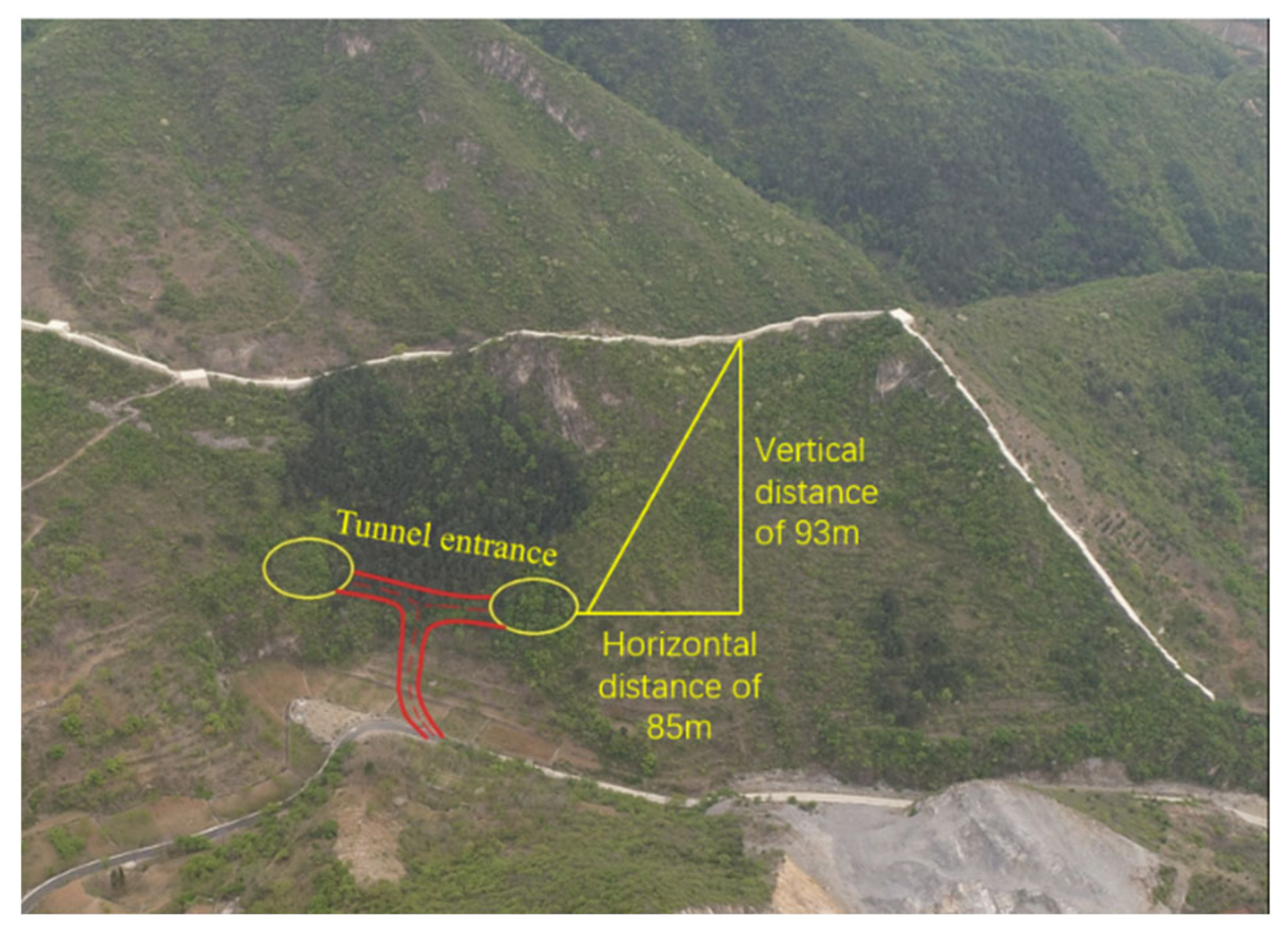

3.1. Project Situation

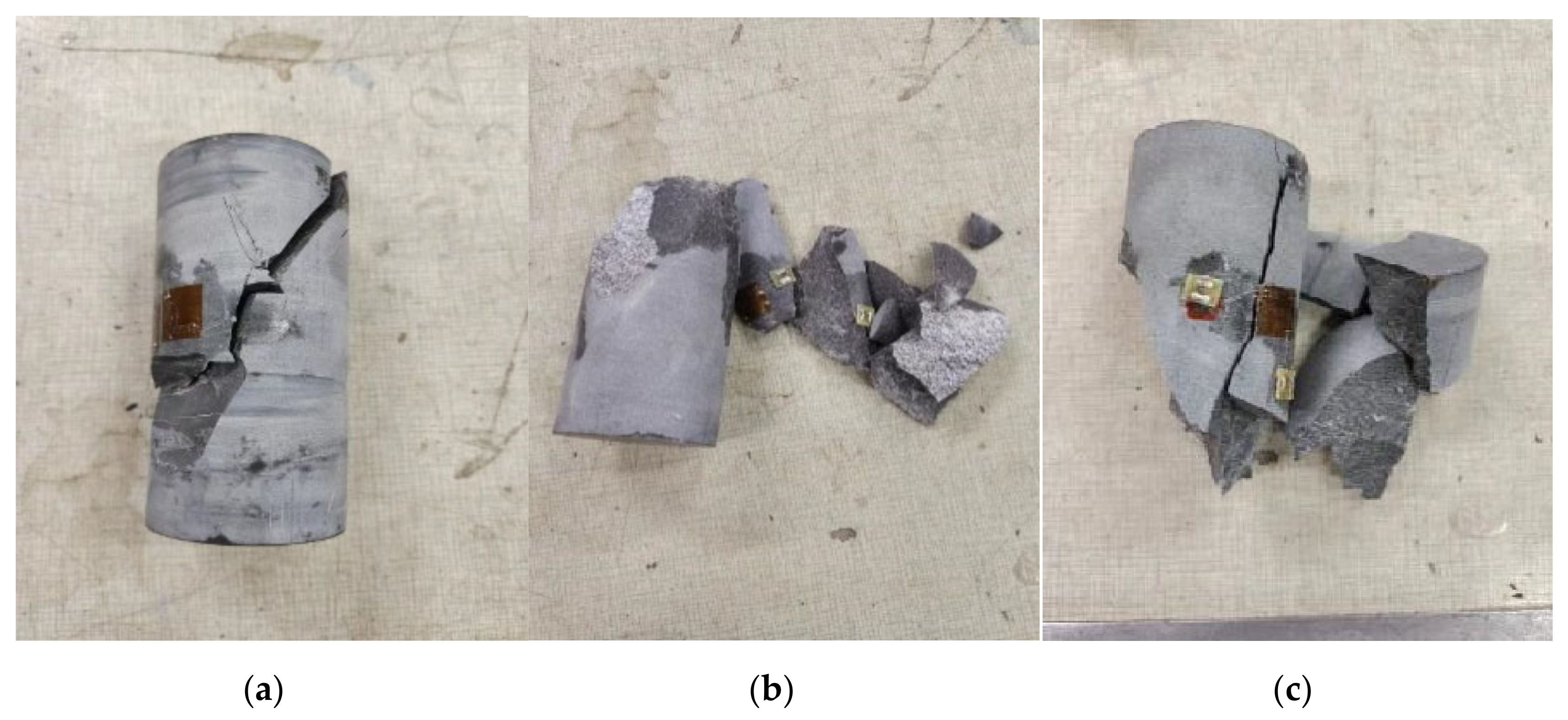

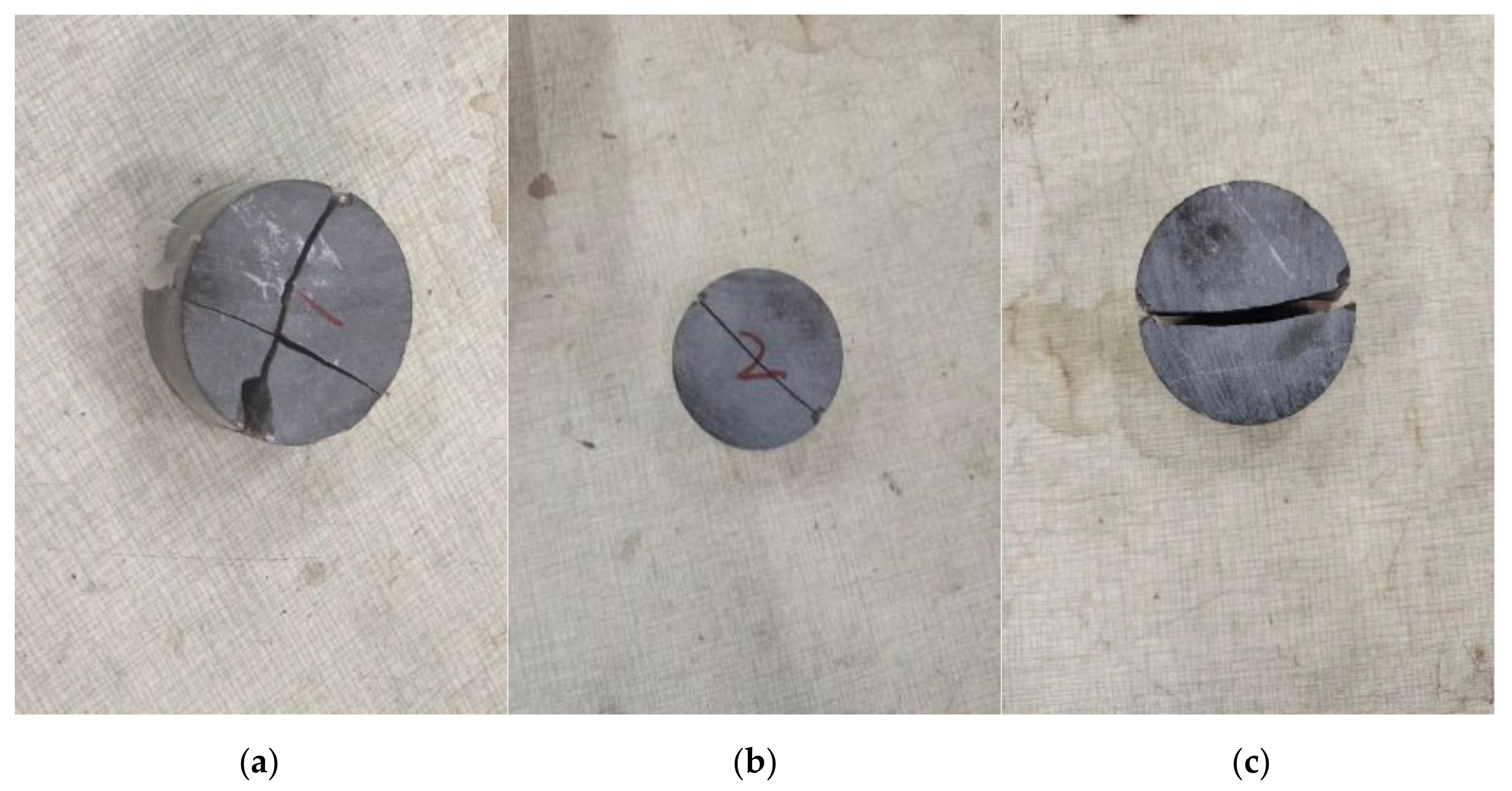

3.2. Rock Mechanics Tests

3.3. Test Scheme

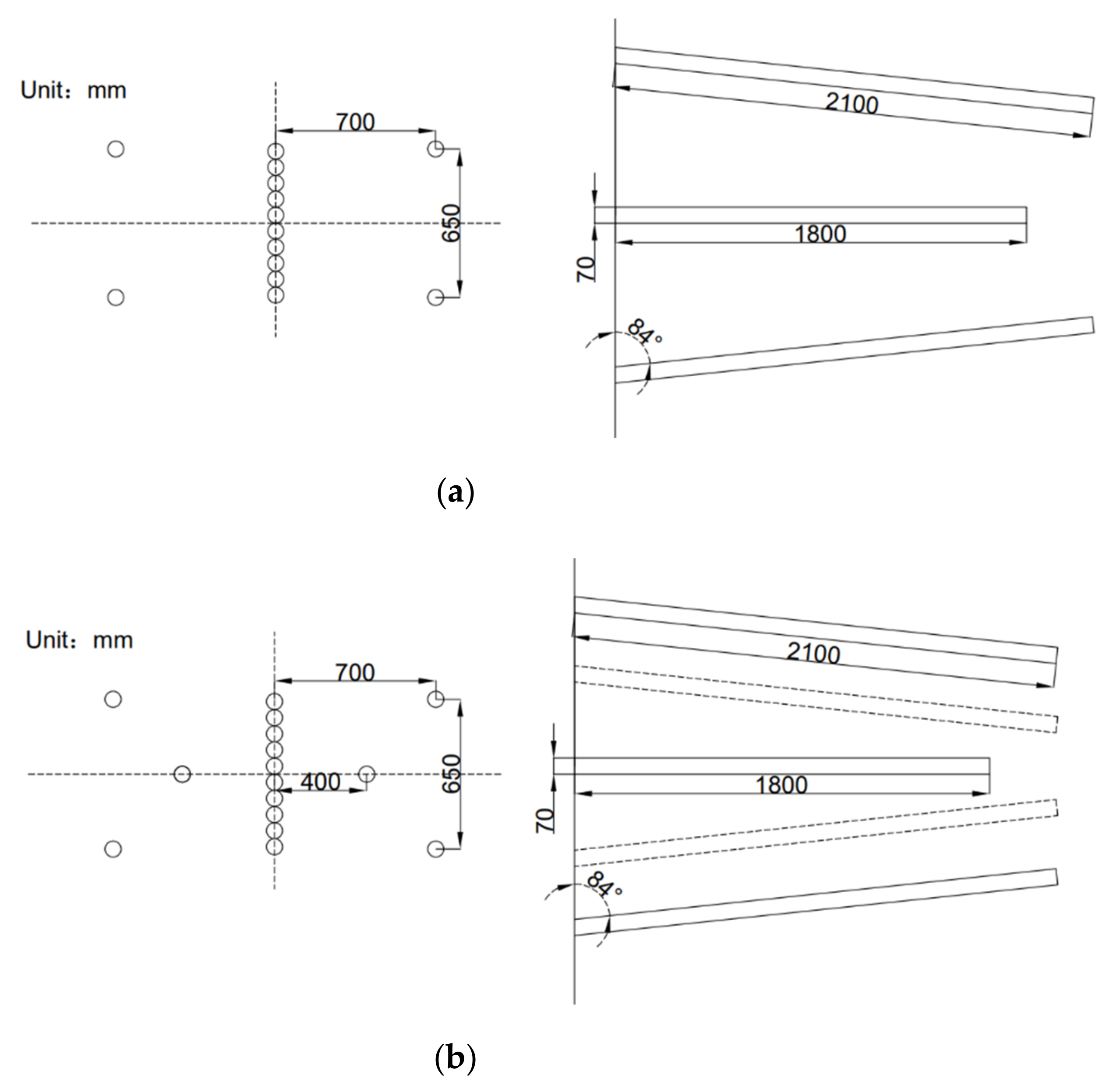

3.3.1. Design of Rock Mass Cracking Parameters

3.3.2. Test Scheme of Cutting Excavation

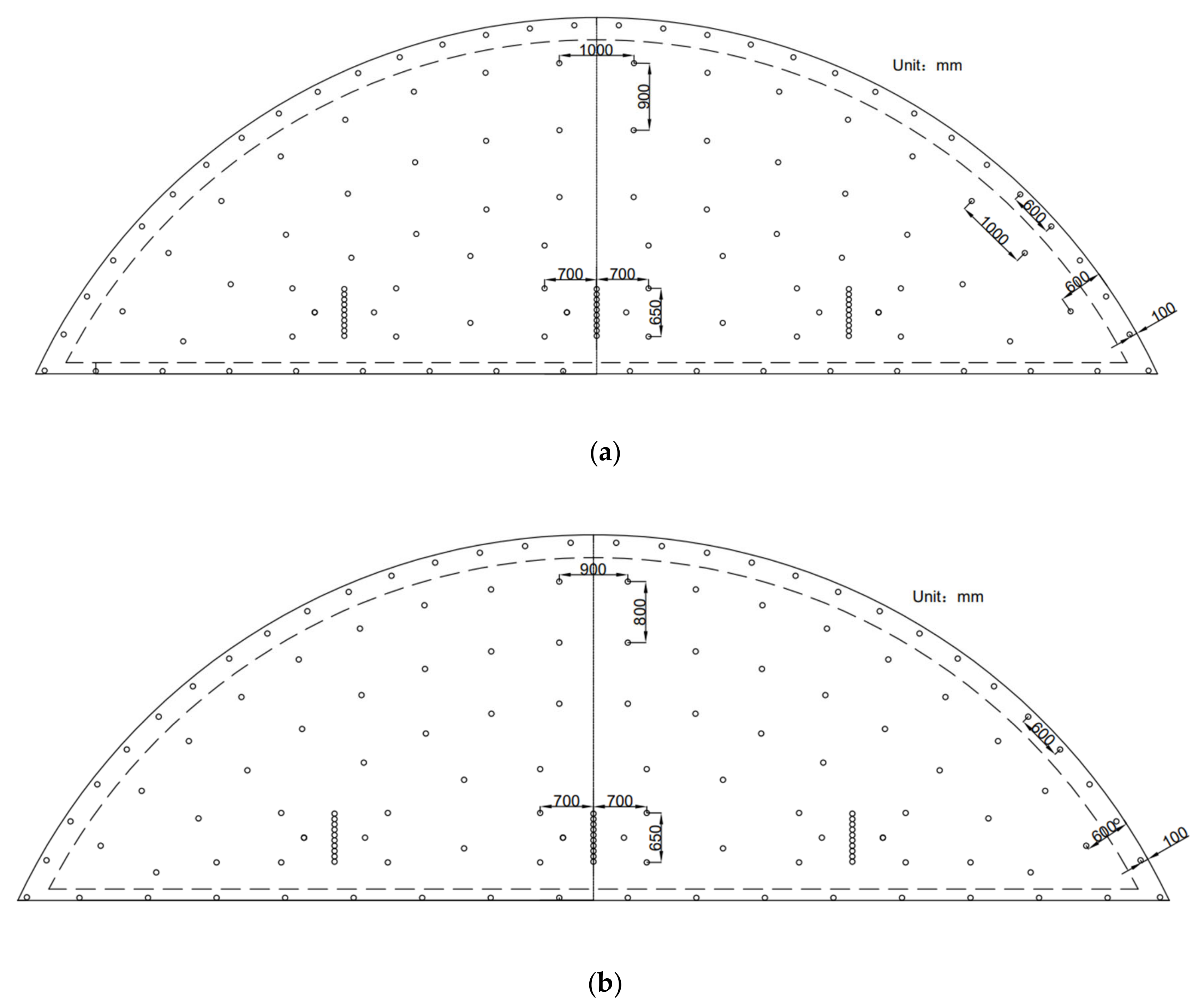

3.3.3. Test Scheme of Upper Step Excavation

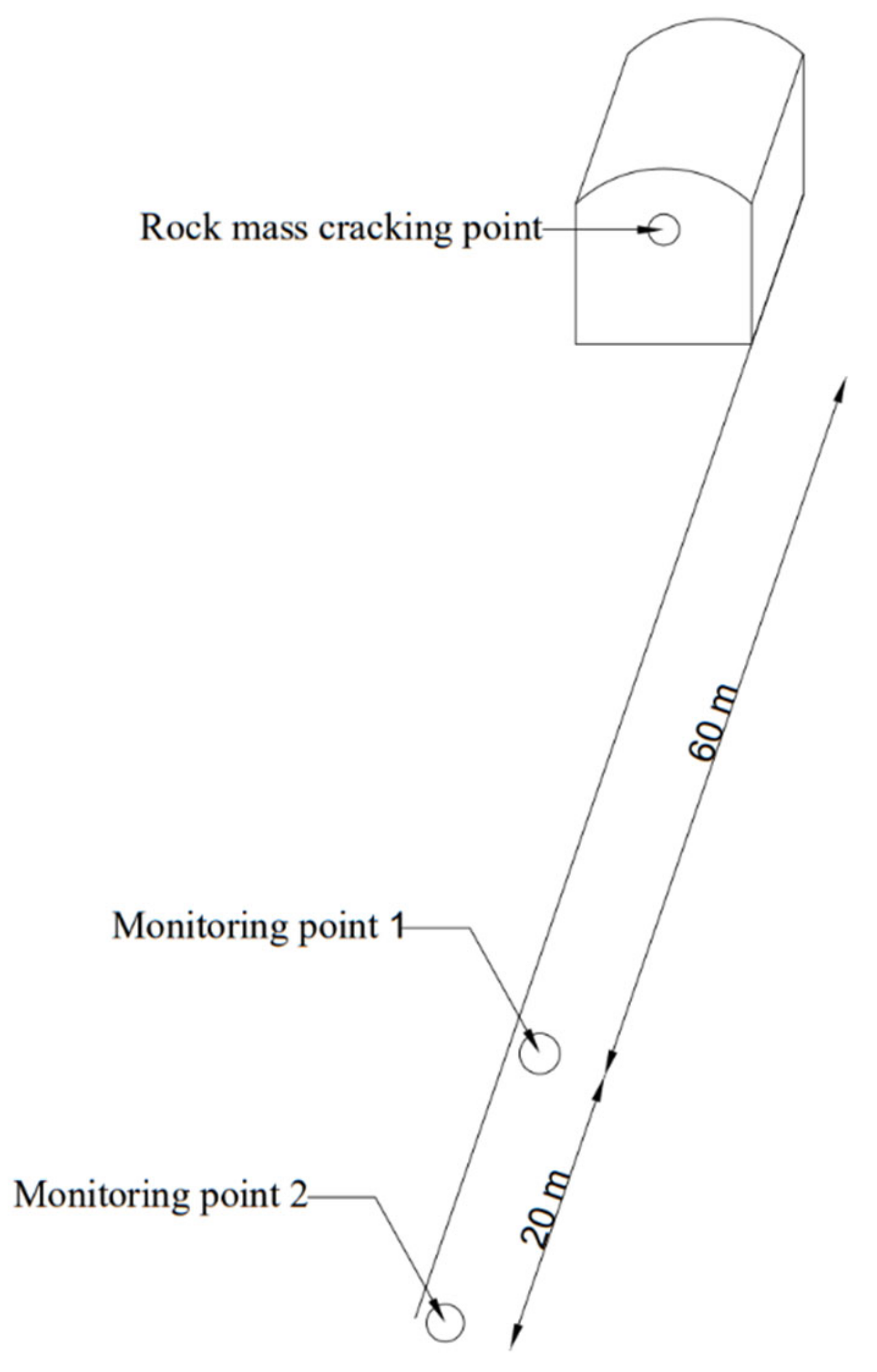

3.3.4. Vibration Monitoring Scheme

4. Results and Analysis

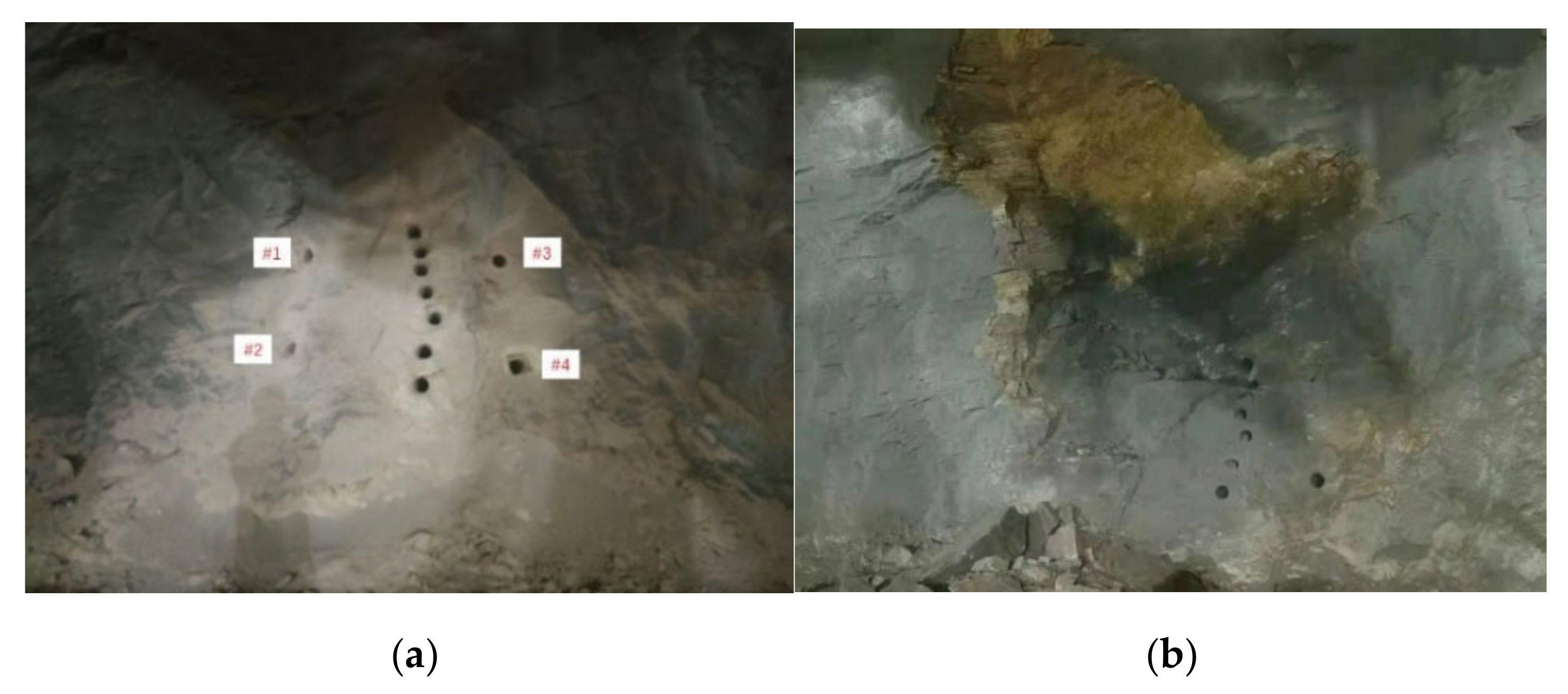

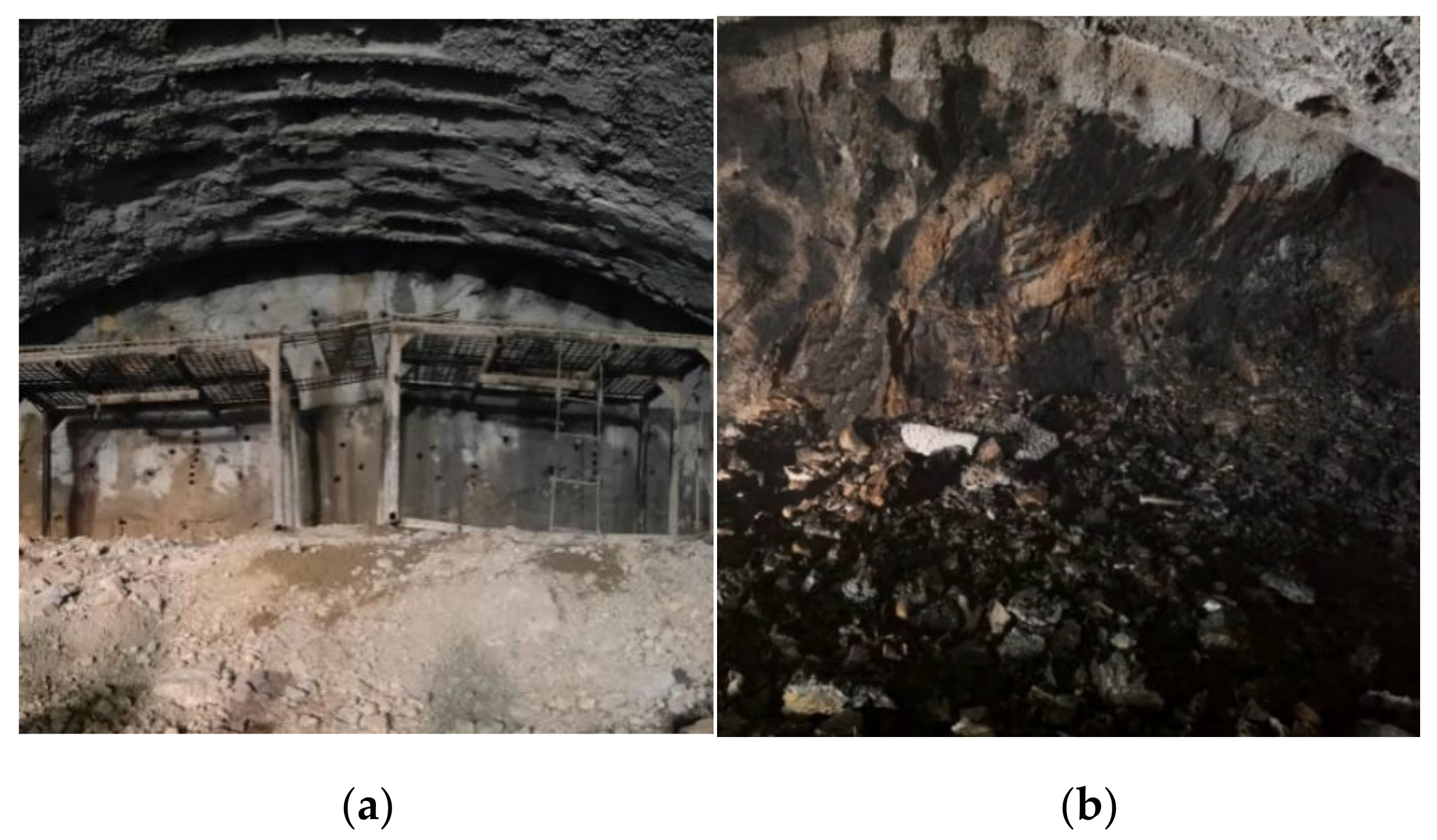

4.1. Results and Analysis of Cutting Excavation Tests

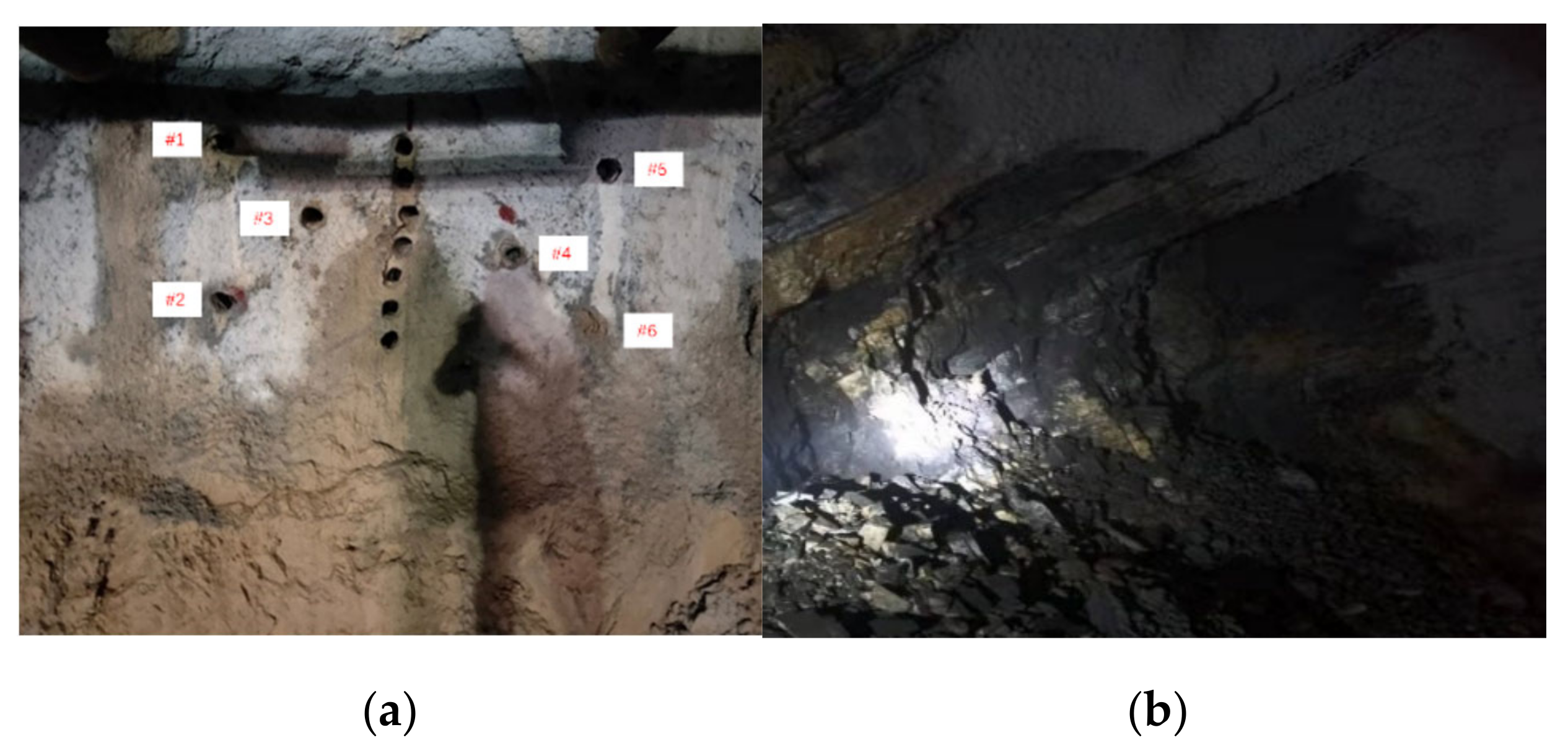

4.2. Results and Analysis of Upper Step Excavation Tests

4.3. Results and Analysis of Vibration Monitoring

5. Conclusions

- The rock mass cracking effect of the cutting mode of “central vertical empty hole + double wedge cutting hole” is better than that of the cutting mode of “central vertical empty hole + single wedge cutting hole”. The stripping rock volume in the cutting excavation can reach 6.7 m3 once with the cutting mode of “central vertical empty hole + double wedge cutting hole”. The rock fragmentation is relatively uniform and suitable, and the distribution of the rock blocks is relatively concentrated. It is proved that the high-pressure gas expansion rock-cracking technology can achieve ideal cutting rock mass cracking effect in hard rock tunnel with the proper cutting mode.

- The rock mass cracking effect of the auxiliary hole network parameter of “0.8 m × 0.7 m” is better than that of the auxiliary hole network parameter of “1.0 m × 0.9 m”. The stripping rock volume in the upper step excavation can reach 39 m3 when the cutting mode of “central vertical empty hole + double wedge cutting hole” is used to match the auxiliary hole network parameter of “0.8 m × 0.7 m”. The rock fragmentation is relatively uniform, and the distribution area of rock blocks is mainly within 3 m in front of the tunnel face. It is proved that the high-pressure gas expansion rock-cracking technology can achieve an ideal excavation effect in hard rock tunnel with a suitable cutting mode and hole network parameters.

- The blast vibration logger with the trigger lever of 0.1 cm/s was not triggered, which was at 60 m away from the rock mass cracking point. It indicates that the vibration of monitoring point is less than 0.10 cm/s, which meets the safe allowable vibration speed of general ancient buildings and historic sites. It is proved that the high-pressure gas expansion rock-cracking technology can realize the safe and environmentally friendly excavation of hard rock tunnel under the Great Wall. As long as there is the high quality of hole plugging and no punching, the high-pressure gas expansion rock-cracking technology has the advantages of little vibration, low noise and less flying rocks.

- High-pressure gas expansion rock-cracking technology can realize the safe and efficient excavation of hard rock tunnel, and the vibration generated by its rock-cracking process does not affect the safety of the Great Wall. This is the first application for the continuous non-explosion excavation of hard rock tunnel near historic sites. It brings a new idea of rock cracking for hard-rock projects located in the city center, near important buildings or in other complex construction environments. In this paper, the excavation plan of the hard rock tunnel near the historic site is formed around high-pressure gas expansion rock-cracking technology. However, the plugging technology needs to be further improved to raise the efficiency and quality of plugging, so as to provide a high guarantee for the rock-cracking effect of high-pressure gas expansion rock-cracking technology.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jafri, T.H.; Yoo, H. REV Application in DEM Analysis of Non-Vibrational Rock Splitting Method to Propose Feasible Borehole Spacing. Appl. Sci. 2018, 8, 335. [Google Scholar] [CrossRef] [Green Version]

- De Graaf, W.W.; Spiteri, W. A preliminary qualitative evaluation of a hydraulic splitting cylinder for breaking rock in deep-level mining. J. South. Afr. Inst. Min. Metall. 2018, 118, 891–897. [Google Scholar] [CrossRef]

- Qiu, Z.G.; Ji, Y.; Zhang, F.P.; Yan, G.L. Experimental Investigation and Numerical Modeling of Elastic Modulus Variation with Stress during Hydration and Expansion Process of Static Cracking Agent. Appl. Sci. 2021, 11, 3955. [Google Scholar] [CrossRef]

- Hao, B.Y.; Huang, H.; Feng, Z.J.; Wang, K. The Static Breaking Technique for Sustainable and Eco-Environmental Coal Mining. Sci. World J. 2014, 14, 248792. [Google Scholar]

- Wang, S.G.; Zhu, S.Y.; Yuen, P.L. Assessment of Ground-Borne Vibration Impact on Nearby Underground Facilities Induced by Ground Surface Excavation. J. Constr. Div. Am. Soc. Civ. Eng. 2021, 147, 04021071. [Google Scholar] [CrossRef]

- Yoon, B.J.; Lee, K.S.; Lee, J.H. A Novel Predictable Rock Breaker Using Intelligent Hydraulic Control with ICT Convergences. Appl. Sci. 2019, 9, 3333. [Google Scholar] [CrossRef] [Green Version]

- Qiu, W.; Zhang, G.S.; Fan, K.; Li, X.; Ma, G.Z. Construction Technology with Boom Type Heading Applied to Unsymmetrical Pressure Shallow Depth and Large Span Tunnel. Min. Constr. Technol. 2021, 42, 16–20. [Google Scholar]

- Xiao, Y.; Yang, Q.X.; Jiang, Y.J. Numerial Simulation Analysis of Milling Parameters with Tunnel Milling Excavation Method. Railw. Std. Des. 2016, 60, 100–104. [Google Scholar]

- Zhang, Y.N.; Deng, H.W.; Ke, B.; Gao, F. Research on the Explosion Effects and Fracturing Mechanism of Liquid Carbon Dioxide Blasting. Min. Metall. Explor. 2022, 39, 521–530. [Google Scholar] [CrossRef]

- Zeng, Y.Q.; Li, H.B.; Xia, X.; Deng, S.C.; Zuo, H.; Yue, H.Z.; Luo, H. Research on Time-frequency Characteristics for Blasting Vibration Signal of CO2 Blasting by Frequency Slice Wavelet Transform. Eng. Lett. 2020, 28, 1047–1057. [Google Scholar]

- Wang, B.; Li, H.B. Numerical simulation of rock fractures induced by CO2 blasting. IOP Conf. Ser. Earth Environ. Sci. 2021, 861, 042065. [Google Scholar] [CrossRef]

- Xia, J.Q.; Dou, B.; Tian, H.; Zheng, J.; Cui, G.D.; Kashif, M. Research on Initiation of Carbon Dioxide Fracturing Pipe Using the Liquid Carbon Dioxide Phase-Transition Blasting Technology. Energies 2021, 14, 521. [Google Scholar] [CrossRef]

- Yuan, H.L.; Chen, C.; Yu, J.X.; Liu, X.Y.; Dong, B. Liquid CO2 Phase Change Fracturing and Vibration Monitoring in Roadbed Slope Excavation. J. Phys. Conf. Ser. 2021, 50, 012116. [Google Scholar]

- Jia, J.Z.; Wang, D.M.; Li, B.; Tian, X.Y. Study of the influencing factors of the liquid CO2 phase change fracturing effect in coalseams. PLoS ONE. 2021, 16, 0254996. [Google Scholar] [CrossRef]

- Sui, H.Y.; Su, T.M.; Hu, R.L.; Yang, K.; Cheng, Y.X. Liquid CO2 Phase-Transition Rock Fracturing: A Novel Technology for Safe Rock Excavation. Appl. Sci. 2022, 12, 68. [Google Scholar] [CrossRef]

- Li, Q.Y.; Chen, G.; Luo, D.Y.; Ma, H.P.; Liu, Y. An experimental study of a novel liquid carbon dioxide rock-breaking technology. Int. J. Rock Mech. Min. Sci. 2020, 128, 104244. [Google Scholar] [CrossRef]

- Li, B.L.; Wang, E.Y.; Hu, S.B.; Wang, X.F.; Liu, B. A Study of Vibration Velocity Attenuation Induced by Pneumatic Rock Breaking with Carbon Dioxide Ice Powder for Safety Assessment. Rock Mech. 2021, 54, 6481–6493. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Deng, J.R.; Deng, H.W.; Ke, B. Peridynamics simulation of rock fracturing under liquid carbon dioxide blasting. Int. J. Damage Mech. 2019, 28, 1038–1052. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Deng, J.R.; Ke, B.; Deng, H.W.; Li, J.L. Experimental Study on Explosion Pressure and Rock Breaking Characteristics under Liquid Carbon Dioxide Blasting. Adv. Civ. Eng. 2018, 11, 7840125. [Google Scholar] [CrossRef]

- Ke, B.; Zhou, K.P.; Ren, G.F.; Shi, J.; Zhang, Y.N. Positive Phase Pressure Function and Pressure Attenuation Characteristic of a Liquid Carbon Dioxide Blasting System. Energies 2019, 12, 4134. [Google Scholar] [CrossRef] [Green Version]

- Liu, D.W.; Jian, Y.H.; Zhang, Z.L.; Zhang, S.; Huang, Z.; Chen, S.J. High Pressure Gas Expansion Fracturing Excavation Method for the Contact Channel of Urban Metro in Hard Rock Strata. CN109736827B, 31 January 2020. [Google Scholar]

- Liu, D.W.; Tang, Y.; Xu, Q.; Cao, M.; Jiang, S.L.; Zhang, J.J. A Method for Testing the Cumulative Damage to the Surrounding Rock with High Pressure Gas Expansion Rock Cracking Method in Hard Rock. CN111781277B, 2 November 2021. [Google Scholar]

- Peng, H.D.; Liu, D.W.; Chu, F.J.; Jian, Y.H. Test on High Pressure Gas Expansion Rock Cracking in Hard Rock Tunnel. Rock Soil Mech. 2018, 39, 242–248. [Google Scholar]

- Liu, D.W.; Zhang, Z.L.; Chu, F.J.; Jian, Y.H.; Zhang, S.; Huang, Z. Cutting Tests of High Pressure Gas Expansion Rock-breaking Technology in Urban Small Cross-section Hard Rock Tunne. Blasting 2019, 36, 104–111. [Google Scholar]

- Liu, D.W.; Tang, Y.; Cai, C.W.; Jian, Y.H. A Rock Fracturing Method Using High-Pressure Gas Expansion: Case Study on Its Application in Hangzhou-Lin’an Intercity Railway. Adv. Civ. Eng. 2021, 14, 6654471. [Google Scholar] [CrossRef]

- Peng, H.D.; Chu, F.J.; Yang, G.; Chen, Z.; Peng, Y.J. Effective Level Evaluation of Rock Breaking of Tunnel High Pressure and Engineering Application. Blasting 2018, 35, 164–170. [Google Scholar]

- Liu, D.W.; Qiu, F.K.; Jia, H.R.; Zhang, Z.L.; Huang, D.H. Safety Evaluation of Excavation Construction with High Pressure Gas Expansion Method of Subway Liaison Channel. J. Saf. Environ. 2019, 19, 1511–1517. [Google Scholar]

- Liu, D.W.; Tang, Y.; Zhang, J.J.; Zhang, W.M. A Gas-Thermal Expansion Pipe Rock-breaking Device and Its Rock-Breaking Method. CN113091545A, 9 July 2021. [Google Scholar]

- Liu, J.P.; Han, Z.W.; Liu, X.B.; Su, Y.; Bi, X.L. A Kind of Thermal Expansion Rock Splitting Agent. CN104961387B, 25 January 2017. [Google Scholar]

- Ma, D.; Duan, H.; Zhang, J.; Liu, X.; Li, Z. Numerical simulation of water-silt inrush hazard of fault rock: A three-phase flow model. Rock Mech. 2022, 55, 5163–5182. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.; Zhang, J. Solid grain migration on hydraulic properties of fault rocks in underground mining tunnel: Radial seepage experiments and verification of permeability prediction. Tunn. Undergr. Space Technol. 2022, 126, 104525. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.; Zhang, J.; Bai, H. A state-of-the-art review on rock seepage mechanism of water inrush disaster in coal mines. Int. J. Coal Sci. Technol. 2022, 9, 50. [Google Scholar] [CrossRef]

- GB 6722-2014; Safety Regulations for Blasting. China Standard Press: Beijing, China, 2014.

| Category of Fracturing Hole | Hole Diameter (mm) | Hole Depth (m) | Hole Spacing (m × m) | Single-Hole Charge (kg) |

|---|---|---|---|---|

| Cutting hole | 70 | 2.1 | / | 1.3 |

| Auxiliary hole | 70 | 1.8 | 1.0 × 0.9, 0.8 × 0.7 | 1.0 |

| Test Number | Cutting Mode | Hole Category | Hole Diameter (mm) | Hole Depth (m) | Quantity of Holes | Angles (°) | Charge (kg) | Charge Length (m) |

|---|---|---|---|---|---|---|---|---|

| 1 | Single wedge | Cutting hole | 70 | 2.1 | 4 | 84 | 1.3 | 1.0 |

| Empty hole | 70 | 1.8 | 10 | 90 | / | / | ||

| 2 | Double wedge | Cutting hole | 70 | 2.1 | 6 | 84 | 1.3 | 1.0 |

| Empty hole | 70 | 1.8 | 10 | 90 | / | / |

| Test Number | Hole Category | Hole Diameter (mm) | Hole Depth (m) | Network Parameter (m × m) | Quantity of Holes | Angles (°) | Charge (kg) | Charge Length (m) |

|---|---|---|---|---|---|---|---|---|

| 3 | Cutting hole | 70 | 2.1 | / | 18 | 84 | 1.3 | 1.0 |

| Empty hole | 70 | 1.8 | / | 30 | 90 | / | / | |

| Auxiliary hole | 70 | 1.8 | 1.0 × 0.9 | 44 | 90 | 1.0 | 0.8 | |

| 4 | Cutting hole | 70 | 2.1 | / | 18 | 84 | 1.3 | 1.0 |

| Empty hole | 70 | 1.8 | / | 30 | 90 | / | / | |

| Auxiliary hole | 70 | 1.8 | 0.8 × 0.7 | 50 | 90 | 1.0 | 0.8 |

| Test Number | Cutting Mode | Quantity of Expansion Pipe | Mass of Gas-Generating Agent (kg) | Depth of Cutting Space (m) | Stripping Rock Volume (m3) | Unit Consumption (kg·m−3) | Rock Fragmentation (m) |

|---|---|---|---|---|---|---|---|

| 1 | Single wedge | 4 | 5.2 | 1.7 | 4.3 | 1.21 | 0.2–0.45 |

| 2 | Double wedge | 6 | 7.8 | 1.8 | 6.7 | 1.16 | 0.2–0.4 |

| Test Number | Network Parameter (m × m) | Quantity of Expansion Pipe | Mass of Gas-Generating Agent (kg) | Depth (m) | Stripping Rock Volume (m3) | Unit Consumption (kg·m−3) | Rock Fragmentation (m) |

|---|---|---|---|---|---|---|---|

| 3 | 1.0 × 0.9 | 62 | 67.4 | 1.4 | 22 | 3.06 | 0.25–0.6 |

| 4 | 0.8 × 0.7 | 68 | 73.4 | 1.5 | 39 | 1.88 | 0.2–0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, D.; Wang, C.; Tang, Y.; Chen, H. Application of High-Pressure Gas Expansion Rock-Cracking Technology in Hard Rock Tunnel near Historic Sites. Appl. Sci. 2023, 13, 1017. https://doi.org/10.3390/app13021017

Liu D, Wang C, Tang Y, Chen H. Application of High-Pressure Gas Expansion Rock-Cracking Technology in Hard Rock Tunnel near Historic Sites. Applied Sciences. 2023; 13(2):1017. https://doi.org/10.3390/app13021017

Chicago/Turabian StyleLiu, Dunwen, Chong Wang, Yu Tang, and Haofei Chen. 2023. "Application of High-Pressure Gas Expansion Rock-Cracking Technology in Hard Rock Tunnel near Historic Sites" Applied Sciences 13, no. 2: 1017. https://doi.org/10.3390/app13021017