A Modeling Design Method for Complex Products Based on LSTM Neural Network and Kansei Engineering

Abstract

Featured Application

Abstract

1. Introduction

2. Methods

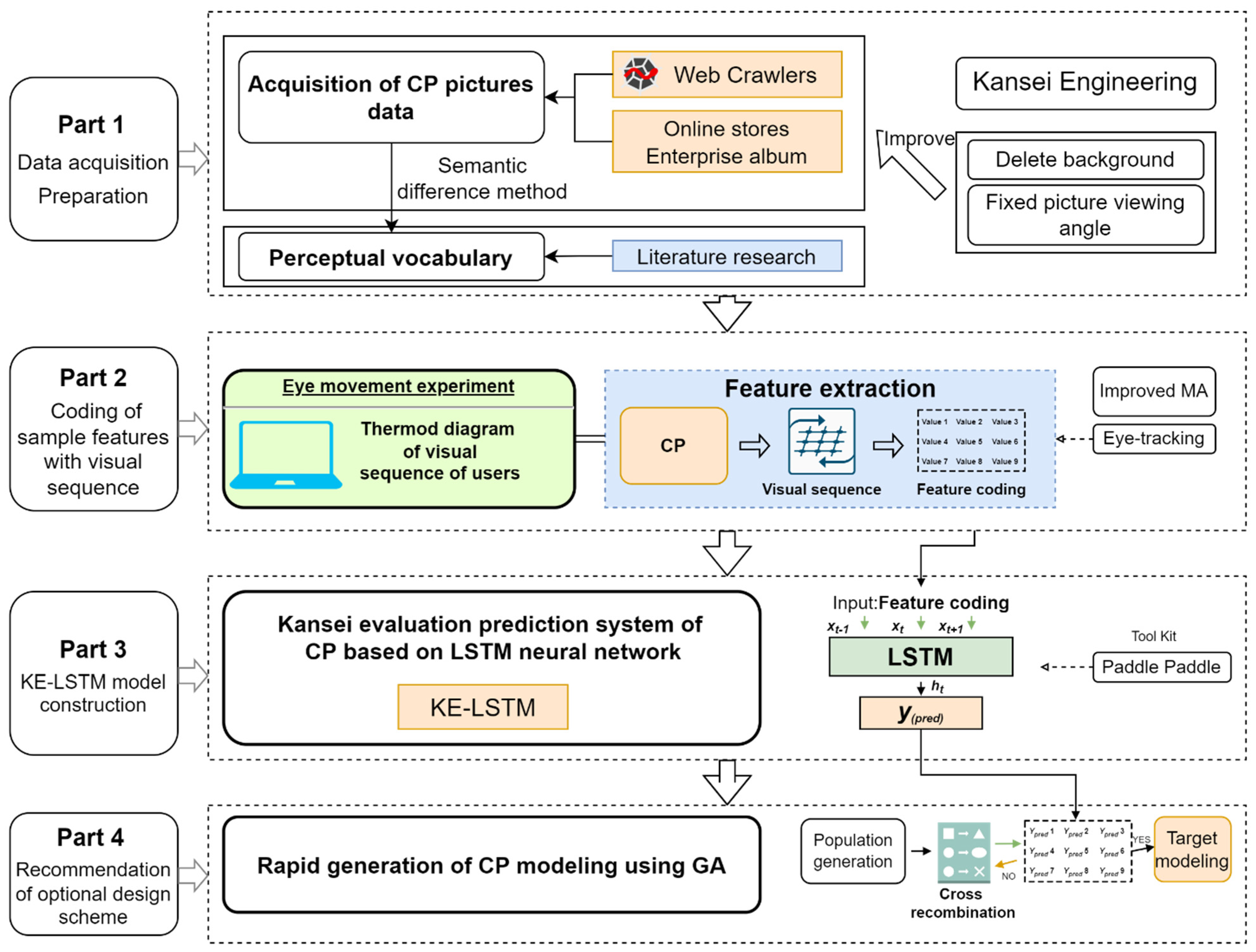

2.1. Research Framework

2.2. Acquisition of Sample Picture Data

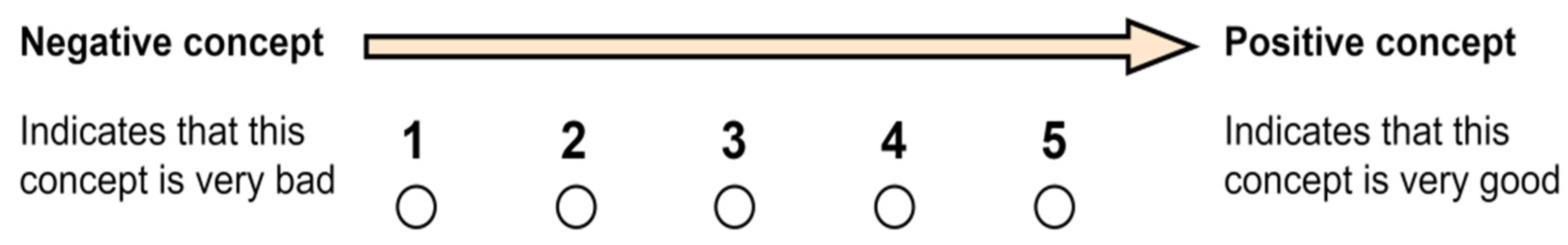

2.3. Acquisition of Perceptual Evaluation Data

2.4. Acquisition of Sample Feature Visual Sequence

2.5. Coding of Samples’ Modeling Features

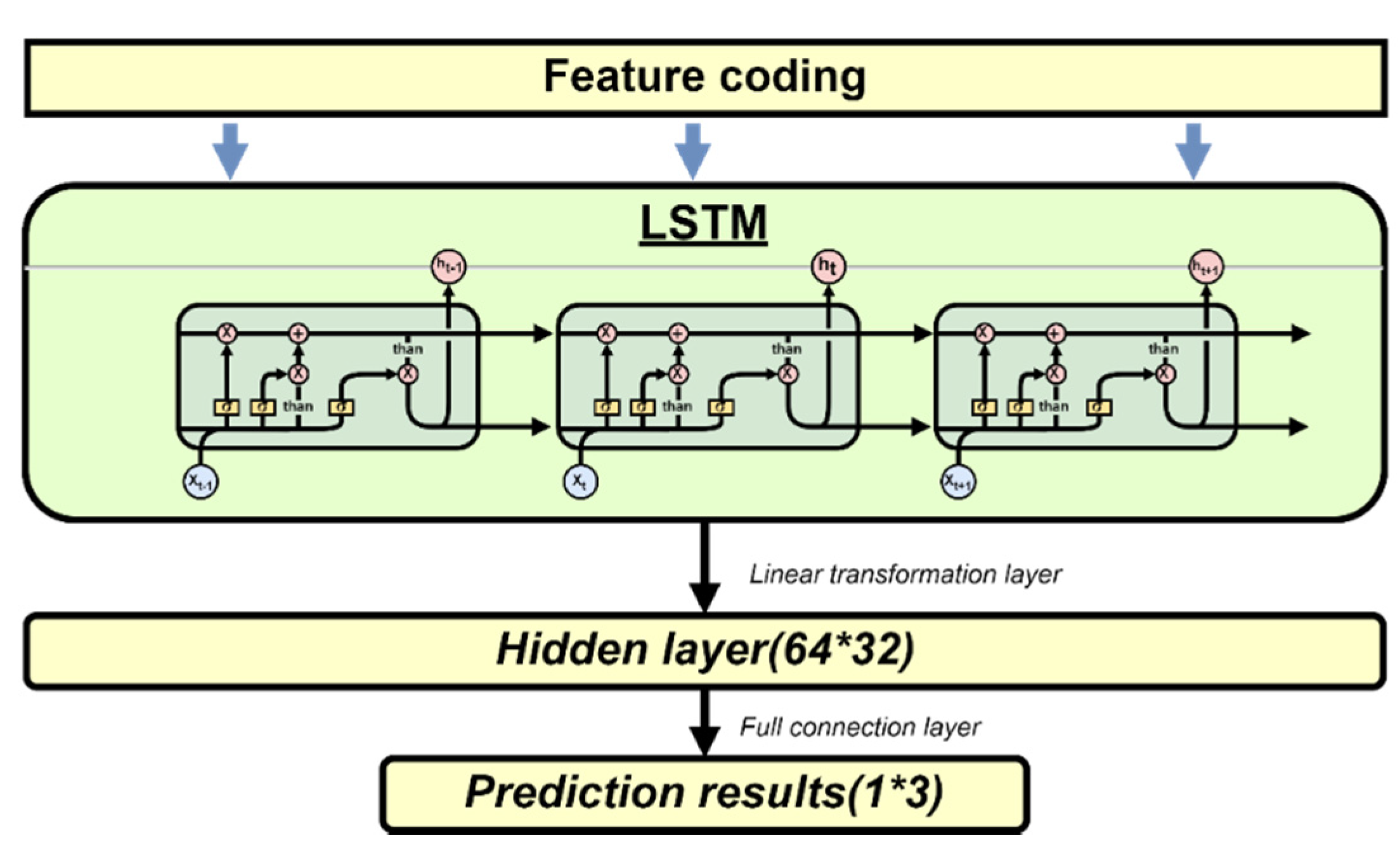

2.6. Construction of the LSTM Model

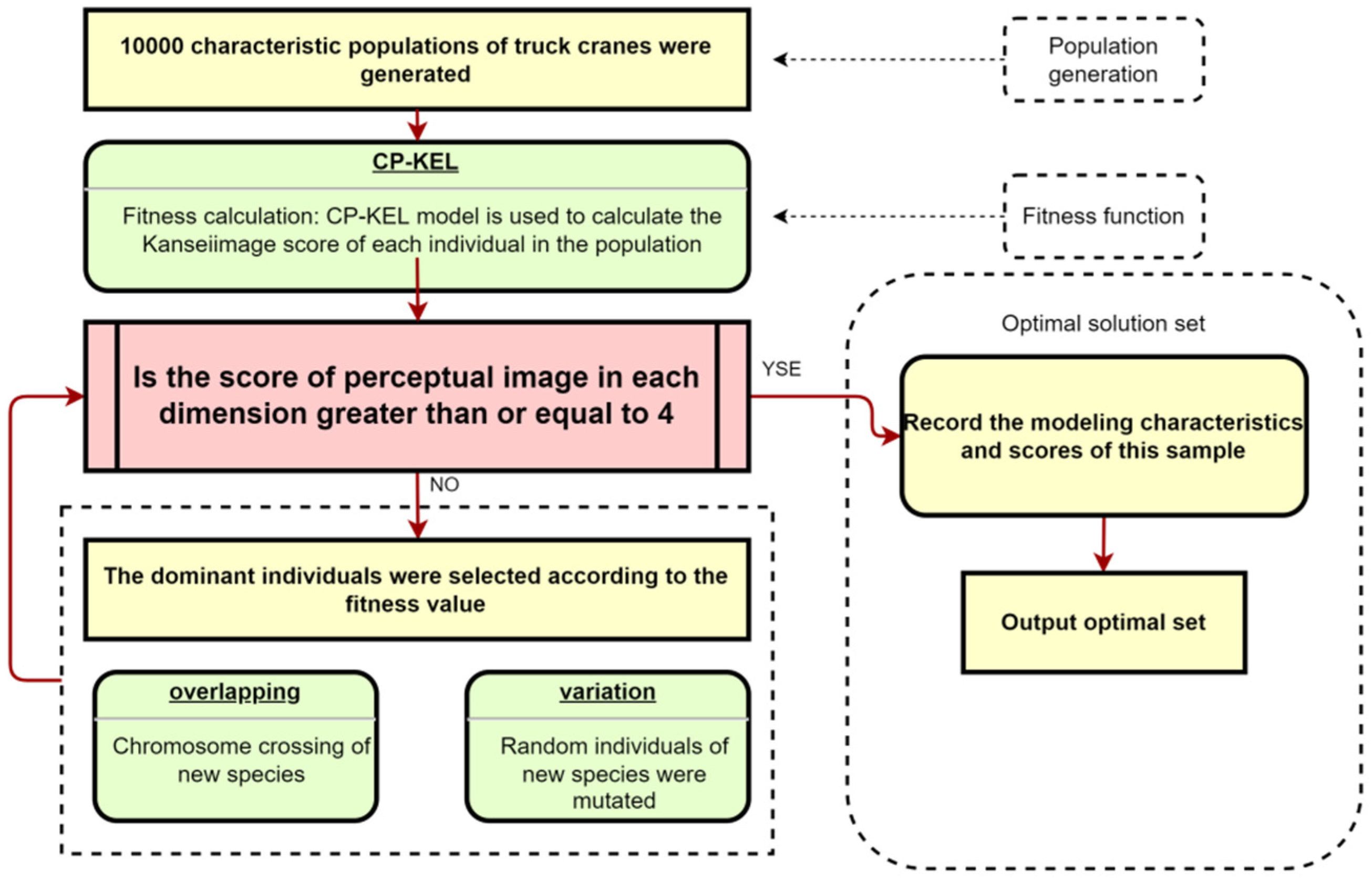

2.7. Construction of GA Model

3. Empirical Study

3.1. Acquisition of Truck Cranes Picture Data

3.2. Acquisition of the Perceptual Evaluation Data of Truck Cranes

3.3. Acquisition of Perceptual Evaluation Data

3.4. Acquisition of Sample Feature Visual Sequence

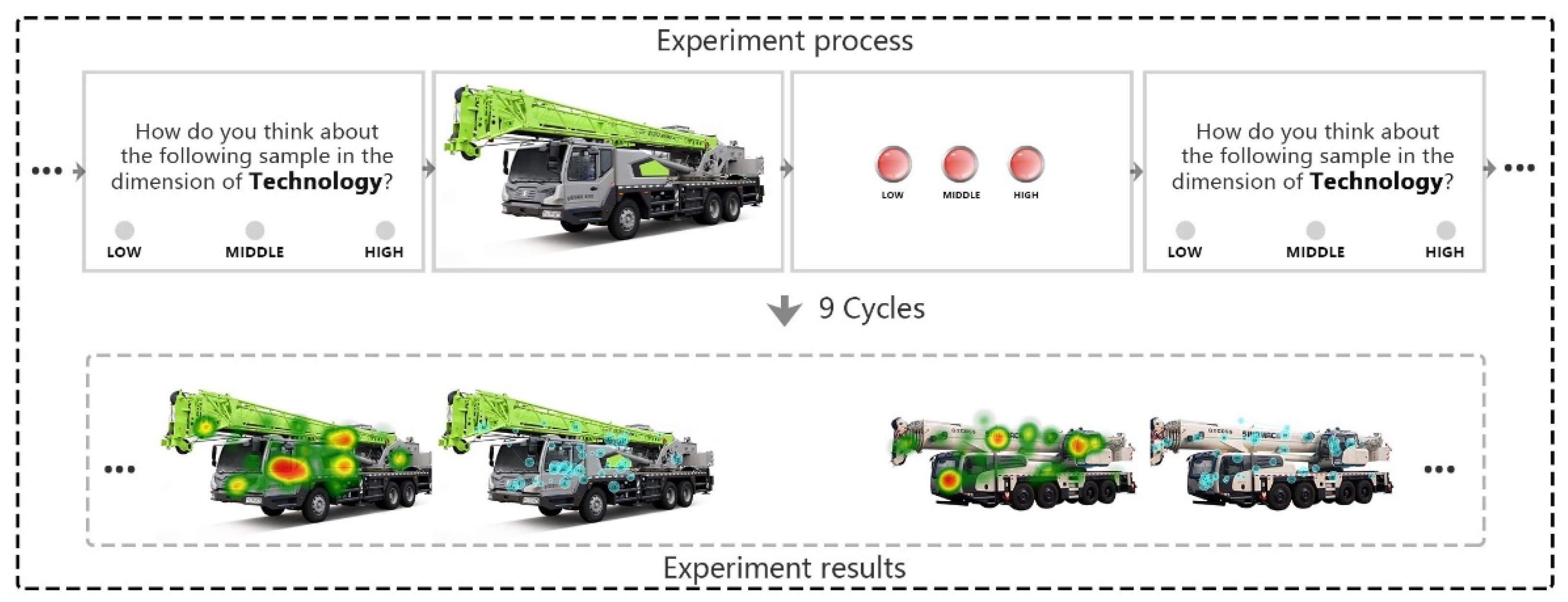

- (1)

- Samples

- (2)

- Participants

- (3)

- Devices

- (4)

- Experiment procedure

- (5)

- Results and analysis

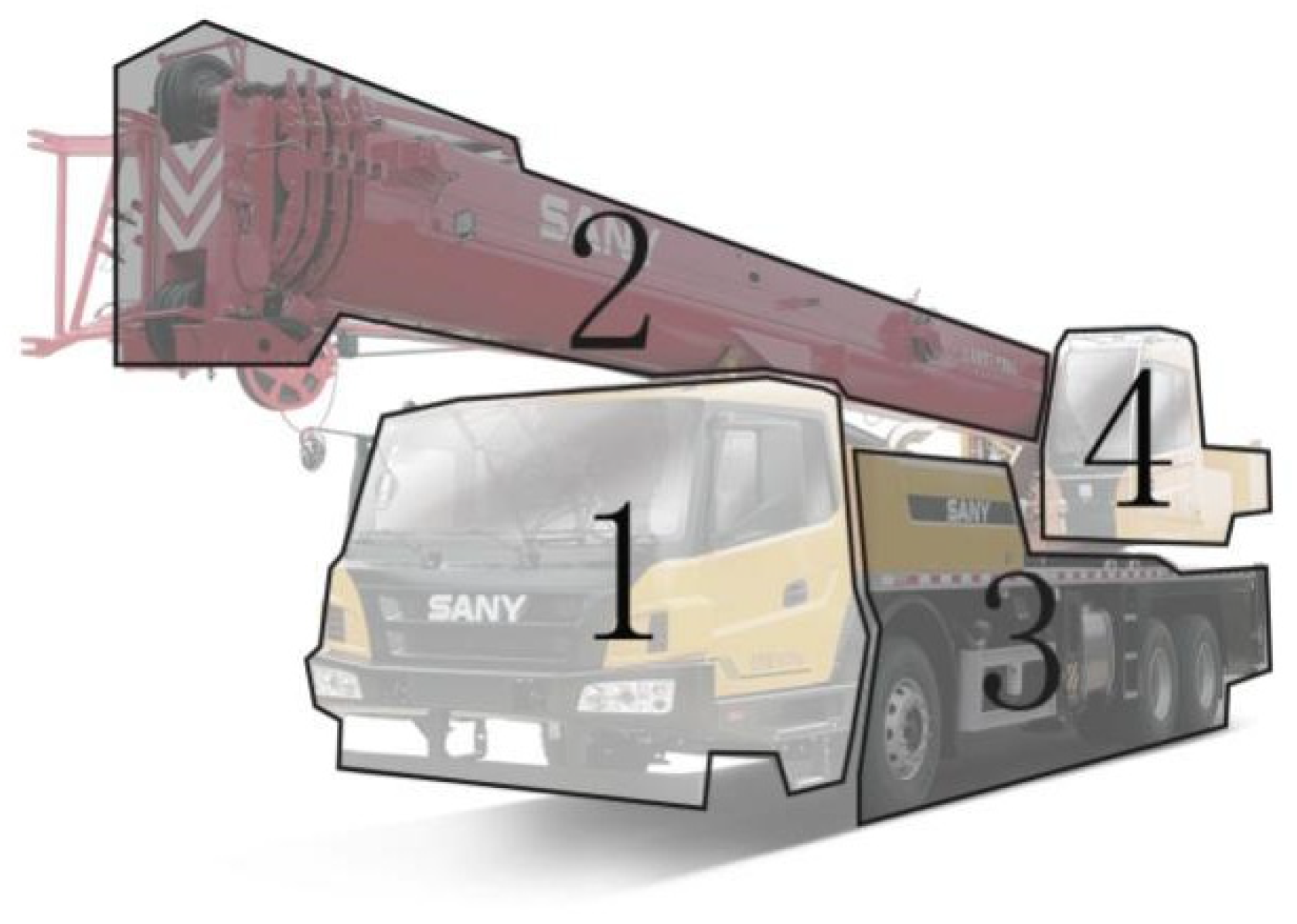

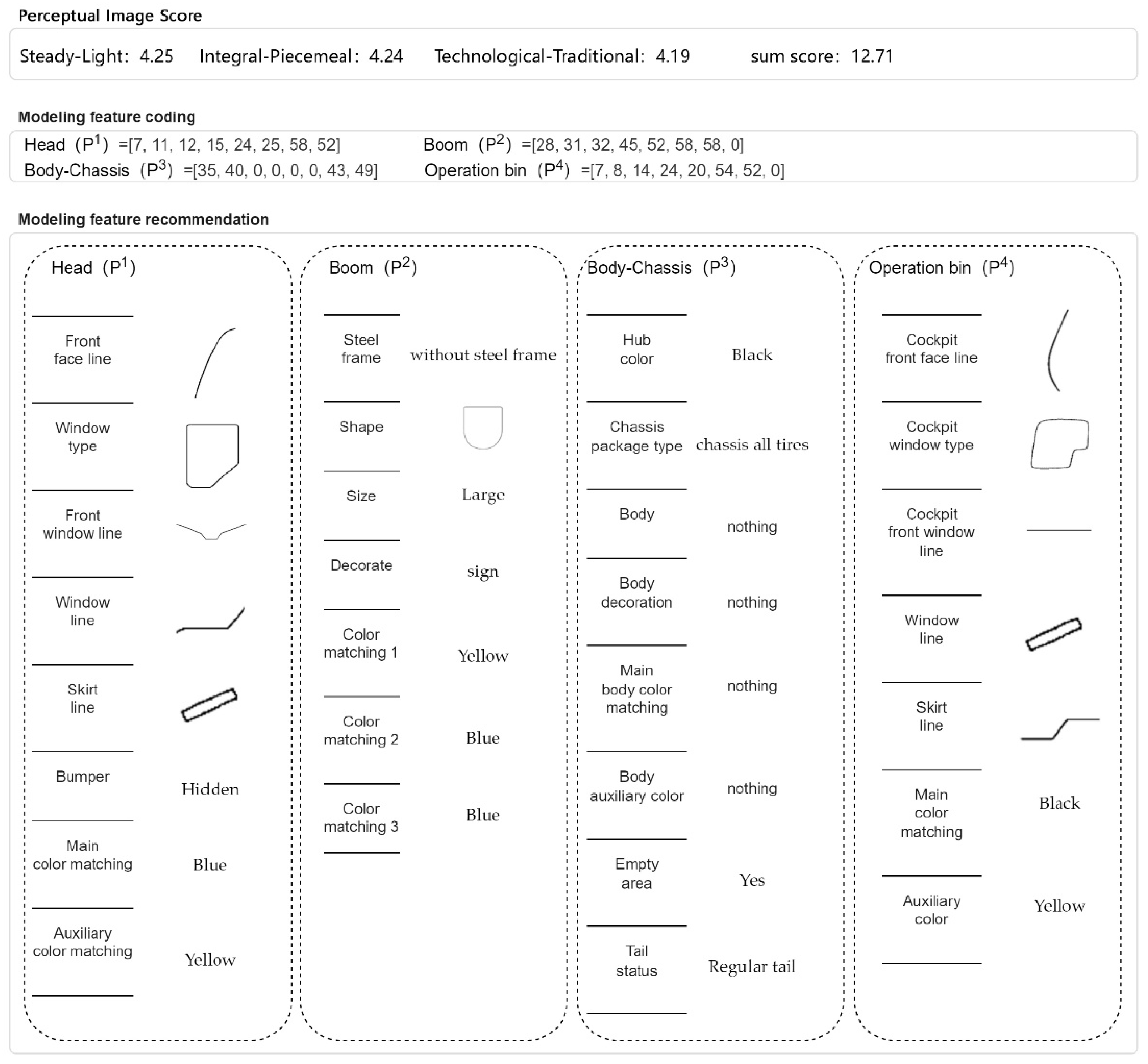

3.5. Coding of Sample’s Modeling Features

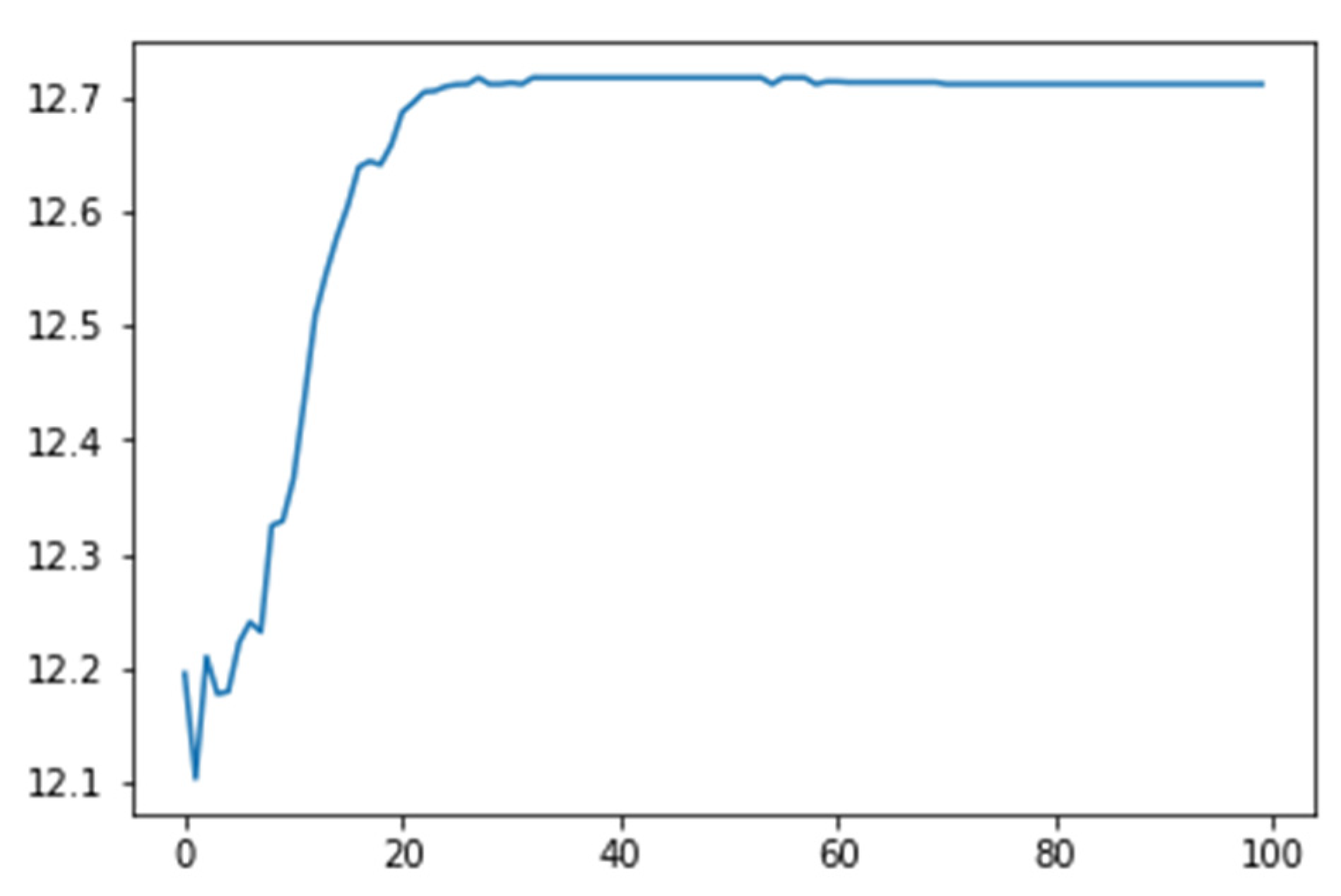

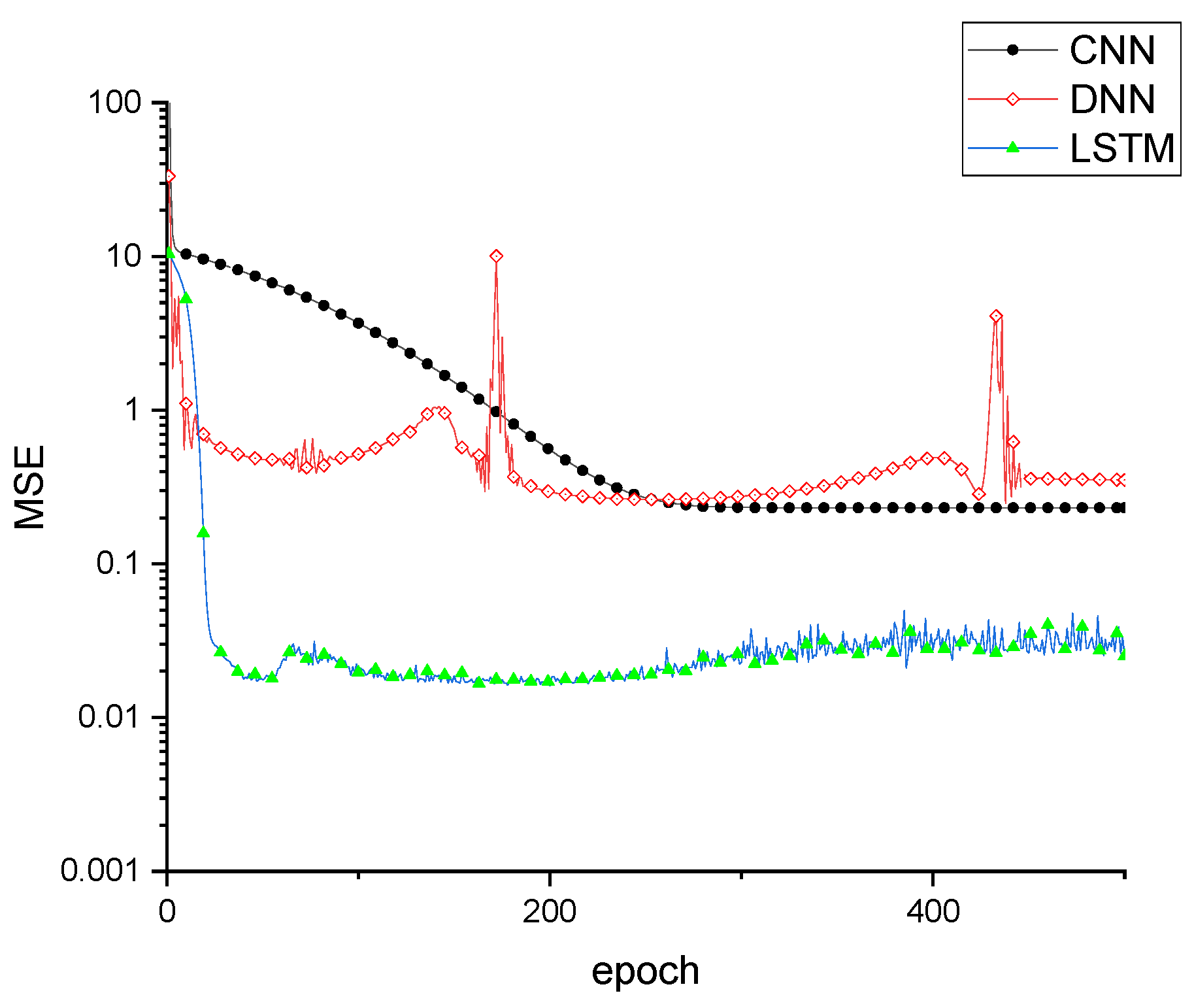

3.6. Model Construction and Perceptual Evaluation

3.7. Establishment of the GA Model

4. Discussion

5. Conclusions

- (1)

- We argue that users’ visual sequence will affect their perception and evaluation when observing CPs, and the user’s observation sequence should be taken into account when establishing the mapping relationship model between the product modeling features and the perceptual images.

- (2)

- The neural network of LSTM was applied to construct a perceptual evaluation model (KE–LSTM) in order to effectively handle the timing data. It could simulate the visual sequence of CPs observed by human eyes, effectively process the modeling information of CPs with temporal characteristics, and improve the robustness of the model. Moreover, KE–LSTM has a higher model accuracy than DNN and CNN.

- (3)

- To deconstruct the modeling features of CPs, we propose an improved MA method based on the temporal-association function. It encodes the representative samples into a modeling feature set including visual sequence data and facilitate the input of the LSTM neural network to mine its timing information and improve the accuracy of the model.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Davies, A.; Hobday, M. The Business of Projects: Managing Innovation in Complex Products and Systems. In The Business of Projects: Managing Innovation in Complex Products and Systems; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Rocca, G.L.; Tooren, M.J.L.V. Enabling distributed multi-disciplinary design of complex products: A knowledge based engineering approach. J. Des. Res. 2007, 5, 333–352. [Google Scholar] [CrossRef]

- Gann, D.M.; Salter, A.J. Innovation in project-based, service-enhanced firms: The construction of complex products and systems. Res. Policy 2000, 29, 955–972. [Google Scholar] [CrossRef]

- Zhang, N.; Yang, Y.; Zheng, Y.; Su, J. Module partition of complex mechanical products based on weighted complex networks. J. Intell. Manuf. 2017, 30, 1973–1998. [Google Scholar] [CrossRef]

- Xue, D.Y.; Imaniyan, D. An Integrated Framework for Optimal Design of Complex Mechanical Products. J. Comput. Inf. Sci. Eng. 2021, 21, 041004. [Google Scholar] [CrossRef]

- Wang, W.; Fan, W.H.; Chang, T.Q.; Xiong, G.L. Design Optimization Process of Complex Product Based on MDO. Appl. Mech. Mater. 2014, 10–12, 155–159. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhou, Q.; Li, B.; Visser, S. A Method of Numerical Control Equipment Appearance Design Based on Product Identity. In Mechanical Engineering and Control Systems—Proceedings of 2015 International Conference on Mechanical Engineering and Control Systems (MECS2015); World Scientific: Singapore, 2016. [Google Scholar]

- Chen, S.-B.; Yu, N.; Yao, Y.-S.; Liu, H.-F.; Zhang, W.-S.; Liu, J.-H.; Gu, R.; Li, K.; Yang, Y.-P. A New Design Method of Mechanical and Electrical Products Appearance Modeling Based on Entity Patterns Gene. In Proceedings of the 2017 International Conference on Mathematics, Modelling and Simulation Technologies and Applications (MMSTA 2017), Xiamen, China, 24–25 December 2017; pp. 212–218. [Google Scholar]

- Zhang, Q.; Lu, X.; Peng, Z.; Ren, M. Perspective: A review of lifecycle management research on complex products in smart-connected environments. Int. J. Prod. Res. 2019, 57, 6758–6779. [Google Scholar] [CrossRef]

- Kim, S.; Kandampully, J.; Bilgihan, A. The influence of eWOM communications: An application of online social network framework. Comput. Hum. Behav. 2018, 80, 243–254. [Google Scholar] [CrossRef]

- Sahoo, N.; Dellarocas, C.; Srinivasan, S. The Impact of Online Product Reviews on Product Returns. Inf. Syst. Res. 2018, 29, 723–738. [Google Scholar] [CrossRef]

- Gu, P.; Sosale, S. Product modularization for life cycle engineering. Robot. Comput. -Integr. Manuf. 1999, 15, 387–401. [Google Scholar] [CrossRef]

- Agard, B.; Bassetto, S. Modular Design for Quality and Cost. In Proceedings of the Systems Conference (SysCon), 2012 IEEE International, Vancouver, BC, Canada, 19–22 March 2012. [Google Scholar]

- ElMaraghy, H.A.; Mahmoudi, N. Concurrent design of product modules structure and global supply chain configurations. Int. J. Comput. Integr. Manuf. 2009, 22, 483–493. [Google Scholar] [CrossRef]

- Nagamachi, M. Kansei engineering as a powerful consumer-oriented technology for product development. Appl. Ergon. 2002, 33, 289–294. [Google Scholar] [CrossRef] [PubMed]

- Nagamachi, M. Kansei Engineering: A new ergonomic consumer-oriented technology for product development. Int. J. Ind. Ergon. 1995, 15, 3–11. [Google Scholar] [CrossRef]

- Zhao, W.; Qiang, L.; Li, W.; Yang, C. Research on Evaluation Method of Product Style Semantics Based on Neural Network. Res. J. Appl. Sci. Eng. Technol. 2013, 6, 4330–4335. [Google Scholar] [CrossRef]

- Hsiao, S.W.; Tsai, H.C. Applying a hybrid approach based on fuzzy neural network and genetic algorithm to product form design. Int. J. Ind. Ergon. 2014, 35, 411–428. [Google Scholar] [CrossRef]

- Lin, Y.C.; Lai, H.H.; Yeh, C.H.; Hung, C.H. A Hybrid Approach to Determining the Best Combination on Product Form Design. In Proceedings of the International Conference on Knowledge-Based and Intelligent Information and Engineering Systems, Melbourne, Australia, 14–16 September 2005; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Jiang, H.; Kwong, C.K.; Liu, Y.; Ip, W.H. A methodology of integrating affective design with defining engineering specifications for product design. Int. J. Prod. Res. 2015, 53, 2472–2488. [Google Scholar] [CrossRef]

- Polignano, M.; Narducci, F.; de Gemmis, M.; Semeraro, G. Towards Emotion-aware Recommender Systems: An Affective Coherence Model based on Emotion-driven Behaviors. Expert Syst. Appl. 2021, 170, 114382. [Google Scholar] [CrossRef]

- Hong, Y.; Zeng, X.Y.; Wang, Y.Y.; Bruniaux, P.; Chen, Y. CBCRS: An open case-based color recommendation system. Knowl.-Based Syst. 2018, 141, 113–128. [Google Scholar] [CrossRef]

- Xue, L.; Jin, Z.Y.; Yan, H.; Pan, Z.J. Development of novel fashion design knowledge base by integrating conflict rule processing mechanism and its application in personalized fashion recommendations. Text. Res. J. 2022, 004051752211298. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Shi, Y.Y.; Guo, Y.Q.; Xu, C.Q.; Zhang, E.W.; Tang, J.X.; Fang, Z.J. Fashion Evaluation Method for Clothing Recommendation Based on Weak Appearance Feature. Sci. Program. 2017, 2017, 1–12. [Google Scholar] [CrossRef]

- Hwangbo, H.; Kim, Y.S.; Cha, K.J. Recommendation system development for fashion retail e-commerce. Electron. Commer. Res. Appl. 2018, 28, 94–101. [Google Scholar] [CrossRef]

- Chen, H.-Y.; Yang, C.-C.; Ko, Y.-T.; Chang, Y.-M.; Chang, H.-C. Product form feature selection methodology based on numerical definition-based design. Concurr. Eng. Res. Appl. 2014, 22, 183–196. [Google Scholar] [CrossRef]

- Fan, K.K.; Chiu, C.H.; Yang, C.C. Green technology automotive shape design based on neural networks and support vector regression. Eng. Comput. Int. J. Comput. Aided Eng. Softw. 2014, 31, 1732–1745. [Google Scholar]

- Guo, F.; Liu, W.L.; Liu, F.T.; Wang, H.; Wang, T.B. Emotional design method of product presented in multi-dimensional variables based on Kansei Engineering. J. Eng. Des. 2014, 25, 194–212. [Google Scholar] [CrossRef]

- Fu, Q.; Lv, J.; Tang, S.; Xie, Q. Optimal Design of Virtual Reality Visualization Interface Based on Kansei Engineering Image Space Research. Symmetry 2020, 12, 1722. [Google Scholar] [CrossRef]

- Kwapień, J.; Drozdz, S. Physical approach to complex systems. Phys. Rep. A Rev. Sect. Phys. Lett. Sect. C 2012, 515, 115–226. [Google Scholar] [CrossRef]

- Quan, H.; Li, S.; Hu, J. Product Innovation Design Based on Deep Learning and Kansei Engineering. Appl. Sci. 2018, 8, 2397. [Google Scholar] [CrossRef]

- Schmidhuber, J. Deep learning in neural networks: An overview. Neural Netw. 2015, 61, 85–117. [Google Scholar] [CrossRef]

- Qin, Z.; Hui, W.; Dong, J.; Zhong, G.; Xin, S. Prediction of Sea Surface Temperature using Long Short-Term Memory. IEEE Geosci. Remote Sens. Lett. 2017, 14, 1745–1749. [Google Scholar]

- Han, J.X.; Ma, M.Y.; Wang, K. Product modeling design based on genetic algorithm and BP neural network. Neural Comput. Appl. 2021, 33, 4111–4117. [Google Scholar] [CrossRef]

- Chou, J.R. A Kansei evaluation approach based on the technique of computing with words. Adv. Eng. Inform. 2016, 30, 1–15. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, C.H.; Li, P.K. Kansei clustering for emotional design using a combined design structure matrix. Int. J. Ind. Ergon. 2012, 42, 416–427. [Google Scholar] [CrossRef]

- Zhai, L.Y.; Khoo, L.P.; Zhong, Z.W. A rough set based decision support approach to improving consumer affective satisfaction in product design. Int. J. Ind. Ergon. 2009, 39, 295–302. [Google Scholar] [CrossRef]

- Osgood, C.E. Exploration in semantic space: A personal diary. J. Soc. Issues 1971, 27, 5–64. [Google Scholar] [CrossRef]

- Wu, Y.X. Product form evolutionary design system construction based on neural network model and multi-objective optimization. J. Intell. Fuzzy Syst. 2020, 39, 7977–7991. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Zhang, L.; Chu, X.; Xue, D. Function Module Partition for Complex Products and Systems Based on Weighted and Directed Complex Networks. J. Mech. Des. 2016, 139, 021101. [Google Scholar] [CrossRef]

- Chen, W. Research and Application of "Rhythm and Rhyme" in the Modelling Design on Agricultural Machinery Product. In Proceedings of the 2020 4th International Conference on Electrical, Automation and Mechanical Engineering (EAME2020), Beijing, China, 21–22 June 2020; pp. 908–912. [Google Scholar]

- Gers, F.A.; Schraudolph, N.N.; Schmidhuber, J. Learning precise timing with LSTM recurrent networks. J. Mach. Learn. Res. 2003, 3, 115–143. [Google Scholar] [CrossRef][Green Version]

- Kumar, S. Neural Networks: A Classroom Approach; Tata McGraw-Hill Education: NewYork, NY, USA, 2004. [Google Scholar]

- Boryczko, J.; Blachnik, M.; Golak, S. Optimization of Warehouse Operations with Genetic Algorithms. Appl. Sci. 2020, 10, 4817. [Google Scholar]

- Wang, D. Zoomlion Truck Crane Design; Hunan University: Changsha, China, 2014. [Google Scholar]

- Xiao, H. A Research on the Form Feature of Truck Crane Base on the Perceptual Intention; Hunan University: Changsha, China, 2012. [Google Scholar]

- Wang, Y.H.; Yu, S.H.; Chen, D.K.; Chu, J.N.; Liu, Z.; Wang, J.L.; Ma, N. Artificial intelligence design decision making model based on deep learning. Comput. Integr. Manuf. Syst. 2019, 25, 9. [Google Scholar]

- Franceschini, F.; Maisano, D. Decision concordance with incomplete expert rankings in manufacturing applications. Res. Eng. Des. 2020, 31, 471–490. [Google Scholar] [CrossRef]

- Gunay Molu, N.; Ozkan, B. Adaptation into Turkish of Fear and Behavioral Intentions Scale. Anadolu Psikiyatr. Derg.-Anatol. J. Psychiatry 2018, 19, 80–86. [Google Scholar] [CrossRef]

- Gearhart, A.; Booth, D.T.; Sedivec, K.; Schauer, C. Use of Kendall’s coefficient of concordance to assess agreement among observers of very high resolution imagery. Geocarto Int. 2013, 28, 517–526. [Google Scholar] [CrossRef]

- Girzadas, D.V.; Harwood, R.C.; Dearie, J.; Garrett, S. A comparison of standardized and narrative letters of recommendation. Acad. Emerg. Med. 1998, 5, 1101–1104. [Google Scholar] [CrossRef] [PubMed]

- Beckman, T.J.; Lee, M.C.; Rohren, C.H.; Pankratz, V.S. Evaluating an instrument for the peer review of inpatient teaching. Med. Teach. 2003, 25, 131–135. [Google Scholar] [CrossRef] [PubMed]

- Kendall, M.G.; Smith, B.B. The problem of m rankings. Ann. Math. Stat. 1939, 10, 275–287. [Google Scholar] [CrossRef]

- Friedman, L.; Stern, H.; Brown, G.G.; Mathalon, D.H.; Turner, J.; Glover, G.H.; Gollub, R.L.; Lauriello, J.; Lim, K.O.; Cannon, T.; et al. Test-retest and between-site reliability in a multicenter fMRI study. Hum. Brain Mapp. 2008, 29, 958–972. [Google Scholar] [CrossRef]

- Stephens, J.P.; Vos, G.A.; Stevens, E.M.; Moore, J.S. Test-retest repeatability of the Strain Index. Appl. Ergon. 2006, 37, 275–281. [Google Scholar] [CrossRef][Green Version]

- Lane, H.G.; Driessen, R.; Campbell, K.; Deitch, R.; Turner, L.; Parker, E.A.; Hager, E.R. Development of the PEA-PODS (Perceptions of the Environment and Patterns of Diet at School) Survey for Students. Prev. Chronic Dis. 2018, 15, E88. [Google Scholar] [CrossRef]

- Dhakal, P.; Gamble, J.; Creedy, D.K.; Newnham, E. Development of a tool to assess students’ perceptions of respectful maternity care. Midwifery 2022, 105, 103228. [Google Scholar] [CrossRef]

- Haykin, S. Neural Networks and Learning Machines, 3/E; Pearson Education India: Delhi, India, 2009. [Google Scholar]

- Cai, M.; Liu, J. Maxout neurons for deep convolutional and LSTM neural networks in speech recognition. Speech Commun. 2016, 77, 53–64. [Google Scholar] [CrossRef]

- Lee, K.; Choi, C.; Shin, D.H.; Kim, H.S. Prediction of Heavy Rain Damage Using Deep Learning. Water 2020, 12, 1942. [Google Scholar] [CrossRef]

- Do, N.Q.; Selamat, A.; Krejcar, O.; Yokoi, T.; Fujita, H. Phishing Webpage Classification via Deep Learning-Based Algorithms: An Empirical Study. Appl. Sci. 2021, 11, 9210. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Noreen, S.; Ashraf, M.A.; Ya-nan, Q. Multi-Lingual Language Variety Identification using Conventional Deep Learning and Transfer Learning Approaches. Int. Arab J. Inf. Technol. 2022, 19, 705–712. [Google Scholar] [CrossRef]

- Huang, L.; Zhang, Y.; Pan, W.J.; Chen, J.Y.; Qian, L.P.; Wu, Y. Visualizing Deep Learning-Based Radio Modulation Classifier. IEEE Trans. Cogn. Commun. Netw. 2021, 7, 47–58. [Google Scholar] [CrossRef]

- Saranya, N.; Srinivasan, K.; Kumar, S.K.P. Banana ripeness stage identification: A deep learning approach. J. Ambient. Intell. Humaniz. Comput. 2021, 13, 4033–4039. [Google Scholar] [CrossRef]

- Liu, D.; Li, Y.; Lin, J.P.; Li, H.Q.; Wu, F. Deep Learning-Based Video Coding: A Review and a Case Study. Acm Comput. Surv. 2020, 53, 1–35. [Google Scholar] [CrossRef]

- Hodson, T.O. Root-mean-square error (RMSE) or mean absolute error (MAE): When to use them or not. Geosci. Model Dev. 2022, 15, 5481–5487. [Google Scholar] [CrossRef]

| Perceptual Vocabularies | ||

|---|---|---|

| Steady–light | Integral–piecemeal | Technological–traditional |

| Sample | Technological– Traditional | Steady–Light | Integral–Piecemeal | |

|---|---|---|---|---|

| Mean Evaluation Values | X1 | 4 | 4.4 | 3.9 |

| X2 | 3.2 | 3.8 | 3.9 | |

| X3 | 4.3 | 4.4 | 4 | |

| X4 | 4.3 | 3.9 | 3.7 | |

| X5 | 3.8 | 3.7 | 3.4 | |

| … | … | … | … | |

| X206 | 4.3 | 4.3 | 4.3 | |

| Reliability and validity test | Kendall’s concordance coefficient (W) | 0.608 | ||

| p | 0.000 | |||

| Sample | Technological- Traditional | Steady–Light | Integral–piecemeal | |

|---|---|---|---|---|

| Mean Evaluation Values | X1 | 4.1 | 4.2 | 4 |

| X2 | 2.8 | 3.9 | 3.8 | |

| X3 | 4.2 | 4.6 | 4.4 | |

| X4 | 4.2 | 3.9 | 3.8 | |

| X5 | 3.7 | 3.8 | 3.6 | |

| … | … | … | … | |

| X206 | 4.4 | 4.2 | 4.8 | |

| Reliability and validity test | Kendall’s concordance coefficient (W) | 0.603 | ||

| p | 0.000 | |||

| Pearson correlation coefficient of the two experiment results | 0.917 | |||

| Technological–Traditional | Integral–Piecemeal | Steady–Light | |

|---|---|---|---|

| High score |  |  |  |

| 4.3 points | 4.3 points | 4.0 points | |

| Middle score |  |  |  |

| 3.0 points | 3.5 points | 3.4 points | |

| Low score |  |  |  |

| 2.8 points | 2.7 points | 2.7 points |

| Visual-Interest Region | Mean Score |

|---|---|

| Head | 4.75 |

| Body | 3.08 |

| Boom | 3.09 |

| Operation bin | 2.58 |

| Chassis | 1.5 |

| Component | Item | Category | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Code | Name | |||||||||||

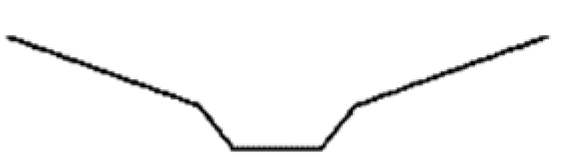

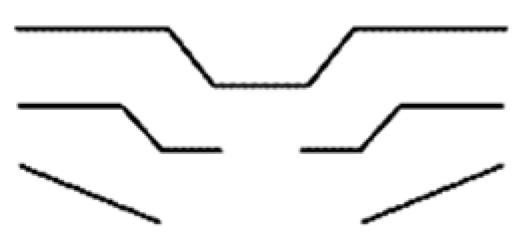

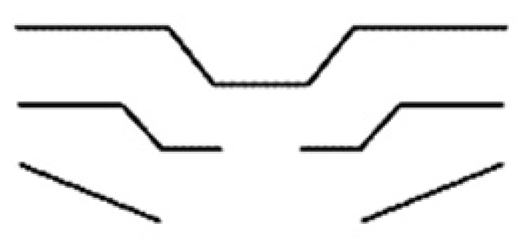

| Head (P1) | P11 | Front face line | None |  |  |  |  |  |  | |||

| 01 | 02 | 03 | 04 | 05 | 06 | 07 | ||||||

| P12 | Window type |  |  |  |  | |||||||

| 08 | 09 | 10 | 11 | |||||||||

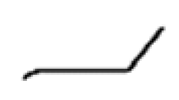

| P13 | Front window line |  |  |  | ||||||||

| 12 | 13 | 14 | ||||||||||

| P14 | Window line |  |  |  |  |  |  |  |  |  |  | |

| 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | |||

| P15 | Skirt line |  |  |  |  |  |  |  |  |  |  | |

| 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | |||

| P16 | Bumper | Hidden | Exposed | |||||||||

| 25 | 26 | |||||||||||

| P17 | Main color matching | Yellow | Green | Black | Gray | White | Red | Blue | ||||

| 52 | 53 | 54 | 55 | 56 | 57 | 58 | ||||||

| P18 | Auxiliary color matching | Yellow | Green | Black | Gray | White | Red | Blue | ||||

| 52 | 53 | 54 | 55 | 56 | 57 | 58 | ||||||

| Boom (P2) | P21 | Steel frame | With steel frame | Without steel frame | ||||||||

| 27 | 28 | |||||||||||

| P22 | Shape |  |  |  | ||||||||

| 29 | 30 | 31 | ||||||||||

| P23 | Size | Large | Medium | Small | ||||||||

| 32 | 33 | 34 | ||||||||||

| P24 | Decorate | Structure | Sign | None | ||||||||

| 45 | 46 | 47 | ||||||||||

| P25 | Color matching 1 | Yellow | Green | Black | Gray | White | Red | Blue | ||||

| 52 | 53 | 54 | 55 | 56 | 57 | 58 | ||||||

| P26 | Color matching 2 | Yellow | Green | Black | Gray | White | Red | Blue | ||||

| 52 | 53 | 54 | 55 | 56 | 57 | 58 | ||||||

| P27 | Color matching 3 | Yellow | Green | Black | Gray | White | Red | Blue | ||||

| 52 | 53 | 54 | 55 | 56 | 57 | 58 | ||||||

| Body-Chassis (P3) | P31 | Hub color | Black | White | ||||||||

| 54 | 56 | |||||||||||

| P32 | Chassis package type | Chassis bread wrapping | Chassis line wrapping | Chassis warning line wrapping | Chassis all tires | |||||||

| 37 | 38 | 39 | 40 | |||||||||

| P33 | Body | Yes | No | |||||||||

| 41 | 42 | |||||||||||

| P34 | Body decoration | Color division | Structure division | Mark/logo Division | No decoration | |||||||

| 45 | 46 | 47 | 48 | |||||||||

| P35 | Main body color matching | Yellow | Green | Black | Gray | White | Red | Blue | ||||

| 52 | 53 | 54 | 55 | 56 | 57 | 58 | ||||||

| P36 | Body auxiliary color | Yellow | Green | Black | Gray | White | Red | Blue | ||||

| 52 | 53 | 54 | 55 | 56 | 57 | 58 | ||||||

| P37 | Empty area | Yes | No | |||||||||

| 43 | 44 | |||||||||||

| P38 | Tail status | Regular tail | Messy tail | No tail | ||||||||

| 49 | 50 | 51 | ||||||||||

| Operation bin (P4) | P41 | Cockpit front face line | None |  |  |  |  |  |  | |||

| 01 | 02 | 03 | 04 | 05 | 06 | 07 | ||||||

| P42 | Cockpit window type |  |  |  |  | |||||||

| 08 | 09 | 10 | 11 | |||||||||

| P43 | Cockpit front window line |  |  |  | ||||||||

| 12 | 13 | 14 | ||||||||||

| P44 | Window line |  |  |  |  |  |  |  |  |  |  | |

| 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | |||

| P45 | Skirt line |  |  |  |  |  |  |  |  |  |  | |

| 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | |||

| P46 | Main color matching | Yellow | Green | Black | Gray | White | Red | Blue | ||||

| 52 | 53 | 54 | 55 | 56 | 57 | 58 | ||||||

| P47 | Auxiliary color | Yellow | Green | Black | Gray | White | Red | Blue | ||||

| 52 | 53 | 54 | 55 | 56 | 57 | 58 | ||||||

| Sample | Head (P1) | Boom (P2) | Body–Chassis (P3) | Operation bin (P4) |

|---|---|---|---|---|

| X1 | [1,11,13,15,15,25,54,55] | [28,31,34,45,53,53,54] | [36,39,42,0,0,0,44,50] | [1,11,14,15,15,55,54] |

| X2 | [1,8,14,19,15,26,52,54] | [28,31,33,47,52,52,52] | [36,39,41,47,54,52,44,49] | [4,8,14,19,15,54,52] |

| X3 | [1,8,14,19,23,26,56,58] | [28,30,32,47,57,56,56] | [35,37,41,46,58,56,44,49] | [1,8,14,19,23,56,58] |

| X4 | [3,11,13,15,16,26,56,54] | [27,31,34,45,53,53,54] | [36,38,41,46,56,53,44,50] | [1,11,14,15,15,56,54] |

| X5 | [1,9,13,15,23,26,55,54] | [27,31,33,45,53,53,54] | [36,38,41,46,55,53,44,49] | [1,9,14,15,15,55,54] |

| … | … | … | … | … |

| X206 | [5,8,14,21,22,26,56,54] | [28,30,32,47,57,56,56] | [36,37,41,46,56,54,43,49] | [1,8,14,21,22,56,54] |

| Model Structure | MSE | RMSE |

|---|---|---|

| LSTM | 0.02 | 0.14 |

| CNN | 0.23 | 0.48 |

| DNN | 0.30 | 0.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, J.-J.; Luo, P.-S.; Liu, Q.; Sun, F.-A.; Zhu, L.-M. A Modeling Design Method for Complex Products Based on LSTM Neural Network and Kansei Engineering. Appl. Sci. 2023, 13, 710. https://doi.org/10.3390/app13020710

Duan J-J, Luo P-S, Liu Q, Sun F-A, Zhu L-M. A Modeling Design Method for Complex Products Based on LSTM Neural Network and Kansei Engineering. Applied Sciences. 2023; 13(2):710. https://doi.org/10.3390/app13020710

Chicago/Turabian StyleDuan, Jin-Juan, Ping-Sheng Luo, Qi Liu, Feng-Ao Sun, and Li-Ming Zhu. 2023. "A Modeling Design Method for Complex Products Based on LSTM Neural Network and Kansei Engineering" Applied Sciences 13, no. 2: 710. https://doi.org/10.3390/app13020710

APA StyleDuan, J.-J., Luo, P.-S., Liu, Q., Sun, F.-A., & Zhu, L.-M. (2023). A Modeling Design Method for Complex Products Based on LSTM Neural Network and Kansei Engineering. Applied Sciences, 13(2), 710. https://doi.org/10.3390/app13020710