Determining Factors of Fixed Offshore Platform Inspections in Indonesia

Abstract

1. Introduction

2. Conceptual Background

2.1. Inspections

2.2. Fixed Offshore Platforms

2.3. Fixed Offshore Platform Inspections

Previous Research on Fixed Offshore Platform Inspections

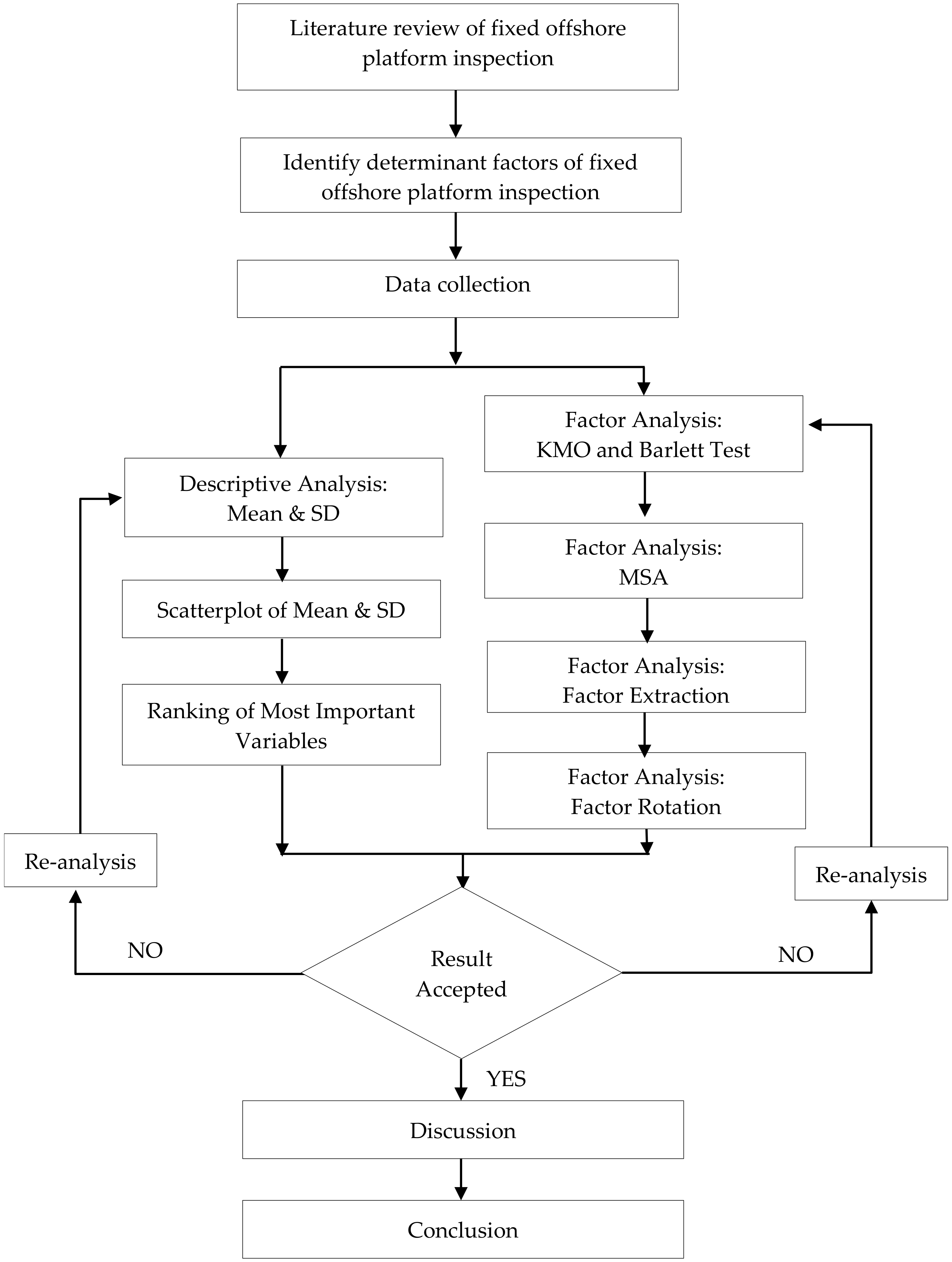

3. Method

3.1. Data Collection

3.2. Data Analysis

4. Results

4.1. Profiles of Respondents

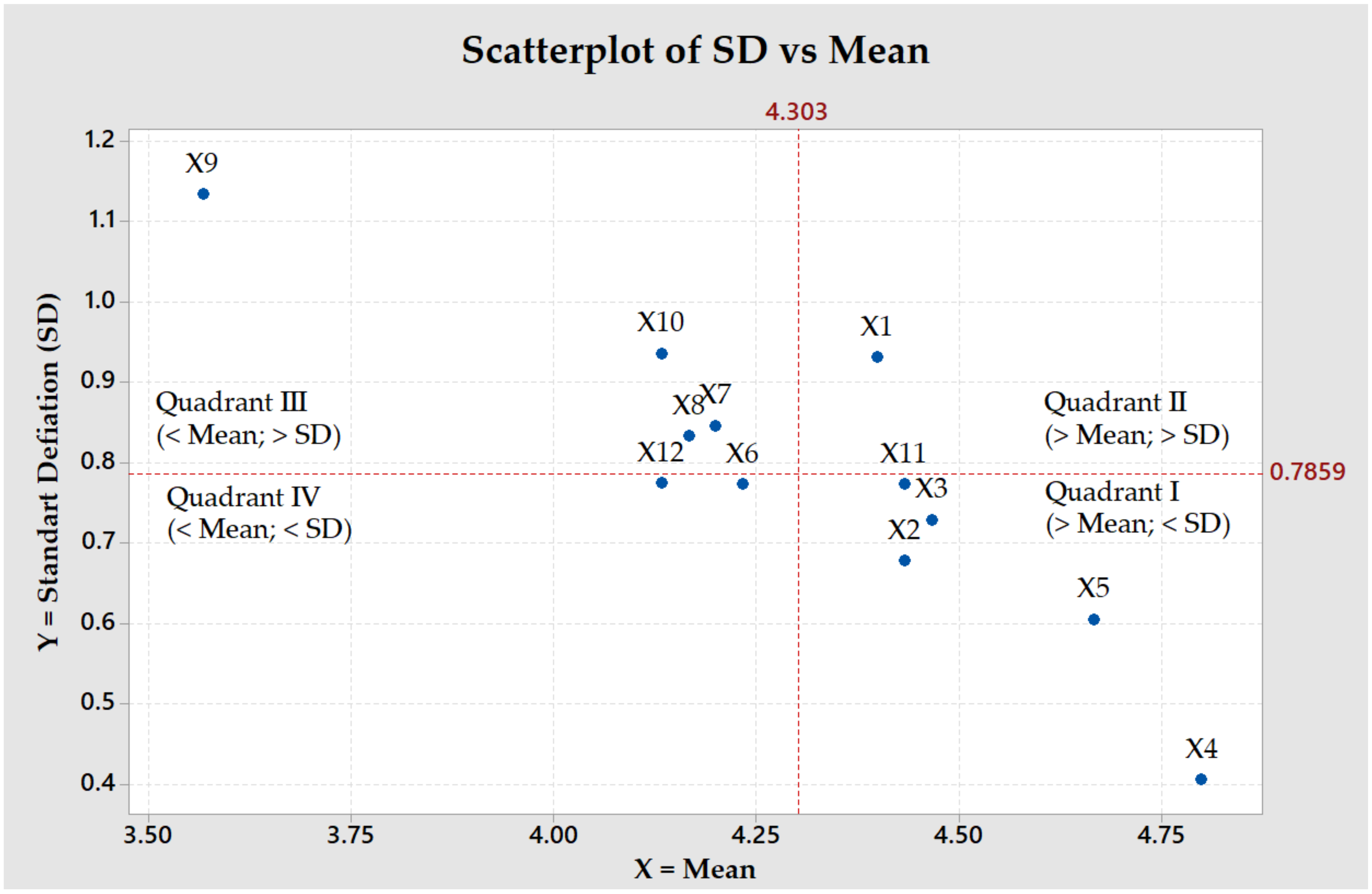

4.2. Result of Data Distribution

4.3. Factor Analysis Result

4.3.1. Kaiser–Meyer–Olkin (KMO) and Barlett Tests

4.3.2. Measured Sampling Adequacy (MSA)

4.3.3. Factor Extraction

4.3.4. Factor Rotation

5. Discussion

5.1. Environmental Conditions

5.2. Structural Design

5.3. Anomalies and Defects

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sarker, S.; Kim, D.; Azad, M.S.; Sinsabvarodom, C.; Guk, S. Influence of Optimal Intensity Measures Selection in Engineering Demand Parameter of Fixed Jacket Offshore Platform. Appl. Sci. 2021, 11, 10745. [Google Scholar] [CrossRef]

- Khalili, H.; Oterkus, S.; Barltrop, N.; Bharadwaj, U. Updating the Distributions of Uncertain Parameters Involved in Fatigue Analysis. J. Mar. Sci. Eng. 2020, 8, 778. [Google Scholar] [CrossRef]

- SKK Migas. SKK Migas Annual Report 2019: Expanding Investment towards the 1 Million BOPD Oil Production; Humas SKK Migas: Jakarta, Indonesia, 2019. [Google Scholar]

- Pereira, C.; Silva, A.; Ferreira, C.; de Brito, J.; Flores-Colen, I.; Silvestre, J.D. Uncertainty in Building Inspection and Diagnosis: A Probabilistic Model Quantification. Infrastructures 2021, 6, 124. [Google Scholar] [CrossRef]

- Bonvicini, S.; Bernardini, G.; Scarponi, G.E.; Cassina, L.; Collina, A.; Cozzani, V. A Methodology for Response Gap Analysis in Offshore Oil Spill Emergency Management. Mar. Pollut. Bull. 2022, 174, 113272. [Google Scholar] [CrossRef] [PubMed]

- Directorate General of Marine Space. Karawang Regengy Waters Affected by Oil Spill. Available online: https://kkp.go.id/djprl/p4k (accessed on 1 February 2022).

- Tawekal, J.R.; Tawekal, R.L. Risk Reliability-Based Underwater Inspection Method for Jacket Platforms in Indonesia. Int. J. Struct. Integr. 2018, 9, 603–615. [Google Scholar] [CrossRef]

- Tawekal, R.L.; Purnawarman, F.D.; Muliati, Y. Development of Risk-Reliability Based Underwater Inspection for Fixed Offshore Platforms in Indonesia. MATEC Web Conf. 2018, 147, 05002. [Google Scholar] [CrossRef][Green Version]

- Hatoum, M.B.; Piskernik, M.; Nassereddine, H. A Holistic Framework for the Implementation of Big Data throughout a Construction Project Lifecycle. In Proceedings of the 37th International Symposium on Automation and Robotics in Construction, ISARC 2020: From Demonstration to Practical Use-To New Stage of Construction Robot, Kitakyushu, Japan, 27–28 October 2020; pp. 1299–1306. [Google Scholar]

- Tolentino, D.; Ruiz, S.E. Influence of Structural Deterioration over Time on the Optimal Time Interval for Inspection and Maintenance of Structures. Eng. Struct. 2014, 61, 22–30. [Google Scholar] [CrossRef]

- Luque, J.; Straub, D. Risk-Based Optimal Inspection Strategies for Structural Systems Using Dynamic Bayesian Networks. Struct. Saf. 2019, 76, 68–80. [Google Scholar] [CrossRef]

- Gholami, H.; Asgarian, B.; Asil Gharebaghi, S. Practical Approach for Reliability-Based Inspection Planning of Jacket Platforms Using Bayesian Networks. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2020, 6, 04020029. [Google Scholar] [CrossRef]

- Edirisinghe, R.; London, K.A.; Kalutara, P.; Aranda-Mena, G. Building Information Modelling for Facility Management: Are We There Yet? Eng. Constr. Archit. Manag. 2017, 24, 1119–1154. [Google Scholar] [CrossRef]

- Huang, Z.; Tan, C.L.; Lu, Y.; Wong, N.H. Holistic Analysis and Prediction of Life Cycle Cost for Vertical Greenery Systems in Singapore. Build. Environ. 2021, 196, 107735. [Google Scholar] [CrossRef]

- El-Reedy, M.A. Risk-Based Inspection Technique. In Offshore Structures; Elsevier: Amsterdam, The Netherlands, 2020; pp. 543–607. [Google Scholar]

- Guédé, F. Risk-Based Structural Integrity Management for Offshore Jacket Platforms. Mar. Struct. 2019, 63, 444–461. [Google Scholar] [CrossRef]

- Markeset, T.; Moreno-Trejo, J.; Kumar, R. Maintenance of Subsea Petroleum Production Systems: A Case Study. J. Qual. Maint. Eng. 2013, 19, 128–143. [Google Scholar] [CrossRef]

- Lu, W.; Wu, L.; Xu, J.; Lou, J. Construction E-Inspection 2.0 in the COVID-19 Pandemic Era: A Blockchain-Based Technical Solution. J. Manag. Eng. 2022, 38, 04022032. [Google Scholar] [CrossRef]

- Guo, C.; Liang, Z. A Predictive Markov Decision Process for Optimizing Inspection and Maintenance Strategies of Partially Observable Multi-State Systems. Reliab. Eng. Syst. Saf. 2022, 226, 108683. [Google Scholar] [CrossRef]

- Morato, P.G.; Papakonstantinou, K.G.; Andriotis, C.P.; Nielsen, J.S.; Rigo, P. Optimal Inspection and Maintenance Planning for Deteriorating Structural Components through Dynamic Bayesian Networks and Markov Decision Processes. Struct. Saf. 2022, 94, 102140. [Google Scholar] [CrossRef]

- Feng, F. Design and Analysis of Tall and Complex Structures; Elsevier: Amsterdam, The Netherlands, 2018; ISBN 9780081010181. [Google Scholar]

- Chakrabarti, S.K. Hydrodynamics of Offshore Structures; WIT Press: Southampton, UK, 1987. [Google Scholar]

- Amiri, N.; Shaterabadi, M.; Kashyzadeh, K.R.; Chizari, M. A Comprehensive Review on Design, Monitoring, and Failure in Fixed Offshore Platforms. J. Mar. Sci. Eng. 2021, 9, 1349. [Google Scholar] [CrossRef]

- Tian, X.; Sun, X.; Liu, G.; Deng, W.; Wang, H.; Li, Z.; Li, D. Optimization Design of the Jacket Support Structure for Offshore Wind Turbine Using Topology Optimization Method. Ocean Eng. 2022, 243, 110084. [Google Scholar] [CrossRef]

- Konstandakopoulou, F.; Konstantinidou, M.; Pnevmatikos, N.; Hatzigeorgiou, G.D. Safety and Performance of Offshore Platforms Subjected to Repeated Earthquakes. Infrastructures 2020, 5, 38. [Google Scholar] [CrossRef]

- Yasseri, S.F.; Bahai, H.; Mahani, R.B. Inspection Planning of Offshore Steel Jacket Structures for Fatigue Damage. Int. J. Offshore Polar Eng. 2017, 27, 252–259. [Google Scholar] [CrossRef]

- Ahmad, K.; Langdon, A.; Frieze, P.A. An Expert System for Offshore Structure Inspection and Maintenance. NDT E Int. 1992, 25, 40. [Google Scholar] [CrossRef]

- Onoufriou, T. Reliability Based Inspection Planning of Offshore Structures. Mar. Struct. 1999, 12, 521–539. [Google Scholar] [CrossRef]

- Ratnayake, R.M.C. Mechanization of Static Mechanical Systems Inspection Planning Process the State of the Art. J. Qual. Maint. Eng. 2015, 21, 227–248. [Google Scholar] [CrossRef]

- Abdallah, A.M.; Atadero, R.A.; Ozbek, M.E. A Comprehensive Uncertainty-Based Framework for Inspection Planning of Highway Bridges. Infrastructures 2021, 6, 27. [Google Scholar] [CrossRef]

- Zou, G.; Faber, M.H.; González, A.; Banisoleiman, K. Fatigue Inspection and Maintenance Optimization: A Comparison of Information Value, Life Cycle Cost and Reliability Based Approaches. Ocean Eng. 2021, 220, 108286. [Google Scholar] [CrossRef]

- Weber, P.; Medina-Oliva, G.; Simon, C.; Iung, B. Overview on Bayesian Networks Applications for Dependability, Risk Analysis and Maintenance Areas. Eng. Appl. Artif. Intell. 2012, 25, 671–682. [Google Scholar] [CrossRef]

- Schoefs, F.; Tran, T.-B. Reliability Updating of Offshore Structures Subjected to Marine Growth. Energies 2022, 15, 414. [Google Scholar] [CrossRef]

- Fahrni, L.; Thies, P.R.; Johanning, L.; Cowles, J. Scope and Feasibility of Autonomous Robotic Subsea Intervention Systems for Offshore Inspection, Maintenance and Repair; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- McLean, D.L.; Taylor, M.D.; Giraldo Ospina, A.; Partridge, J.C. An Assessment of Fish and Marine Growth Associated with an Oil and Gas Platform Jacket Using an Augmented Remotely Operated Vehicle. Cont. Shelf Res. 2019, 179, 66–84. [Google Scholar] [CrossRef]

- Mojtahedi, A.; Hokmabady, H.; Yaghubzadeh, A.; Mohammadyzadeh, S. An Improved Model Reduction-Modal Based Method for Model Updating and Health Monitoring of an Offshore Jacket-Type Platform. Ocean Eng. 2020, 209, 107495. [Google Scholar] [CrossRef]

- Rongen, G.; Morales-Nápoles, O.; Kok, M. Expert Judgment-Based Reliability Analysis of the Dutch Flood Defense System. Reliab. Eng. Syst. Saf. 2022, 224, 108535. [Google Scholar] [CrossRef]

- Leontaris, G.; Morales-Nápoles, O.; Dewan, A.; Wolfert, A.R.M. Decision Support for Offshore Asset Construction Using Expert Judgments for Supply Disruptions Risk. Autom. Constr. 2019, 107, 102903. [Google Scholar] [CrossRef]

- Ioannou, I.; Aspinall, W.; Rush, D.; Bisby, L.; Rossetto, T. Expert Judgment-Based Fragility Assessment of Reinforced Concrete Buildings Exposed to Fire. Reliab. Eng. Syst. Saf. 2017, 167, 105–127. [Google Scholar] [CrossRef]

- Lee, J. Statistics, Descriptive. In International Encyclopedia of Human Geography; Elsevier: Amsterdam, The Netherlands, 2020; pp. 13–20. [Google Scholar]

- Zafri, N.M.; Rony, A.I.; Adri, N. Analysis of Pedestrian Crossing Speed and Waiting Time at Intersections in Dhaka. Infrastructures 2019, 4, 39. [Google Scholar] [CrossRef]

- Al-Rousan, T.M.; Umar, A.A.; Al-Omari, A.A. Characteristics of Crashes Caused by Distracted Driving on Rural and Suburban Roadways in Jordan. Infrastructures 2021, 6, 107. [Google Scholar] [CrossRef]

- Risimati, B.; Gumbo, T. Exploring the Applicability of Location-Based Services to Delineate the State Public Transport Routes Integratedness within the City of Johannesburg. Infrastructures 2018, 3, 28. [Google Scholar] [CrossRef]

- Astarini, S.D.; Utomo, C. Performance-Based Building Design of High-Rise Residential Buildings in Indonesia. Sustainability 2020, 12, 7103. [Google Scholar] [CrossRef]

- Wen, C.-H.; Lin, W.-W. Customer Segmentation of Freight Forwarders and Impacts on the Competitive Positioning of Ocean Carriers in the Taiwan–Southern China Trade Lane. Marit. Policy Manag. 2016, 43, 420–435. [Google Scholar] [CrossRef]

- Mvududu, N.H.; Sink, C.A. Factor Analysis in Counseling Research and Practice. Couns. Outcome Res. Eval. 2013, 4, 75–98. [Google Scholar] [CrossRef]

- Nichols, N.W.; Khan, R.; Ng, S.M.; Lee, L.A. A Strengthening, Modification & Repair (SMR) Decisionmaking Toolkit for Structural Integrity Management (SIM) of Ageing Offshore Structures. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Nusa Dua, Indonesia, 20–22 October 2015; pp. 1–11. [Google Scholar] [CrossRef]

- Zhao, S.X.; Bi, C.W.; Sun, Z.Z. Engineering Analysis of the Dynamic Characteristics of an Electrical Jacket Platform of an Offshore Wind Farm under Seismic Loads. Appl. Ocean Res. 2021, 112, 102692. [Google Scholar] [CrossRef]

- Arcigni, F.; Abhinav, K.A.; Collu, M.; Venturini, M. Analysis of Tripod Supported Offshore Wind Turbines under Conditions of Marine Growth. Ocean Eng. 2021, 220, 108441. [Google Scholar] [CrossRef]

- Nichols, N.W.; Khan, R. Structural Integrity Management System (SIMS) Implementation within PETRONAS’ Operations. J. Mar. Eng. Technol. 2015, 14, 61–69. [Google Scholar] [CrossRef]

- Chandrasekaran, S. Dynamic Analysis and Design of Offshore Structures; Springer: New Delhi, India, 2015; Volume 5, ISBN 9788132222774. [Google Scholar]

- Syed Ahmad, S.Z.A.; Abu Husain, M.K.; Mohd Zaki, N.I.; Mukhlas, N.A.; Mat Soom, E.; Azman, N.U.; Najafian, G. Offshore Structural Reliability Assessment by Probabilistic Procedures—A Review. J. Mar. Sci. Eng. 2021, 9, 998. [Google Scholar] [CrossRef]

- Ghadimi, B.; Taghikhany, T. Dynamic Response Assessment of an Offshore Jacket Platform with Semi-Active Fuzzy-Based Controller: A Case Study. Ocean Eng. 2021, 238, 109747. [Google Scholar] [CrossRef]

- Mazaheri, P.; Asgarian, B.; Gholami, H. Assessment of Strengthening, Modification, and Repair Techniques for Aging Fixed Offshore Steel Platforms. Appl. Ocean Res. 2021, 110, 102612. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, T.; Guo, J.; He, Z.; Ma, H. Strength Reserve Assessment on Pitting-Corroded Jacket Offshore Platforms Based on the Modified Generalized Constitutive Model. Thin-Walled Struct. 2021, 169, 108494. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.; Wang, W.; Li, X.; Wang, B. Influence of Corrosion Damage on Fatigue Limit Capacities of Offshore Wind Turbine Substructure. J. Mar. Sci. Eng. 2022, 10, 1011. [Google Scholar] [CrossRef]

- Ji, C.Y.; Xue, H.Z.; Shi, X.H.; Gaidai, O. Experimental and Numerical Study on Collapse of Aged Jacket Platforms Caused by Corrosion or Fatigue Cracking. Eng. Struct. 2016, 112, 14–22. [Google Scholar] [CrossRef]

| No. | Author | Purpose | Variable | Method |

|---|---|---|---|---|

| 1 | Guede [16] | Risk assessment and inspection plan development | Risks and consequences | Risk-based assessment |

| 2 | Ratnayake [29] | Reviewing the evolution of inspections of aging oil and gas facilities | Inspection strategies and industry challenges | |

| 3 | Markeset et al. [17] | Identify and discuss maintenance challenges and maintenance practices for subsea oil production systems | Failure and maintenance | |

| 4 | Onoufirou [28] | Discuss the development and application of inspection techniques for fixed and floating platforms as well as jack-up drilling rigs | Reliability | Reliability-based inspection |

| 5 | Tawekal and Tawekal [7] | Implementation of risk-reliability-based underwater inspection | Probability of failure | |

| 6 | Ahmad et al. [27] | Assess severity and recommend corrective action | Database of platform | Other methods (expert system; EMA and CMCM; Bayesian networks; and cost–benefit analysis) |

| 7 | Mojtahedi [36] | Sketching a health monitoring system to solve the problem of limitations and deficiencies of sensor networks as well as solve localization problems | Database of platform | |

| 8 | Zou et al. [31] | Development of maintenance optimization by utilizing value of information (VoI) calculations and Bayesian decision optimization | Lifetime fatigue reliability, LCC, and VoI | |

| 9 | Tolentino and Ruiz [10] | Analyze the effect of time variations structural capacity on optimal time intervals for the inspection and maintenance of offshore platform | Cost, structural demand, and time |

| Items | Subitems | N | % |

|---|---|---|---|

| Position | Manager Lecturer (Ph.D.) | 28 2 | 93.33 6.67 |

| Work experience (years) | 15–19 20–25 >25 | 19 10 1 | 63.33 33.33 3.33 |

| Total | 100 |

| Code | Variable | Mean | Standard Deviation | Rank |

|---|---|---|---|---|

| X1 X2 X3 X4 X5 X6 X7 X8 X9 X10 X11 X12 | The year of manufacture The type of fixed offshore platform Structural configuration The number of instances of damage The number of instances of corrosion The amount of modifications Marine growth The magnitude of scour on the seabed Debris Ocean waves and currents Weather and climate The depth of the seawater | 4.40 4.43 4.47 4.80 4.67 4.23 4.20 4.17 3.57 4.13 4.43 4.13 | 0.93 0.68 0.73 0.41 0.61 0.77 0.85 0.83 1.14 0.94 0.77 0.78 | 6 4 3 1 2 11 7 8 10 9 5 12 |

| Code | Variable | Quadrant | Rank |

|---|---|---|---|

| X4 X5 X3 X2 X11 X1 X7 X8 X10 X9 X6 X12 | The number of instances of damage The number of instances of corrosion Structural configuration The type of fixed offshore platform Weather and climate The year of manufacture Marine growth The magnitude of scour on the seabed Ocean waves and currents Debris The number of modifications The depth of the seawater | I I I I I II III III III III IV IV | 1 2 3 4 5 6 7 8 9 10 11 12 |

| X2 | X3 | X4 | X5 | X6 | X7 | X8 | X10 | X11 | X12 | |

|---|---|---|---|---|---|---|---|---|---|---|

| X2 | 0.627 a | −0.284 | −0.259 | 0.156 | −0.170 | −0.244 | −0.359 | 0.090 | 0.075 | 0.360 |

| X3 | −0.284 | 0.677 a | −0.305 | 0.061 | −0.422 | 0.084 | 0.401 | −0.110 | −0.090 | −0.307 |

| X4 | −0.259 | −0.305 | 0.626 a | −0.534 | 0.141 | 0.063 | 0.261 | −0.046 | 0.017 | −0.291 |

| X5 | 0.156 | 0.061 | −0.534 | 0.532 a | −0.143 | −0.056 | −0.202 | 0.326 | −0.489 | 0.188 |

| X6 | −0.170 | −0.422 | 0.141 | −0.143 | 0.740 a | −0.412 | −0.187 | −0.013 | 0.216 | −0.052 |

| X7 | −0.244 | 0.084 | 0.063 | −0.056 | −0.412 | 0.791 a | 0.192 | −0.299 | −0.097 | −0.061 |

| X8 | −0.359 | 0.401 | 0.261 | −0.202 | −0.187 | 0.192 | 0.601 a | −0.292 | −0.193 | −0.509 |

| X10 | 0.090 | −0.110 | −0.046 | 0.326 | −0.013 | −0.299 | −0.292 | 0.738 a | −0.565 | −0.105 |

| X11 | 0.075 | −0.090 | 0.017 | −0.489 | 0.216 | −0.097 | −0.193 | −0.565 | 0.709 a | 0.048 |

| X12 | 0.360 | −0.307 | −0.291 | 0.188 | −0.052 | −0.061 | −0.509 | −0.105 | 0.048 | 0.671 a |

| Code | Variable | Communalities | Varimax-Rotated Loading Factor | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| X8 | The magnitude of scour on the seabed | 0.753 | 0.866 | - | - |

| X10 | Ocean waves and currents | 0.796 | 0.860 | - | - |

| X11 | Weather and climate | 0.805 | 0.791 | - | - |

| X12 | The depth of the seawater | 0.514 | 0.651 | - | - |

| X2 | The type of fixed offshore platform | 0.603 | - | 0.772 | - |

| X3 | Structural configuration | 0.734 | - | 0.768 | - |

| X6 | The number of modifications | 0.747 | - | 0.830 | - |

| X7 | Marine growth | 0.638 | - | 0.660 | - |

| X4 | The number of instances of damage | 0.828 | - | - | 0.837 |

| X5 | The number of instances of corrosion | 0.781 | - | - | 0.843 |

| Eigenvalues | - | - | 4.052 | 1.819 | 1.326 |

| % variance | - | - | 40.522 | 18.194 | 13.259 |

| Cum % variance | - | - | 40.522 | 58.716 | 71.976 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sidiq, R.B.; Utomo, C.; Silvianita. Determining Factors of Fixed Offshore Platform Inspections in Indonesia. Appl. Sci. 2023, 13, 737. https://doi.org/10.3390/app13020737

Sidiq RB, Utomo C, Silvianita. Determining Factors of Fixed Offshore Platform Inspections in Indonesia. Applied Sciences. 2023; 13(2):737. https://doi.org/10.3390/app13020737

Chicago/Turabian StyleSidiq, Rizky Bahtiar, Christiono Utomo, and Silvianita. 2023. "Determining Factors of Fixed Offshore Platform Inspections in Indonesia" Applied Sciences 13, no. 2: 737. https://doi.org/10.3390/app13020737

APA StyleSidiq, R. B., Utomo, C., & Silvianita. (2023). Determining Factors of Fixed Offshore Platform Inspections in Indonesia. Applied Sciences, 13(2), 737. https://doi.org/10.3390/app13020737