Experimental Study of Vertical Tail Model Flow Control Based on Oscillating Jet

Abstract

1. Introduction

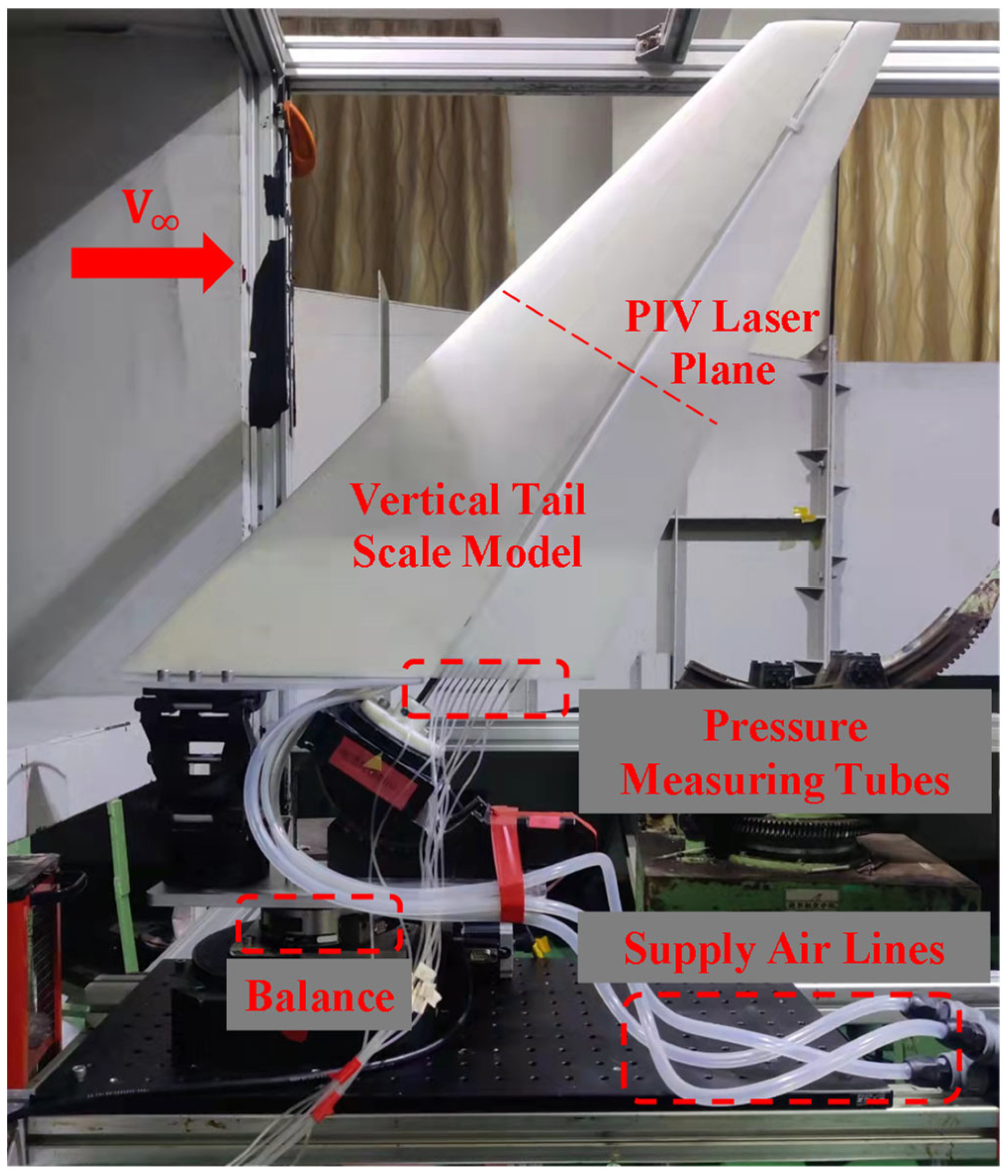

2. Experimental Setup and Methods

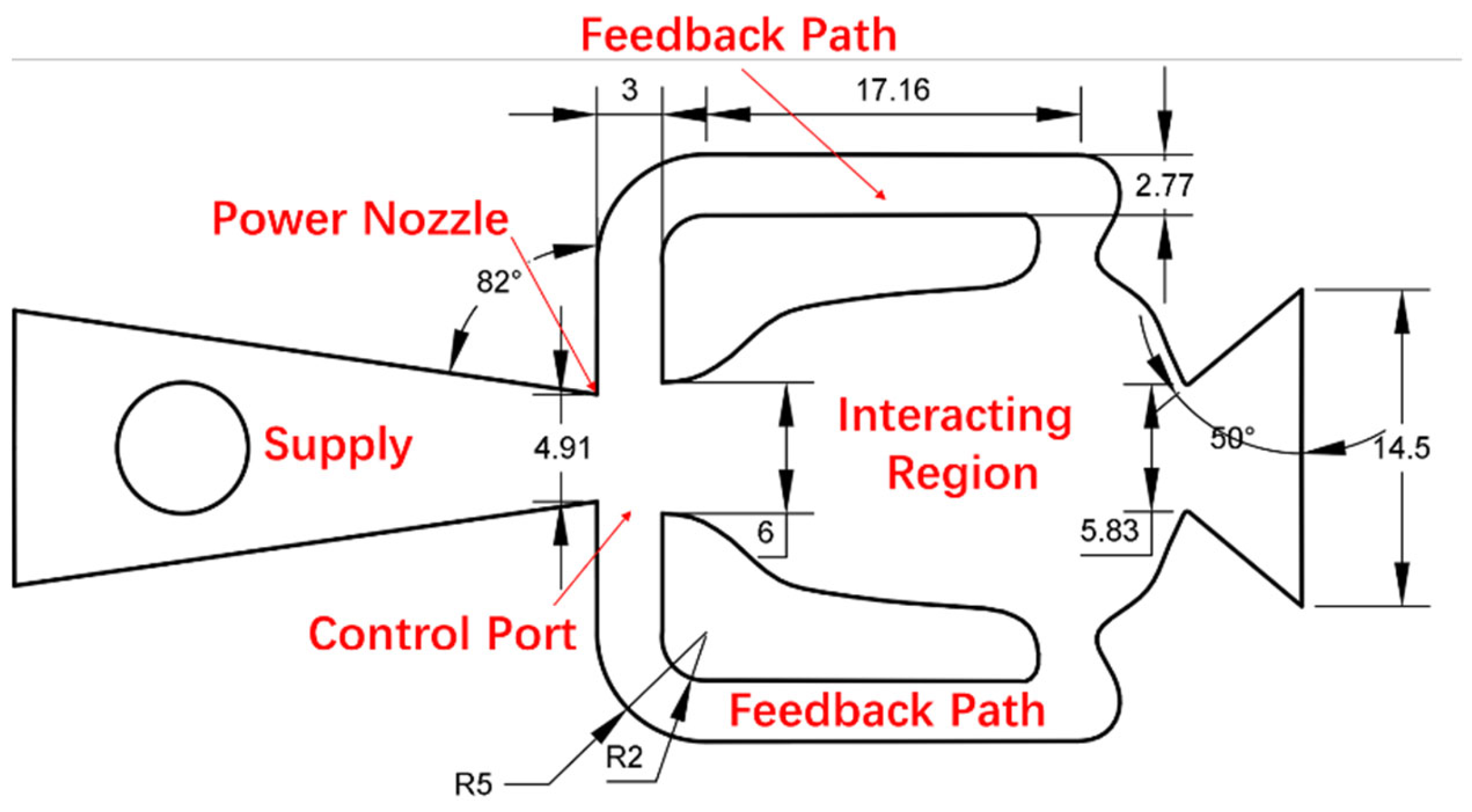

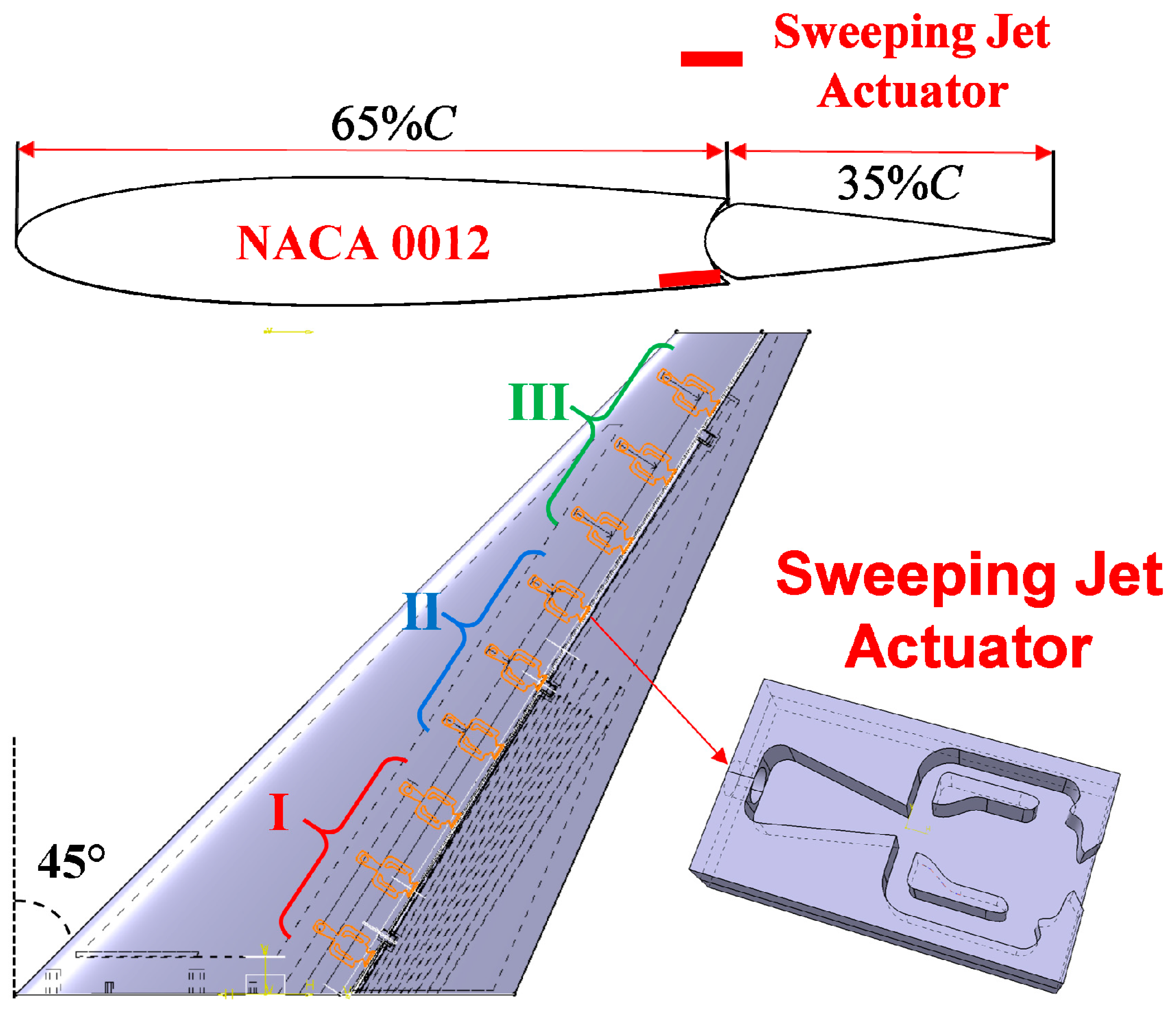

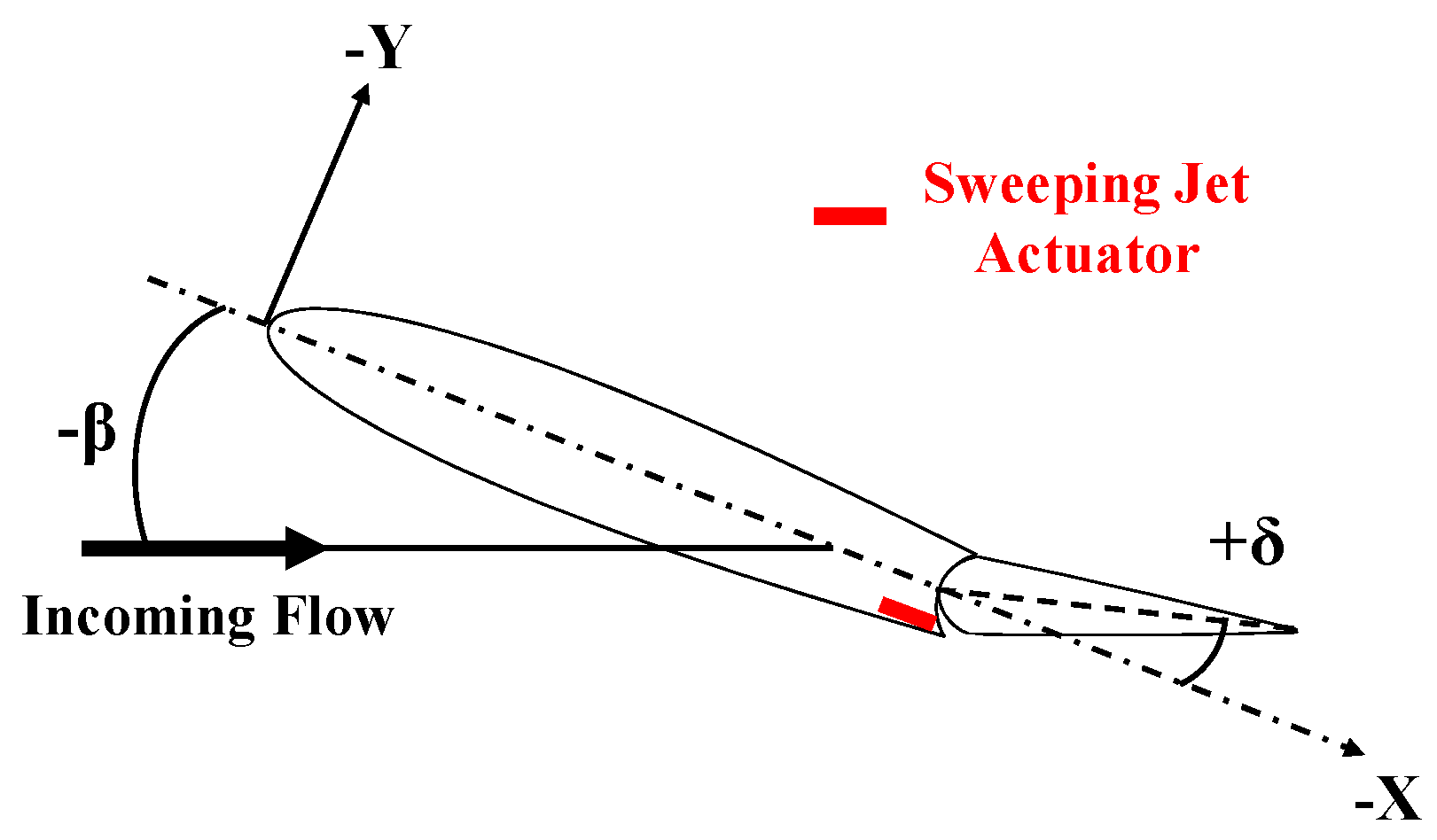

2.1. Actuator Structure and Vertical Tail Model Design

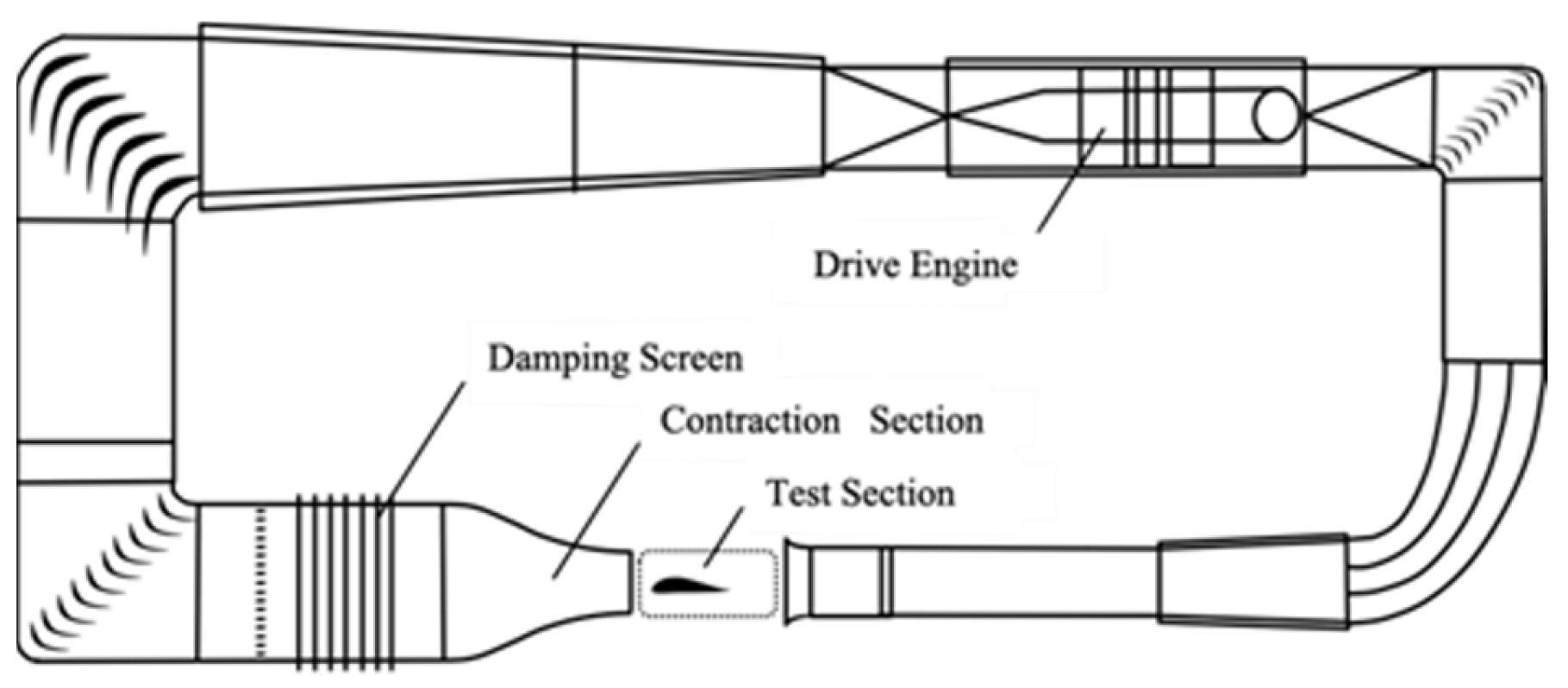

2.2. Experimental Equipment and Testing System

3. Results and Discussion

3.1. Study on Exit Velocity Characteristics of Actuator

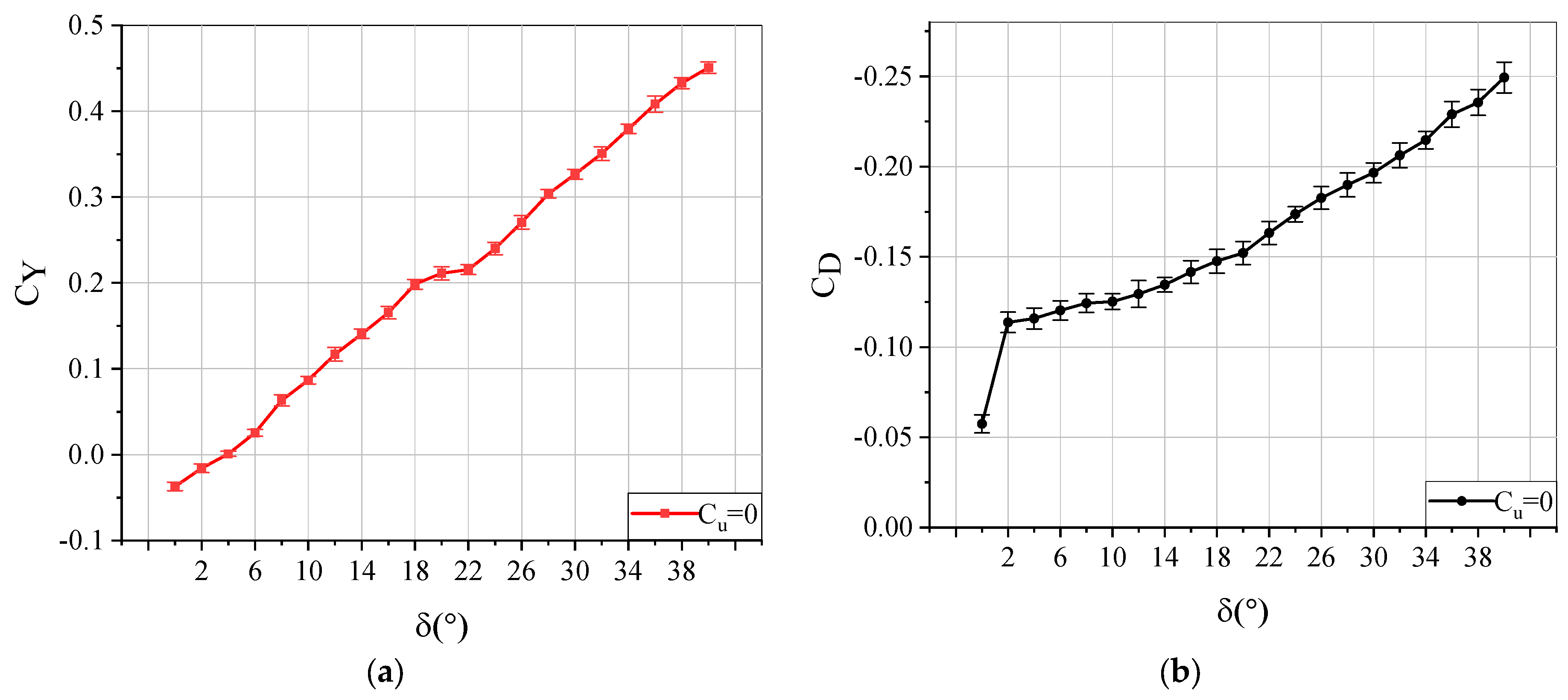

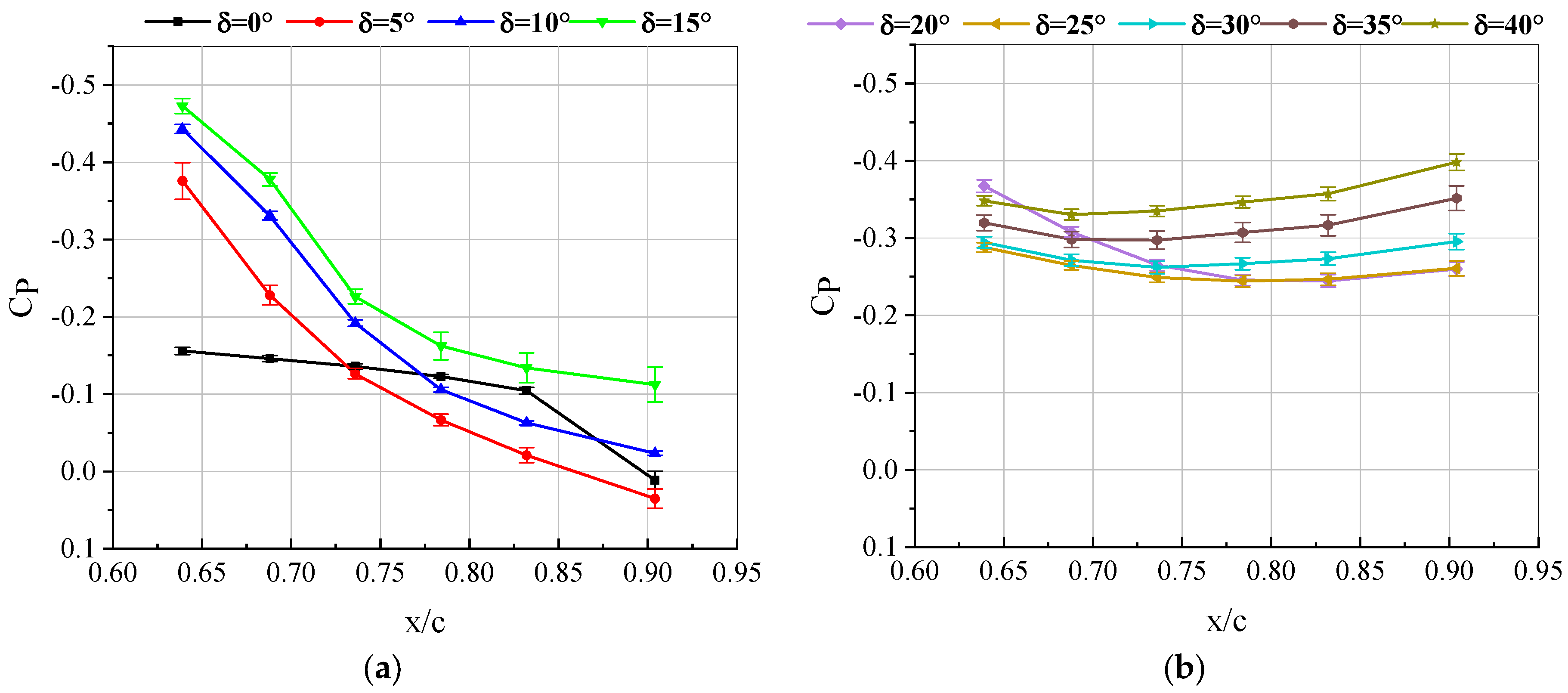

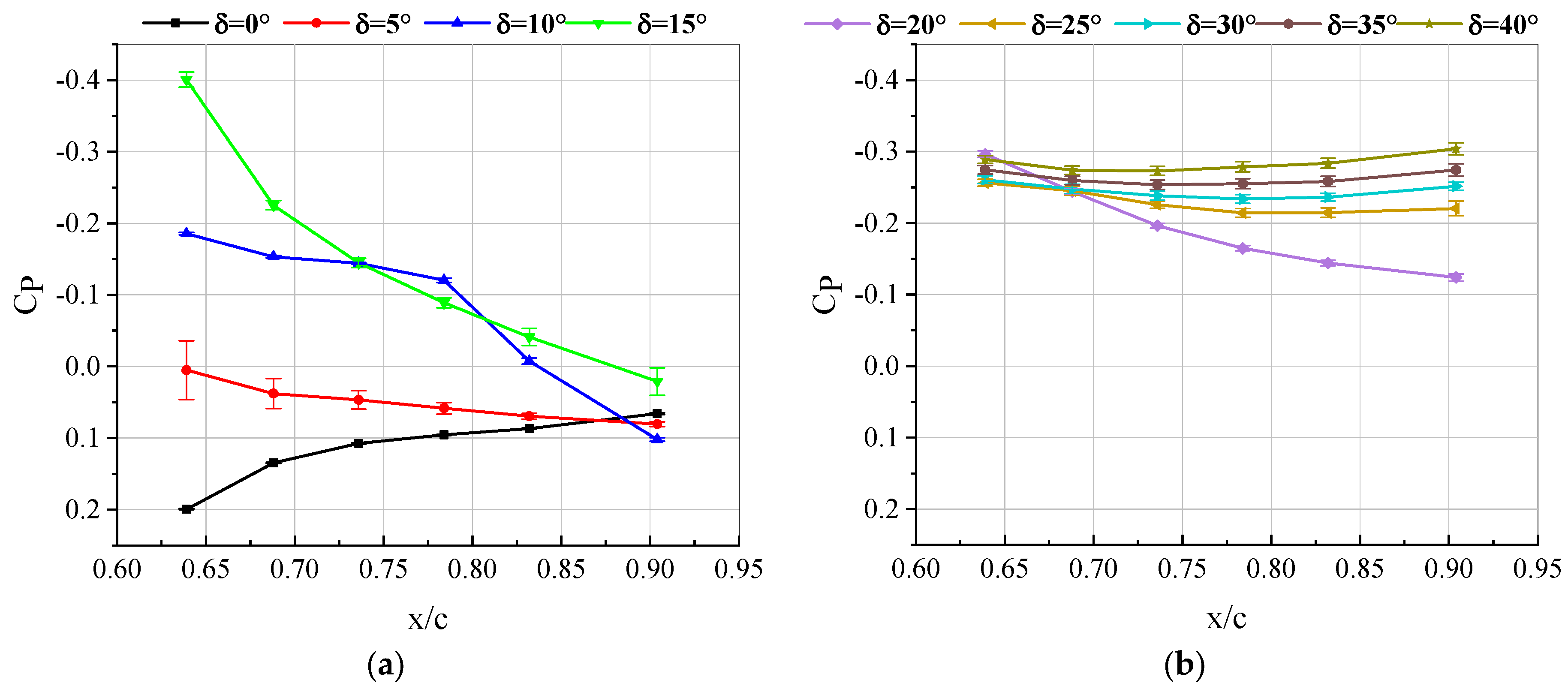

3.2. Study on Basic Aerodynamic Characteristics of Vertical Tail Model

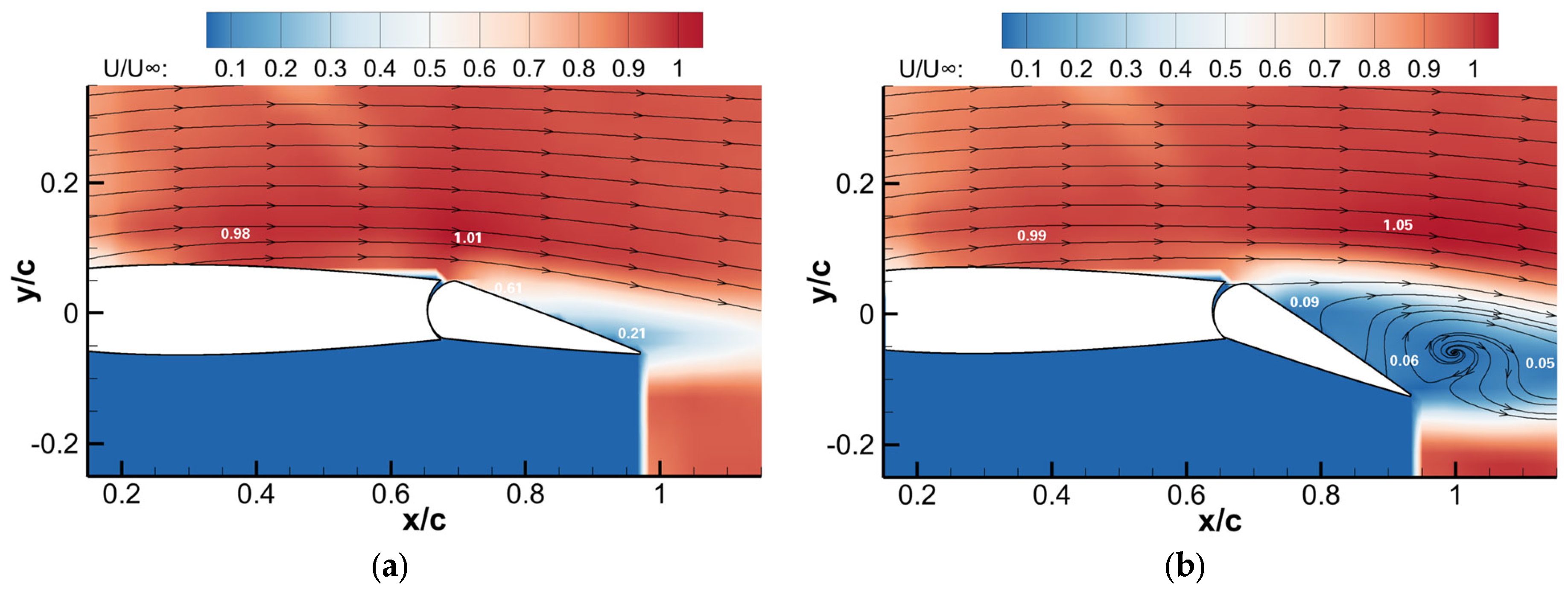

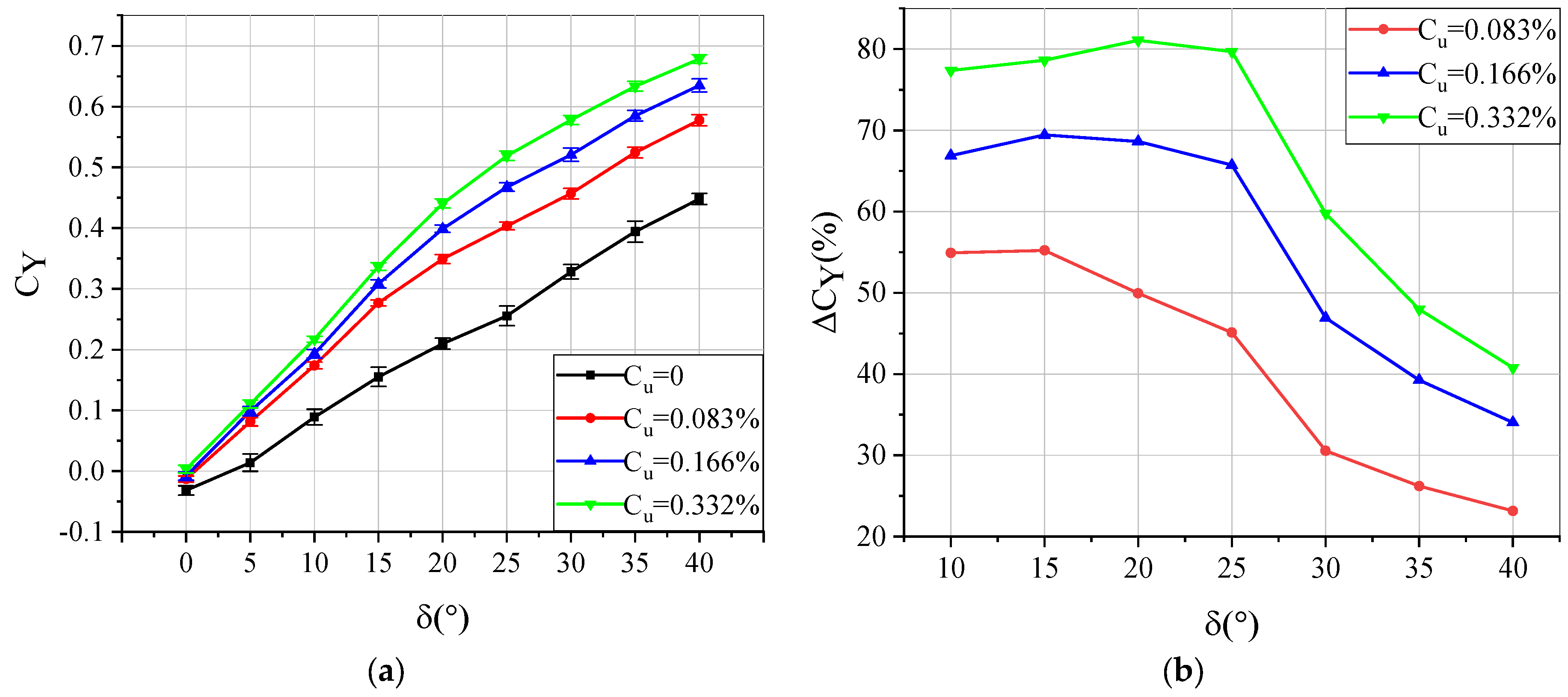

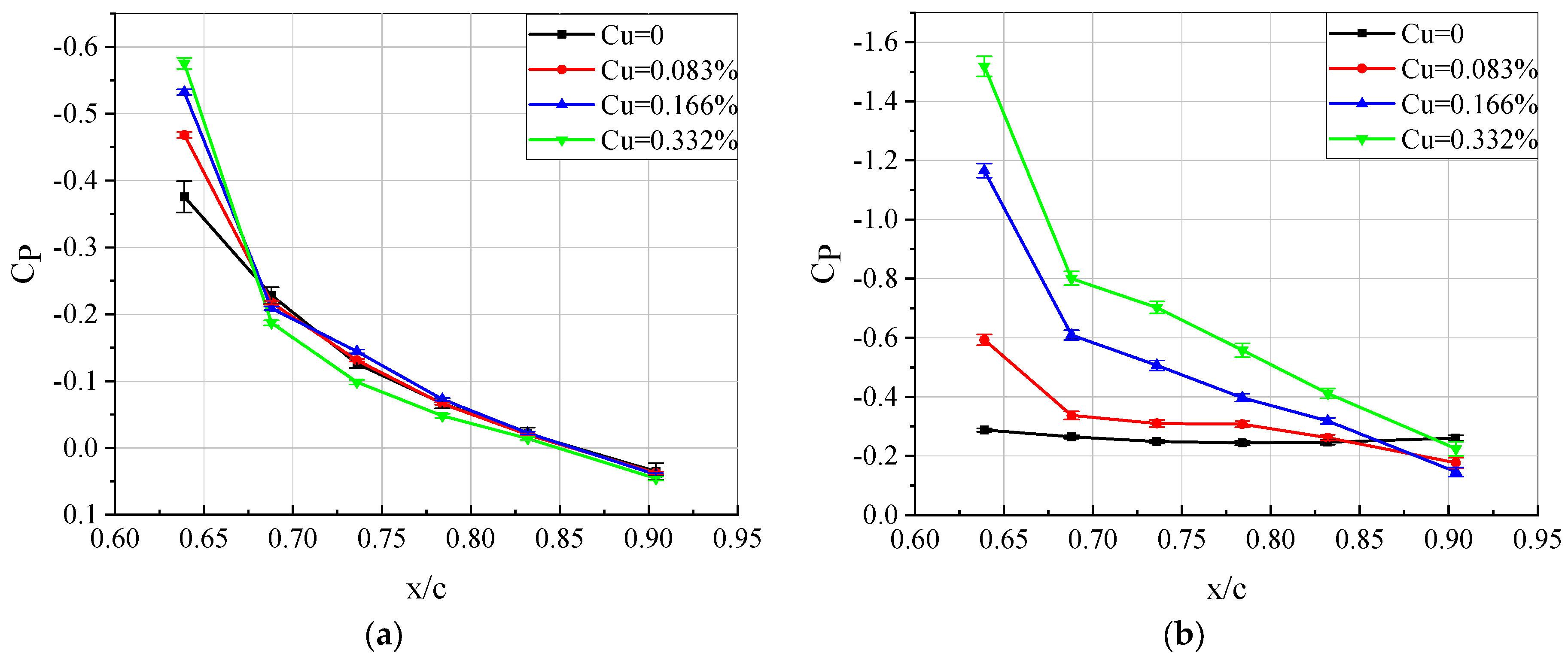

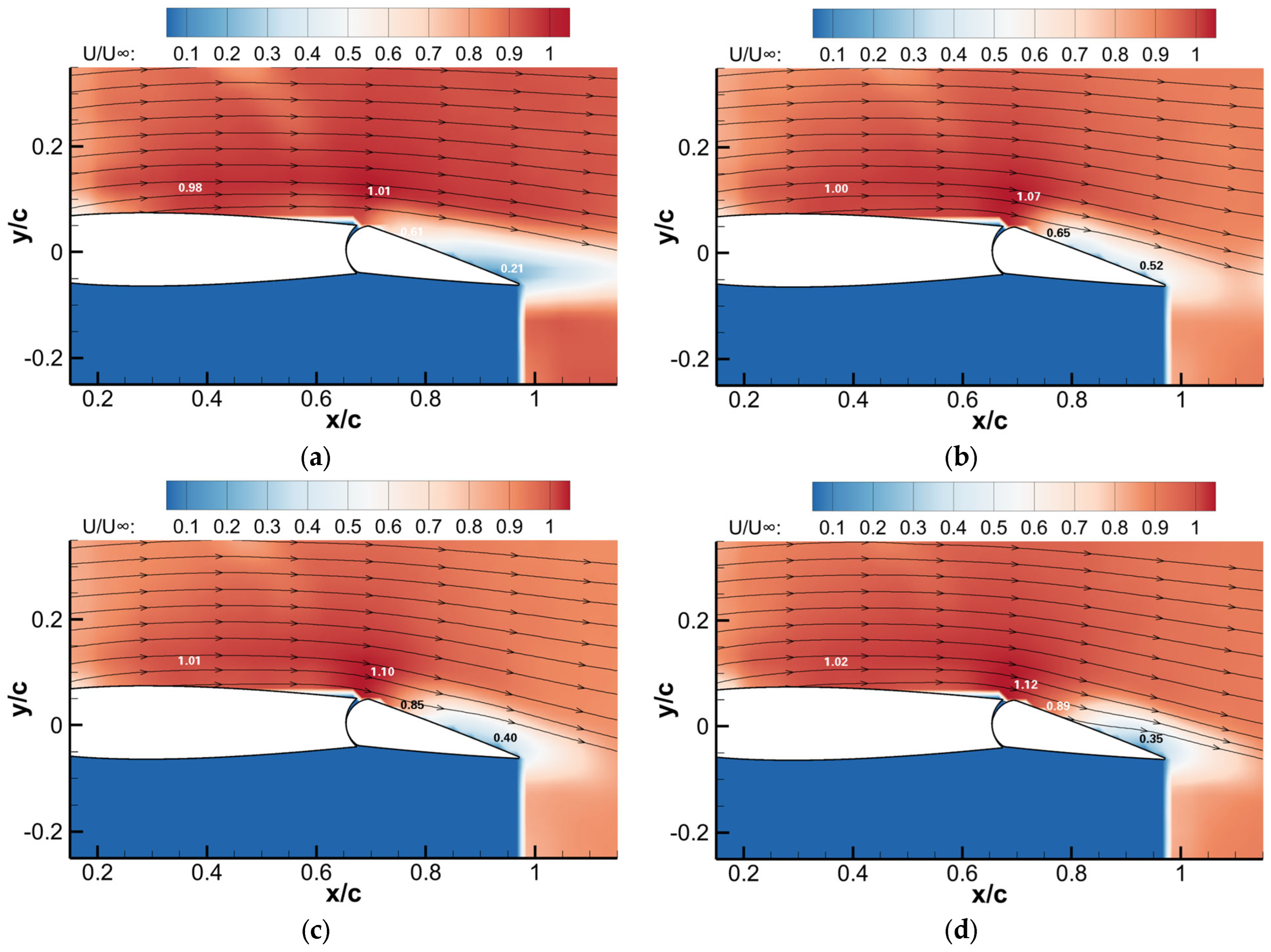

3.3. Study on Flow Control of Vertical Tail under Different Momentum Coefficients

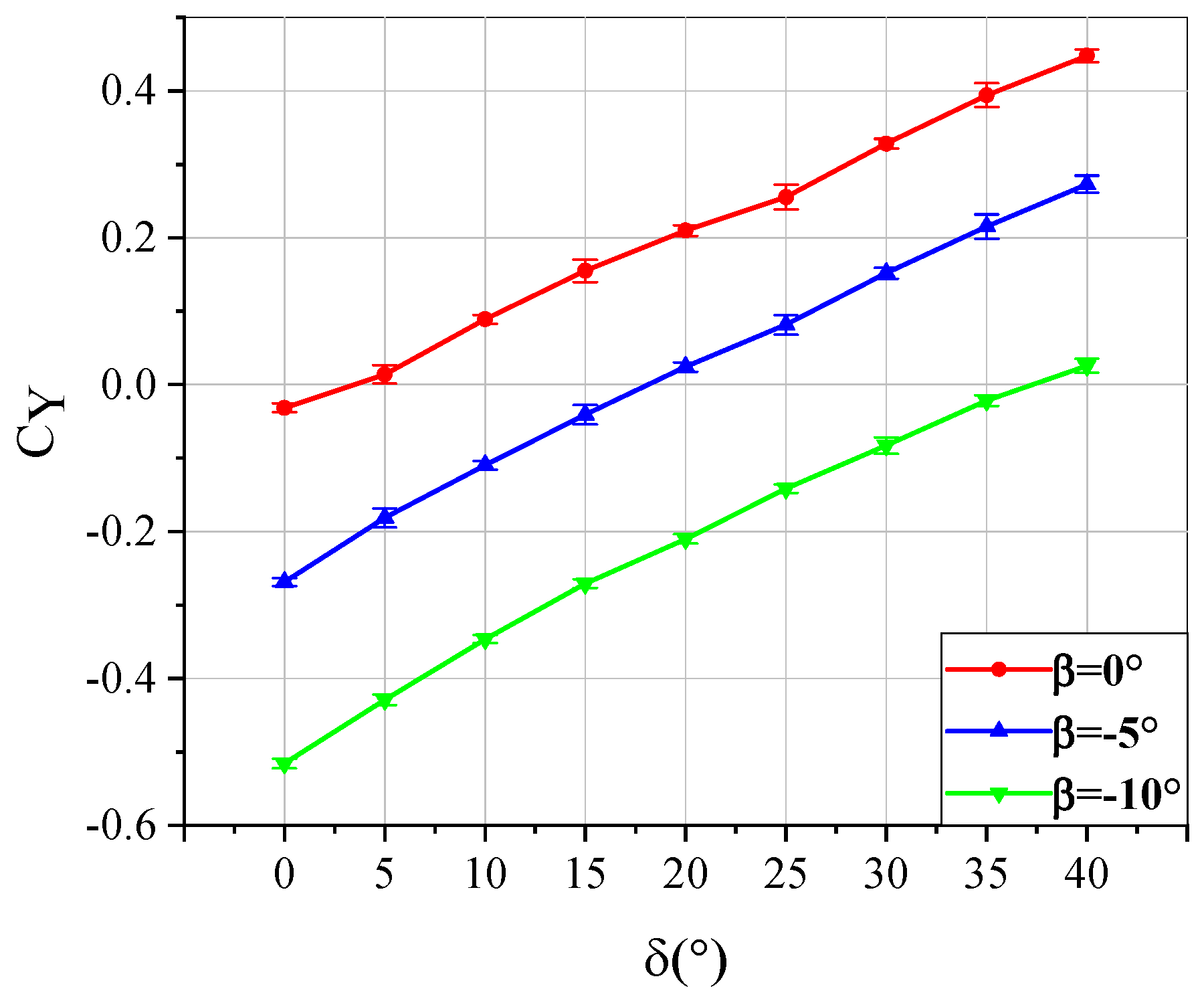

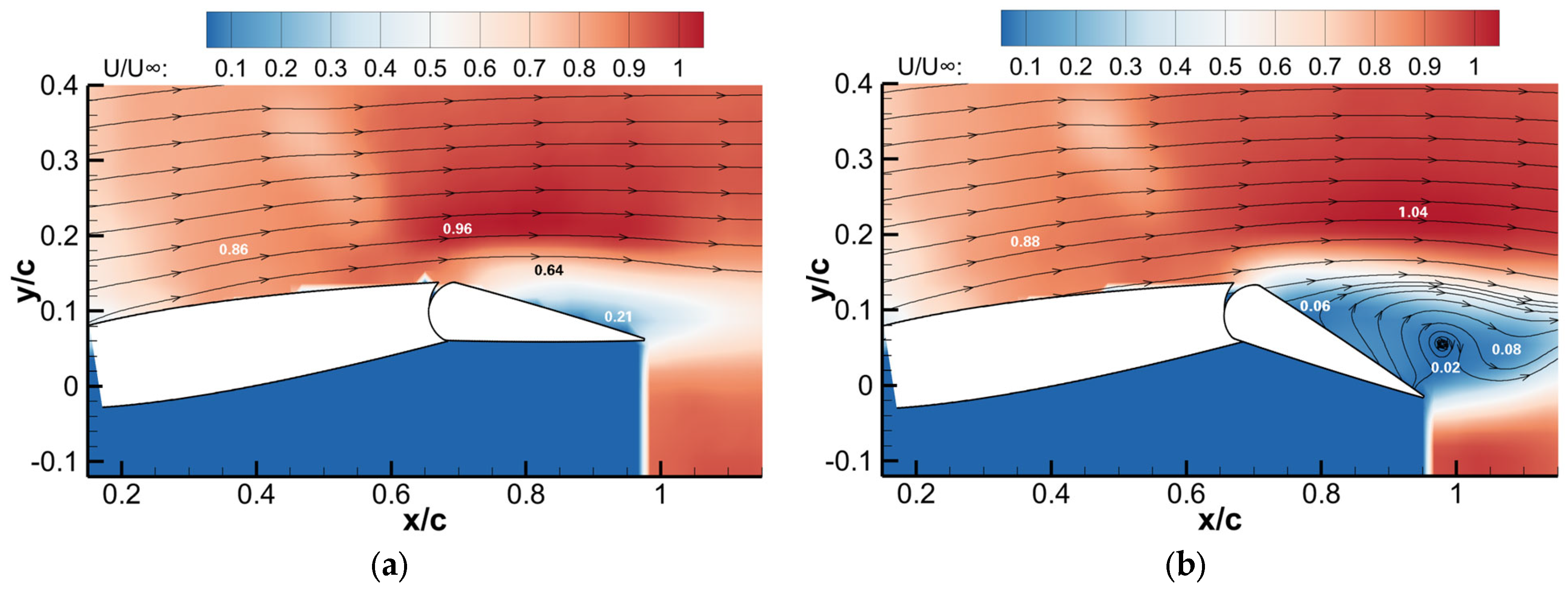

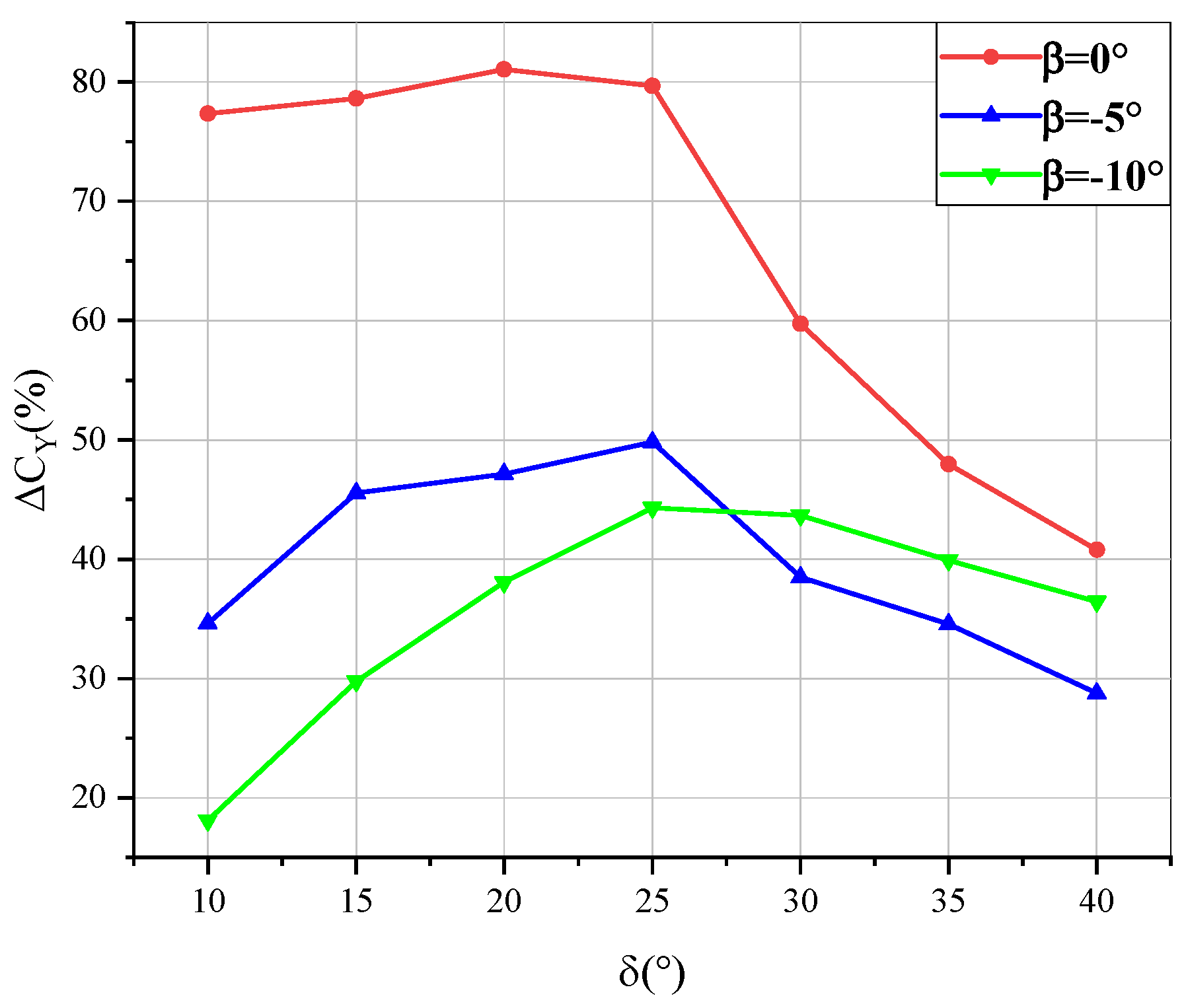

3.4. Study on Flow Control of Vertical Tail under Different Sideslip Angles

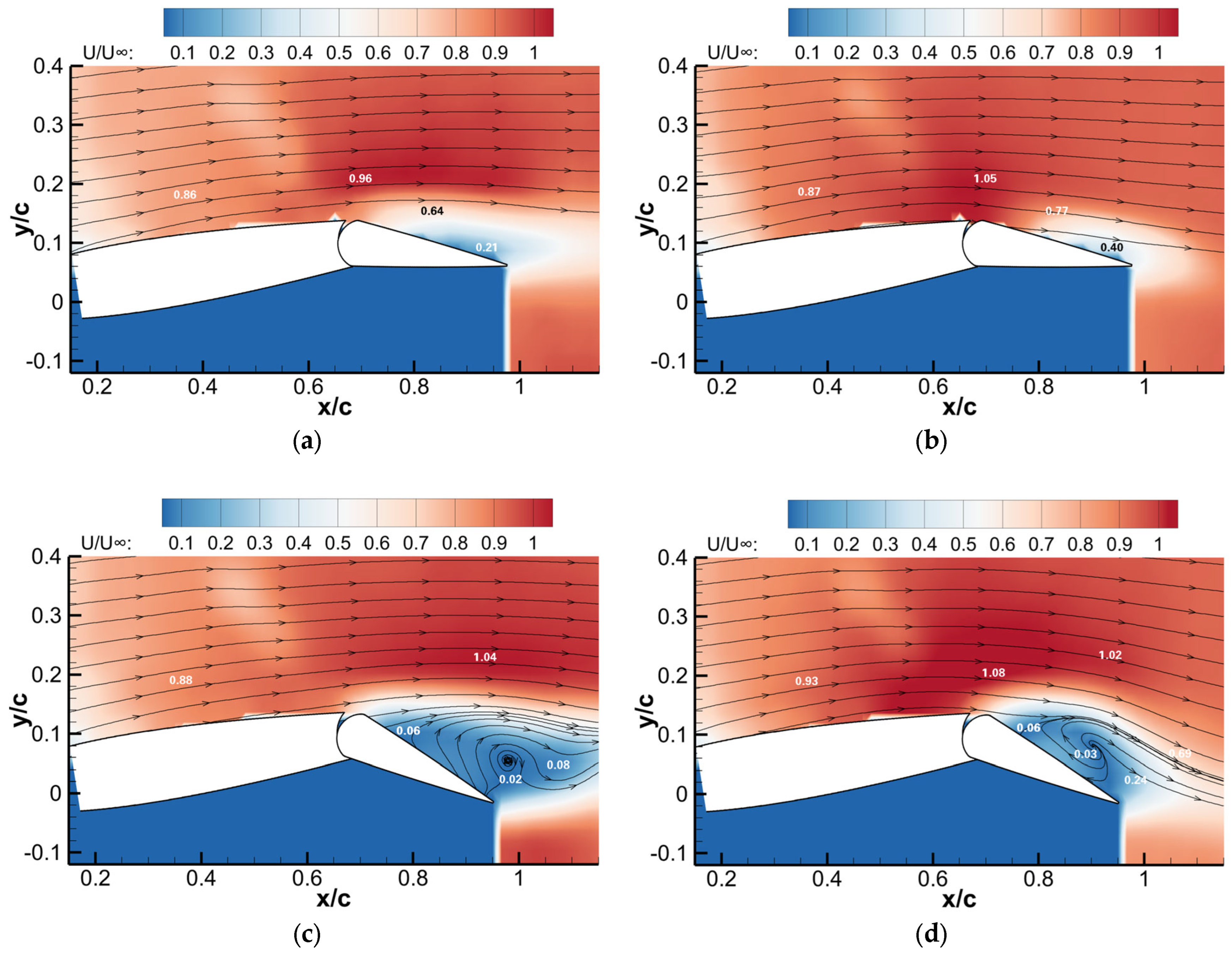

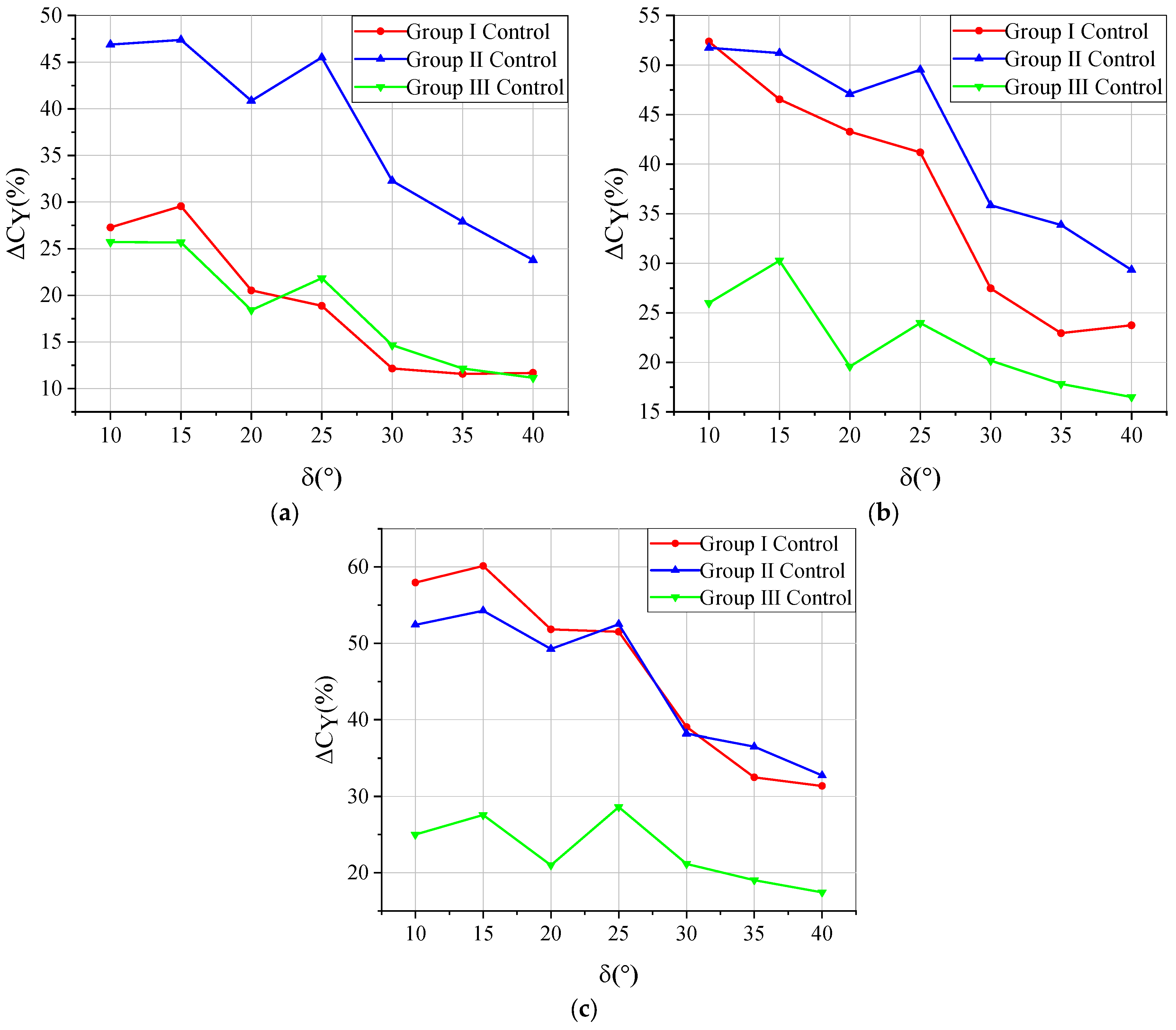

3.5. Study on Flow Control of Vertical Tail in Different Spanwise Positions

4. Conclusions

- The oscillating jet applied to the trailing edge of the stabilizer can significantly increase the vertical tail lateral force. At a −10° sideslip angle, 40° rudder deflection angle, and 2.12 × 105 experimental Reynolds number conditions, the increment of the lateral force can reach 36.5% when flow control is applied.

- With the increase in the deflection angle of the vertical tail rudder, apparent flow separation occurs on the rudder, which is the main reason for reducing the vertical tail rudder efficiency. After the oscillating jet flow control is applied, the flow separation on the rudder is suppressed, and the rudder effect of the vertical tail is restored. In addition, high-speed jet injection accelerates the flow on the vertical tail stabilizer, and the increase in the vertical tail circulation further improves the lateral force coefficient.

- We can improve the lateral force coefficient of the vertical tail model by applying oscillating jet flow control alone at different spanwise positions. Because the rudder area and flow separation are different at different spanwise locations, the energy required for flow control and the flow control effect are different, which will provide a basis for the optimal layout of actuators and engineering practice.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Aref | reference area, m2 |

| b | span, m |

| c | chord, m |

| Re | Reynolds number |

| Cp | pressure coefficient |

| Cμ | momentum coefficient |

| CY | lateral force coefficient |

| Ptap | surface pressure, Pa |

| P∞ | static pressure, Pa |

| qm | mass flow, kg/s |

| Ujet | jet velocity, m/s |

| U∞ | velocity, m/s |

| β | sideslip angle, ° |

| δ | rudder deflection angle, ° |

| ρ | density, kg/m3 |

| ε | turbulence intensity |

References

- Seele, R.; Graff, E.; Lin, J.; Wygnanski, I. Performance Enhancement of a Vertical Tail Model with Sweeping Jet Actuators. In Proceedings of the 51st AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Grapevine, TX, USA, 7–10 January 2013. [Google Scholar] [CrossRef]

- Whalen, E.A.; Shmilovich, A.; Spoor, M.; Tran, J.; Vijgen, P.; Lin, J.C.; Andino, M. Flight Test of an Active Flow Control Enhanced Vertical Tail. AIAA J. 2018, 56, 3393–3398. [Google Scholar] [CrossRef]

- Lin, J.C.; Whalen, E.A.; Andino, M.Y.; Graff, E.C.; Lacy, D.S.; Washburn, A.E.; Gharib, M.; Wygnanski, I.J. Full-Scale Testing of Active Flow Control Applied to a Vertical Tail. J. Aircr. 2019, 56, 1376–1386. [Google Scholar] [CrossRef]

- Lin, J.C.; Andino, M.Y.; Alexander, M.G.; Whalen, E.A.; Spoor, M.A.; Tran, J.T.; Wygnanski, I.J. An Overview of Active Flow Control Enhanced Vertical Tail Technology Development. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016. [Google Scholar] [CrossRef]

- Hirsch, D.; Gharib, M. Schlieren Visualization and Analysis of Sweeping Jet Actuator Dynamics. AIAA J. 2018, 56, 2947–2960. [Google Scholar] [CrossRef]

- Portillo, D.J.; Hoffman, E.N.; Garcia, M.; LaLonde, E.; Hernandez, E.; Combs, C.S.; Hood, L. Modal Analysis of a Sweeping Jet Emitted by a Fluidic Oscillator. In Proceedings of the AIAA Aviation 2021 Forum, Virtual Event, 2–6 August 2021. [Google Scholar] [CrossRef]

- Katz, Y.; Nishri, B.; Wygnanski, I. The delay of turbulent boundary layer separation by oscillatory active control. Phys. Fluids A Fluid Dyn. 1989, 1, 179–181. [Google Scholar] [CrossRef]

- Choephel, T.; Coder, J.; Maughmer, M. Airfoil Boundary-Layer Flow Control Using Fluidic Oscillators. In Proceedings of the 30th AIAA Applied Aerodynamics Conference, New Orleans, LA, USA, 25–28 June 2012. [Google Scholar] [CrossRef]

- Koklu, M. The Effects of Sweeping Jet Actuator Parameters on Flow Separation Control. AIAA J. 2013, 56, 100–110. [Google Scholar] [CrossRef] [PubMed]

- Koklu, M.; Owens, L.R. Flow Separation Control Over a Ramp Using Sweeping Jet Actuators. In Proceedings of the 7th AIAA Flow Control Conference, Atlanta, GA, USA, 16–20 June 2014. [Google Scholar] [CrossRef]

- Koklu, M.; Owens, L.R. Comparison of Sweeping Jet Actuators with Different Flow-Control Techniques for Flow-Separation Control. AIAA J. 2017, 55, 848–860. [Google Scholar] [CrossRef]

- Melton, L.; Koklu, M. Active Flow Control Using Sweeping Jet Actuators on a Semi-Span Wing Model. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016. [Google Scholar] [CrossRef]

- Slupski, B.J.; Kara, K. Effects of Feedback Channels and Coanda Surfaces on the Performance of Sweeping Jet Actuator. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar] [CrossRef]

- Slupski, B.Z.; Kara, K. Effects of Geometric Parameters on Performance of Sweeping Jet Actuator. In Proceedings of the 34th AIAA Applied Aerodynamics Conference, Washington, DC, USA, 13–17 June 2016. [Google Scholar] [CrossRef]

- Slupski, B.Z.; Kara, K.; Parezanovic, V.; Kyritsis, D. Experimental Inner Pressure Analysis of a Sweeping Jet Actuator. In Proceedings of the 36th AIAA Applied Aerodynamics Conference 2018, Atlanta, GA, USA, 25–29 June 2018. [Google Scholar] [CrossRef]

- Seele, R.; Graff, E.; Gharib, M.; Taubert, L.; Lin, J.; Wygnanski, I. Improving Rudder Effectiveness with Sweeping Jet Actuators. In Proceedings of the 6th AIAA Flow Control Conference, New Orleans, LA, USA, 25–28 June 2012. [Google Scholar] [CrossRef]

- Andino, M.Y.; Lin, J.C.; Washburn, A.E.; Whalen, E.A.; Graff, E.C.; Wygnanski, I.J. Flow Separation Control on a Full-Scale Vertical Tail Model Using Sweeping Jet Actuators. In Proceedings of the 53rd AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 5–9 January 2015. [Google Scholar] [CrossRef]

- Andino, M.Y.; Lin, J.C.; Roman, S.; Graff, E.C.; Gharib, M.; Whalen, E.A.; Wygnanski, I.J. Active Flow Control on Vertical Tail Models. AIAA J. 2019, 57, 3322–3338. [Google Scholar] [CrossRef] [PubMed]

- Dandois, J.; Verbeke, C.; Ternoy, F. Performance Enhancement of a Vertical Tail Model with Sweeping Jets. AIAA J. 2020, 58, 5202–5215. [Google Scholar] [CrossRef]

- Löffler, S.; Staats, M.; Grund, T.; Weiss, J. Increasing the Effectiveness of a Vertical Stabilizer by Combining Pulsed Jet Actuation at the Leading Edge and the Rudder Hinge Line. In Proceedings of the 36th AIAA Applied Aerodynamics Conference 2018, Atlanta, GA, USA, 25–29 June 2018. [Google Scholar] [CrossRef]

- Loeffler, S.; Rohlfs, L.; Staats, M.; Weiss, J. Flow Field Investigation on a Vertical Stabilizer with Pulsed Jet Actuation by Means of PIV Measurements. In Proceedings of the AIAA Aviation 2019 Forum, Dallas, TX, USA, 17–21 June 2019. [Google Scholar] [CrossRef]

- Scholz, P.; Singh, V.M.; Gebhardt, A.; Löffler, S.; Weiss, J. The Efficiency of Different Flow Control Methods on a Vertical Tail. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar] [CrossRef]

- Singh, V.M.; Scholz, P. Circulation Control Experiments on a Vertical Tail. In Fundamentals of High Lift for Future Civil Aircraft; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Whalen, E.A.; Lacy, D.S.; Lin, J.C.; Andino, M.Y.; Washburn, A.E.; Graff, E.C.; Wygnanski, I.J. Performance Enhanced of a Full Scale Vertical Tail Model Equipped with Active Flow Control. In Proceedings of the 53rd AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 5–9 January. [CrossRef]

- Melton, L.P. Active Flow Separation Control on a NACA 0015 Wing Using Fluidic Actuators. In Proceedings of the 7th AIAA Flow Control Conference, Atlanta, GA, USA, 16–20 June 2014. [Google Scholar] [CrossRef]

| Variable | Range | Precision (FS) |

|---|---|---|

| Fx | 165 N | 1.00% |

| Fy | 165 N | 1.00% |

| Fz | 495 N | 1.00% |

| Mx | 15 N-m | 1.00% |

| My | 15 N-m | 1.00% |

| Mz | 15 N-m | 1.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, X.; Dong, H.; Gu, Y.; Cheng, K.; Zhang, F. Experimental Study of Vertical Tail Model Flow Control Based on Oscillating Jet. Appl. Sci. 2023, 13, 786. https://doi.org/10.3390/app13020786

Cao X, Dong H, Gu Y, Cheng K, Zhang F. Experimental Study of Vertical Tail Model Flow Control Based on Oscillating Jet. Applied Sciences. 2023; 13(2):786. https://doi.org/10.3390/app13020786

Chicago/Turabian StyleCao, Xingyu, Hao Dong, Yunsong Gu, Keming Cheng, and Fan Zhang. 2023. "Experimental Study of Vertical Tail Model Flow Control Based on Oscillating Jet" Applied Sciences 13, no. 2: 786. https://doi.org/10.3390/app13020786

APA StyleCao, X., Dong, H., Gu, Y., Cheng, K., & Zhang, F. (2023). Experimental Study of Vertical Tail Model Flow Control Based on Oscillating Jet. Applied Sciences, 13(2), 786. https://doi.org/10.3390/app13020786