Seismic Characteristics of a Geotextile Tube-Reinforced Embankment and Shallow Foundations Laid on Liquefiable Soil

Abstract

:1. Introduction

2. Materials and Methods

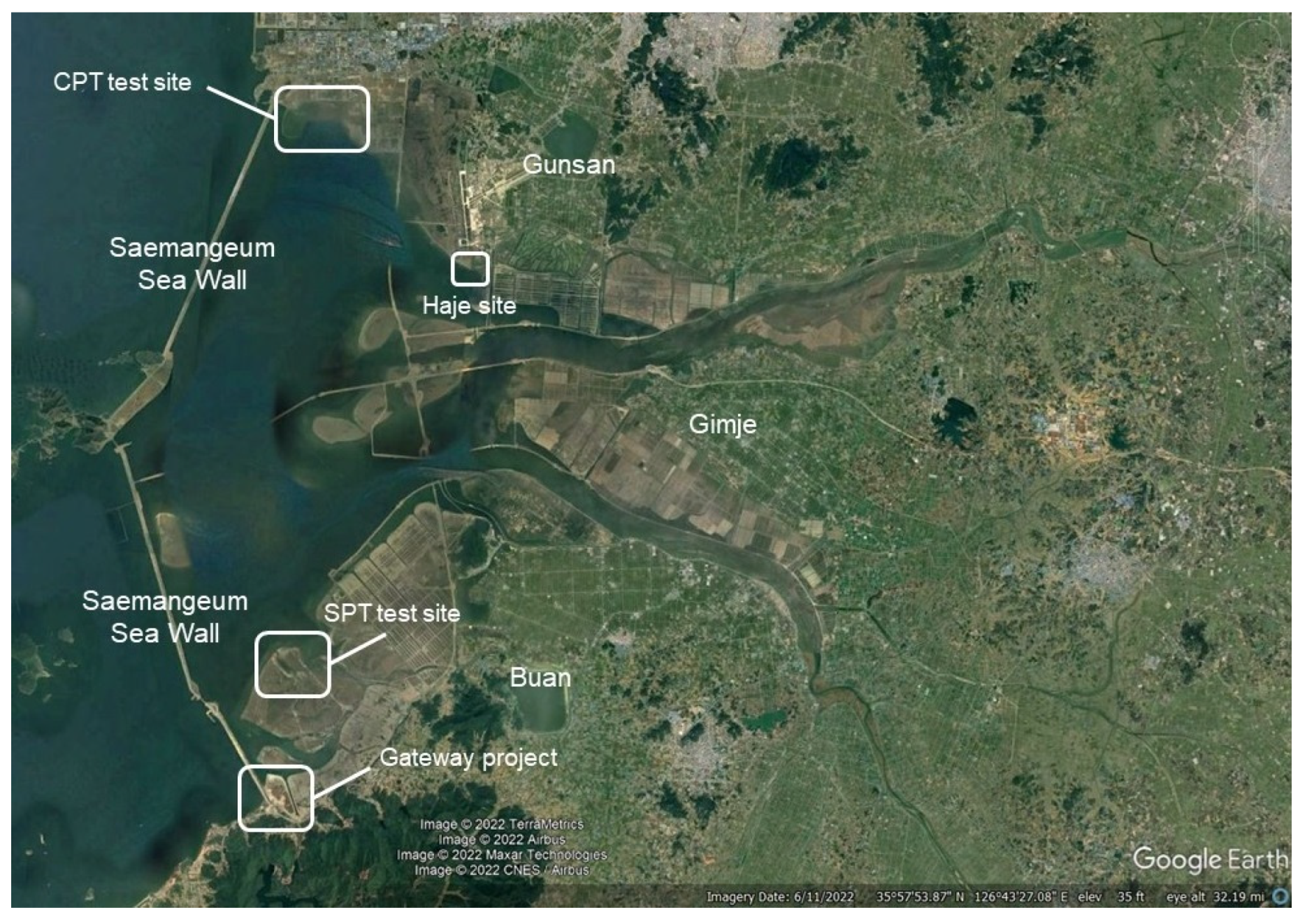

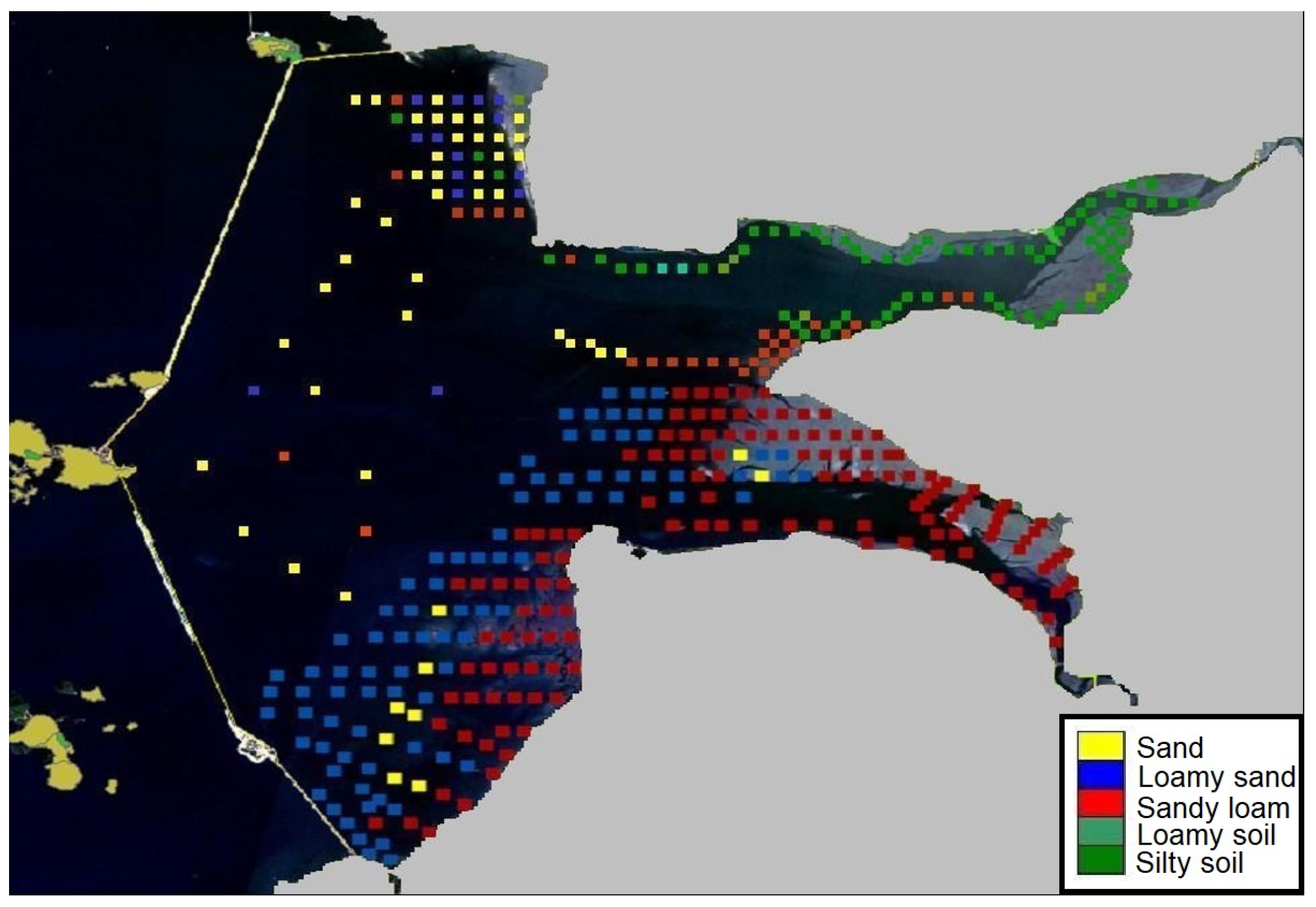

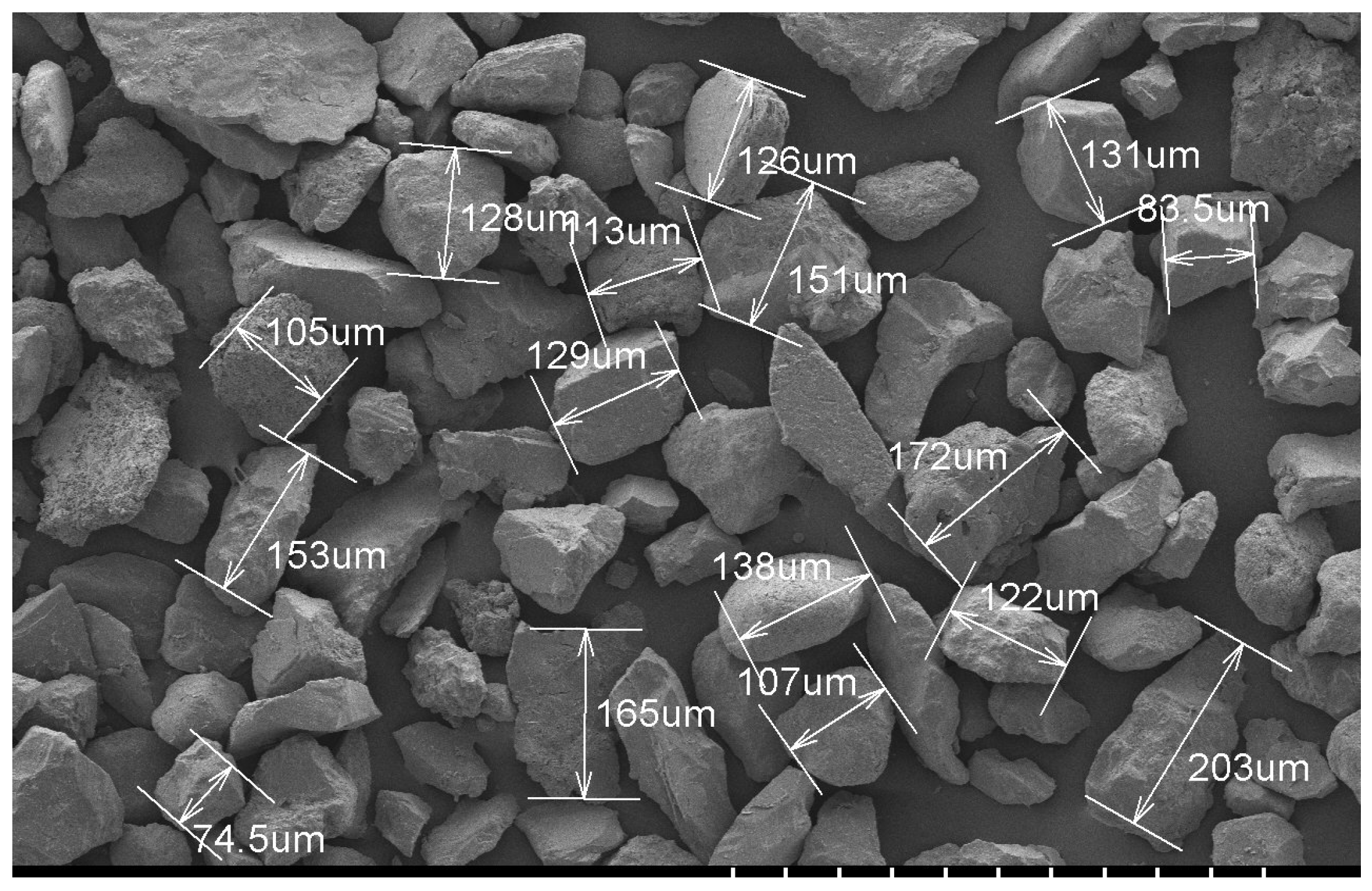

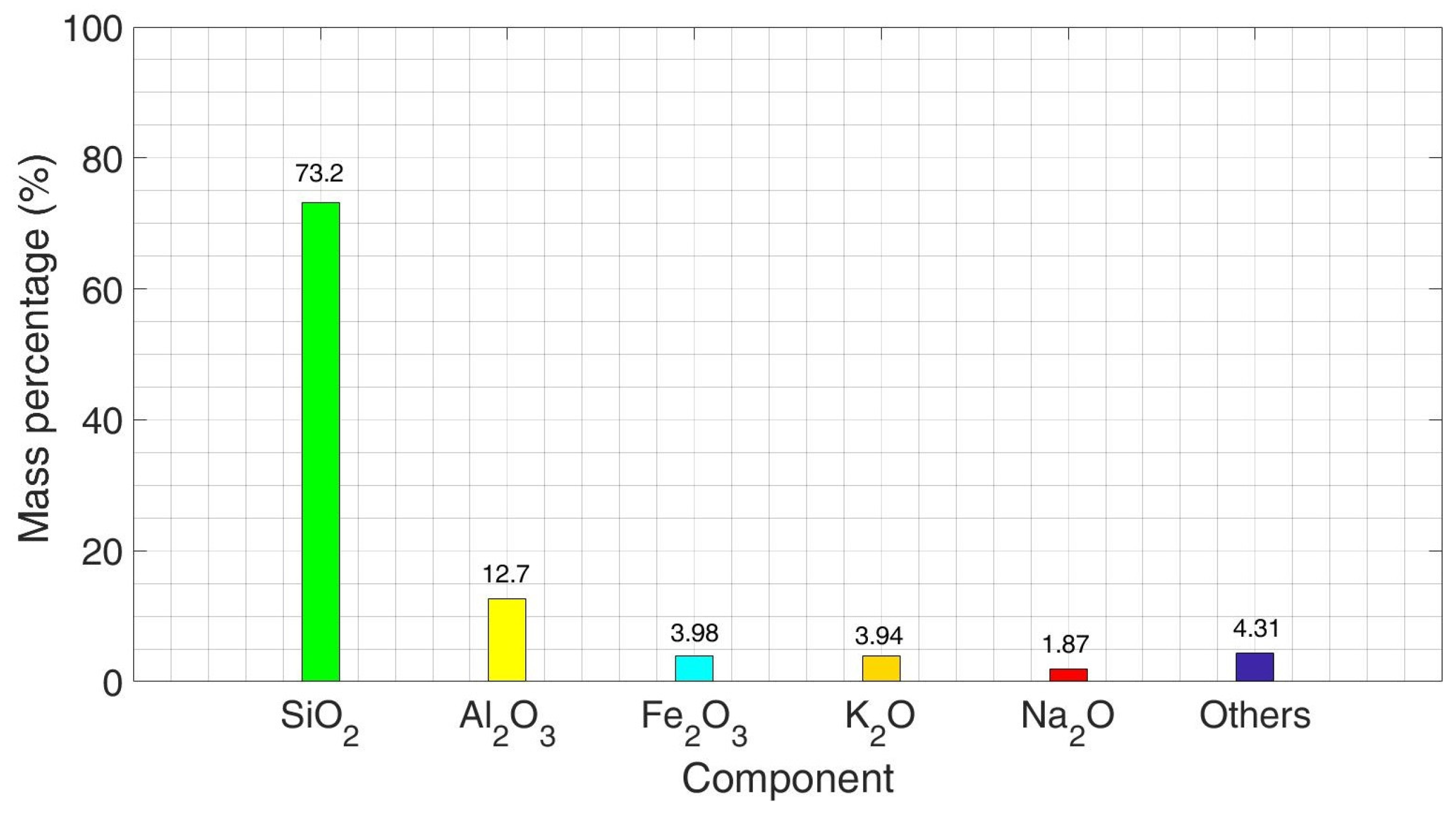

2.1. Soil Properties of Saemangeum Ground and Dreged Sand

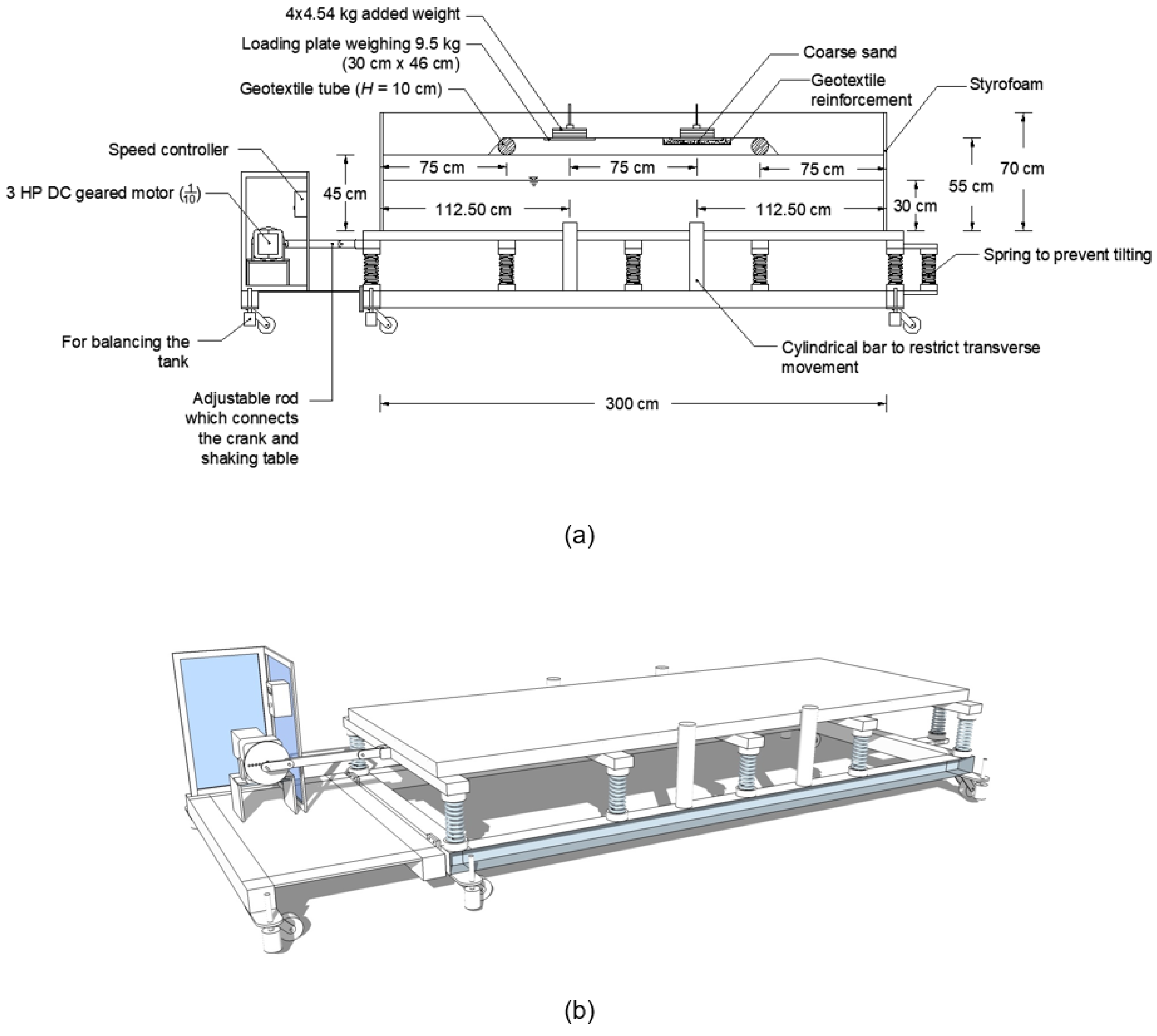

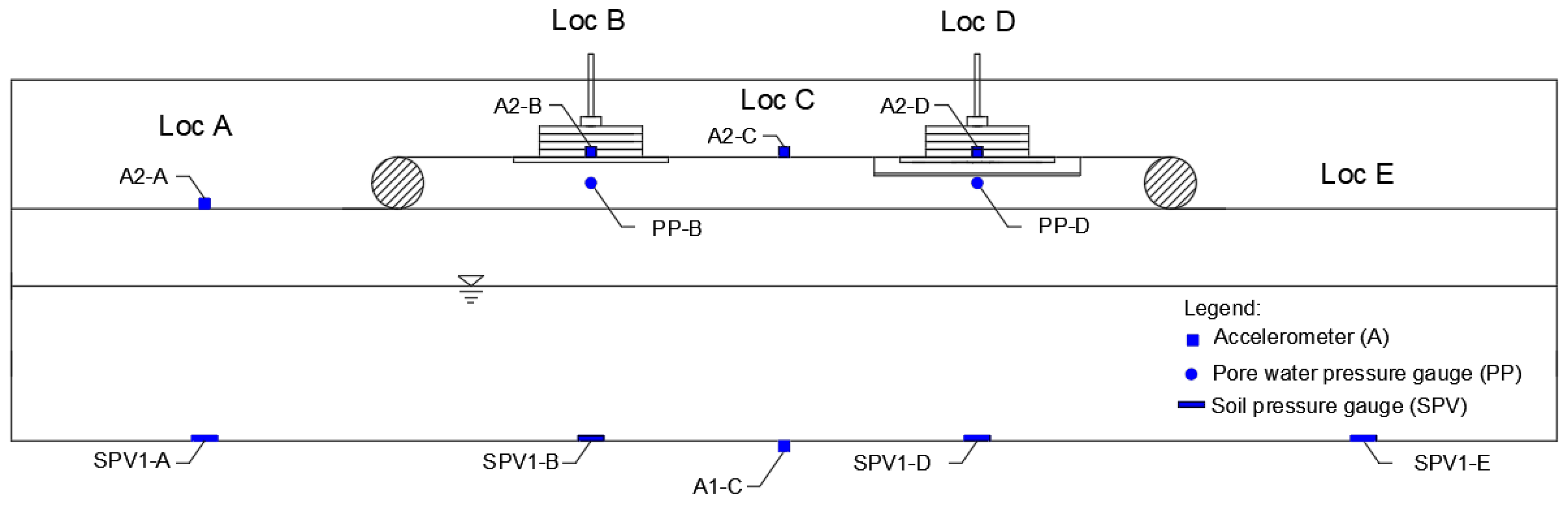

2.2. Shaking Table Apparatus and Scale Model Setup

2.3. Calculation of the Initial Stress, Interpolated Acceleration, Shear Stress, and Shear Strain

3. Results

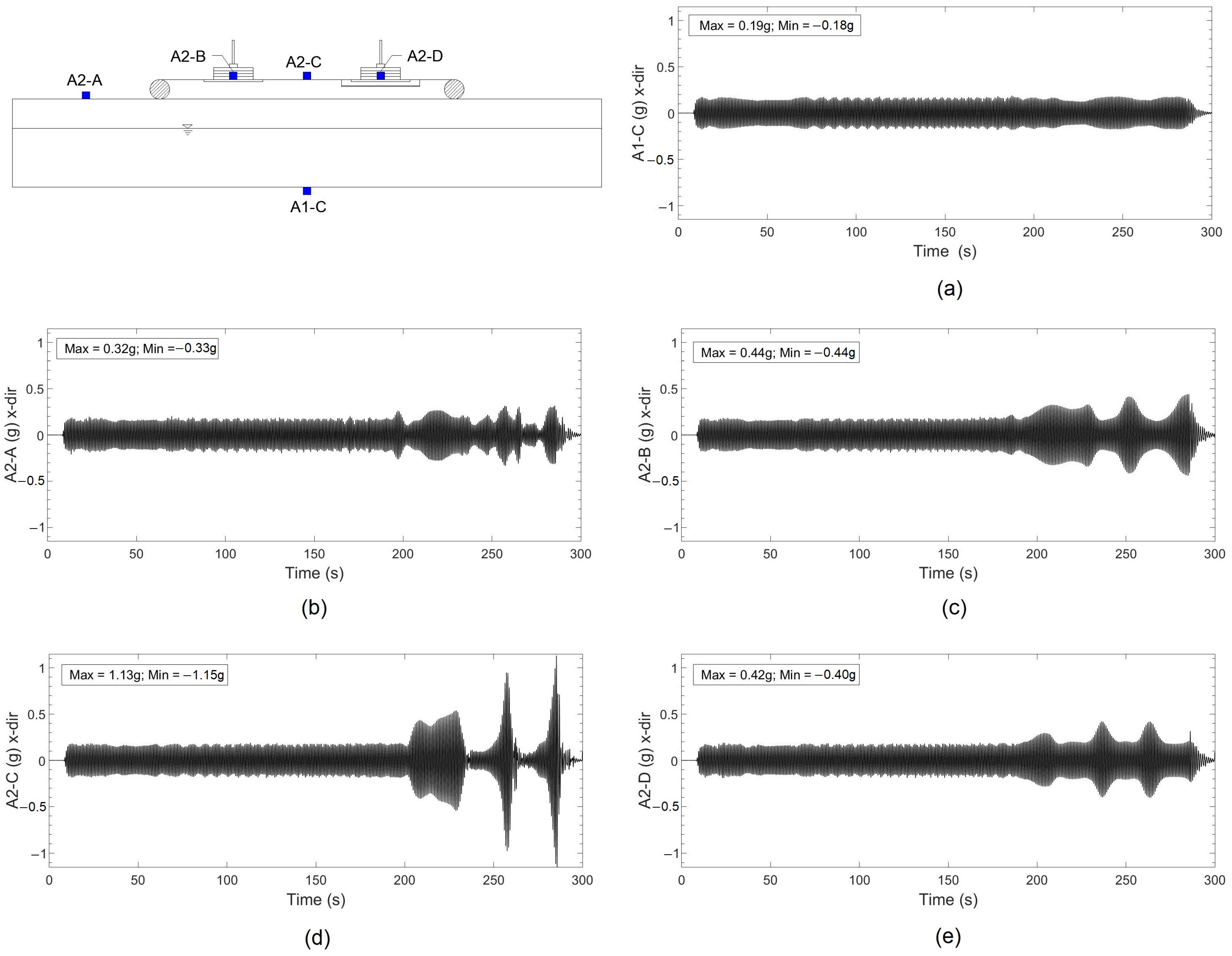

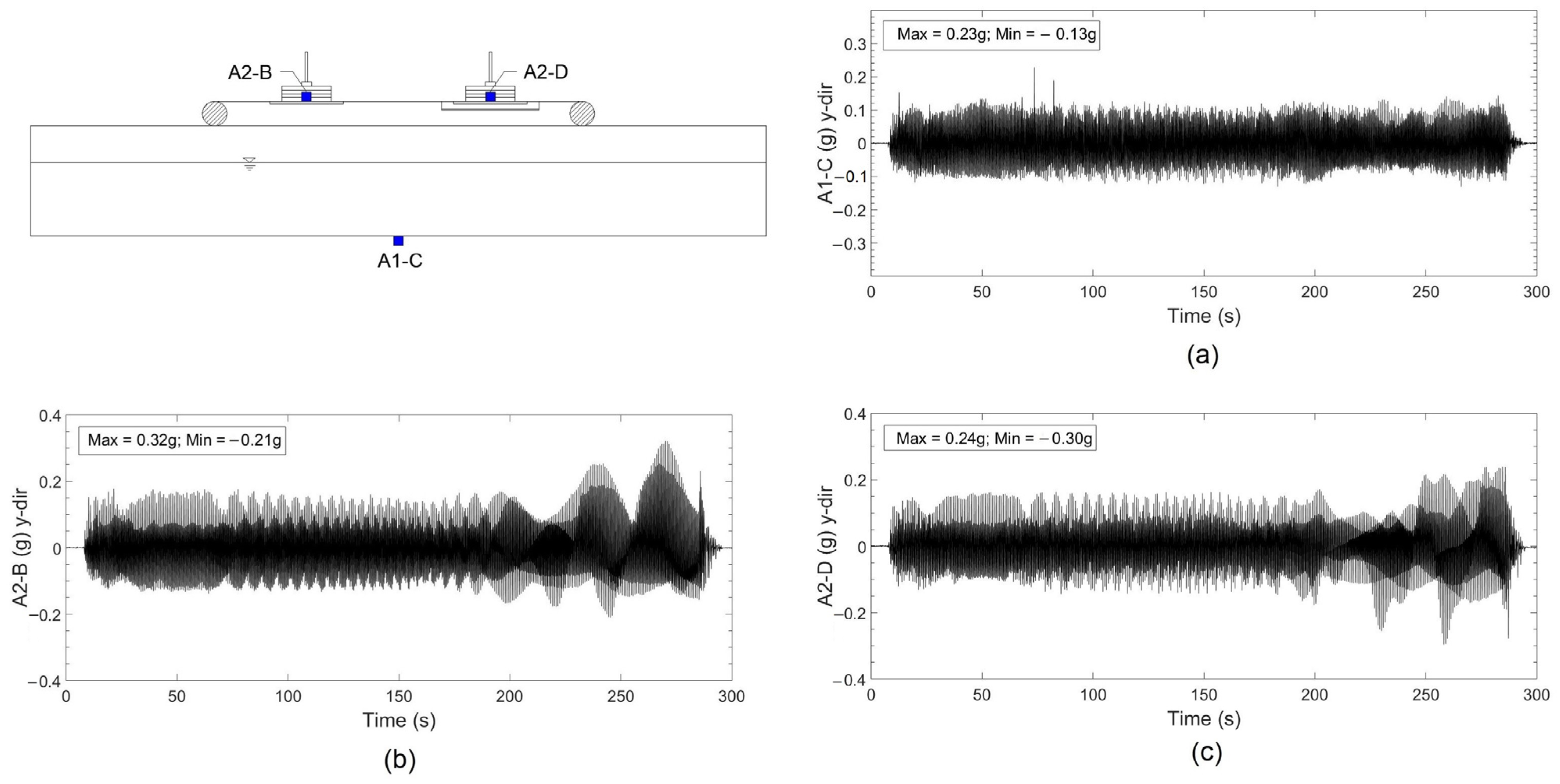

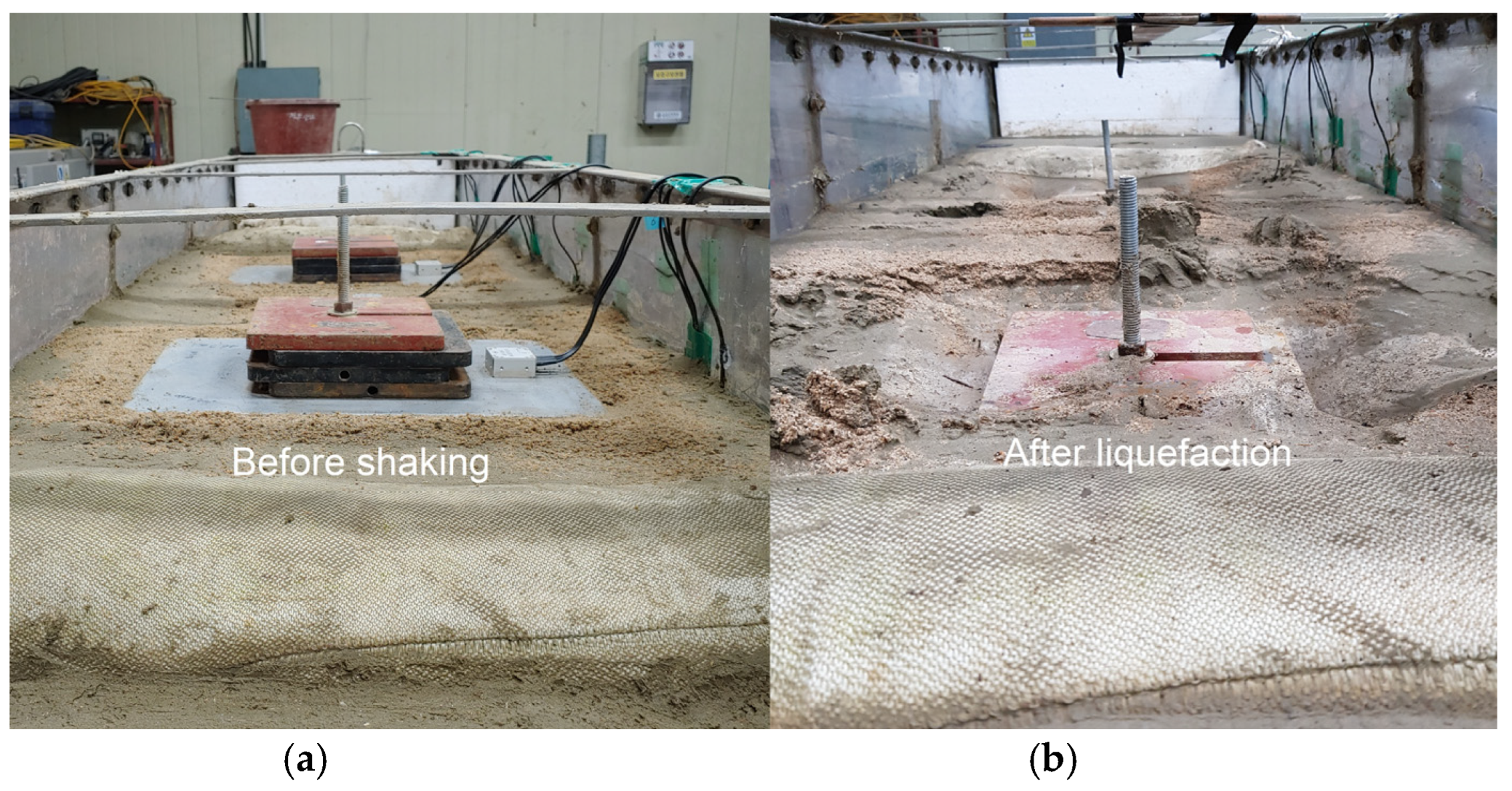

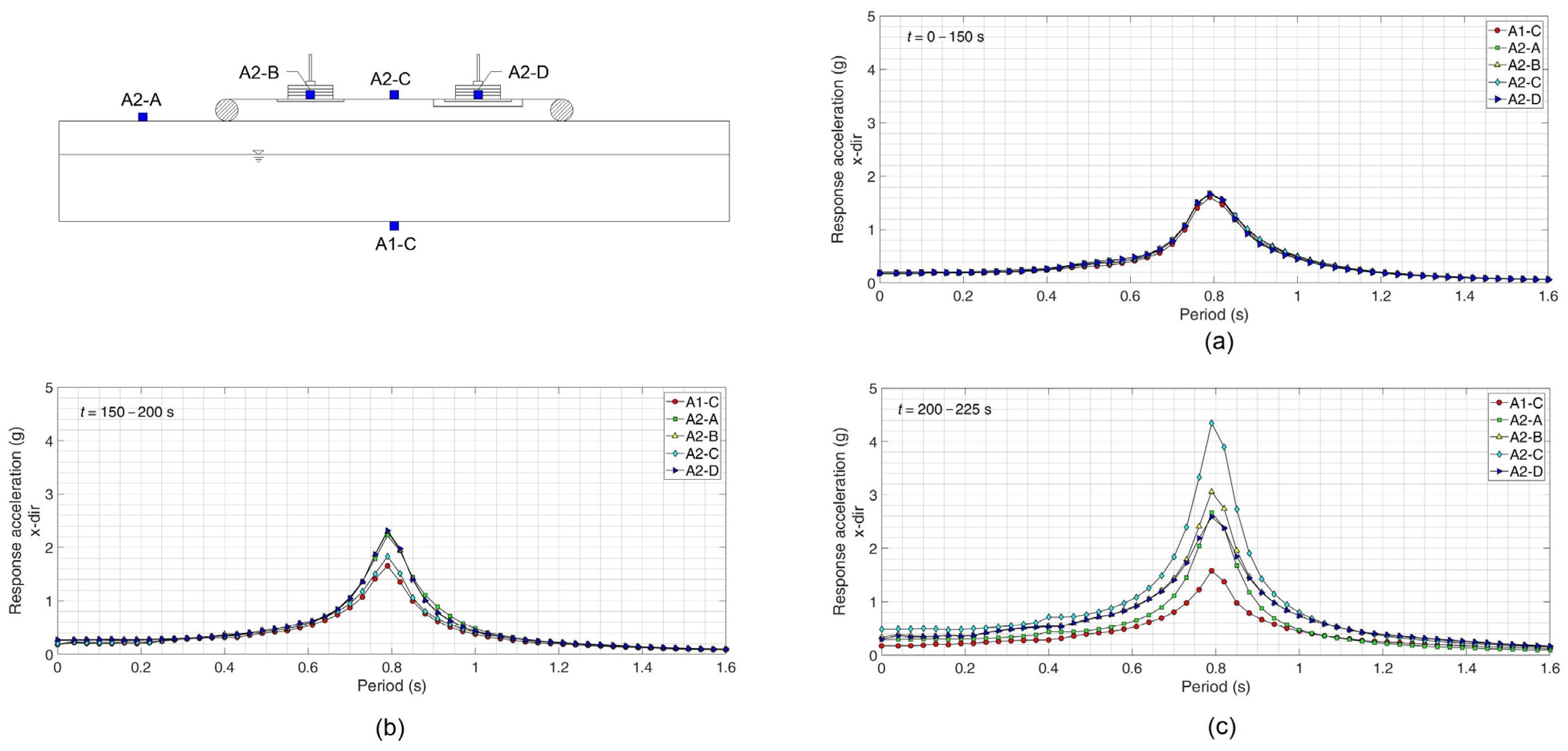

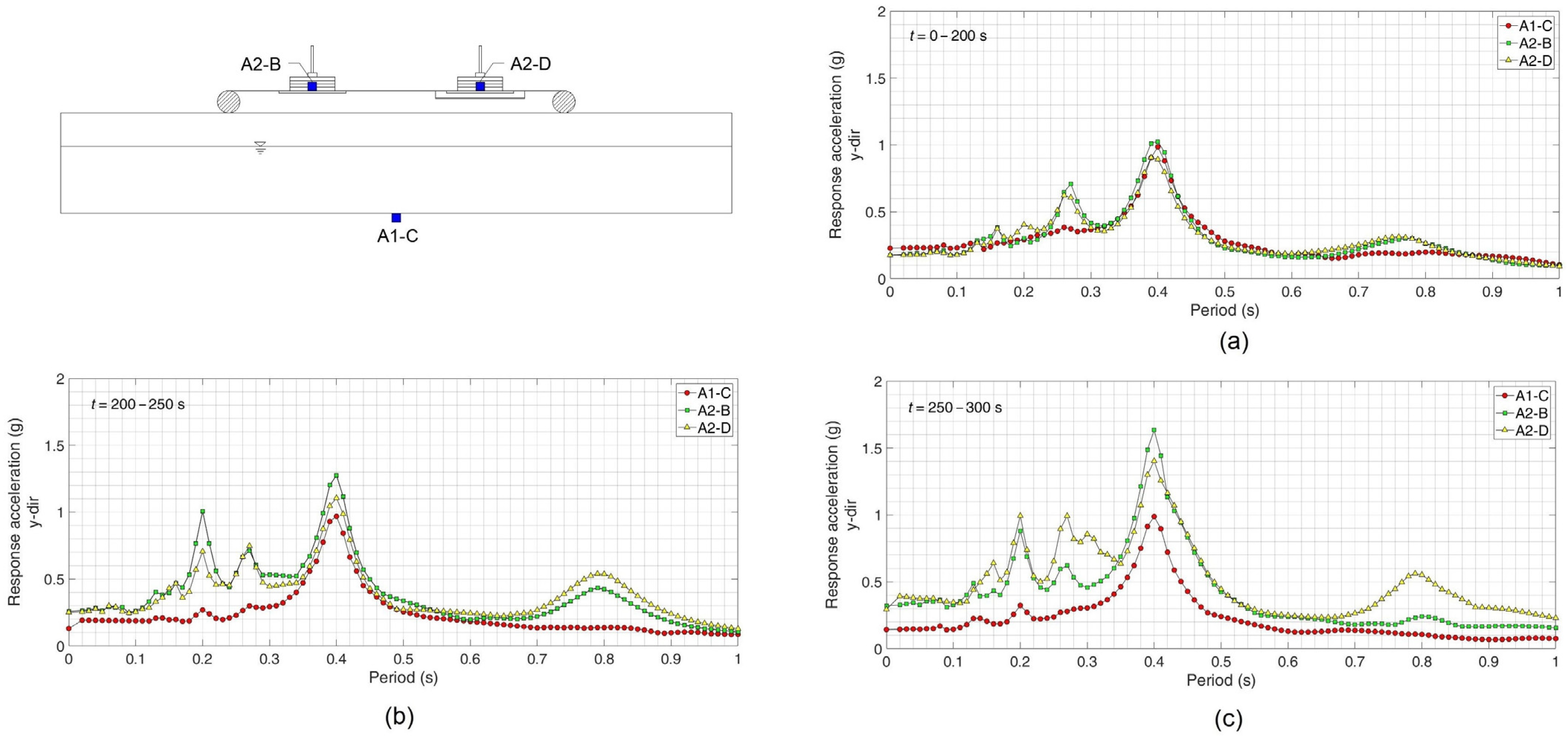

3.1. Recorded Accelarations and Response Spectra

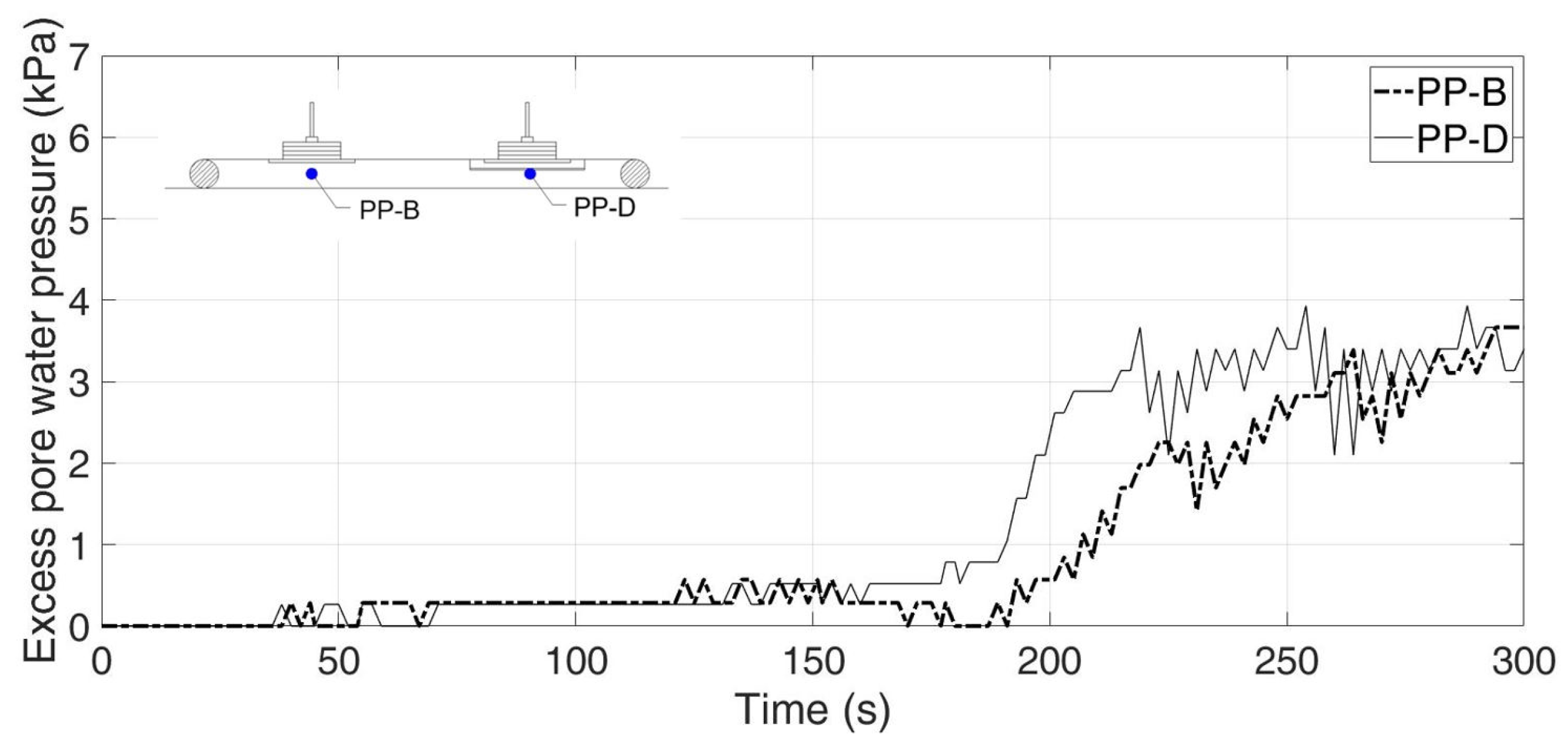

3.2. Excess Pore Water Pressures

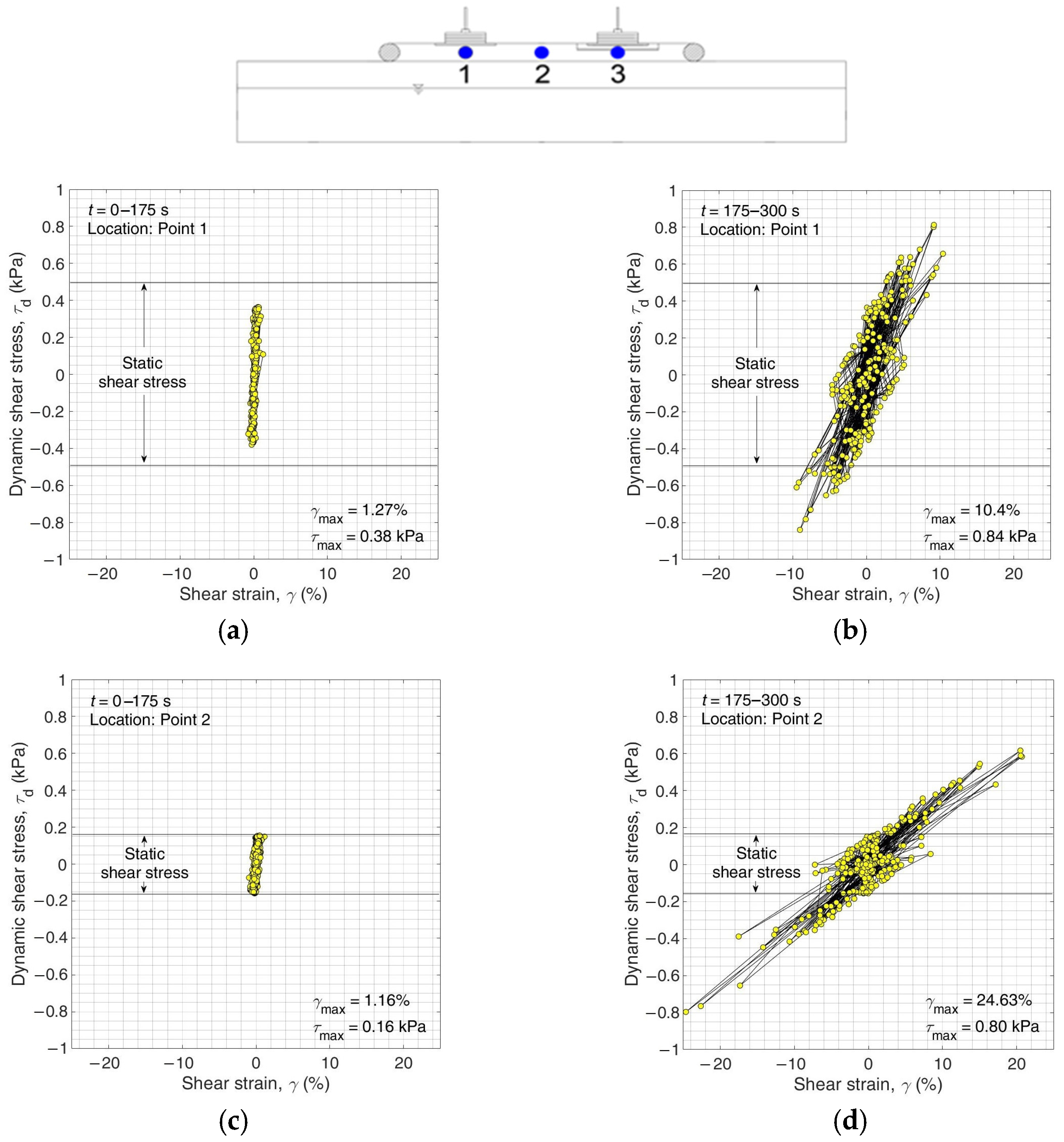

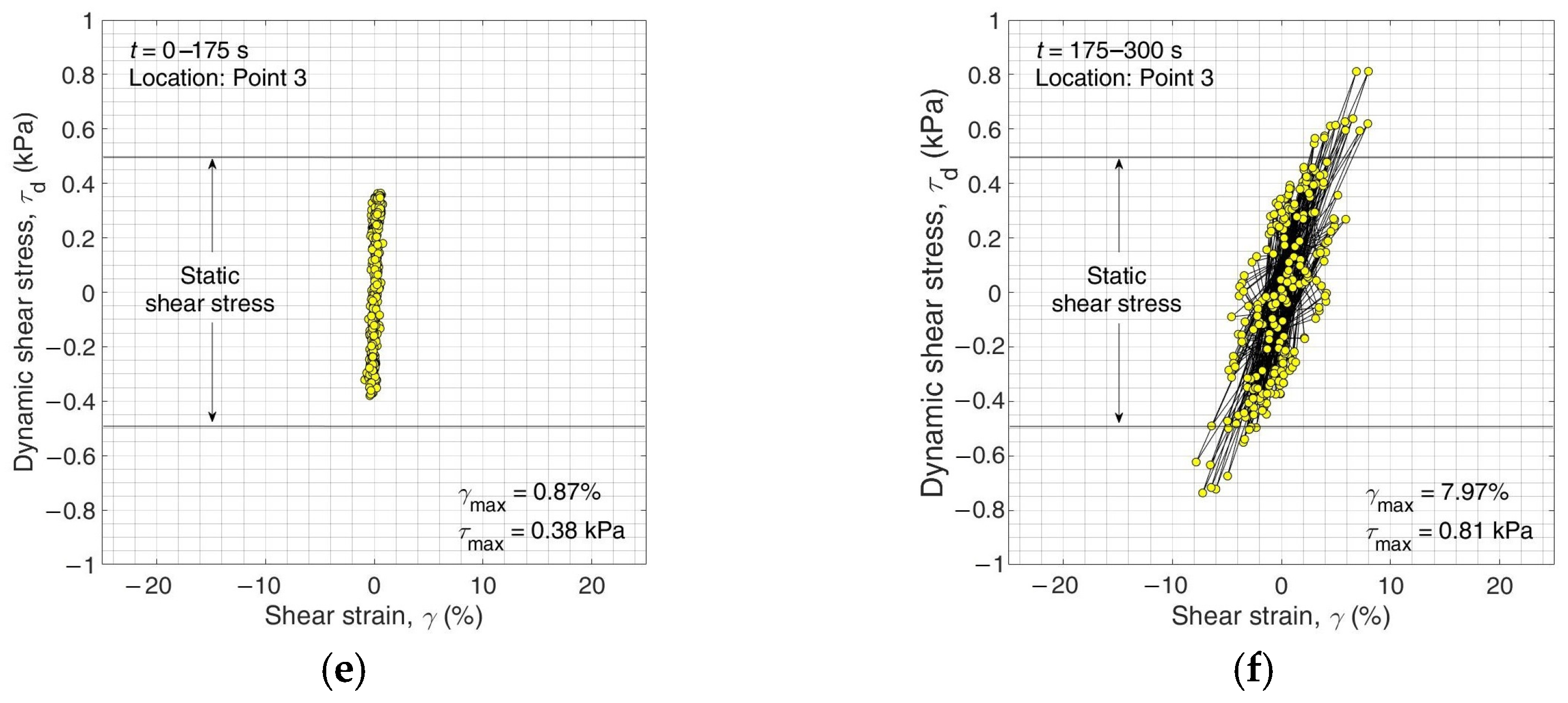

3.3. Stress Paths

4. Conclusions

- The liquefaction of the embankment was a reaction to the liquefaction of the outside soil as water seeped into it, showing the susceptibility of Saemangeum silty sand to seepage-induced liquefaction, even at a partially saturated state. It was observed that at t = 0 s to 200 s, pore pressure rise at PP-B and PP-D of the embankment was negligible. A sudden rise in pore rise was then observed at t = 200 s to 300 s.

- Larger surface accelerations were observed in the embankment soil in comparison to the outside soil, indicating the importance of analyzing the liquefaction potential of soils not only at the site area but also near embankments because this could cause severe damage to structures inside the embankment. The surface horizontal accelerations during shaking at A2-C were excessively large at about t = 250 s to 300 s, which reached a maximum surface acceleration of 1.15 g, about 6 times larger than the input acceleration.

- Although higher excess pore water pressures were experienced earlier at location D, the shallow foundation at location D sustained slightly lesser damage, which could be mainly due to the effect of the geotextile and soil improvement. The settlement of the shallow foundation was reduced by 3 cm due to the addition of geotextile and soil improvement.

- Since higher excess pore water pressures were experienced earlier at location D, it is recommended to use a more permeable geosynthetic reinforcement to lower the rise in pore pressure during shaking.

- Further studies regarding the cost-effectiveness and advantages of geosynthetics are recommended.

- An experiment conducted by the authors on a dry embankment resulted in cracks and severe inertia-induced damage to the shallow foundations. Hence, the state of the embankment will result in different damages.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Farzampour, A.; Kamali-Asl, A. Seismic hazard assessment for two cities in Eastern Iran. Earthq. Struct. 2015, 8, 681–697. [Google Scholar] [CrossRef]

- Hu, J.; Liu, H. Identification of ground motion intensity measure and its application for predicting soil liquefaction potential based on the Bayesian network method. Eng. Geol. 2019, 248, 34–49. [Google Scholar] [CrossRef]

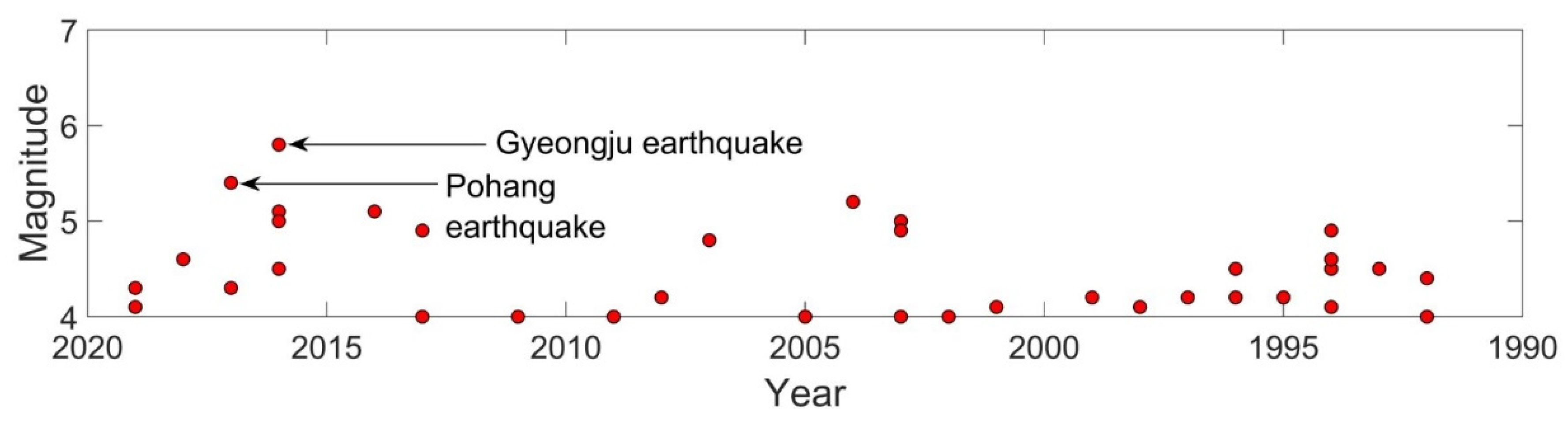

- Jee, H.W.; Han, S.W. Assessment of seismic risk of a typical RC building for the 2016 Gyeongju and potential earthquakes. Earthq. Struct. 2021, 20, 337–351. [Google Scholar]

- Buyuksarac, A.; Isik, E.; Harirchian, E. A case study for determination of seismic risk priorities in Van (Eastern Turkey). Earthq. Struct. 2021, 20, 445–455. [Google Scholar]

- Sonmezer, Y.B.; Akyuz, A.; Kayabali, K. Investigation of the effect of grain size on liquefaction potential of sands. Geomech. Eng. 2020, 20, 243–254. [Google Scholar]

- Yang, Y.; Xu, R.; Li, Y.; Li, Z. Study on seismic response characteristics of full light-weight concrete prefabricated utility tunnels. Earthq. Struct. 2021, 21, 51–62. [Google Scholar]

- Koga, Y.; Matsuo, O. Shaking table tests of embankments resting on liquefiable sandy ground. Soils Found. 1990, 30, 162–174. [Google Scholar] [CrossRef] [Green Version]

- Zhuang, H.; Wang, R.; Chen, G.; Miao, Y.; Zhao, K. Shear modulus reduction of saturated sand under large liquefaction-induced deformation in cyclic torsional shear tests. Eng. Geol. 2018, 240, 110–122. [Google Scholar] [CrossRef]

- Huang, Y.; Wen, Z.; Wang, L.; Zhu, C. Centrifuge testing of liquefaction mitigation effectiveness on sand foundations treated with nanoparticles. Eng. Geol. 2019, 249, 249–256. [Google Scholar] [CrossRef]

- Kim, H.J.; Dinoy, P.R. Two-dimensional consolidation analysis of geotextile tubes filled with fine-grained material. Geotext. Geomemb. 2021, 49, 1149–1164. [Google Scholar] [CrossRef]

- Beaty, M.H.; Byrne, P.M. UBCSAND Constitutive Model Version 904aR; Itasca: Minneapolis, MN, USA, February 2011; Available online: https://bouassidageotechnics.files.wordpress.com/2016/12/ubcsand_udm_documentation.pdf (accessed on 12 December 2022).

- Boulanger, R.W.; Ziotopoulou, K. PM4Sand (Version 3.1): A Sand Plasticity Model for Earthquake Engineering Applications; Rep. No. UCD/CGM-17/01; University of California: Berkeley, CA, USA, 2017. [Google Scholar]

- Nasiri, F.; Javdanian, H.; Heidari, A. Seismic response analysis of embankment dams under decomposed earthquakes. Geomech. Eng. 2020, 21, 35–51. [Google Scholar]

- Naik, S.P.; Gwon, O.; Park, K.; Kim, Y.S. Land damage mapping and liquefaction potential analysis of soils from the epicentral region of 2017 Pohang Mw 5.4 earthquake, South Korea. Sustainability 2020, 12, 1234. [Google Scholar] [CrossRef] [Green Version]

- Hong, T.K.; Lee, J.; Park, S.; Kim, W. Time-advanced occurrence of moderate-size earthquakes in a stable intraplate region after a megathrust earthquake and their seismic properties. Sci. Rep. 2018, 8, 13331. [Google Scholar] [CrossRef] [PubMed]

- Yasuda, S.; Ishihara, K.; Harada, K.; Shinkawa, N. Effect of soil improvement on ground subsidence due to liquefaction. Soils Found. 1996, 36, 99–107. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S. Reducing liquefaction potential using dynamic compaction and construction of stone columns. Geotech. Geol. Eng. 2001, 19, 169–182. [Google Scholar] [CrossRef]

- Shen, M.; Juang, C.H.; Ku, C.S.; Khoshnevisan, S. Assessing effect of dynamic compaction on liquefaction potential using statistical methods—A case study. Georisk 2019, 13, 341–348. [Google Scholar] [CrossRef]

- Sasaki, Y.; Taniguchi, E. Shaking table tests on gravel drains to prevent liquefaction of sand deposits. Soils Found. 1982, 22, 1–4. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- García-Torres, S.; Madabhushi, G.S. Performance of vertical drains in liquefaction mitigation under structures. Bull. Earthq. Eng. 2019, 17, 5849–5866. [Google Scholar] [CrossRef] [Green Version]

- Jung, C.; Ceglarek, R.; Clauvelin, T.; Ayeldeen, M.; Kim, D. Deep soil mixing in Sabkha soils for foundation support in United Arab Emirates. Int. J. Geosynt. Ground Eng. 2020, 6, 1–5. [Google Scholar] [CrossRef]

- Hasheminezhad, A.; Bahadori, H. On the deep soil mixing method in the mitigation of liquefaction-induced bearing capacity degradation of shallow foundations. Geomech. Geoeng. 2022, 17, 334–346. [Google Scholar] [CrossRef]

- Miller, E.A.; Roycroft, G.A. Compaction grouting test program for liquefaction control. J. Geotech. Geoenviron. Eng. 2004, 130, 355–361. [Google Scholar] [CrossRef]

- Gallagher, P.M.; Conlee, C.T.; Rollins, K.M. Full-scale field testing of colloidal silica grouting for mitigation of liquefaction risk. J. Geotech. Geoenviron. Eng. 2007, 133, 186–196. [Google Scholar] [CrossRef] [Green Version]

- Porcino, D.; Marcianò, V.; Granata, R. Undrained cyclic response of a silicate-grouted sand for liquefaction mitigation purposes. Geomech. Geoeng. 2011, 6, 155–170. [Google Scholar] [CrossRef]

- Salvatore, E.; Modoni, G.; Mascolo, M.C.; Grassi, D.; Spagnoli, G. Experimental evidence of the effectiveness and applicability of colloidal nanosilica grouting for liquefaction mitigation. J. Geotech. Geoenviron. Eng. 2020, 146, 04020108. [Google Scholar] [CrossRef]

- Seed, H.B.; Idriss, I.M. Simplified procedure for evaluating soil liquefaction potential. J. Soil Mech. Div. 1971, 97, 1249–1273. [Google Scholar] [CrossRef]

- Youd, T.L.; Idriss, I.M.; Andrus, R.D.; Arango, I.; Castro, G.; Christian, J.T.; Dobry, R.; Liam Finn, W.D.L.; Harder, L.F., Jr.; Hynes, M.E.; et al. Liquefaction resistance of soils: Summary report from the 1996 NCEER and 1998 NCEER/NSF workshops on evaluation of liquefaction resistance of soils. J. Geotech. Geoenviron. Eng. 2001, 127, 817–833. [Google Scholar] [CrossRef] [Green Version]

- Cetin, K.O.; Seed, R.B.; Der Kiureghian, A.; Tokimatsu, K.; Harder Jr, L.F.; Kayen, R.E.; Moss, R. 0.E. Standard penetration test-based probabilistic and deterministic assessment of seismic soil liquefaction potential. J. Geotech. Geoenviron. Eng. 2004, 130, 1314–1340. [Google Scholar] [CrossRef] [Green Version]

- Lombardi, D.; Bhattacharya, S. Liquefaction of soil in the Emilia-Romagna region after the 2012 Northern Italy earthquake sequence. Nat. Haz. 2014, 73, 1749–1770. [Google Scholar] [CrossRef]

- Ortiz-Hernández, E.; Chunga, K.; Toulkeridis, T.; Pastor, J.L. Soil liquefaction and other seismic-associated phenomena in the city of Chone during the 2016 Earthquake of Coastal Ecuador. Appl. Sci. 2022, 12, 7867. [Google Scholar] [CrossRef]

- SDIA (Saemangeum Development and Investment Agency). Available online: http://www.saemangeum.go.kr (accessed on 1 October 2021).

- Palmeira, E.M.; Melo, D.L.A.; Moraes-Filho, I.P. Geotextile filtration opening size under tension and confinement. Geotext. Geomemb. 2019, 47, 566–576. [Google Scholar] [CrossRef]

- Bridle, R.J.; Barr, B.I.G.; John, S. Hydraulically-filled geomembrane bags for land reclamation. Geosyn. Int. 2018, 5, 435–442. [Google Scholar] [CrossRef]

- Alvarez, I.E.; Rubio, R.; Ricalde, H. Beach restoration with geotextile tubes as submerged breakwaters in Yucatan, Mexico. Geotext. Geomemb. 2007, 42, 233–241. [Google Scholar] [CrossRef]

- Kim, H.J.; Won, M.S.; Jamin, J.C. Finite-element analysis on the stability of geotextile tube-reinforce embankments under scouring. Int. J. Geomech. 2015, 15, 06014019. [Google Scholar] [CrossRef]

- Maurer, B.W.; Gustafson, A.C.; Bhatia, S.K.; Palomino, A.M. Geotextile dewatering of flocculated, fiber reinforced fly-ash slurry. Fuel 2012, 97, 411–417. [Google Scholar] [CrossRef]

- Monkul, M.M.; Yamamuro, J.A. Influence of silt size and content on liquefaction behavior of sands. Can. Geotech. J. 2011, 48, 931–942. [Google Scholar] [CrossRef]

- Adampira, M.; Derakhshandi, M.; Ghalandarzadeh, A. Experimental study on seismic response characterstics of liquefiable soil layers. J. Earthq. Eng. 2019, 25, 1287–1315. [Google Scholar] [CrossRef]

- Kim, H.S. Development of simplified liquefaction program for the prediction of the seismic response of Saemangeum silty sand. Ph.D. Dissertation, Kunsan National University, Gunsan, Republic of Korea, 2020. [Google Scholar]

- Robertson, P.K. Soil behaviour type from the CPT: An update. In Proceedings of the 2nd International Symposium on Cone Penetration Testing, Hundtington Beach, CA, USA, 9–11 May 2010. [Google Scholar]

- Tsuchida, H. Prediction and countermeasure against the liquefaction in sand deposits. In Abstract of the Seminar in the Port and Harbor Research Institute; Ministry of Transport: Yokosuka, Japan, 1970; pp. 31–333. [Google Scholar]

- Miura, S.; Toki, S. A sample preparation method and its effect on static and cyclic deformation-strength properties of sand. Soils Found. 1982, 22, 61–77. [Google Scholar] [CrossRef] [Green Version]

- Wichtmann, T.; Steller, K.; Triantafyllidis, T. On the influence of the sample preparation method on strain accumulation in sand under high-cyclic loading. Soil Dyn. Earthq. Eng. 2020, 131, 106028. [Google Scholar] [CrossRef]

- Unni Kartha, G.; Beena, K.S.; Mohamed Thahir, C.P. Shake table studies on embankments on liquefiable soil. In Soil Dynamics and Earthquake Geotechnical Engineering; Springer: Singapore, 2019. [Google Scholar]

- Pramaditya, A.; Fathani, T.F. Geotechnical centrifuge test of reinforced road embankment against earthquake-induced liquefaction. Geomate J. 2021, 21, 115–122. [Google Scholar] [CrossRef]

| Property | Unit | Quantity |

|---|---|---|

| Specific Gravity, Gs | NA | 2.71 |

| Percent Passing #200 sieve | % | 26.20 |

| Soil Classification (USCS) | NA | SM |

| Permeability | cm/s | 2.09 × 10−3 |

| Void Ratio in loosest state, emax | NA | 1.37 |

| Void Ratio in densest state, emin | NA | 0.68 |

| Description | Test Method | Unit | Quantity | |

|---|---|---|---|---|

| Tensile strength: | Weft | ASTM D4595 | kN/m | 169 |

| Warp | ASTM D4595 | kN/m | 176 | |

| Elongation: | Weft | ASTM D4595 | % | 14 |

| Warp | ASTM D4595 | % | 14 | |

| Apparent opening size (AOS) | ASTM D4751 | μm | 315 | |

| Permeability | ASTM D4491 | cm/s | 8.5 × 10−3 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-J.; Dinoy, P.R.; Reyes, J.V.; Kim, H.-S.; Park, T.-W.; Choi, H.-S. Seismic Characteristics of a Geotextile Tube-Reinforced Embankment and Shallow Foundations Laid on Liquefiable Soil. Appl. Sci. 2023, 13, 785. https://doi.org/10.3390/app13020785

Kim H-J, Dinoy PR, Reyes JV, Kim H-S, Park T-W, Choi H-S. Seismic Characteristics of a Geotextile Tube-Reinforced Embankment and Shallow Foundations Laid on Liquefiable Soil. Applied Sciences. 2023; 13(2):785. https://doi.org/10.3390/app13020785

Chicago/Turabian StyleKim, Hyeong-Joo, Peter Rey Dinoy, James Vincent Reyes, Hyeong-Soo Kim, Tae-Woong Park, and Hee-Seong Choi. 2023. "Seismic Characteristics of a Geotextile Tube-Reinforced Embankment and Shallow Foundations Laid on Liquefiable Soil" Applied Sciences 13, no. 2: 785. https://doi.org/10.3390/app13020785