Heat Transfer Characteristics of Modular Heat Storage Wall Solar Greenhouse Based on Active Heat Storage System

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Materials

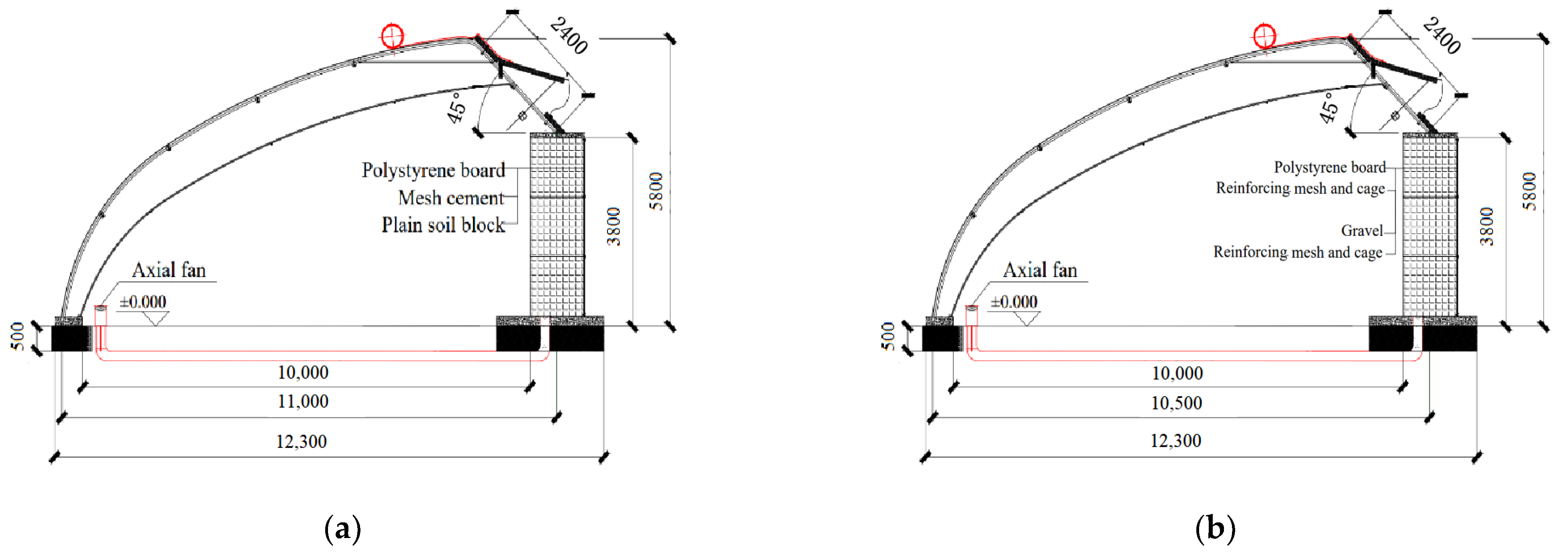

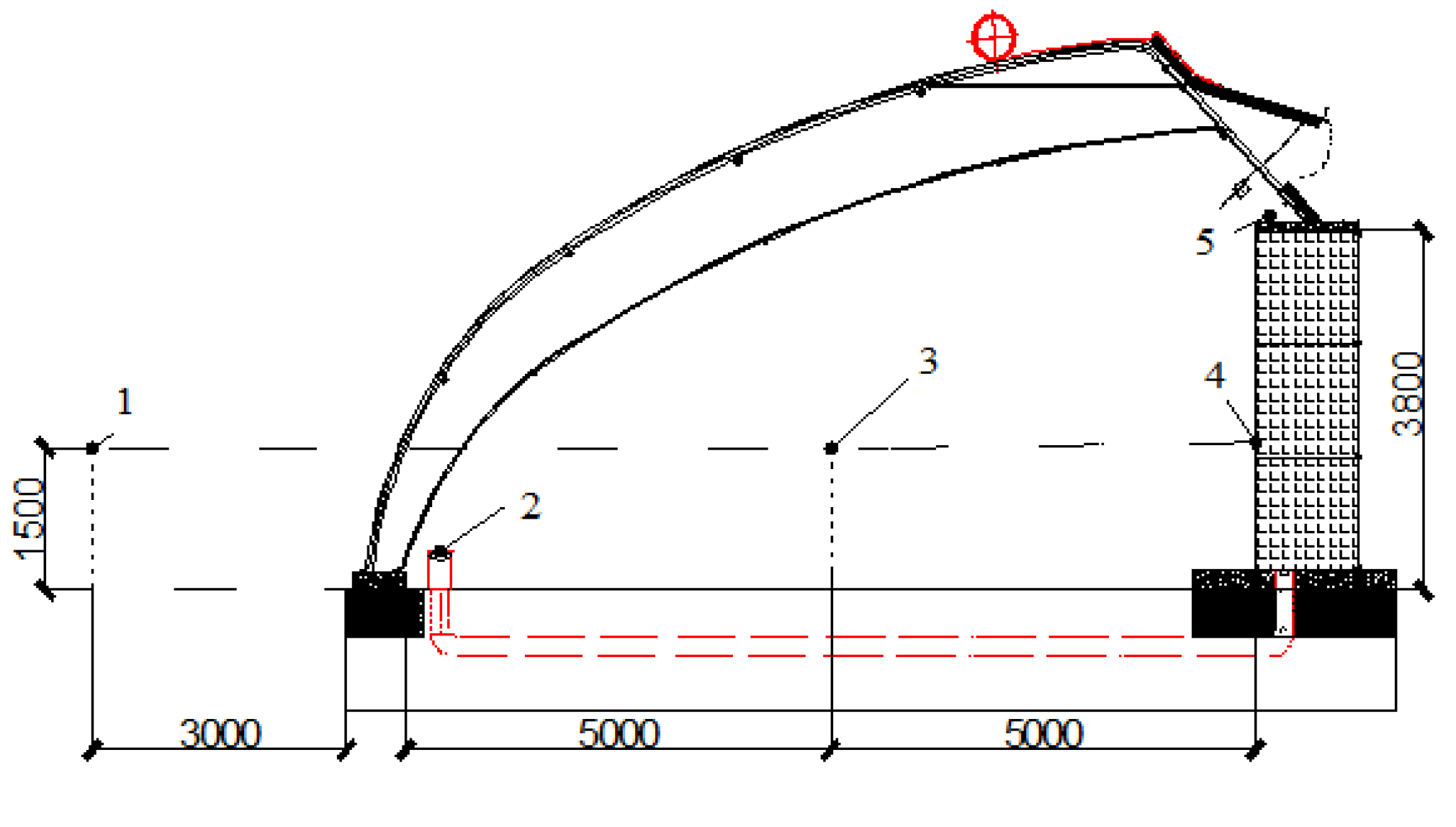

2.1.1. Test Greenhouses

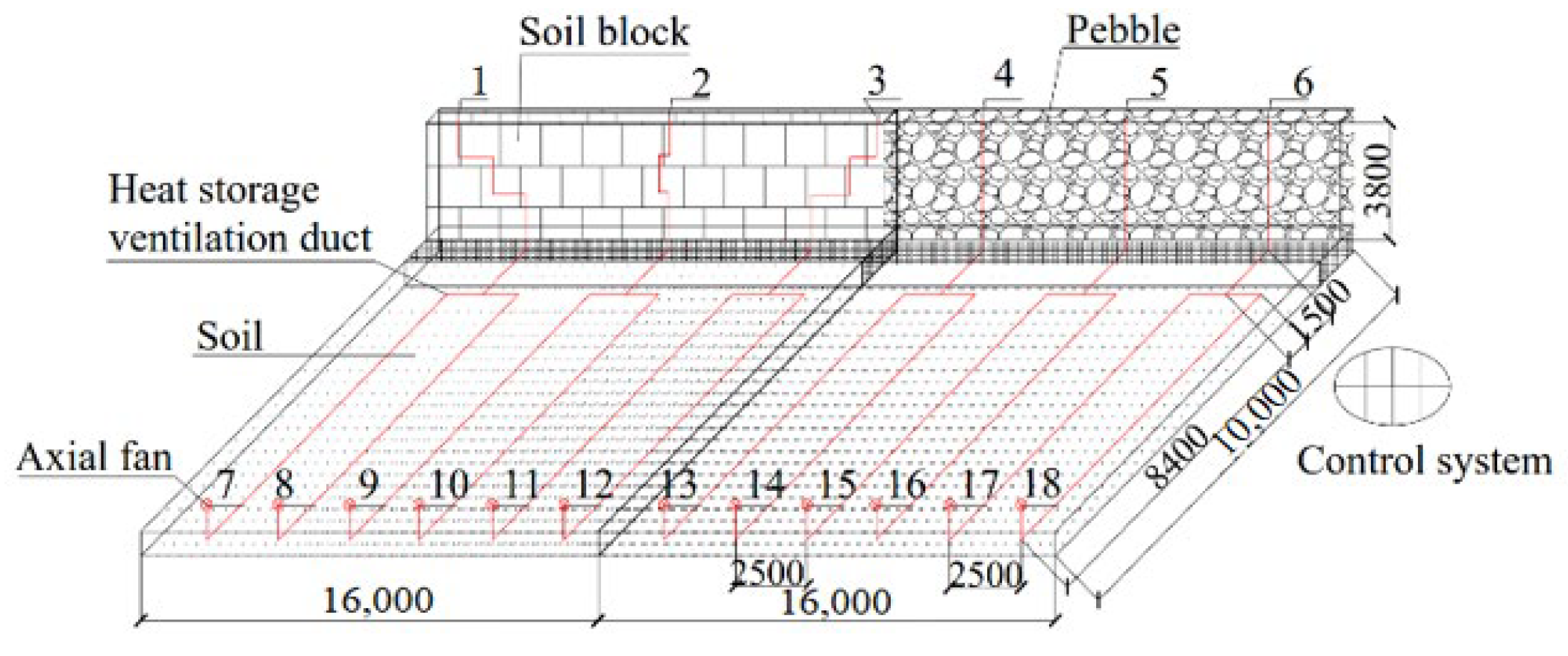

2.1.2. Active Thermal Storage Circulation System

2.1.3. Testing Instruments

2.2. Wall Construction Process

2.3. Measurement Point Arrangement

2.4. Data Processing

3. Analyses of Environmental Parameters of Different Modular Wall Greenhouses

3.1. Comparative Analyses of Temperatures inside and outside the Greenhouse

3.2. Temperature Analysis inside the Greenhouses during the Test Period

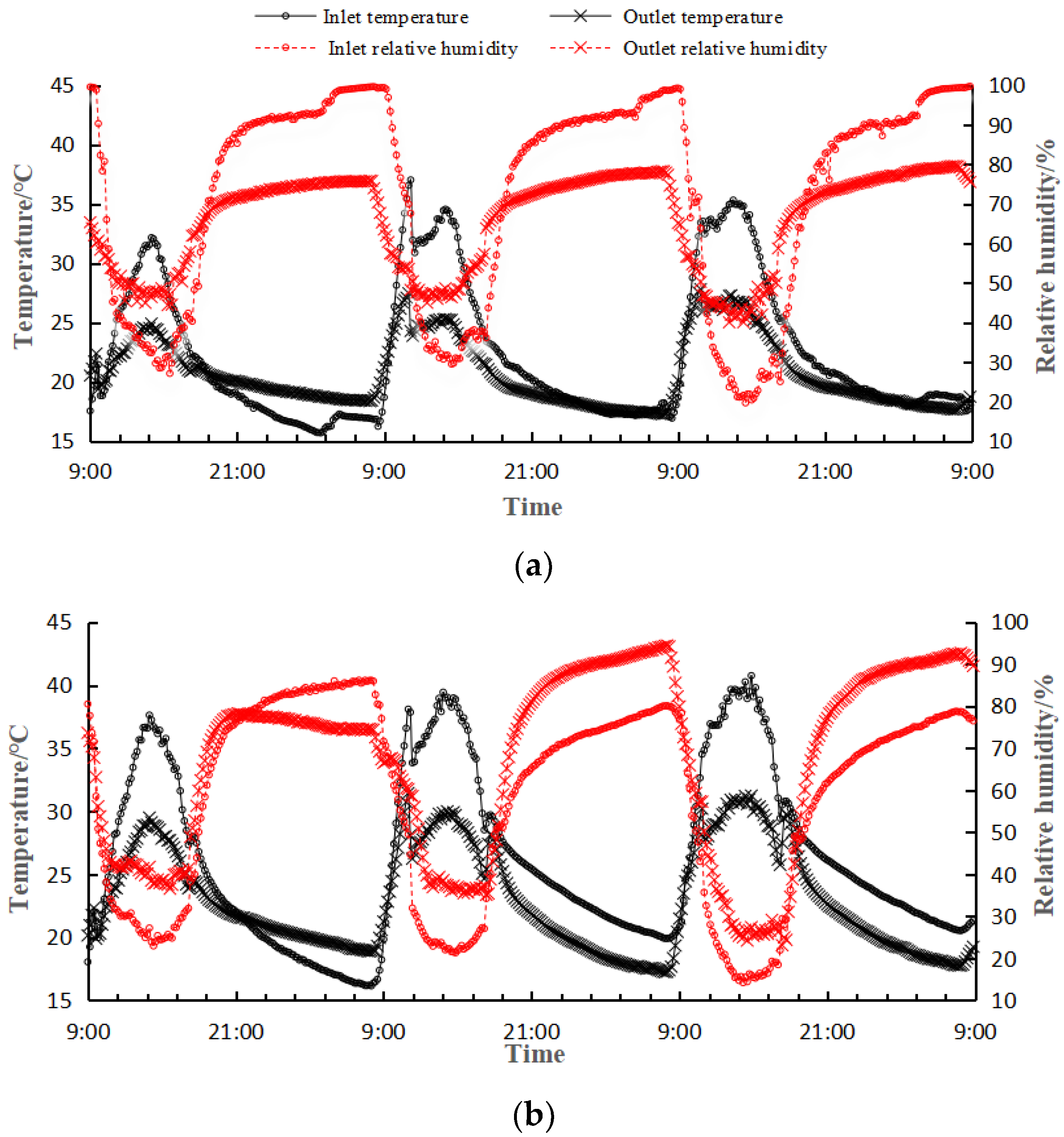

3.3. Comparative Analyses of the Inlet and Outlet Air Temperature and Humidity in the Greenhouse on Typical Sunny Days

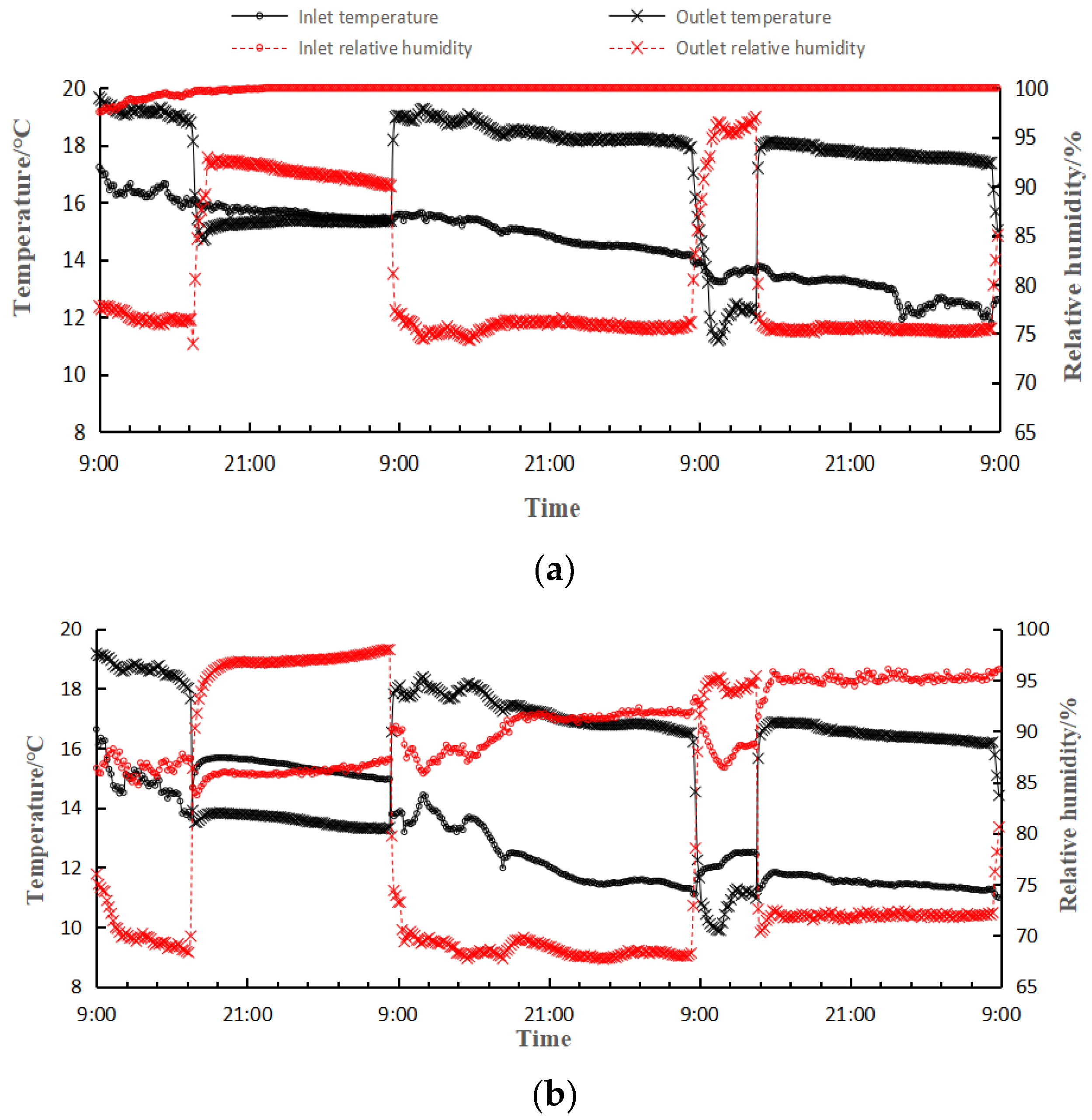

3.4. Comparative Analyses of the Temperature and Humidity of the Air Inlet and Outlet in the Greenhouse on Typical Cloudy Days

3.5. The Significance Analyses of Environmental Parameters of Two Greenhouse on Typical Sunny and Cloudy Days

3.6. Analysis of an Active Heat Storage System Heat Transfer and Passive Heat Storage of Walls

3.6.1. Active Passive Heat Storage and Heat Release

3.6.2. Energy Efficiency Ratio

4. Discussion

- (1)

- On typical cloudy days, the relative humidity at the air inlet of SG was generally high, reaching 96% on average, which was consistent with the results of the previous study [35]. The relative humidity at the air inlet of both SG and PG was close to 100%, which may arise from the shutting down of the active thermal storage circulation system on cloudy days. Meanwhile, the hot air was hovering over the top of internal environment, which resulted in the accumulation of moisture at the air inlet. In terms of the back wall material, the water absorption and permeability of soil was higher than that of stone. Combined with the less density of soil than that of pebbles, the relative humidity of both SG and PG air inlets were high. Then, the relative humidity of SG tended to reach 100%.

- (2)

- As shown in Table 1, the active heat transfer accounted for a smaller percentage in the sunny heat storage and exothermic stages, which was different from the active heat transfer percentage of G1 and G2 of 30.02% and 34.32% studied by related research [7] This may be on account of no difference in the calculated values of ντ, Hin and Hout involved in the computational formula of heat transfer in Equations (1) and (2) of this paper. Meanwhile, V: 0.16, 0.27 m3 and A: 0.009, 0.02 m2 in this paper were different from the total volume of ducts (5.60, 8.98 m3) and cross-sectional area (0.152, 0.235 m2) in a previous study [7]. Structural optimization of the active heat storage circulation system will be carried out subsequently to improve its active heat storage capacity.

- (3)

- The back wall material structure and heat storage method were crucial to improve the thermal insulation and heat storage of the solar greenhouse [36,37]. In this paper, the back wall materials and the horizontal positions of the air inlet and outlet of the two greenhouses were different. Thus, no single analysis of the thermal insulation and heat storage performance of a single greenhouse can be performed. The difference of duct arrangement structure caused by the back wall material made it difficult to analyze the heat transfer characteristics. However, the heat storage mode and the horizontal height of air inlet and outlet of the two greenhouses were identical. Thus, a comparative analysis was conducted between the two greenhouses [38], in order to determine the greenhouse with better heat insulation and heat storage. The next step will be to consider the analysis of the heat transfer performance of a single greenhouse under the condition of natural temperature difference.

5. Conclusions

- (1)

- The data test analysis of 28 consecutive days showed that the average indoor air temperature at night was 15.51 and 15.07 °C for SG and PG, respectively. Meanwhile, the average outdoor air temperature at night was 4.41 °C. Therefore, both modular greenhouses can effectively increase the nighttime temperature by 10–12 °C. That is, the nighttime insulation performance of both greenhouses was good. However, SG was slightly better than PG.

- (2)

- In terms of the active heat transfer characteristics, the difference of average air temperature between the inlet and outlet of SG and PG during the heat storage period was 5.03 and 5.98 °C, respectively. The average relative humidity difference was 17.15% and 11.40% and the average heat storage duration was 6.8 and 6.6 h, respectively. In addition, the difference of average relative humidity between the inlet and outlet of SG and PG was 1.04 and 2.37 °C. The average relative humidity difference between the inlet and outlet of SG and PG was 15.99% and 11.50%, respectively. The average heat release duration was 10 and 10.5 h. The difference of the average temperature and the relative humidity between the inlet and outlet of SG and PG indicated that the insulation effect of SG was better and the speed of increasing temperature was faster at night than that of PG. On typical cloudy days, the average temperature difference between the inlet and outlet of SG and PG was 2.89 and 3.90 °C, respectively. The difference of average relative humidity was 19.92% and 15.87%, respectively. Besides, the average duration of heat release was 11 h. The difference of average temperature between the inlet and outlet of SG was smaller than that of PG in the heat release. The difference of average relative humidity was SG > PG. Therefore, the heat preservation and storage performance of SG was slightly better than PG. The thermal performance of heliogreenhouse with a modular heat storage wall can effectively improve the growth of crop tomatoes.

- (3)

- During the heat storage and release period on sunny heat storage stage, sunny day exothermic phase, and cloudy exothermic phase, the total heat transfer of SG was 464.87, 110.44 and 54.82 MJ, respectively, while the total heat transfer of PG was 264.16, 61.60 and 46.89 MJ, respectively. The heat storage capacity of the two greenhouses was much larger than the heat release, which indicated that the heat storage performance of the two greenhouses was good. Thereinto, the heat storage and heat release of SG were higher than that of PG. In addition, the maximum energy efficiency ratio of SG and PG was 92.12 and 79.55, respectively, in the heat storage phase on typical sunny days. The maximum energy efficiency ratio of SG and PG was 16.78 and 15.21 in the heat release phase on typical sunny days, respectively. Additionally, the maximum energy efficiency ratio of SG and PG was 30.11 and 28.15 in the heat release phase on typical cloudy days, respectively. This revealed that the energy saving effect of the active system in the greenhouse under different weather is very good, where the heat storage phase on typical sunny days was the optimum.

- (4)

- The construction cost of the modular heat storage wall heliogreenhouse was reduced by 70–160 yuan/m2 compared with the traditional heat storage solar greenhouse and backfilled assembly heat storage wall solar greenhouse. Moreover, the construction time of the modular heat storage wall solar greenhouse was short.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bao, E.C.; Zou, Z.R.; Zhang, Y. CFD simulation of heat transfer on back wall of active heat storage solar greenhouse with different airflow directions. J. Agric. Eng. 2018, 34, 169–177. [Google Scholar]

- Greenhouse Data System. Department of Rural Mechanization Management, Ministry of Agriculture and Rural Affairs. 30 June 2021. Available online: http://data.sheshiyuanyi.com/AreaData/ (accessed on 10 September 2021).

- Wu, Y.W.; Zhang, Y.; Bao, E.C.; Cao, K.; Zou, Z.R. Research progress of modular heat storage wall solar greenhouse. Agric. Eng. Technol. 2022, 42, 54–58. [Google Scholar]

- Chen, C.; Li, Z.; Guan, Y.; Han, Y.Q.; Ling, H.S. Influence of manufacturing methods on thermal performance of phase change heat storage materials in solar greenhouse. Trans. Chin. Soc. Agric. Eng. 2012, 28, 186–191. [Google Scholar]

- Xu, F.; Shang, C.; Li, H.; Xue, X.; Sun, W.; Chen, H.; Li, Y.; Zhang, Z.; Li, X.; Guo, W. Comparison of thermal and light performance in two typical Chinese solar greenhouses in Beijing. Int. J. Agric. Biol. Eng. 2019, 12, 24–32. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Guo, S.; Wei, B.; He, X.; Sun, J.; Shu, S. Study on heat transfer characteristics of straw block wall in solar greenhouse. Energy Build. 2017, 139, 91–100. [Google Scholar] [CrossRef]

- Bao, E.C.; Cao, Y.F.; Zou, Z.R.; Zhang, Y. Heat transfer characteristics of solar greenhouse with active heat storage walls with different structures. Trans. Chin. Soc. Agric. Eng. 2019, 35, 189–197. [Google Scholar]

- Han, F.; Chen, C.; Hu, Q.; He, Y.; Wei, S.; Li, C. Modeling method of an active–passive ventilation wall with latent heat storage for evaluating its thermal properties in the solar greenhouse. Energy Build. 2021, 238, 110840. [Google Scholar] [CrossRef]

- Shi, P.P.; Lu, J.; Yang, H.X.; Li, X.L.; Zhou, H.; Wang, B. Influence of construction method of heat storage layer on heat storage performance of solar greenhouse composite phase change wall. Acta Energ. Sin. 2018, 39, 1511–1518. [Google Scholar]

- Li, X.F.; Chen, Q.Y. The effect of wall materials and their combinations on the thermal insulation performance of solar greenhouse walls. Chin. J. Eco-Agric. 2006, 14, 185–189. [Google Scholar]

- Zhou, S.; Zhang, Y.; Cheng, R.F.; Yang, Q.Z.; Fang, H.; Zhou, B.; Lu, W.; Zahng, F. Evaluation on heat preservation effects in micro-environment of large-scale greenhouse with active heat storage system. Trans. Chin. Soc. Agric. Eng. 2016, 32, 218–225. [Google Scholar]

- Zou, Z. Performance and advantage analysis of modular solar greenhouse. Agric. Eng. Technol. 2020, 40, 10–12. [Google Scholar]

- Zhang, J.; Zou, Z.R.; Zhang, Y.; Sun, Y.C. Preliminary study on the performance of a new type of gravel heat storage wall solar greenhouse. North. Hortic. 2016, 46–50. [Google Scholar] [CrossRef]

- Pi, J.; Liu, J.; Xia, L.R.; Meng, L.L. Research and design of environmental control system based on active heat storage solar greenhouse. Chin. J. Agric. Mach. Chem. 2019, 40, 132–136. [Google Scholar]

- Zhang, B.; Fan, X.; Liu, M.; Hao, W. Experimental study of the burning-cave hot water soil heating system in solar greenhouse. Renew. Energy 2016, 87, 1113–1120. [Google Scholar] [CrossRef]

- Guan, Y.; Chen, C.; Li, Z.; Han, Y.Q.; Ling, H.S. Improving the thermal environment of solar greenhouse by phase change thermal storage wall. Trans. Chin. Soc. Agric. Eng. 2012, 28, 194–201. [Google Scholar]

- Guan, Y.; Chen, C.; Ling, H.S.; Han, Y.Q.; Yan, Q.Y. Analysis of heat transfer characteristics of triple-structure phase change heat storage wall in solar greenhouse. Trans. Chin. Soc. Agric. Eng. 2013, 29, 166–173. [Google Scholar]

- Zhang, C.; Sun, J.; Yin, S.; Zhu, G.; Xi, Y. Temperature contrast test of various types of solar greenhouses in Beijing suburbs. Agric. Eng. 2021, 11, 21–26. [Google Scholar]

- Guan, Y.; Wang, T.M.; Wei, M.T.; Liu, T.M.; Hu, W.L.; Duan, S.J. Thermal performance test of flat-plate microheat tube array heat storage wall in solar greenhouse. Trans. Chin. Soc. Agric. Eng. 2021, 37, 205–212. [Google Scholar]

- Zhang, Y.; Gao, W.B.; Zou, Z.R. CFD simulation and performance test of heat transfer on the back wall of solar greenhouse with active heat storage. Trans. Chin. Soc. Agric. Eng. 2015, 31, 203–211. [Google Scholar]

- Wu, Z.X.; Wang, Q.; Zhang, Y.; Zou, Z.R.; Yan, L.L. Performance test of energy-saving active heat storage rear wall of solar greenhouse in Qinghai area. China Agric. Meteorol. 2020, 41, 86–93. [Google Scholar]

- Bao, E.C.; Shen, T.T.; Zhang, Y.; Cao, K.; Cao, Y.F.; Chen, D.Y.; He, B.; Zou, Z.R. Thermal performance analysis of solar greenhouse with fabricated active heat storage wall. Trans. Chin. Soc. Agric. Eng. 2018, 34, 178–186. [Google Scholar]

- Zou, Z.R.; Liu, X.F.; Li, Y.J. A Modular Splicing Solar Greenhouse Back Wall. CN207597641U, 10 July 2018. [Google Scholar]

- Zhang, Y.; Zou, Z.R. A Solar Greenhouse with Heat Storage Back Wall. CN102630526A, 15 August 2012. [Google Scholar]

- Zhang, Y.; Zou, Z.R. A Back Wall Solar Greenhouse with Active Daylighting and Self Heat Storage of Solidified Soil. CN103416261A, 4 December 2013. [Google Scholar]

- Zhang, Y. A Rammed Earth Wall Forming Method and Device Based on Phase Change Solidified Soil. CN106639005A, 10 May 2017. [Google Scholar]

- Zhang, Y. A Rammed Earth Wall Forming Device Based on Beam String. CN206888272U, 16 January 2018. [Google Scholar]

- Sun, Y.C. Research on Structure Optimization and Heat Transfer Characteristics of Three-Dimensional Circulation Active Heat Storage System in Solar Greenhouse. Ph.D. Thesis, Northwest A&F University, Xianyang, China, 2020. [Google Scholar]

- Zhao, R.Y.; Fan, C.Y.; Xue, D.H.; Qian, Y.M. Air Conditioning (Fourth Edition); China Construction Industry Press: Beijing, China, 2009. [Google Scholar]

- Ma, C.W.; Miao, X.W. Agricultural Bio-Environmental Engineering; China Agricultural Press: Beijing, China, 2005. [Google Scholar]

- Guo, E.G.; Wang, C.; Qi, G.F.; Cai, Y. Effects of typical weather in northern regions on atmospheric particulate matter in urban forests. China Environ. Sci. 2013, 33, 1185–1198. [Google Scholar]

- Li, Y.M.; Li, Y.X.; Yue, X.; Liu, X.A.; Li, T.L. Experiment on heat storage and release performance of water-based energy-saving solar greenhouse. J. Shenyang Agric. Univ. 2021, 52, 306–313. [Google Scholar]

- Li, S.J. Facility Horticulture; China Agricultural University Press: Beijing, China, 2002. [Google Scholar]

- Bao, E.C. Research on the Heat Transfer Characteristics of the Active Heat Storage Cycle System of the Fabricated Solar Greenhouse. Ph.D. Thesis, Northwest A&F University, Xianyang, China, 2018. [Google Scholar]

- Zhou, B.; Zhang, Y.; Fang, H.; Yang, Q.C.; Ao, H.D. Design and performance test of light and simple prefabricated solar greenhouse with heating and dehumidification system. Chin. J. Agric. Eng. 2016, 32, 226–232. [Google Scholar]

- Zhang, Y.; Xu, Y.J.; Chen, Y.; Zhang, K.X.; Ni, X.Y. Test of heat storage and release performance of new phase change material and its application in greenhouse. Trans. Chin. Soc. Agric. Eng. 2021, 37, 218–226. [Google Scholar]

- Wu, G.F.; Huang, H.Y.; Sun, E.H.; Xu, Y.D.; Chen, F.H.; Chang, Z.Z. Insulation performance of solar greenhouse with different wall materials. J. Jiangsu Agric. Sci. 2015, 31, 441–448. [Google Scholar]

- Meng, L.L.; Bao, E.C.; Xia, L.R.; Zou, Z.R.; Qi, C.L. Performance test analysis of different new solar greenhouse structures in northern Jiangsu Province. Jiangsu Agric. Sci. 2020, 48, 238–244. [Google Scholar]

| Performance Parameter | Sunny Heat Storage Stage | Sunny Day Exothermic Phase | Cloudy Exothermic Phase | |||

|---|---|---|---|---|---|---|

| SG | PG | SG | PG | SG | PG | |

| Active heat transfer/MJ | 56.38 | 47.25 | −15.10 | −14.37 | −29.81 | −27.87 |

| Passive heat transfer/MJ | 408.49 | 216.91 | −95.34 | −47.23 | −25.01 | −19.92 |

| General biography Heat/MJ | 464.87 | 264.16 | −110.44 | −61.60 | −54.82 | −46.89 |

| Proportion of active heat transfer | 0.12 | 0.14 | 0.23 | 0.23 | 0.54 | 0.59 |

| Date | Weather | Temperature/°C |

|---|---|---|

| 30 January 2021 | Cloudy | −4~12 |

| 31 January 2021 | Cloudy | −3~10 |

| 1 February 2021 | Sunny day | −4~13 |

| 2 February 2021 | Sunny day | −5~8 |

| 3 February 2021 | Cloudy | −2~14 |

| 4 February 2021 | Cloudy day/Cloudy | −2~7 |

| 5 February 2021 | Sunny day/Cloudy | −3~16 |

| 6 February 2021 | Sunny day/Cloudy | −2~17 |

| 7 February 2021 | Cloudy/Sunny day | −1~12 |

| 8 February 2021 | Sunny day | −2~12 |

| 9 February 2021 | Cloudy/Sunny day | −2~13 |

| 10 February 2021 | Sunny day/Cloudy | −1~15 |

| 11 February 2021 | Cloudy/Sunny day | −1~14 |

| 12 February 2021 | Sunny day/Cloudy | −1~17 |

| 13 February 2021 | Rainy day/Sunny day | −3~11 |

| 14 February 2021 | Sunny day/Cloudy | 0~16 |

| 15 February 2021 | Cloudy day/Cloudy | −2~11 |

| 16 February 2021 | Sunny day | −3~16 |

| 17 February 2021 | Cloudy day | −2~14 |

| 18 February 2021 | Cloudy | 1~16 |

| 19 February 2021 | Sunny day | 1~20 |

| 20 February 2021 | Sunny day | 2~21 |

| 21 February 2021 | Sunny day/Cloudy | 3~23 |

| 22 February 2021 | Sunny day/Cloudy | 5~19 |

| 23 February 2021 | Sunny day/Cloudy | 5~19 |

| 24 February 2021 | Rain and snow/Cloudy day | 0~7 |

| 25 February 2021 | Cloudy day | 0~6 |

| 26 February 2021 | Cloudy day | 0~9 |

| 27 February 2021 | Cloudy day | 1~11 |

| 28 February 2021 | Rainy day | 1~5 |

| Parameters | SG | PG |

|---|---|---|

| Average minimum air temperature/°C | 12.12 | 12.52 |

| Average maximum air temperature/°C | 32.38 | 32.32 |

| Average daily air temperature/°C | 18.47 | 18.47 |

| Average daytime temperature (09:00–17:00)/°C | 24.40 | 25.26 |

| Average night air temperature (17:00–next 09:00)/°C | 15.51 | 15.07 |

| Number of days with minimum temperature ≤ 8 °C/d | 21 | 18 |

| Number of days with minimum temperature ≤ 5 °C/d | 0 | 0 |

| Number of days with maximum temperature ≥ 25 °C/d | 21 | 22 |

| Number of days with average daytime temperature (09:00–17:00) ≥ 18 °C/d | 22 | 22 |

| Module Type | Inlet Air | Outlet Air | ||

|---|---|---|---|---|

| Temperature/°C | Relative Humidity/% | Temperature/°C | Relative Humidity/% | |

| SG | 33.18 ± 0.80 | 38.17 ± 10.44 | 24.94 ± 0.20 | 47.63 ± 1.24 |

| PG | 37.14 ± 1.57 * | 26.61 ± 6.36 | 29.07 ± 0.81 ** | 43.22 ± 8.95 |

| Module Type | Inlet Air | Outlet Air | ||

|---|---|---|---|---|

| Temperature/°C | Relative Humidity/% | Temperature/°C | Relative Humidity/% | |

| SG | 15.42 ± 0.07 *** | 100.00 ± 0.00 *** | 18.93 ± 0.12 *** | 74.97 ± 0.27 *** |

| PG | 13.65 ± 0.36 | 87.51 ± 0.69 | 17.96 ± 0.17 | 68.90 ± 0.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, D.; Cui, B.; Zhang, Y.; Wu, X.; Zou, Z.; Bao, E. Heat Transfer Characteristics of Modular Heat Storage Wall Solar Greenhouse Based on Active Heat Storage System. Appl. Sci. 2023, 13, 846. https://doi.org/10.3390/app13020846

Wu D, Cui B, Zhang Y, Wu X, Zou Z, Bao E. Heat Transfer Characteristics of Modular Heat Storage Wall Solar Greenhouse Based on Active Heat Storage System. Applied Sciences. 2023; 13(2):846. https://doi.org/10.3390/app13020846

Chicago/Turabian StyleWu, Delin, Bowen Cui, Yao Zhang, Xue Wu, Zhirong Zou, and Encai Bao. 2023. "Heat Transfer Characteristics of Modular Heat Storage Wall Solar Greenhouse Based on Active Heat Storage System" Applied Sciences 13, no. 2: 846. https://doi.org/10.3390/app13020846