A Novel 3D Topography Stitching Algorithm Based on Reflectance and Multimap

Abstract

:1. Introduction

- Manual: this can be performed by the user, using either transparency, region pointing or colocalization of overlapping maps. Most manual techniques rely on a visual inspection of all elementary maps, which is a slow process, highly dependent on the user, and prone to registration error. On the other hand, automatic stitching algorithms were historically created for images before topography. Many techniques were first developed for image stitching, also called panorama, and then adapted for topography, with various success rates. Automatic stitching is much faster than manual stitching: Montgomery et al. [9] explained that the manual stitching of a pair of maps can reach 30 min, while the automatic stitching would only take a few seconds. Thus, larger stitching can be performed in a shorter period of time with automatic stitching.

- Geometric: this type of stitching uses metadata, such as absolute or relative positions of elementary maps, to perform the registration [10,11]. This technique is fast, but its precision depends on the accuracy and robustness of the profilometer. Geometric stitching is the most used in commercial profilometers. It can also be used for prepositioning before finer registration with a more accurate technique [12].

- Fiducialization: these algorithms consist in marking a surface to perform registration on the markers measured in profilometry [13,14]. Markers on the surface can either be all unique or form a unique pattern all over the surface, but a unique solution must be found by the registration step. Markers can be generated, such as with Focused Ion Beam (FIB) [15], or already on the surface, such as structures in microfluidics [16] and semi-conductors. This technique can be useful for stitching small-scale topographies by adding distinctive features on the surface. This comes at the cost of surface integrity, and a need for post-processing to remove markers before analyzing the original surface.

- Global optimization of differences: this is generally described as a minimization of differences between overlapping regions of elementary maps, in the least-square method meaning. Chen et al. compute the correct displacements along x, y and z axes to apply on elementary maps in order to perform in-plane registration [17]. Global optimization of differences is more accurate than geometric stitching, but is more noise-sensitive, such as in flat or small-scale surfaces. Global optimization algorithms can be used for registration. Simulated annealing has been explained by van Laarhoven and Aarts [18] using an analogy with the annealing process of solids. A faster version of the simulated annealing optimization algorithm was presented by Szu and Hartley [19]. Simulated annealing has been tested by Kirkpatrick et al. [20] on various combinatory problems. Lensch et al. [21] proposed a silhouette-based registration and stitching algorithm using simulation annealing optimization. On the other hand, a genetic algorithm can also be used. Genetic algorithms have been explained by Holland [22], Forest [23], Davis [24] and Gendreau and Potvin [25] as algorithms inspired by the natural selection of genes, using generation of an initial population of solutions to test, selection of best solutions at each iteration, and merging and mutation of parameters to find an optimal solution to a problem. Local search with genetic algorithms has been detailed by Mühlenbein [26]. The use of genetic algorithms for image registration and stitching appeared in the works of Xu and Sun [27], Yetis et al. [28], Wang and Xu [29] and Prejmerean [30]. Another global optimization algorithm, called particle swarm algorithm, is presented by Kennedy and Eberhart [31], Shi and Eberhart [32], Bratton and Kennedy [33] (in an attempt to define a standard for particle swarm algorithm). An overview of the particle swarm algorithm and its variants was written by Poli et al. [34]. Another variant, called the radius particle swarm optimization, was introduced by Anantathanavit and Munlin [35]. A 3D surface stitching algorithm based on particle swarm optimization was used by Zhu et al. [36] for the stitching of cylindrical surfaces. Combining prepositioning and global optimization of differences reduces errors during registration and reduces run-time of stitching as less solutions need to be explored before finding the optimal solution for the registration.

- Computer vision-based: this is historically linked to image processing before surface stitching. The goal of these algorithms is to find the maximum number of similarities between two elementary maps. This category is divided into two subsets: direct methods and feature detection methods [37]. Direct methods use all pixels of overlapping regions to perform in-plane registration. Cross-correlation-based registration is an example of a direct method [12]. When the maximum of cross-correlation is found when moving overlapping maps, the correct displacement to apply to each map is determined for the registration [8]. On the other hand, feature detection methods first extract points-of-interests on a map, before performing the in-plane registration on such points, also called features. Many descriptors (algorithms to find features) exist. The first major one, developed by Lowe [38], is the SIFT (Scale-Invariant Feature Transform) descriptor [39,40,41]. This descriptor was originally used for object recognition, but its usefulness for automatic image stitching came soon after [42]. Many other feature descriptors were developed with either increased precision or robustness, or shorter run time for the extraction, such as SURF [43,44], U-SURF [45], Harris Corner [46], BRISK [47], FAST [48], MSER [49,50], Min Eigen [51], ORB [52] or KAZE [53]. Table 1 provides more details about each descriptor. Tareen and Saleem [54] compare feature descriptors (SIFT, SURF, KAZE, AKAZE (a variant of KAZE), ORB and BRISK) and their performance for image registration, such as scale invariability, feature extraction run time and registration accuracy. A RANSAC (RANdom SAmple Consensus) algorithm [41,55] is used in feature detection to extract the most relevant features before performing the registration. Computer vision-based stitching algorithms can be very precise but also costly in time. While feature detection method aims at reducing run time by selecting a subset of interesting features for the registration, the use of these is viable with sufficiently large maps to observe a shorter run time compared to direct methods if features can be extracted, such as for surface defects or large structures. However, computer vision-based algorithms, and especially feature detection algorithms, cannot find features of high quality, i.e., of high gradient, or might find too many features of low quality, which behave in the same way as noise for the registration algorithm.

2. Materials and Methods

2.1. Topographical Measurements

- A.

- Polymer rod abraded with FEPA grade 80 SiC abrasive paper: the aim is to verify that each tested algorithm can perform good quality stitching on a simple configuration. Succeeding in this test means that the test stitching algorithm has no major flaw, can handle non-measured points and can process elementary topographic maps with measurement uncertainties.

- B.

- Mirror-polished copper rod with indentations, dust and hair: a mirror-polished copper rod with indentations, dust and hair. As the surface is an Independent Multi-Physics (IMP) surface because of the presence of polishing, indentation, hair adhesion and dust adhesion, this is suitable to evaluate the flexibility of a stitching algorithm and its ability to perform a correct registration with various conditions within the same stitching. Moreover, two roughness scales (macroscopic and microscopic) are present and stitching algorithms should be able to register both at the same time.

- C.

- Arm skin replica: this test case evaluates the ability of a stitch algorithm to perform registration on macroscopic morphological structures. Moreover, as the polymer used for replication is more sensitive to thermal drift, this increases the difficulty of stitching as uncertainties might be amplified.

- D.

- Titanium alloy TA6V rod abraded with FEPA grade 80 SiC abrasive paper: as this surface contains a fractal pattern, the test evaluates the stitching algorithm ability to stitch a fractal pattern for many elementary maps, and to register microscopic morphological structures.

2.2. New Reflectance-Based Stitching Algorithm

2.2.1. Naive Reflectance Algorithm

2.2.2. Exhaustive Enumeration Reflectance Algorithm

2.2.3. Two-Step Reflectance Algorithm

2.3. Description of the Evaluation Criteria for Stitching Algorithms

2.3.1. Visual Inspection (Qualitative Criterion)

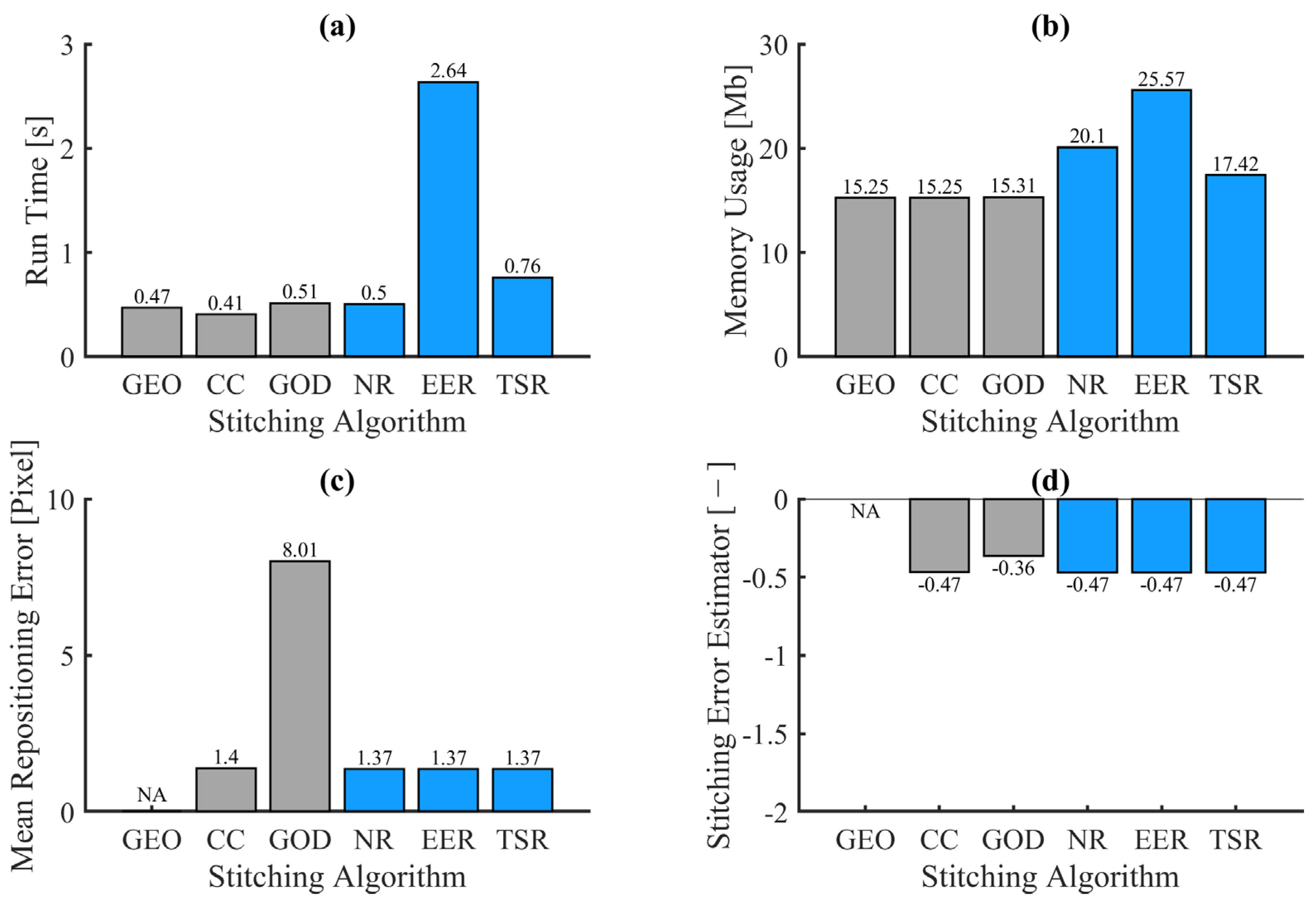

2.3.2. Stitching Run Time and Memory Usage (Quantitative Criteria)

2.3.3. Mean Repositioning Error (Quantitative Indicator)

2.3.4. Stitching Error Estimator (Quantitative Criterion)

3. Results

3.1. Test Case A—Polymer Abrasion

3.2. Test Case B—IMP Mirror-Polished Copper

3.3. Test Case C—Arm Skin Replica

3.4. Test Case D—Titanium Alloy Abrasion

3.5. Comparison between Test Cases

4. Discussion

- Minimization of run time;

- Minimization of memory usage;

- Minimization of mean repositioning error;

- Minimization of stitching error estimator.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GEO | GEOmetric stitching |

| CC | Cross-Correlation stitching |

| GOD | Global Optimization of Differences stitching |

| NR | Naive Reflectance stitching |

| EER | Exhaustive Enumeration Reflectance stitching |

| TSR | Two-Step Reflectance stitching |

| SEE | Stitching Error Estimator |

| SGL | Stitching Gain Lift plot |

References

- Brown, C.A.; Hansen, H.N.; Jiang, X.J.; Blateyron, F.; Berglund, J.; Senin, N.; Bartkowiak, T.; Dixon, B.; Le Goïc, G.; Quinsat, Y.; et al. Multiscale analyses and characterizations of surface topographies. CIRP Ann. 2018, 67, 839–862. [Google Scholar] [CrossRef]

- Wyant, J.C.; Schmit, J. Large field of view, high spatial resolution, surface measurements. Int. J. Mach. Tools Manuf. 1998, 38, 691–698. [Google Scholar] [CrossRef]

- Jansen, M.; Schellekens, P.; Haitjema, H. Development of a double sided stitching interferometer for wafer characterization. CIRP Ann. 2006, 55, 555–558. [Google Scholar] [CrossRef]

- Guibert, R.; Hanafi, S.; Deltombe, R.; Bigerelle, M.; Brown, C.A. Comparison of three multiscale methods for topographic analyses. Surf. Topogr. Metrol. Prop. 2020, 8, 024002. [Google Scholar] [CrossRef]

- Mironova, A.; Robache, F.; Deltombe, R.; Guibert, R.; Nys, L.; Bigerelle, M. Digital Cultural Heritage Preservation in Art Painting: A Surface Roughness Approach to the Brush Strokes. Sensors 2020, 20, 6269. [Google Scholar] [CrossRef]

- ISO 25178-2; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2021.

- Deltombe, R.; Kubiak, K.J.; Bigerelle, M. How to select the most relevant 3D roughness parameters of a surface: Relevance of 3D roughness parameters. Scanning 2014, 36, 150–160. [Google Scholar] [CrossRef] [Green Version]

- Marinello, F.; Bariani, P.; Chiffre, L.D.; Hansen, H.N. Development and analysis of a software tool for stitching three-dimensional surface topography data sets. Meas. Sci. Technol. 2007, 18, 1404–1412. [Google Scholar] [CrossRef]

- Montgomery, P.C.; Benatmane, A.; Fogarassy, E.; Ponpon, J.P. Large area, high resolution analysis of surface roughness of semiconductors using interference microscopy. Mater. Sci. Eng. B 2002, 91–92, 79–82. [Google Scholar] [CrossRef]

- Dong, B.; Xiao, W.; Pan, F.; Che, L. High-precision spherical subaperture stitching interferometry based on digital holography. Opt. Lasers Eng. 2018, 110, 132–140. [Google Scholar] [CrossRef]

- King, C.W.; Bibby, M. Development of a Metrology Workstation for Full-aperture and Sub-aperture Stitching Measurements. Procedia CIRP 2014, 13, 359–364. [Google Scholar] [CrossRef]

- Paul, P.; Knoll, A.W.; Holzner, F.; Duerig, U. Field stitching in thermal probe lithography by means of surface roughness correlation. Nanotechnology 2012, 23, 385307. [Google Scholar] [CrossRef] [PubMed]

- King, C. A New Approach to Stitching Optical Metrology Data; University of London: London, UK, 2008. [Google Scholar]

- Kammers, A.D.; Daly, S. Small-scale patterning methods for digital image correlation under scanning electron microscopy. Meas. Sci. Technol. 2011, 22, 125501. [Google Scholar] [CrossRef]

- Rust, M.A.; Todd, R.I. High Resolution Surface Studies of Superplastic Deformation. Mater. Sci. Forum 2007, 551–552, 615–620. [Google Scholar] [CrossRef]

- Xu, Z.; Li, S.; Burns, D.J.; Shilpiekandula, V.; Taylor, H.K.; Yoon, S.F.; Youcef-Toumi, K.; Reading, I.; Fang, Z.; Zhao, J.; et al. Three-dimensional profile stitching based on the fiducial markers for microfluidic devices. Opt. Commun. 2009, 282, 493–499. [Google Scholar] [CrossRef]

- Chen, S.; Xue, S.; Wang, G.; Tian, Y. Subaperture stitching algorithms: A comparison. Opt. Commun. 2017, 390, 61–71. [Google Scholar] [CrossRef]

- van Laarhoven, P.J.M.; Aarts, E.H.L. Simulated annealing. In Simulated Annealing: Theory and Applications: Mathematics and Its Applications, vol 37; Springer: Dordrecht, The Netherlands, 1987; pp. 7–15. [Google Scholar] [CrossRef]

- Szu, H.; Hartley, R. Fast simulated annealing. Phys. Lett. A 1987, 122, 157–162. [Google Scholar] [CrossRef]

- Kirkpatrick, S.; Gelatt, C.D.; Vecchi, M.P. Optimization by Simulated Annealing. Science 1983, 220, 671–680. [Google Scholar] [CrossRef]

- Lensch, H.P.A.; Heidrich, W.; Seidel, H.-P. A Silhouette-Based Algorithm for Texture Registration and Stitching. Graph. Model. 2001, 63, 245–262. [Google Scholar] [CrossRef] [Green Version]

- Holland, J.H. Genetic Algorithms. Sci. Am. 1992, 267, 66–73. [Google Scholar] [CrossRef]

- Forrest, S. Genetic Algorithms: Principles of Natural Selection Applied to Computation. Science 1993, 261, 872–878. [Google Scholar] [CrossRef] [Green Version]

- Davis, L. Handbook of Genetic Algorithms; Van Nostrand Reinhold: New York, NY, USA, 1991. [Google Scholar]

- Gendreau, M.; Potvin, J.-Y. (Eds.) Handbook of Metaheuristics. In International Series in Operations Research & Management Science, 2nd ed.; Springer: New York, NY, USA, 2010; ISBN 978-1-4419-1663-1. [Google Scholar]

- Mühlenbein, H. Genetic algorithms. In Local Search in Combinatorial Optimization; Aarts, E., Lenstra, J.K., Eds.; Princeton University Press: Princeton, NJ, USA, 2003; pp. 137–172. [Google Scholar]

- Xu, Y.; Sun, C. Image Stitching Method Based on Genetic Algorithm. Adv. Eng. 2017, 126, 7. [Google Scholar]

- Yetis, H.; Baygin, M.; Karakose, M. A New Micro Genetic Algorithm Based Image Stitching Approach for Camera Arrays at Production Lines. JOIG 2017, 5, 20–24. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Xu, L. A Global Optimized Registration Algorithm for Image Stitching. In Proceedings of the 2008 Congress on Image and Signal Processing, Sanya, China, 27–30 May 2008; Volume 3, pp. 525–529. [Google Scholar]

- Prejmerean, V. The Stitching of Images. In Proceedings of the 2006 IEEE International Conference on Automation, Quality and Testing, Robotics, Cluj-Napoca, Romania, 25–28 May 2006; Volume 2, pp. 386–391. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95—International Conference on Neural Networks, Perth, Australia, 27 November–1 December 1995; Volume 4, pp. 1942–1948. [Google Scholar]

- Shi, Y.; Eberhart, R.C. Empirical study of particle swarm optimization. In Proceedings of the 1999 Congress on Evolutionary Computation-CEC99 (Cat. No. 99TH8406), Washington, DC, USA, 6–9 July 1999; Volume 3, pp. 1945–1950. [Google Scholar]

- Bratton, D.; Kennedy, J. Defining a Standard for Particle Swarm Optimization. In Proceedings of the 2007 IEEE Swarm Intelligence Symposium, Honolulu, HI, USA, 1–5 April 2007; pp. 120–127. [Google Scholar]

- Poli, R.; Kennedy, J.; Blackwell, T. Particle swarm optimization: An overview. Swarm Intell. 2007, 1, 33–57. [Google Scholar] [CrossRef]

- Anantathanavit, M.; Munlin, M. Radius Particle Swarm Optimization. In Proceedings of the 2013 International Computer Science and Engineering Conference (ICSEC), Nakhonpathom, Thailand, 4–6 September 2013; pp. 126–130. [Google Scholar]

- Zhu, F.; Guo, P.; Chen, X. A sub-aperture stitching algorithm for cylindrical surfaces. In Proceedings of the 9th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Advanced Optical Manufacturing Technologies, Chengdu, China, 16 January 2019; Volume 10838, p. 1083805. [Google Scholar]

- Agier, R. Recalage de Groupes D’Images Médicales 3D Par Extraction de Points D’Intérêt. Ph.D. Thesis, Université de Lyon, Lyon, France, 2017. [Google Scholar]

- Lowe, D.G. Object recognition from local scale-invariant features. In Proceedings of the Seventh IEEE International Conference on Computer Vision, Kerkyra, Greece, 20–27 September 1999; Volume 2, pp. 1150–1157. [Google Scholar]

- Brown, M.; Lowe, D. Invariant Features from Interest Point Groups. In Proceedings of the British Machine Vision Conference 2002, Cardiff, UK, 2–5 September 2002; pp. 23.1–23.10. [Google Scholar]

- Brown, M.; Lowe, D.G. Recognising panoramas. In Proceedings of the Ninth IEEE International Conference on Computer Vision, Nice, France, 13–16 October 2003; Volume 2, pp. 1218–1225. [Google Scholar]

- Moretti, M.; Gambucci, G.; Leach, R.K.; Senin, N. Assessment of surface topography modifications through feature-based registration of areal topography data. Surf. Topogr. Metrol. Prop. 2019, 7, 025003. [Google Scholar] [CrossRef]

- Brown, M.; Lowe, D.G. Automatic Panoramic Image Stitching using Invariant Features. Int. J. Comput. Vis. 2007, 74, 59–73. [Google Scholar] [CrossRef] [Green Version]

- Bay, H.; Tuytelaars, T.; Van Gool, L. Surf: Speeded up robust features. In Proceedings of the European Conference on Computer Vision, Graz, Austria, 7–13 May 2006; pp. 404–417. [Google Scholar]

- Li, L.; Liu, Q.; Huang, W. Robust subaperture stitching method based on three-dimensional surface data matching. OE 2019, 58, 034103. [Google Scholar] [CrossRef]

- Valgren, C.; Lilienthal, A. Sift, Surf and Seasons: Long-term Outdoor Localization Using Local Features. In Proceedings of the 3rd European Conference on Mobile Robots, ECMR’07, Freiburg, Germany, 19–21 September 2007. [Google Scholar]

- Harris, C.; Stephens, M. A combined corner and edge detector. In Proceedings of the Fourth Alvey Vision Conference, Manchester, UK, 31 August–2 September 1988; pp. 147–152. [Google Scholar]

- Leutenegger, S.; Chli, M.; Siegwart, R.Y. BRISK: Binary Robust invariant scalable keypoints. In Proceedings of the 2011 International Conference on Computer Vision, Barcelona, Spain, 6–13 November 2011; pp. 2548–2555. [Google Scholar]

- Rosten, E.; Drummond, T. Fusing Points and Lines for High Performance Tracking. In Proceedings of the International Conference on Computer Vision, Beijing, China, 17–21 October 2005; pp. 1508–1515. [Google Scholar]

- Matas, J.; Chum, O.; Urban, M.; Pajdla, T. Robust wide-baseline stereo from maximally stable extremal regions. Image Vis. Comput. 2004, 22, 761–767. [Google Scholar] [CrossRef]

- Obdržálek, D.; Basovník, S.; Mach, L.; Mikulík, A. Detecting Scene Elements Using Maximally Stable Colour Regions. In Research and Education in Robotics-EUROBOT 2009; Communications in Computer and Information Science; Gottscheber, A., Obdržálek, D., Schmidt, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; Volume 82, pp. 107–115. ISBN 978-3-642-16369-2. [Google Scholar]

- Shi, J. Good features to track. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition CVPR-94, Seattle, WA, USA, 21–23 June 1994; pp. 593–600. [Google Scholar]

- Rublee, E.; Rabaud, V.; Konolige, K.; Bradski, G. ORB: An efficient alternative to SIFT or SURF. In Proceedings of the 2011 International Conference on Computer Vision, Barcelona, Spain, 6–13 November 2011; pp. 2564–2571. [Google Scholar]

- Alcantarilla, P.F.; Bartoli, A.; Davison, A.J. KAZE Features. In Proceedings of the Computer Vision–ECCV 2012; Fitzgibbon, A., Lazebnik, S., Perona, P., Sato, Y., Schmid, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 214–227. [Google Scholar]

- Tareen, S.A.K.; Saleem, Z. A comparative analysis of SIFT, SURF, KAZE, AKAZE, ORB, and BRISK. In Proceedings of the 2018 International Conference on Computing, Mathematics and Engineering Technologies (iCoMET), Sukkur, Pakistan, 3–4 March 2018; pp. 1–10. [Google Scholar]

- Juan, L.; Oubong, G. SURF applied in panorama image stitching. In Proceedings of the 2010 2nd International Conference on Image Processing Theory, Tools and Applications, Paris, France, 7–10 July 2010; pp. 495–499. [Google Scholar]

- Phong, B.T. Illumination for computer generated pictures. Commun. ACM 1975, 18, 311–317. [Google Scholar] [CrossRef] [Green Version]

- Lemesle, J.; Robache, F.; Le Goic, G.; Mansouri, A.; Brown, C.A.; Bigerelle, M. Surface Reflectance: An Optical Method for Multiscale Curvature Characterization of Wear on Ceramic—Metal Composites. Materials 2020, 13, 1024. [Google Scholar] [CrossRef] [Green Version]

- Yan, L.; Luo, W.; Yan, G.; Wang, X.; Zhang, H.; Chao, L.; Ma, D.; Tang, X. Subaperture stitching testing for fine flat mirrors with large apertures using an orthonormal polynomial fitting algorithm. Opt. Lasers Eng. 2019, 120, 49–58. [Google Scholar] [CrossRef]

- Gao, F.; Jiang, Z.; Zhao, Z.; Li, B. Measurement of aspheric surface combining point diffraction interferometry and annular subaperture stitching. Opt. Eng. 2015, 54, 014102. [Google Scholar] [CrossRef]

- Bariani, P. Dimensional Metrology for Microtechnology; Technical University of Denmark: Kongens Lyngby, Denmark, 2005. [Google Scholar]

| Feature Descriptor | Descriptor Full Name | References |

|---|---|---|

| SIFT | Scale-Invariant Feature Transform | [38,39,40,41,42] |

| SURF | Speeded-Up Robust Features | [43,44] |

| U-SURF | U-Speeded-Up Robust Features | [45] |

| Harris Corner | Harris Corner | [46] |

| BRISK | Binary Robust Invariant Scalable Keypoints | [47] |

| FAST | FAST | [48] |

| MSER | Maximally Stable Extremal Regions | [49,50] |

| Min Eigen | Minimum Eigenvalue | [51] |

| ORB | Oriented FAST and Rotated BRIEF | [52] |

| KAZE | KAZE (Reference to the word “Wind” in Japanese) | [53] |

| Test Case ID | Stitching Size [X × Y Pixels Per Elementary Map] | Measurement Apparatus | Objective Lens (X-Y Lateral Resolutions [µm]) | Roughness Scales |

|---|---|---|---|---|

| A | 2 × 2 [640 × 480] | Interferometer, ZygoTM NewView 7300 | ×50 (0.219 × 0.219) | Mesoscopic |

| B | 3 × 3 [2040 × 2040] | Focus variation microscope, AliconaTM Portable | ×10 (0.999 × 0.999) | Macroscopic and Microscopic |

| C | 5 × 5 [1840 × 1840] | Focus variation microscope, AliconaTM InfiniteFocus G5 | ×20 (0.436 × 0.436) | Macroscopic |

| D | 10 × 13 [640 × 480] | Interferometer, BrukerTM ContourGT | ×115 (0.198 × 0.198) | Microscopic |

| Elementary Topography | Indentation | Abrasion |

|---|---|---|

| X × Y Dimensions (pixels) | 2040 × 2040 | 480 × 640 |

| Exhaustive Enumeration Run Time (s) | 97.3 | 6.52 |

| Two-Step Run Time (s) | 16.3 | 0.89 |

| Speed Up Ratio | 5.96 | 7.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lemesle, J.; Guibert, R.; Bigerelle, M. A Novel 3D Topography Stitching Algorithm Based on Reflectance and Multimap. Appl. Sci. 2023, 13, 857. https://doi.org/10.3390/app13020857

Lemesle J, Guibert R, Bigerelle M. A Novel 3D Topography Stitching Algorithm Based on Reflectance and Multimap. Applied Sciences. 2023; 13(2):857. https://doi.org/10.3390/app13020857

Chicago/Turabian StyleLemesle, Julie, Robin Guibert, and Maxence Bigerelle. 2023. "A Novel 3D Topography Stitching Algorithm Based on Reflectance and Multimap" Applied Sciences 13, no. 2: 857. https://doi.org/10.3390/app13020857