1. Introduction

The vibrational characteristics of structures represent one of the key design targets in mechanical, aerospace, and civil engineering, as well as in many other domains. Typically, the dynamic behavior is described by a linear model which relates time-varying input forces on the structure of interest to its (also time-varying) displacements [

1]. Most often, modal models which are based on the so-called modal parameters eigenfrequencies, mode shapes, and modal damping are used due to their intuitive physical interpretability [

2]. In this context, one also speaks of poles containing the combined information of eigenfrequency and modal damping. Building up and evaluating these models is, depending on the chosen approach, either called computational or experimental modal analysis (EMA). Even though simulations have improved in recent years, real-world experiments are still needed in cases in which high accuracy is essential, or in order to calibrate the computational analyses, as, for example, demonstrated by Ellinger and Zaeh [

3]. EMA is typically performed under laboratory conditions [

4], which may not be sufficient for capturing the vibrational characteristics of a generally nonlinear system using the linear modal model. In contrast, operational modal analysis (OMA) is performed under operational conditions, an approach which is typically more accurate but comes with additional challenges such as only partial or missing input force measurements [

4].

Given a set of data, a variety of methods exists for estimating the modal parameters of a system. In case the modes are identified one at a time rather than all at once, they are called single-degree-of-freedom methods [

5]. Popular examples include the peak-picking, the circle-fit, and the line-fit methods [

5], as well as the two-stage least squares identification presented by Altintas [

6]. When dealing with closely spaced modes, so-called multi-degree-of-freedom (MDOF) methods, which consider multiple modes simultaneously, typically perform better [

5]. This can, for example, be done by solving a nonlinear optimization problem [

5,

6], the global rational fraction polynomial method [

5], the least squares rational function (LSRF) method [

7], global singular value decomposition (SVD) [

5], the least squares complex exponential (LSCE) method [

8], the least squares complex frequency-domain (LSCF) method or its polyreference version, the so called "PolyMAX" method [

9], or various stochastic subspace identification (SSI) methods [

10]. Depending on whether they operate on time series or frequency information, these algorithms can either be clustered as time-domain (e.g., SSI or the LSCE method) or frequency-domain (e.g., the circle-fit method, global SVD, or the LSCF method) approaches.

The algorithms themselves are beyond the scope of this paper. However, all approaches have in common that the model order must be set, which directly relates to the question of how many modes are to be identified. Although strategies exist for determining a suitable model order based on the measured data, it is more common to first considerably overestimate the number of modes and identify modal parameters for several model orders and, second, to select an appropriate number of modes based on the combined information [

4,

5]. This approach helps to reduce biases in the identified modes [

4]. However, when proceeding in this way, many spurious or mathematical modes occur which must be separated from the true, physical modes. The central element of this strategy is the so-called stabilization diagram, which displays the identified modes in a model order over frequency plot [

4].

In the past, selecting appropriate modes from the stabilization diagram has required a high level of user interaction and expert knowledge [

11,

12]. To simplify the process, Scionti et al. [

13] first made use of several methods to eliminate spurious modes applicable to state spaced models and, second, introduced a set of rules to mimic the selection of modes by the user. The rules depend on several parameters, for which default values were set. They found that the proposed approach performs well on in-flight flutter data for an aircraft. A short review on such mode separation rules, which, in the end, emulate the actions and decisions of an experienced user, was provided by van der Auweraer and Peeters [

14]. The latter further mentioned in-flight data analysis and structural health monitoring as possible applications. Their work was extended by Lau et al. [

1], who also referred to Scionti et al. [

13] by developing a rule-based automatic modal parameter selection approach. Peer group comparisons between modal analysis novices and experts on two comprehensive data sets proved that the approach leads to skill-independent results and an overall productivity gain of 50%.

A different approach was followed by Scionti and Lanslots [

11], who compared several Fuzzy c-means clustering techniques with and without an additional genetic algorithm (GA) for the initialization of finding pole candidates. It was found that the Gustafson–Kessel algorithm with initial values from a GA resulted in the best clusters of poles. Some clusters were immediately discarded based on their contribution ratio, their compactness measures, and corresponding thresholds. For each remaining cluster, the pole closest to its center was chosen as the final result, which was positively evaluated by comparing it to the poles found by experts.

All of the works presented still rely on user-defined thresholds and are thus not fully automated [

12]. This drawback was overcome by Reynders et al. [

12], who, in addition to a very comprehensive literature review, proposed a three-stage approach for fully automated modal parameter estimation. First, all modes were classified as either spurious or potentially stable by eleven soft and three hard validation criteria. Second, the remaining poles were hierarchically clustered to find similar modes and, finally, the mode with a modal damping closest to the median damping of the corresponding cluster was selected. The approach was successfully tested on several data sets. However, the results were only benchmarked against modal parameters retrieved by a manual analysis. A comparison of the modal model with the original data set was not performed. A very similar strategy was followed by Neu et al. [

15]. However, the latter allowed larger damping values, used different features representing the soft validation criteria, and selected the final poles by averaging all pole candidates per cluster. Additionally, they examined the influence of the maximum model order and found that their approach was less sensitive to it than that by Reynders et al. [

12]. The method was applied to an OMA data set and successfully compared to EMA and finite element analysis results. Mugnaini et al. [

16] proposed slight adaptations to the approach of Neu et al. [

15] and proved their effectiveness in an ablation study for a helicopter blade data set. Additionally, the eigenfrequency identification was validated on a simulated data set. Again, no validation against the original data set was conducted in Neu et al. [

15] and Mugnaini et al. [

16].

It can be concluded that a consensus has been formed in the state-of-the-art regarding the basic approach of automatically extracting modal parameters [

12,

15,

16]. However, it was not evaluated how well the identified modal model replicates the original data set using, for example, the frequency response assurance criterion (FRAC), nor was this the focus of the modal parameter extraction. Furthermore, the parameters which required user input in earlier approaches [

1,

11,

13,

14] were replaced by metrics performed on the input data set [

12,

15,

16], which is believed to unnecessarily restrict the solution space for the final modal parameters. The present paper presents an alternative approach, in which Bayesian optimization is used to find the optimal values of any required hyperparameters. The deviation between the identified modal model and the original data set is used as a cost function. This also ensures a high level of validity for the final modal model.

The remainder of this paper is structured as follows:

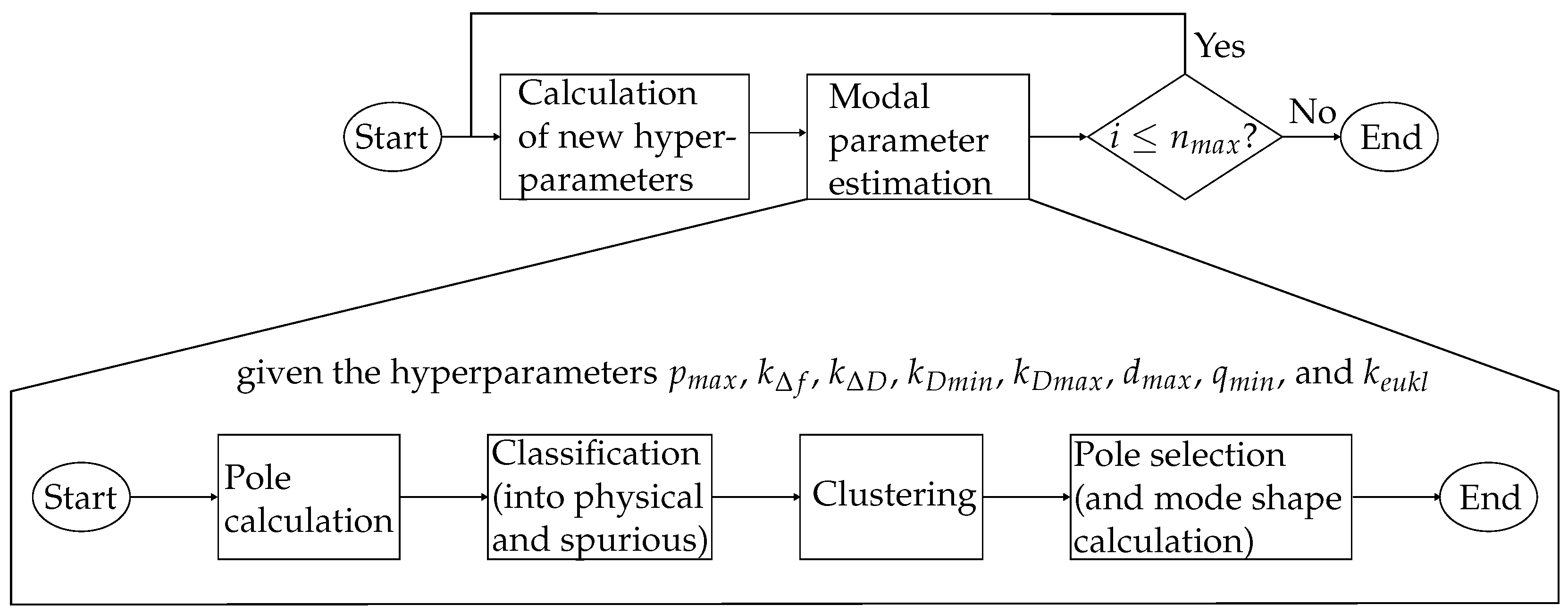

Section 2 presents the proposed approach in general. It will be shown how modal parameters are extracted based on a few hyperparameters, which will subsequently be optimized using a Bayesian optimization approach.

Section 3, on the one hand, validates the proposed approach on a synthetic test data set. On the other hand, modal parameters were extracted from input data measured on a machine tool. Additionally, the results from both data sets were benchmarked against the MATLAB

® function

modalfit. Last,

Section 4 summarizes the main content of the paper and offers an outlook to future research.

3. Application

In this section, the application of the approach presented in

Section 2 is described for two use cases: First, synthetic test data were simulated using a sixth-order MDOF oscillator model (see

Section 3.1). In this case, the ground truth values of the modal parameters were known per definition, and their estimated values could be directly compared to their reference values. Artificial noise was superimposed to show the robustness of the proposed approach. Second, data measured on a real-world machine tool test bench were used as input for the automated modal parameter estimation approach (see

Section 3.2). In both cases, the resulting modal parameters were benchmarked against the function

modalfit from the signal processing toolbox of the well-established numerical computation program MATLAB

®.

3.1. Synthetic Test Data

To test the proposed approach, an oscillator with six degrees of freedom (DOFs) was set up as shown in

Figure 4 and used for simulating synthetic reference input data. Using a time-domain simulation, six FRFs were calculated from an input force at the first mass

to the displacement at all DOFs. To demonstrate the robustness of the AutoEMA method, normal (Gaussian) noise with zero mean was superimposed to the respective outputs

. Additionally, the (damped) eigenvalue problem was solved, resulting in estimates for the mode shapes, the eigenfrequencies, and the modal damping ratios. These modal parameters are, in the following, regarded as ground truth values and to be estimated using both the MATLAB

® and the AutoEMA approach.

Regarding the AutoEMA approach,

Table 2 shows the value range constraining the hyperparameters of the modal parameter estimation in the Bayesian optimization process and their initial values. These boundaries were considered to be wide in order to keep the solution space as widely open as possible. Note that the minimum damping of a mode

was set to the lowest physically meaningful value of 0%, so it was excluded from the optimization in this case. Per definition, the regularization parameter

r cannot be optimized and was also fixed. However, the value

r of

has been found to be suitable for many data sets, including the one used herein and the real-world data shown in

Section 3.2. The initial values were chosen arbitrarily within the bounds, as the result of the Bayesian optimization was found to be widely insensitive. In total, 40 iterations, that is, evaluations of the cost function (see

Section 2.2), were made.

The same data were also fed into the MATLAB® function modalfit. It requires the number of modes to be determined as an input parameter. In this case, it was set to the true value of six modes, which was also identified automatically by the AutoEMA approach. The modalfit function has implemented both the LSCE and the LSRF algorithms. Here, the default LSCE method was used.

Figure 5 shows the (simulated) reference FRF from a force input

at the first DOF to the displacement

at the same DOF alongside the reconstructed FRFs from both the MATLAB

® and AutoEMA modal models. It can be seen that both approaches estimated the original FRF well despite the presence of noise. However, the AutoEMA approach slightly outperformed the MATLAB

® approach in the low frequency region up to 150

.

Figure 6 shows the conformance of the estimated mode shapes with the (simulated) reference data quantified by the modal assurance criterion (MAC) [

20], which is defined as

In this case, are mode shapes being compared, and, again, denotes the complex conjugation and the transpose of a vector . Similar to the FRAC, a value of 0% indicates no correlation at all, and a result of 100% states a perfect coincidence between the two mode shapes. It can be seen that both approaches estimated the reference mode shapes equally well with very high concordance.

To assess the accuracy of eigenfrequencies

, the natural frequency difference (NFD) criterion can be used [

21]:

By slightly adapting Equation (

6), a similar comparison can be made regarding the modal damping ratios

using the natural damping difference (NDD):

Both criteria indicate perfect coincidence with a value of 0% and increase with a rising difference between the damping ratios and eigenfrequencies to be compared, respectively.

Table 3 and

Table 4 show these criteria along with the absolute values for the synthetic data use case. Again, it can be seen that both approaches estimated the reference modal damping ratios and eigenfrequencies well with maximum deviations of

% and

% of the NFD and NDD, respectively.

3.2. Machine Tool Data

A second data set was acquired on a DMG DMC duo Block 55H machine tool in order to demonstrate the robustness and effectiveness of the proposed modal parameter extraction method (i.e., the AutoEMA method). As illustrated in

Figure 7, the machine tool consists of a machine tool bed and a workpiece table (WPT), enabling movement in the global

z-axis.

The machine tool’s vibrational response was measured at 17 nodes in all three spatial directions. Four Kistler

® triaxial accelerometers (two times type 8762A10 and two times type 8762A50) were used together with a National Instruments (NI)

® cDAQ-9198 rack with three type NI

®-9232 modules and one type NI

®-9234 module. The measurements were repeated for four WPT positions z

, z

, z

, and z

along the

z-axis with impulse hammer excitations in

x-,

y-, and

z-directions. The node points are shown in

Figure 7 and described in

Table 5. In particular, a corner of the machine tool bed (

) was chosen as the excitation node. For each WPT position, the data acquisition has resulted in 153 FRFs (17 nodes measured in three spatial directions for three excitation directions). The FRFs were calculated as the average of three hammer hits for a measurement duration of 4

with a sampling rate of 10,240

.

The approach presented in

Section 2 was applied for each WPT position using the same parameter bounds as in the synthetic data use case (see

Table 2). Because of the more complicated structure, the optimization was stopped after 100 iterations in this case.

Table 6 shows the final values of the hyperparameters (see

Table 1) for all considered WPT positions. It can be seen that most parameters have been estimated quite similarly over all WPT positions. However, some outliers exist as, for example, the maximum model order

for WPT position z

. The data set contained redundant measurements since, for each WPT position, three measurements for each DOF resulting from three different excitation directions had been made. It is believed that redundancy has supported the estimation of the eigenfrequencies and the modal damping ratios. However, the mode shape information was only extracted from measurements with an excitation in the

y-direction as the input force was the easiest to control in that direction, thus leading to the best mode shape estimations.

The same data were also fed into the MATLAB® modalfit function, which requires the number of modes being determined as an input parameter. In order to obtain comparable results, it was set to the same number which the AutoEMA approach has found. For this use case, no meaningful results could be produced with the LSCE algorithm, leaving only the LSRF method for the evaluations. It is noteworthy that the modal parameter estimation using the AutoEMA method took less than one minute on a laptop with four Intel® i7-7700HQ CPU cores, whereas a run of the LSRF algorithm required 22 and 48 on a simulation workstation with 24 Intel® Xeon® Gold 5220R CPU cores. As a result, the MATLAB® approach was only run for WPT position z.

Figure 8 shows the correlation between the mode shapes found by MATLAB

® and the proposed approach for the frequency range up to 300

, which was determined by the MAC. It can be seen that most modes were found by both methods, indicated by MAC values higher than 80%. However, some modes were only found by the AutoEMA method but not by the MATLAB

® function, and vice versa. Given that, as will be shown below, the match between the modal models and the input data was very high in both cases, this result indicates modes that were either not well observed or highly damped.

Figure 9 qualitatively illustrates the resulting match between the mean input FRFs and the reconstructed mean FRFs from the modal model for two WPT positions. It can be seen that there is a very high level of concordance between the input and fitted data for both positions for the AutoEMA approach, thus highlighting the validity of the model. However, there were higher deviations for the MATLAB

® approach at position

, especially in the high frequency region. This outcome was also confirmed by the mean FRAC values of

% for the AutoEMA FRF at position z

and

% for the MATLAB

® FRF, respectively. In general, even FRAC values of 70% are considered to be a good match [

22].

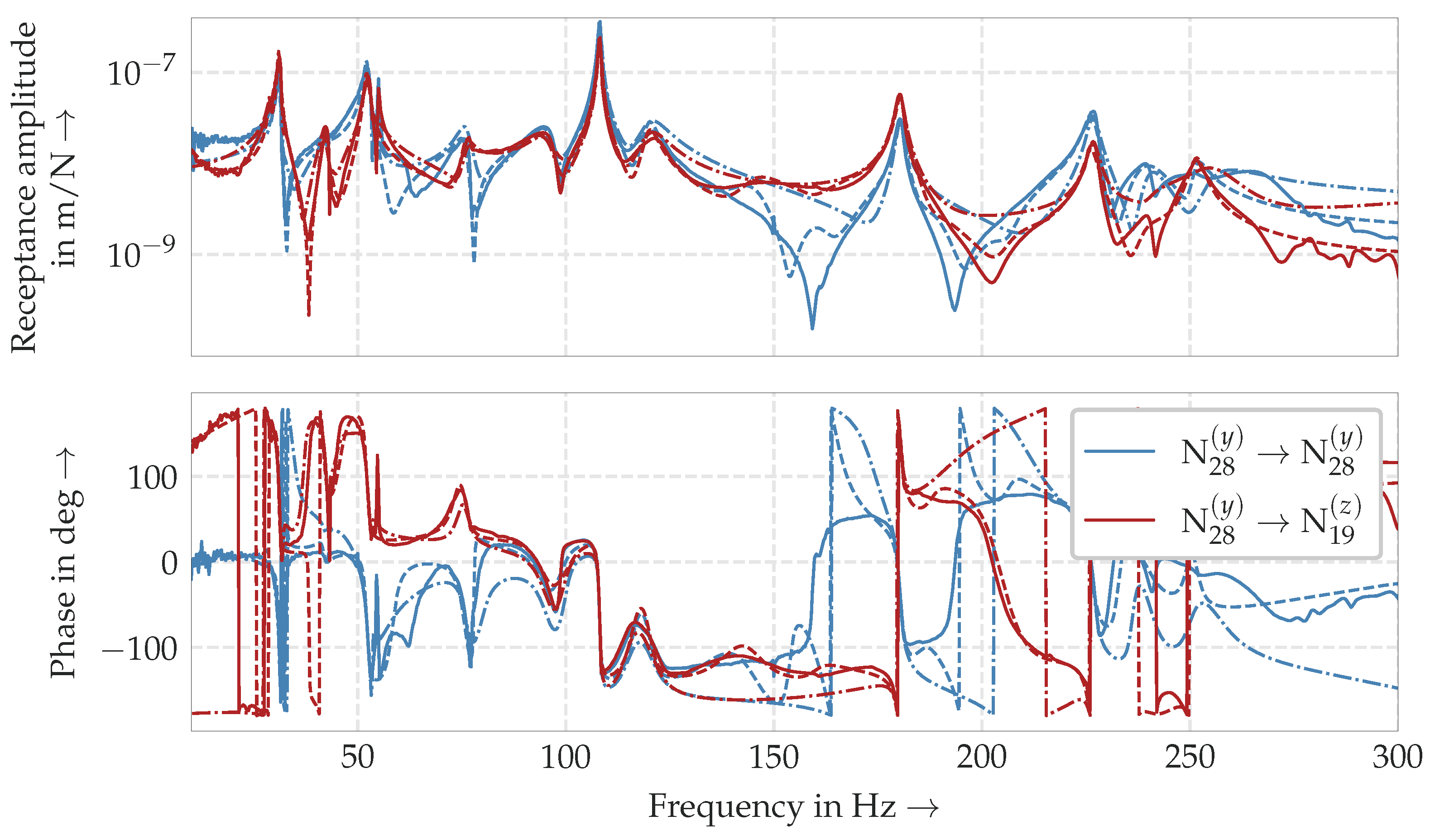

The same conclusion can be drawn by looking at the individual FRFs in

Figure 10. It can be seen that, for both approaches, the direct driving point FRF from a force at node

in the

y-direction to the measured displacement at the same node in the same coordinate direction and the FRF from a force at node

in the

y-direction to the measured deflection at one of the edges of the machine tool (node

) in

z-direction were approximated very well by the modal models. Regarding the AutoEMA approach, the same was also true for other FRFs, which is shown in

Table 7: Only for 10% of the measured FRFs at all WPT positions, the modal model leads to a fitted FRF with, measured by the FRAC value, less than

% concordance. However, the MATLAB

® approach on average approximates the input FRFs only with a match of

% and one-tenth of them even worse than with

% concordance.

Table 8 shows a comparison of eigenfrequencies estimated by the MATLAB

® and the AutoEMA approach for the machine tool data use case. It can be seen that both approaches estimate very similar eigenfrequencies with a maximum NFD (see Equation (

6)) of only

%. This holds especially true considering that even a mean relative eigenfrequency difference of

% is sufficient for many applications [

23]. However, the MATLAB

® approach seemed to generally estimate higher modal damping ratios with NDDs up to

%, as can be seen in

Table 9.

Table 10 and

Table 11 show the first eight identified eigenfrequencies and modal damping ratios using the AutoEMA method for WPT position z

, which is the one with the lowest number of identified eigenmodes (26 modes up to 300

). Similar modes at the other positions were found using the MAC [

24], and their eigenfrequencies and damping ratios are also listed. It can be seen that the modes 1 to 4 exhibited only a low level of dependency on the WPT position, whereas the eigenfrequency and modal damping ratios of modes 5 to 8 changed from position z

to position z

. This result can also be seen in the comparison of the mean measured and fitted FRFs in

Figure 9.