Digital Twin-Driven Framework for TBM Performance Prediction, Visualization, and Monitoring through Machine Learning

Abstract

:1. Introduction

2. Literature Review

2.1. The Origin of the Digital Twin

2.2. Machine Learning and Performance Prediction Applications

2.3. The Digital Twin Applications in the Product Lifecycle

2.4. Problem Statement and Objective

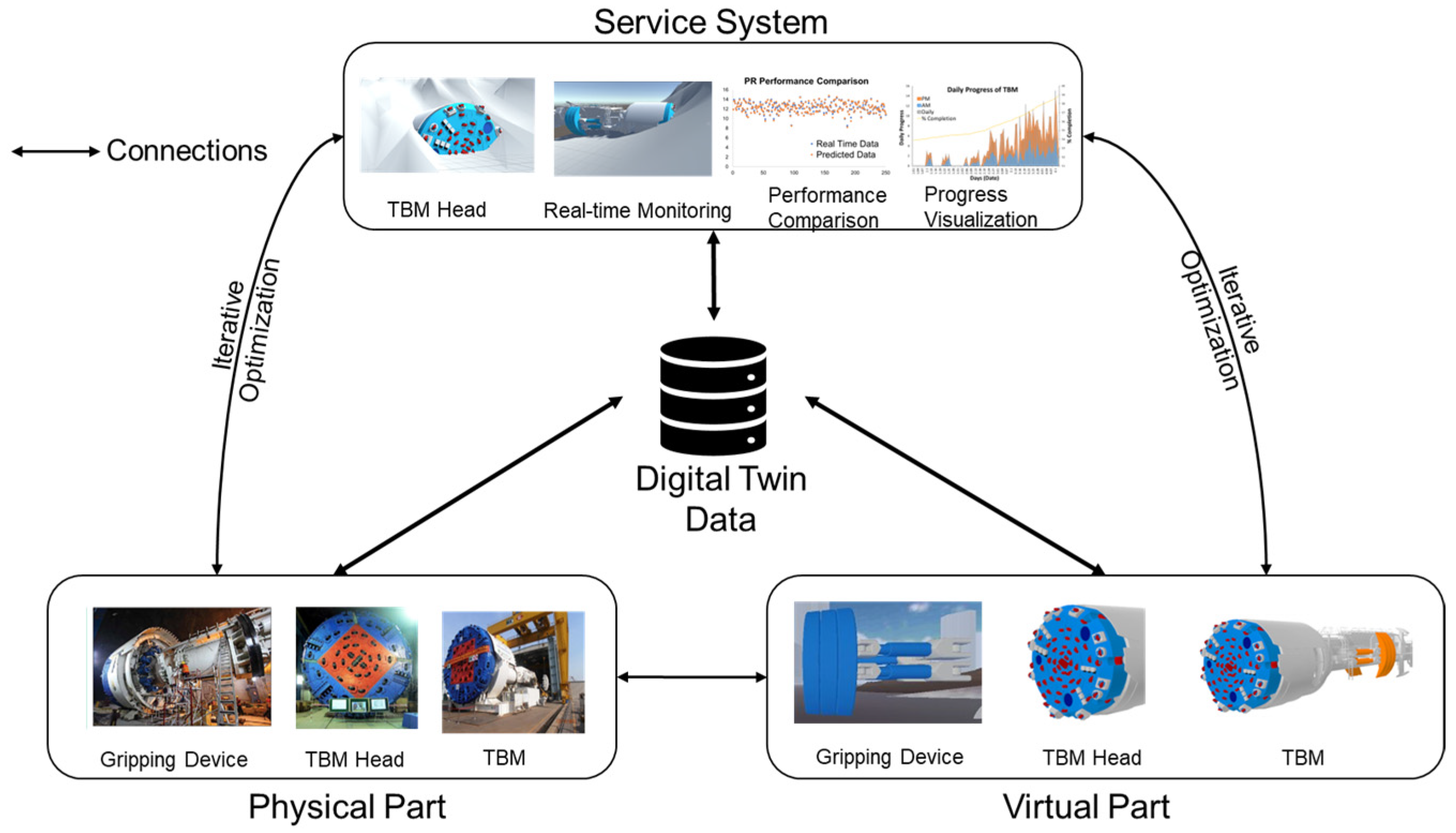

3. Digital Twin Framework for TBM Performance Visualization and Monitoring

3.1. TBM Digital Twin

3.2. TBM Digital Twin Structure

3.2.1. Digital Twin Physical Entities

3.2.2. Digital Twin Virtual Models

3.2.3. Digital Twin Data

3.2.4. Digital Twin Services

3.2.5. Digital Twin Connections

3.3. Digital Twin-Based Framework for TBM Performance Visualization and Monitoring Method

4. Digital Twin Modelling Methodology

4.1. Data Collection

4.2. Input Parameters

4.2.1. Machine Performance Parameters

4.2.2. Geological Rock Parameters

4.2.3. Data Normalization

4.3. TBM Twin Modelling

4.4. Model Training Algorithm

4.4.1. Support Vector Regression (SVR)

4.4.2. Artificial Neural Network (ANN)

4.4.3. Integrated SVR-ANN Model

4.5. Model Training

4.6. Model Performance Predictors

5. Theoretical Case Study, Results, and Discussion

5.1. Project Overview

5.2. Result and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial intelligence |

| AEC | Architecture, engineering, and construction |

| ANFIS | Adaptive neuro–fuzzy interference system |

| ANN | Artificial neural network |

| AR | Advance rate |

| BFGS | Broyden–Fletcher–Goldfarb–Shanno algorithm |

| CAD | Computer-aided design |

| DT | Digital twin |

| FS | Feature space |

| GMDH | Group modeling of data handling |

| ICA | Imperialist competitive algorithm |

| IoT | Internet of things |

| ML | Machine learning |

| MLP | Multilayer perceptron |

| NJHEP | Neelum Jhelum hydroelectric project |

| NASA | National aeronautics and space administration |

| O&M | Operation and maintenance |

| PR | Penetration rate |

| PSO | Particle swarm optimization |

| ReLU | Rectified linear unit |

| RMR | Rock mass rating |

| R2 | Coefficient of determination |

| RMSE | Root mean squared error |

| RPM | Revolutions per minute |

| RQD | Rock quality designation |

| SVM | Support vector machine |

| SVR | Support vector regression |

| TBM | Tunnel boring machine |

| UCS | Uniaxial compressive strength |

| UI | Utilization Index |

| VAF | Variance accounted for |

References

- Sharafat, A.; Khan, M.S.; Latif, K.; Seo, J. BIM-Based Tunnel Information Modeling Framework for Visualization, Management, and Simulation of Drill-and-Blast Tunneling Projects. J. Comput. Civ. Eng. 2021, 35, 04020068. [Google Scholar] [CrossRef]

- Mahdevari, S.; Shahriar, K.; Yagiz, S.; Akbarpour Shirazi, M. A Support Vector Regression Model for Predicting Tunnel Boring Machine Penetration Rates. Int. J. Rock Mech. Min. Sci. 2014, 72, 214–229. [Google Scholar] [CrossRef]

- Jung, J.-H.; Chung, H.; Kwon, Y.-S.; Lee, I.-M. An ANN to Predict Ground Condition Ahead of Tunnel Face Using TBM Operational Data. KSCE J. Civ. Eng. 2019, 23, 3200–3206. [Google Scholar] [CrossRef]

- Zhou, J.; Qiu, Y.; Zhu, S.; Armaghani, D.J.; Li, C.; Nguyen, H.; Yagiz, S. Optimization of Support Vector Machine through the Use of Metaheuristic Algorithms in Forecasting TBM Advance Rate. Eng. Appl. Artif. Intell. 2021, 97, 104015. [Google Scholar] [CrossRef]

- Sharafat, A.; Latif, K.; Park, S.; Seo, J. Risk Assessment of TBM Advanced Rate in the Difficult Ground Using Event Tree Analysis (ETA). In Proceedings of the KSCE, Virtual, 21–26 September 2021; pp. 39–40. [Google Scholar]

- Sharafat, A.; Tanoli, W.A.; Raptis, G.; Seo, J.W. Controlled Blasting in Underground Construction: A Case Study of a Tunnel Plug Demolition in the Neelum Jhelum Hydroelectric Project. Tunn. Undergr. Sp. Technol. 2019, 93, 103098. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Koopialipoor, M.; Marto, A.; Yagiz, S. Application of Several Optimization Techniques for Estimating TBM Advance Rate in Granitic Rocks. J. Rock Mech. Geotech. Eng. 2019, 11, 779–789. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Mohamad, E.T.; Narayanasamy, M.S.; Narita, N.; Yagiz, S. Development of Hybrid Intelligent Models for Predicting TBM Penetration Rate in Hard Rock Condition. Tunn. Undergr. Sp. Technol. 2017, 63, 29–43. [Google Scholar] [CrossRef]

- Latif, K.; Sharafat, A.; Seo, J. Predicting TBM Advanced Rate in Difficult Ground Conditions Based on the Artificial Neural Network Using Different Training Functions. In Proceedings of the KSCE, Virtual, 21–26 September 2021; pp. 23–24. [Google Scholar]

- Latif, K.; Sharafat, A.; Park, S.; Seo, J. Digital Twin-Based Hybrid Approach to Visualize the Performance of TBM. In Proceedings of the KSCE, Busan, Republic of Korea, 20 October 2022; pp. 3–4. [Google Scholar]

- Alvarez Grima, M.; Verhoef, P.N.W. Forecasting Rock Trencher Performance Using Fuzzy Logic. Int. J. Rock Mech. Min. Sci. 1999, 36, 413–432. [Google Scholar] [CrossRef]

- Alvarez Grima, M.; Bruines, P.A.; Verhoef, P.N.W. Modeling Tunnel Boring Machine Performance by Neuro-Fuzzy Methods. Tunn. Undergr. Sp. Technol. 2000, 15, 259–269. [Google Scholar] [CrossRef]

- Ghasemi, E.; Yagiz, S.; Ataei, M. Predicting Penetration Rate of Hard Rock Tunnel Boring Machine Using Fuzzy Logic. Bull. Eng. Geol. Environ. 2014, 73, 23–35. [Google Scholar] [CrossRef]

- Yagiz, S.; Karahan, H. Application of Various Optimization Techniques and Comparison of Their Performances for Predicting TBM Penetration Rate in Rock Mass. Int. J. Rock Mech. Min. Sci. 2015, 80, 308–315. [Google Scholar] [CrossRef]

- Jahed Armaghani, D.; Faradonbeh, R.S.; Momeni, E.; Fahimifar, A.; Tahir, M.M. Performance Prediction of Tunnel Boring Machine through Developing a Gene Expression Programming Equation. Eng. Comput. 2018, 34, 129–141. [Google Scholar] [CrossRef]

- Benardos, A.G.; Kaliampakos, D.C. Modelling TBM Performance with Artificial Neural Networks. Tunn. Undergr. Sp. Technol. 2004, 19, 597–605. [Google Scholar] [CrossRef]

- Zhou, C.; Ding, L.; Zhou, Y.; Zhang, H.; Skibniewski, M.J. Hybrid Support Vector Machine Optimization Model for Prediction of Energy Consumption of Cutter Head Drives in Shield Tunneling. J. Comput. Civ. Eng. 2019, 33, 04019019. [Google Scholar] [CrossRef]

- Afradi, A.; Ebrahimabadi, A.; Hallajian, T. Prediction of the Penetration Rate and Number of Consumed Disc Cutters of Tunnel Boring Machines (TBMs) Using Artificial Neural Network (ANN) and Support Vector Machine (SVM)—Case Study: Beheshtabad Water Conveyance Tunnel in Iran. Asian J. Water Environ. Pollut. 2019, 16, 49–57. [Google Scholar] [CrossRef]

- Afradi, A.; Ebrahimabadi, A.; Hallajian, T. Prediction of Tunnel Boring Machine Penetration Rate Using Ant Colony Optimization, Bee Colony Optimization and the Particle Swarm Optimization, Case Study: Sabzkooh Water Conveyance Tunnel. Min. Miner. Depos. 2020, 14, 75–84. [Google Scholar] [CrossRef]

- Yu, G.; Wang, Y.; Mao, Z.; Hu, M.; Sugumaran, V.; Wang, Y.K. A Digital Twin-Based Decision Analysis Framework for Operation and Maintenance of Tunnels. Tunn. Undergr. Sp. Technol. 2021, 116, 104125. [Google Scholar] [CrossRef]

- Bonitz, L.; Pugachev, A.; Arnold, M.; Janoske, U.; Hassfeld, S.; Abel, D.; Bicsak, A.; Mueller, C. “Digital Twin” Based Approach to Patient Specific Diagnosis and Therapy of OSA. Sleep Med. 2019, 64, S45. [Google Scholar] [CrossRef]

- Björnsson, B.; Borrebaeck, C.; Elander, N.; Gasslander, T.; Gawel, D.R.; Gustafsson, M.; Jörnsten, R.; Lee, E.J.; Li, X.; Lilja, S.; et al. Digital Twins to Personalize Medicine. Genome Med. 2020, 12, 4. [Google Scholar] [CrossRef]

- Terkaj, W.; Gaboardi, P.; Trevisan, C.; Tolio, T.; Urgo, M. A Digital Factory Platform for the Design of Roll Shop Plants. CIRP J. Manuf. Sci. Technol. 2019, 26, 88–93. [Google Scholar] [CrossRef]

- Urbina Coronado, P.D.; Lynn, R.; Louhichi, W.; Parto, M.; Wescoat, E.; Kurfess, T. Part Data Integration in the Shop Floor Digital Twin: Mobile and Cloud Technologies to Enable a Manufacturing Execution System. J. Manuf. Syst. 2018, 48, 25–33. [Google Scholar] [CrossRef]

- Zhuang, C.; Liu, J.; Xiong, H. Digital Twin-Based Smart Production Management and Control Framework for the Complex Product Assembly Shop-Floor. Int. J. Adv. Manuf. Technol. 2018, 96, 1149–1163. [Google Scholar] [CrossRef]

- Bilberg, A.; Malik, A.A. Digital Twin Driven Human–Robot Collaborative Assembly. CIRP Ann. 2019, 68, 499–502. [Google Scholar] [CrossRef]

- Coraddu, A.; Oneto, L.; Baldi, F.; Cipollini, F.; Atlar, M.; Savio, S. Data-Driven Ship Digital Twin for Estimating the Speed Loss Caused by the Marine Fouling. Ocean Eng. 2019, 186, 106063. [Google Scholar] [CrossRef]

- Cai, Y.; Wang, Y.; Burnett, M. Using Augmented Reality to Build Digital Twin for Reconfigurable Additive Manufacturing System. J. Manuf. Syst. 2020, 56, 598–604. [Google Scholar] [CrossRef]

- Xiong, M.; Wang, H.; Fu, Q.; Xu, Y. Digital Twin–Driven Aero-Engine Intelligent Predictive Maintenance. Int. J. Adv. Manuf. Technol. 2021, 114, 3751–3761. [Google Scholar] [CrossRef]

- Xu, Z.; Ji, F.; Ding, S.; Zhao, Y.; Zhou, Y.; Zhang, Q.; Du, F. Digital Twin-Driven Optimization of Gas Exchange System of 2-Stroke Heavy Fuel Aircraft Engine. J. Manuf. Syst. 2021, 58, 132–145. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, S.; Cheng, H. An Application Framework of Digital Twin and Its Case Study. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 1141–1153. [Google Scholar] [CrossRef]

- Sharafat, A.; Latif, K.; Park, S.; Seo, J. Digital Twin-Driven Optimization of Blast Design for Underground Construction. In Proceedings of the KSCE, Seoul, Republic of Korea, 20 October 2022; pp. 1–2. [Google Scholar]

- Kim, J.; Kim, S.-A. Lifespan Prediction Technique for Digital Twin-Based Noise Barrier Tunnels. Sustainability 2020, 12, 2940. [Google Scholar] [CrossRef]

- Yu, G.; Zhang, S.; Hu, M.; Wang, Y.K. Prediction of Highway Tunnel Pavement Performance Based on Digital Twin and Multiple Time Series Stacking. Adv. Civ. Eng. 2020, 2020, 8824135. [Google Scholar] [CrossRef]

- Sharafat, A.; Khan, M.S.; Latif, K.; Tanoli, W.A.; Park, W.; Seo, J. BIM-GIS-Based Integrated Framework for Underground Utility Management System for Earthwork Operations. Appl. Sci. 2021, 11, 5721. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A.Y.C. Enabling Technologies and Tools for Digital Twin. J. Manuf. Syst. 2021, 58, 3–21. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a Semantic Construction Digital Twin: Directions for Future Research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. A BIM-Data Mining Integrated Digital Twin Framework for Advanced Project Management. Autom. Constr. 2021, 124, 103564. [Google Scholar] [CrossRef]

- Grieves, M. Digital Twin: Manufacturing Excellence through Virtual Factory Replication. White Pap. 2014, 1, 1–7. [Google Scholar]

- Richnák, P. Current Trend of Industry 4.0 in Logistics and Transformation of Logistics Processes Using Digital Technologies: An Empirical Study in the Slovak Republic. Logistics 2022, 6, 79. [Google Scholar] [CrossRef]

- Pech, M.; Vrchota, J. Classification of Small- and Medium-Sized Enterprises Based on the Level of Industry 4.0 Implementation. Appl. Sci. 2020, 10, 5150. [Google Scholar] [CrossRef]

- Tubis, A.A.; Grzybowska, K. In Search of Industry 4.0 and Logistics 4.0 in Small-Medium Enterprises—A State of the Art Review. Energies 2022, 15, 8595. [Google Scholar] [CrossRef]

- Glaessgen, E.; Stargel, D. The Digital Twin Paradigm for Future NASA and U.S. Air Force Vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 April 2012. [Google Scholar]

- Tao, F.; Zhang, M. Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Alexopoulos, K.; Nikolakis, N.; Chryssolouris, G. Digital Twin-Driven Supervised Machine Learning for the Development of Artificial Intelligence Applications in Manufacturing. Int. J. Comput. Integr. Manuf. 2020, 33, 429–439. [Google Scholar] [CrossRef]

- Koopialipoor, M.; Nikouei, S.S.; Marto, A.; Fahimifar, A.; Jahed Armaghani, D.; Mohamad, E.T. Predicting Tunnel Boring Machine Performance through a New Model Based on the Group Method of Data Handling. Bull. Eng. Geol. Environ. 2019, 78, 3799–3813. [Google Scholar] [CrossRef]

- Gordan, B.; Koopialipoor, M.; Clementking, A.; Tootoonchi, H.; Tonnizam Mohamad, E. Estimating and Optimizing Safety Factors of Retaining Wall through Neural Network and Bee Colony Techniques. Eng. Comput. 2019, 35, 945–954. [Google Scholar] [CrossRef]

- Min, Q.; Lu, Y.; Liu, Z.; Su, C.; Wang, B. Machine Learning Based Digital Twin Framework for Production Optimization in Petrochemical Industry. Int. J. Inf. Manag. 2019, 49, 502–519. [Google Scholar] [CrossRef]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.-Y.; Nee, A.Y.C. Digital Twin-Driven Product Design Framework. Int. J. Prod. Res. 2019, 57, 3935–3953. [Google Scholar] [CrossRef]

- Umair, M.; Sharafat, A.; Lee, D.-E.; Seo, J. Impact of Virtual Reality-Based Design Review System on User’s Performance and Cognitive Behavior for Building Design Review Tasks. Appl. Sci. 2022, 12, 7249. [Google Scholar] [CrossRef]

- Gao, Y.; Qian, S.; Li, Z.; Wang, P.; Wang, F.; He, Q. Digital Twin and Its Application in Transportation Infrastructure. In Proceedings of the IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI), Beijing, China, 15 July–15 August 2021; pp. 298–301. [Google Scholar] [CrossRef]

- Huang, X.; Liu, Q.; Liu, H.; Zhang, P.; Pan, S.; Zhang, X.; Fang, J. Development and In-Situ Application of a Real-Time Monitoring System for the Interaction between TBM and Surrounding Rock. Tunn. Undergr. Sp. Technol. 2018, 81, 187–208. [Google Scholar] [CrossRef]

- Yagiz, S.; Gokceoglu, C.; Sezer, E.; Iplikci, S. Application of Two Non-Linear Prediction Tools to the Estimation of Tunnel Boring Machine Performance. Eng. Appl. Artif. Intell. 2009, 22, 808–814. [Google Scholar] [CrossRef]

- Barton, N. TBM Performance Estimation in Rock Using Q(TBM). Tunnels Tunn. Int. 1999, 31, 30–34. [Google Scholar]

- Gong, Q.M.; Zhao, J. Development of a Rock Mass Characteristics Model for TBM Penetration Rate Prediction. Int. J. Rock Mech. Min. Sci. 2009, 46, 8–18. [Google Scholar] [CrossRef]

- Barton, N.; Lien, R.; Lunde, J. Engineering classification of rock masses for the design of tunnel support. Rock Mech. 1974, 6, 189–236. [Google Scholar] [CrossRef]

- Naithani, A.K. Rock Mass Classification and Support Design using the Q-System. J. Geol. Soc. India 2019, 94, 443. [Google Scholar] [CrossRef]

- Shi, X.; Zhou, J.; Wu, B.; Huang, D.; Wei, W. Support Vector Machines Approach to Mean Particle Size of Rock Fragmentation Due to Bench Blasting Prediction. Trans. Nonferrous Met. Soc. China 2012, 22, 432–441. [Google Scholar] [CrossRef]

- Adoko, A.-C.; Jiao, Y.-Y.; Wu, L.; Wang, H.; Wang, Z.-H. Predicting Tunnel Convergence Using Multivariate Adaptive Regression Spline and Artificial Neural Network. Tunn. Undergr. Sp. Technol. 2013, 38, 368–376. [Google Scholar] [CrossRef]

- Mahdevari, S.; Torabi, S.R. Prediction of Tunnel Convergence Using Artificial Neural Networks. Tunn. Undergr. Sp. Technol. 2012, 28, 218–228. [Google Scholar] [CrossRef]

- Sharafat, A.; Latif, K.; Seo, J. Risk Analysis of TBM Tunneling Projects Based on Generic Bow-Tie Risk Analysis Approach in Difficult Ground Conditions. Tunn. Undergr. Sp. Technol. 2021, 111, 103860. [Google Scholar] [CrossRef]

- Yavari, M.; Mahdavi, S. Prediction of Penetration Rate of TBM Using ANN. In Proceedings of the National Mining Conference, Breckenridge, CO, USA, 19–23 June 2005; pp. 1–10. [Google Scholar]

- Salimi, A.; Esmaeili, M. Utilising of Linear and Non-Linear Prediction Tools for Evaluation of Penetration Rate of Tunnel Boring Machine in Hard Rock Condition. Int. J. Min. Miner. Eng. 2013, 4, 249. [Google Scholar] [CrossRef]

- Javad, G.; Narges, T. Application of Artificial Neural Networks to the Prediction of Tunnel Boring Machine Penetration Rate. Min. Sci. Technol. 2010, 20, 727–733. [Google Scholar] [CrossRef]

| Type of Data | Properties | Name | Unit | Min Value | Max Value | Average Value |

|---|---|---|---|---|---|---|

| Input | Machine parameters | Boring energy | (N/mm2) | 0.9 | 24.9 | 11.97 |

| RPM | (Rev/min) | 2.1 | 5.4 | 3.70 | ||

| Torque | (KN-m) | 100 | 2700 | 1336.34 | ||

| Thrust force | (KN) | 1502 | 8239 | 3871.56 | ||

| Speed | (mm/min) | 25 | 58 | 44.98 | ||

| Gripper pressure | (bar) | 184 | 249 | 197.65 | ||

| Total revolution | (Rev/min) | 61 | 188 | 106.94 | ||

| Rock properties | Q-value | Q-value (theo) | 3 | 4 | 3.75 | |

| Q-value (TBM) | 2 | 5 | 3.91 | |||

| Output | Penetration | mm/rpm | 8 | 14.8 | 12.19 | |

| Advance rate | m/h | 1.26 | 3.69 | 2.73 | ||

| Parameter | Sandstone | Siltstone | Mudstone |

|---|---|---|---|

| Color | Gray | Brown–reddish-brown | Reddish-brown |

| Weathering | Fresh–slightly | Fresh–Slightly | Fresh–slightly |

| Structure | Massive, blocky, locally irregular | Blocky, Tabular, Locally Irregular | Tabular, blocky, irregular |

| Grain size | Fine–medium | Very fine–Medium | Very fine |

| Bedding | Thick–massive | Thin | Very thin–yhin |

| Bulk density, kg/m3 | 2730 | 2771 | 2722 |

| Uniaxial compressive strength, MPa | 86.0 | 56.5 | 33.0 |

| Average rock quality classification | Good | Fair | Poor |

| Volumetric joint count (joints/m3) | 1–22 | 3–25 | 3–25 |

| Number of joints sets | 2 + random to 3 + random | 3 to 3 + random | 3 to 3 + random |

| Joint roughness, waviness | Rough, planar–undulating | Rough–smooth, planar | Smooth, planar |

| Joint aperture or thickness (mm) | <0.1–10 | 0.1–10 | 0.25–5 |

| Joint filling | Clean, sandy particles, or hard calcite | Clean, sandy, or silty coatings | Silty or clayey coatings, occasionally soft clay |

| Algorithm | PR | AR | ||||

|---|---|---|---|---|---|---|

| R2 | RMSE | VAF | R2 | RMSE | VAF | |

| SVR | 0.960705 | 0.043628 | 0.960705 | 0.961474 | 0.017447 | 0.961782 |

| ANN | 0.969098 | 0.034308 | 0.969098 | 0.973454 | 0.012022 | 0.973659 |

| SVR-ANN | 0.9694 | 0.033973 | 0.969402 | 0.973602 | 0.011955 | 0.973843 |

| ANN-lbfgs | 0.969098 | 0.034308 | 0.969098 | 0.973454 | 0.012022 | 0.973659 |

| ANN-sgd | 0.953988 | 0.051084 | 0.954006 | 0.94675 | 0.024115 | 0.946851 |

| ANN-ADAM | 0.943473 | 0.062759 | 0.943655 | 0.939158 | 0.027553 | 0.939315 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Latif, K.; Sharafat, A.; Seo, J. Digital Twin-Driven Framework for TBM Performance Prediction, Visualization, and Monitoring through Machine Learning. Appl. Sci. 2023, 13, 11435. https://doi.org/10.3390/app132011435

Latif K, Sharafat A, Seo J. Digital Twin-Driven Framework for TBM Performance Prediction, Visualization, and Monitoring through Machine Learning. Applied Sciences. 2023; 13(20):11435. https://doi.org/10.3390/app132011435

Chicago/Turabian StyleLatif, Kamran, Abubakar Sharafat, and Jongwon Seo. 2023. "Digital Twin-Driven Framework for TBM Performance Prediction, Visualization, and Monitoring through Machine Learning" Applied Sciences 13, no. 20: 11435. https://doi.org/10.3390/app132011435

APA StyleLatif, K., Sharafat, A., & Seo, J. (2023). Digital Twin-Driven Framework for TBM Performance Prediction, Visualization, and Monitoring through Machine Learning. Applied Sciences, 13(20), 11435. https://doi.org/10.3390/app132011435