Cement Stabilization of Waste from Contaminated Soils in Terms of Its Installation into Engineered Landfill

Abstract

1. Introduction

2. Basic Information on the Presented Case Studies

2.1. Storage Facility (Landfill) of the Chemical Plant

2.2. Remediation Works in a Former Coking Plant Concerning Pollution with Petroleum Compounds

3. Materials and Methods

3.1. Engineered Landfill Concept

3.2. Soil and Water Conditions of Engineered Landfill

3.3. Cement Stabilisation of Engineered Landfill

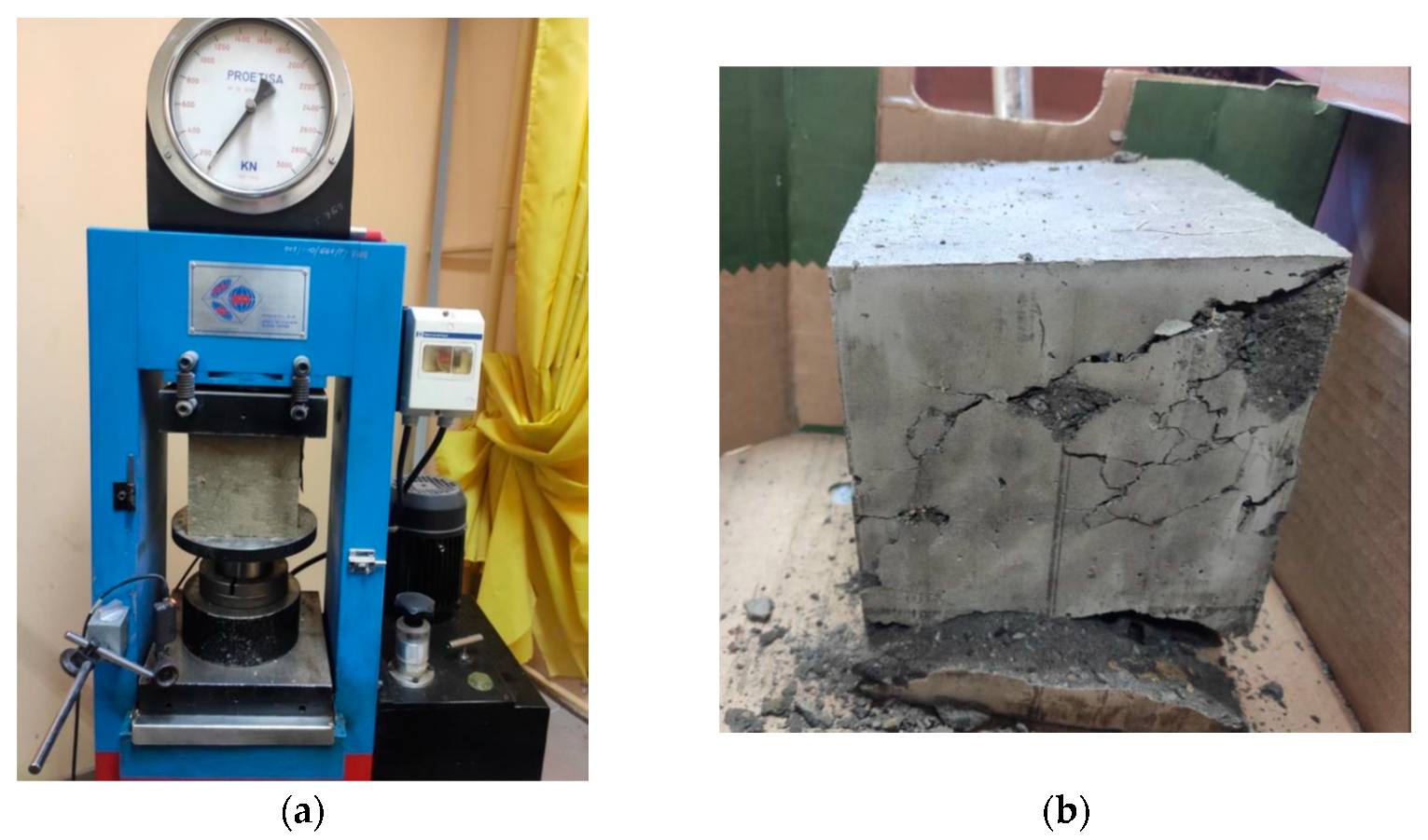

3.4. Testing of Petroleum Contaminated Soil Mixed with Cement, Optionally with Addition of 1.5% of Carbon Powder

4. Results of Tests of Physical and Strength Parameters of Slag Cement-Stabilized Waste and Contaminated Soil

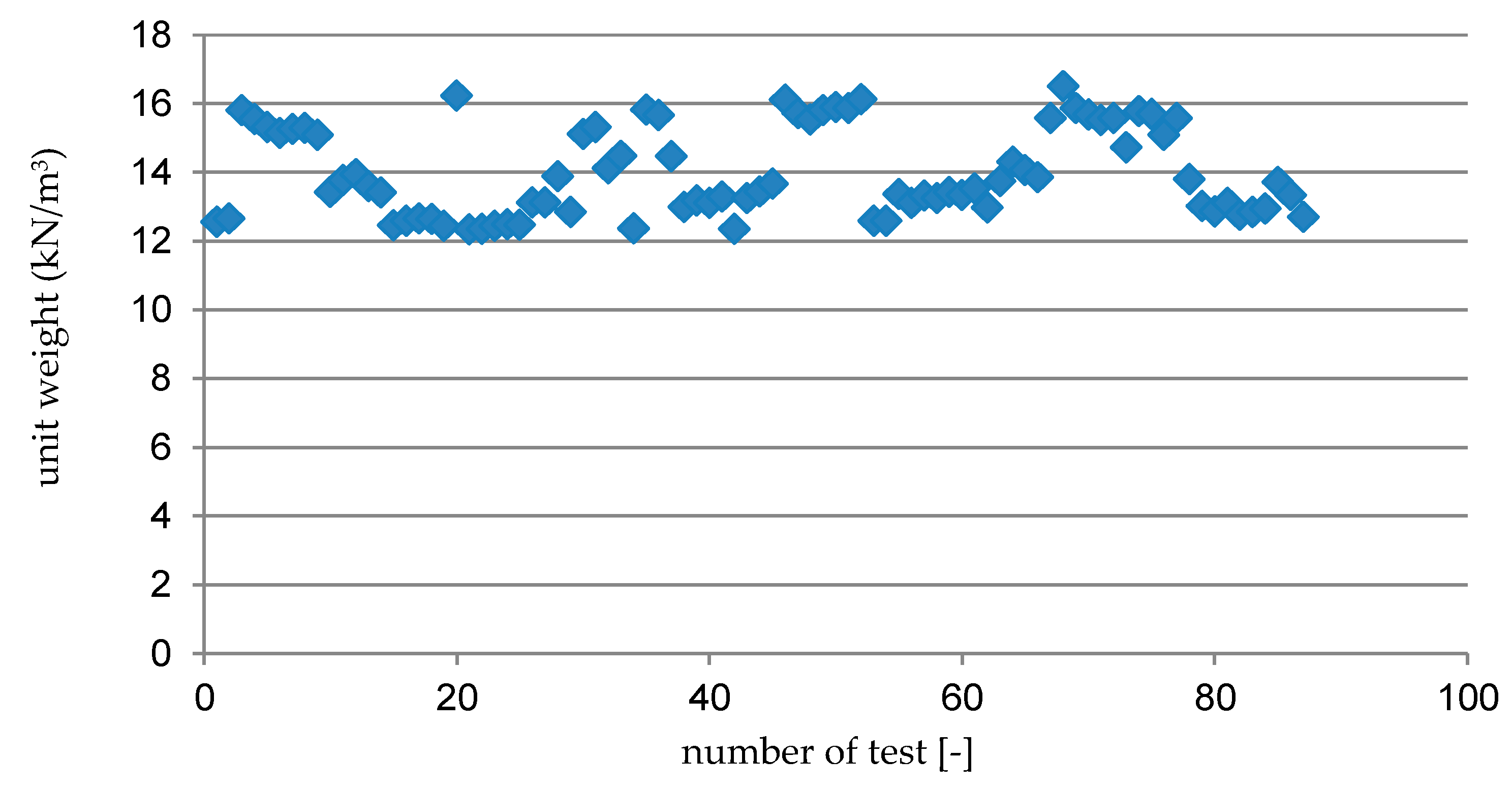

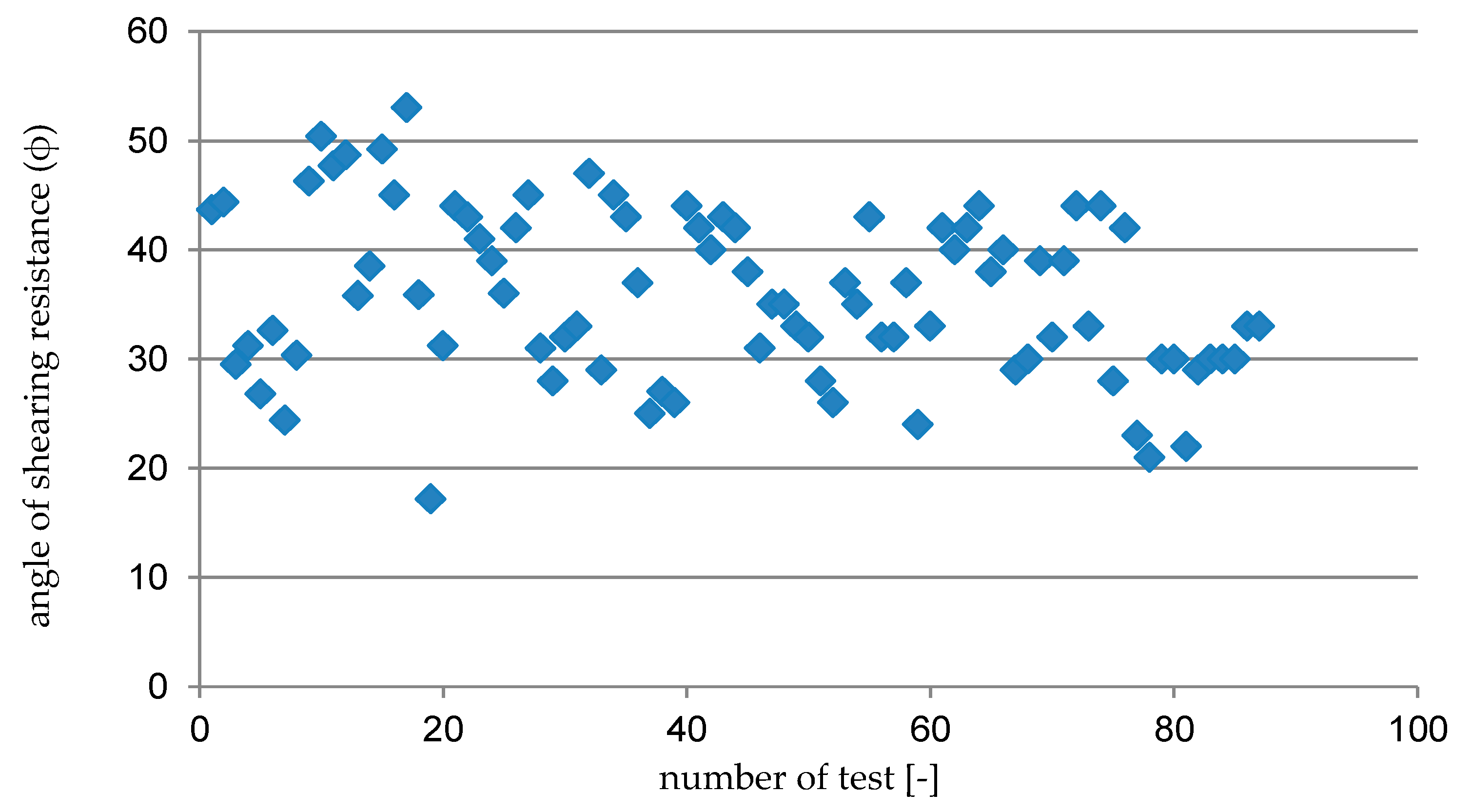

4.1. Results of Stabilized Waste Testing

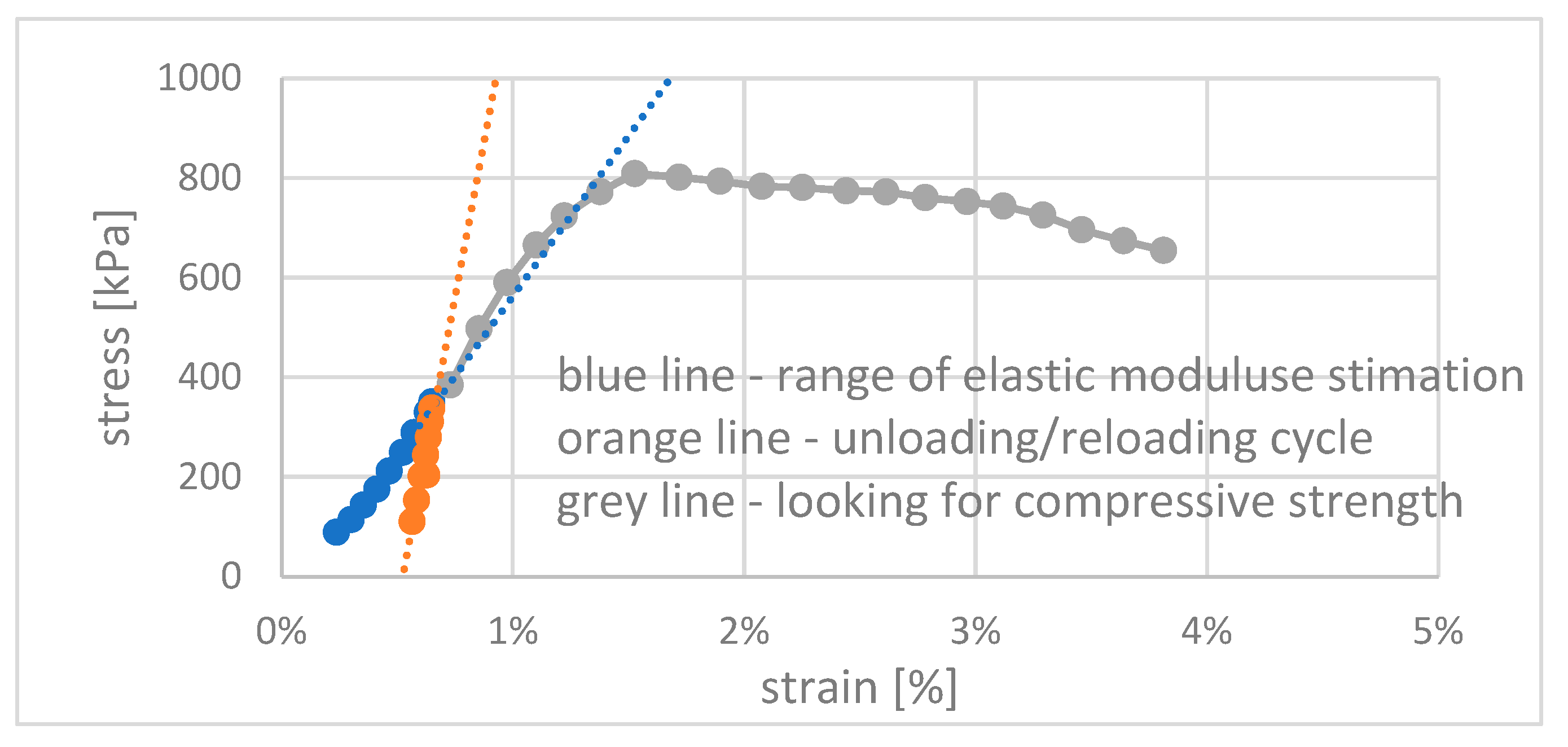

4.2. Results Obtained for a Petroleum Contaminated Soil–Cement Composite

5. Calculations of Stability for the Planned Engineered Landfill

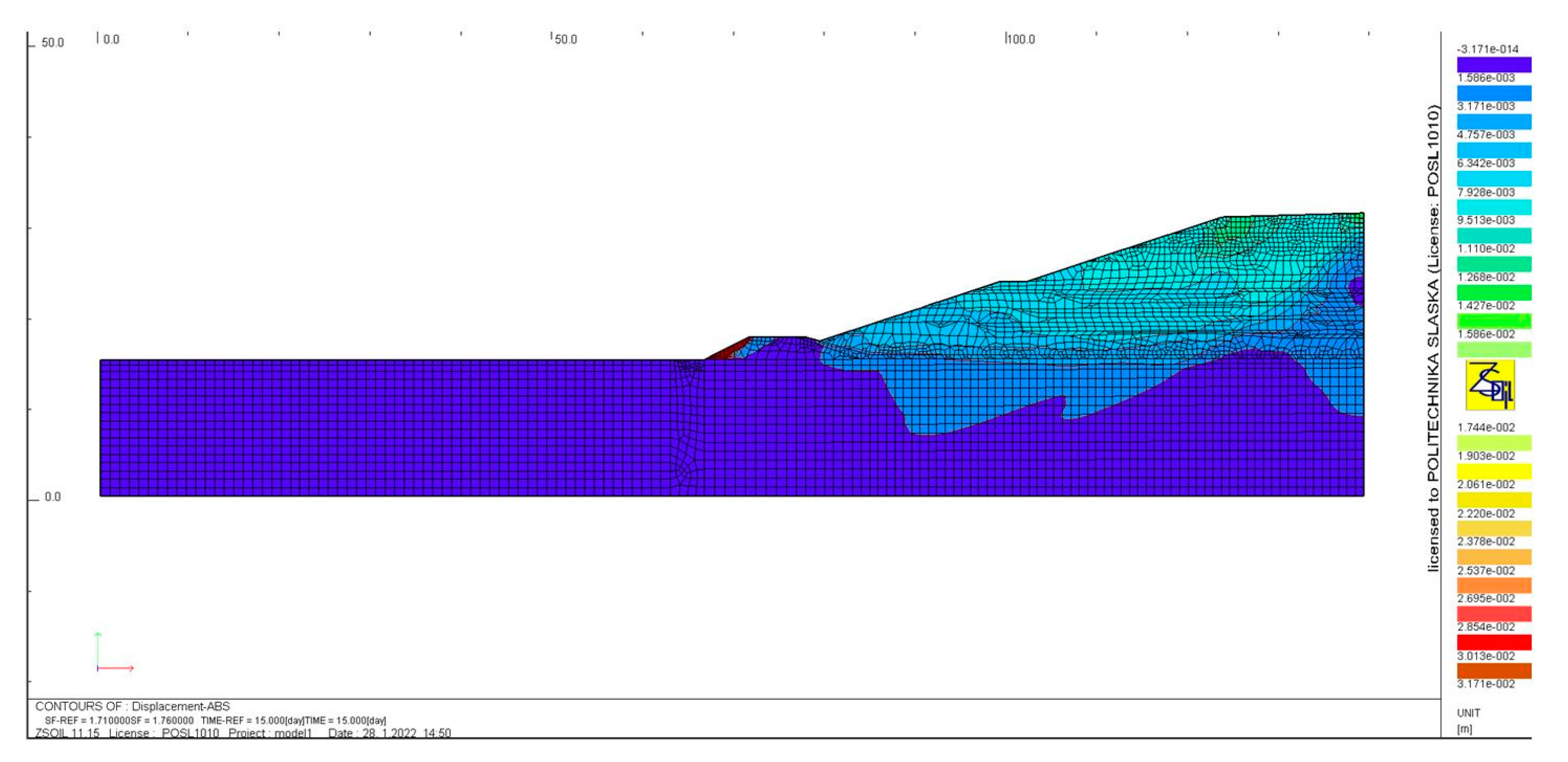

5.1. Model and Calculation Assumptions Based on Case 1 Results (Chemical Plant)

- -

- Assumption of a safety factor (SFn) equal to an initial value defined by the user (SF0)—most commonly a boundary problem of the system equilibrium state is solved, an initial stress distribution is determined in the analyzed object (“in situ” state), caused, for example, by its own state or other constant static loads. In this case, meeting the conditions of elastic–plastic equilibrium corresponds to achieving the safety factor SF = 1.0;

- -

- For each calculation step, assuming SFn+1= SFn + ΔSF (step ΔSF in the described models was defined at 0.01), while at the same time calculating cn+1 = c/SFn+1 and tgϕn+1 = tgϕn/SFn+1. By step-wise reduction in cohesion c and angle of shearing resistance tangent ϕ, a less stable system is obtained with each calculation step;

- -

- Solving the problem using software, with the necessary iterations;

- -

- Performing system stability calculations for the assumed sequence of safety factors, until solution divergence is achieved in two consecutive steps—if an iterative process divergence occurs (manifesting in the occurrence of very large deformations, often with a qualitatively different form than those in the equilibrium state), it means that with the currently assumed safety factor, the structure is not stable;

- -

- Determination of the safety factor when solution divergence is obtained SFn ≤ SF ≤ SFn+1—the last value of the SF-reducing coefficient at which an equilibrium state can still be achieved is assumed as the safety factor value.

5.2. Calculation Results

6. Discussion

7. Conclusions, Reservations and Prospects for Further Developments

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| ϕ | is the angle of shearing resistance |

| c | is the cohesion of the soil |

| E | is the Young’s modulus of the soil |

| ν | is the Poisson’s ratio of the soil |

| Ip | is the plasticity index of the soil |

| wL | is the liquid limit of the soil |

| Iom | is the organic content of the soil |

| τf | is the shear stress on the surface of shear |

| σ | is the total normal stress |

| Qmax | is the maximum shear force |

| a | is the specimen side length |

| r | is the horizontal displacement of shearbox at force Qmax |

| γ | is the unit weight of specimen |

| m | is the specimen weight |

| V | is the specimen volume |

| g | is the gravitational acceleration |

| xk | is the characteristic value of the parameter |

| x(n) | is the arithmetic mean of the parameter |

| s | is the sample standard deviation |

| δ | is the dilatancy angle of the soil |

| SF | is the safety factor. |

References

- Kaźmierczak, U.; Lorenc, M.W.; Strzałkowski, P. The analysis of the existing terminology related to a post-mining land use: A proposal for new classification. Environ. Earth Sci. 2017, 76, 693. [Google Scholar] [CrossRef]

- Łupieżowiec, M.; Rybak, J.; Różański, Z.; Dobrzycki, P.; Jędrzejczyk, W. Design and Construction of Foundations for Industrial Facilities in the Areas of Former Post-Mining Waste Dumps. Energies 2022, 15, 5766. [Google Scholar] [CrossRef]

- Krzysztofik, R.; Dulias, R.; Kantor-Pietraga, I.; Spórna, T.; Dragan, W. Paths of urban planning in a post-mining area. A case study of a former sandpit in southern Poland. Land Use Policy 2020, 99, 104801. [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.; Ivannikov, A.; Khayrutdinov, A.; Tyulyaeva, Y. Geotechnology using composite materials from man-made waste is a paradigm of sustainable development. Mater. Today Proc. 2021, 38, 2078–2082. [Google Scholar] [CrossRef]

- Majer, S.; Budziński, B. Utilization of recycled materials in road construction. In Proceedings of the International Multidisciplinary Scientific Ge-oConference: SGEM, Albena, Bulgaria, 2–8 July 2018; pp. 247–252. [Google Scholar]

- Kawalec, J. Full scale tests of embankments constructed with industrial wastes as the way to confirm their usefulness. In Proceedings of the 3rd International Conference on Structural Engineering, Mechanics and Computation SEMC, Cape Town, South Africa, 10–12 September 2007; pp. 275–276. [Google Scholar]

- Gorbatyuk, N.; Adigamov, A.; Kobelev, O.; Pashkov, A. Reducing the environmental impact of mining production through the use of man-made waste. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1164, 012001. [Google Scholar] [CrossRef]

- Ozbay, G.; Jones, M.; Gadde, M.; Isah, S.; Attarwala, T. Design and Operation of Effective Landfills with Minimal Effects on the Environment and Human Health. J. Environ. Public Health 2021, 2021, 6921607. [Google Scholar] [CrossRef] [PubMed]

- Zástĕrová, P.; Niemiec, D.; Marschalko, M.; Durd’Ák, J.; Duraj, M.; Yilmaz, I.; Drusa, M. Analysis the Purposes of Land Use Planning on the Hard Coal Tailing Dumps. IOP Conf. Ser. Earth Environ. Sci. 2016, 44, 022034. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.; Luo, T.; Xia, P.; Mu, H.; Sun, P.; Wang, X.; Wang, J. In-Situ Leaching Mining Technique for Deep Bauxite Extraction and the Countermeasures for Water Pollution Prevention: An Example in the Ordos Basin, China. Water 2023, 15, 2381. [Google Scholar] [CrossRef]

- Rodríguez-Pacheco, R.; García, G.; Caparrós-Ríos, A.V.; Robles-Arenas, V.; García-García, C.; Millán, R.; Pérez-Sanz, A.; Alcolea-Rubio, L.A. Mineralogy, Geochemistry and Environmental Hazards of Different Types of Mining Waste from a Former Mediterranean Metal Mining Area. Land 2023, 12, 499. [Google Scholar] [CrossRef]

- Oliveira, M.L.S.; Valença, G.O.; Pinto, D.; Moro, L.D.; Bodah, B.W.; de Vargas Mores, G.; Grub, J.; Adelodun, B.; Neckel, A. Hazardous Elements in Sediments Detected in Former Decommissioned Coal Mining Areas in Colombia: A Need for Environmental Recovery. Sustainability 2023, 15, 8361. [Google Scholar] [CrossRef]

- Kawalec, J.; Grygierek, M.; Koda, E.; Osiński, P. Lessons learned on geosynthetics applications in road structures in Silesia mining region in Poland. Appl. Sci. 2019, 9, 1122. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Nahazanan, H.; Nasir, N.A.M.; Huseien, G.F.; Saad, A.H. Calcium-Based Binders in Concrete or Soil Stabilization: Challenges, Problems, and Calcined Clay as Partial Replacement to Produce Low-Carbon Cement. Materials 2023, 16, 2020. [Google Scholar] [CrossRef] [PubMed]

- Duszyński, R.; Duszyńska, A.; Cantré, S. New experiences in dike construction with soil-ash composites and fine-grained dredged materials. Stud. Geotech. Et Mech. 2017, 39, 17–24. [Google Scholar] [CrossRef]

- Sidiq, A.; Robert, D.J.; O’Donnell, B.; Setunge, S.; Swarup, A.; Tostvrsnik, F. Investigation of Enzyme-Based Soil Stabilization in Field Application. J. Mater. Civ. Eng. 2023, 35, 04023086. [Google Scholar] [CrossRef]

- Phutthananon, C.; Tippracha, N.; Jongpradist, P.; Tunsakul, J.; Tangchirapat, W.; Jamsawang, P. Investigation of Strength and Microstructural Characteristics of Blended Cement-Admixed Clay with Bottom Ash. Sustainability 2023, 15, 3795. [Google Scholar] [CrossRef]

- Khalil, A.; Taha, Y.; Benzaazoua, M.; Hakkou, R. Applied Methodological Approach for the Assessment of Soil Contamination by Trace Elements around Abandoned Coal Mines—A Case Study of the Jerada Coal Mine, Morocco. Minerals 2023, 13, 181. [Google Scholar] [CrossRef]

- Opiso, E.M.; Tabelin, C.B.; Maestre, C.V.; Aseniero, J.P.J.; Arima, T.; Villacorte-Tabelin, M. Utilization of Palm Oil Fuel Ash (POFA) as an Admixture for the Synthesis of a Gold Mine Tailings-Based Geopolymer Composite. Minerals 2023, 13, 232. [Google Scholar] [CrossRef]

- Rybak, J.; Kongar-Syuryun, C.; Tyulyaeva, Y.; Khayrutdinov, A.M. Creation of backfill materials based on industrial waste. Minerals 2021, 11, 739. [Google Scholar] [CrossRef]

- PN-S-96012:1997 Drogi Samochodowe. Podbudowa I Ulepszone PodłOżE Z Gruntu Stabilizowanego Cementem (Car Roads. Foundation and Improved Subgrade Made of Cement-Stabilized Soil.). 1997. Available online: https://sklep.pkn.pl/pn-s-96012-1997p.html (accessed on 17 October 2023). (In Polish).

- Malina, G. Ecotoxicological and environmental problems associated with the former chemical plant in Tarnowskie Gory, Poland. Toxicology 2004, 205, 157–172. [Google Scholar] [CrossRef]

- Witkowski, A.; Kowalczyk, A.; Rubin, H.; Rubin, K. Groundwater quality and migration of pollutants in the multi-aquifer system of the former chemical works “Tarnowskie Góry” area. Pol. Geol. Inst. Spec. Pap. 2008, 24, 123–130. [Google Scholar]

- Witkowski, A.; Rubin, H. Groundwater quality in the Tarnowskie Góry distict based on monitoring data results. Podzem. Voda 2003, 9, 20–27. [Google Scholar]

- Wysokiński, L.; Majer, E. Problemy budowy składowiska odpadów niebezpiecznych w Tarnowskich Górach. Przegląd Geol. 2002, 50, 959–965. (In Polish) [Google Scholar]

- PN-B-04481:1988 Grunty Budowlane—Badania Próbek Gruntu (Construction Land. Soil Sample Testing). 1988. Available online: https://sklep.pkn.pl/pn-b-04481-1988p.html (accessed on 17 October 2023). (In Polish).

- Gago, F.; Mužík, J.; Bulko, R. The Slope Stability Solution Using Meshless Local Petrov-Galerkin Method. Transp. Res. Procedia 2019, 40, 686–693. [Google Scholar] [CrossRef]

- Truty, A.; Urbański, A.; Grodecki, M.; Podleś, K. Computer aided models of landslides and their protection problems. Sci.-Technol. Pap. Commun. Eng. Technol. Repub. Pol. 2009, 88, 395–419. [Google Scholar]

- Jendrysik, K.; Pachnicz, M.; Dudziński, P. Parameters of the constitutive model of geomaterials formed with the use of DSM dry technology. E3S Web Conf. 2019, 97, 02028. [Google Scholar] [CrossRef]

- Zheng, Y.; Tang, X.; Zhao, S.; Deng, C.; Lei, W. Strength reduction and step-loading finite element approaches in geotechnical engineering. J. Rock Mech. Geotech. Eng. 2009, 1, 21–30. [Google Scholar] [CrossRef]

- Gago, F.; Valletta, A.; Mužík, J. Formulation of a Basic Constitutive Model for Fine—Grained Soils Using the Hypoplastic Framework. Civ. Environ. Eng. 2021, 17, 450–455. [Google Scholar] [CrossRef]

- Glubiak-Witwicka, E.; Wdziekońska, D.; Plewnia, B.; Szczygieł, A. Ocena stanu środowiska w rejonie obiektów objętych monitoringiem lokalnym, na terenie województwa śląskiego. Wojewódzki Insp. Ochr. Środowiska W Katowicach Bibl. Monit. Środowiska 2012, 37–43. (In Polish) [Google Scholar]

- Oliva-González, A.; Ruiz-Pozo, A.; Gallardo-Amaya, R.; Yulady Jaramillo, H. Landslide risk assessment in slopes and hillsides. Methodology and application in a real case. DYNA 2019, 86, 143–152. [Google Scholar] [CrossRef]

- Brasse, K.; Tracz, T.; Zdeb, T.; Rychlewski, P. Influence of Soil-Cement Composition on its Selected Properties. MATEC Web Conf. 2018, 163, 06006. [Google Scholar] [CrossRef][Green Version]

- Jończyk-Szostek, M.; Kanty, P.; Rybak, J.; Saloni, J.; Trybocka, K. Uniaxial Testing of Soil–Cement Composites to Obtain Correlations to Be Used in Numerical Modeling. Appl. Sci. 2023, 13, 10268. [Google Scholar] [CrossRef]

- Belebchouche, C.; Bensebti, S.-E.; Ould-Said, C.; Moussaceb, K.; Czarnecki, S.; Sadowski, L. Stabilization of Chromium Waste by Solidification into Cement Composites. Materials 2023, 16, 6295. [Google Scholar] [CrossRef] [PubMed]

- Peck, R.B. Advantages and limitation of the observational method in applied soil mechanics. Geotechnique 1969, 19, 171–187. [Google Scholar] [CrossRef]

- Abdrabbo, F.M.; Gaaver, K.E. Applications of the observational method in deep foundations. Alex. Eng. J. 2012, 51, 269–279. [Google Scholar] [CrossRef]

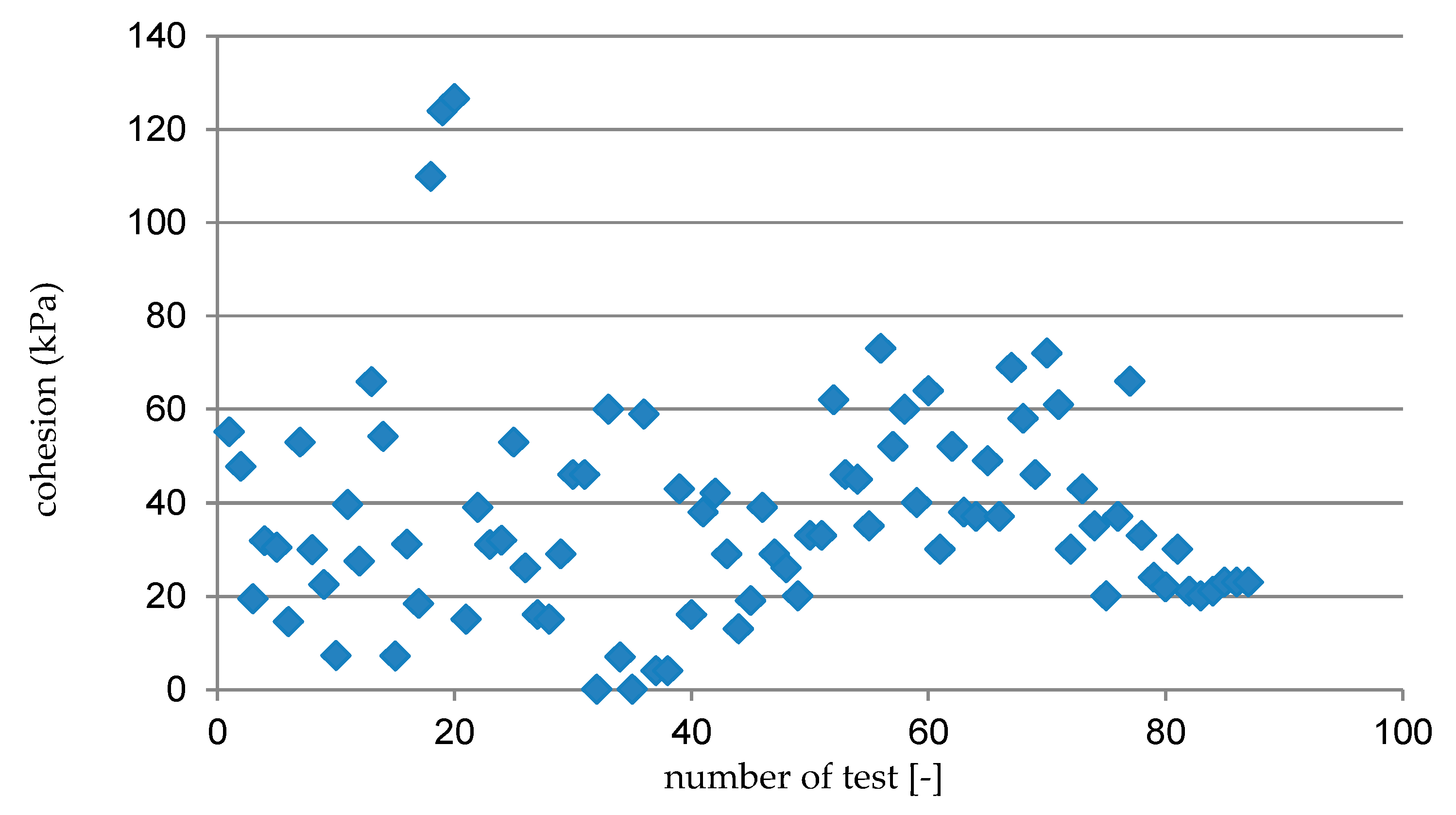

| Mean Value | Standard Deviation | Characteristic Value | |

|---|---|---|---|

| Unit weight [kN/m3] | 14.00 | 1.28 | 14.64 |

| Angle of shearing resistance [°] | 35.79 | 7.62 | 31.98 |

| Cohesion [kPa] | 37.64 | 23.46 | 25.91 |

| Time of Curing [Days] | Soil–Cement Composite | Soil–Cement Composite + 1.5% Active Carbon | |

|---|---|---|---|

| compressive strength [MPa] | 7 | 2.547 | 2.729 |

| 28 | 3.749 | 4.129 | |

| increase [%] | 32.1% | 33.9% | |

| elastic modulus [MPa] | 7 | 509.700 * | 374.780 |

| 28 | 473.550 | 540.260 | |

| increase [%] | −7.6% * | 30.6% | |

| unloading/reloading elastic modulus [MPa] | 28 | 768.420 | 829.880 |

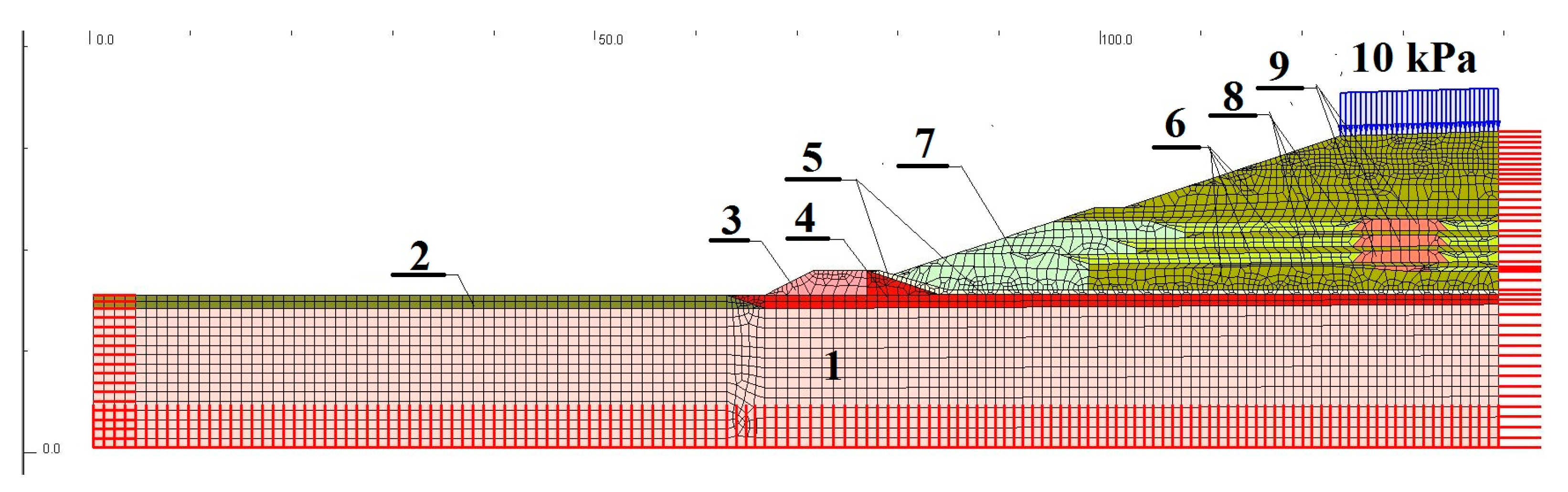

| Type of Ground | Coulomb–Mohr Model Performance Parameters | |

|---|---|---|

| 1. | Ground, MSa, ID = 40% | E = 68 MPa, ϕ = 32°, c = 1 kPa, ν = 0.26, γ = 18.5 kN/m3, ψ = 2° |

| 2. | Made ground | E = 5 MPa, ϕ = 10°, c = 10 kPa, ν = 0.3, γ = 16 kN/m3, ψ = 0° |

| 3. | Earth dike (outer part) MSa, ID = 50% | E = 80 MPa, ϕ = 33°, c = 1 kPa, ν = 0.25, γ = 18.5 kN/m3, ψ = 3° |

| 4. | Earth dike (inner part), landfill bottom, Clay | E = 23 MPa, ϕ = 13°, c = 60 kPa, ν = 0.25, γ = 18.5 kN/m3, ψ = 3° |

| 5. | Drainage layer, MSa, ID = 40% | E = 68 MPa, ϕ = 32°, c = 1 kPa, ν = 0.26, γ = 18.5 kN/m3, ψ = 2° |

| 6. | Compacted made grounds | E = 10 MPa, ϕ = 20°, c = 10 kPa, ν = 0.2, γ = 18 kN/m3, ψ = 0° |

| 7. | Outer slopes, compacted made grounds | E = 10 MPa, ϕ = 20°, c = 10 kPa, ν = 0.2, γ = 18 kN/m3, ψ = 0° |

| 8. | Cement stabilized wastes | E = 10 MPa, ϕ = 32°, c = 26 kPa, ν = 0.3, γ = 14.6 kN/m3, ψ = 0° |

| 9. | Inner earth dike, compacted made grounds | E = 10 MPa, ϕ = 20°, c = 10 kPa, ν = 0.2, γ = 18 kN/m3, ψ = 0° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwiecień, S.; Podgórska, A.; Rybak, J.; Štefánik, M.; Cheben, V. Cement Stabilization of Waste from Contaminated Soils in Terms of Its Installation into Engineered Landfill. Appl. Sci. 2023, 13, 11485. https://doi.org/10.3390/app132011485

Kwiecień S, Podgórska A, Rybak J, Štefánik M, Cheben V. Cement Stabilization of Waste from Contaminated Soils in Terms of Its Installation into Engineered Landfill. Applied Sciences. 2023; 13(20):11485. https://doi.org/10.3390/app132011485

Chicago/Turabian StyleKwiecień, Sławomir, Alicja Podgórska, Jarosław Rybak, Martin Štefánik, and Vlastimil Cheben. 2023. "Cement Stabilization of Waste from Contaminated Soils in Terms of Its Installation into Engineered Landfill" Applied Sciences 13, no. 20: 11485. https://doi.org/10.3390/app132011485

APA StyleKwiecień, S., Podgórska, A., Rybak, J., Štefánik, M., & Cheben, V. (2023). Cement Stabilization of Waste from Contaminated Soils in Terms of Its Installation into Engineered Landfill. Applied Sciences, 13(20), 11485. https://doi.org/10.3390/app132011485