Experimental Research and Numerical Analysis of Marine Oil Leakage and Accidental Ignition in Fishing Vessels

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Set-Up

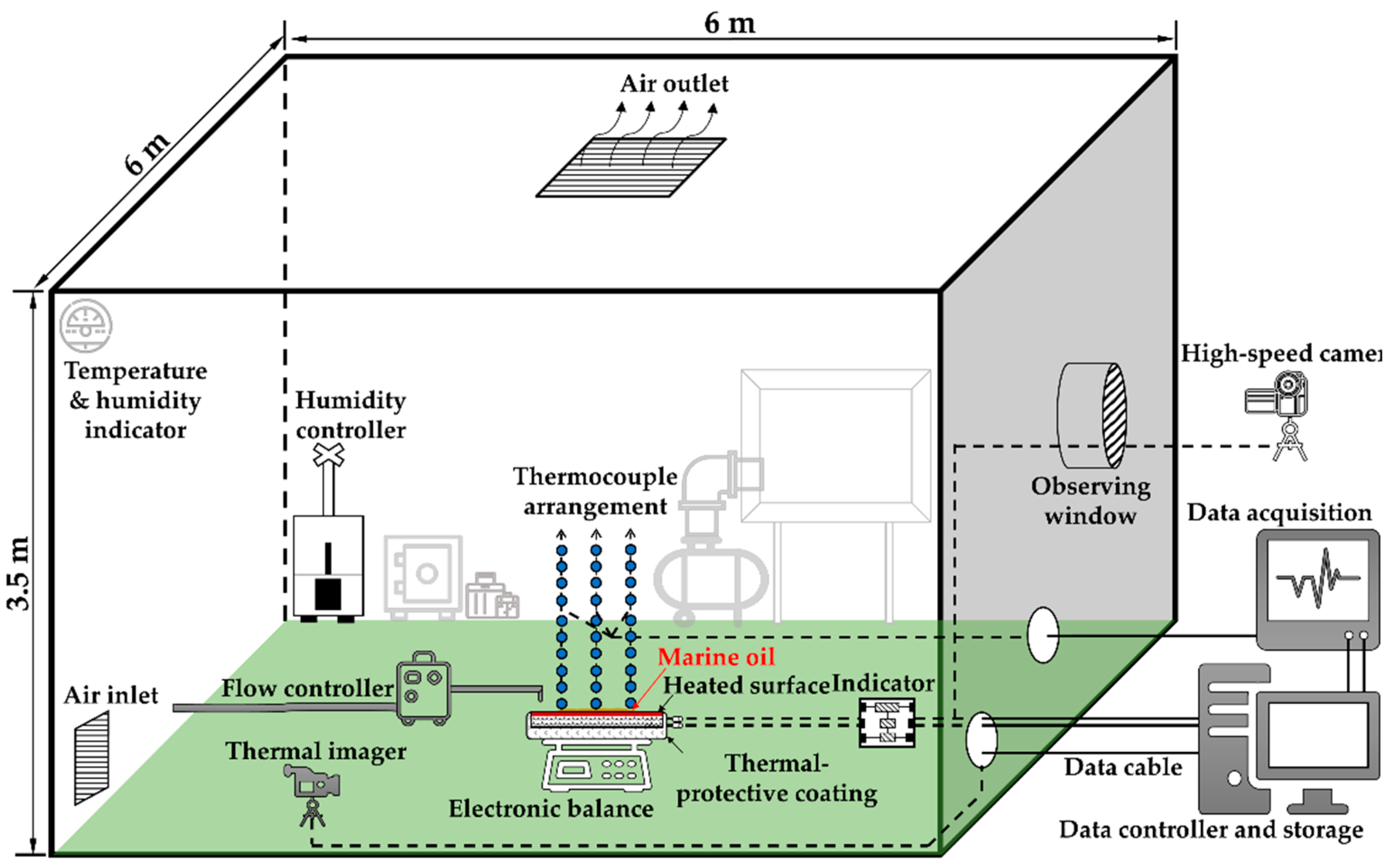

2.1.1. Experimental Site

2.1.2. Experimental Apparatus

2.1.3. Marine Oil Properties

2.2. Numerical Procedure

2.2.1. Physical Model

2.2.2. Governing Equation

- Regarding the evaporation process of leaked marine oil (Tl ≥ Tsat), the mass transfer rate of phase transition is shown in Equation (5).

- Regarding the condensation process of leaked oil (Tv < Tsat), the mass transfer rate of phase transition is shown in Equation (6).

2.2.3. Initial and Boundary Conditions

3. Results and Discussion

3.1. Evaporation Mechanism of Marine Oil Ignition by Heated Surface

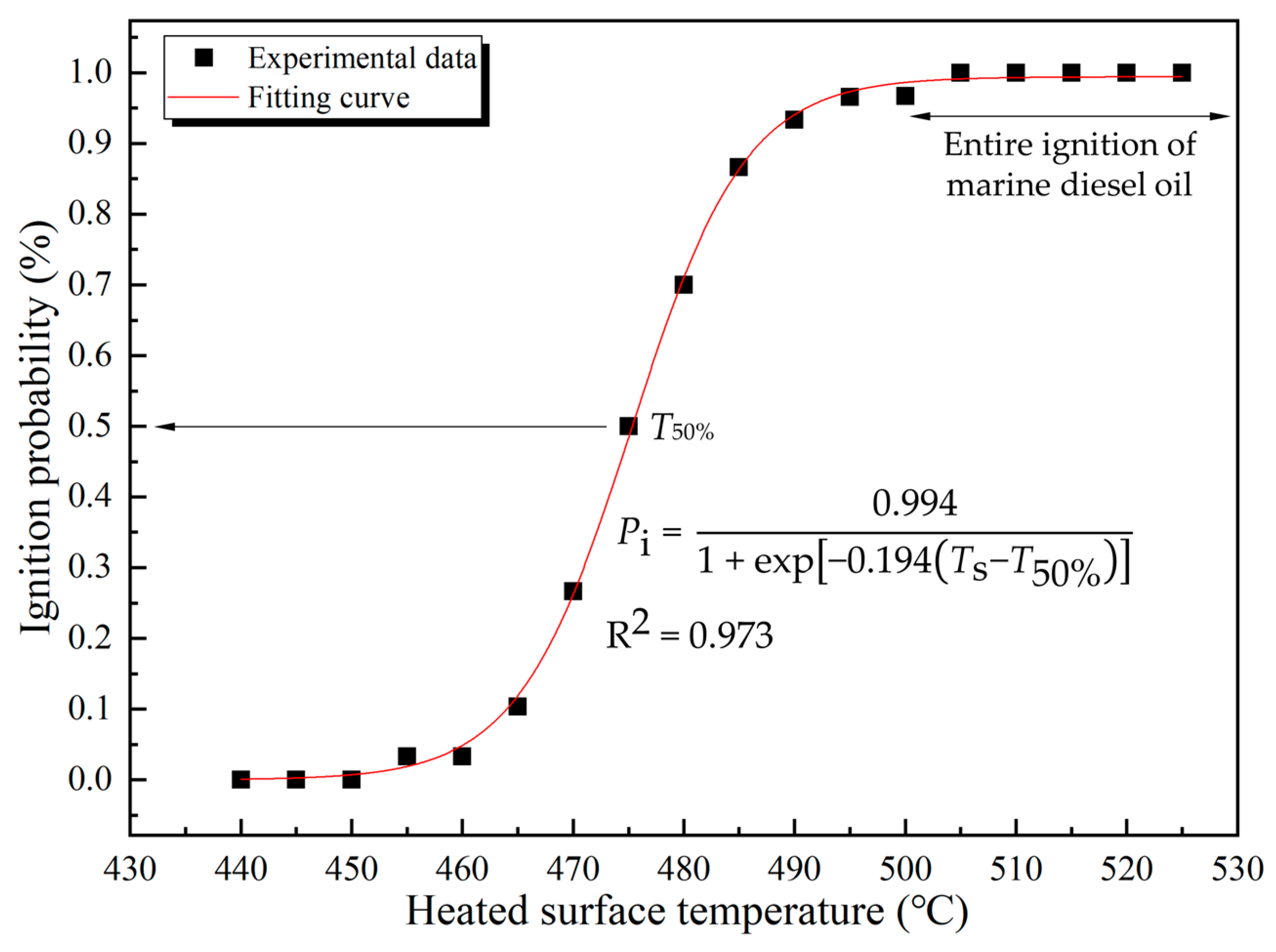

3.2. Ignition Probability of Marine Oil on Heated Surface

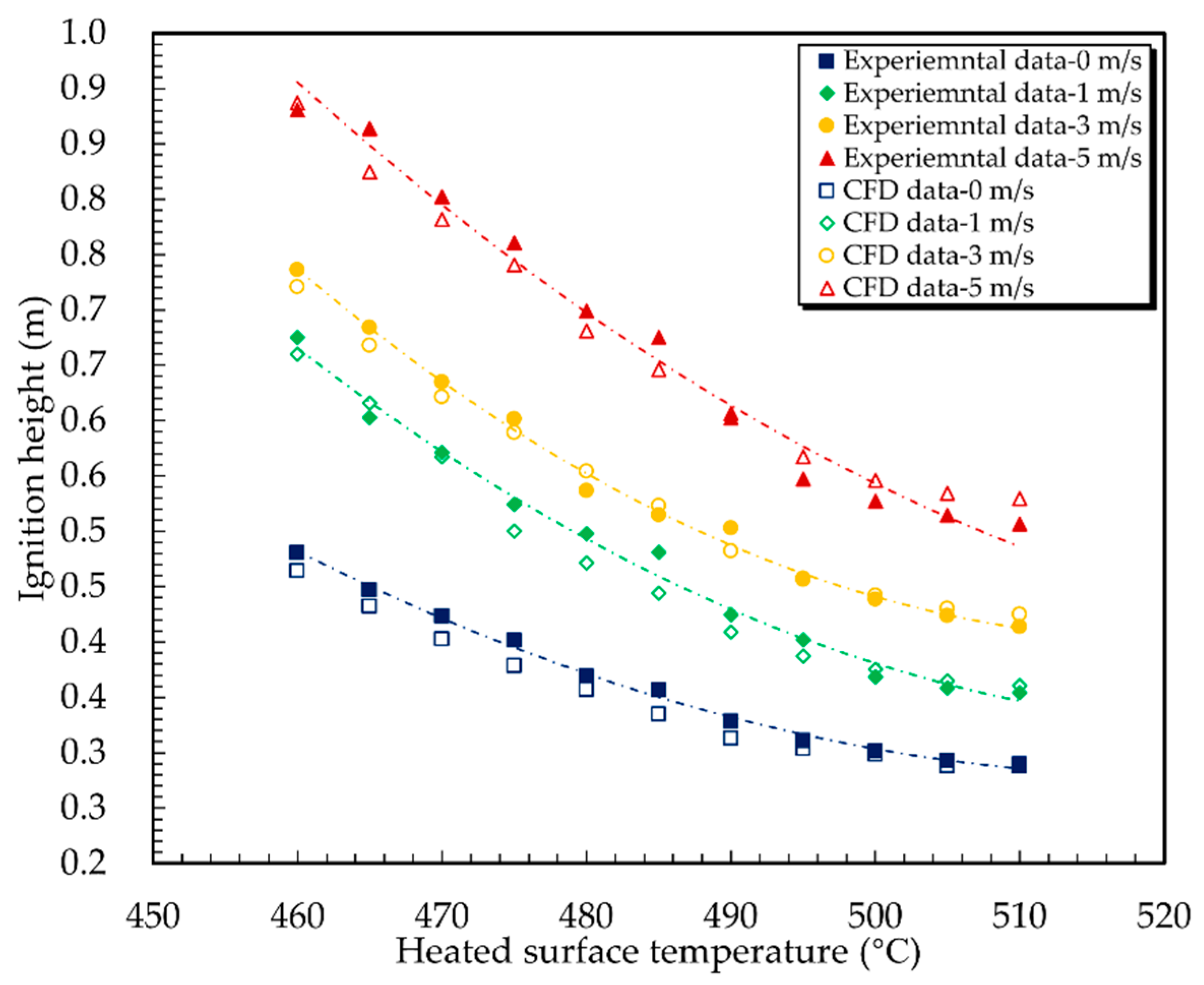

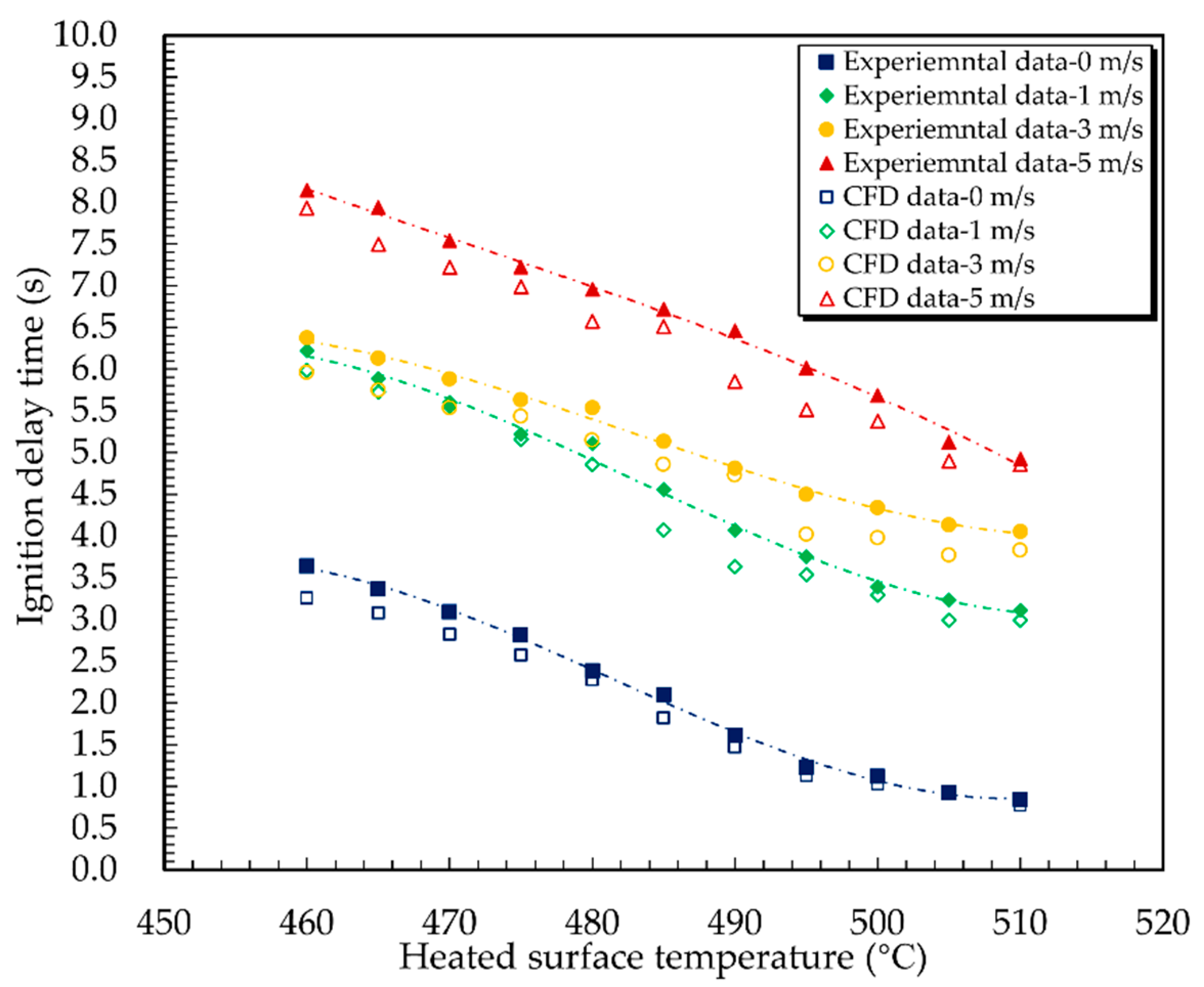

3.3. Effect of Ventilation on Marine Oil Ignition in Engine Room

3.4. Effect of Humidity on Marine Oil Ignition in Engine Room

4. Conclusions and Recommendations

- Elevated heated-surface temperatures lead to significantly different initial ignition positions of marine oil, and the distance between the ignition height and oil is closely related to heated-surface and environmental factors. Higher initial ignition occurs without mechanical ventilation, and the flame spreads along a path to the remaining oil surface. A lower ignition position occurs under ventilation, forming stable combustion.

- The ignition probability of marine oil shows a gradual increasing trend with elevated heated-surface temperatures. The prediction model developed in Equation (14) can be applied to assist in the investigation of fire sources caused by marine oil leakage in a fishing vessel’s engine room.

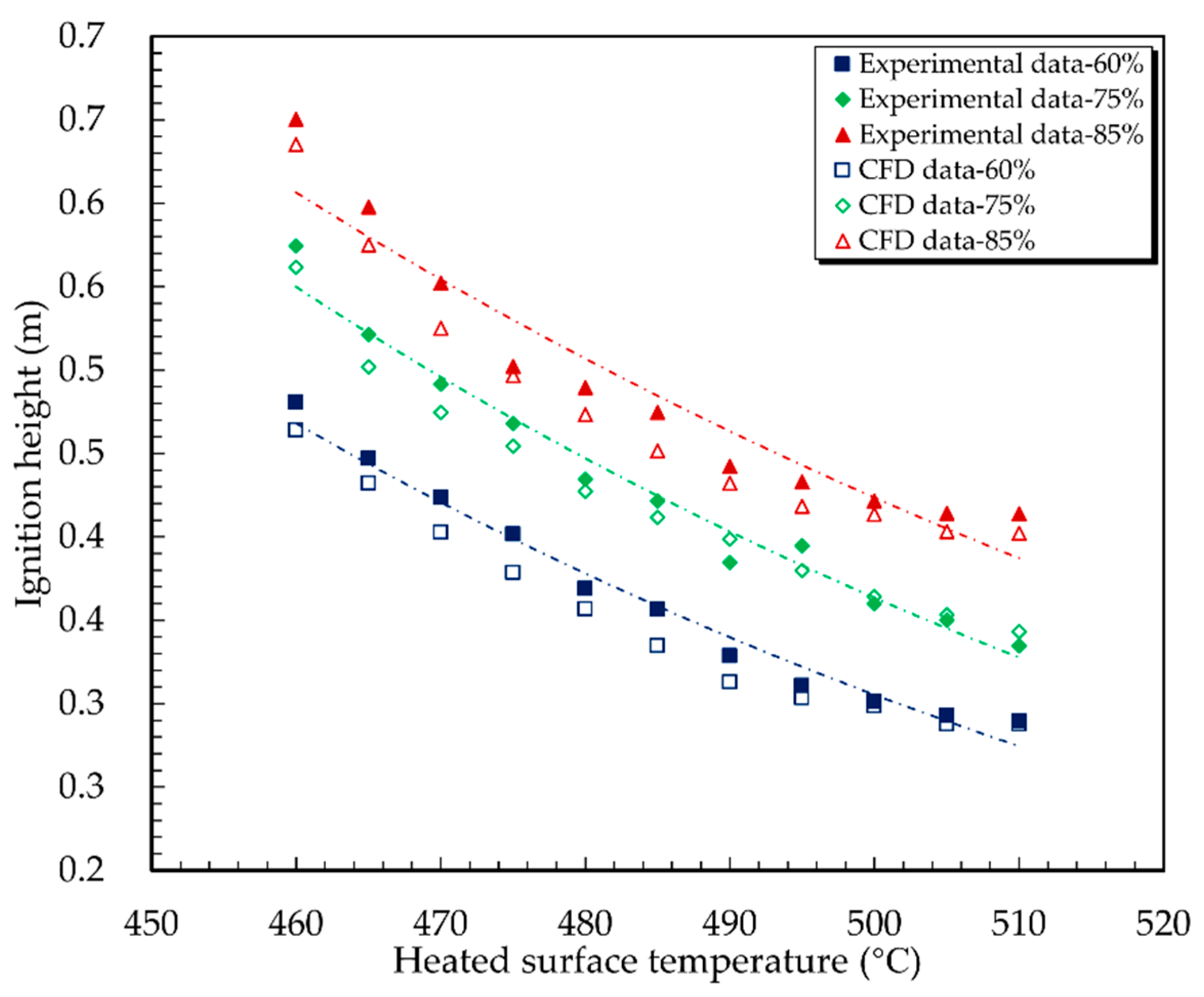

- The ignition height of the marine oil on the heated surface presents a downward trend with the increase in heated-surface temperature. This indicates that at the same heated-surface temperature, the enhanced engine room’s wind velocity results in a longer ignition delay time for the leaked marine oil.

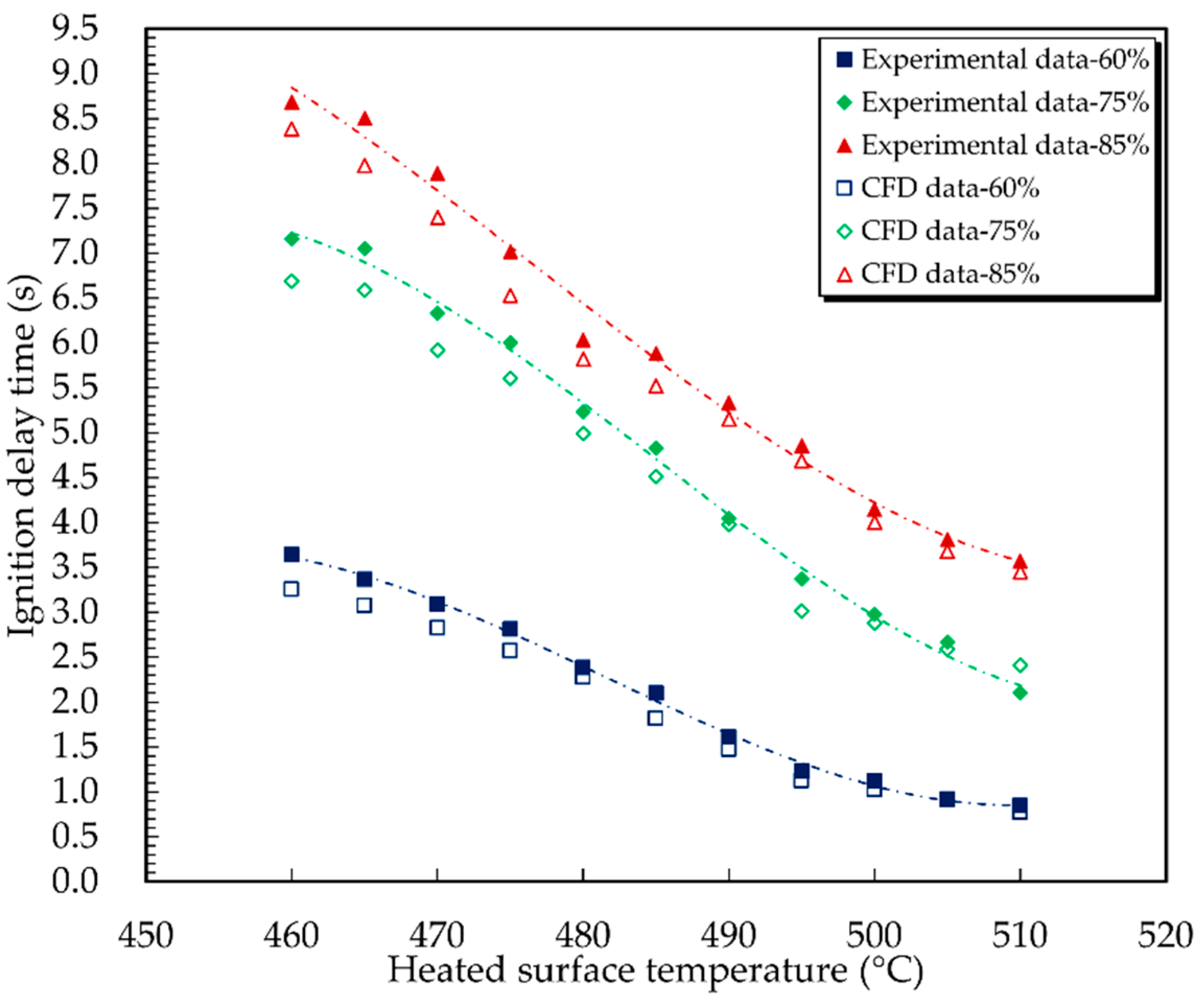

- The engine room’s humidity inhibits the upward transfer of heat; however, the degree of inhibition is limited. It is found that the increase in humidity in the fishing vessel’s engine room has a significant impact on the ignition delay time of the marine oil on the heated surface.

- Identify leakage sources of fuel. This requires inspecting marine diesel and lubricant oil piping lines for loose fittings and missing bolts on flanges and non-metallic hoses in areas where the high temperature takes place. The safety supervisor should regularly assess these components to identify potential leakage sources of marine fuel.

- Shield potentially heated surfaces. As the materials used to insulate the heated surfaces will degrade in marine operation processes, resulting in them becoming soaked in oil, it is recommended that they are checked consistently. Even if the insulation of the piping system shows to be in good condition, careful checking is essential in finding hidden, smaller heated spots which could trigger an initial ignition if in contact with marine fuel.

- Transform the prevention model. As the ventilation conditions in an engine room are enhanced, the ignition position of leaked fuel above a heated surface gradually increases. This means there should be different requirements for the location of fire monitoring sensors. It is recommended to add thermographic examination or temperature sensors above the potential heated surface of equipment, which can be used to monitor the formation of initial fire nucleus.

- Regulate the ventilation system. The strength of the ventilation condition increases the evaporation rate of leaked diesel on a heated surface and the particle velocity in the environmental flow field. As a result, the evaporative phase change rate of leaked diesel on a heated surface in an engine room will be promoted. Decision makers should ensure that the ventilation system is closed to avoid airflow conditions that promote the evaporation of leaked marine fuel and accelerate the possibility of fire.

- Perform evaluation under multiple indexes. Due to the increase in the humidity in a vessel’s engine room, the ignition delay time of leaked fuel above a heated surface increases. Because hazards still exist, it is recommended that monitoring data based on multiple indexes should be established to evaluate environmental safety. The influence of humidity on the evaporative phase variable of fuel on a heated surface and the rise in the engine room temperature must be considered comprehensively. Due to the inhibition effect of humidity on engine room temperature and evaporation phase transition, it is necessary to strengthen safety inspections and find the existence of leaked fuel in advance to better avoid fire risks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- The National Transportation Safety Board. Marine Accident Brief: Engine Room Fire Aboard Fishing Vessel Lucky Angel. Available online: https://www.ntsb.gov/investigations/AccidentReports/Reports/MAB2125.pdf (accessed on 10 December 2020).

- Veritas, D.N. Engine Room Fires Can Be Avoided; DNV: Veritasveien, Norway, 2000. [Google Scholar]

- Baalisampang, T.; Abbassi, R.; Garaniya, V.; Khan, F.; Dadashzadeh, M. Review and analysis of fire and explosion accidents in maritime transportation. Ocean Eng. 2018, 158, 350–366. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, S.K.; Kim, J.D.; Lee, J.M.; Kim, J.H. Ship structures: Design loads and reliability assessment. Appl. Sci. 2023, 13, 7633. [Google Scholar] [CrossRef]

- Fabiano, B.; Currò, F.; Pastorino, R.; Borghi, M.D. Oil spills: From statistical analysis to quantitative risk assessment. In Oil and Hydrocarbon Spills III; Modelling, Analysis and Control; WIT: Southampton, UK, 2002; pp. 429–441. Available online: https://www.witpress.com/Secure/elibrary/papers/OIL02/OIL02040FU.pdf (accessed on 1 January 2002).

- McNay, J.; Puisa, R.; Vassalos, D. Analysis of effectiveness of fire safety in machinery spaces. Fire Saf. J. 2019, 108, 102859. [Google Scholar] [CrossRef]

- Fabiano, B.; Currò, F.; Reverberi, A.P.; Pastorino, R. Port safety and the container revolution: A statistical study on human factor and occupational accidents over the long period. Saf. Sci. 2010, 48, 980–990. [Google Scholar] [CrossRef]

- Sung, I.A.; Rafet, E.K. Application of a CREAM based framework to assess human reliability in emergency response to engine room fires on ships. Ocean Eng. 2020, 216, 108078. [Google Scholar] [CrossRef]

- Spyrou, K.J.; Koromila, I.A. A risk model of passenger ship fire safety and its application. Reliab. Eng. Syst. Saf. 2020, 200, 106937. [Google Scholar] [CrossRef]

- Zhang, H.; Li, C.; Zhao, N.; Chen, B.Q.; Ren, H.; Kang, J. Fire risk assessment in engine rooms considering the fire-induced domino effects. J. Mar. Sci. Eng. 2022, 10, 1685. [Google Scholar] [CrossRef]

- Li, C.; Zhang, H.; Zhang, Y.; Kang, J. Fire risk assessment of a ship’s power system under the conditions of an engine room fire. J. Mar. Sci. Eng. 2022, 10, 1658. [Google Scholar] [CrossRef]

- Bao, J.; Bian, Z.; Li, B.; Li, Y.; Gong, Y. A hybrid approach for quantitative analysis of fire hazards in enclosed vehicle spaces on ro-ro passenger ships. Sustainability 2023, 15, 13059. [Google Scholar] [CrossRef]

- Antão, P.; Sun, S.; Teixeira, A.P.; Soares, C.G. Quantitative assessment of ship collision risk influencing factors from worldwide accident and fleet data. Reliab. Eng. Syst. Saf. 2023, 234, 109166. [Google Scholar] [CrossRef]

- Ahmed, S.; Li, T.; Huang, S.; Cao, J. Dynamic and quantitative risk assessment of Cruise ship pod propulsion system failure: An integrated Type-2 Fuzzy-Bayesian approach. Ocean Eng. 2023, 279, 114601. [Google Scholar] [CrossRef]

- Tunçel, A.L.; Beşikçi, E.B.; Akyuz, E.; Arslan, O. Safety analysis of fire and explosion (F&E) accidents risk in bulk carrier ships under fuzzy fault tree approach. Saf. Sci. 2023, 158, 105972. [Google Scholar] [CrossRef]

- Wang, K.; Ming, Y.; Wang, H.; Liu, X.; Qian, X.; Shi, T. Failure analysis and correction models for upward flame characteristics subjected to shipping container fire. Eng. Fail. Anal. 2023, 152, 107519. [Google Scholar] [CrossRef]

- Wang, K.; Wang, J.; Shi, T.; Qian, X.; He, Y. Effects of adjacent space on spill flame of chemical hazardous materials container fire. Int. J. Therm. Sci. 2020, 156, 106457. [Google Scholar] [CrossRef]

- Vairo, T.; Cademartori, D.; Clematis, D.; Carpanese, M.P.; Fabiano, B. Solid oxide fuel cells for shipping: A machine learning model for early detection of hazardous system deviations. Process Saf. Environ. Prot. 2023, 172, 184–194. [Google Scholar] [CrossRef]

- Shao, Y.; Kang, H.K.; Lee, Y.H.; Królczyk, G.; Gardoni, P.; Li, Z.X. A preliminary risk assessment on development the fuel gas supply system of a small LNG fueled fishing ship. Ocean Eng. 2022, 258, 111645. [Google Scholar] [CrossRef]

- Su, S.; Wang, L.; Nie, Y.; Gu, X. Numerical computation and characteristic analysis on the center shift of fire whirls in a ship engine room fire. Saf. Sci. 2012, 50, 12–18. [Google Scholar] [CrossRef]

- Su, S.; Wang, L. Three dimensional reconstruction of the fire in a ship engine room with multilayer structures. Ocean Eng. 2013, 70, 201–207. [Google Scholar] [CrossRef]

- Kang, H.J.; Choi, J.; Lee, D.; Park, B.J. A framework for using computational fire simulations in the early phases of ship design. Ocean Eng. 2017, 129, 335–342. [Google Scholar] [CrossRef]

- Park, B.C.; Lim, C.; Oh, S.J.; Lee, J.E.; Jung, M.J.; Shin, S.C. Development of fire consequence prediction model in fuel gas supply system room with changes in operating conditions during liquefied natural gas bunkering. Appl. Sci. 2022, 12, 7996. [Google Scholar] [CrossRef]

- Wang, K.; Liu, Z.; Qian, X.; Huang, P. Long-term consequence and vulnerability assessment of thermal radiation hazard from LNG explosive fireball in open space based on full-scale experiment and PHAST. J. Loss Prev. Process Ind. 2017, 46, 13–22. [Google Scholar] [CrossRef]

- Lan, Q.; Han, F.; Liu, Y.; Li, W.; Wang, Z. Effects of ventilation system design on flame behavior and smoke characteristics for mitigating marine engine room fire hazards. Ocean Eng. 2023, 281, 114890. [Google Scholar] [CrossRef]

- Li, C.; Mao, J.; Kang, Z.; Zhao, S.; Ren, H. Influence of firefighting intervention on fire spread characteristics in ship engine room. J. Mar. Sci. Eng. 2023, 11, 877. [Google Scholar] [CrossRef]

- Nubli, H.; Fajri, A.; Prabowo, A.R.; Khaeroman; Sohn, J.M. CFD implementation to mitigate the LNG leakage consequences: A review of explosion accident calculation on LNG-fueled ships. Procedia Struct. Integr. 2022, 41, 343–350. [Google Scholar] [CrossRef]

- Xie, C.; Huang, L.; Deng, J.; Wang, R.; Hao, G. Hazard assessment and hazard mitigation of fuel leak inside a ship elevator for LNG-fueled vessel. Ocean Eng. 2022, 259, 111943. [Google Scholar] [CrossRef]

- Xie, Y.; Liu, L.; Hao, Z.; Xu, Z.; Qin, J.; Zhu, J. Numerical simulation and experimental study of gas diffusion in a ship engine room. Ocean Eng. 2023, 271, 113638. [Google Scholar] [CrossRef]

- Zong, S.; Liu, K.; Qiu, W.; Gao, Z.; Wang, J. Numerical and experimental analysis of fire resistance for bulkhead and deck structures of ships and offshore installations. J. Mar. Sci. Eng. 2023, 11, 1200. [Google Scholar] [CrossRef]

- Singh, G.; Esmaeilpour, M.; Ratner, A. Investigation of combustion properties and soot deposits of various US crude oils. Energies 2019, 12, 2368. [Google Scholar] [CrossRef]

- Wang, J.; Jiao, Y.; Shi, L.; Xie, Q.; Li, G.; Liu, J.; Chen, W.; Zhang, S. An experimental and non-dimensional study on the vertical temperature distribution of a sealed ship engine room fire. Ocean Eng. 2018, 165, 22–33. [Google Scholar] [CrossRef]

- Liu, W.; Wang, L.; Su, S.; Wu, Z.; Guo, Y.; Du, K. Study of the flame flow and combustion characteristics of pool fires around a bluff body in the ship engine room. Case Stud. Therm. Eng. 2021, 28, 101514. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, Y.; Jia, J.; Chen, X.; Yao, W.; Lu, S. Experimental and theoretical analysis of the smoke layer height in the engine room under the forced air condition. Fire 2023, 6, 16. [Google Scholar] [CrossRef]

- Wang, K.; Ming, Y.; Zhao, H.; Jiao, Y.; Shi, T.; Zhang, Q. Effect of shock-flame interactions on initial damage characteristics in highway tunnel under hazmat tanker truck accident. Tunn. Undergr. Space Technol. 2022, 130, 104763. [Google Scholar] [CrossRef]

- Wang, K.; He, Y.; Liu, Z.; Qian, X. Experimental study on optimization models for evaluation of fireball characteristics and thermal hazards induced by LNG vapor Cloud explosions based on colorimetric thermometry. J. Hazard. Mater. 2019, 366, 282–292. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Guo, Y.; Xia, Z.; Lao, X.; Su, S.; Yuan, Z.; Wu, Z. Experimental study on mass burning rate and flame geometry of pool fires under two-way indirect ventilation in Ship’s engine room. Case Stud. Therm. Eng. 2023, 41, 102595. [Google Scholar] [CrossRef]

- Stamou, A.; Kuqo, P.; Douklias, A.; Antonopoulos, M.; Kostovasili, M.; Karagiannidis, L.; Amditis, A. The implementation of a smart lifejacket for assisting passengers in the evacuation of large passenger ships. Appl. Sci. 2023, 13, 2522. [Google Scholar] [CrossRef]

- Lekomtsev, A.V.; Ilyushin, P.Y.; Martyushev, D.A. Experience of implementing an intensifying device on the developed mobile well production treatment unit. Chem. Petrol. Eng. 2018, 54, 213–219. [Google Scholar] [CrossRef]

- Lekomtsev, A.V.; Ilyushin, P.Y.; Stepanenko, I.B.; Mekhanoshina, O.R.; Bakaneev, V.S.; Korobov, G.Y.; Kang, W. Technology of stable water-oil emulsion breaking by magnetic impact. Chem. Petrol. Eng. 2021, 57, 98–105. [Google Scholar] [CrossRef]

- Vairo, T.; Quagliati, M.; Giudice, T.D.; Barbucci, A.; Fabiano, B. From land- to water-use-planning: A consequence based case-study related to cruise ship risk. Saf. Sci. 2017, 97, 120–133. [Google Scholar] [CrossRef]

| Density at 15 °C (kg/m3) | Flash Point (°C) | Kinematic Viscosity at 50 °C (cSt) | Pour Point (°C) | Water Content (v/v) | Cetane Number | |

|---|---|---|---|---|---|---|

| Marine diesel oil | 991 | 63 | 180 | 24 | 0.5% | 40~60 |

| Parameter | Internal Temperature (°C) | External Temperature (°C) | Relative Humidity (%) | Internal Airflow Velocity (m/s) | Atmospheric Pressure (MPa) |

|---|---|---|---|---|---|

| Value | 45 | 32 | 60 | 1.0 | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, N.; Zhang, B.; Liu, X.; Wang, K.; Wang, H. Experimental Research and Numerical Analysis of Marine Oil Leakage and Accidental Ignition in Fishing Vessels. Appl. Sci. 2023, 13, 11510. https://doi.org/10.3390/app132011510

Li N, Zhang B, Liu X, Wang K, Wang H. Experimental Research and Numerical Analysis of Marine Oil Leakage and Accidental Ignition in Fishing Vessels. Applied Sciences. 2023; 13(20):11510. https://doi.org/10.3390/app132011510

Chicago/Turabian StyleLi, Na, Bin Zhang, Xiaolei Liu, Kan Wang, and Hao Wang. 2023. "Experimental Research and Numerical Analysis of Marine Oil Leakage and Accidental Ignition in Fishing Vessels" Applied Sciences 13, no. 20: 11510. https://doi.org/10.3390/app132011510