Abstract

Product assembly is often the last step in the manufacturing process. This task is usually performed by an assembly worker who needs to have practical experience and expertise. For complex products, the assembly may require a long time to study assembly plans. This paper presents a custom-designed Pick-to-Light system using Poka Yoke principles to make this activity easier. The created modular system with two-stage verification serves to guide the assembler precisely. It shows him on the display which parts he should use in a strictly defined assembly step. Our proposal aims to shorten assembly time and reduce the number of errors, which was supported by a case study in a small company with 30 employees. After analysing the data, we can declare that the proposed system significantly reduces the time required for assembly from 7 to 35% and reduces the error rate by 35%. The solution is scalable and flexible, as it can be easily adapted to display assembly steps for a different product.

1. Introduction

In today’s rapidly evolving industrial landscape, the pursuit of efficiency and error reduction has become paramount. A vital concept is emerging as manufacturers strive to optimize their production processes: Poka Yoke. The Japanese term “mistake-proofing” or “inadvertent error prevention” has gained significant recognition as an indispensable tool in quality management and smart production systems [1]. This study delves into the importance of Poka Yoke in contemporary manufacturing, specifically focusing on its implementation through the Pick-to-Light (PTL) system. By the end of this introduction, you will understand why this research is essential, why the chosen model is defensible, and what advantages it offers modern industries [2].

1.1. Importance of Our Study

In the relentless quest for operational excellence, reducing errors, enhancing efficiency, and minimizing waste cannot be overstated. Manufacturers today face many challenges, ranging from the growing complexity of production processes to the ever-increasing demands for high-quality products. The margin for error has dwindled, and the consequences of even minor mistakes can ripple through the entire supply chain, impacting customer satisfaction and profitability. In this context, Poka Yoke is a powerful strategy to tackle these challenges head-on.

1.2. Defending the Model

While Yoke’s suitability from both theoretical and practical perspectives is unquestionable, the theoretical foundation of Poka Yoke draws from the principles of Lean and Six Sigma methodologies, which have long been proven to enhance efficiency and reduce defects in manufacturing. It aligns perfectly with the overarching goal of modern smart production systems—minimizing variability and ensuring consistent, high-quality output. On a practical level, the simplicity and effectiveness of Poka Yoke make it an attractive solution for manufacturers across industries [1]. It is not confined to specific sectors, making it versatile and applicable in various contexts.

1.3. Advantages of Poka Yoke with Pick to Light

The marriage of Poka Yoke with the Pick-to-Light system presents a compelling solution. Pick to Light is a technology-driven approach that uses visual cues to guide workers through tasks, reducing the risk of picking errors and speeding up order fulfilment. Combined with Poka Yoke principles, it creates a robust system that virtually eliminates product assembly, packaging, and order processing errors. This approach enhances efficiency and improves worker morale by reducing the stress associated with repetitive, error-prone tasks.

1.4. Rationale and Objectives

The rationale behind this study is clear: to explore and demonstrate the transformative potential of Poka Yoke when integrated with the Pick-to-Light system within smart production environments. Our specific objectives include [3]

- Investigating the theoretical underpinnings of Poka Yoke and its compatibility with modern manufacturing principles;

- Assessing the practical implications and advantages of combining Poka Yoke with the Pick-to-Light system;

- Providing actionable insights and recommendations for manufacturers looking to implement this model.

In summary, this research sheds light on Poka Yoke’s vital role in the modern manufacturing, defending its theoretical soundness and practical applicability [2]. By integrating Poka Yoke with the Pick-to-Light system, we aim to showcase how this model can revolutionize smart production systems, providing a roadmap for organizations striving for excellence in efficiency and quality control.

1.5. Poka Yoke and Pick to Light

The term Poka Yoke, in English Mistake Proofing or Error Proofing, is composed of two Japanese words “Poka”—unintentional mistake and “Yokeru”—prevent. The Poka Yoke concept has been used in various forms since the beginning of mass production. Its author was the Japanese innovator Shigeo Shingo, the first to present this method at Yamada Electronic Company in 1961. However, like most Japanese methods, this one became better known worldwide only after its use in the United States of America in the 1980s and 1990s. The initiator for the Poka Yoke implementation in the American automobile industry was the expert Hiroyuki Hirano, who successfully adapted it to the requirements of the American sector [4]. The Poka Yoke principles are shown in Figure 1.

Figure 1.

The Poka Yoke principle [4].

The design of an “error prevention tool” is a procedure in which mechanisms are introduced into the process environment or the process itself to prevent a given erroneous operation from occurring at all [3]. The method is preventive and based on the principle of zero error occurrence in the process. Control elements focus on the initial stage of the process and the inputs themselves before the active activities that add additional value to the inputs occur.

An error in the production process is defined as any deviation from the predetermined technological, possibly working, drawing requirements, or even the smallest deviation from the correct product functioning. Almost all mistakes can be prevented in some way [5]. The cause of errors in the process is, in most cases, the employee themself.

Errors can generally be divided into two categories:

- Process errors arise from incorrect production environment design, workplace, procedures, etc.

- Errors caused by employees—the human factor is at work here.

The main mission of the Poka Yoke method is to identify and prevent errors. If they do occur, the defective product must not reach the customer.

Pick to Light is a method within the logistics and warehouse system that increases the effectiveness and process efficiency of picking goods from shelving plans. The basis of this method is light indicators directly placed on shelves or racks, which show the operator which items to select and in what quantity. The operator turns on the light indicator for a specific item and takes it, confirming the task’s completion. In this way, the possibility of confusion or the incorrect selection of goods is minimized and the speed and accuracy of the process is increased [4,5].

The connection of Poka Yoke and Pick to Light could be realized in such a way that the light indicators in the Pick-to-Light system would be designed to indicate specific items to be selected and possible errors or deficiencies in the performed tasks. For example, if the operator picked the wrong item or in the incorrect quantity, the system would use indicator lights to indicate this error [6]. This way, Poka Yoke would be used to prevent errors in the Pick-to-Light process and ensure that the operator picks the correct items in the right quantity. Both systems, Poka Yoke and Pick to Light, contribute to improving the quality, accuracy and efficiency of production processes. Reducing errors, increasing productivity and enhancing safety are benefits that can directly impact the success and competitiveness of smart manufacturing systems [3,7]. The implementation of Poka Yoke and Pick to Light in smart manufacturing systems can face some challenges:

Poka Yoke [6]:

- Implementation complexity: Designing and implementing Poka Yoke requires thorough production process analysis, potential error identification and the creation of appropriate control mechanisms. It can be time and resource-intensive.

- Changing work practices: Introducing Poka Yoke may require changing work practices and employee habits. Some employees may resist change, so providing adequate training and support for their adaptation is important.

- Integration with existing systems: In the case of smart manufacturing systems, it can be a challenge to integrate Poka Yoke with existing technologies and control systems. Ensuring compatibility and interoperability may require technical adjustments and effort.

Pick to Light [7]:

- Implementation costs: Pick to Light can be quite expensive to implement. It requires investments in light indicators, sensors, control systems and possibly the modification of racking systems.

- Physical installation: Implementing the Pick-to-Light system requires installing light indicators on racks or shelves. The installation can be complex and requires modifications to existing infrastructure.

- Maintenance and management: The Pick-to-Light system requires regular maintenance and management. Light indicators, sensors and other components must be monitored and repaired in case of malfunctions or wear.

- Adaptation to changing needs: Intelligent manufacturing systems can change and expand, so it is necessary to ensure that the Pick-to-Light system can adapt to new requirements and extensions.

Overall, it is important to remember that implementing Poka Yoke and Pick to Light in intelligent manufacturing systems requires careful planning, adaptation to specific needs and active change management [7].

2. Literature Review

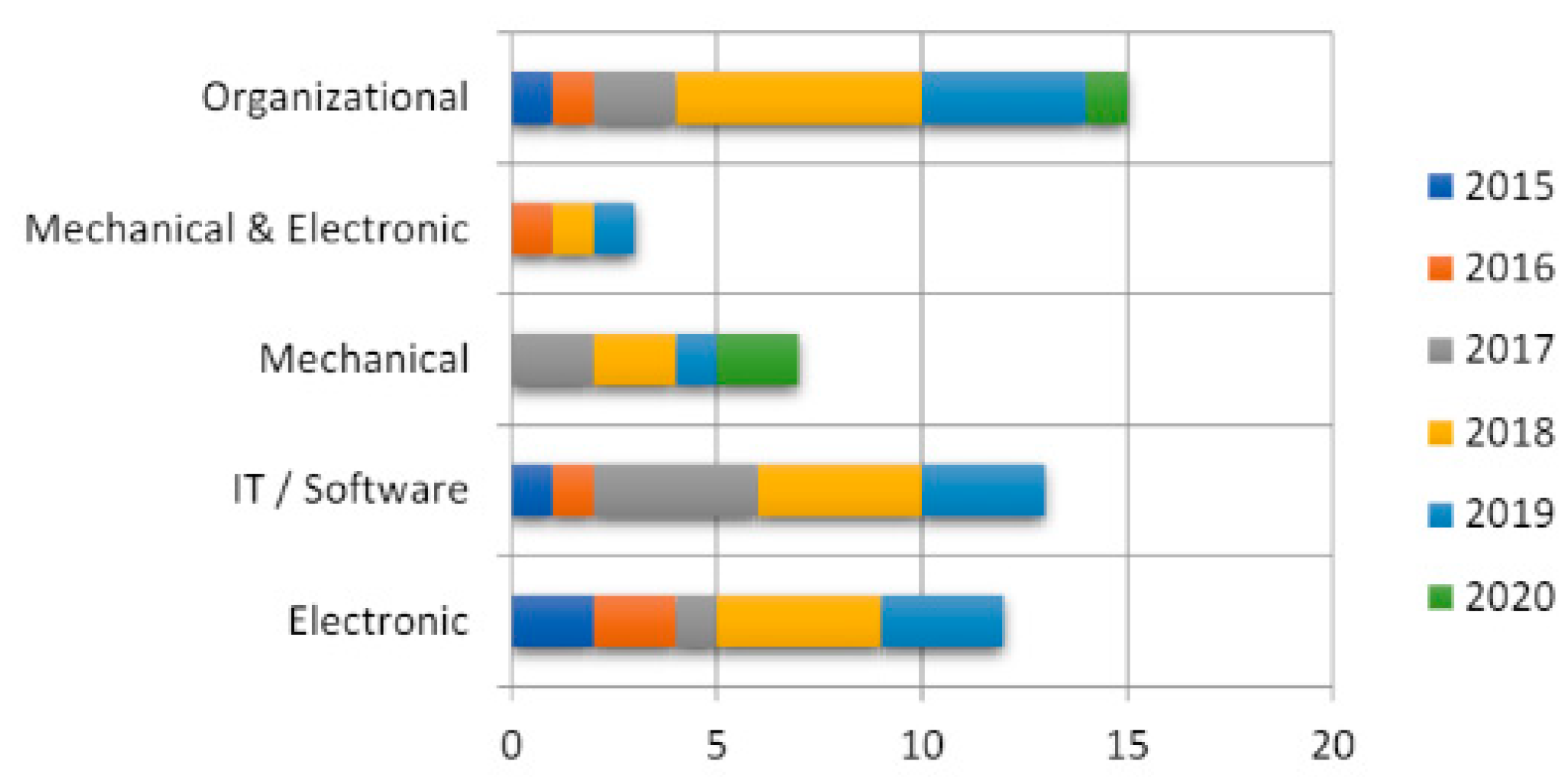

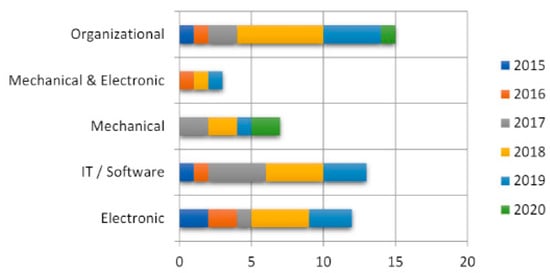

Poka-Yoke is an approach that enables an effective way to improve process quality. Its basic principle is the identification of errors already at their source and the prevention of subsequent errors. The use of the Poka Yoke approach has been applied for several years in various areas; e.g., the authors Dudek-Burlikovska in [8] described the application in the automotive industry in the production of engines and assembly of gearboxes. In a study by Belu et al. [9], they used Poka Yoke in image analysis and fault identification. A regular video camera captured the image and then converted it into a monochrome matrix capable of identifying and classifying the type of failure. Another application of Poka Yoke is shown in the production of air pipes [10], and in the production and assembly of compressors [11]. The authors Widjajanto et al. give a more comprehensive overview of the application of this approach in [2]. Based on their analysis and evaluation of 50 literary sources, which discussed the possibilities of applying Poka Yoke to eliminate errors, they presented the following division of individual areas (Figure 2).

Figure 2.

Literature review of Poka Yoke (authors own processing).

These were mostly solutions in production areas. The application of Poka Yoke is also possible in the field of business operations. The proposal for such an application is presented in the paper “From engineering design to information system design” [12]. However, the present also brings new elements and connections to this approach. We can see this in the Martinelli et al. contribution [3], who propose an effective Poka Yoke solution by combining convolutional neural networks and lean manufacturing tools to develop intelligent production lines. Human error is the most common cause of failures in automated production lines. The elimination of this factor is described by Alogla et al. in their paper [13].

The papers collectively suggest that Pick-to-Light visual guidance systems can be effective in various applications. Sodhi [14] presents LightGuide, a system that projects guidance hints directly on a user’s body to guide hand movements with high accuracy. Yang [15] explores LightGuide as a directional feedback solution for visually impaired individuals, showing that it outperforms a baseline haptic solution in terms of efficiency and accuracy in navigation. Lastly, Chung [16] presents Guiding Light, an indoor navigation assistance system that uses projection-based augmented reality to provide way-finding information. These papers collectively demonstrate the potential of Pick-to-Light visual guidance systems in improving movement guidance, navigation, and visibility.

The following papers collectively provide insights into the pick-to-light system in manufacturing. Tosin [17] presents a pick-by-light system using RS-485 serial communication and TCP/IP with the Modbus protocol, showing that it can improve productivity in item retrieval. Wan-mi introduces a pick-to-light system based on the CAN bus, highlighting its effectiveness in improving logistics operations. Qiang discusses the principle, construction, and design considerations of the pick-to-light system, emphasizing its potential to enhance logistics efficiency [18]. Daneshjo [19] focuses on designing and upgrading the assembly process in the automotive industry, specifically the Pick-to-Light system, to improve component installation and time measurement. These papers collectively demonstrate the benefits and potential of pick-to-light systems in manufacturing, including increased productivity and improved logistics operations.

In the presented article, we are focusing on the possibility of using our Pick-to-Light system to eliminate errors caused by operators in assembly of small components.

Basic Functions of Poka Yoke

Every error occurring in the process has two stages of its development: it is soon to appear or has already fully manifested itself. The knowledge that the error could appear soon is called prevention or a preventive measure. Notice of a mistake that has already manifested itself is called detection. The Poka-Yoke method has three basic functions to its interventions to an already existing error [20]:

- (1)

- Shutdown function;

- (2)

- Control function;

- (3)

- Warning function.

The control and shutdown functions are used to identify errors and interrupt production if a given error occurs. Combining the two functions of the Poka Yoke method makes it possible to achieve the maximum protective effect in the discovery and termination of serial errors arising during serial production in large batches [20,21]. When detecting the presence of an error in the process, the production flow is stopped, which prevents defects and makes production more efficient. On the other hand, eliminating random recoverable errors is very costly [21].

The warning function is obligated to notify the employee of the error on the production line, equipment or machine. As a typical example, a warning with light signalling when an error is found can be mentioned. Alerted by a light signal, the employee sees the given problem, evaluates it and then decides on appropriate measures to eliminate it. This is a relatively cheaper solution than, for example, the control function. The disadvantage is that the employee is responsible for interrupting the process. This means that in the event of his inattention, failures may occur [22].

After all, the fact remains that man is forgetful and tends to make various oversights. Therefore, employees are very often warned that they are making mistakes. The approach subsequently intimidates and disgusts employees, lowers work morale and, most importantly, does not solve the problem. Poka Yoke is a technique that deals with solving any problem. We divide individual types of means of this method based on their functions and settings into [20,22]

- A control device located directly at the source of the error—before the failure occurs. A typical example is a pin that prevents incorrect orientation of the workpiece from being processed. These means are often the most effective solution.

- The 100% control for detection—using a low-cost sensing device such as a limit switch. In case of the presence of any abnormality, light or sound signalling is activated.

- Immediate measures to stop the operation in the event of an error—an example is a blocking circuit that automatically shuts down the machine from operation.

The means used to detect errors in the process may not immediately represent increased costs. Examples include a locking pin located in a jig or a limit switch that responds to the location of a part. However, applying these means should not be an attempt to eliminate the need for specific work skills [23].

Another example is a counter or an alarm that prompts the worker to perform a task. That action can be moving the defective piece to the space for failures. With the help of a sensor located in the storage space, the presence of a defect will be recorded, and only then can the given process continue. The examples mentioned above do not only represent error prevention; they depend on the employee, who must react accordingly. Properly motivating and involving employees in product improvement or the process can significantly reduce errors [24].

Company managers must have an idea in the field of quality management. This idea must be fully supported by creating a corporate culture through which employees would be motivated, and this vision would be accepted, either by providing time and support resources to work teams when analysing a problem or by introducing a reward system to motivate employees [23,25].

After a detailed analysis of the Poka Yoke and Pick-to-Light methodology, this paper aims to examine the potential of the chosen methods for implementation in a specific case in an enterprise on a selected sample of respondents.

Before the solution itself, we defined the basic questions that we will try to verify during the solution of our implementation for a specific solution.

- Research question 1: does the introduction of Pick to Light affect the assembly process?

- Research question 2: how do socio-demographic characteristics influence working with Pick to Light?

- Research question 3: does the number of assembly operation repetitions affect the overall assembly of the production batch?

- Research question 4: does the introduction of Pick to Light affect the overall assembly error rate?

3. Materials and Methods

Our research design includes a comprehensive review of the relevant literature, case studies from various industries, and data analysis to accomplish these objectives. We will examine both quantitative and qualitative data to provide a well-rounded understanding of the impact of Poka Yoke with Pick to Light in smart production systems. This multi-faceted approach ensures that our study advances theoretical knowledge and offers practical guidance for organizations seeking to enhance their production efficiency and quality [2].

We can use a wide variety of means to detect errors and malfunctions. Sensors used in the Poka Yoke method are divided into two groups [26]:

- Contact means—those that touch the tested part. The most frequently used tools are limit switches and micro switches. These can track the presence of a piece, cutting tool or mould and they are special in their flexibility. They are used to ensure the interruption of the process until the given piece takes the correct position or if it has the wrong shape. The mentioned method also uses other means based on contact, such as distance switches, displacement, part, metal passage sensors, and several other mechanical solutions.

- Non-contact means—these do not require direct contact. They find their application when working with translucent, opaque and transparent pieces. Photoelectric switches can be mentioned as a type of non-contact means. These work in two ways. The first way is to work with transparent objects. In this case, two units are used, one of which sends a light beam to the other, which is its recipient. This type is either in the on state, if the light passes through the object, or in the off state if there is an obstacle in the beam’s path. The second way is the reflex type of photoelectric switch. It reacts to the presence of an object only after the reflection of a light beam from its surface.

3.1. Pick-to-Light System

Poka Yoke minimizes unintentional errors or errors due to inattention to almost 100%. The group of solution systems also includes other methods, such as Pick by Voice, Pick and Work, Pick by Vision and so on. Even though these systems are mostly implemented in logistics, they are increasingly finding their place in assembly as well [27].

Devices using the principles of the Pick-to-Light system are adapted so that a given assembly or storage cannot be carried out in more than one way. The main means of these devices are optical signalling elements that gradually light up, placed above each warehouse position, respectively (cell). When a component is removed from any situation, the worker’s hand will interrupt the light beam, causing the corresponding signalling to go out and another signalling to be lit in another position. The system is capable of notifying the worker of a possible error with a light or sound warning [28].

In this way, the presence of paper expenses, assembly sheets, etc., is unnecessary. The flawless worker workflow is monitored by a sophisticated system that navigates him during assembly and warns him if he has made a mistake.

From the point of view of increasing the production process quality, the Pick-to-Light systems represent the philosophy of “zero error rate”. Visual control of the production process is used in several industrial areas (electrical and automotive industries, logistics, storage, etc.) [29].

The main benefits of Pick-to-Light systems are:

- Increasing work productivity;

- Improving quality;

- Reducing the occurrence of errors to zero;

- Continuous inventory;

- Connection to ERP and warehouse systems;

- Increasing flexibility;

- Speed of new personnel training.

The Pick-to-Light system is used in the order-picking environment. It allows the employee (male or female) to quickly and easily find the right position using lights or LED displays. Each tag represents an item in the storage location. In addition to guiding the employee to the exact location, the light shows the same amount of items in the rack’s bins. The system requires confirmation before the item is selected.

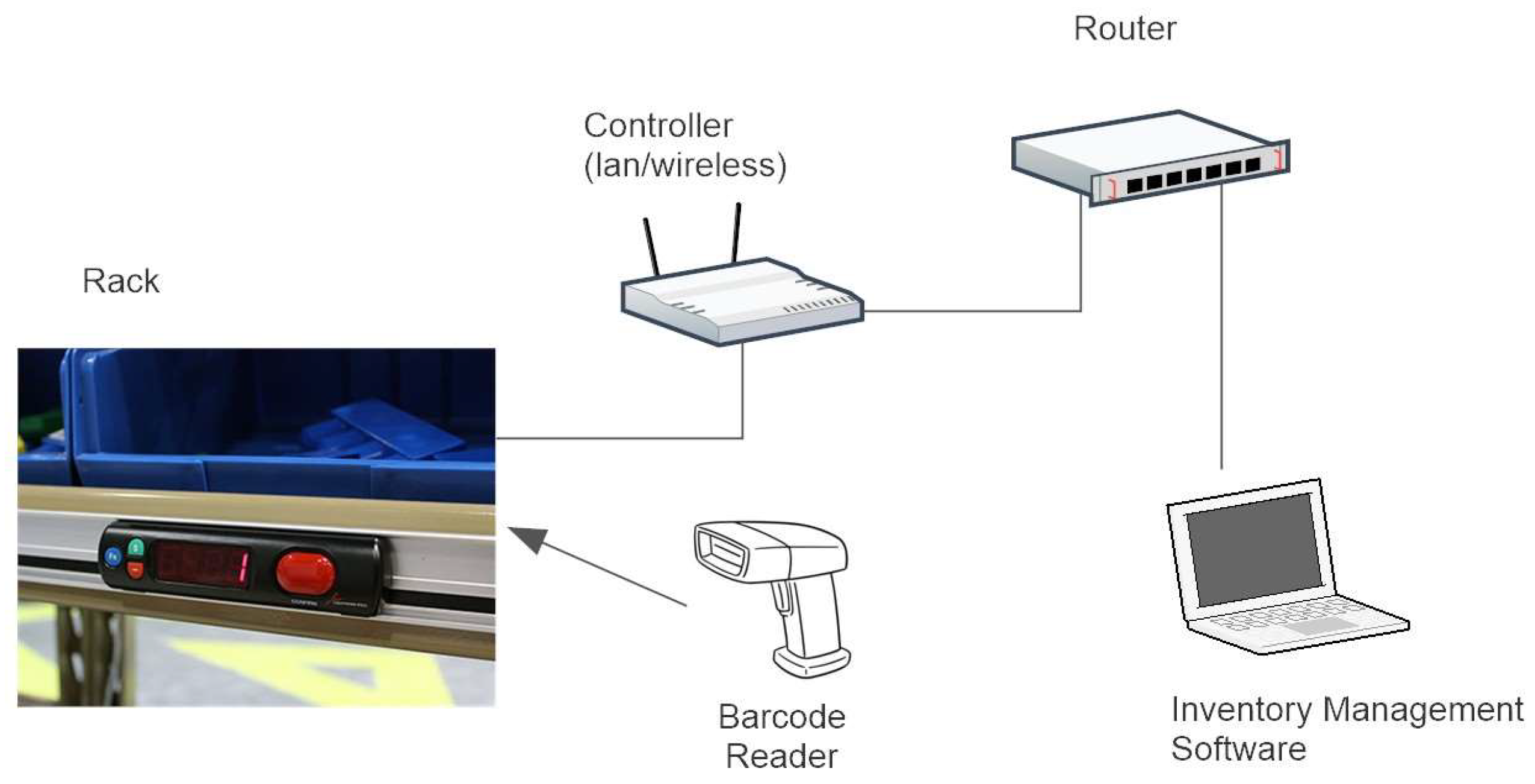

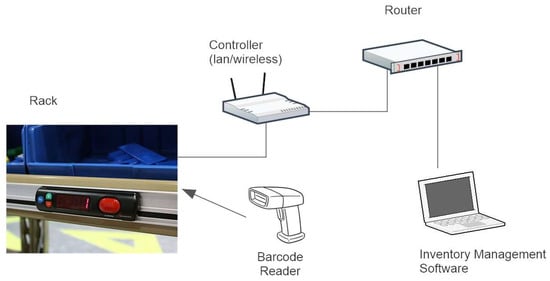

As Figure 3 shows, the architecture of the PTL system consists of the following components.

Figure 3.

Pick-to-Light system architecture.

- A rack consisting of multiple Pick-to-Light units;

- A bar code reader for scanning items inserted and removed from the rack;

- A control unit/controller (network or wireless) connected to the Pick-to-Light system;

- A router or network hub;

- A remote PC installed with real-time material inventory management software.

The PTL system works as follows. In the rack of several rows, an optical sensor and a control unit are mounted on each controlled cell. Each row has several cells connected to a control unit that ensures sensing and informing the employee. Subsequently, several units are connected to a central router, which sends all information to the inventory management software (IMS). The unloading and storage of individual components in the cell is recorded using a barcode reader [28,30].

This information is sent to IMS, which informs the operators in the warehouse about the box preparation with the exact number of parts. After it is inserted into the IMS cell, it keeps inventory records and loads the program for the specified assembly. According to the requirements, the individual cells are explained in the exact order, and the number of pieces is displayed on the LED display. When selecting a component, the employee’s hand is read using an optical sensor and the operation is completed. Subsequently, another cell is illuminated, and the employee repeats the process [30]. The individual steps are entered into the control units connected to the router.

Linking the Poka Yoke and Pick-to-Light methods in the intelligent manufacturing system can be achieved by integrating and cooperating with these systems. Here is a possible approach to connect them [31]:

- Error identification and indications synchronization: Create a communication interface between the Poka Yoke and Pick-to-Light systems to exchange information about identified errors and requirements for picking goods. For example, suppose the Poka Yoke system detects an error in the assembly process. In that case, it can inform the Pick-to-Light system so that the corresponding indicators show the operator that the item is not needed or is incorrect.

- Education and training of employees: Employees should be trained and educated about the functionality of both systems and how to work with them properly. They must be informed on interpreting indications, recognising errors, and taking the correct steps to repair or select items.

- Integration with the central control system: Poka Yoke and Pick-to-Light systems should be integrated with the central control system of the intelligent manufacturing system. This ensures coordination and synchronization between production processes, error identification, selection indications and other aspects of the system.

- Performance monitoring and analysis: Systems should be able to collect performance data such as picking accuracy, error response time, time statistics and other relevant data. These data should be analysed and used to identify process improvement and optimization opportunities.

Integrating Poka Yoke and Pick to Light in an intelligent manufacturing system will allow the creation of a connected and efficient system that minimizes errors, increases productivity and improves production quality [32].

3.2. Procedure for Implementing the Poka Yoke Method Using Pick to Light

Part of the presented implementation is the creation of the Pick-to-Light device, labelled Spider 1, and the assembly model procedure part of the extruder with a motor. The goal is to create a training workplace for employees focusing on increasing production efficiency. Subsequently, we designed the assembly procedure of the sample component, which allows the simulation of the Poka Yoke method. An important prerequisite for the model workplace creation was acquiring the necessary knowledge in the Pick-to systems, or Pick-by and Poka Yoke methodology. With the proposed simulation workplace, it is possible to create assignments prepared by employees to develop assembly procedures [33]. As mentioned in the previous text, Pick to Light belongs to the group of solution systems using the principles of the Poka Yoke method. It means it minimizes unintentional errors, or errors due to inattention to almost 100%. The given device ensures that the given assembly or storage cannot be carried out in multiple ways. The presence of paper expenses, assembly sheets, etc. is not necessary. A sophisticated system monitors the worker’s flawless workflow, which not only navigates him during assembly but also warns him if he has made a mistake [34]. The procedure for programming the given device and its functioning is described in the next part of the paper.

The basic elements of the Pick-to-Light device are the following components:

- Optical-reflective sensors with LED indicators: These sensors are equipped with 2 LEDs and a comparator. They emit infrared light, which bounces off objects and returns to a photodiode, allowing them to detect interruptions in the beam caused by obstructions (e.g., an operator’s hand or plastic rod). They display red and green colours, with green indicating a suitable container and red signifying the programming mode or an incorrect container. Eight such sensors are positioned in the device’s upper bars, and their sensitivity can be adjusted via a built-in trimmer on the printed circuit board.

- Control unit with display and power supply: The core of the control unit is an ATmega 128-8 bit AVR processor responsible for system operation and control. It runs the SPIDER1FINAL program developed in Bascom-AVR IDE (2.0.8.1).

- Integrated display unit: The control unit features a BOLYMIN BC1602A display, a 2 × 16 STN yellow-green display with LED backlight.

- Power supply and connectivity: The control unit is powered by a 5V/DC adapter and has ports for connecting drawers and the AC/DC adapter at the rear.

- Functional unit (Figure 4): The Spider 1 device consists of a rectangular aluminium structure divided by a 2 mm thick aluminium plate. Aluminium sheets protect its sides, covered with a self-adhesive carbon 3D film for durability. Plastic containers with dimensions of 75 × 102 × 160 mm are placed inside, designed with a 45° raised rear for easy component insertion and removal. Sensors and LEDs are positioned above these containers in aluminium rails.

Figure 4. Constructed Pick-to-Light device labelled Spider 1.

Figure 4. Constructed Pick-to-Light device labelled Spider 1. - Portability: Spider 1 is a lightweight, compact, and portable device designed to meet customer needs.

- Additional components: The device includes two connecting cables made by modifying SCART-SCART cables with D-SUB MALE connectors. The wires are differentiated by the colour of their covers (grey and black). The power supply for the PTL device is AC/DC with a 10 W model, supporting input voltages of 100–240 V at 50–60 Hz and providing an output of 5 V/2 A through a 5.5/2.1 mm connector.

The created Spider 1 device works as follows: After the initial press of the start button, the device turns on. A quick test will run and the LED indicators will light up on the front panel, as well as a test of the optical-reflective sensors. After the test, information about the device status is displayed on the LED display. If the device is in order, assembly sequences will be selected from the program database. After starting the sequences and correctly arranging the boxes with components, the LED indicator above the box with the selected component lights up green. If the LED indicator flashes in predetermined intervals, it means the selection of a larger number of pieces is determined by the number of flashes of the LED diode. Text information about the order and number of pieces is shown on the display. If we want to proceed to the next step, we have to put our hand in the box with the illuminated part, and then the optical sensor detects the hand’s presence and moves to the next operation. Subsequently, another diode lights up and defines another component. Such a procedure is repeated according to a predefined assembly procedure. The description of the experimental assembly procedure is given in Section 3.3.

Pick to Light, on the other hand, is a specialized technology in the realms of manufacturing and logistics designed to enhance precision and productivity in picking and assembly operations [35]. The amalgamation of these methodologies entails the creation of a systematic approach, guiding workers toward the accurate selection of items and quantities with minimal room for error. This approach is structured as a comprehensive procedure [36]:

- Firstly, it involves the meticulous definition of implementation objectives and scope, addressing specific error types and identifying areas of application. Subsequently, a rigorous analysis of existing processes is conducted, incorporating worker observations, historical error-data review, and comprehensive process flow analysis.

- Selecting an appropriate Pick-to-Light system is pivotal, necessitating thorough research considering product types, facility layouts, and budgetary considerations. The design phase involves collaboration with system providers to tailor the plan, focusing on light placement, display configurations, and seamless integration with existing infrastructure.

- Installation and setup proceed as per design specifications, ensuring flawless functioning of components like lights, displays, and sensors. Employee training is paramount, enabling them to effectively utilize the system by understanding its operation, information interpretation, and response mechanisms [37].

- The system undergoes rigorous testing with various products and scenarios to unveil potential issues, followed by calibration for pinpoint accuracy. An integrated monitoring and feedback mechanism is established, continually tracking performance and fostering employee feedback for necessary adjustments.

- Continuous improvement, grounded in data analysis, drives enhancements and system updates. Documentation and standardization provide clear guidelines for system use, ensuring employee adherence. Maintenance and support frameworks are instituted, guaranteeing system integrity and addressing technical issues promptly.

- Regular evaluations assess the system’s effectiveness and ROI calculation quantifies financial benefits. Finally, successful initial implementations may prompt system expansion into other critical areas. This comprehensive procedure effectively minimises errors and defects by integrating Poka Yoke with Pick-to-Light technology, significantly enhancing manufacturing or picking process efficiency and product [38].

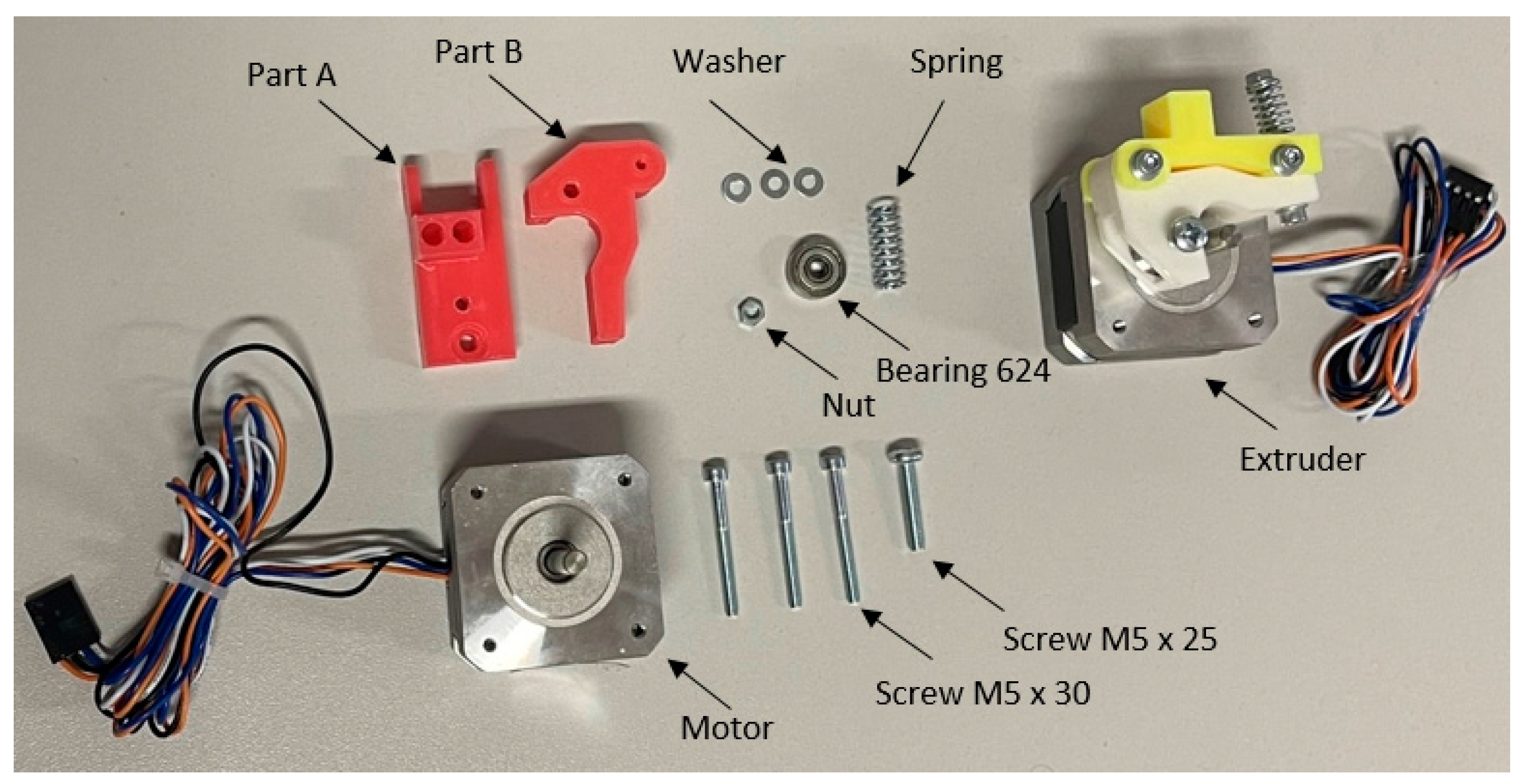

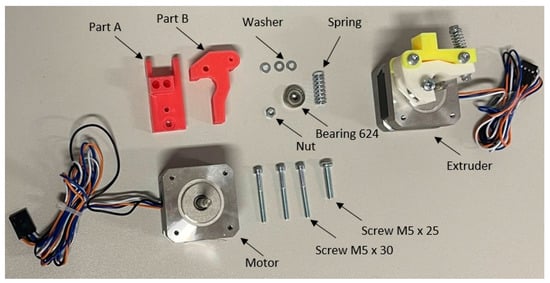

3.3. Model Component

In the article, we focused on the assembly of small material components. The model part is an extruder with a motor serving as a filling feeder in 3D printers; see Figure 5 [39]. It is a modular part composed of several smaller components. Its 8 basic parts described in the assembly procedure are sufficient for testing purposes [40].

Figure 5.

Extruder with the motor in unfolded and folded state.

Workplace—this consists of a work table used to place the created PTL device. This is a modular table, manufactured by Bewatech.

The assembly procedure of the model part consists of a graphic and verbal assembly procedure of the extruder with a motor.

Step 1—insertion of bearing 624 into plastic part A.

Step 2—fixing the bearing with an M5 × 20 screw.

Step 3—connection of plastic parts A and B.

Step 4—attaching parts A and B to the motor with M5 × 25 screws with a washer.

Step 5—transversing the connection of parts A and B with an M5 × 30 screw with a washer.

Step 6—securing the M5 screw with a washer, a spring washer and a nut.

Several components are required to carry out these assembly steps, including a single-row ball bearing (bearing 6208 STN 02 4630), screws of various sizes and types, washers, a helical cylindrical compression spring, and precision hexagonal low nuts. Additionally, specific working tools, such as an L hexagonal Allen key and a Phillips screwdriver, are needed to complete the assembly process effectively.

4. Results

The complex methodology of the test consists of two parts. The first part simulates the production process of the model part construction without introducing the PTL device. The PTL device is already implemented in the investigated process in the second part. The main monitored and compared parameters are the length of one production cycle, one production batch, the total error rate of the process, etc, basic tendencies of carrying out training in a simulated environment. Both tests were performed on a selected sample of 30 participants. Basic socio-demographic data are presented in Table 1.

Table 1.

Participants’ socio-demographic characteristics.

4.1. Test before Application of PTL

With the constant improvement in produced parts, components or sometimes entire objects, the number of different variants of their construction also increases. This emphasises the number of elements that must be in the workplace in a given situation. Individual components are usually prepared in containers or complete sets, and the worker chooses the ones he needs based on the printed specification or assembly procedure. The employee entrusted with the assembly of the model part has trays with various components placed on the work table, representing the workplace. Based on the prepared assembly procedure, he prepares the individual containers and starts assembling the model part.

This classic approach to assembly activities carries several negatives. The most important ones can be ranked:

- -

- The length of the assembly-procedure training unnecessarily extends the start of the assembly process;

- -

- Frequent viewing of the assembly procedure—another unnecessary waste of time;

- -

- The constant pressure exerted by the moderator causes inattention and tension, resulting in errors and inappropriate pieces;

- -

- The simulation of such a situation arouses unnecessary nervousness and uncertainty in the student;

- -

- The workplace becomes uncomfortable and less and less psychologically bearable.

As mentioned, the test was conducted on a selected sample of 30 employees of an SME company. We gradually measured individual preparatory times and assembly operations, which we recorded in a Table 2. The first step was the components and individual tools needed for assembly. This operation ranged from 20–30 s, with an average workplace preparation time of 24.7 s per production batch of 10 pieces. The second operation was the initial employee training on safety and health protection. These operations lasted 5–20 s, with an average training time of 11.2 s. The third operation studies the technological procedure printed in A4 format (see Figure 6). The initial study took place in the range of 24–37 s, with an average time of 30 s. Subsequently, the component was assembled according to the manual described in Section 3.3. Assembly consisting of six steps was in the range of 56–70 s, while the average assembly time of one component was 63.83 s. Each employee repeated the assembly 10 times, which were recorded in a table. Subsequently, an optical check of connection and functionality took place. It is a non-time-consuming test that lasted 4.5 s on average. The last operation was the final storage of the assembled extruders in the transport box. This operation lasted from 4 to 9 s, with an average time of 6.43 s.

Table 2.

Time measurement before the PTL introduction.

Figure 6.

Assembly workplace without PTL.

4.2. Test with PTL Application

The manufacturing process of assembling the model part begins with placing the PTL device at the workplace and describing its basic functions. An employee posing as a (manager) of the dummy process puts the stacks in the device and runs diagnostics on its hardware. It will then program the individual steps and thus enable the assembly process to start. Then, a selected sample of employees who use the PTL system will be tested. Assembly workplace with PTL are shown in Figure 7.

Figure 7.

Assembly workplace with PTL.

Important parameters that were analysed after applying the principles of the Poka Yoke method were mainly the length of production of one piece, the entire production batch and the presence of incorrectly made parts. An important parameter is also the employee feeling when comparing both simulated situations. Time measurement after the introduction of PTL are shown in Table 3.

Table 3.

Time measurement after the introduction of PTL.

Results for research question 1: After the set limit in the number of pieces or the elapsed time was over, the recorded information was compared and analysed. The first was the component and tool preparation. A reduction in time was noted during this operation. We achieved this by inserting ready-made assembly boxes with components into the body of the Spider 1 device. The running time was reduced from 24.7 to 22.63 s during this operation. Our running time was reduced from 11.16 to 8.8 s during the second training operation. We achieved this mainly because the employee was familiar with the use of the PTL Spider 1 system. The biggest time saving of, more than 50% of the time, was achieved when studying the procedure, as the PTL system illuminates the order in which the individual components of the extruder are to be assembled. The total assembly time of one component was reduced from 63.8 to 57.4 s, representing a saving of around 11%. A more significant reduction in the average extruder assembly times occurred when assembling a production batch of 10 pieces when, after studying and testing, the time was reduced from 789.76 s to 639.6 s, which represents a saving of almost 20% for ten pieces. When checking the connection, there was only a slight reduction in the average time. A more significant decrease in time occurred after the PTL application when storing in the handling box, which we attribute to the fact that the employees were already familiar with where and how to store the extruder from previous testing.

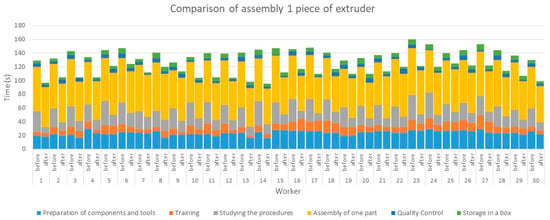

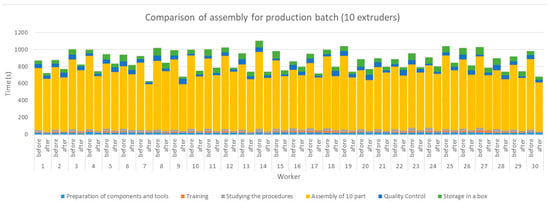

4.3. Evaluation of the Pick-to-Light System Introduction

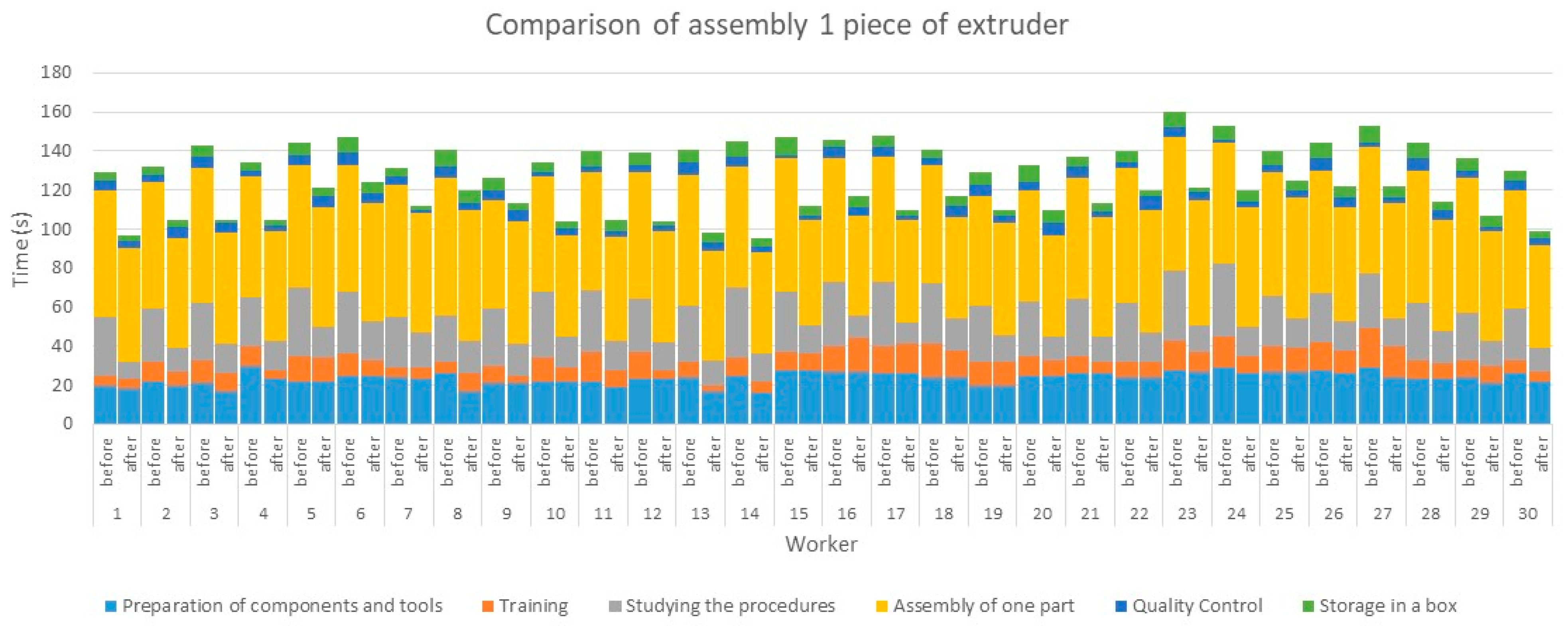

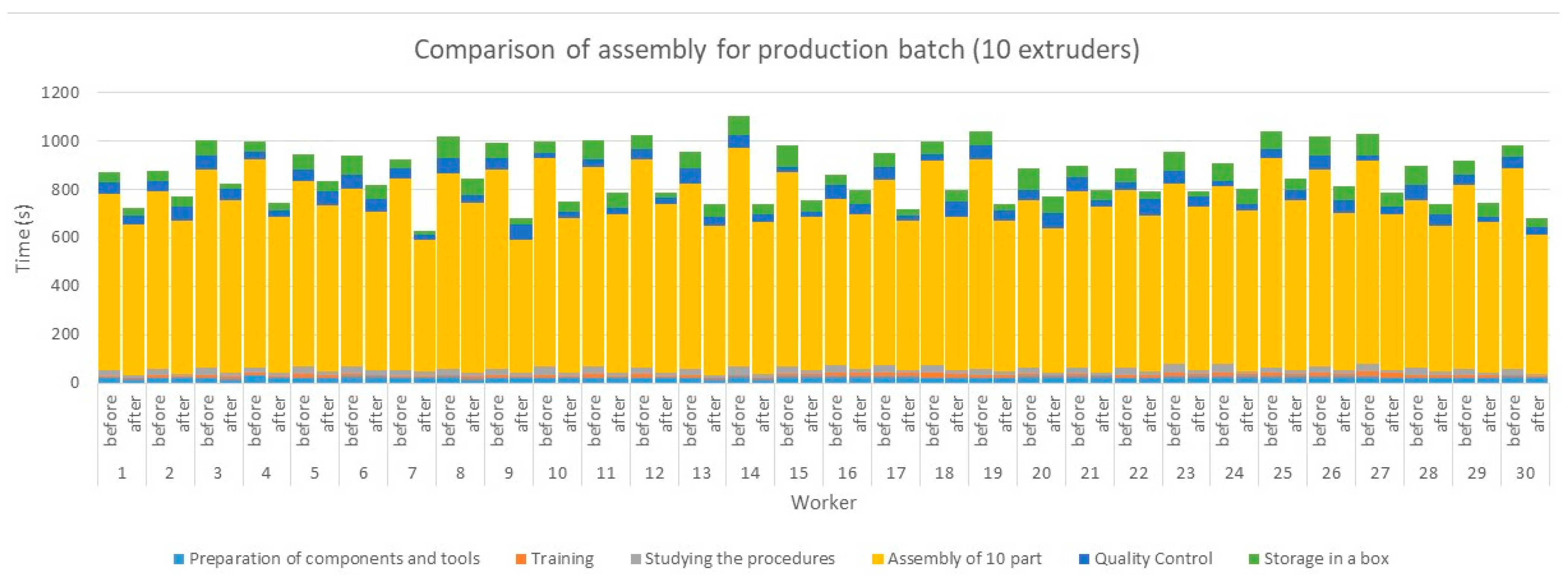

When evaluating the process’s efficiency, we focused on several factors. The introduction of the PTL system can bring many advantages for operations that ensure the picking of goods. Figure 8 and Figure 9 show the assembly times of individual workers for one piece and a production batch.

Figure 8.

Comparison of assembly times before and after the PTL introduction for the 1 piece.

Figure 9.

Comparison of assembly times before and after the PTL introduction for the production batch.

Results for research question 2: When assembling one piece of the extruder, we observed the greatest reduction in time for worker number 14, where the total time was reduced from 145 s to 95 s, which represents a reduction in time of 35%. It was a 25-year-old man with a high school education who worked as an assembly worker. His assembly experience contributed to a significant reduction in time. In general, he praised the system tested by us. The smallest time saving was achieved by worker number 9. From the 126 s of classic extruder assembly, his time was reduced to 113 s, representing a shortening of the operation by 11%. Worker 25 also achieved the same shortening by 11% from 140 s to 125 s. In the first case, it was a 43-year-old woman and a service worker, in the second case, a 54-year-old man and a production worker. Both of them answered after one test that the designed device seemed small and difficult to operate.

Results for research question 3: During the production batch assembly, we can state that the preparatory operations did not change to the production batch, but we recorded a time saving during the production-batch assembly. The greatest time savings of up to 33% were achieved by worker number 14. The smallest savings of only 7% were achieved by worker number 16, and his total time was reduced from 859 s to 798 s. All tested workers said that they liked the introduction of PTL system and could imagine its deployment in the company in the future.

Another evaluated factor that we focused on was the error occurrence before and after the PTL introduction shown in Table 4 and Table 5.

Table 4.

Errors occurrence before the PTL introduction.

Table 5.

Error occurrence after the PTL introduction.

Results for research question 4: From the mentioned measurement of errors, we can conclude that 30 workers made 34 errors during the assembly of 10 extruders before introducing the PTL system. After presenting our PTL system, only 22 errors occurred, representing a decrease in the error rate of 35%. Table 5 shows that errors significantly decreased at seven, eight and nine repetitions. We assume that we can substantially reduce the error rate by implementing several repetitions and getting used to the PTL system.

5. Conclusions

In general, Poka Yoke is a system that prevents production errors and minimises costs associated with error corrections. The implementation of Poka Yoke rests in identifying potential errors in production processes and implementing measures to prevent these errors. The PTL system can be an effective tool for implementing Poka Yoke in production engineering. First of all, the PTL system simplifies the process of dispatching goods by using light indicators that direct employees to retrieve the correct goods from specific positions. This reduces the risk of making a mistake by choosing the wrong product. Therefore, implementing a PTL system can be an effective way to minimize errors occurring in the picking process. In addition, the PTL system can also be integrated into production management processes. For example, light indicators can signal whether a certain step in the process has been completed correctly. Employees can thus be informed of errors and can correct them immediately. This improves the efficiency and productivity of the production process and reduces the need for costly repairs later.

It is difficult to provide the exact advantages and disadvantages of the PTL system in terms of socio-demographic factors, as these factors may vary depending on the specific operation and user group. Nevertheless, we can summarize some possible advantages and disadvantages of the PTL system in relation to various socio-demographic factors:

Advantages:

- Improved work safety: The PTL system can benefit older employees or employees with health limitations who might be prone to injuries when manually picking components.

- Simplified training process: The PTL system may be easier for some user groups to control and master, which may mean less training time and improved productivity.

- Increased accuracy: The PTL system can benefit employees with limited ability to concentrate, leading to improved accuracy and reduced errors.

Disadvantages:

- High implementation costs: The PTL system can be expensive to implement and may require training of employees to use it, which may be difficult for some user groups.

- The need for a technological background: the PTL system requires using technologies such as sensors, light indicators and computer systems, which may not be suitable for some operations or user groups.

- Potential exclusion of certain groups: The PTL system may exclude employees with limited technology access or who are visually or hearing impaired, which may discriminate against these groups.

Overall, we could say that the Pick-to-Light system can have both advantages and disadvantages depending on the specific user group. The 30 employees aged 22 to 57 that we tested praised the prototype workplace with the PTL system. We also consider its simplicity and modularity as a significant advantage of our system, with the possibility of scanning eight boxes with parts. Future trends in Pick to Light and Poka Yoke speak of a direction focused on digitization and automation. With the growing demand for fast and efficient logistics, this technology could be increasingly used to streamline processes. In addition, PTL systems could use new technologies such as augmented reality to provide even more accurate and efficient navigational guidance and instructions for warehouse workers. They can also be used more for personalized and faster shipments, where their orders would be sent to the customer immediately after processing in the warehouses. New PTL systems may also be developed, such as mobile applications that allow warehouse workers to access order and instruction information anywhere, anytime. New possibilities can also be created to use data from these systems to improve process efficiency and better understand the logistics situation in the warehouse.

Overall, the future of Pick-to-Light systems will depend on how the overall field of logistics and warehouse processes will evolve and innovations in technology and customer needs.

Author Contributions

Conceptualization, J.T. and J.H.; methodology, J.T. and S.H.; software, J.H.; validation, L.K. and S.H.; formal analysis, J.T.; investigation, J.T. and S.H.; resources, L.K.; data curation, J.H.; writing—original draft preparation, J.H.; writing—review and editing, S.H. and L.K.; visualization, J.T. and J.H.; supervision, J.T.; project administration, L.K.; funding acquisition, J.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the projects 0613/SBAD/4821 granted by Ministry of Education and Science of Poland and KEGA 038TUKE-4/2022 granted by the Ministry of Education, Science, Research and Sport of the Slovak Republic.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

As the authors of the article, we would like to thank the research team of the progressive production technologies for the support of research works by the grant agency APVV-19-0590 and also the projects VEGA 1/0268/22 and KEGA 038TUKE-4/2022, supported by the Ministry of Education, Science, Research and Sport of the Slovak Republic.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tsou, J.-C.; Chen, J.-M. Dynamic model for a defective production system with Poka-Yoke. J. Oper. Res. Soc. 2005, 56, 799–803. [Google Scholar] [CrossRef]

- Widjajanto, S.; Purba, H.H.; Jaqin, C. Novel POKA-YOKE approaching toward Industry-4.0: A literature review. Oper. Res. Eng. Sci. Theory Appl. 2020, 3, 65–83. [Google Scholar] [CrossRef]

- Martinelli, M.; Lippi, M.; Gamberini, R. Poka Yoke Meets Deep Learning: A Proof of Concept for an Assembly Line Application. Appl. Sci. 2022, 12, 11071. [Google Scholar] [CrossRef]

- Mandičák, T.; Mesároš, P.; Tkáč, M. Impact of management decisions based on managerial competencies and skills developed through BIM technology on performance of construction enterprises. Pollack Period. 2018, 13, 131–140. [Google Scholar] [CrossRef]

- Trebuna, P.; Pekarcikova, M.; Dic, M. Comparing Modern Manufacturing Tools and Their Effect on Zero-Defect Manufacturing Strategies. Appl. Sci. 2022, 12, 11487. [Google Scholar] [CrossRef]

- Baechler, A.; Baechler, L.; Autenrieth, S.; Kurtz, P.; Hoerz, T.; Heidenreich, T.; Kruell, G. A Comparative Study of an Assistance System for Manual Order Picking—Called Pick-by-Projection—With the Guiding Systems Pick-by-Paper, Pick-by-Light and Pick-by-Display. In Proceedings of the 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 523–531. [Google Scholar]

- Powell, D.J.; Romero, D. Digital Lean Manufacturing: A Literature Review. In Proceedings of the 2021 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 13–16 December 2021; pp. 659–662. [Google Scholar]

- Dudek-Burlikowska, M.; Szewieczek, D. The Poka-Yoke method as an improving quality tool of operations in the process. J. Achiev. Mater. Manuf. Eng. 2009, 36, 95–102. [Google Scholar]

- Belu, N.; Ionescu, L.M.; Misztal, A.; Mazăre, A. Poka Yoke system based on image analysis and object recognition. Mod. Technol. Ind. Eng. 2015, 95, 012138. [Google Scholar] [CrossRef]

- Pankaj, S.; Tarun, Y. Review Paper on “Productivity Improvement by using Poka-Yoke”. Int. Res. J. Eng. Technol. 2018, 5, 761–763. [Google Scholar]

- Vinayagasundaram, R.; Velmurugan, C. Implementation of Zero Defect through POKA YOKE Approaches in the Assembly Line of Compressor Manufacturing Industry. Int. J. Pure Appl. Math. 2018, 119, 2319–2332. [Google Scholar]

- Zhang, A. Quality improvement through Poka-Yoke: From engineering design to information system design. Int. J. Six Sigma Compet. Advant. 2014, 8, 147–159. [Google Scholar] [CrossRef]

- Alogla, A.A.; Alruqi, M. Aircraft Assembly Snags: Human Errors or Lack of Production Design? Aerospace 2021, 8, 391. [Google Scholar] [CrossRef]

- Sodhi, R.; Benko, H.; Wilson, A. LightGuide: Projected visualizations for hand movement guidance. In Proceedings of the SIGCHI Conference on Human Factors in Computing Systems (CHI ’12), Austin, TX, USA, 5–10 May 2012; Association for Computing Machinery: New York, NY, USA, 2012; pp. 179–188. [Google Scholar]

- Yang, C.; Xu, S.; Yu, T.; Liu, G.; Yu, C.; Shi, Y. LightGuide: Directing Visually Impaired People along a Path Using Light Cues. In Proceedings of the ACM on Interactive, Mobile, Wearable and Ubiquitous Technologies; Association for Computing Machinery: New York, NY, USA, 2021; Volume 5, p. 84. [Google Scholar] [CrossRef]

- Chung, J.; Kim, I.-J.; Schmandt, C. Guiding Light: Navigation assistance system using projection based augmented reality. In Proceedings of the IEEE International Conference on Consumer Electronics (ICCE), Las Vegas, NV, USA, 9–12 January 2011; pp. 881–882. [Google Scholar]

- Tosin, T. Perancangan dan Implementasi Komunikasi RS-485 Menggunakan Protokol Modbus RTU dan Modbus TCP Pada Sistem Pick-By-Light. Komputika J. Sist. Komput. 2021, 10, 85–91. [Google Scholar] [CrossRef]

- Sitthikarn, P.; Hakimi, P. Pick to Light Systems; Faculty of Engineering, Thammasat University: Bangkok, Thailand, 2016. [Google Scholar]

- Daneshjo, N.; Mares, A.; Pajerska, E.D.; Hajduova, Z. Designing and Upgrading the Assembly Process and Verifying the Performance of the Pick to Light System Program. Adv. Sci. Technol. Res. J. 2018, 12, 126–135. [Google Scholar] [CrossRef] [PubMed]

- Blecharz, P. Basics of Modern Quality Management; Ekopress: Praha, Czech Republic, 2011; p. 122. [Google Scholar]

- Hirano, H.; Shibun, N.K. POKA-YOKE Improving Product Quality by Preventing Defects; Productivity Press: New York, NY, USA, 1988; p. 275. [Google Scholar]

- Martisovic, R. Poka Yoke. Available online: http://www.produktivne.sk/vsetko-o-lean/metody/poka-yoke/ (accessed on 4 April 2023).

- Saleh, J.I. The Role of Empovering Leadership in Enhancing the Adaptive Penformance of Employees. Acta Technol. 2022, 8, 1–6. [Google Scholar] [CrossRef]

- Saderova, J.; Rosova, A.; Behunova, A.; Behun, M.; Sofranko, M.; Khouri, S. Case study: The simulation modelling of selected activity in a warehouse operation. Wirel. Netw. 2022, 28, 431–440. [Google Scholar] [CrossRef]

- Mildorf, L. Poka-Yoke: Prevention of Discrepancies in the Production Process. Available online: http://katedry.fmmi.vsb.cz/639/qmag/mj41-cz.pdf (accessed on 5 April 2023).

- Straka, M. Design of a Computer-Aided Location Expert System Based on a Mathematical Approach. Mathematics 2021, 9, 1052. [Google Scholar] [CrossRef]

- Andriolo, A.; Battini, D.; Calzavara, M.; Gamberi, M.; Peretti, U.; Persona, A.; Pilati, F.; Sgarbossa, F. New RFID pick-to-light system: Operating characteristics and future potential. Int. J. RF Technol. Res. Appl. 2016, 7, 43–63. [Google Scholar] [CrossRef]

- Pick to Light Systems. Available online: http://www.marpex.sk/riesenia-a-technologie/pick-to-light/ (accessed on 5 April 2023).

- Hrehova, S.; Vagaska, A. Computer Models as Appropriate Tools in Elearning. In Proceedings of the INTED2017: 11th International Technology, Education and Development Conference, Valencia, Spain, 6–8 March 2017; pp. 8871–8877. [Google Scholar]

- Richnák, P.; Fidlerová, H. Impact and Potential of Sustainable Development Goals in Dimension of the Technological Revolution Industry 4.0 within the Analysis of Industrial Enterprises. Energies 2022, 15, 3697. [Google Scholar] [CrossRef]

- Dąbrowska, M.; Medyński, D.; Bieliński, W.; Kolbusz, K. Reorganization of the assembly station in the production process of the sliding floor for reloading ramps in the context of improving the quality of the finished product. Technol. I Autom. Montażu (Assem. Tech. Technol.) 2022, 117, 28–35. [Google Scholar] [CrossRef]

- Kochańska, J.; Burduk, A.; Markowski, M.; Kłusek, A.; Wojciechowska, M. Improvement of Factory Transport Efficiency with Use of WiFi-Based Technique for Monitoring Industrial Vehicles. Sustainability 2023, 15, 1113. [Google Scholar] [CrossRef]

- Pačaiová, H.; Korba, P.; Hovanec, M.; Galanda, J.; Šváb, P.; Lukáč, J. Use of Simulation Tools for Optimization of the Time Duration of Winter Maintenance Activities at Airports. Sustainability 2021, 13, 1095. [Google Scholar] [CrossRef]

- Kolbusz, P. The use of the six sigma methodology in a project improving the manufacturing process. Technol. I Autom. Montażu 2022, 118, 8–19. [Google Scholar] [CrossRef]

- Kaľavský, P.; Rozenberg, R.; Korba, P.; Kelemen, M., Jr.; Antoško, M.; Sabo, J.; Džunda, M. Research of the Photo-Optical Method Application for Measuring Selected Data on the Movement of a Parachute for Type M-282. Appl. Sci. 2021, 11, 5637. [Google Scholar] [CrossRef]

- Medyński, D.; Bonarski, P.; Motyka, P.; Wysoczański, A.; Gnitecka, R.; Kolbusz, K.; Dąbrowska, M.; Burduk, A.; Pawelec, Z.; Machado, J. Digital Standardization of Lean Manufacturing Tools According to Industry 4.0 Concept. Appl. Sci. 2023, 13, 6259. [Google Scholar] [CrossRef]

- Lishchenko, N.; Piteľ, J.; Larshin, V. Online Monitoring of Surface Quality for Diagnostic Features in 3D Printing. Machines 2022, 10, 541. [Google Scholar] [CrossRef]

- Stockinger, C.; Steinebach, T.; Petrat, D.; Bruns, R.; Zöller, I. The Effect of Pick-by-Light-Systems on Situation Awareness in Order Picking Activities. Procedia Manuf. 2020, 45, 96–101. [Google Scholar] [CrossRef]

- Kaščak, J.; Gašpár, Š.; Paško, J.; Knapčíková, L.; Husár, J.; Baron, P.; Török, J. Design of an Atypical Construction of Equipment for Additive Manufacturing with a Conceptual Solution of a Printhead Intended for the Use of Recycled Plastic Materials. Appl. Sci. 2021, 11, 2928. [Google Scholar] [CrossRef]

- Mascenik, J.; Coranic, T. Experimental Determination of the Coefficient of Friction on a Screw Joint. Appl. Sci. 2022, 12, 11987. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).