A System for Monitoring and Normative Qualification of Building Structure Vibrations Induced by Nearby Construction Works

Abstract

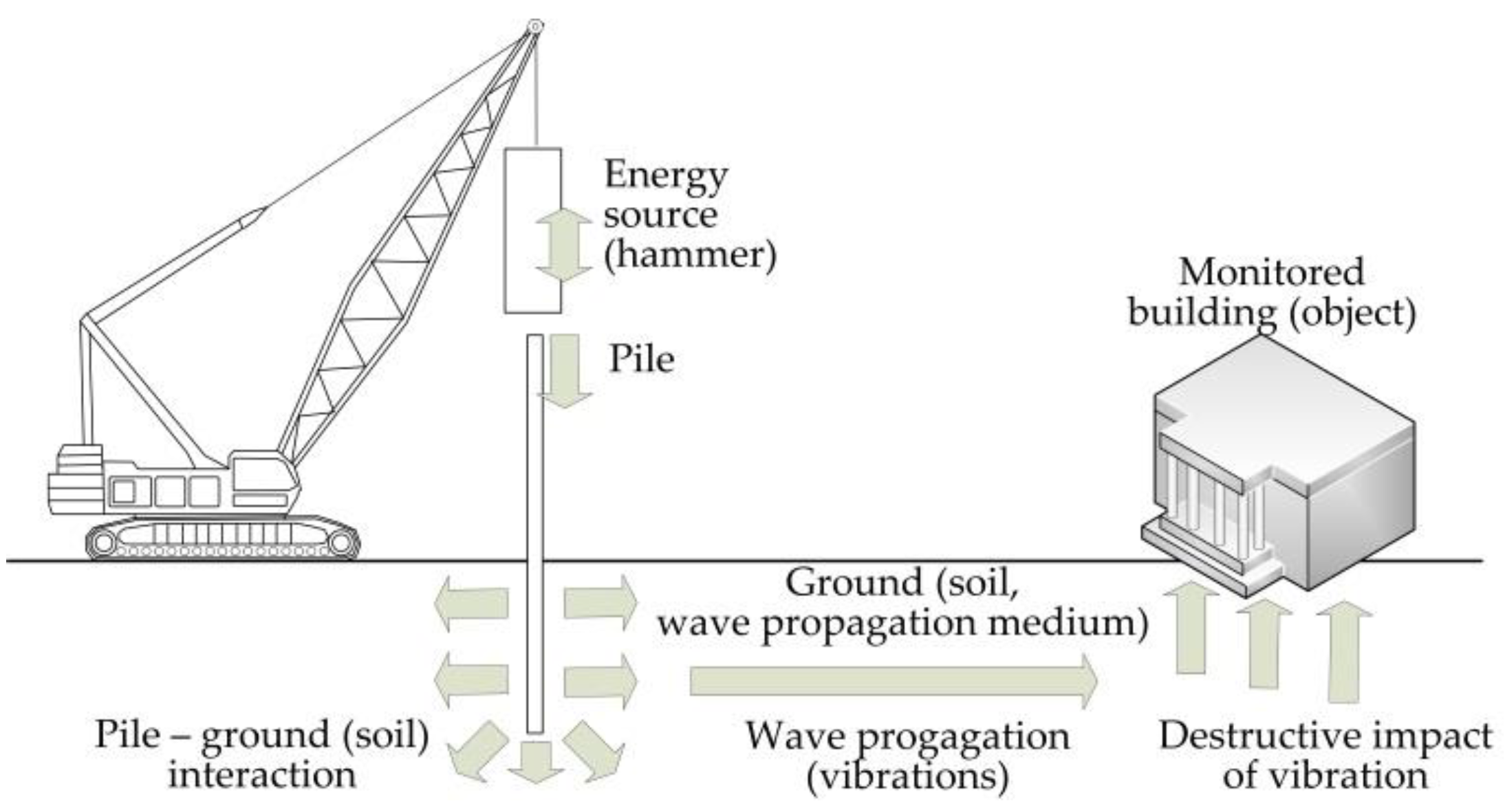

1. Introduction

1.1. The Difficulty of Estimating the Parameters of the Waves

1.2. Directions of Research Work

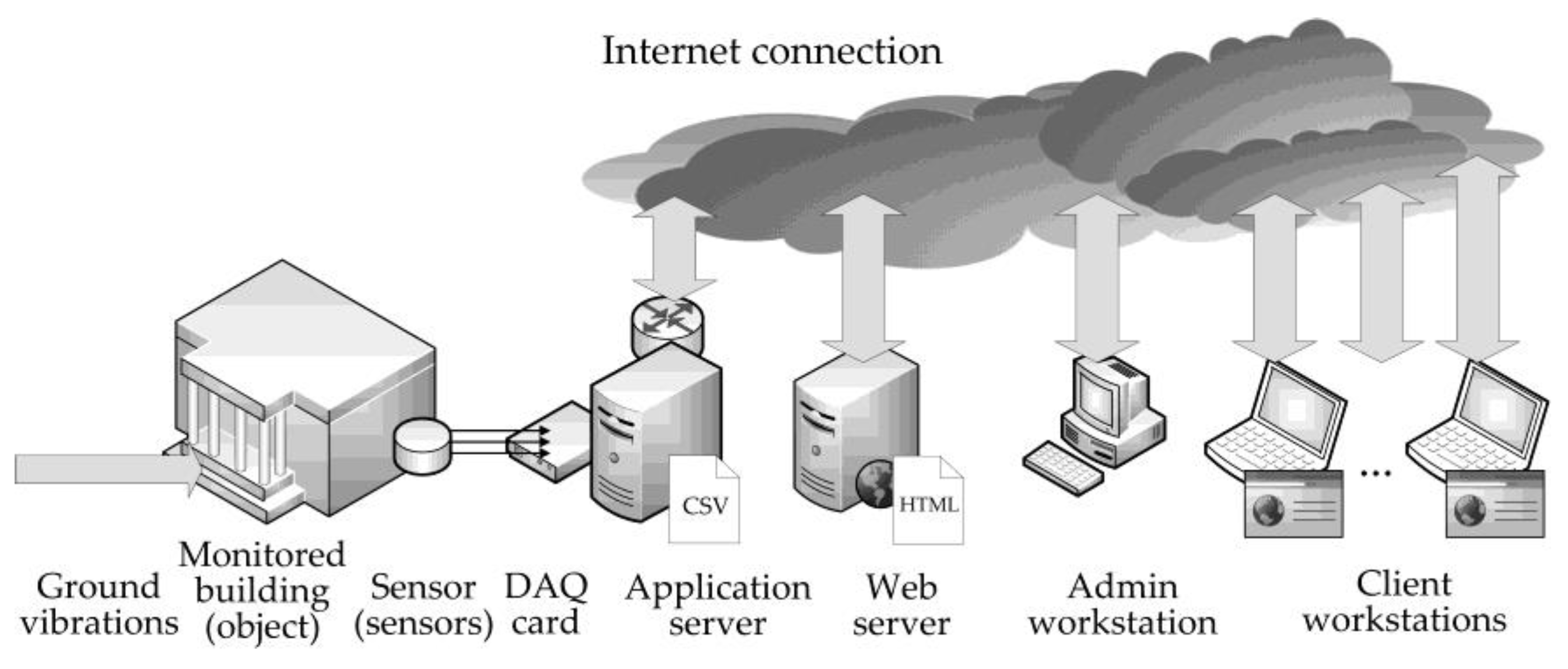

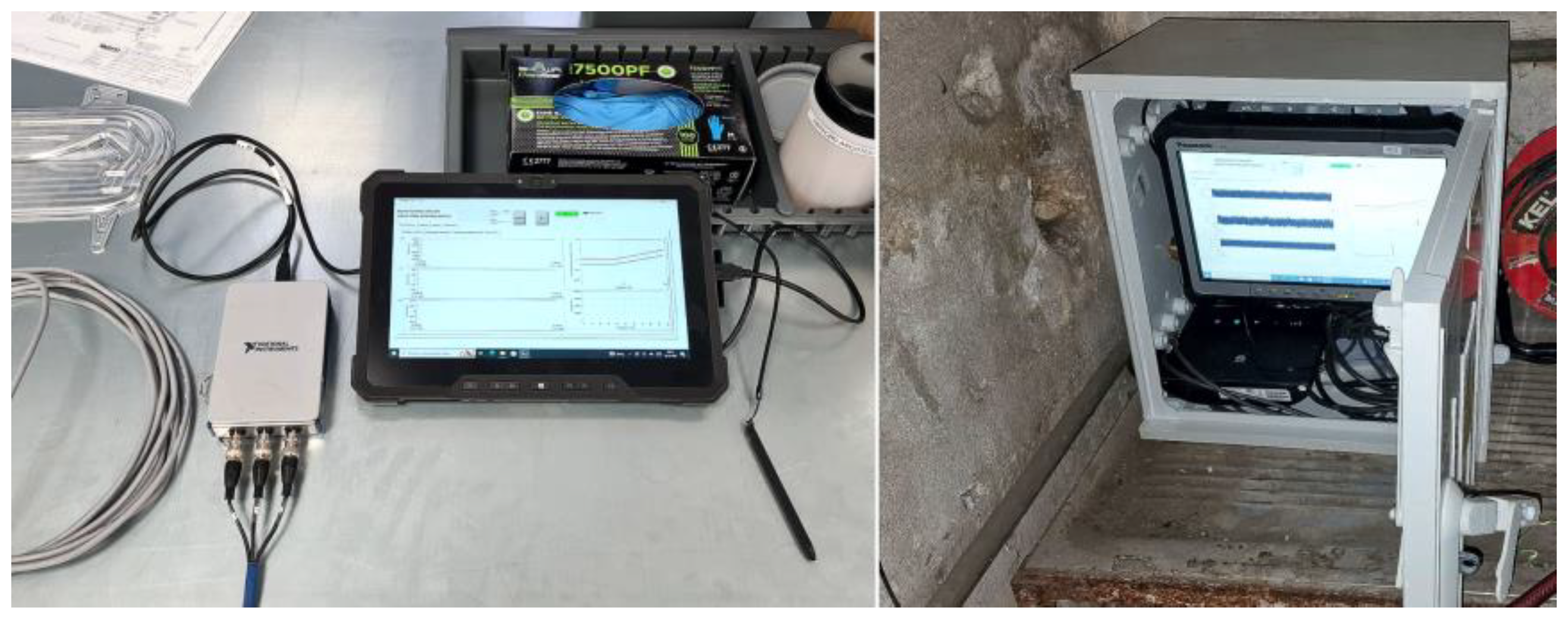

2. The Measuring System for Monitoring Vibrations of Building Structures

- Possibility to modify the code regarding the collected data,

- Remote access to online data with different access levels, i.e., administrator (possibility to modify the code and presentation method) and user (viewing current data and data from a selected period),

- Generation of results, allowing immediate confirmation of whether the vibration value is allowed by the standard.

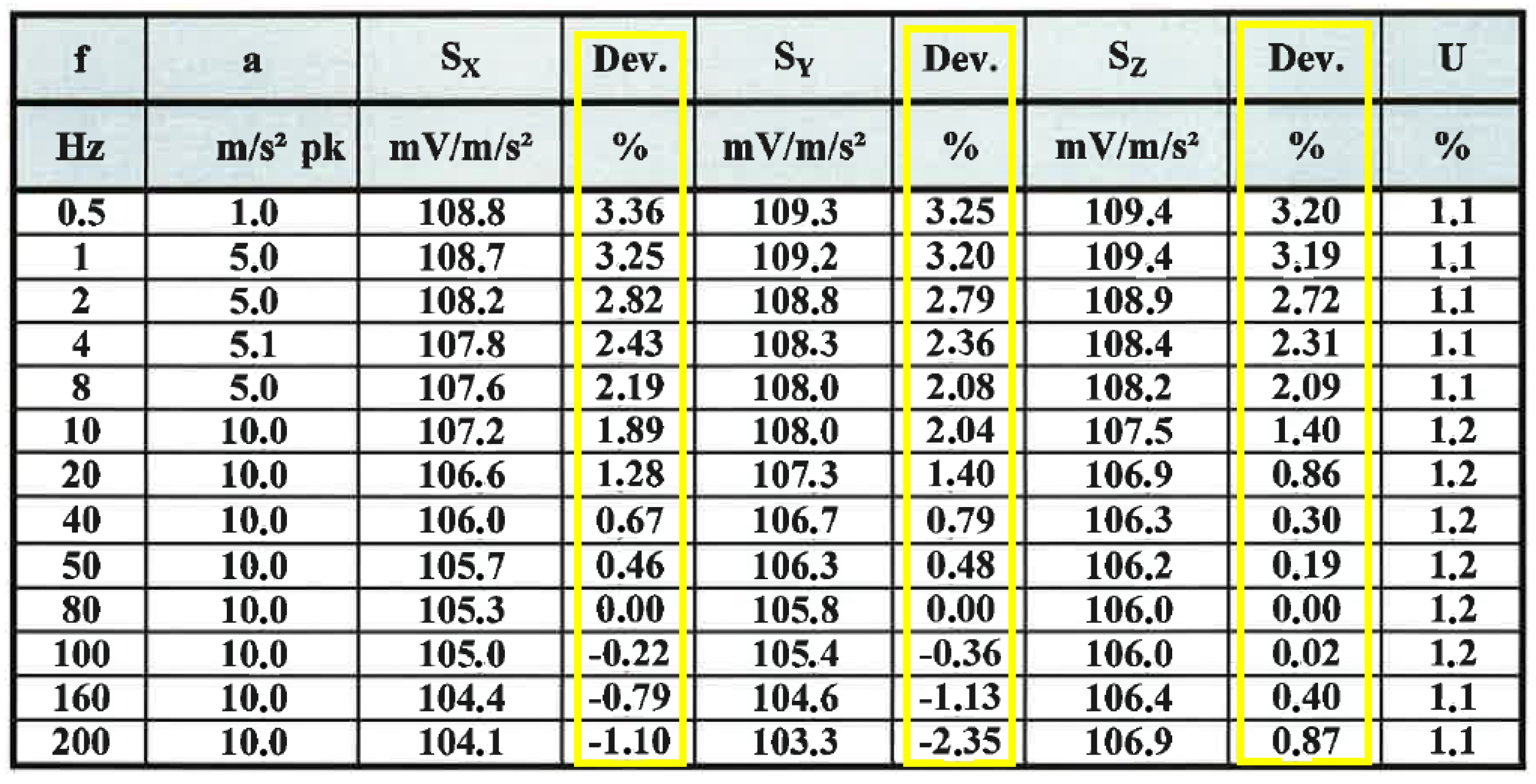

- Calibration or evaluation of bias and precision using reference standards or reference materials,

- Systematic assessment of the factors influencing the result,

- Testing method robustness through variation of controlled parameters, such as incubator temperature volume dispensed,

- Comparison of results achieved with other validated methods,

- Interlaboratory comparisons,

- Evaluation of measurement uncertainty of the results based on an understanding of the theoretical principles of the method and practical experience of the performance of the sampling or test method.

- |En| ≤ 1—comparison result “satisfactory”, no additional action is required.

- |En| > 1—result of the comparison is “unsatisfactory”, corrective action should be taken.

- Initial declaration of the program’s working time (e.g., 1 week),

- Parallel readout of measurement values from 3 accelerometer channels,

- Filtering the signal with a low-pass filter,

- Filter data with 1/3 octave filter,

- Numerical integration,

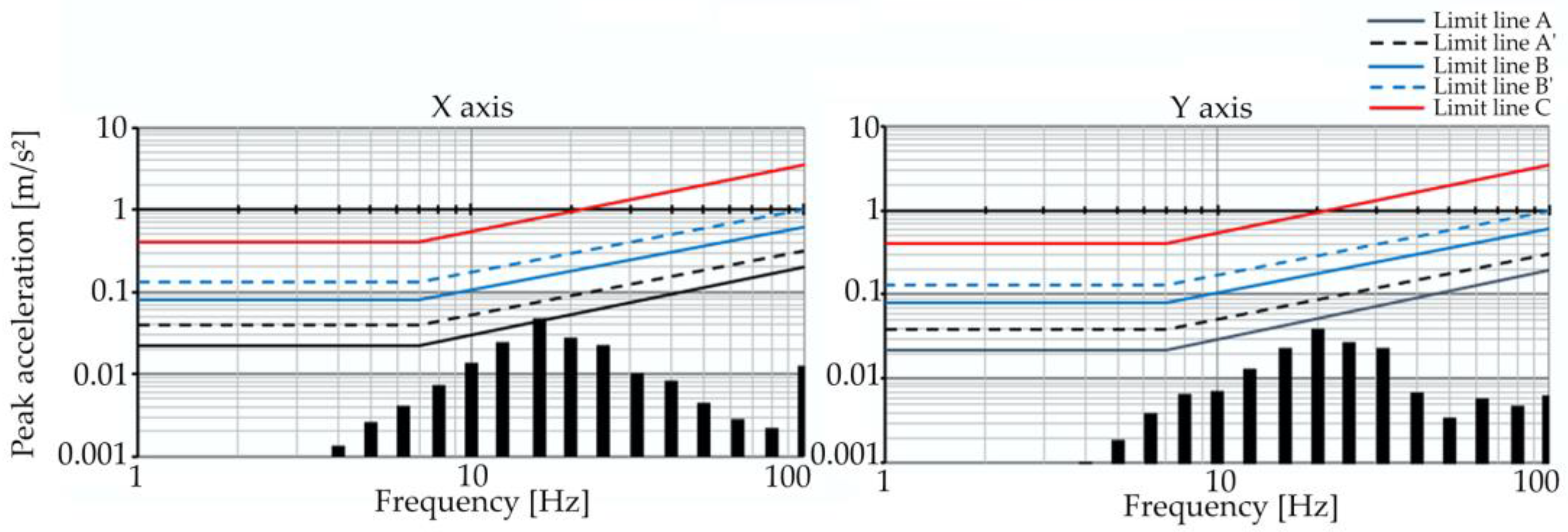

- Generating the dependence (maximal amplitude of acceleration versus frequency),

- Comparison of the characteristics of with the values permitted by the standard [37],

- Data export as a CSV file (comma-separated values) to a webserver,

- Data formatting according to the template applied on the webserver,

- Presentation of data to the user.

- -

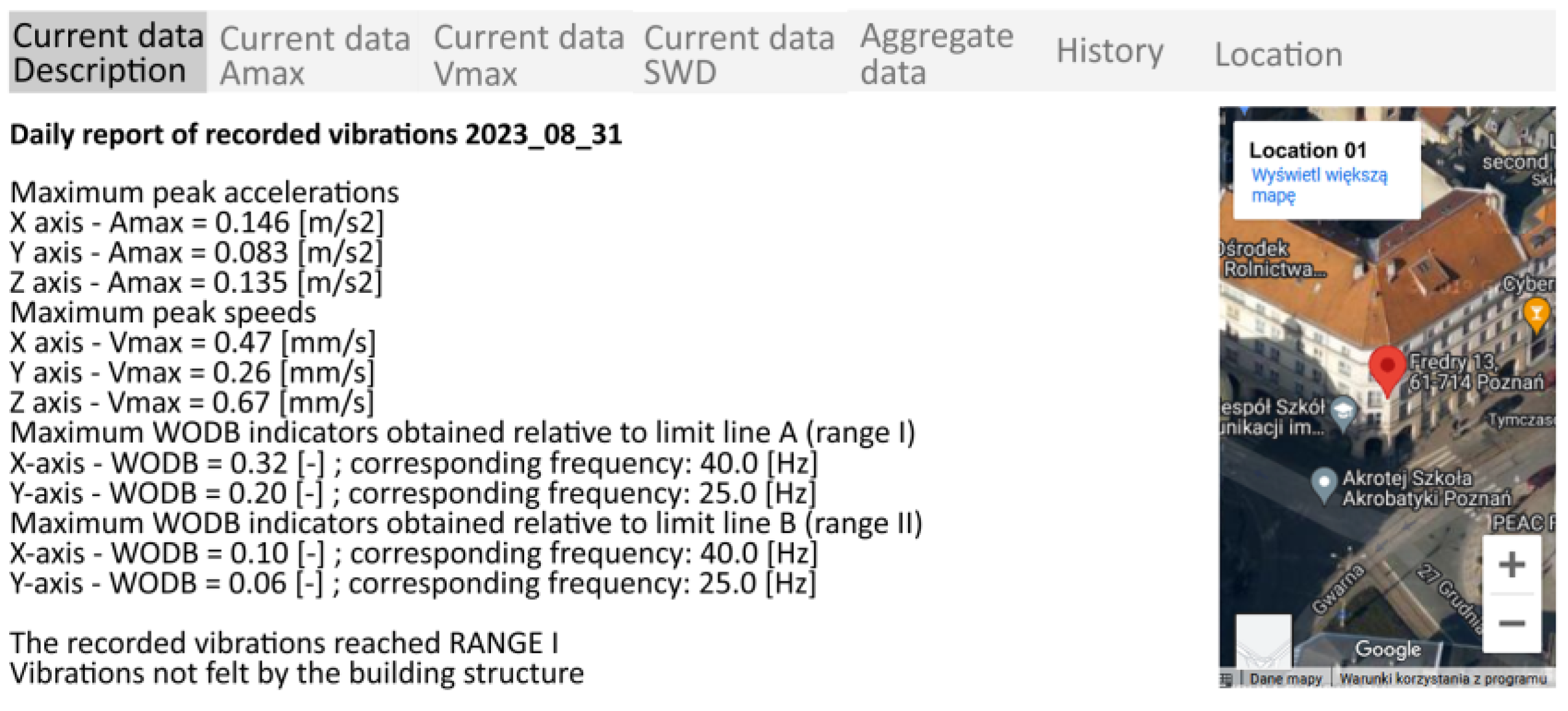

- “Current data—Description”—daily summary of data on the maximum values of accelerations in three axes, maximum values of speeds in three axes, maximum values of the normative WODB index, and a summary in the form of qualifying vibrations to one of the normative vibration impact zones on the object (Figure 11).

- -

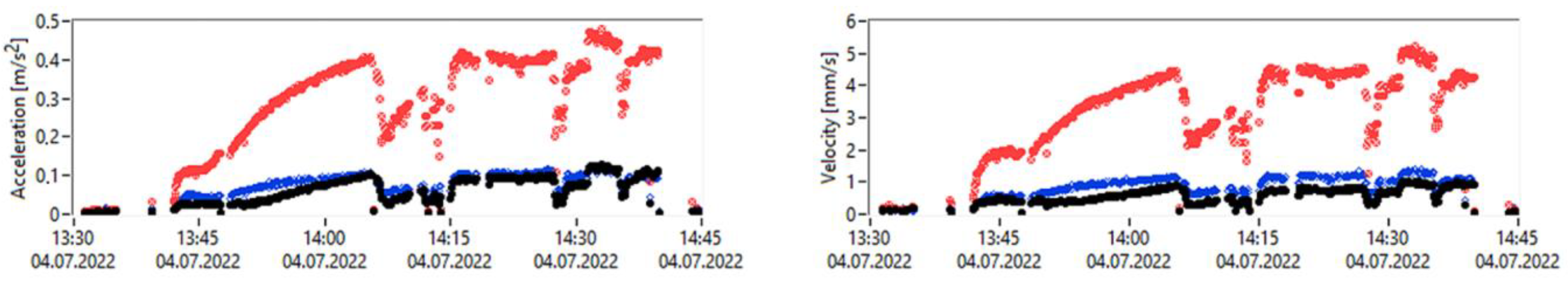

- “Current data—Amax”—graphical presentation of the peak acceleration values, A (m/s2), of vibrations in three directions recorded on the current day. It is possible to select a specific point with the mouse pointer and read the acceleration values at the indicated point in time (Figure 12).

- -

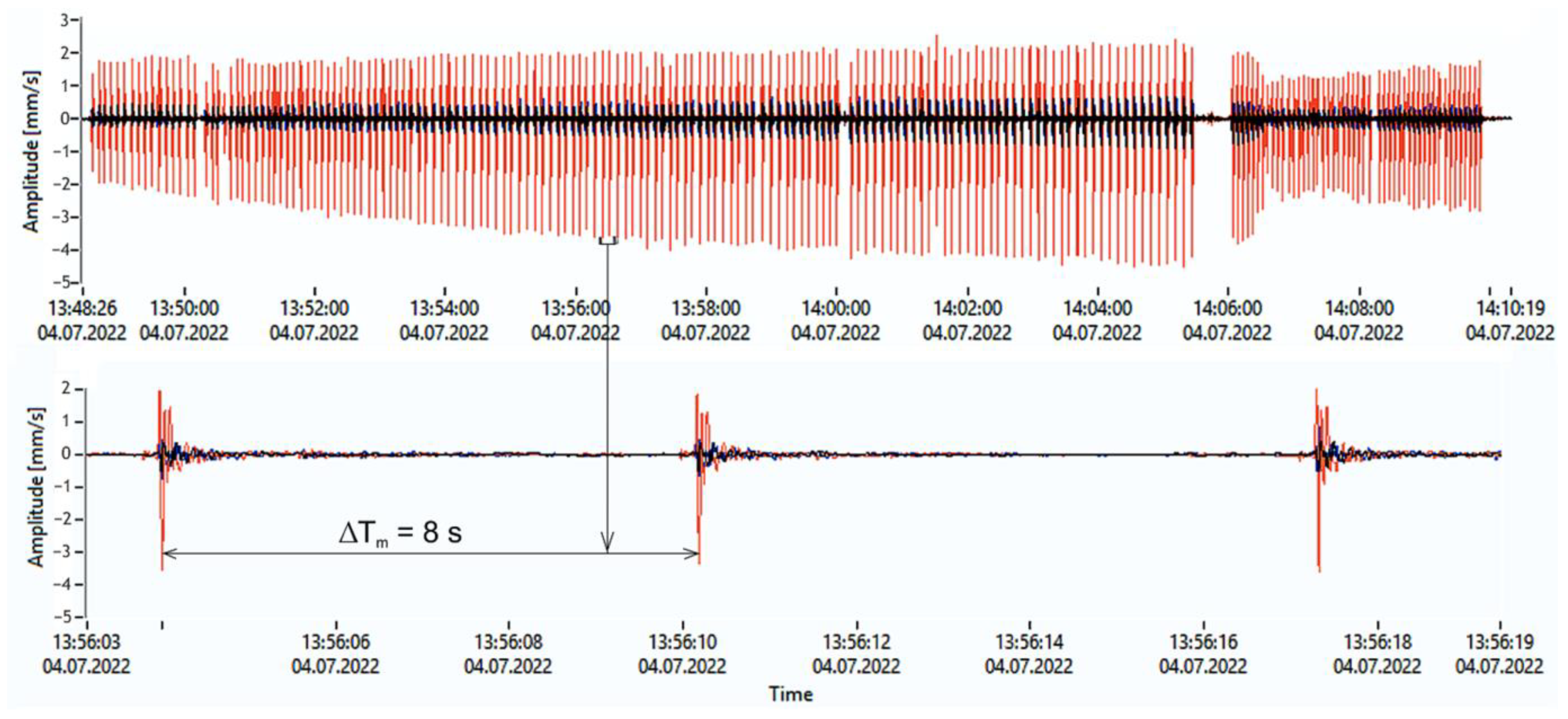

- “Current data—Vmax”—graphical presentation of the peak values of the velocity, V (m/s), of vibrations in three directions recorded on the current day. It is possible to select a specific point with the mouse pointer and read the acceleration values at the indicated point in time (Figure 13).

- -

- “Current data—SWD”—graphical presentation of WODB index values recorded on the current day. The indicators are presented on the SWD scale in order to later qualify the vibrations to one of the impact zones (Figure 14). Qualification for impact zones is carried out in accordance with the guidelines of the standard [37].

- -

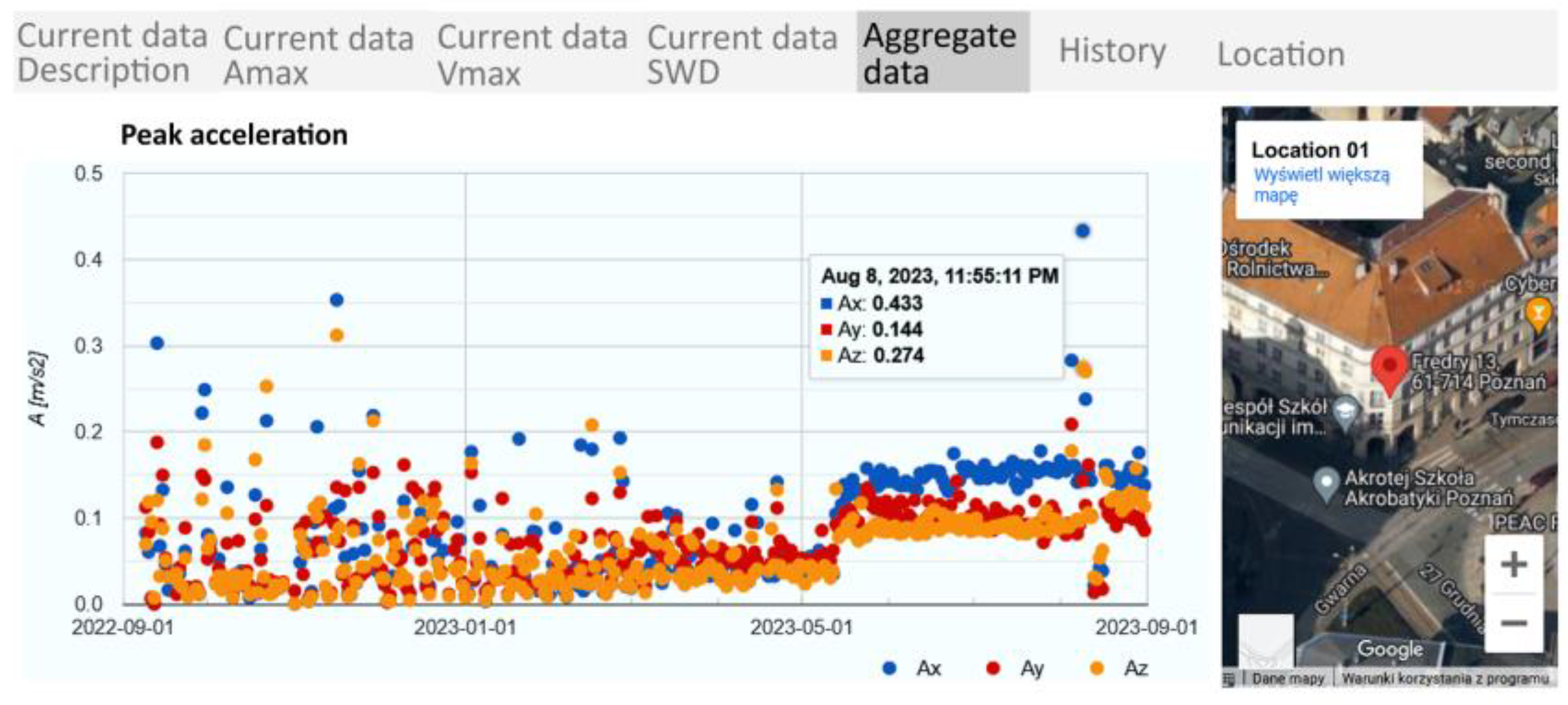

- “Aggregate data”—graphical presentation of the peak acceleration values, A (m/s2), of vibrations in three directions recorded since the start of the system operation (Figure 15).

- -

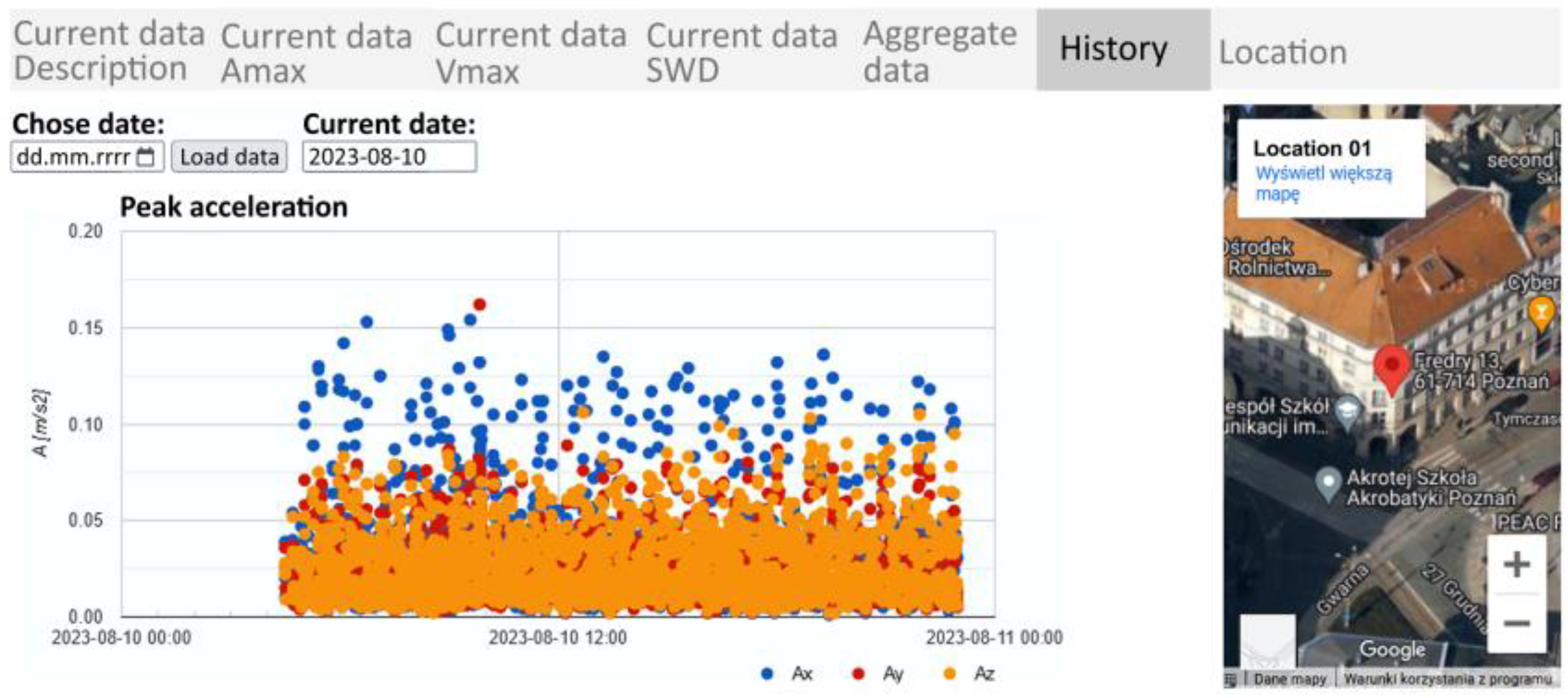

- “History”—presentation of historical time courses of peak acceleration values and presentation of WODB index values recorded on the date indicated by the user (Figure 16).

3. Results

4. Conclusions

- Data can be accessed in a form recorded directly by the sensors, but the user receives practical information about the compliance of the vibration values with the normative requirements (Figure 22).

- The system user has local and remote access to the recorded results (Figure 3).

- The measurement system combines elements from different suppliers and allows for their smooth cooperation.

- The total cost of the original system (sensors, a data acquisition card, and software) is significantly less than the cost of a closed system provided by recognised vendors of such solutions (e.g., Brüel and Kjær, Svantek).

- The system provides reliable data (confirmed during interlaboratory comparisons) while maintaining high reliability (no downtime tested in applications during field tests).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rahman, N.A.A.; Musir, A.A.; Dahalan, N.H.; Ghani, A.N.A.; Khalil, M.K.A. Review of Vibration Effect during Piling Installation to Adjacent Structure. AIP Conf. Proc. 2017, 1901, 110009. [Google Scholar] [CrossRef]

- Crispino, M.; D’Apuzzo, M. Measurement and Prediction of Traffic-Induced Vibrations in a Heritage Building. J. Sound Vib. 2001, 246, 319–335. [Google Scholar] [CrossRef]

- Hester, J.; Prabhu, S.; Atamturktur, S.; Sorber, J. Remote and Wireless Long-term Vibration Monitoring of Historic Monuments. Procedia Eng. 2017, 199, 3302–3307. [Google Scholar] [CrossRef]

- Pacheco, J.; Oliveira, G.; Magalhães, F.; Moutinho, C.; Cunha, Á. Vibration-Based Monitoring of Wind Turbines: Influence of Layout and Noise of Sensors. Energies 2021, 14, 441. [Google Scholar] [CrossRef]

- Wang, W.; Xue, Y.; He, C.; Zhao, Y. Review of the Typical Damage and Damage-Detection Methods of Large Wind Turbine Blades. Energies 2022, 15, 5672. [Google Scholar] [CrossRef]

- Zhang, H.; Pan, C.; Wang, Y.; Xu, M.; Zhou, F.; Yang, X.; Zhu, L.; Zhao, C.; Song, Y.; Chen, H. Fault Diagnosis of Coal Mill Based on Kernel Extreme Learning Machine with Variational Model Feature Extraction. Energies 2022, 15, 5385. [Google Scholar] [CrossRef]

- Jablonski, A. Hybrid Model of Rolling-Element Bearing Vibration Signal. Energies 2022, 15, 4819. [Google Scholar] [CrossRef]

- Scislo, L. High Activity Earthquake Swarm Event Monitoring and Impact Analysis on Underground High Energy Physics Research Facilities. Energies 2022, 15, 3705. [Google Scholar] [CrossRef]

- Stagg, M.S.; Siskind, D.E. Effects of Blast Vibration on Construction Material Cracking in Residential Structures. J. Perform. Constr. Facil. 2005, 19, 222–228. [Google Scholar]

- Ścisło, Ł.; Guinchard, M. Source Based Measurements and Monitoring of Ground Motion Conditions during Civil Engineering Works for High Luminosity Upgrade of the LHC. In Proceedings of the ICSV26 Proceedings, Montreal, QC, Canada, 7–11 July 2019; pp. 1–9. [Google Scholar]

- Łacny, Ł.; Ścisło, Ł.; Guinchard, M. Application of Probabilistic Power Spectral Density Technique to Monitoring the Long-Term Vibrational Behaviour of CERN Seismic Network Stations. Vib. Phys. Syst. 2020, 31, 2020311. [Google Scholar] [CrossRef]

- Fiala, P.; Degrande, G.; Augusztinovicz, F. Numerical Modelling of Ground-Borne Noise and Vibration in Buildings Due to Surface Rail Traffic. J. Sound Vib. 2007, 301, 718–738. [Google Scholar] [CrossRef]

- Colaço, A.; Costa, P.A.; Amado-Mendes, P.; Godinho, L.; Calçada, R. Mitigation of Vibrations and Re-Radiated Noise in Buildings Generated by Railway Traffic: A Parametric Study. Procedia Eng. 2017, 199, 2627–2632. [Google Scholar] [CrossRef]

- Nagy, A.B.; Fiala, P.; Márki, F.; Augusztinovicz, F.; Degrande, G.; Jacobs, S.; Brassenx, D. Prediction of Interior Noise in Buildings Generated by Underground Rail Traffic. J. Sound Vib. 2006, 293, 680–690. [Google Scholar] [CrossRef]

- Chiliński, B.; Zawisza, M. Analysis of Bending and Angular Vibration of the Crankshaft with a Torsional Vibrations Damper. J. Vibroeng. 2016, 18, 5353–5363. [Google Scholar] [CrossRef][Green Version]

- Kafle, B.; Zhang, L.; Mendis, P.; Herath, N.; Maizuar, M.; Duffield, C.; Thompson, R.G. Monitoring the Dynamic Behavior of The Merlynston Creek Bridge Using Interferometric Radar Sensors and Finite Element Modeling. Int. J. Appl. Mech. 2017, 9, 1750003. [Google Scholar] [CrossRef]

- Nasim Khan Raja, B.; Miramini, S.; Duffield, C.; Chen, S.; Zhang, L. A Simplified Methodology for Condition Assessment of Bridge Bearings Using Vibration Based Structural Health Monitoring Techniques. Int. J. Str. Stab. Dyn. 2021, 21, 2150133. [Google Scholar] [CrossRef]

- Calcina, S.V.; Piroddi, L.; Ranieri, G. Fast Dynamic Control of Damaged Historical Buildings: A New Useful Approach for Structural Health Monitoring after an Earthquake. ISRN Civ. Eng. 2013, 2013, 527604. [Google Scholar] [CrossRef]

- Luzi, G.; Monserrat, O.; Crosetto, M. Real Aperture Radar Interferometry as a Tool for Buildings Vibration Monitoring: Limits and Potentials from an Experimental Study; Ancona. AIP Conf. Proc. 2012, 1457, 309–317. [Google Scholar] [CrossRef]

- Talich, M. Monitoring of Horizontal Movements of High-Rise Buildings and Tower Transmitters by Means of Ground-Based Interferometric Radar. In Proceedings of the International Archives of the Photogrammetry Remote Sensing and Spatial Information Sciences Proceedings of the GeoInformation for Disaster Management (Gi4DM), Istanbul, Turkey, 18–21 March 2018; Volume XLII-3/W4, pp. 499–504. [Google Scholar] [CrossRef]

- Deckner, F.; Viking, K.; Hintze, S. Ground Vibrations Due to Pile and Sheet Pile Driving—Prediction Models of Today; SGF Rapport; Victoria Svahn and Tara Wood: Gothenburg, Sweden, 2012; pp. 107–112. [Google Scholar]

- Chen, A.; Cheng, F.; Wu, D.; Tang, X. Ground Vibration Propagation and Attenuation of Vibrating Compaction. J. Vibroeng. 2019, 21, 1342–1352. [Google Scholar] [CrossRef]

- Athanasopoulos, G.A.; Pelekis, P.C. Ground Vibrations from Sheetpile Driving in Urban Environment: Measurements, Analysis and Effects on Buildings and Occupants. Soil Dyn. Earthq. Eng. 2000, 19, 371–387. [Google Scholar] [CrossRef]

- Richart, F.E.; Hall, J.R.; Woods, R.D. Vibrations of Soils and Foundations. In Prentice-Hall International Series in Theoretical and Applied Mechanics; Prentice-Hall: Englewood Cliffs, NJ, USA, 1970. [Google Scholar]

- Sreekala, R.; Lakshmanan, N.; Muthumani, K.; Gopalakrishnan, N.; Sathishkumar, K. Potential of Vibration Studies in the Soil Characterization Around Power Plants—A Case Study; Missouri University of Science and Technology: Arlington, TX, USA, 2008; p. 8. [Google Scholar]

- Qin, Z.; Chen, L.; Song, C.; Sun, L. Field Tests to Investigate the Penetration Rate of Piles Driven by Vibratory Installation. Shock. Vib. 2017, 2017, 7236956. [Google Scholar] [CrossRef]

- Deckner, F.; Viking, K.; Hintze, S. Wave Patterns in the Ground: Case Studies Related to Vibratory Sheet Pile Driving. Geotech. Geol. Eng. 2017, 35, 2863–2878. [Google Scholar] [CrossRef]

- Homayoun Rooz, A.F.; Hamidi, A. A Numerical Model for Continuous Impact Pile Driving Using ALE Adaptive Mesh Method. Soil Dyn. Earthq. Eng. 2019, 118, 134–143. [Google Scholar] [CrossRef]

- Kim, D.S.; Lee, J. Source and Attenuation Characteristics of Various Ground Vibrations. In Geotechnical Earthquake Engineering and Soil Dynamics III; Amer Society of Civil Engineers: Reston, VA, USA, 1998; pp. 1507–1517. [Google Scholar]

- do Nascimento Setúbal, F.A.; de Souza Custódio Filho, S.; Soeiro, N.S.; Mesquita, A.L.A.; Nunes, M.V.A. Force Identification from Vibration Data by Response Surface and Random Forest Regression Algorithms. Energies 2022, 15, 3786. [Google Scholar] [CrossRef]

- Khoubani, A.; Ahmadi, M.M. Numerical Study of Ground Vibration Due to Impact Pile Driving. Proc. Inst. Civ. Eng.-Geotech. Eng. 2014, 167, 28–39. [Google Scholar] [CrossRef]

- Sofiste, T.V.; Godinho, L.; Costa, P.A.; Soares, D.; Colaço, A. Numerical Modelling for Prediction of Ground-Borne Vibrations Induced by Pile Driving. Eng. Struct. 2021, 242, 112533. [Google Scholar] [CrossRef]

- Yu, A.; Jiang, P.; Lin Wang, Z. Nanogenerator as Self-Powered Vibration Sensor. Nano Energy 2012, 1, 418–423. [Google Scholar] [CrossRef]

- Andò, B.; Baglio, S.; Bulsara, A.R.; Marletta, V. Toward a Self-Powered Vibration Sensor: The Signal Processing Strategy. Energies 2021, 14, 754. [Google Scholar] [CrossRef]

- Meng, Y.; Yang, J.; Liu, S.; Xu, W.; Chen, G.; Niu, Z.; Wang, M.; Deng, T.; Qin, Y.; Han, M.; et al. Nano-Fiber Based Self-Powered Flexible Vibration Sensor for Rail Fasteners Tightness Safety Detection. Nano Energy 2022, 102, 107667. [Google Scholar] [CrossRef]

- Rubes, O.; Chalupa, J.; Ksica, F.; Hadas, Z. Development and Experimental Validation of Self-Powered Wireless Vibration Sensor Node Using Vibration Energy Harvester. Mech. Syst. Signal Process. 2021, 160, 107890. [Google Scholar] [CrossRef]

- PN-B-02170; Ocena Szkodliwości Drgań Przekazywanych Przez Podłoże Budynku. Polski Komitet Normalizacyjny: Warsaw, Poland, 2016.

- SN 640312:2013; Vibrations—Vibration Effects in Buildings. Swiss Standards: Zürich, Switzerland, 2014.

- DIN 4150-3Vibrations in Buildings—Part 3: Effects on Structures, German Institute for Standardisation: Berlin, Germany, 2016.

- UNI 9916:2014; Criteria for the Measurement of Vibrations and the Assessment of Their Effects on Buildings. Italian National Standards Body: Rome, Italy, 2014.

- Monti, G.; Fumagalli, F.; Marano, G.C.; Quaranta, G.; Rea, R.; Nazzaro, B. Effects of Ambient Vibrations on Heritage Buildings: Overview and Wireless Dynamic Monitoring Application; L’Aquila University: Rome, Italy, 2015; Volume 1, pp. 217–229. [Google Scholar]

- Massarsch, K.R.; Fellenius, B.H. Ground vibrations from pile and sheet pile driving. In Proceedings of the International Conference on Piling and Deep Foundations, Stockholm, Sweden, 21–23 May 2014; Volume 1, pp. 131–139. [Google Scholar]

- ISO/IEC 17025:2017; General Requirements for the Competence of Testing and Calibration Laboratories. International Organization for Standarization: Geneva, Switzerland, 2017.

- PN-EN ISO/IEC 17043:2011; Ocena Zgodności—Ogólne Wymagania Dotyczące Badania Biegłości. Polski Komitet Normalizacyjny: Warsaw, Poland, 2011.

- Szcześniak, W.; Ataman, M. Płaskie struktury przegubowe obciążone impulsem siły. Autobusy Tech. Eksploat. Syst. Transp. 2013, 14, 1457–1464. [Google Scholar]

| Parameter | Value |

|---|---|

| Type | Piezoelectric |

| Number of axes | 3 (triaxial) |

| Sensitivity | 1000 mV/g ± 5% |

| Frequency response (±3 dB) | 0.2–3700 Hz |

| Mounted resonant frequency | 16 kHz |

| Dynamic range | 8 g |

| Linearity | ±1% of range |

| Warmup time | <10 s |

| Residual noise (24 °C) | 0.4–9.0 μg/Hz0.5 |

| Voltage | 22–28 V DC |

| Current | 2–10 mA DC |

| Parameter | Value |

|---|---|

| DAQ type | Dynamic signal acquisition module |

| Number of channels | 3 input channels |

| ADC resolution | 24 bits |

| Type of ADC | Delta-Sigma (with analogue prefiltering) |

| Input signal range | ±30 V |

| Sampling mode | Simultaneous |

| Frequency (internal time base) | 13.1072 MHz |

| Accuracy (internal time base) | ±100 ppm |

| Data rate range using internal time base | 0.985–12.8 kS/s/channel |

| Noise at maximum sample rate | 106 μV |

| Middle Frequency (Hz) | Accredited Laboratory | Developed System | |||

|---|---|---|---|---|---|

| Peak Acceleration in 1/3 oct (m·s−2) | En (-) | ||||

| Direction X | Direction Y | Direction X | Direction Y | ||

| 1 | 0.00005 | 0.00005 | 0.00007 | 0.00050 | 0.32 |

| 2 | 0.00005 | 0.00007 | 0.00009 | 0.00029 | 0.26 |

| 5 | 0.00007 | 0.00011 | 0.00010 | 0.00017 | 0.11 |

| 10 | 0.00009 | 0.00021 | 0.00017 | 0.00030 | 0.11 |

| 20 | 0.00068 | 0.00147 | 0.00079 | 0.00179 | 0.06 |

| 50 | 0.00886 | 0.04412 | 0.00751 | 0.04184 | 0.02 |

| 100 | 0.03168 | 0.06526 | 0.01366 | 0.04622 | 0.12 |

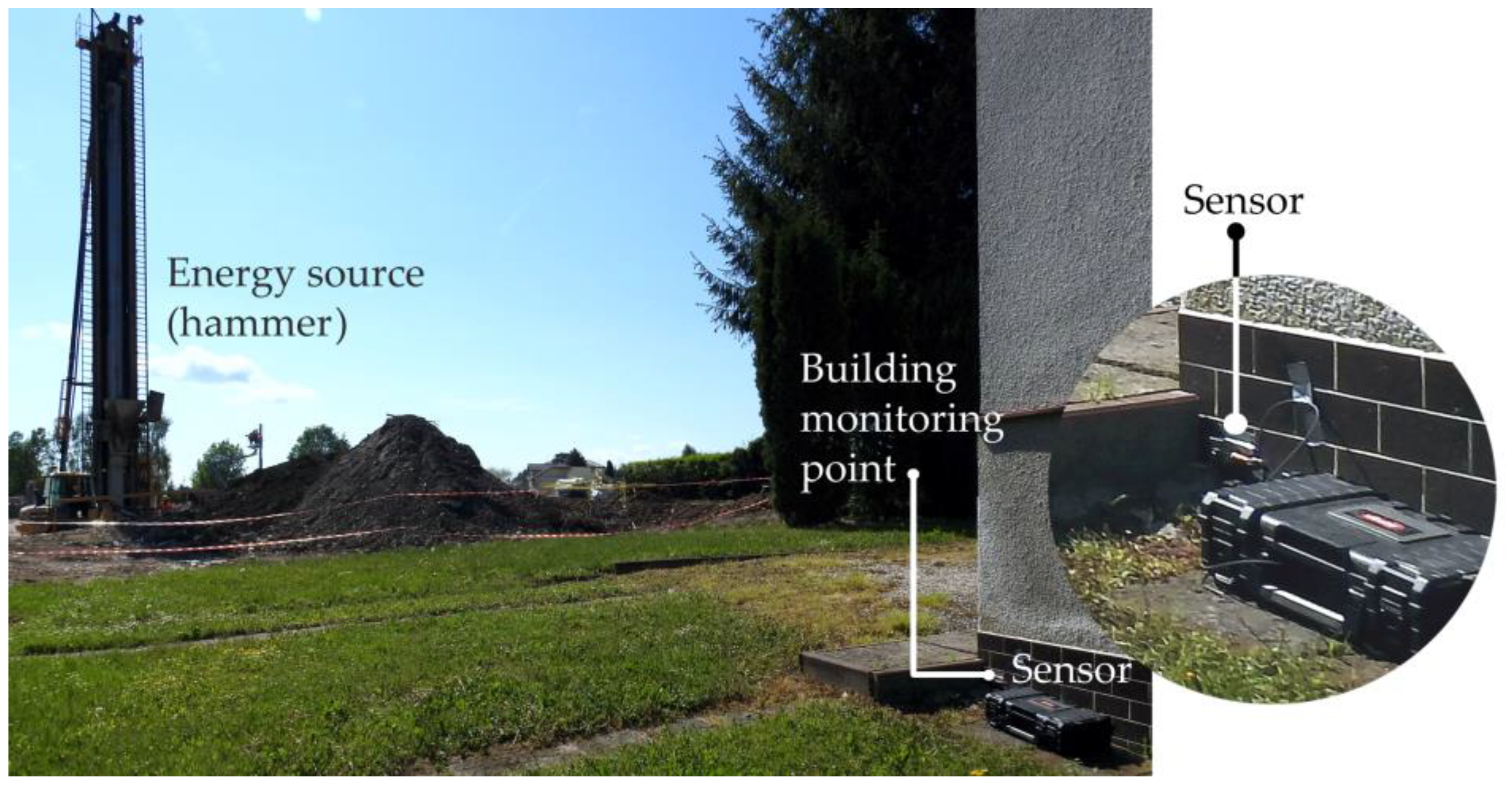

| No. | Type of Construction Investment (Location) | Monitoring Period | Source of Vibration Impact |

|---|---|---|---|

| 1 | Reconstruction of the building (Zabierzów, Poland) | October 2019–November 2019 | Demolition works of the reinforced concrete slab of the garage floor |

| 2 | Construction of a new sugar silo (Chełmrza, Poland) | March 2018–June 2019 | Piling the silo structure (FRANKI piles) |

| 3 | Making foundation piles in a road facility (Miasto Lubawskie, Poland) | September 2019–October 2019 | Piling for the foundation of the new bridge (FRANKI piles) |

| 4 | Construction of a service building (Kraków, Poland) | October 2019 | Vibrating driving of steel profiles |

| 5 | Construction of a multi-family building (Kraków, Poland) | January 2020–February 2020 | Vibration driving of steel sheet piles (larsen) |

| 6 | Reconstruction of the railway line (Kraków, Poland) | April 2020–May 2020 | Vibration driving of steel sheet piles (larsen) |

| 7 | Reconstruction of the railway line (Katowice, Poland) | February 2021–May 2022 | Demolition and construction work related to the construction of a new viaduct |

| 8 | Reconstruction of the tram line (Poznań, Poland) | September 2022–August 2023 | Construction of a new tram line |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hypki, M.; Sumorek, A.; Kawecki, B.; Buczaj, M. A System for Monitoring and Normative Qualification of Building Structure Vibrations Induced by Nearby Construction Works. Appl. Sci. 2023, 13, 11717. https://doi.org/10.3390/app132111717

Hypki M, Sumorek A, Kawecki B, Buczaj M. A System for Monitoring and Normative Qualification of Building Structure Vibrations Induced by Nearby Construction Works. Applied Sciences. 2023; 13(21):11717. https://doi.org/10.3390/app132111717

Chicago/Turabian StyleHypki, Mateusz, Andrzej Sumorek, Bartosz Kawecki, and Marcin Buczaj. 2023. "A System for Monitoring and Normative Qualification of Building Structure Vibrations Induced by Nearby Construction Works" Applied Sciences 13, no. 21: 11717. https://doi.org/10.3390/app132111717

APA StyleHypki, M., Sumorek, A., Kawecki, B., & Buczaj, M. (2023). A System for Monitoring and Normative Qualification of Building Structure Vibrations Induced by Nearby Construction Works. Applied Sciences, 13(21), 11717. https://doi.org/10.3390/app132111717