Experimental Study about the Influence of Storage Conditions of Bulk Cement on the Early-Age Stiffness Evolution of Cementitious Pastes

Abstract

:1. Introduction

2. EMM-ARM in the Literature

| Study | Material 1 | Cement 2 | Curing | Experimental Variables |

|---|---|---|---|---|

| [9] | C | CEM I 42.5 R | T = 20 °C RH = 50% | Methodology |

| [12] | CP M | CEM I 52.5 CEM IV/A 32.5R (FA) | N.A. 3 | Methodology Additive |

| [18] | CP | CEM I 42.5R | T = 20 °C RH = 50% | w/c ratio Filler |

| [19] | C | CEM I 42.5R | T = 9.2 °C RH = N.A. | Mold (in-situ application) |

| [21] | SC | CEMI42.5R | N.A. | Mold Sampling (in-situ application) |

| [22] | CP | CEM II/B-L 32.5N CEM I 42.5R | T = 20 °C; 40 °C | w/c ratio Temperature |

| [23] | M; SA | CEM I 42.5 R CEM II/B-L 32.5N | N.A. | Mix composition |

| [13] | C | CEM I 52.5N PMES CP2 | T = 19.2 ± 0.5 °C | Methodology validation (Round Robin) |

| [24] | C | CEM I 52.5 N PMES CP2 CEM II 42.5R CEM II/A-L 42.5R | T = 20 ± 2 °C | Mold Mix composition (in situ application) |

| [25] | C | CEM I 52.5R-SR 3 | T = 20 °C | Filler |

| [26] | C | CEM I 52.5 S/SR-3 | T = 20 °C; 40 °C | Temperature Mix composition |

| [27] | CP | WCAP | T = 20° C | w/c ratio |

| [28] | HLM | N.A. | T = 20 °C RH = 95% | w/c ratio |

| [29] | LCM | CEM I 42.5 R | T = 20 °C RH = 95% | w/c ratio |

| [30] | LCM | CEM I—42.5 R | N.A. | Temperature Mix composition |

| [31] | CP | WCAP | T = 20° C | w/c ratio |

3. Experimental Campaign

3.1. Materials and Test Nomenclature

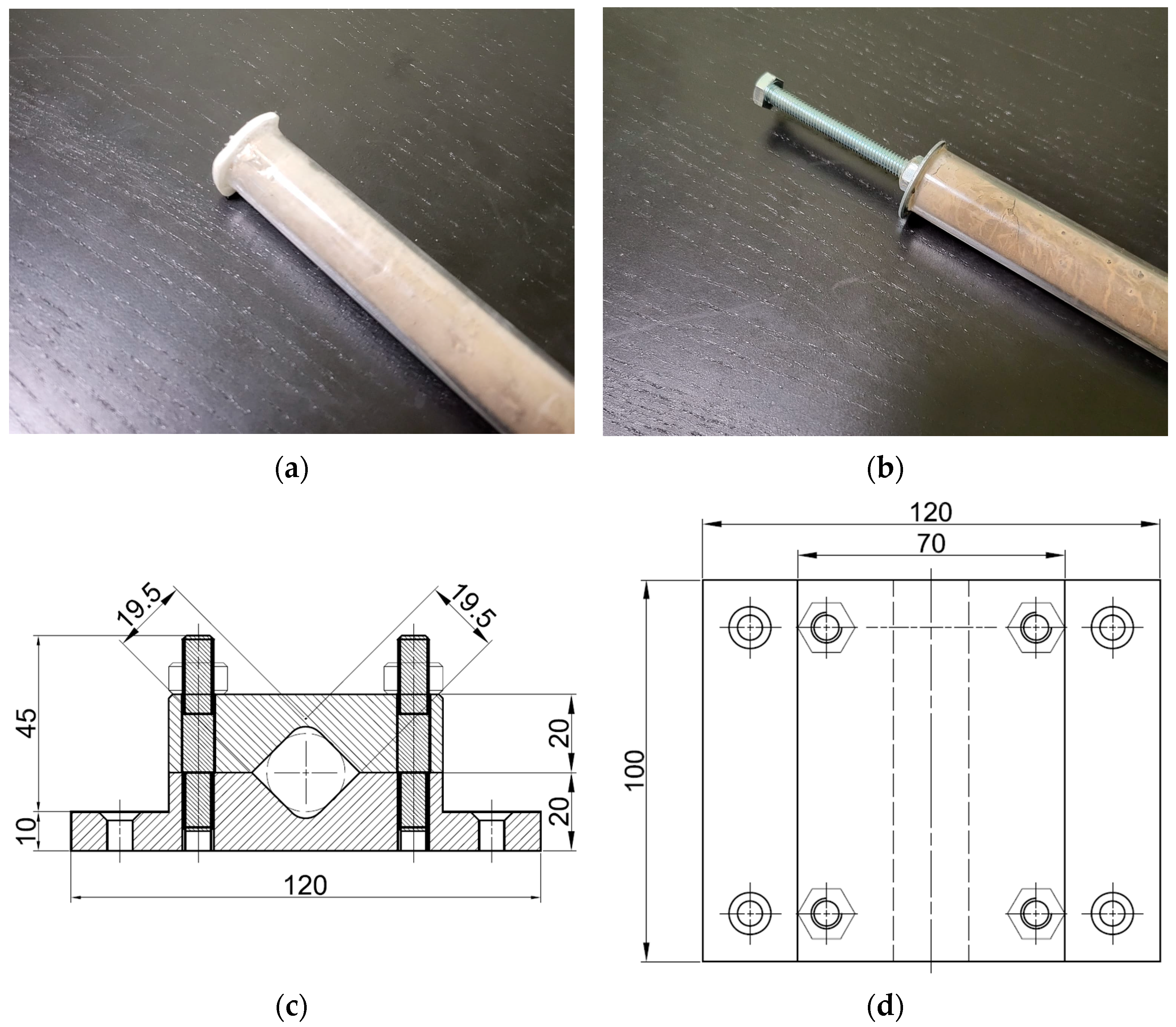

3.2. Specimens and Test Setup

3.3. Data Processing Procedure

4. Results and Discussion

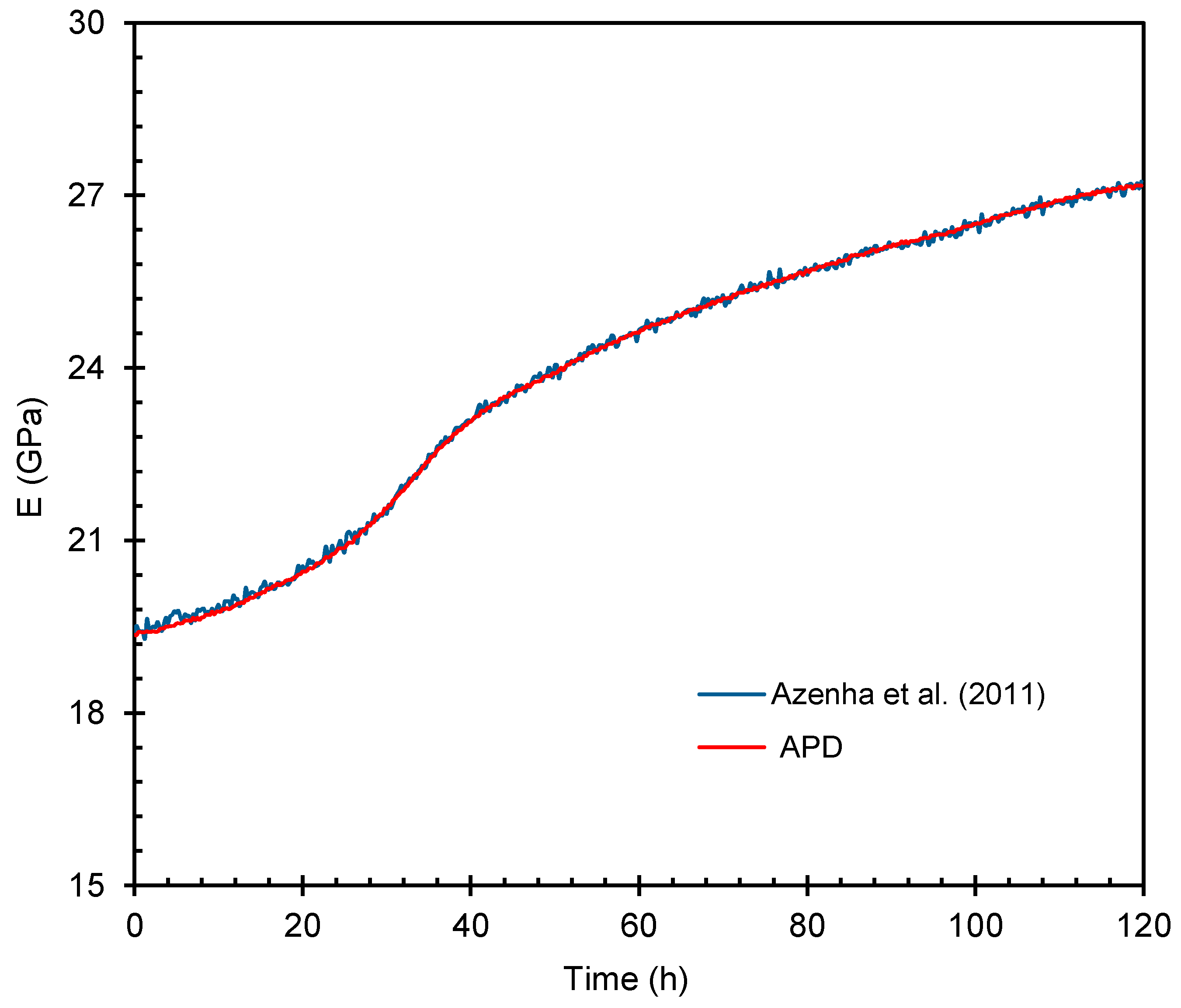

4.1. Benchmark Response Curves

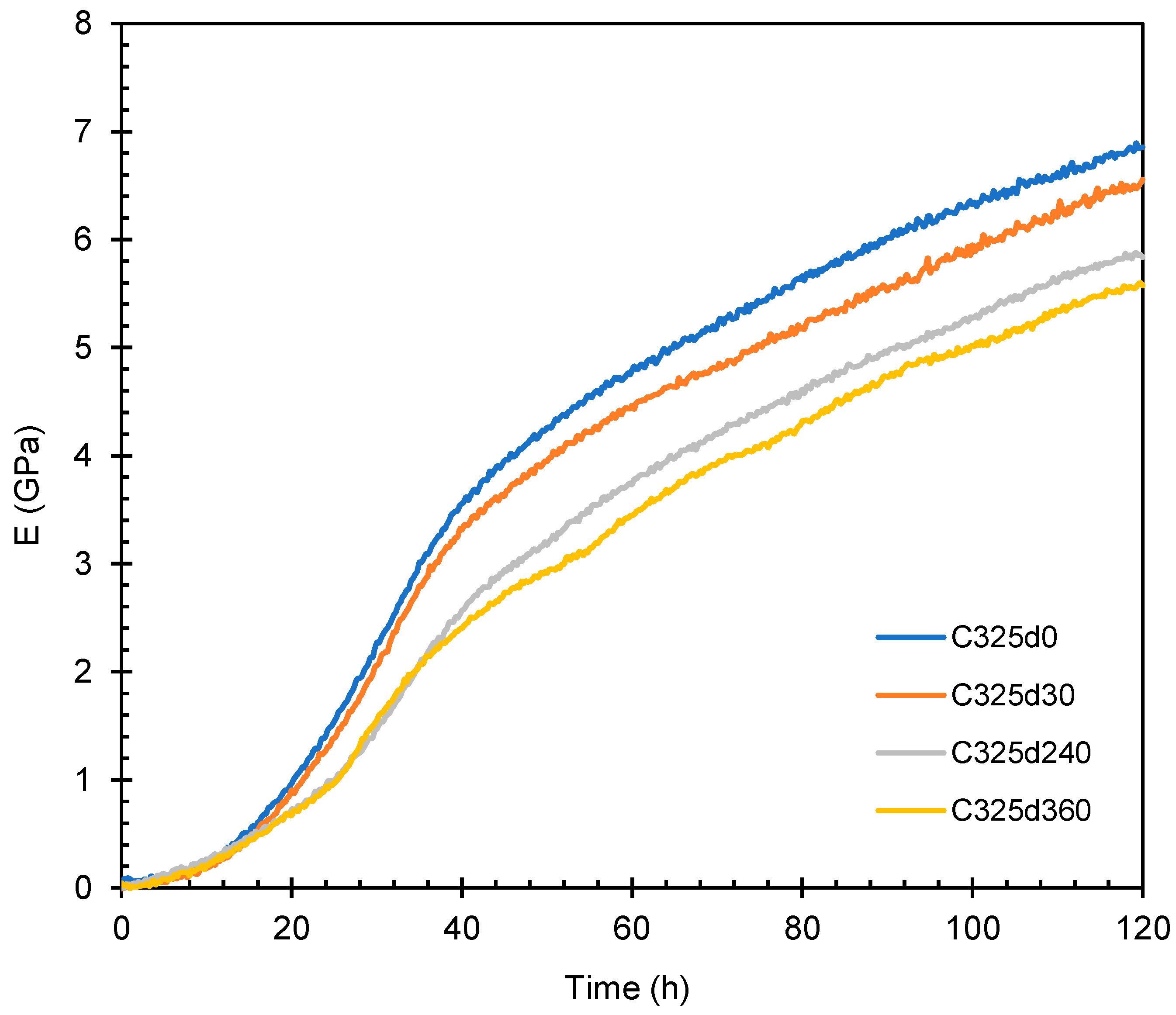

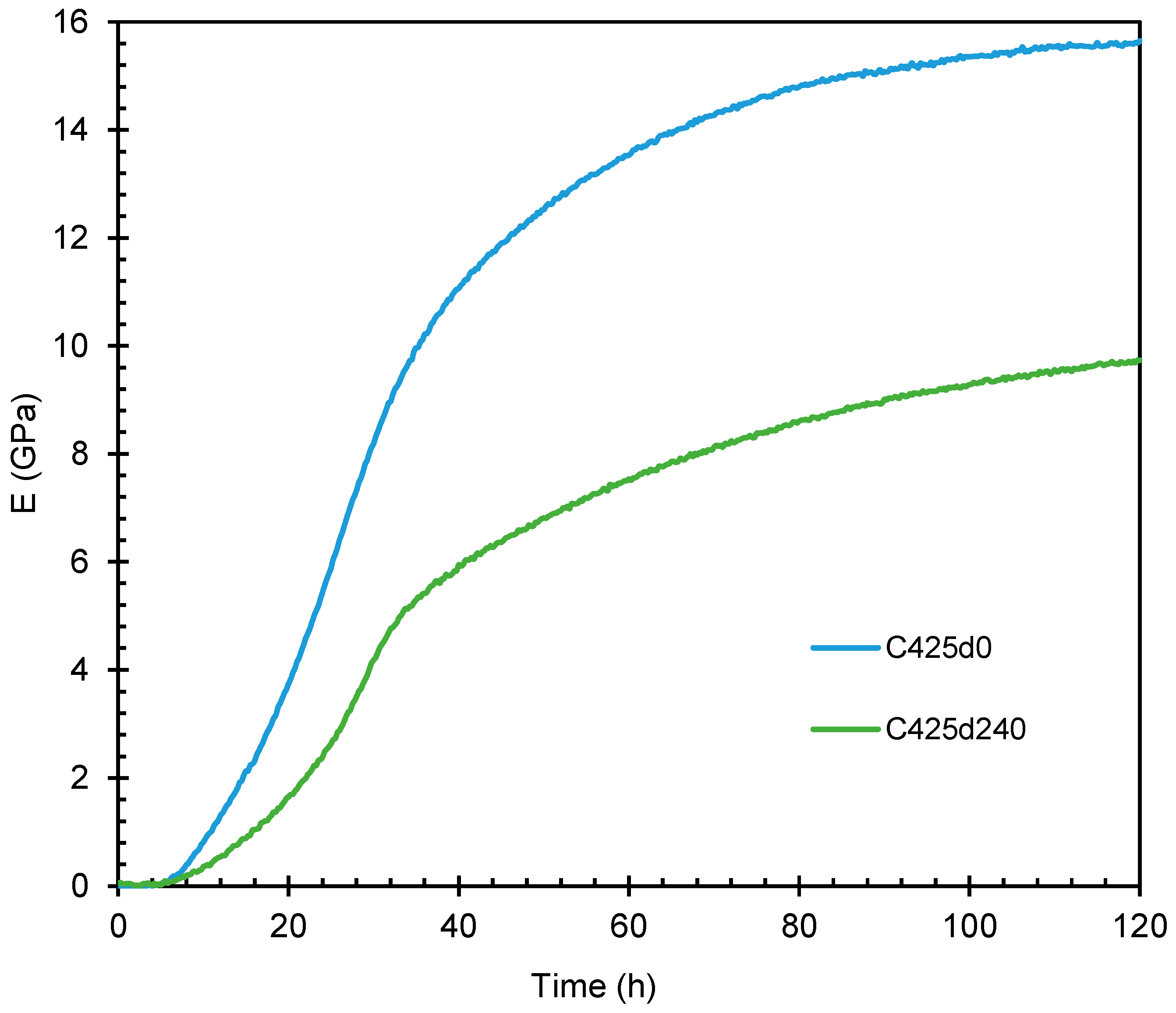

4.2. Effect of Storage

4.3. Effect of Temperature

5. Conclusions

- -

- The material stored in uncontrolled conditions undergoes phenomena that have negative effects on both Young’s modulus and hardening rate as storage time increases. The observed trend was very marked for CEM II/A, characterized by higher clinker presence, with a reduction in the elastic modulus after 240 days of storage equal to 38% at 120 h since casting. The pozzolanic cement (CEM IV/B) proved to be less sensitive to the phenomenon of prehydration, with an 18.7% reduction in the elastic modulus observed at 120 h since casting on specimens produced from cement stored for one year; nevertheless, the effect cannot be neglected;

- -

- a reduction in curing temperature of 5 °C with respect to the reference ordinary value of 20 °C induces a delay in the Young’s modulus evolution of pozzolanic cement paste, with a 25% reduction in E at 120 h since casting.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ISTAT. 14° Censimento Generale della Popolazione e delle Abitazioni. Istituto Nazionale di Statistica. 2001. Available online: https://ebiblio.istat.it/sebinaopac/resource/14-censimento-generale-della-popolazione-e-delle-abitazioni (accessed on 21 July 2023).

- ICOMOS. Principles for the Analysis, Conservation and Structural Restoration of Architectural Heritage. 2003. Available online: https://www.icomos.org/images/DOCUMENTS/Charters/structures_e.pdf (accessed on 8 August 2023).

- Ramaglia, G.; Lignola, G.P.; Balsamo, A.; Prota, A.; Manfredi, G. Seismic strengthening of masonry vaults with abutments using textile-reinforced mortar. J. Compos. Constr. 2017, 21, 04016079. [Google Scholar] [CrossRef]

- Follador, V.; Carpanese, P.; Donà, M.; da Porto, F. Effect of retrofit interventions on seismic fragility of Italian residential masonry buildings. Int. J. Disaster Risk Reduct. 2023, 91, 103668. [Google Scholar] [CrossRef]

- Alecci, V.; De Stefano, M.; Focacci, F.; Luciano, R.; Rovero, L.; Stipo, G. Strengthening masonry arches with lime-based mortar composite. Buildings 2017, 7, 49. [Google Scholar] [CrossRef]

- Vailati, M.; Mercuri, M.; Angiolilli, M.; Gregori, A. Natural-fibrous lime-based mortar for the rapid retrofitting of heritage masonry buildings. Fibers 2021, 9, 68. [Google Scholar] [CrossRef]

- Adami, C.E.; Vintzileou, E. Interventions to historic masonries: Investigation of the bond mechanism between stones or bricks and grouts. Mater. Struct. 2008, 41, 255–267. [Google Scholar] [CrossRef]

- Massazza, F.; Oberti, G. Durability of pozzolanic cements and Italian experience in mass concrete. In Proceedings of the Durability of Concrete, Second International Conference, Montreal, QC, Canada, 4–9 August 1991. [Google Scholar]

- Azenha, M.; Magalhães, F.; Faria, R.; Cunha, Á. Measurement of concrete E-modulus evolution since casting: A novel method based on ambient vibration. Cem. Concr. Res. 2010, 4, 1096–1105. [Google Scholar] [CrossRef]

- Serdar, M.; Gabrijel, I.; Schlicke, D.; Staquet, S.; Azenha, M. Advanced Techniques for Testing of Cement-Based Materials; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Malhotra, V.M.; Carino, N.J. Handbook on Nondestructive Testing of Concrete; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Azenha, M.; Faria, R.; Magalhães, F.; Ramos, L.; Cunha, A. Measurement of the E-modulus of cement pastes and mortars since casting, using a vibration based technique. Mater. Struct. 2011, 45, 81–92. [Google Scholar] [CrossRef]

- Delsaute, B.; Boulay, C.; Granja, J.; Carette, J.; Azenha, M.; Dumoulin, C.; Karaiskos, G.; Deraemaeker, A.; Staquet, S. Testing Concrete E-modulus at Very Early Ages Through Several Techniques: An Inter-laboratory Comparison. Strain 2016, 52, 91–109. [Google Scholar] [CrossRef]

- Dubina, E.; Black, L.; Sieber, R.; Plank, J. Interaction of water vapour with anhydrous cement minerals. Adv. Appl. Ceram. 2010, 109, 260–268. [Google Scholar] [CrossRef]

- Dubina, E.; Plank, J. Influence of moisture-and CO2-induced ageing in cement on the performance of admixtures used in construction chemistry. ZKG Int. 2012, 10, 60–68. [Google Scholar]

- Whittaker, M.; Al-Mutawa, F.; Leon, L.; Plank, J.; Dubina, E.; Arkless, L. The effect of prehydration on the engineering properties of CEM I Portland cement. Adv. Cem. Res. 2013, 25, 12–20. [Google Scholar] [CrossRef]

- Adamtsevic, A.; Eremin, A.; Pustovgar, A.; Pashkevich, S.; Nefedov, S. Research on the Effect of Prehydration of Portland Cement Stored in Normal Conditions. Appl. Mech. Mater. 2014, 670, 376–381. [Google Scholar] [CrossRef]

- Maia, L.; Azenha, M.; Faria, R.; Figueiras, J. Influence of the cementitious paste composition on the E-modulus and heat of hydration evolutions. Cem. Concr. Res 2011, 41, 799–807. [Google Scholar] [CrossRef]

- Azenha, M.; Ramos, L.; Aguilar, R.; Granja, J. Continuous monitoring of concrete E-modulus since casting based on modal identification: A case study for in situ application. Cem. Concr. Compos. 2012, 34, 881–890. [Google Scholar] [CrossRef]

- Van Overschee, P.; De Moor, B. Subspace Identification for Linear Systems: Theory—Implementation—Applications; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1996. [Google Scholar]

- Silva, J.; Azenha, M.; Correia, A.; Granj, J. Continuous monitoring of sand–cement stiffness starting from layer compaction with a resonant frequency-based method: Issues on mould geometry and sampling. Soils Found. 2014, 54, 56–66. [Google Scholar] [CrossRef]

- Granja, J.; Azenha, M.; de Sousa, C.; Ferreira, C. Comparison between different experimental techniques for stiffness monitoring of cement pastes. J. Adv. Concr. Technol. 2014, 12, 45–61. [Google Scholar] [CrossRef]

- Azenha, M.; Silva, J.; Granja, J.; Gomes-Correia, A. A Retrospective View of EMM-ARM: Application to Quality Control in Soil-improvement and Complementary Development. Procedia Eng. 2016, 143, 339–346. [Google Scholar] [CrossRef]

- Granja, J.; Azenha, M. Towards a robust and versatile method for monitoring E-modulus of concrete since casting: Enhancements and extensions of EMM-ARM. Strain 2017, 53, e12232. [Google Scholar] [CrossRef]

- Velay-Lizancos, M.; Azenha, M.; Martínez-Lage, I.; Vázquez-Burgo, P. Addition of biomass ash in concrete: Effects on E-Modulus, electrical conductivity at early ages and their correlation. Constr. Build. Mater. 2017, 157, 1126–1132. [Google Scholar] [CrossRef]

- Velay-Lizancos, M.; Martinez-Lage, I.; Azenha, M.; Granja, J.; Vazquez-Burgo, P. Concrete with fine and coarse recycled aggregates: E-modulus evolution, compressive strength and non-destructive testing at early ages. Constr. Build. Mater. 2018, 193, 323–331. [Google Scholar] [CrossRef]

- Mazaheripour, H.; Faria, R.; Ye, G.; Schlangen, E.; Granja, J.; Azenha, M. Microstructure-Based Prediction of the Elastic Behaviour of Hydrating Cement Pastes. Appl. Sci. 2018, 8, 442. [Google Scholar] [CrossRef]

- Garijo, L.; Azenha, M.; Ramesh, M.; Lourenço, P.; Ruiz, G. Stiffness evolution of natural hydraulic lime mortars at early ages measured through EMM-ARM. Constr. Build. Mater. 2019, 216, 405–415. [Google Scholar] [CrossRef]

- Ramesh, M.; Azenha, M.; Lourenço, P.B. Mechanical properties of lime–cement masonry mortars in their early ages. Mater. Struct. 2019, 52, 13. [Google Scholar] [CrossRef]

- Ramesh, M.; Azenha, M.; Lourenço, P.B. Study of Early Age Stiffness Development in Lime–Cement Blended Mortars. In Structural Analysis of Historical Constructions; Aguilar, R., Torrealva, D., Moreira, S., Pando, M.A., Ramos, L.F., Eds.; RILEM Bookseries; Springer: Cham, Switzerland, 2019; Volume 18, pp. 397–404. [Google Scholar] [CrossRef]

- Dunant, C.F.; Granja, J.; Muller, A.; Azenha, M.; Scrivener, K. Microstructural simulation and measurement of elastic modulus evolution of hydrating cement pastes. Cem. Conc. Res. 2020, 130, 106007. [Google Scholar] [CrossRef]

- Russo, T.; Ribeiro, R.R.; Araghi, A.; Lameiras, R.D.M.; Granja, J.; Azenha, M. Continuous Monitoring of Elastic Modulus of Mortars Using a Single-Board Computer and Cost-Effective Components. Buildings 2023, 13, 1117. [Google Scholar] [CrossRef]

- Rocha Ribeiro, R.; Granja, J.; Lameiras, R.; Azenha, M. A Cost-Effective Micro-controller Based System for EMM-ARM Tests in Cement Paste. In Proceedings of the International RILEM Conference on Synergising Expertise towards Sustainability and Robustness of CBMs and Concrete Structures, Milos Island, Greece, 15–16 June 2023; pp. 399–412. [Google Scholar] [CrossRef]

- Russo, T.; Azenha, M.; Granja, J. Open-Source EMM-ARM Implementation for Mortars Based on Single-Board Computer. In Proceedings of the International RILEM Conference on Synergising Expertise towards Sustainability and Robustness of CBMs and Concrete Structures, Milos Island, Greece, 15–16 June 2023; pp. 380–391. [Google Scholar] [CrossRef]

- S2X, S.R.L. S2-DDA User’s Manual; S2X S.R.L.: Campobasso, Italy, 2021. [Google Scholar]

- Rainieri, C.; Fabbrocino, G. Operational Modal Analysis of Civil Engineering Structures: An Introduction and Guide for Applications; Springer: New York, NY, USA, 2014. [Google Scholar]

- Final Report of RILEM TC 185-ATC ‘Advanced Testing of Cement-Based Materials during Setting and Hardening’; Reinhardt, H.W.; Grosse, C.U. (Eds.) RILEM: Paris, France, 2005; ISBN 2-912143-81-0. [Google Scholar]

- Regulation (EU) No 305/2011 of the European Parliament and of the Council of 9 March 2011 Laying Down Harmonised Conditions for the Marketing of Construction Products and Repealing Council Directive 89/106/EEC. Available online: https://eur-lex.europa.eu/legal-content/PL/TXT/?uri=CELEX%3A32011R0305 (accessed on 15 February 2022).

| Specimen | Material | Experimental Variable | |

|---|---|---|---|

| T (°C) | Time (Day) | ||

| C325d0 | CEM IV/B (P) 32.5 R-SR | 20 ± 0.5 | 0 |

| C325d30 | CEM IV/B (P) 32.5 R-SR | 20 ± 0.5 | 30 |

| C325d240 | CEM IV/B (P) 32.5 R-SR | 20 ± 0.5 | 240 |

| C325d360 | CEM IV/B (P) 32.5 R-SR | 20 ± 0.5 | 360 |

| C425d0 | CEM II/A-LL 42.5 R | 20 ± 0.5 | 0 |

| C425d240 | CEM II/A-LL 42.5 R | 20 ± 0.5 | 240 |

| C325T20 | CEM IV/B (P) 32.5 R-SR | 20 ± 0.5 | 0 |

| C325T15 | CEM IV/B (P) 32.5 R-SR | 15 ± 0.5 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cieri, L.; Cassese, P.; Fabbrocino, G.; Occhiuzzi, A.; Rainieri, C. Experimental Study about the Influence of Storage Conditions of Bulk Cement on the Early-Age Stiffness Evolution of Cementitious Pastes. Appl. Sci. 2023, 13, 11734. https://doi.org/10.3390/app132111734

Cieri L, Cassese P, Fabbrocino G, Occhiuzzi A, Rainieri C. Experimental Study about the Influence of Storage Conditions of Bulk Cement on the Early-Age Stiffness Evolution of Cementitious Pastes. Applied Sciences. 2023; 13(21):11734. https://doi.org/10.3390/app132111734

Chicago/Turabian StyleCieri, Luigi, Paolino Cassese, Giovanni Fabbrocino, Antonio Occhiuzzi, and Carlo Rainieri. 2023. "Experimental Study about the Influence of Storage Conditions of Bulk Cement on the Early-Age Stiffness Evolution of Cementitious Pastes" Applied Sciences 13, no. 21: 11734. https://doi.org/10.3390/app132111734