2.1. Construction Principles of Risk Indicators

The purpose of establishing the risk evaluation index system of tunnel lining demolition construction is to analyze the risk factors existing in the process of tunnel lining demolition construction and to measure the overall risk of tunnel lining demolition construction. Therefore, the index system must scientifically, objectively, reasonably, and comprehensively reflect all factors affecting the safety of tunnel lining demolition construction [

18,

19]. However, it is very difficult to establish a set of scientific and reasonable risk evaluation index systems. Therefore, it is necessary to analyze and judge according to certain principles in order to better solve this problem.

(1) Systematic principle

Tunnel lining demolition construction is a huge and complex man-machine system related to engineering geological conditions and production and construction organization. To evaluate its risk and establish the risk evaluation index system, we need to think about it with the idea of system engineering so that the index can reflect the factors affecting the risk of tunnel lining demolition construction as comprehensively as possible [

20].

(2) Scientific principle

The construction of a risk evaluation index system for tunnel lining demolition construction must conform to the actual situation of tunnel lining demolition construction, based on the actual characteristics of the project and scientific theory, so as to ensure the objectivity and reliability of the index system [

21].

(3) Conciseness principle

The construction of the risk evaluation index system of tunnel lining demolition construction should be based on the comprehensive and systematic analysis of various potential risk factors during the construction period, and the main risk factors affecting the safety of high-rise lining demolition construction should be determined as the research object of risk evaluation, so as to ensure the key control of those risk factors with high frequency and serious consequences.

(4) Independence principle

Any indicator system is composed of a certain number of indicators. Each indicator should not only have clear content but also be relatively independent. The indicators at the same level do not overlap each other, and there is no inclusion or intersection between them [

22].

(5) Universality principle

A set of scientific and reasonable index systems should be able to reflect the situation of the whole industry. At the same time, through appropriate transformation, the risk assessment of different tunnel lining demolition construction can be carried out [

23,

24].

(6) Combination of qualitative and quantitative principles

The construction of the index system should meet the principle of combining qualitative and quantitative analysis; that is, on the basis of qualitative analysis, quantitative treatment should be carried out. Only through quantification can we accurately reflect the risk of lining demolition construction. The risk assessment of road lining demolition construction is advanced, which studies the possibility of risk occurrence and the possible loss. The quantitative analysis of this problem mainly relies on the statistical data of similar risks in the past. For qualitative indicators lacking statistical data, the scoring method can be used to approximate the quantification by using expert opinions [

25].

(7) Feasibility principle

The selection of evaluation indexes should be practical and operable. It is necessary to consider that the evaluation index system can be implemented under realistic conditions. The data required for obtaining the index value should be easy to investigate and collect, and the index should be easy to understand and calculate so as to ensure the smooth progress of the evaluation work [

26].

2.2. Identification and Determination of Risk Indicators

The task of risk identification for tunnel lining demolition construction is to distinguish and classify the risk factors hidden in each link of tunnel lining demolition construction by using effective risk identification methods so that the managers can identify the existing risk factors and the impact these risk factors may have on the whole construction process, and preliminarily rank the risk factors, so as to determine the main risk factors [

27]. The general risk identification process includes determining the risk identification objectives, identifying the most important project participants, collecting data, estimating the form of project risk, and identifying potential project risks. The identification steps of tunnel lining demolition construction risk also follow such a process [

28].

According to the example of the tunnel lining demolition project, the demolition process is comprehensively analyzed. Based on the opinions of relevant experts, it is mainly divided into five aspects: geological conditions, tunnel design, lining state, construction method, and construction organization. The influencing factors of tunnel lining demolition construction are analyzed from these five aspects:

(1) Geological conditions

The grade of surrounding rock, groundwater, and in situ stress are mainly considered. The surrounding rock of the tunnel is subject to secondary disturbance and sudden reduction in radial support force (especially the weak initial support of the tunnel or the removal section of the initial support) during the demolition of the existing structure. The surrounding rock is prone to instability and collapse, especially in the broken section of the surrounding rock. The surrounding rock is classified according to the integrity of rock mass and rock strength. The weak and broken surrounding rock is prone to large deformation, and the corresponding lining structure is different, which also determines the pretreatment measures before demolition [

29]. Water-rich areas and high ground stress conditions are large, which are prone to mud and water inrush, and the corresponding demolition risks are also very different.

(2) Tunnel design

The lining structure and tunnel section are mainly considered. The lining structure is mainly divided into plain concrete and reinforced concrete. The removal of plain concrete is relatively easy, and the removal of reinforced concrete has good integrity. The removal of reinforced concrete has a large mutual disturbance, and the corresponding construction risks are different. The tunnel section has various forms, such as a rectangle, circle, horseshoe, etc.; the section curvature affects the stability of the lining structure, and the risk of demolition operation is also different [

30].

(3) Lining state

Service time, structural deterioration, maintenance period, and lining defects are mainly considered. Generally, the existing tunnel lining structure that needs to be demolished has very serious quality defects or structural diseases [

31], which is a major potential safety hazard, making it very prone to safety accidents in demolition operations. The defects of the lining itself refer to the structural problems caused by nonstandard operation during lining construction. The longer the service time, the greater the degree of structural deterioration; the longer the maintenance period and the greater the degree of lining defects, the more likely the lining structure is to be damaged and the higher the risk of lining demolition.

(4) Construction method

It mainly considers pretreatment measures, demolition location, demolition scope, demolition sequence, demolition means, lining reconstruction, monitoring, and measurement. The pretreatment measures include surrounding rock strengthening support and waterproof and drainage measures to ensure the stability of lining replacement surrounding rock and avoid mud and water inrush. The demolition positions include the demolition of the lining vault, arch waist, side wall, and full section demolition. The demolition risks at different positions must be different, and it is easy to see that the risk of full-section demolition is higher. The demolition scope is divided into circumferential angle and longitudinal distance, and the size of the demolition scope directly affects the construction difficulty and progress. The demolition sequence mainly includes longitudinal and circumferential aspects. The disturbance and damage to the existing lining structure caused by demolition do not match the degree of damage it can withstand, which will cause disturbance and collapse of the UN demolished parts in the demolition operation. A demolition refers to the demolition methods of the lining structure, including blasting, mechanical, and manual methods. Different methods have different demolition efficiency and risks. Lining reconstruction includes the timing of lining reconstruction, whether the lining is plain concrete or reinforced concrete, and whether the lining is strengthened. Lining reconstruction directly determines the safety of the tunnel lining demolition process. During the lining removal process, monitoring and measurement are used as auxiliary means to measure the stress and deformation of the lining structure in the non-operation area so as to ensure the safety of the demolition in the operation area.

(5) Construction organization

Management, equipment, construction personnel level, emergency measures, and other measures are mainly considered. The organization ability and mobilization ability of the project tunnel lining demolition construction management team and the team with high management level can overcome the difficulties in construction, solve the risk events, and ensure the construction progress [

32]. Equipment mainly refers to the removal of trolleys and large mechanized equipment, one of which ensures the construction speed, and the other ensures the construction safety. The level of construction personnel refers to the equipment operation proficiency, technical level, and lining removal experience of on-site construction personnel, especially whether they have removal experience, which greatly affects the smooth implementation of lining removal construction. Emergency measures refer to taking timely and appropriate measures to ensure the safety of demolition construction in case of a large-scale collapse of lining, falling blocks of adjacent lining concrete, mud and water inrush, etc.

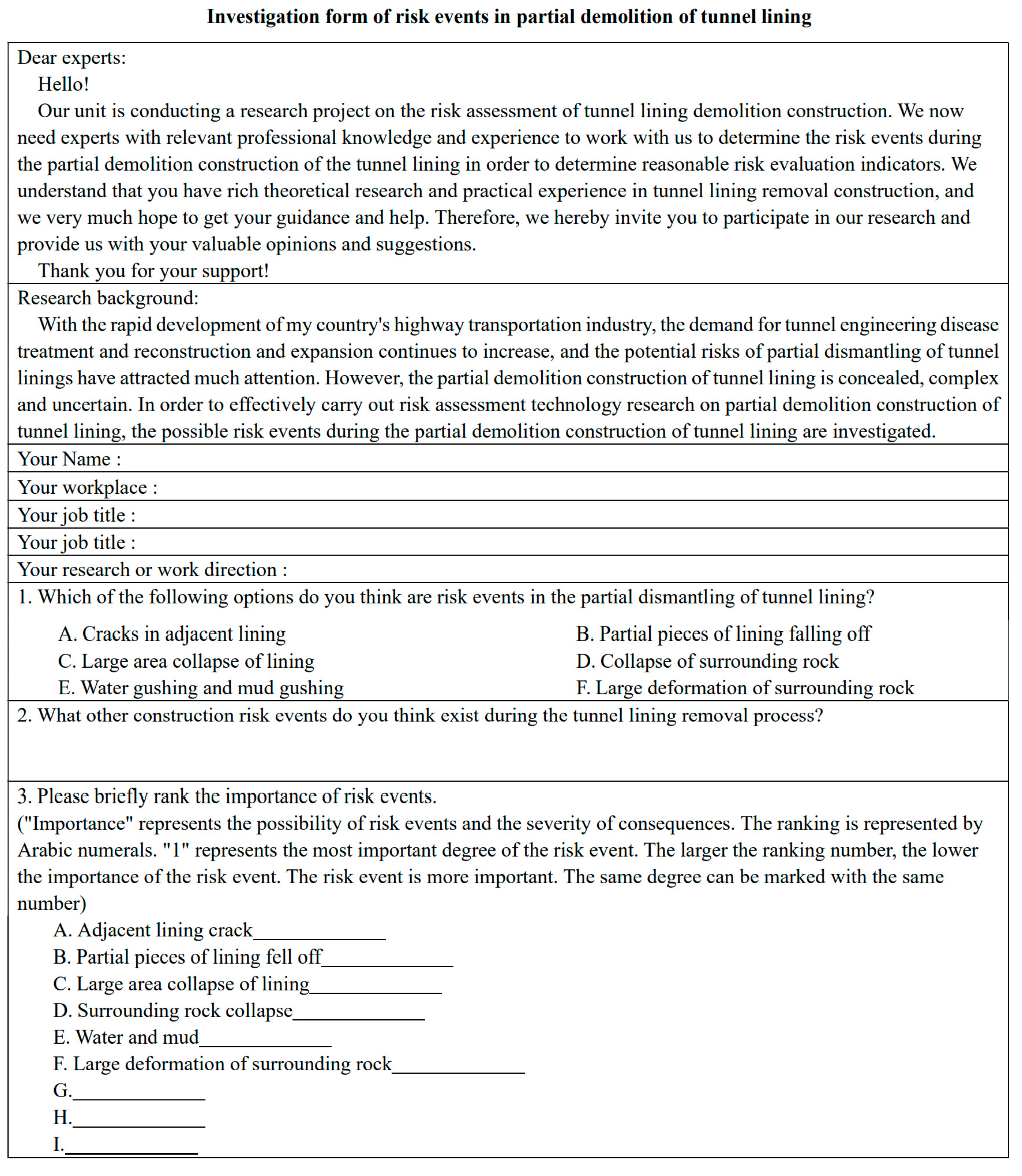

(6) Method for determining risk indicators

In order to further determine the risk events and risk factors of tunnel lining demolition construction, a questionnaire was sent to experts in the industry to obtain more practical results. Through two rounds of questionnaires (see

Appendix A for details), the following 65 valid data were obtained, including 23 valid data in the first round and 42 valid data in the second round. Through the first round of questionnaires, the results are shown in

Figure 1. It is concluded that the risk events of tunnel lining demolition construction mainly include adjacent lining cracks, accidental lining falling or collapse, surrounding rock collapse and affecting the operation of adjacent lines. Among them, the cracking of adjacent lining refers to the damage to adjacent structures caused by lining removal. Accidental falling or collapse of the lining refers to the accidental falling of the lining during the removal process, resulting in personal injury and equipment damage. Surrounding rock collapse refers to the collapse of surrounding rock during lining removal, resulting in casualties, equipment damage, and cost increases. The impact on the operation of adjacent lines refers to the damage to the structure and equipment of adjacent lines caused by the removal of lining and the failure of normal operation. Through the second round of questionnaires, the risk factors corresponding to the possible risk events in the tunnel lining demolition construction are obtained, as shown in

Figure 2,

Figure 3,

Figure 4 and

Figure 5. After comprehensive analysis, the tunnel lining demolition indicators are shown in

Figure 6.