Partial Substitution of Wheat Flour with Palm Flour in Pasta Preparation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Experimental Design and Preparation of the Pasta

2.3. Cooking Time, Cooking Yield, Cooking Loss, and Texture Profile

2.4. Physical-Chemical Quality

2.5. Colorimetric Analysis, Pigments, and Bioactive Compounds

2.6. Pigments and Bioactive Compounds

2.7. Morphology of Particles

2.8. Statistical Analysis

3. Results and Discussions

3.1. Cooking Properties and Texture Profile

3.2. Physical-Chemical Quality

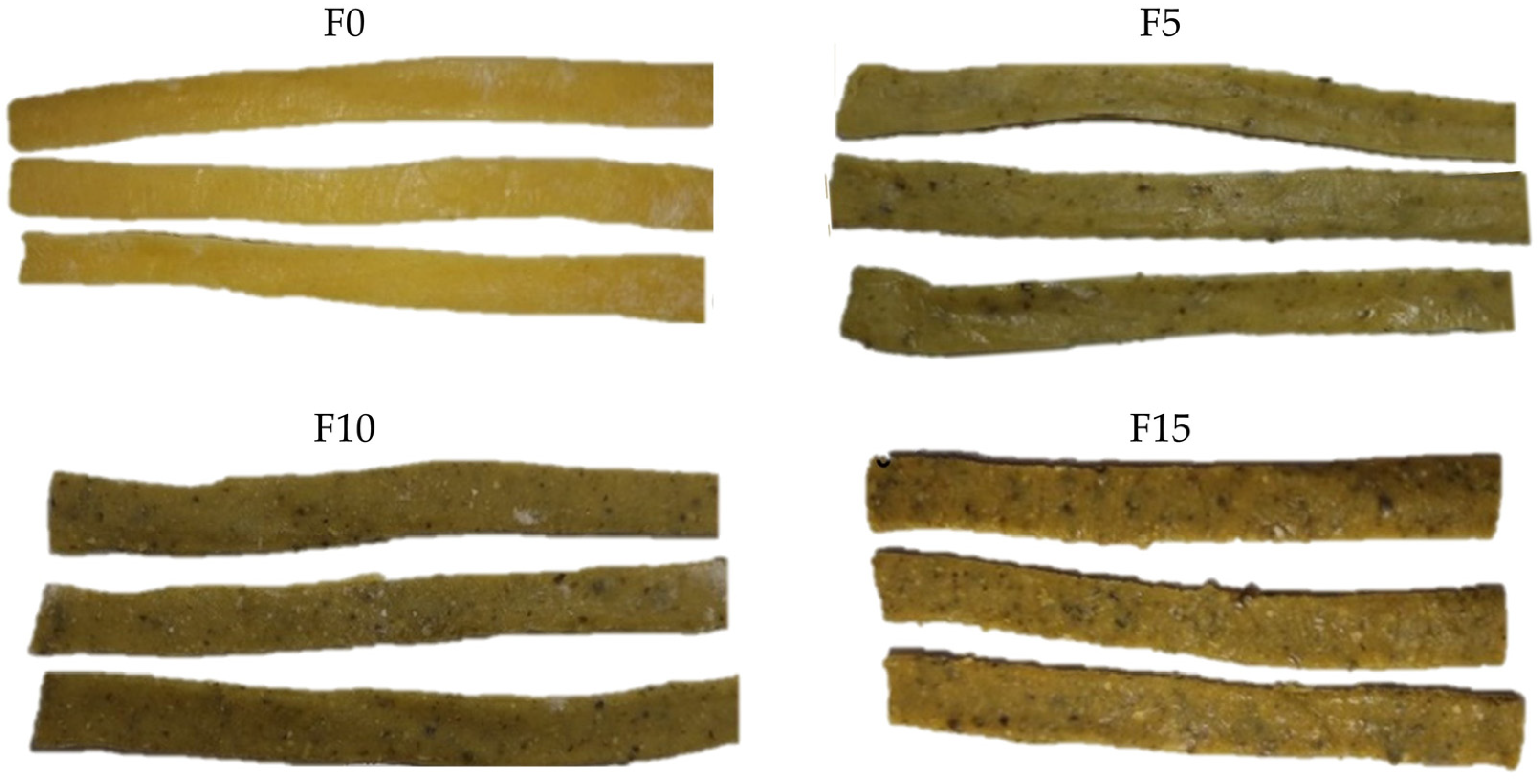

3.3. Colorimetric Analysis, Pigments, and Bioactive Compounds

3.4. Morphology of Particles

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Renoldi, N.; Brennan, C.S.; Lagazio, C.; Peressini, D. Evaluation of technological properties, microstructure and predictive glycaemic response of durum wheat pasta enriched with psyllium seed husk. LWT 2021, 151, 112203. [Google Scholar] [CrossRef]

- Bokić, J.; Škrobot, D.; Tomić, J.; Šeregelj, V.; Abellan-Victorio, A.; Moreno, D.A.; Ilić, N. Broccoli sprouts as a novel food ingredient: Nutritional, functional and sensory aspects of sprouts enriched pasta. LWT 2022, 172, 114203. [Google Scholar] [CrossRef]

- Coello, K.E.; Peñas, E.; Martinez-Villaluenga, C.; Elena Cartea, M.; Velasco, P.; Frias, J. Pasta products enriched with moringa sprout powder as nutritive dense foods with bioactive potential. Food Chem. 2021, 360, 130032. [Google Scholar] [CrossRef] [PubMed]

- Sahin, A.W.; Hardiman, K.; Atzler, J.J.; Vogelsang-O’Dwyer, M.; Valdeperez, D.; Münch, S.; Cattaneo, G.; O’Riordan, P.; Arendt, E.K. Rejuvenated Brewer’s Spent Grain: The impact of two BSG-derived ingredients on techno-functional and nutritional characteristics of fibre-enriched pasta. Innov. Food Sci. Emerg. Technol. 2021, 68, 102633. [Google Scholar] [CrossRef]

- Chaloulos, P.; Bazanis, A.E.; Georgiadou, M.; Protonotariou, S.; Mandala, I. Effect of drying and grinding or micro-grinding process on physical and rheological properties of whole cladode (Opuntia ficus-indica) flour. LWT 2021, 151, 112171. [Google Scholar] [CrossRef]

- De Farias, P.M.; de Vasconcelos, L.B.; Ferreira, M.E.S.; Pascall, M.; Tapia-Blácido, D.R. Nopal cladode (Opuntia ficus-indica) flour: Production, characterization, and evaluation for producing bioactive film. Food Packag. Shelf Life 2021, 29, 100703. [Google Scholar] [CrossRef]

- Balli, D.; Cecchi, L.; Innocenti, M.; Bellumori, M.; Mulinacci, N. Food by-products valorisation: Grape pomace and olive pomace (pâté) as sources of phenolic compounds and fiber for enrichment of tagliatelle pasta. Food Chem. 2021, 355, 129642. [Google Scholar] [CrossRef] [PubMed]

- du Toit, A.; de Wit, M.; Osthoff, G.; Hugo, A. Antioxidant properties of fresh and processed cactus pear cladodes from selected Opuntia ficus-indica and O. robusta cultivars. S. Afr. J. Bot. 2018, 118, 44–51. [Google Scholar] [CrossRef]

- Liguori, G.; Gentile, C.; Gaglio, R.; Perrone, A.; Guarcello, R.; Francesca, N.; Fretto, S.; Inglese, P.; Settanni, L. Effect of addition of Opuntia ficus-indica mucilage on the biological leavening, physical, nutritional, antioxidant and sensory aspects of bread. J. Biosci. Bioeng. 2020, 129, 184–191. [Google Scholar] [CrossRef]

- Bouazizi, S.; Montevecchi, G.; Antonelli, A.; Hamdi, M. Effects of prickly pear (Opuntia ficus-indica L.) peel flour as an innovative ingredient in biscuits formulation. LWT 2020, 124, 109155. [Google Scholar] [CrossRef]

- Brazilian Food Composition Table (TBCA). University of São Paulo (USP). Food Research Center (FoRC), Version 7.2. São Paulo; 2023. Available online: http://www.fcf.usp.br/tbca (accessed on 7 September 2023).

- Jia, F.; Ma, Z.; Hu, X. Controlling dough rheology and structural characteristics of chickpea-wheat composite flour-based noodles with different levels of Artemisia sphaerocephala Krasch. gum addition. Int. J. Biol. Macromol. 2020, 150, 605–616. [Google Scholar] [CrossRef] [PubMed]

- Kolarič, L.; Minarovičová, L.; Lauková, M.; Karovičová, J.; Kohajdová, Z. Pasta noodles enriched with sweet potato starch: Impact on quality parameters and resistant starch content. J. Texture Stud. 2020, 51, 464–474. [Google Scholar] [CrossRef] [PubMed]

- Majzoobi, M.; Layegh, B.; Farahnaky, A. Inclusion of Oat Flour in the Formulation of Regular Salted Dried Noodles and Its Effects on Dough and Noodle Properties. J. Food Process Preserv. 2014, 38, 48–58. [Google Scholar] [CrossRef]

- Zhu, F.; Li, J. Physicochemical and sensory properties of fresh noodles fortified with ground linseed (Linum usitatissimum). LWT 2019, 101, 847–853. [Google Scholar] [CrossRef]

- Instituto Adolfo Lutz. Métodos Físico-Químicos para Análise de Alimentos, 4th ed.; 1ª Edição Online: São Paulo, Brazil, 2008.

- Jacobs, M.B. Micro-Kjeldahl Method for Biologicals. J. Am. Pharm. Assoc. 1951, 40, 151–153. [Google Scholar] [CrossRef] [PubMed]

- Folch, J.; Lees, M.; Sloane, G.H. A Simple Method for the Isolation and Purification of Total Lipides From Animal Tissues. J. Biol. Chem. 1957, 226, 497–509. [Google Scholar] [CrossRef] [PubMed]

- Nagata, M.; Yamashita, I. Simple Method for Simultaneous Determination of Chlorophyll and Carotenoids in Tomato Fruit. Nippon Shokuhin Kogyo Gakkaishi 1992, 39, 925–928. [Google Scholar] [CrossRef]

- Waterhouse, A.L. Determination of total phenolics. Curr. Protoc. Food Anal. Chem. 2002, 6, 8. [Google Scholar]

- Li, L.; Zhou, W.; Wu, A.; Qian, X.; Xie, L.; Zhou, X.; Zhang, L. Effect of Ginkgo Biloba Powder on the Physicochemical Properties and Quality Characteristics of Wheat Dough and Fresh Wet Noodles. Foods 2022, 11, 698. [Google Scholar] [CrossRef]

- Marti, A.; Pagani, M.A. What can play the role of gluten in gluten free pasta? Trends Food Sci. Technol. 2013, 31, 63–71. [Google Scholar] [CrossRef]

- Baah, R.O.; Duodu, K.G.; Emmambux, M.N. Cooking quality, nutritional and antioxidant properties of gluten-free maize—Orange-fleshed sweet potato pasta produced by extrusion. LWT 2022, 162, 113415. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Wang, Y.; Ho, C.T.; Patiguli, M.; Zhang, Y.; Yu, B.; Zhang, C.; Aadil, R.M.; Qu, W.; Xiao, R.; et al. Addition of chlorophyll microcapsules to improve the quality of fresh wheat noodles. LWT 2023, 183, 114940. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, C.; Hong, J.; Li, L.; Zheng, X.; Bian, K.; Guan, E. Effect of heat treatment and salt addition on the physicochemical properties and quality of fresh noodles. Int. J. Food Sci. Technol. 2020, 55, 2783–2793. [Google Scholar] [CrossRef]

- Uthai, N.; Chetyakamin, L. Effect of partial substitution of wheat flour with tamarind seed flour on physical, chemical, antioxidant and sensory properties of noodles. Afr. J. Food Agric. Nutr. Dev. 2020, 20, 16063–16184. [Google Scholar] [CrossRef]

- Di Bella, G.; Vecchio, G.L.; Albergamo, A.; Nava, V.; Bartolomeo, G.; Macrì, A.; Bacchetta, L.; Turco, V.L.; Potortì, A.G. Chemical characterization of Sicilian dried nopal [Opuntia ficus-indica (L.) Mill.]. J. Food Compos. Anal. 2022, 106, 104307. [Google Scholar] [CrossRef]

- Joint FAO/WHO Food Standards Programme. CODEXALIMENTARIUSCOMMISSION Codex Alimentarius; Food Agriculture Organization: Rome, Italy, 1992. [Google Scholar]

- Wang, Z.; Wang, K.; Zhang, M.; Duan, M.; Tuersuntuoheti, T.; Li, M.; Wang, J.; Ren, X. Effect of electron beam irradiation on shelf life, noodle quality, and volatile compounds of fresh millet-wheat noodles. J. Food Process Preserv. 2021, 45, e16064. [Google Scholar] [CrossRef]

- Belviranlı, B.; Al-Juhaimi, F.; Özcan, M.M.; Ghafoor, K.; Babiker, E.E.; Alsawmahi, O.N. Effect of location on some physico-chemical properties of prickly pear (Opuntia ficus-indica L.) fruit and seeds. J. Food Process Preserv. 2019, 43, e13896. [Google Scholar] [CrossRef]

- Xiong, X.; Wang, J.; Liu, C.; Zheng, X.; Bian, K.; Guan, E. Quality changes in fresh noodles prepared by different heat treatments during storage. J. Food Process Preserv. 2021, 45, e15506. [Google Scholar] [CrossRef]

- Li, M.; Ma, M.; Zhu, K.X.; Guo, X.N.; Zhou, H.M. Critical conditions accelerating the deterioration of fresh noodles: A study on temperature, pH, water content, and water activity. J. Food Process Preserv. 2017, 41, e13173. [Google Scholar] [CrossRef]

- Seetapan, N.; Limparyoon, N.; Yooberg, R.; Leelawat, B.; Charunuch, C. Influence of addition of extruded rice flour on preparation and quality of fresh gluten-free yellow alkaline noodles. J. Cereal Sci. 2019, 90, 102828. [Google Scholar] [CrossRef]

- Zhao, Y.; Huang, Z.H.; Zhou, H.M.; Zhang, J.; Ma, L. Preventing the browning of fresh wet noodle sheets by aqueous ozone mixing: Browning and physicochemical properties. J. Cereal Sci. 2022, 104, 103428. [Google Scholar] [CrossRef]

- Tangthanantorn, J.; Wichienchot, S.; Sirivongpaisal, P. Development of fresh and dried noodle products with high resistant starch content from banana flour. Food Sci. Technol. 2022, 42, e68720. [Google Scholar] [CrossRef]

- Silva, M.L.T.; Brinques, G.B.; Gurak, P.D. Use of sprouts byproduct flour for fresh pasta production. Braz. J. Food Technol. 2019, 22, e2018063. [Google Scholar] [CrossRef]

- Chang, H.C.; Chen, H.H.; Hu, H.H. Textural changes in fresh egg noodles formulated with seaweed powder and full or partial replacement of cuttlefish paste. J. Texture Stud. 2011, 42, 61–71. [Google Scholar] [CrossRef]

- Rachman, A.; Brennan, M.A.; Morton, J.; Brennan, C.S. Effect of cassava and banana flours blend on physico-chemical and glycemic characteristics of gluten-free pasta. J. Food Process Preserv. 2019, 43, e14084. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Li, S.; Gao, A.; Dong, S. Structural changes of proteins in fresh noodles during their processing. Int. J. Food Prop. 2017, 20, S202–S213. [Google Scholar] [CrossRef]

- Duan, Y.; Zhou, S.; Liu, R.; Wen, Y.; Xing, Y.; Yu, X. Physicochemical, sensorial and microcosmic properties of Chinese dried noodles fortified with unhulled and hulled flaxseed flour. Int. J. Food Sci. Technol. 2022, 57, 676–683. [Google Scholar] [CrossRef]

- Bao, H.; Zhou, J.; Yu, J.; Wang, S. Effect of drying methods on properties of potato flour and noodles made with potato flour. Foods 2021, 10, 1115. [Google Scholar] [CrossRef]

- Liu, J.; Meenu, M.; Xu, B. Effect of unripe banana flour and wheat gluten on physicochemical characteristics and sensory properties of white salted noodles. J. Food Process Preserv. 2020, 44, e14513. [Google Scholar] [CrossRef]

- Jia, F.; Ye, K.; Zhang, C.; Zhang, S.; Fu, M.; Liu, X.; Guo, R.; Yang, R.; Zhang, H.; Wang, J. Effects of vitamin C on the structural and functional characteristics of wheat gluten. Grain Oil Sci. Technol. 2022, 5, 79–86. [Google Scholar] [CrossRef]

- Kayama, K.; Wei, R.; Zhang, Y.; Wu, F.; Su, Z.; Dong, J.; Liu, X. Effects of Tea Powder on the Cooking Properties, Antioxidative Potential and Volatile Profiles of Dried Noodles. Foods 2022, 11, 858. [Google Scholar] [CrossRef]

- Padalino, L.; Costa, C.; Del Nobile, M.A.; Conte, A. Extract of Salicornia europaea in fresh pasta to enhance phenolic compounds and antioxidant activity. Int. J. Food Sci. Technol. 2019, 54, 3051–3057. [Google Scholar] [CrossRef]

| Components | * Wheat Flour (%) | * Chicken Egg (%) | ** Palm Flour (%) |

|---|---|---|---|

| Moisture (%) | 13.0 | 75.6 | 16.9 |

| Carbohydrates (%) | 75.1 | 1.6 | 60.6 |

| Protein (%) | 9.8 | 13.0 | 6.0 |

| Lipids (%) | 1.4 | 8.9 | 1.2 |

| Dietary fiber (%) | 2.3 | na | nq |

| Ash (%) | 0.8 | 0.8 | 16.4 |

| Formulation | Wheat Flour (%) | Palm Flour (%) | Egg * (%) |

|---|---|---|---|

| F0 | 100 | 0 | 50 |

| F5 | 95 | 5 | 50 |

| F10 | 90 | 10 | 50 |

| F15 | 85 | 15 | 50 |

| Variables | F0 | F5 | F10 | F15 |

|---|---|---|---|---|

| * OCT (s) | 317 ± 14 d | 373 ± 6 c | 435 ± 4 b | 493 ± 10 a |

| * CY (%) | 66.7 ± 3.5 a | 51.8 ± 1.9 b | 44.5 ± 1.8 c | 51.8 ± 2.6 b |

| * LC (%) | 3.3 ± 0.4 c | 4.0 ± 0.3 b | 7.6 ± 1.5 a | 9.1 ± 0.5 a |

| Hardness (kg) | 5.22 ± 0.16 c | 6.29 ± 0.06 b | 6.80 ± 0.02 b | 8.39 ± 0.23 a |

| Adhesiveness (kg s) | −0.60 ± 0.14 a | −0.24 ± 0.03 b | −0.30 ± 0.02 b | −0.18 ± 0.01 b |

| Chewability (kg) | 3.89 ± 0.08 c | 5.81 ± 0.23 b | 5.51 ± 0.33 b | 7.75 ± 0.18 a |

| Variables | F0 | F5 | F10 | F15 |

|---|---|---|---|---|

| Moisture (%) | 38.4 ± 1.1 c | 35.4 ± 0.3 d | 40.1 ± 0.3 b | 42.9 ± 0.5 a |

| Ash (%) | 1.05 ± 0.05 d | 1.67 ± 0.08 c | 2.28 ± 0.04 b | 3.05 ± 0.02 a |

| Total acidity (%) | 1.96 ± 0.02 c | 3.14 ± 0.04 b | 3.71 ± 0.01 b | 6.41 ± 0.03 a |

| pH | 5.97 ± 0.02 a | 5.43 ± 0.03 b | 5.23 ± 0.01 c | 5.01 ± 0.03 d |

| Starch (g/100 g) | 41.0 ± 2.4 a | 32.6 ± 1.7 b | 25.6 ± 0.8 c | 22.6 ± 1.5 c |

| Proteins (g/100 g) | 12.28 ± 0.10 b | 11.95 ± 0.10 b | 12.90 ± 0.12 a | 14.00 ± 0.06 a |

| Lipids (g/100 g) | 5.22 ± 0.24 a | 5.68 ± 0.01 a | 5.83 ± 0.15 a | 5.34 ± 0.49 a |

| Variables | F0 | F5 | F10 | F15 |

|---|---|---|---|---|

| L* | 61.66 ± 0.31 a | 53.18 ± 0.85 c | 54.97 ± 1.55 bc | 56.18 ± 0.94 b |

| a* | 4.62 ± 0.09 a | 1.75 ± 0.37 b | 1.54 ± 0.03 b | 0.59 ± 0.05 c |

| b* | 21.37 ± 1.73 a | 16.38 ± 0.60 b | 12.72 ± 0.68 c | 8.44 ± 0.37 d |

| Chlorophyll a (mg/100 g) | 0.00 ± 0.00 c | 0.12 ± 0.03 b | 0.25 ± 0.03 a | 0.34 ± 0.07 a |

| Chlorophyll b (mg/100 g) | 0.00 ± 0.00 | 0.02 ± 0.02 b | 0.04 ± 0.01 a | 0.02 ± 0.01 a |

| Vitamin C (mg/100 g) | 7.2 ± 0.7 c | 25.1 ± 2.7 b | 29.5 ± 1.9 ab | 33.0 ± 1.8 a |

| Phenolics (mg of Gallic acid/100 g) | 5.5 ± 5.6 c | 71.6 ± 5.3 c | 116.6 ± 10.3 b | 152.0 ± 14.3 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodrigues, D.S.; Cavalcanti, M.T.; Gomes, C.A.; Araújo, J.S.; Lima, R.P.; Moreira, I.d.S.; Monteiro, S.S.; Pereira, E.M. Partial Substitution of Wheat Flour with Palm Flour in Pasta Preparation. Appl. Sci. 2023, 13, 12123. https://doi.org/10.3390/app132212123

Rodrigues DS, Cavalcanti MT, Gomes CA, Araújo JS, Lima RP, Moreira IdS, Monteiro SS, Pereira EM. Partial Substitution of Wheat Flour with Palm Flour in Pasta Preparation. Applied Sciences. 2023; 13(22):12123. https://doi.org/10.3390/app132212123

Chicago/Turabian StyleRodrigues, David Santos, Mônica Tejo Cavalcanti, Cristiano Alves Gomes, Jucilene Silva Araújo, Renato Pereira Lima, Inacia dos Santos Moreira, Shênia Santos Monteiro, and Emmanuel Moreira Pereira. 2023. "Partial Substitution of Wheat Flour with Palm Flour in Pasta Preparation" Applied Sciences 13, no. 22: 12123. https://doi.org/10.3390/app132212123