Influence of the Main Blown Film Extrusion Process Parameters on the Mechanical Properties of a High-Density Polyethylene Hexene Copolymer and Linear Low-Density Polyethylene Butene Copolymer Blend Used for Plastic Bags

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

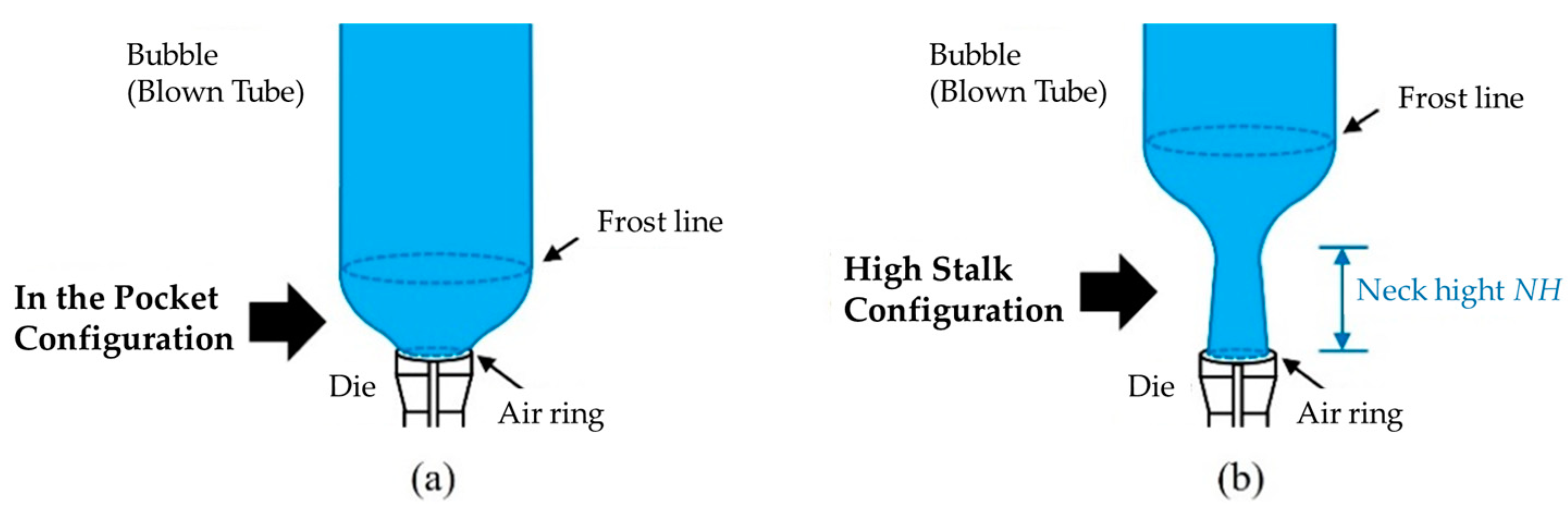

2.2. Manufacturing Samples, Equipment, and Bubble Configuration

2.3. Calculation of Process Parameters

- The blow-up ratio (BUR), which is calculated according to Equation (1), where Df is the ratio of the blown diameter, which is also 2/π (around 0.637) times the width of the collapsed film, and Do is the initial diameter [8].

- The take-up ratio (TUR), defined in Equation (3), is expressed as a ratio between the speed of the film above the height of the freezing line (given with the pulling rollers) and the melting speed at the exit of the die [9].

- The thickness reduction (TR), shown in Equation (7) is the ratio between the opening of the nozzle lips (or die gap) and the final thickness (e) of the film [14], or the ratio between gauges.

- The neck height (NHDD) is calculated according to Equation (8), where the value, in millimeters, is divided by Do. The ratio between the neck height and the die diameter used in the process is due to the different types of dies that are available [15].

- Finally, it is also important to consider the forming ratio (FR). While it is not an independent variable, it relates the TUR with the BUR to determine the grade of symmetry between these two parameters, because the BUR mainly impacts the transverse-direction properties and the TUR mainly impacts the machine-direction properties [13].

2.4. Determination of Mechanical Properties

2.4.1. Elongation at Break

2.4.2. Dart Impact Strength

2.5. Correlation between Process Parameters and Mechanical Properties

3. Results

3.1. Process Parameters

3.2. Mechanical Properties

| Sample | Product and Process Parameters | Mechanical Properties | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Width (cm) | Thickness (µm) | BUR | TUR | TR | NHDD | FR | E in MD (N/mm2) | ε in MD (%) | Fmax in MD (N) | E in TD (N/mm2) | ε in TD (%) | Fmax in TD (N) | Dart Impact (g) | |

| 1 | 88.7 | 9.5 | 4.5 | 5.0 | 105.3 | 11.2 | 1.1 | 658.9 | 269.8 | 11.8 | 715.5 | 365.8 | 11.8 | 297.5 |

| 2 | 86.4 | 9.7 | 4.4 | 5.0 | 103.1 | 8.8 | 1.1 | 569.2 | 299.0 | 12.0 | 647.7 | 401.9 | 12.1 | 300.5 |

| 3 | 87.3 | 9.9 | 4.4 | 5.0 | 100.9 | 5.8 | 1.1 | 656.7 | 294.6 | 14.6 | 665.2 | 496.5 | 6.3 | 106.4 |

| 4 | 92.2 | 18.0 | 4.7 | 3.3 | 55.5 | 12.8 | 0.7 | 622.9 | 470.4 | 24.6 | 550.1 | 528.6 | 18.0 | 216.5 |

| 5 | 98.9 | 16.7 | 5.0 | 3.3 | 59.9 | 10.1 | 0.6 | 647.4 | 436.7 | 26.0 | 772.9 | 733.5 | 17.5 | 152.0 |

| 6 | 97.3 | 16.1 | 5.0 | 3.3 | 62.1 | 7.4 | 0.7 | 628.1 | 384.1 | 24.6 | 722.0 | 589.7 | 15.3 | 152.0 |

| 7 | 85.1 | 10.2 | 4.3 | 5.4 | 98.4 | 11.6 | 1.3 | 363.5 | 265.9 | 16.5 | 347.8 | 523.0 | 8.3 | 159.5 |

| 8 | 88.7 | 9.9 | 4.5 | 5.4 | 100.9 | 9.8 | 1.2 | 263.7 | 268.9 | 13.4 | 278.3 | 511.4 | 9.0 | 176.0 |

| 9 | 88.7 | 10.1 | 4.5 | 5.4 | 98.9 | 7.8 | 1.2 | 525.8 | 280.6 | 16.6 | 410.6 | 534.6 | 7.6 | 124.0 |

| 10 | 81.6 | 11.1 | 4.2 | 3.6 | 90.1 | 11.6 | 0.9 | 742.2 | 297.6 | 15.0 | 803.0 | 509.3 | 12.6 | 218.0 |

| 11 | 81.9 | 11.4 | 4.2 | 3.6 | 87.7 | 9.7 | 0.9 | 552.6 | 363.8 | 13.8 | 762.6 | 443.3 | 14.8 | 254.0 |

| 12 | 82.7 | 11.4 | 4.2 | 3.6 | 87.7 | 7.3 | 0.9 | 584.1 | 365.8 | 17.3 | 761.5 | 464.8 | 10.9 | 158.0 |

| 13 | 88.6 | 11.8 | 4.5 | 4.2 | 84.7 | 11.8 | 0.9 | 517.9 | 329.0 | 17.2 | 637.0 | 617.3 | 9.8 | 132.5 |

| 14 | 88.7 | 12.6 | 4.5 | 4.2 | 79.4 | 9.8 | 0.9 | 408.8 | 286.3 | 13.0 | 427.8 | 524.3 | 7.9 | 99.5 |

| 15 | 89.7 | 13.2 | 4.6 | 4.2 | 75.7 | 7.4 | 0.9 | 493.2 | 329.0 | 15.5 | 496.3 | 532.1 | 7.4 | 108.5 |

| 16 | 96.2 | 19.8 | 4.9 | 2.5 | 50.5 | 11.9 | 0.5 | 625.0 | 431.1 | 25.5 | 704.2 | 647.7 | 17.3 | 162.5 |

| 17 | 96.4 | 19.5 | 4.9 | 2.5 | 51.3 | 9.6 | 0.5 | 538.8 | 417.0 | 22.4 | 515.5 | 622.1 | 16.5 | 168.5 |

| 18 | 97.8 | 18.0 | 5.0 | 2.5 | 55.5 | 7.4 | 0.5 | 548.1 | 408.3 | 22.8 | 663.5 | 678.2 | 15.9 | 120.3 |

| 19 | 43.2 | 43.9 | 2.2 | 1.5 | 22.8 | 12.1 | 0.7 | 554.2 | 796.2 | 54.5 | 584.2 | 1146.4 | 47.1 | 80.4 |

| 20 | 46.4 | 52.1 | 2.4 | 1.5 | 19.2 | 10.1 | 0.7 | 543.3 | 796.5 | 57.0 | 682.5 | 1129.1 | 46.1 | 95.4 |

| 21 | 47.0 | 56.6 | 2.4 | 1.5 | 17.7 | 7.7 | 0.6 | 557.1 | 667.4 | 53.3 | 766.4 | 1063.7 | 36.9 | 90.1 |

| 22 | 97.8 | 22.5 | 5.0 | 3.1 | 44.4 | 11.2 | 0.6 | 379.2 | 367.9 | 26.6 | 384.0 | 454.9 | 11.2 | 230.0 |

| 23 | 87.0 | 10.0 | 4.4 | 5.1 | 99.9 | 11.2 | 1.2 | 416.2 | 270.8 | 12.8 | 555.7 | 391.9 | 7.1 | 198.5 |

| 24 | 84.9 | 13.1 | 4.3 | 4.5 | 76.3 | 9.7 | 1.0 | 617.7 | 340.8 | 20.4 | 682.4 | 481.6 | 11.2 | 186.5 |

| 25 | 89.5 | 13.4 | 4.6 | 4.5 | 74.6 | 7.0 | 1.0 | 670.2 | 348.5 | 21.1 | 604.5 | 502.3 | 9.2 | 128.0 |

4. Discussion

4.1. The Impact of Blow-Up Ratio (BUR) on Mechanical Properties

4.2. The Impact of Take-Up Ratio (TUR) on Mechanical Properties

4.3. The Impact of Thickness Reduction (TR) on Mechanical Properties

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dai, L.; Xu, D. Polyethylene surface enhancement by corona and chemical co-treatment. Tetrahedron Lett. 2019, 60, 1005–1010. [Google Scholar] [CrossRef]

- Khanoonkon, N.; Yoksan, R.; Ogale, A.A. Morphological characteristics of stearic acid-grafted starch-compatibilized linear low density polyethylene/thermoplastic starch blown film. Eur. Polym. J. 2016, 76, 266–277. [Google Scholar] [CrossRef]

- Hoshida, T.; Tsubone, D.; Takada, K.; Kodama, H.; Hasebe, T.; Kamijo, A.; Suzuki, T.; Hotta, A. Controlling the adhesion between diamond-like carbon (DLC) film and high-density polyethylene (HDPE) substrate. Surf. Coatings Technol. 2007, 202, 1089–1093. [Google Scholar] [CrossRef]

- Ronca, S. Polyethylene. In Brydson’s Plastics Materials, 8th ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Chaturvedi, E.; Rajput, N.S.; Upadhyaya, S.; Pandey, P.K. Experimental Study and Mathematical Modeling for Extrusion using High Density Polyethylene. Mater. Today Proc. 2017, 4, 1670–1676. [Google Scholar] [CrossRef]

- Münstedt, H.; Steffl, T.; Malmberg, A. Correlation between rheological behaviour in uniaxial elongation and film blowing properties of various polyethylenes. Rheol. Acta 2005, 45, 14–22. [Google Scholar] [CrossRef]

- Godshall, D.; Wilkes, G.; Krishnaswamy, R.K.; Sukhadia, A.M. Processing-structure-property investigation of blown HDPE films containing both machine and transverse direction oriented lamellar stacks. Polymer 2003, 44, 5397–5406. [Google Scholar] [CrossRef]

- Auksornkul, S.; Soontaranon, S.; Kaewhan, C.; Prasassarakich, P. Effect of the blow-up ratio on morphology and engineering properties of three-layered linear low-density polyethylene blown films. J. Plast. Film Sheeting 2017, 34, 27–42. [Google Scholar] [CrossRef]

- AlMa’adeed, M.A.-A.; Krupa, I. Polyolefin Compounds and Materials: Fundamentals and Industrial Applications, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Chevron Phillips Chemical Company LLC. Marlex ® TRB-115 High Density Polyethylene; Chevron Phillips Chemical Company LLC: The Woodlands, TX, USA, 2021. [Google Scholar]

- ExxonMobil. ExxonMobil TM LLDPE LL 1002xBU Linear Low Density Polyethylene Resin; ExxonMobil: Houston, TX, USA, 2020. [Google Scholar]

- Kalpakjian, S.; Schmid, S.R. Manufactura, Ingeniería y Technología, 7th ed.; Pearson: Mexico City, México, 2014. [Google Scholar]

- Cantor, K. Blown Film Extrusion; Hanser Publications: Cincinnati, OH, USA, 2011. [Google Scholar]

- Kolarik, R.; Zatloukal, M.; Martyn, M. The effect of polyolefin extensional rheology on non-isothermal film blowing process stability. Int. J. Heat Mass Transf. 2012, 56, 694–708. [Google Scholar] [CrossRef]

- Lu, J.; Sue, H.-J.; Rieker, T. Dual crystalline texture in HDPE blown films and its implication on mechanical properties. Polymer 2001, 42, 4635–4646. [Google Scholar] [CrossRef]

- Ajji, A.; Zhang, X.; Elkoun, S. Biaxial orientation in HDPE films: Comparison of infrared spectroscopy, X-ray pole figures and birefringence techniques. Polymer 2005, 46, 3838–3846. [Google Scholar] [CrossRef]

- Wu, W.-L.; Wang, Y.-W. High density polyethylene film toughened with polypropylene and linear low density polyethylene. Mater. Lett. 2019, 257, 126689. [Google Scholar] [CrossRef]

- Briassoulis, D.; Aristopoulou, A.; Bonora, M.; Verlodt, I. Degradation Characterisation of Agricultural Low-density Polyethylene Films. Biosyst. Eng. 2004, 88, 131–143. [Google Scholar] [CrossRef]

- ASTM D882; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2018.

- Chatterjee, T.; Patel, R.; Garnett, J.; Paradkar, R.; Ge, S.; Liu, L.; Forziati, K.T.; Shah, N. Machine direction orientation of high density polyethylene (HDPE): Barrier and optical properties. Polymer 2014, 55, 4102–4115. [Google Scholar] [CrossRef]

- ASTM D1709; Standard Test Methods for Impact Resistance of Plastic Film by the Free-Falling Dart Method. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2018.

- Peacock, A.J. Handbook of Polyethylene: Structures: Properties, and Applications; Marcel Dekker, Inc.: New York, NY, USA; Basel, Switzerland, 2000. [Google Scholar] [CrossRef]

- Simpson, D.; Harrison, I. A Study of the Effects of Processing Parameters on the Morphologies and Tensile Modulus of Hdpe Blown Films: Application of Composite Theories on a Molecular Level to Characterize Tensile Modulus. J. Plast. Film Sheeting 1994, 10, 302–325. [Google Scholar] [CrossRef]

| Property | HDPE-C6 1 | LLDPE-C4 2 |

|---|---|---|

| Melt Index at 190 °C—2.16 kg (g/10 min) | 0.06 | 2.00 |

| Melt Index at 190 °C—21.6 kg (g/10 min) | 9.50 | - |

| Density (g/cm3) | 0.950 | 0.918 |

| Dart Impact (g) | 260 | 60 |

| Tensile Elongation at Break MD (%) | 260 | 620 |

| Tensile Elongation at Break TD (%) | 570 | 770 |

| Elmendorf Tear Strength MD (g) | 15 | 110 |

| Elmendorf Tear Strength TD (g) | 450 | 390 |

| Antiblock (ppm) | 0 | 3500 |

| Slip (ppm) | 0 | 1500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cuesta, F.; Camacho, A.M.; Rubio, E.M. Influence of the Main Blown Film Extrusion Process Parameters on the Mechanical Properties of a High-Density Polyethylene Hexene Copolymer and Linear Low-Density Polyethylene Butene Copolymer Blend Used for Plastic Bags. Appl. Sci. 2023, 13, 12164. https://doi.org/10.3390/app132212164

Cuesta F, Camacho AM, Rubio EM. Influence of the Main Blown Film Extrusion Process Parameters on the Mechanical Properties of a High-Density Polyethylene Hexene Copolymer and Linear Low-Density Polyethylene Butene Copolymer Blend Used for Plastic Bags. Applied Sciences. 2023; 13(22):12164. https://doi.org/10.3390/app132212164

Chicago/Turabian StyleCuesta, Francisco, Ana María Camacho, and Eva María Rubio. 2023. "Influence of the Main Blown Film Extrusion Process Parameters on the Mechanical Properties of a High-Density Polyethylene Hexene Copolymer and Linear Low-Density Polyethylene Butene Copolymer Blend Used for Plastic Bags" Applied Sciences 13, no. 22: 12164. https://doi.org/10.3390/app132212164

APA StyleCuesta, F., Camacho, A. M., & Rubio, E. M. (2023). Influence of the Main Blown Film Extrusion Process Parameters on the Mechanical Properties of a High-Density Polyethylene Hexene Copolymer and Linear Low-Density Polyethylene Butene Copolymer Blend Used for Plastic Bags. Applied Sciences, 13(22), 12164. https://doi.org/10.3390/app132212164