Application of EDEM Simulation for Calculating and Optimizing a Closed Coal Fly Ash Screw Conveyor

Abstract

1. Introduction

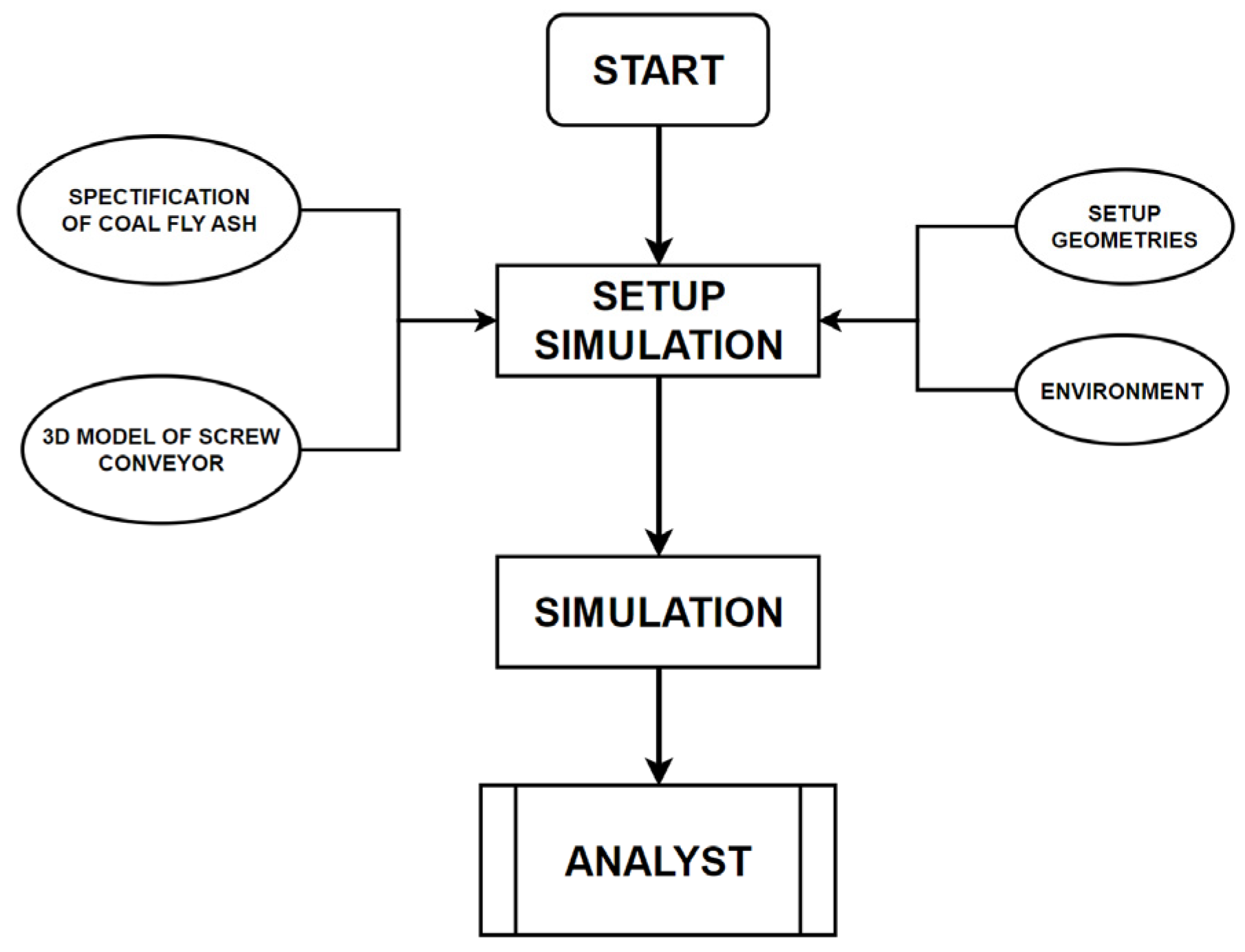

2. Materials and Methods

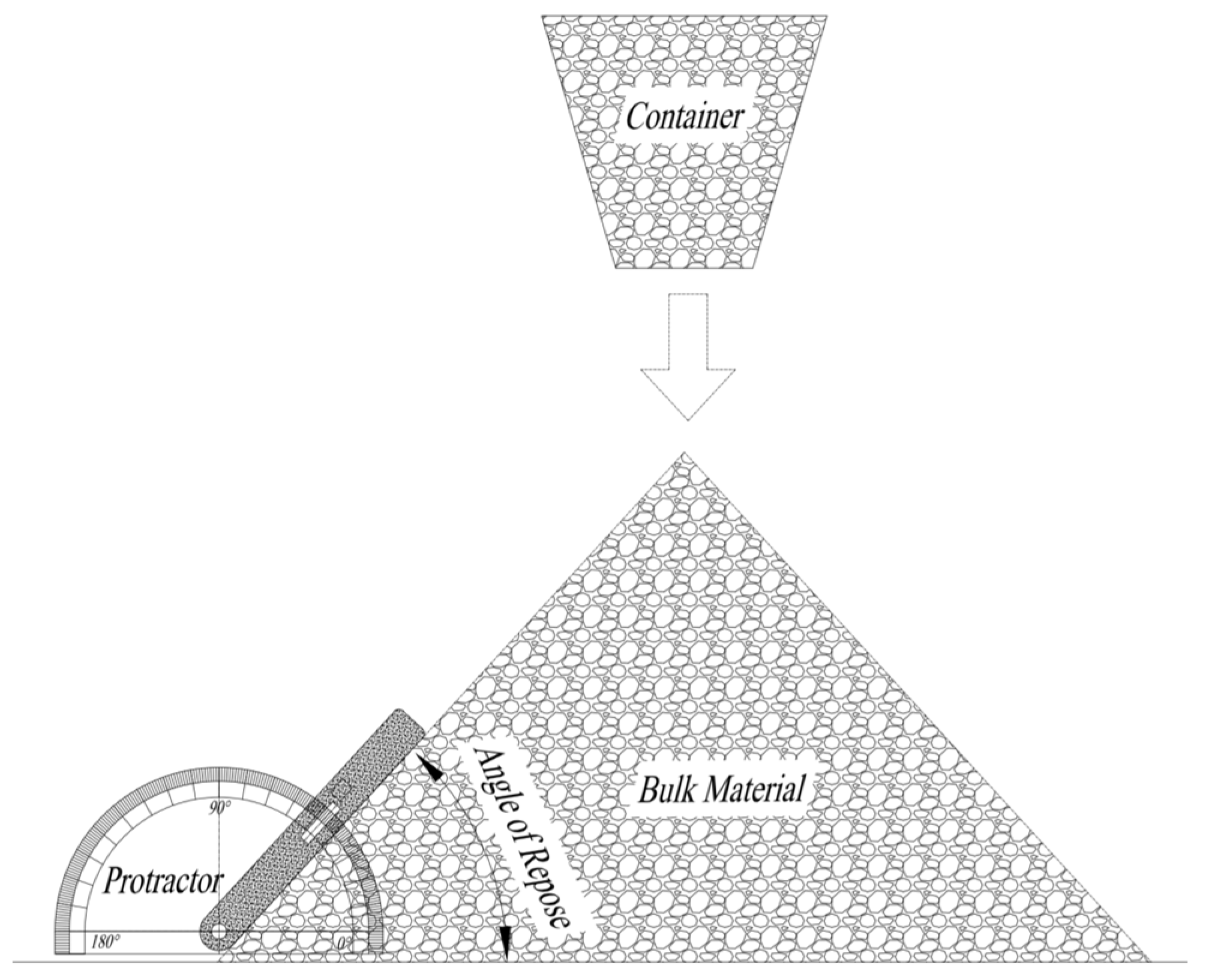

2.1. Specification of Coal Fly Ash

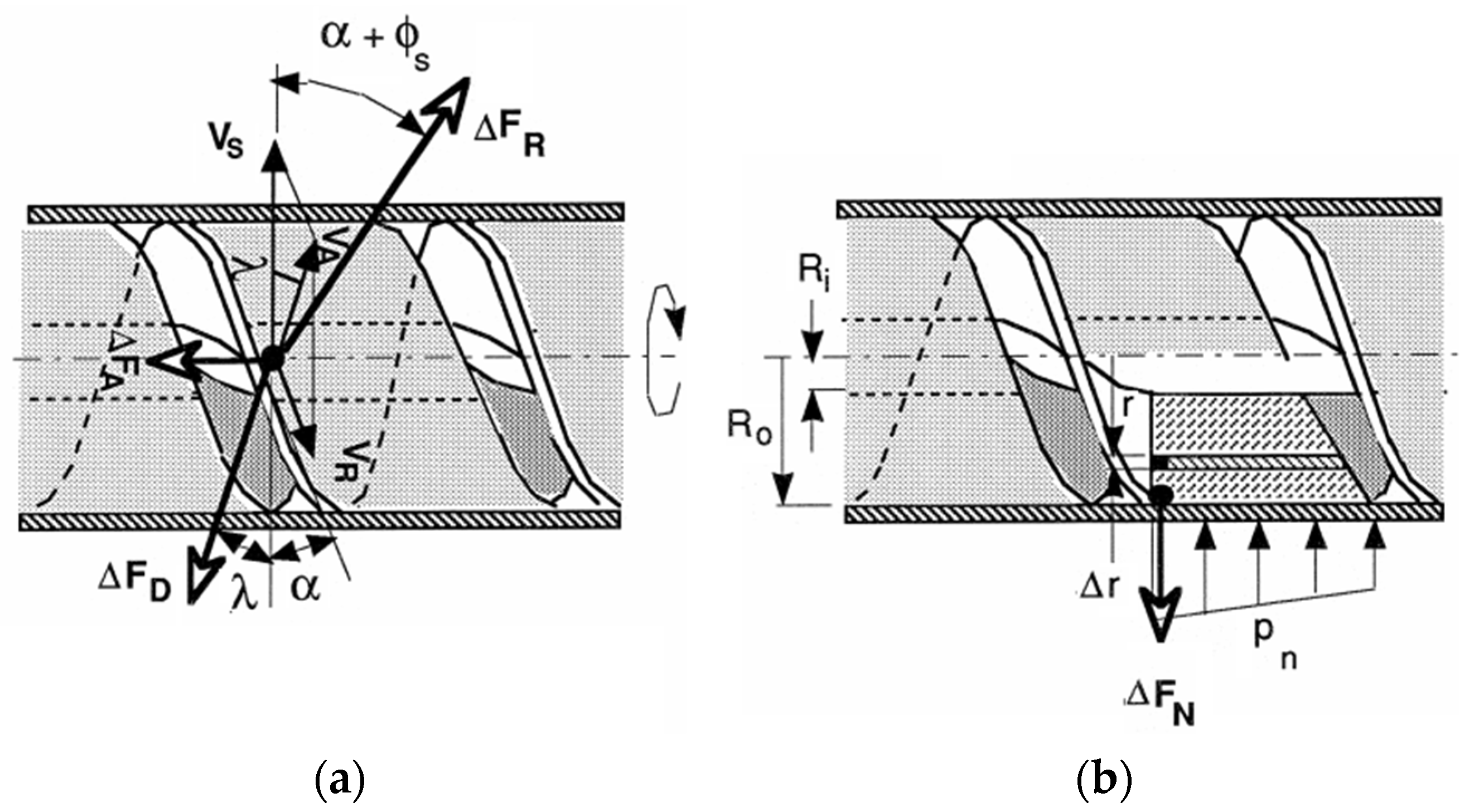

2.2. Methods for Calculating Screw Conveyors

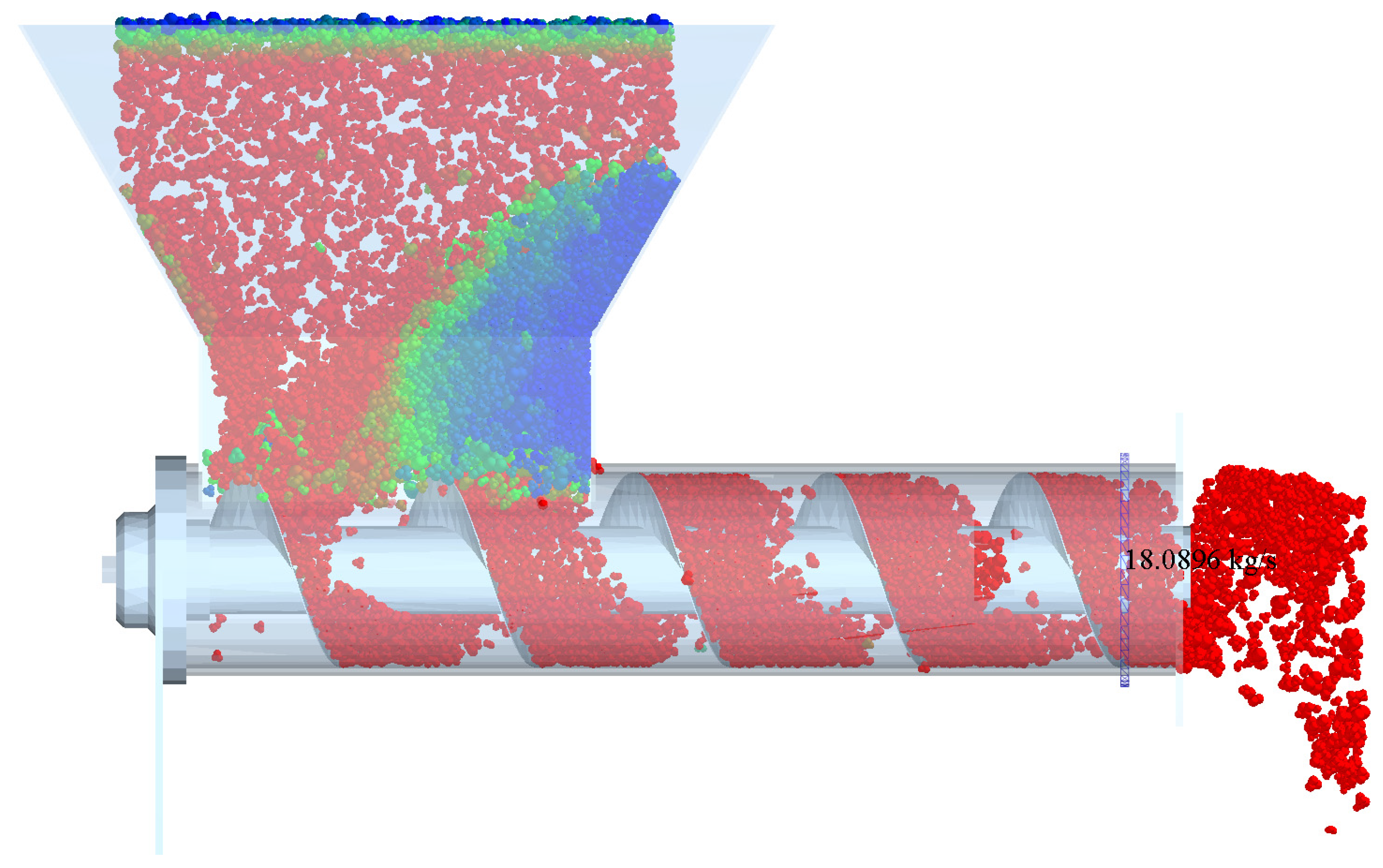

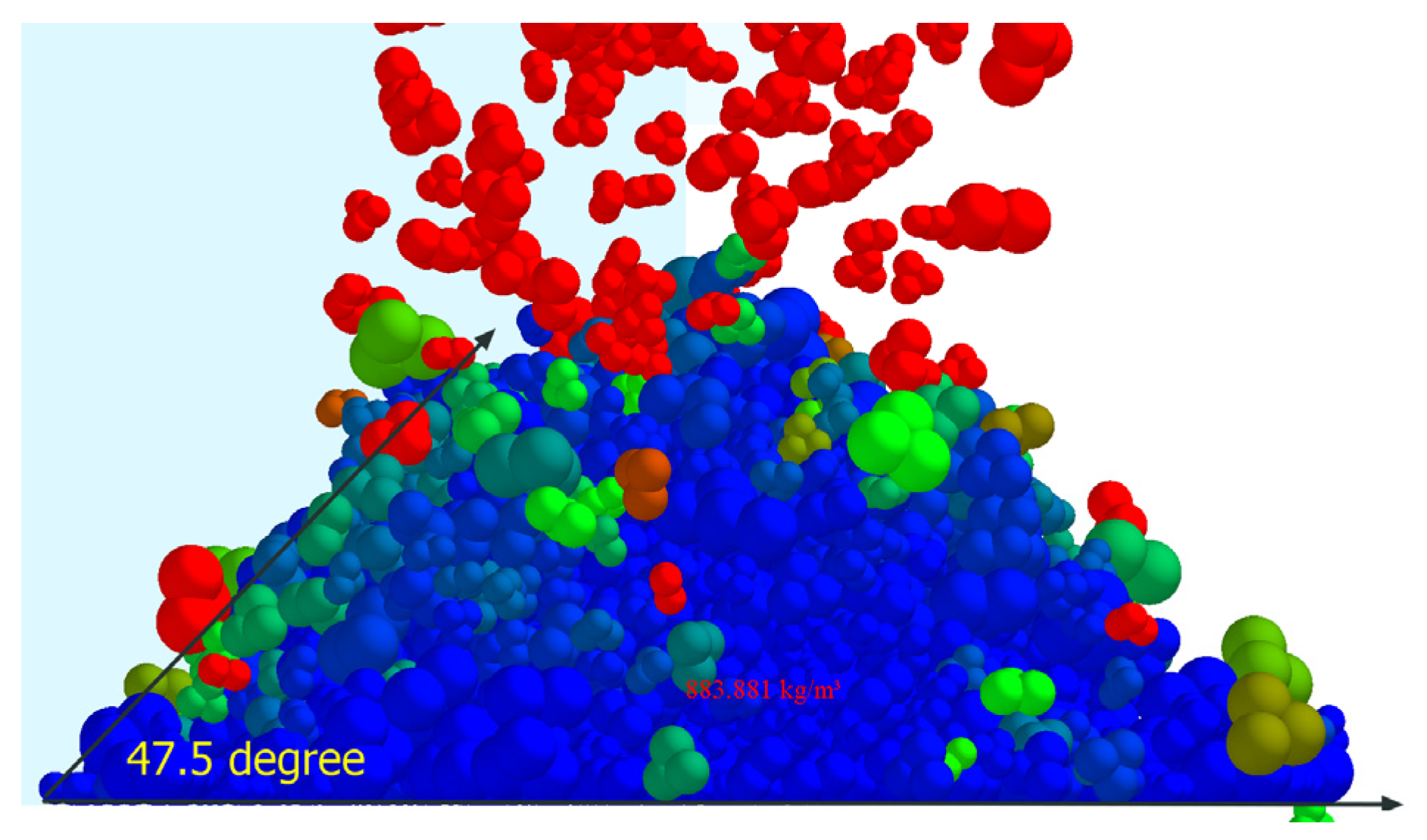

2.3. Altair EDEM Simulation

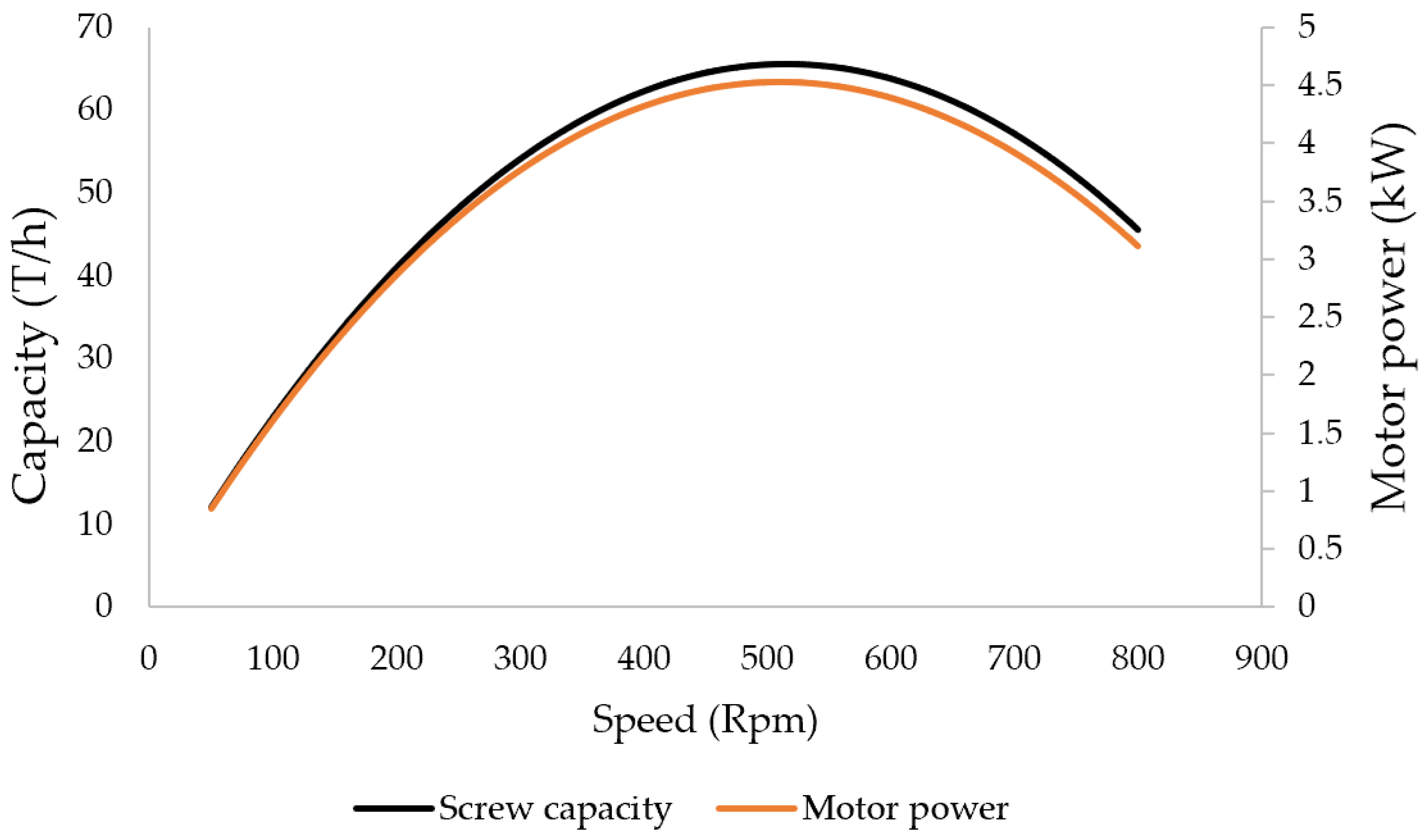

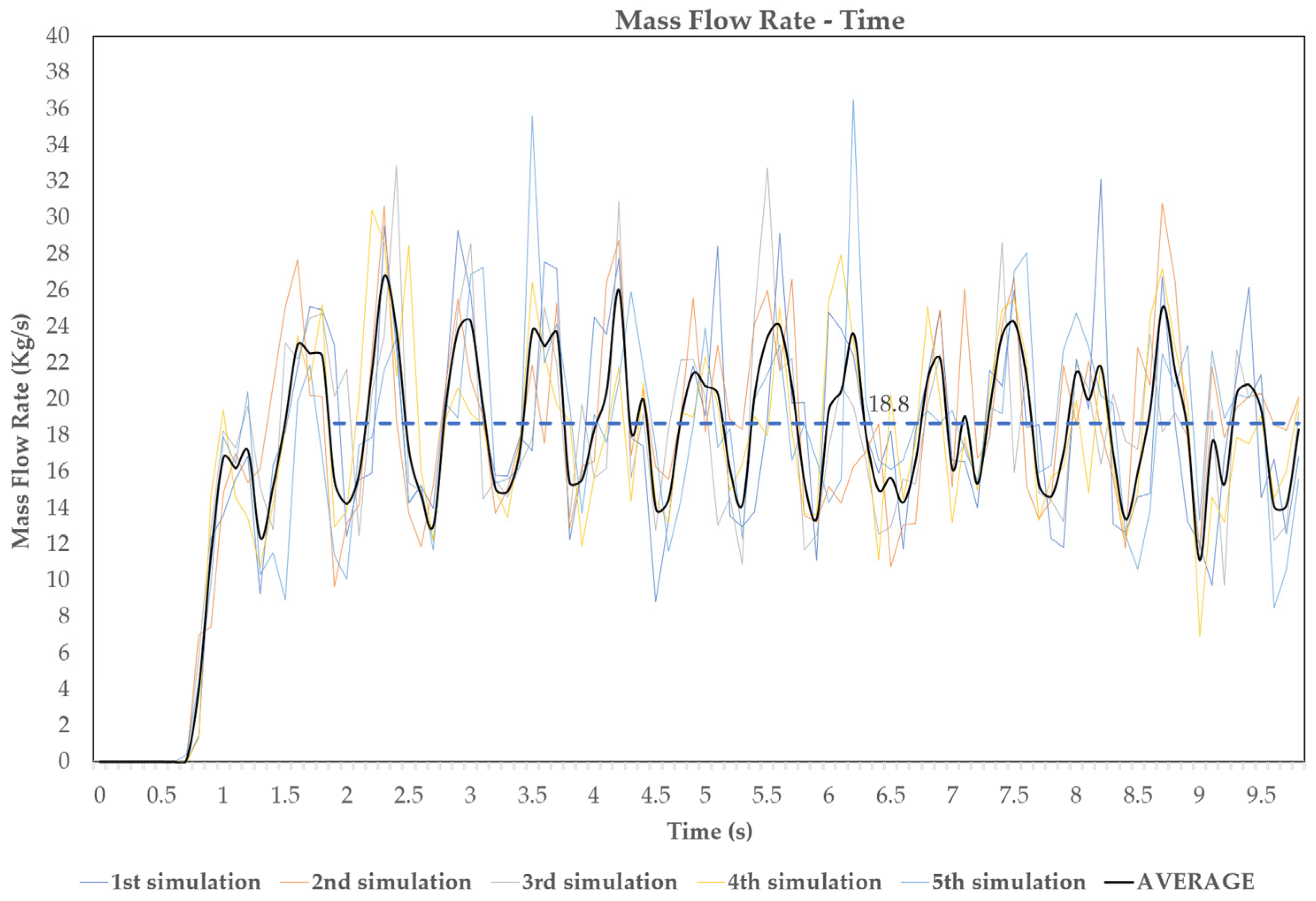

3. Results and Discussion

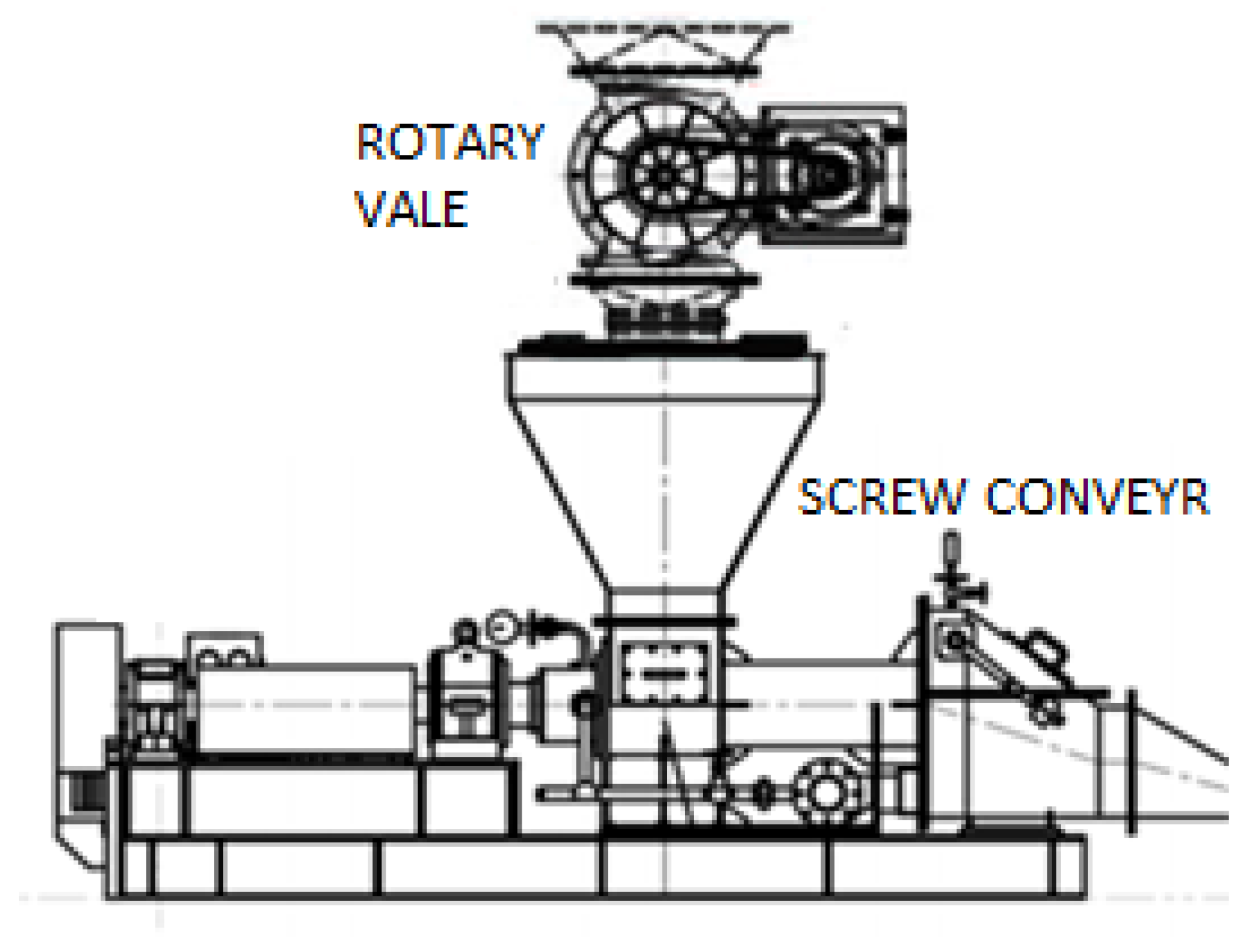

3.1. Created Model Screw Conveyor and Actual Test

3.2. Capacity Discrepancy: Calculation vs. Actual Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tan, Y.; Rackl, M.; Yang, W.; Fottner, J.; Meng, W.; Kessler, S. A comparative study on design standards of screw conveyors in China, Germany and the USA—Part I: Theoretical calculation and quantitative analysis. Particuology 2022, 69, 61–76. [Google Scholar] [CrossRef]

- Chongchitpaisan, P.; Sudsawat, S. A Review on Screw Conveyors for Bulk Materials in Various Applications. Ladkrabang Eng. J. 2022, 39, 1–13. [Google Scholar]

- Roberts, A.W. The influence of granular vortex motion on the volumetric performance of enclosed screw conveyors. Powder Technol. 1999, 104, 56–67. [Google Scholar] [CrossRef]

- Gupta, A.K.; Nott, P.R. Analysis of the Flow of Granular Materials through a Screw Conveyor. arXiv 2021, arXiv:2111.13396. [Google Scholar] [CrossRef]

- Beakawi Al-Hashemi, H.M.; Baghabra Al-Amoudi, O.S. A review on the angle of repose of granular materials. Powder Technol. 2018, 330, 397–417. [Google Scholar] [CrossRef]

- Stoimenov, N.; Ružić, J. Analysis of the particle motion during mechanical alloying using EDEM software. IFAC-Pap. 2019, 52, 462–466. [Google Scholar] [CrossRef]

- Mindlin, R.D. Compliance of elastic bodies in contact. J. Appl. Mech. 1949, 16, 259–268. [Google Scholar] [CrossRef]

- Faishol, A.; Mulyadi; Widodo, E. Capacity and power analysis on inclined screw conveyor using DEM simulation. J. Energy Mech. Mater. Manuf. Eng. 2023, 8, 1–6. [Google Scholar] [CrossRef]

- Yang, W.; Meng, W.; Gao, L.; Tan, Y.; Fottner, J.; Dai, X.; Yao, F.; Yuan, Y.; Sun, X. Analysis of the Screw Flight Wear Model and Wear Regularity of the Bulk Transport in Screw Ship Unloader. Trans. Mech. Eng. 2022, 46, 15–29. [Google Scholar] [CrossRef]

- Zhao, R.; Guo, L.; Gao, W.; Xiao, X.; Liu, Y. Structure Optimization Design of Screw Conveyor based on EDEM. J. Phys. Conf. Ser. 2022, 2200, 012002. [Google Scholar] [CrossRef]

- Coetzee, C.J. Review: Calibration of the discrete element method. Powder Technol. 2017, 310, 104–142. [Google Scholar] [CrossRef]

- Rodriguez, V.A.; Barrios, G.K.P.; Bueno, G.; Tavares, L.M. Coupled DEM-MBD-PRM simulations of high-pressure grinding rolls. Part 1: Calibration and validation in pilot-scale. Miner. Eng. 2022, 177, 107389. [Google Scholar] [CrossRef]

- Boslovyak, P.V.; Emelyanova, G.A. Optimization Mathematical Modeling of the Weight of Metal Structure of Suspended Belt Conveyor Linear Section. IFAC-PapersOnLine 2018, 51, 616–619. [Google Scholar] [CrossRef]

- Kondrakhin, V.P.; Martyushev, N.V.; Klyuev, R.V.; Sorokova, S.N.; Efremenkov, E.A.; Valuev, D.V.; Mengxu, Q. Mathematical Modeling and Multi-Criteria Optimization of Design Parameters for the Gyratory Crusher. Mathematics 2023, 11, 2345. [Google Scholar] [CrossRef]

- Despotović, Ž.V.; Urukalo, D.; Lečić, M.R.; Ćosić, A. Mathematical modeling of resonant linear vibratory conveyor with electromagnetic excitation: Simulations and experimental results. Appl. Math. Model. 2017, 41, 1–24. [Google Scholar] [CrossRef]

- Bui, T.-A.; Tran, V.-T. A Study on Designing Screw Conveyors for Granular Materials Based on Numerical Simulation. In Proceedings of the International Conference on Advanced Mechanical Engineering, Automation, and Sustainable Development 2021 (AMAS2021), Ha Long, Vietnam, 4–7 November 2021; Springer: Cham, Switzerland, 2022; pp. 493–498. [Google Scholar]

- Lanzerstorfer, C. Chemical and physical characterization of cyclone fly ashes from five grate-fired biomass combustion plants. Carpathian J. Earth Environ. Sci. 2014, 9, 129–135. [Google Scholar]

- Tan, Y.; Yu, Y.; Fottner, J.; Kessler, S. Automated measurement of the numerical angle of repose (aMAoR) of biomass particles in EDEM with a novel algorithm. Powder Technol. 2021, 388, 462–473. [Google Scholar] [CrossRef]

- Nguyen, M.D.; Trinh, V.C. Coal ash in Vietnam—Deposition and utilization. A feasibility study. Hanoi—Linkop. 1993, 1–46. [Google Scholar]

- Duc, D.S. Properties of fly ash from a thermal power plant in Vietnam. Int. J. ChemTech Res. 2014, 6, 2656–2659. [Google Scholar]

- Nguyen, T.B.; Nguyen, T.T.; Dinh, H.Q. Research and assessment of the quality of fly ash and high fire slag of thermal power plant and metallurgy plant in VietNam. J. Irrig. Sci. Technol. 2019, 57, 27–39. [Google Scholar]

- Bui, T.-A.; Pham, V.-H.; Nguyen, D.-T.; Bui, N.-T. Effectiveness of Lubricants and Fly Ash Additive on Surface Damage Resistance under ASTM Standard Operating Conditions. Coatings 2023, 13, 851. [Google Scholar] [CrossRef]

- Bui, T.-A.; Bui, N.-T. Investigating the Impact of Fly-Ash Additive on Viscosity Reduction at Different Temperatures: A Comparative Analysis. Appl. Sci. 2023, 13, 7859. [Google Scholar] [CrossRef]

- Gollakota, A.R.K.; Volli, V.; Shu, C.-M. Progressive utilisation prospects of coal fly ash: A review. Sci. Total Environ. 2019, 672, 951–989. [Google Scholar] [CrossRef] [PubMed]

- Koh, S.L.; Lim, Y.S.; Morris, S. Potential of Advanced Coal and Gas Combustion Technologies in GHG Emission Reduction in Developing Countries from Technical, Environmental and Economic Perspective. Energy Procedia 2011, 12, 878–885. [Google Scholar] [CrossRef][Green Version]

- Feng, S.; Li, Y. Study on coal fly ash classified by bulk density. J. Phys. Conf. Ser. 2021, 1732, 012127. [Google Scholar] [CrossRef]

- Lomboy, G.; Sundararajan, S.; Wang, K. Micro- and macroscale coefficients of friction of cementitious materials. Cem. Concr. Res. 2013, 54, 21–28. [Google Scholar] [CrossRef]

- Xie, J.; Dong, M.; Li, S.; Mei, Y.; Shang, Y. An experimental study of fly ash particle oblique impact with stainless surfaces. J. Aerosol Sci. 2018, 123, 27–38. [Google Scholar] [CrossRef]

- Kadurumba, C.H.; Enibe, S.O. Kinematics and Dynamic Evaluation of the Screw Conveyor of a Cassava Centrifuge Dewatering Machine. Niger. J. Technol. 2014, 33, 268–274. [Google Scholar] [CrossRef]

- Zhang, K.; Yu, W.; Li, D.; Zou, D.; Zhang, S. Measurement and simulation validation of numerical model parameters of fresh concrete. Sci. Eng. Compos. Mater. 2021, 28, 437–452. [Google Scholar] [CrossRef]

- Mio, H.; Akashi, M.; Shimosaka, A.; Shirakawa, Y.; Hidaka, J.; Matsuzaki, S. Speed-up of computing time for numerical analysis of particle charging process by using discrete element method. Chem. Eng. Sci. 2009, 64, 1019–1026. [Google Scholar] [CrossRef][Green Version]

| Component | Percentage |

|---|---|

| SiO2 | 57.02% |

| Al2O3 | 23.82% |

| K2O | 6.56% |

| Fe2O3 | 4.69% |

| Material Property Parameters | Value (for Calculation and EDEM Simulation) | EDEM Material Library GEMM_Particle 8454 |

|---|---|---|

| Angle of repose (degree) | 47.5 | 47.51 |

| Bulk density (kg/m3) | 883 | 724.54 |

| Solid density (kg/m3) | 2200 | 1500 |

| The coefficient of static friction | 0.55 | 0.56 |

| The coefficient of rolling friction | 0.08 | 0.1 |

| The coefficient of restitution | 0.5 | 0.55 |

| The coefficient of static friction with steel surface | 0.6 | -- |

| Dimension of Screw Conveyor | Value |

|---|---|

| Diameter D (mm) | 273 |

| Diameter of shaft Dc (mm) | 141 |

| Pitch p (mm) | 250 |

| Length L (mm) | 1300 |

| Balde thickness t (mm) | 8 |

| Radial Clearance C (mm) | 10 |

| Speed of Screw (rpm) | 100–700 |

| No | Speed (rpm) | Mass (ton) | Time (min) | Capacity of Screw Conveyor (m3/h) | Capacity of Screw Conveyor (ton/h) |

|---|---|---|---|---|---|

| 1.1 | 300 | 35 | 33 | 63.6 | 56.3 |

| 1.2 | 300 | 35 | 33 | 63.6 | 56.3 |

| 1.3 | 300 | 35 | 32 | 65.6 | 58.0 |

| 1.4 | 300 | 35 | 34 | 61.8 | 54.6 |

| 1.5 | 300 | 35 | 32 | 65.6 | 58.0 |

| 2.1 | 500 | 35 | 28 | 75.0 | 66.3 |

| 2.2 | 500 | 35 | 27 | 77.8 | 68.8 |

| 2.3 | 500 | 35 | 26 | 80.8 | 71.4 |

| 2.4 | 500 | 35 | 27 | 77.8 | 68.8 |

| 2.5 | 500 | 35 | 28 | 75.0 | 66.3 |

| 3.1 | 700 | 35 | 30 | 70.0 | 61.9 |

| 3.2 | 700 | 35 | 29 | 72.4 | 64.1 |

| 3.3 | 700 | 35 | 31 | 67.7 | 59.9 |

| 3.4 | 700 | 35 | 31 | 67.7 | 59.9 |

| 3.5 | 700 | 35 | 30 | 70.0 | 61.9 |

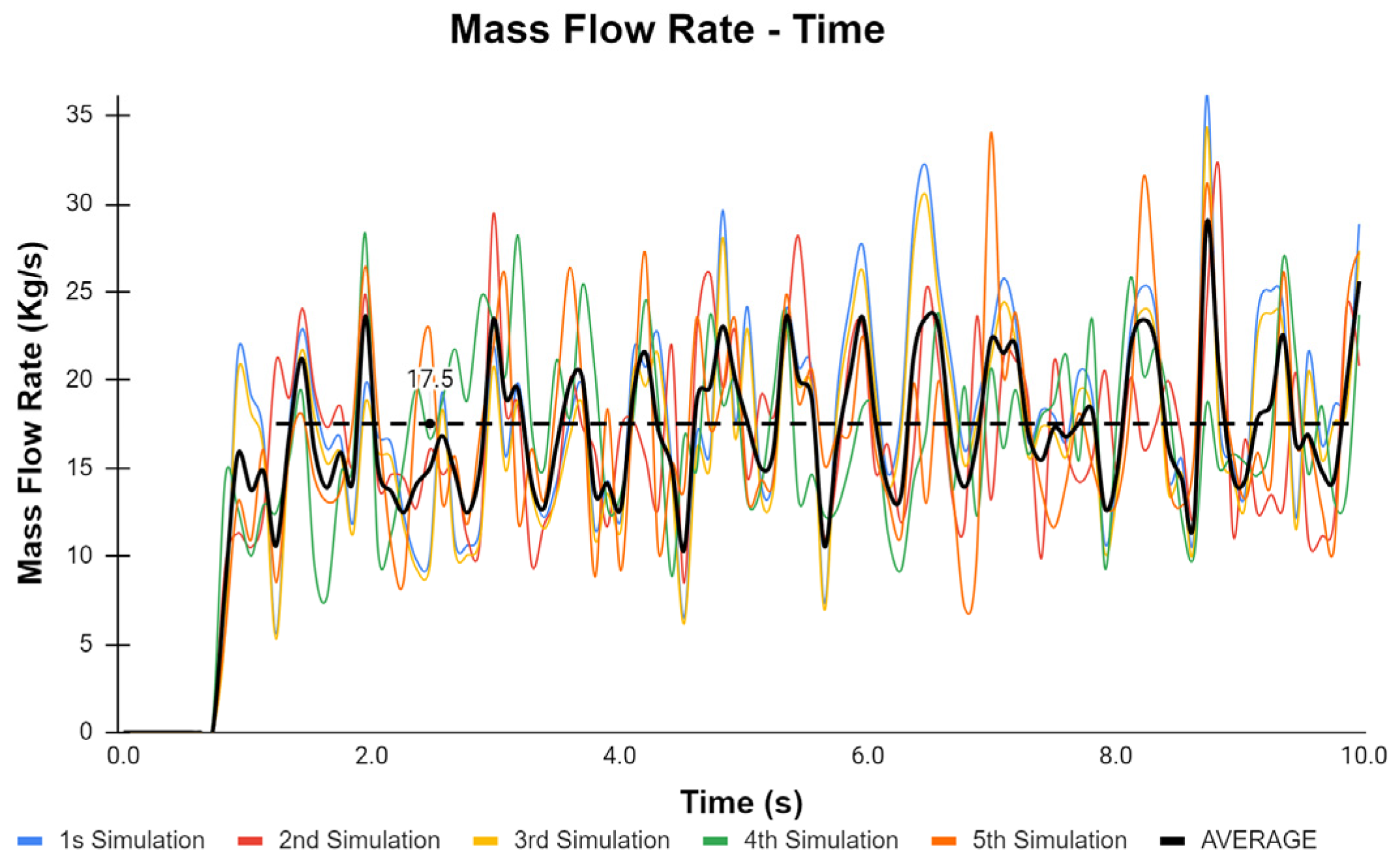

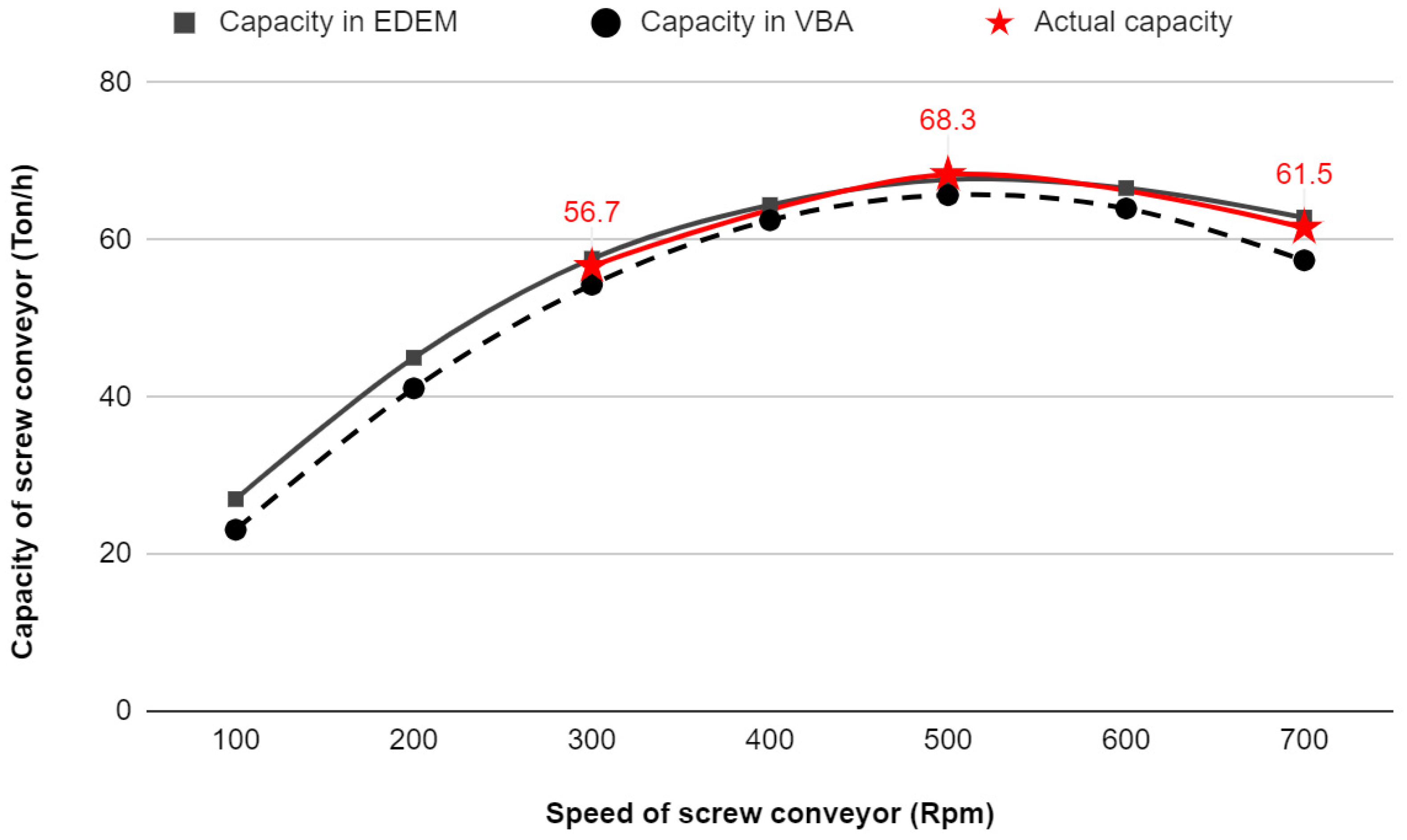

| No. | Speed (rpm) | Capacity in EDEM (kg/s) | Capacity in EDEM (ton/h) | Capacity in VBA (ton/h) | Difference between 2 Methods | Actual Capacity (ton/h) | Deviation Ratio EDEM/VBA (%/%) |

|---|---|---|---|---|---|---|---|

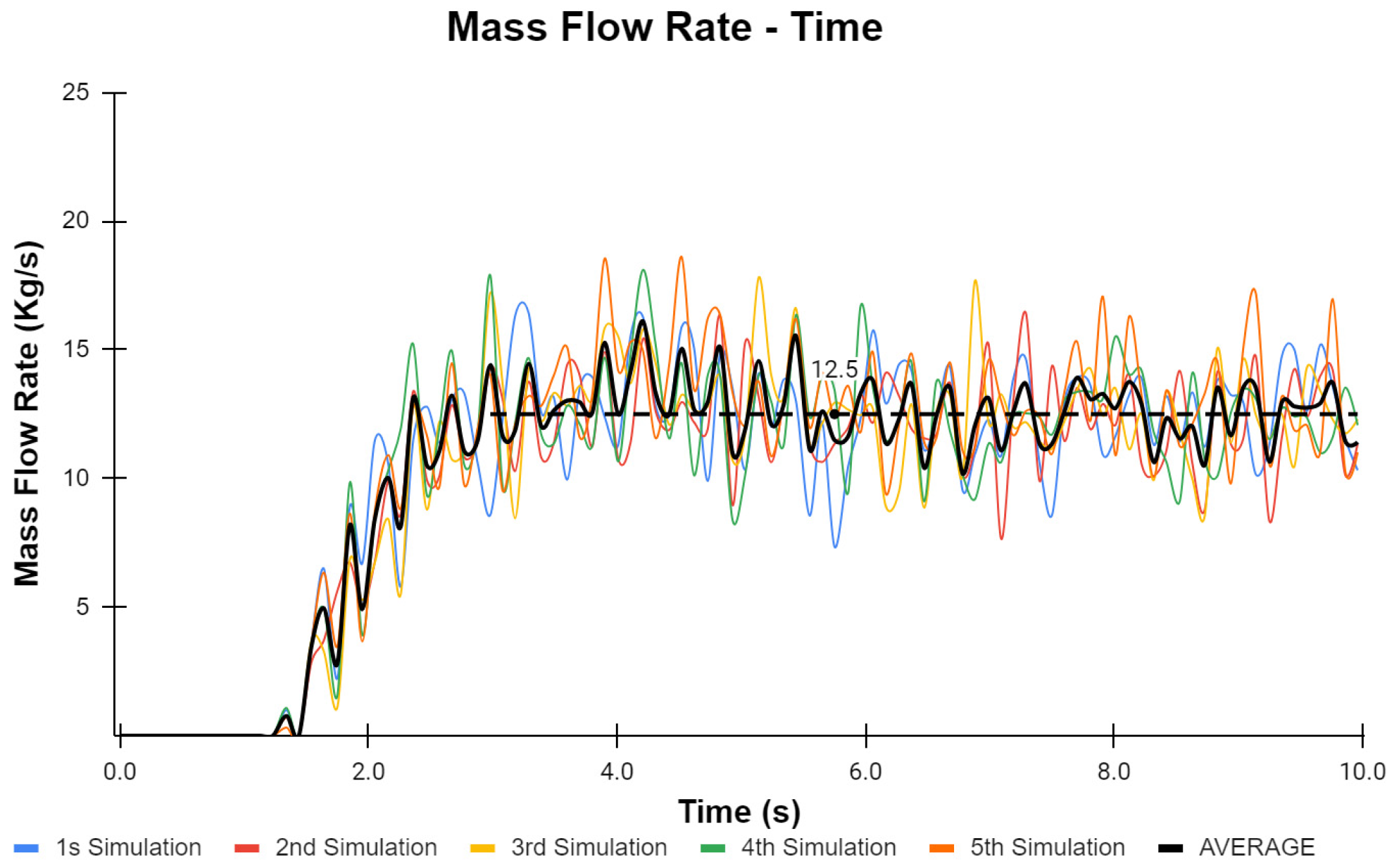

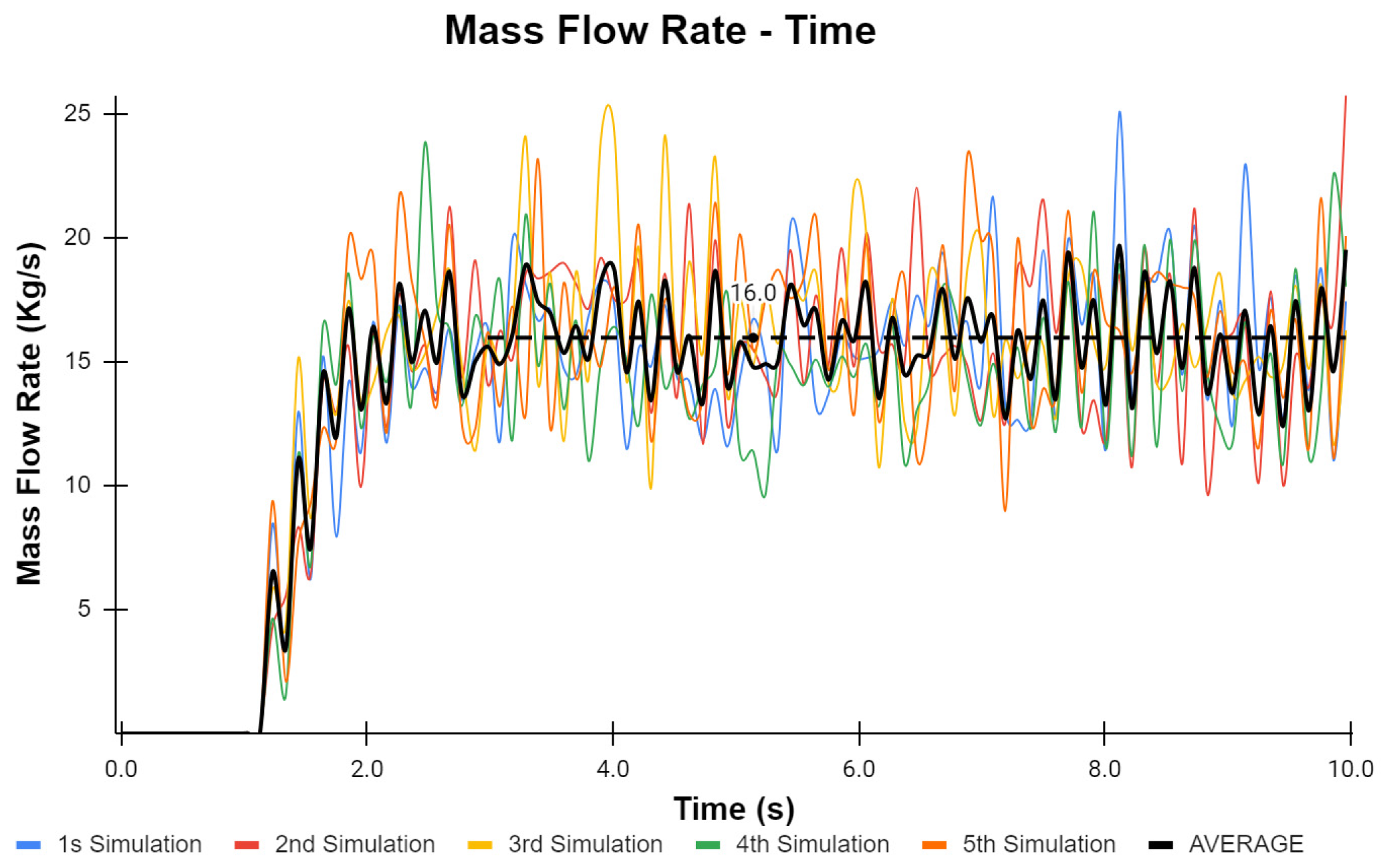

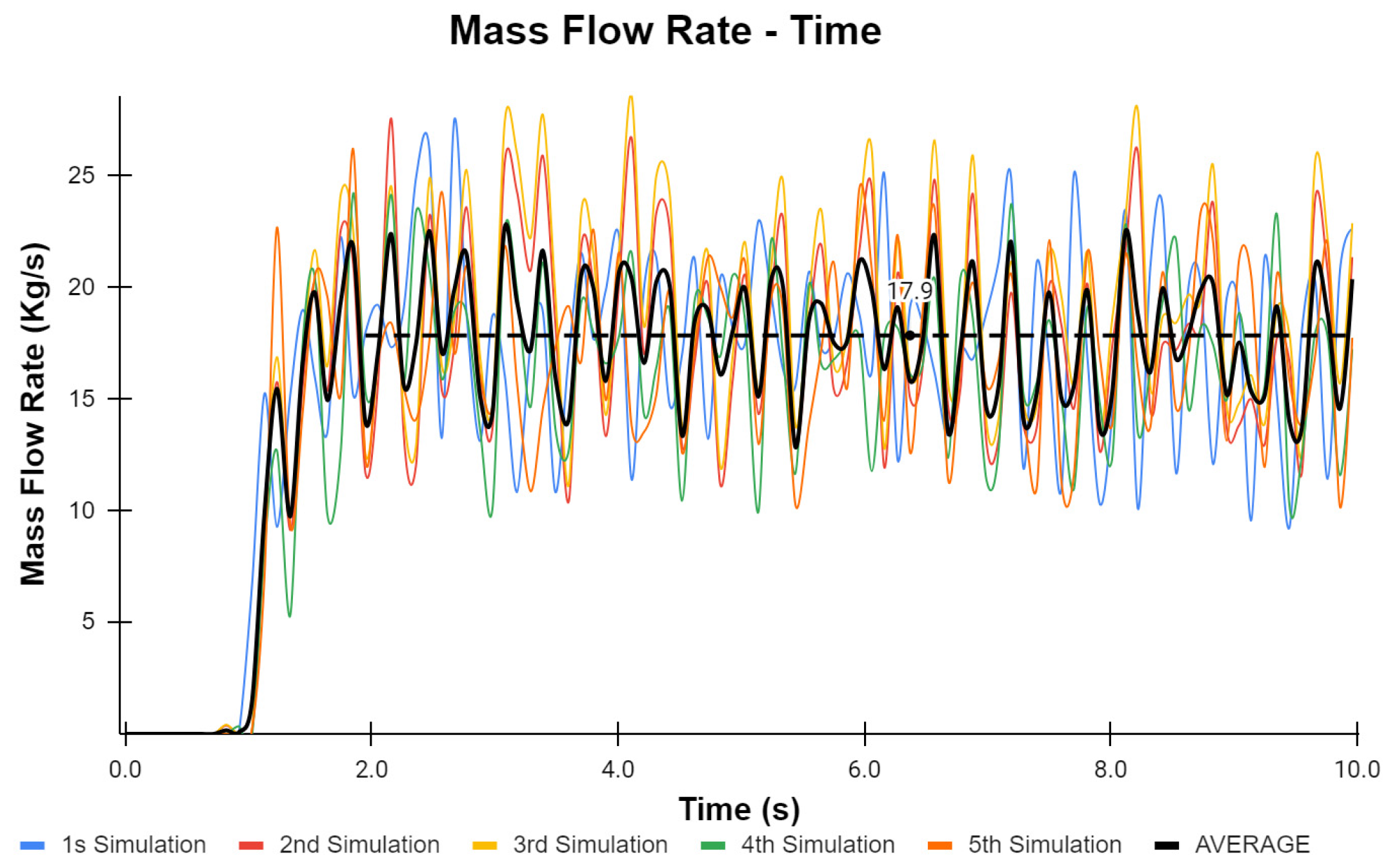

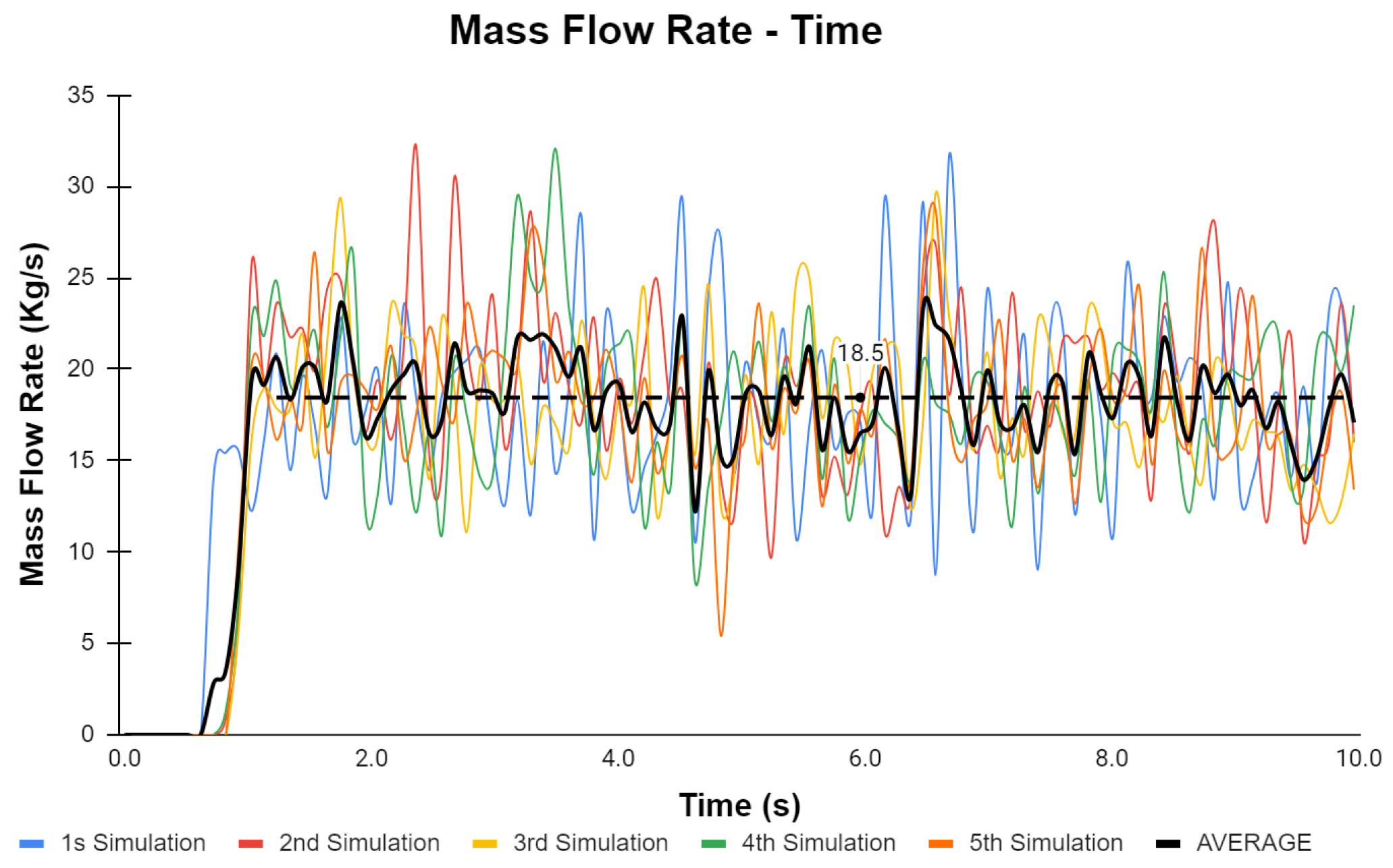

| 1 | 100 | 7.5 | 27.0 | 23.1 | 14.4% | ||

| 2 | 200 | 12.5 | 45.0 | 41.1 | 8.7% | ||

| 3 | 300 | 16.0 | 57.6 | 54.3 | 5.7% | 56.7 | 1.66%/4.17% |

| 4 | 400 | 17.9 | 64.4 | 62.5 | 3.0% | ||

| 5 | 500 | 18.8 | 67.7 | 65.7 | 2.9% | 68.3 | 0.97%/3.87% |

| 6 | 600 | 18.5 | 66.6 | 64.0 | 3.9% | ||

| 7 | 700 | 17.5 | 62.8 | 57.4 | 8.7% | 61.5 | 2.11%/6.74% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tran, V.-T.; Bui, N.-T.; Bui, T.-A. Application of EDEM Simulation for Calculating and Optimizing a Closed Coal Fly Ash Screw Conveyor. Appl. Sci. 2023, 13, 12169. https://doi.org/10.3390/app132212169

Tran V-T, Bui N-T, Bui T-A. Application of EDEM Simulation for Calculating and Optimizing a Closed Coal Fly Ash Screw Conveyor. Applied Sciences. 2023; 13(22):12169. https://doi.org/10.3390/app132212169

Chicago/Turabian StyleTran, Van-Thien, Ngoc-Tam Bui, and Tuan-Anh Bui. 2023. "Application of EDEM Simulation for Calculating and Optimizing a Closed Coal Fly Ash Screw Conveyor" Applied Sciences 13, no. 22: 12169. https://doi.org/10.3390/app132212169

APA StyleTran, V.-T., Bui, N.-T., & Bui, T.-A. (2023). Application of EDEM Simulation for Calculating and Optimizing a Closed Coal Fly Ash Screw Conveyor. Applied Sciences, 13(22), 12169. https://doi.org/10.3390/app132212169