Research on Bidirectional Reservation Method for Anti-Permeation Geomembrane Slack

Abstract

:1. Introduction

2. Geomembrane Slack Methods

2.1. Introduction of Existing Methods

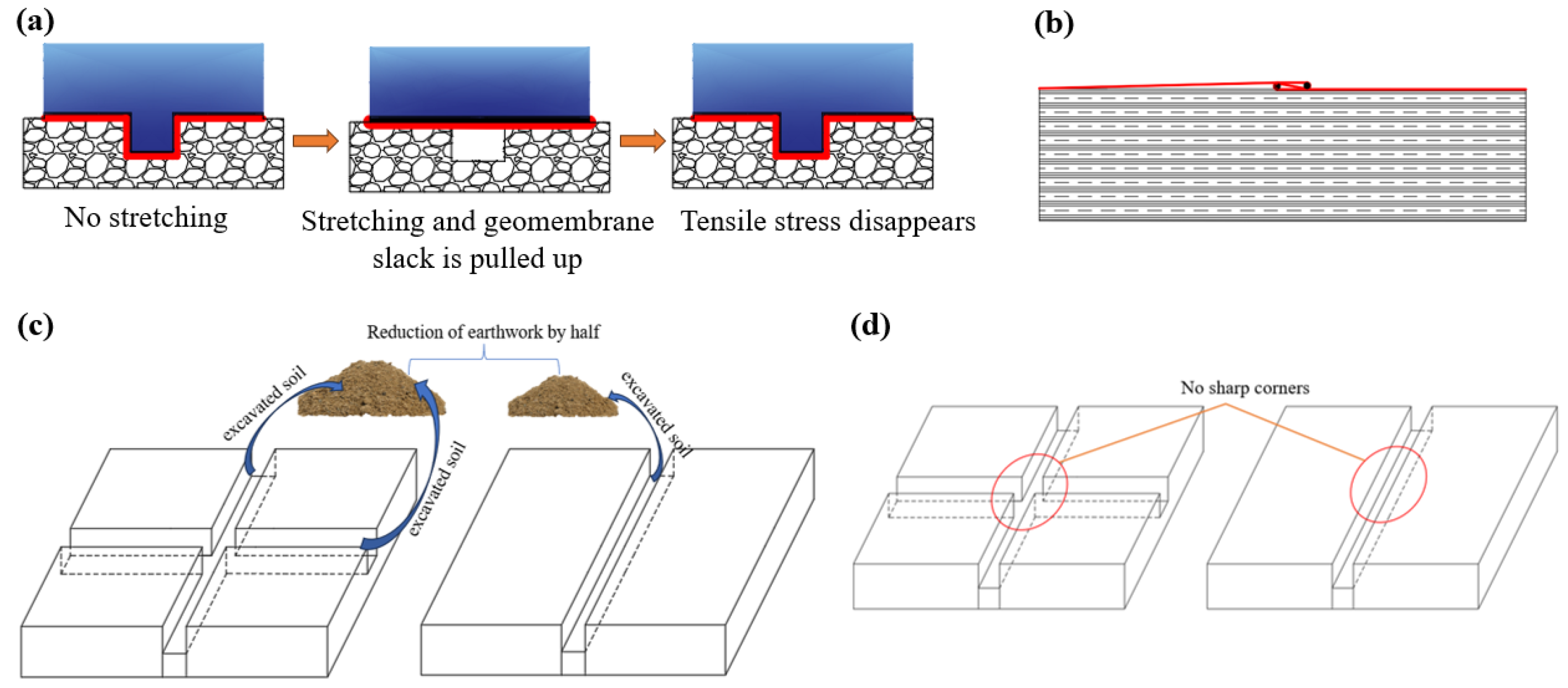

- (1)

- Wave-shaped slack-laying method. When laying geomembranes at construction sites, geomembranes are designed to undulate, as shown in Figure 1a, similar to waves that form during water surface fluctuation. In this process, the amount of raised geomembrane is equivalent to the amount of slack reserved. Although the wave-shaped slack-laying method shown in Figure 1a requires no special structures, relatively little work, and easy operation strategies, the natural slack unfolded during laying without tensioning, which forms a natural wave, produces folds when subjected to overlying water load and backfill pressure. These folds reduce the service life of the geomembrane [23,24,25,26].

- (2)

- Concentrated groove-shaped slack-laying method. Figure 1b shows that the concentrated groove-shaped method involves digging grooves at a certain distance before geomembrane laying. When laying the geomembrane, the reserved part is laid in the grooves dug beforehand. However, when the geomembrane is strained, the groove-shaped centralized laid geomembrane unfolds, making the lower part of the geomembrane in the grooves partially hollow and vulnerable to damage or destruction by water load pressure. Additionally, groove excavation increases the amount of earthwork and makes the gullies in the reservoir area not conducive to geomembrane laying or engineering construction.

- (3)

- Concentrated Z-shaped slack-laying method. Figure 1c shows the concentrated Z-shaped slack-laying method for reservation, in which the geomembrane is folded and laid at intervals, and the overall appearance is Z-shaped. After the reservoir is utilized, when the geomembrane is deformed due to certain factors, such as uneven foundation settlement and temperature changes, the Z-shaped geomembrane is separated. To prevent the geomembrane from folding, neoprene rods are added to the geomembrane bend. Since the reservation is Z-shaped, when the geomembrane deformation is pulled, one layer unfolds, meeting the requirements for reserving a geomembrane.

2.2. Two-Way Reservation Method

2.2.1. Two-Way Reservation Concept

2.2.2. Two-Way Reservation Method

- (1)

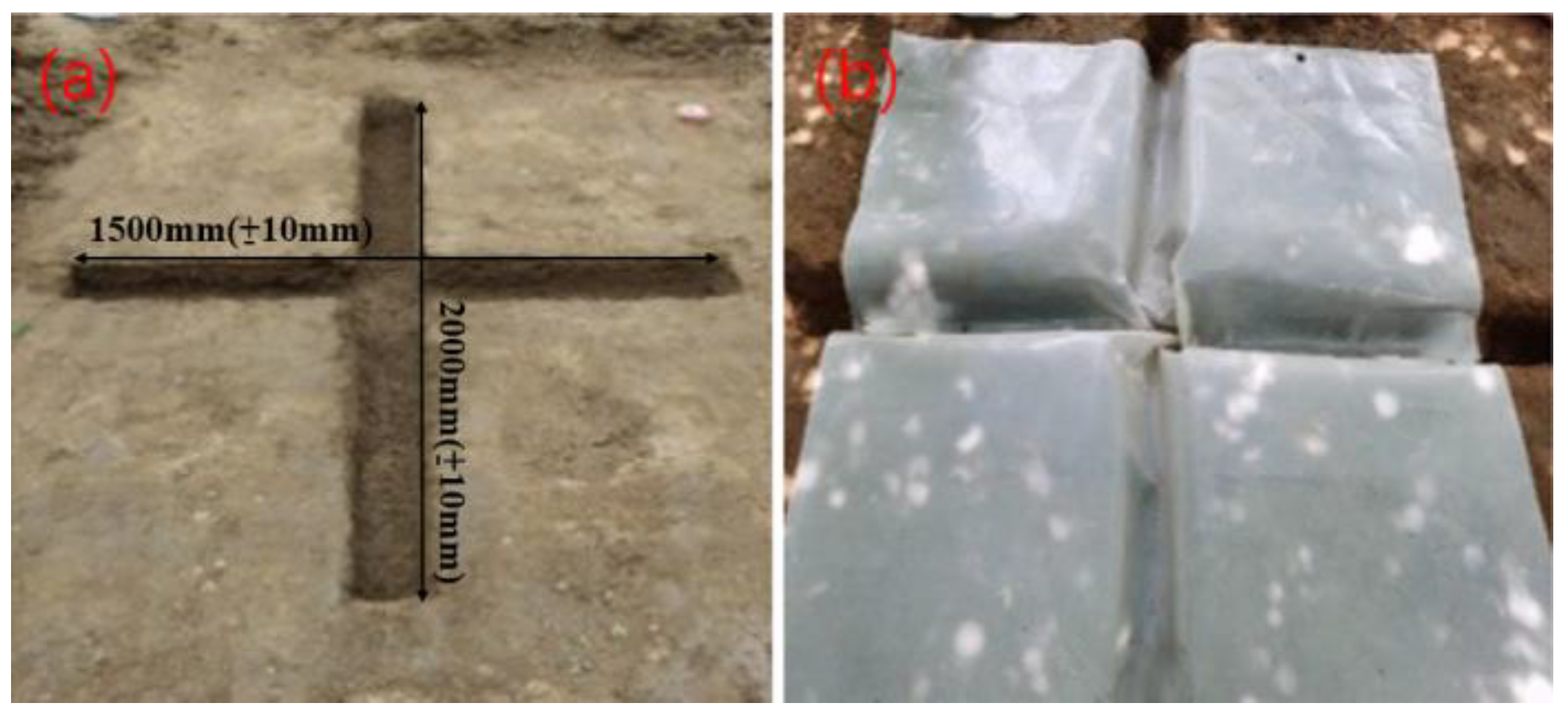

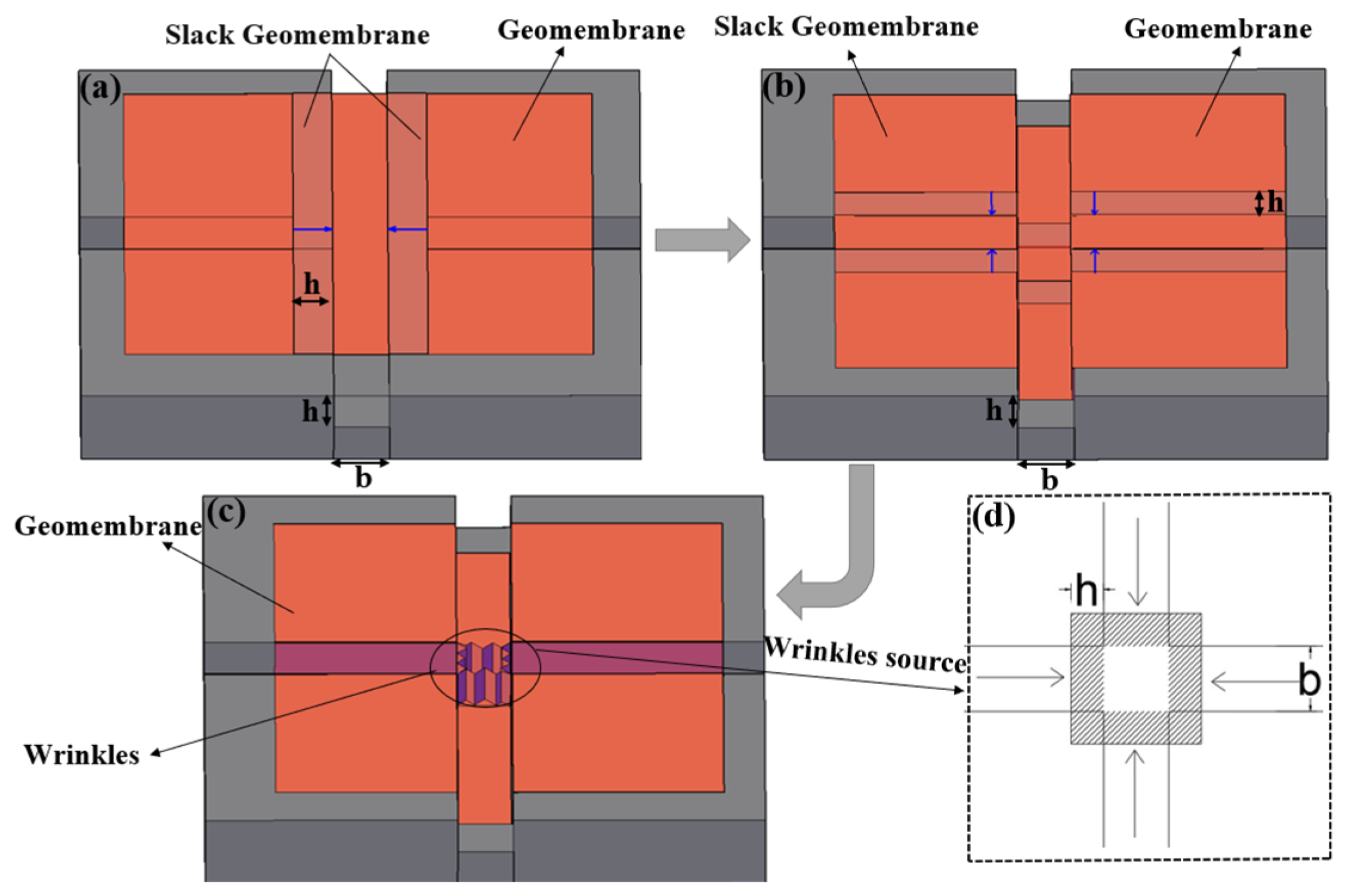

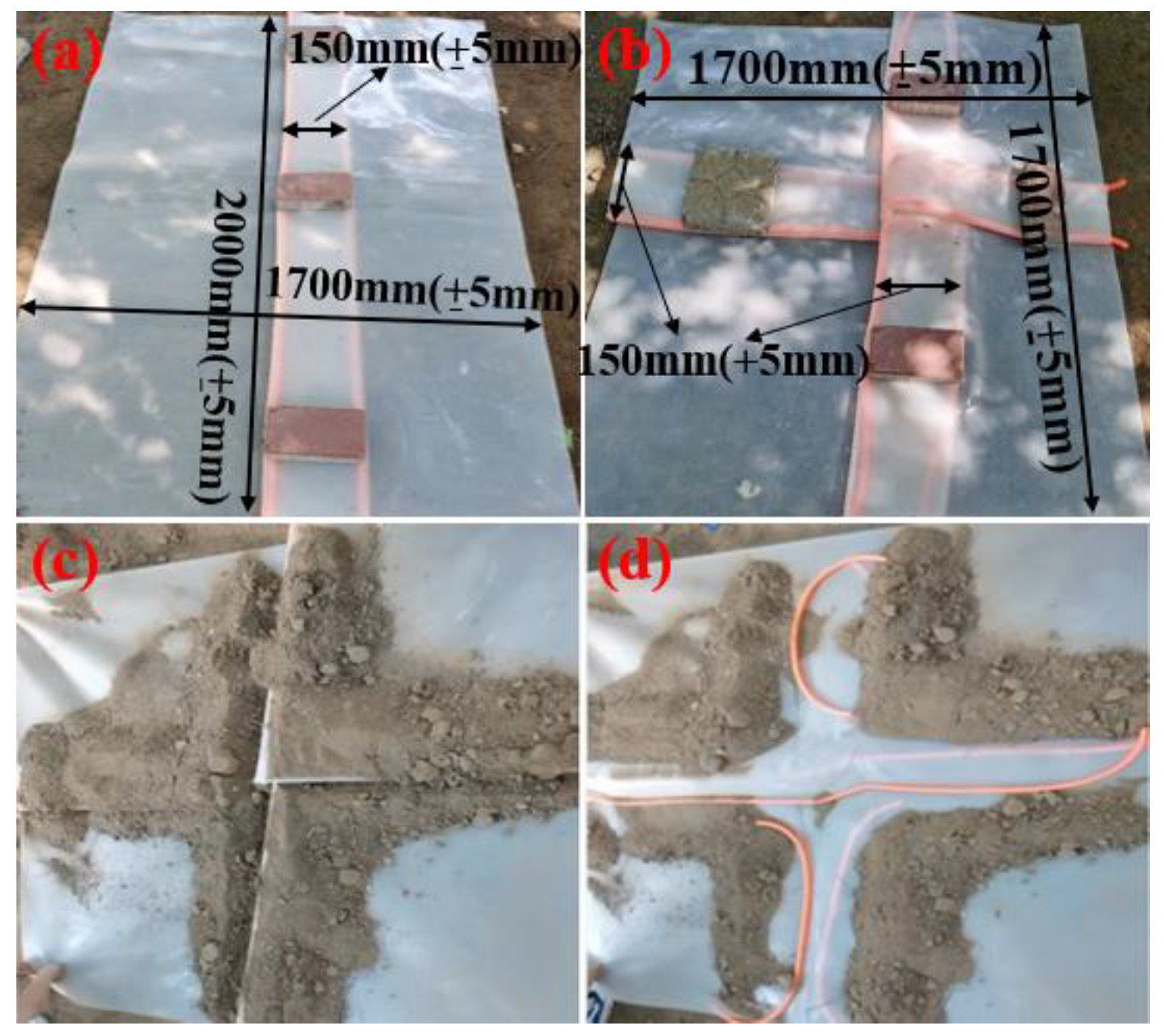

- Cross-groove-shaped laying method. As shown in Figure 2a, the unidirectional recess is modified based on the recess-type slack preparation method by changing the unidirectional recess into a cross-groove-shaped bidirectional recess. In this case, the size of the recess must be determined according to the corresponding specifications [17,18,19]. When the geomembrane is subjected to tensile stress due to environmental changes, the geomembrane in the cross-shaped recess is lifted so that the geomembrane is not tight, even when subjected to tensile stress. Theoretically, when the geomembrane is subjected to tensile stress in any direction, the geomembrane hidden in the cross-shaped grooves will be pulled up. So, the cross-shaped groove can basically address tensile stresses in any direction of the geomembrane.

- (2)

- (3)

- Combined Z- and groove-shaped laying method. By combining the unidirectional Z shape and unidirectional groove shape, a new bidirectional geomembrane slack reservation method can be obtained. As shown in Figure 2c, the unidirectional Z-folded geomembrane is laid on a foundation with a unidirectional groove. In this case, the zigzag folded strip is geometrically perpendicular to the recess.

3. Analysis and Comparison of Different Methods

3.1. Cross-Notch-Type Centralized Laying Relaxation Amount Method Analysis

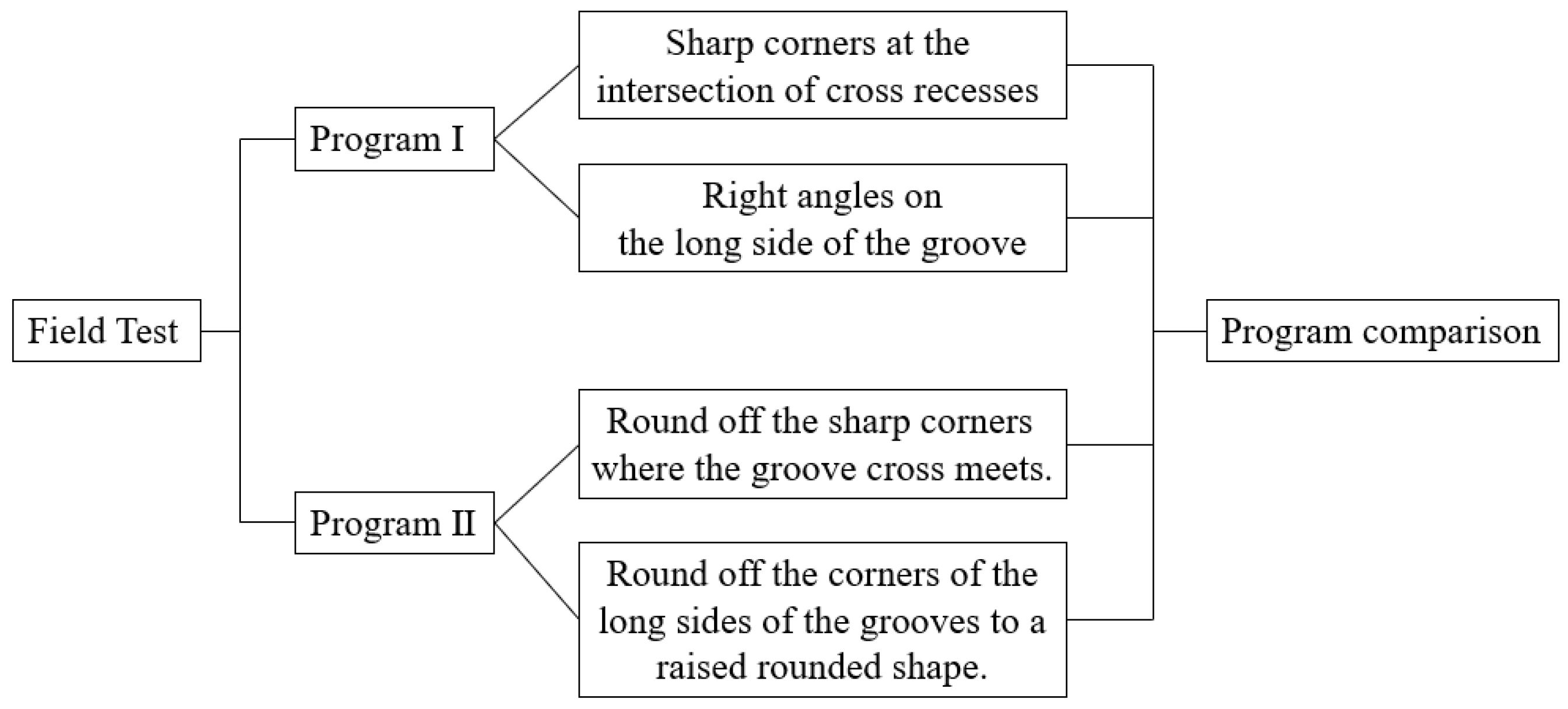

3.1.1. Program Design

3.1.2. Right Angle Program

3.1.3. Plastering Program

3.2. “Z” Cross-Type Two-Way Centralized Lay-Up Relaxation Amount Method Analysis

3.3. Analysis of “Z” and Groove Combination-Type Two-Way Pre-Set Concentration Laying Slack Amount Method

3.4. Comparison of Different Methods

3.4.1. Comparison of Bidirectional and Unidirectional Slack Reservation Methods

3.4.2. Comparison between Different Bidirectional Relaxation Allowance Methods

Advantages

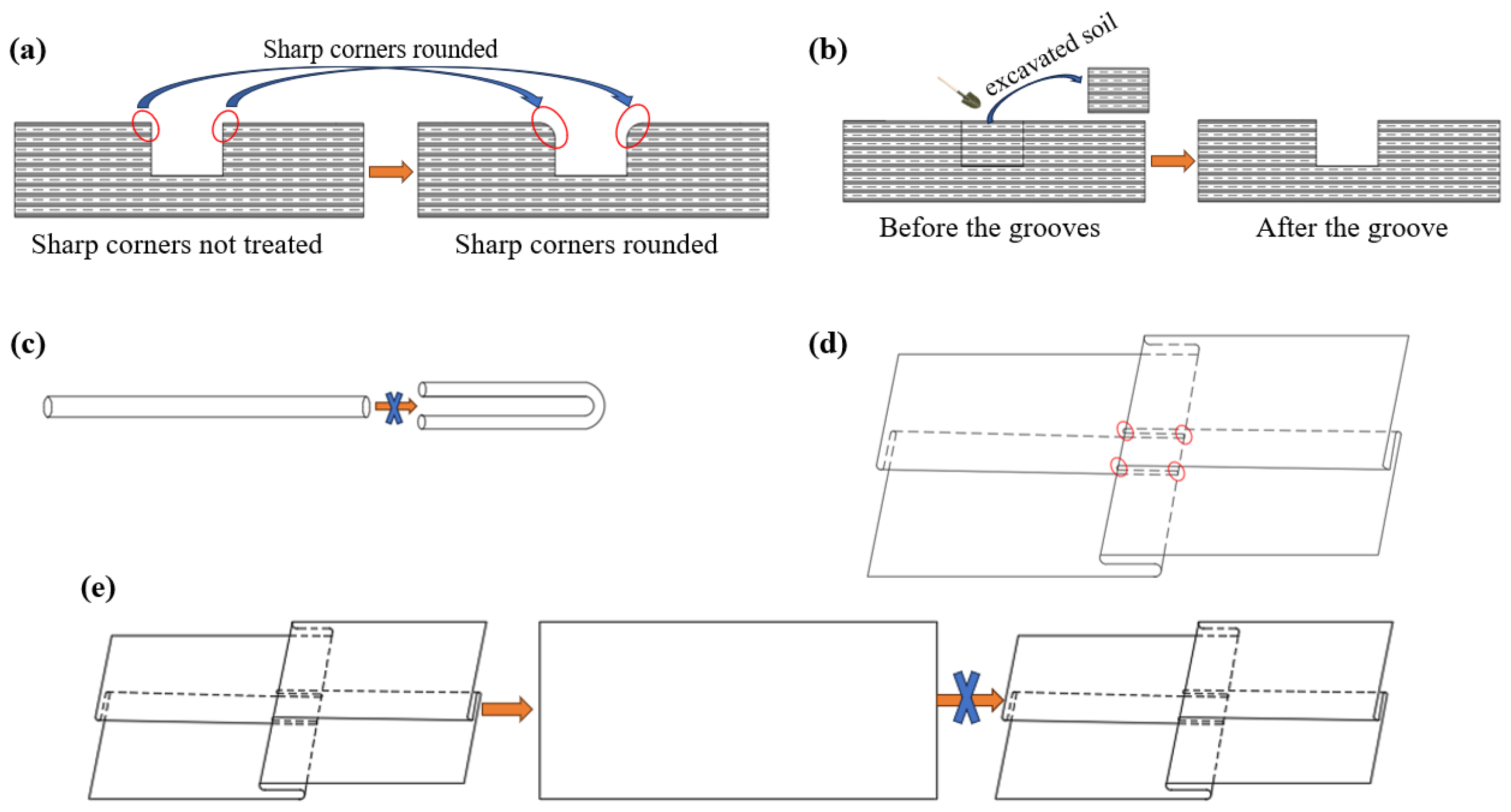

- Bidirectional cross-groove-shaped method: as shown in Figure 9a, the groove-shaped slack can be restored to its original state after the stress disappears and used continuously.

- Bidirectional cross-Z-shaped method: as shown in Figure 9b, the Z-shaped slack is laid directly on the ground. No trenching is needed, saving civil construction work.

- Combined groove- and Z-shaped method: j as shown in Figure 9c, compared with the bidirectional cross-groove-shaped method that requires two grooves to be excavated, the combined groove- and Z-shaped method requires only one groove to be excavated, which saves civil engineering work. k As shown in Figure 9d, the method of combining groove- and Z-shaped methods has only one notch, there is no sharp corner at the intersection of the two notches. This eliminates the need for edge angle detailing.

Disadvantages

- Bidirectional cross-groove-shaped method: j as shown in Figure 10a, the edge angles of the notches cause the geomembrane to crease, which is undesirable. However, the edge angle of the groove is cumbersome to deal with. k As shown in Figure 10b, the presence of grooves requires a large amount of earth excavation, increasing construction costs. l The difficulty of construction is increased.

- Bidirectional cross-Z-shaped method: j as shown in Figure 10c, neoprene rods cannot be folded 180°. k As shown in Figure 10d, it is prone to geomembrane damage at the cross-intersections when folded. l As shown in Figure 10e, a bidirectional Z-shaped slack laid flat on a flat surface may not be restored to its original mount once it has been pulled apart. It cannot be continuously recycled.

- Combined groove- and Z-shaped method: j the cross-Z-shaped method can be used only once. k After one use, it is easily broken under pressure with creases.

4. Discussion

5. Conclusions

- (1)

- Geomembrane folds are concentrated at the cross-intersection of the groove in the bidirectional reservation method, and the space at the cross-intersection can be increased by grinding the four corners to consume excess geomembrane. The corners of the cross-intersection should be polished to a 35° angle of inclination, and the diagonal arc length of the cross-intersection should be 1/2 of the total length of the groove.

- (2)

- The cross-Z-shaped bidirectional folding and reservation method produces a negligible number of folds due to the excessive neoprene rods. However, the required neoprene rods cannot achieve 180-degree folding, which is the largest obstacle to the effective implementation of this method. Once the reserved portion is separated, the folded layer cannot be restored to its original state when the stress disappears, and there is no slack to protect the geomembrane when it is subjected to tensile stress.

- (3)

- The bidirectional reservation method combining the Z- and groove-shaped techniques produces a negligible number of folds, and it does not require a 180° folding layer of neoprene rods. Only a unidirectional U-shaped groove is provided, which greatly reduces the earthwork excavation cost. The disadvantage of this method is that once the unidirectional Z-shaped folded layer is separated, it cannot be restored to its original form and instead becomes a unidirectional reservation mode after one use.

- (4)

- For safety reasons only, bidirectional notch-type allowances should be prioritized for the amount of slack in geomembrane placement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sharma, H.D.; Reddy, K.R. Geoenvironmental Engineering: Site Remediation, Waste Containment and Emerging Waste Management Technologies; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Li, W.L.; Li, Z.Q.; Su, X.C.; Xu, F.; Wei, R.C.; Zhang, B.F. Field Experimental of Eliminating Geomembrane Air Expansion by Vacuumizing for Plain Reservoir. Geotech. Test. J. 2019, 42, 221–231. [Google Scholar] [CrossRef]

- Yu, H.R.; Wei, R.C.; Li, C.; Li, W.L. Experimental Study on Air Expansion Deformation of Composite Geomembrane under Ring-Restrained Condition. Geotech. Test. J. 2020, 43, 1191–1200. [Google Scholar] [CrossRef]

- Lavoie, F.L.; Valentin, C.A.; Kobelnik, M.; Lins da Silva, J.; Lopes, M.D.L. HDPE Geomembranes for Environmental Protection: Two Case Studies. Sustainability 2020, 12, 8682. [Google Scholar] [CrossRef]

- Schmachtenberg, E.; Schoeche, N. Advances in calculating thermally induced stresses in nonlinear viscoelastic materials. Polym. Eng. Sci. 1999, 39, 767–777. [Google Scholar] [CrossRef]

- Imaizumi, S.; Kawamata, K.; Tsuboi, M. Study on thermal stress within the geomembrane liner induced by temperature decrease. In Proceedings of the 7th International Landfill Symposium, Cagliari, Italy, 4–8 October 1999; pp. 115–122. [Google Scholar]

- Krishnaswamy, R.K. Analysis of ductile and brittle failures from creep rupture testing of high-density polyethylene (HDPE) pipes. Polymer 2005, 46, 11664–11672. [Google Scholar] [CrossRef]

- Merry, S.M.; Bray, J.D.; Yoshitomi, S. Axisymmetric temperature- and stress-dependent creep response of ‘new’ and ‘old’ HDPE geomembranes. Geosynth. Int. 2005, 12, 156–161. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, Z.; Wu, Y.; Liu, J. Response of Mechanical Properties of Polyvinyl Chloride Geomembrane to Ambient Temperature in Axial Tension. Appl. Sci. 2021, 11, 10864. [Google Scholar] [CrossRef]

- Wu, H.M.; Shu, Y.M.; Cao, M.J. Development and application of multi-functional biaxial tensile testing machine for geosynthetics. Chin. J. Geotech. Eng. 2014, 36, 170–175. [Google Scholar]

- Frost, J.D.; Karademir, T. Shear-induced changes in smooth geomembrane surface topography at different ambient temperatures. Geosynth. Int. 2015, 23, 113–128. [Google Scholar] [CrossRef]

- Giroud, J.P.; Soderman, K.L. Comparison of Geomembranes Subjected to Differential Settlement. Geosynth. Int. 1995, 2, 953–969. [Google Scholar] [CrossRef]

- Wu, H.; Feng, L.; Teng, Z.; Shu, Y. Model Test on Mechanical and Deformation Property of a Geomembrane Surface Barrier for a High Rockfill Dam. Appl. Sci. 2021, 11, 11505. [Google Scholar] [CrossRef]

- Xu, S.F.; Yang, Y.A.N.G.; Hong, B. Evaluation of temperature stress and stress relaxation properties of HDPE sheet. J. Southeast Univ. 2006, 36, 820–824. [Google Scholar]

- Fang, C.; Xu, S.; Yang, Y. Study on temperature stress of HDPE geomembrane. China Build. Waterproofing 2010, 6, 10–12. [Google Scholar]

- Gao, D.; Zhu, B.; Chen, Y.M. Mechanism and analytic model of wrinkled geomembranes around circular structures subjected to differential settlement. Chin. J. Geotech. Eng. 2008, 30, 1126–1132. [Google Scholar]

- GB50290-98; Brief Introduction of Technical Specification for Application of Synthetic Materials to Soil Engineering GB. China Plan Press: Beijing, China, 1998.

- DL/T 5743-2016; Code for Construction of Geosynthetics for Hydropower and Water Conservancy Projects. Code of China: Beijing, China, 2016.

- SL/T225-98; Standard for Applications of Geosynthetics in Hydraulic and Hydro-Power Engineering. China Water Power Press: Beijing, China, 1998.

- Zheng, X. Talk about evaporation pond laying geomembrane construction requirements. Shanxi Water Resour. 2016, 3, 79–80. [Google Scholar]

- Zhao, E.-H. Design Difficulties and Solutions for Water Supply Project in Tangshan Leting New District. Hebei Water Resour. 2017, 1, 41. [Google Scholar]

- Available online: https://www.docin.com/p-2699715481.html (accessed on 1 May 2023).

- Soong, T.Y.; Koerner, R.M. Behavior of waves in high density polyethylene geomembranes: A laboratory study. Geotext. Geomembr. 1999, 17, 81–104. [Google Scholar] [CrossRef]

- Chappel, M.J.; Rowe, R.K.; Brachman, R.W.I.; Take, W.A. A comparison of geomembrane wrinkles for nine field cases. Geosynth. Int. 2012, 19, 453–469. [Google Scholar] [CrossRef]

- Take, W.A.; Watson, E.; Brachman, R.W.I.; Rowe, R.K. Thermal Expansion and Contraction of Geomembrane Liners Subjected to Solar Exposure and Backfilling. J. Geotech. Geoenvironmental Eng. 2012, 138, 1387–1397. [Google Scholar] [CrossRef]

- Yang, P.; Xue, S.B.; Song, L.; Zhu, X.W. Numerical simulation of geomembrane wrinkle formation. Geotext. Geomembr. 2017, 45, 697–701. [Google Scholar] [CrossRef]

- Popova, M.B.; Iliev, V.D. Analytical model for anisotropic geomembrane composites. Geotext. Geomembr. 1990, 9, 269–280. [Google Scholar] [CrossRef]

- Duvall, D.E. Creep and Stress Rupture Testing of a Polyethylene Geomembrane Under Equal Biaxial Tensile Stress. In Proceedings of the Geosynthetics, Vancouver, BC, Canada, 30 March–1 April 1993; Volume 12, pp. 285–295.

- Lecompte, D.; Smits, A.; Sol, H.; Vantomme, J.; Van Hemelrijck, D. Mixed numerical–experimental technique for orthotropic parameter identification using biaxial tensile tests on cruciform specimens. Int. J. Solids Struct. 2007, 44, 1643–1656. [Google Scholar] [CrossRef]

- Yu, Y.; Rowe, R.K. Development of geomembrane strains in waste containment facility liners with waste settlement. Geotext. Geomembr. 2018, 46, 226–242. [Google Scholar] [CrossRef]

- Yuan, H.; Bai, X.; Zhao, H.; Wang, J. Experimental Study on the Influence of Aging on Mechanical Properties of Geogrids and Bearing Capacity of Reinforced Sand Cushion. Adv. Civ. Eng. 2020, 2020, 8839919.1–8839919.13. [Google Scholar] [CrossRef]

- ASTM D5199-12; Standard Test Method for Measuring the Nominal Thickness of Geosynthetics. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D6693M-20; Standard Test Method for Determining Tensile Properties of Nonreinforced Polyethylene and Nonreinforced Flexible Polypropylene Geomembranes. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D792-20; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D624; Standard Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D3192-09; Standard Test Methods for Carbon Black Evaluation in NR (Natural Rubber). ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D4833M-07; Standard Test Method for Index Puncture Resistance of Geomembranes and Related Products. ASTM International: West Conshohocken, PA, USA, 2020.

| Material Type | Characteristics | Unit | Value | Standard |

|---|---|---|---|---|

| HDPE Geomembrane | Thickness | mm | 0.8 | ASTM D5199-12 [32] |

| Fracture strength | N/mm | 21.2 | ASTM D6693M-20 [33] | |

| Elongation at break | % | 704 | ASTM D6693M-20 [33] | |

| Density | g/cm3 | 0.940 | ASTM D792-20 [34] | |

| Right angle tear strength | N/mm | 99.4 | ASTM D624 [35] | |

| Carbon black content | % | 2.2 | ASTM D3192-09 [36] | |

| Puncture resistance strength | N | 257 | ASTM D4833M-07 [37] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Xue, X.; Li, W.; Han, R.; Li, Z. Research on Bidirectional Reservation Method for Anti-Permeation Geomembrane Slack. Appl. Sci. 2023, 13, 12173. https://doi.org/10.3390/app132212173

Wang W, Xue X, Li W, Han R, Li Z. Research on Bidirectional Reservation Method for Anti-Permeation Geomembrane Slack. Applied Sciences. 2023; 13(22):12173. https://doi.org/10.3390/app132212173

Chicago/Turabian StyleWang, Wansheng, Xia Xue, Wanglin Li, Ruichen Han, and Zheng Li. 2023. "Research on Bidirectional Reservation Method for Anti-Permeation Geomembrane Slack" Applied Sciences 13, no. 22: 12173. https://doi.org/10.3390/app132212173