A Hybrid Heuristic Algorithm for Maximizing the Resilience of Underground Logistics Network Planning

Abstract

:1. Introduction

2. Literature Review

2.1. Underground Logistics Network

2.2. Network Resilience

- Resilience assessment perspective: This study introduces a distinctive approach to resilience assessment. In contrast to conventional methods centered on structural resilience through efficiency assessments, our emphasis lies on appraising the network service level.

- Resilience improvement strategies: Departing from conventional methods that enhance resilience through the allocation of resources for disaster supplies and preparedness, we propose improving the resilience of ground logistics networks by constructing underground networks.

- Network planning perspective: In the planning phase, we not only account for cost and capacity constraints but also assess the impact of constructing an underground logistics network on the resilience of the ground network.

3. Problem Modeling

3.1. Problem Description

3.2. Problem Assumption

- Any underground node corresponding to a ground logistics node is a feasible candidate site.

- The fixed cost of any underground node is the same, and its capacity is the same. The underground arc capacities are the same.

- Disasters only destroy part of the ground network.

3.3. Notations

- Sets and Parameters:

- , set of ground–underground network nodes, .

- , set of ground network nodes, .

- , set of underground candidate nodes, .

- , budget for underground network construction.

- , set of OD pairs.

- , total number of OD pairs.

- , set of ground–underground network arcs.

- , set of Monte Carlo disaster scenarios.

- , potential demand of the OD pair , where is the origin node and is the destination node.

- , capacity of the node .

- , capacity of an arc .

- , fixed cost of the underground arc construction per kilometer.

- , fixed cost of underground node construction.

- , distance of an arc .

- , network–arc indicator (1, if arc is in the ground network; 0, otherwise).

- , network–arc indicator (1, if arc is the arc between the ground node and the corresponding underground node; 0, otherwise).

- Decision variables:

- , binary variable indicating whether the underground node is built (1, if the node is built; 0, otherwise).

- , binary variable indicating whether the underground arc is built (1, if the arc is built; 0, otherwise).

- , binary variable indicating whether the arc is used (1, if the arc is used; 0, otherwise) between the OD pair .

- , satisfied flow along the arc of OD pair .

3.4. Mathematical Model

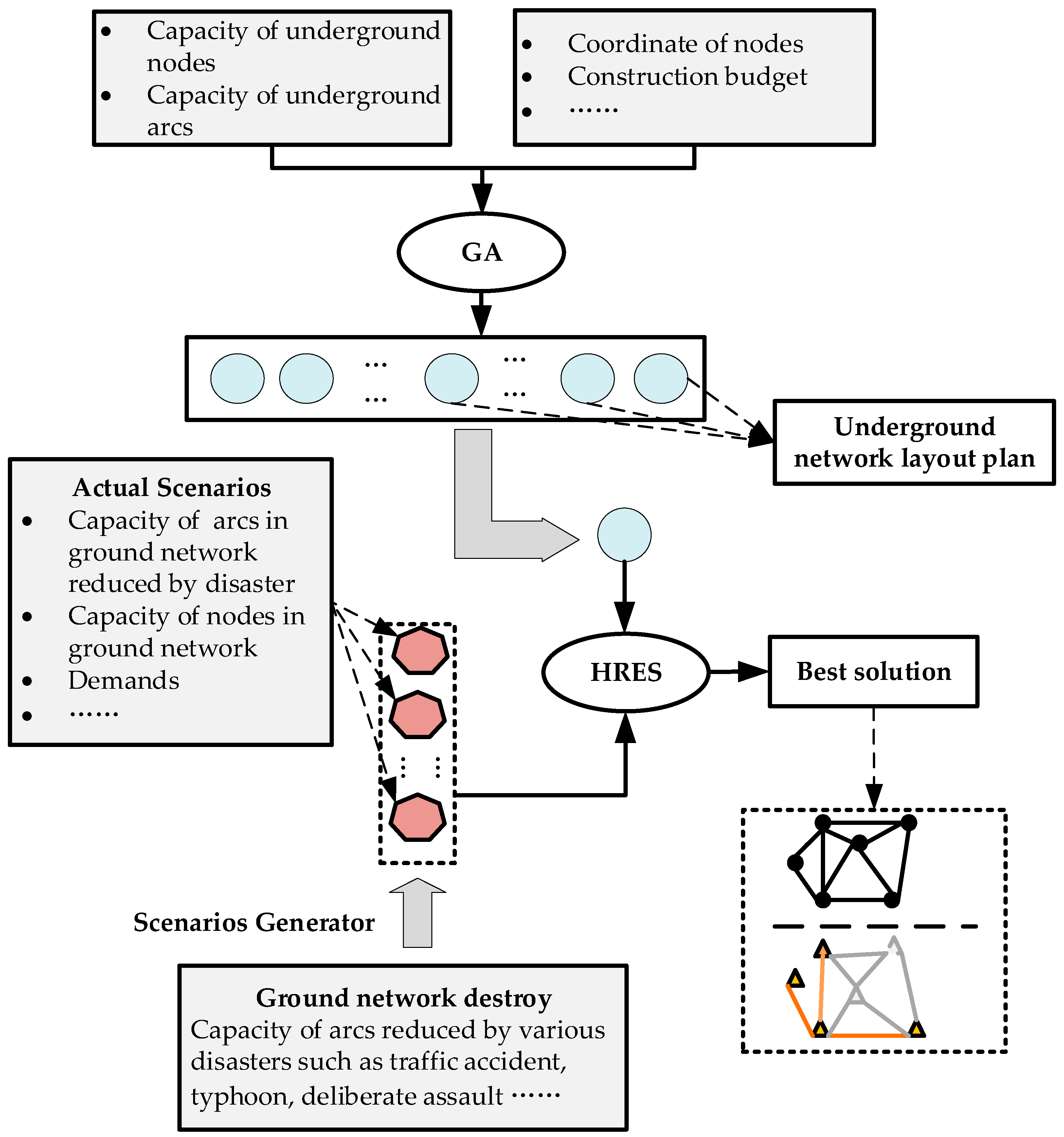

4. Methodology

4.1. Genetic Algorithm

4.1.1. Chromosome Encoding

4.1.2. Crossover and Mutation

4.1.3. Fitness Function

4.2. Heuristic Resilience Evaluation Scheme

5. Case Study

5.1. Background Statement

5.2. Computational Results

6. Conclusions

7. Discussions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| OD | Origin–destination |

| GA | Genetic algorithm |

| HRES | Heuristic resilience evaluation scheme |

References

- Holguín-Veras, J.; Amaya Leal, J.; Sánchez-Diaz, I.; Browne, M.; Wojtowicz, J. State of the Art and Practice of Urban Freight Management: Part I: Infrastructure, Vehicle-Related, and Traffic Operations. Transp. Res. Part. A Policy Pr. 2020, 137, 360–382. [Google Scholar] [CrossRef]

- Lan, S.; Tseng, M.L.; Yang, C.; Huisingh, D. Trends in Sustainable Logistics in Major Cities in China. Sci. Total Environ. 2020, 712, 136381. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, J.; Liao, Z.; Guo, J.; Xie, H.; Peng, Q. An Intelligent Planning Model for the Development and Utilization of Urban Underground Space with an Application to the Luohu District in Shenzhen. Tunn. Undergr. Space Technol. 2021, 112, 103933. [Google Scholar] [CrossRef]

- Van Binsbergen, A.; Bovy, P. Underground Urban Goods Distribution Networks. Innov. Eur. J. Soc. Sci. Res. 2000, 13, 111–128. [Google Scholar] [CrossRef]

- Visser, J.G.S.N. The Development of Underground Freight Transport: An Overview. Tunn. Undergr. Space Technol. 2018, 80, 123–127. [Google Scholar] [CrossRef]

- Zhang, H.; Lv, Y.; Guo, J. New Development Direction of Underground Logistics from the Perspective of Public Transport: A Systematic Review Based on Scientometrics. Sustainability 2022, 14, 3179. [Google Scholar] [CrossRef]

- Yu, P.; Liu, H.; Wang, Z.; Fu, J.; Zhang, H.; Wang, J.; Yang, Q. Development of Urban Underground Space in Coastal Cities in China: A Review. Deep. Undergr. Sci. Eng. 2023, 2, 148–172. [Google Scholar] [CrossRef]

- Chen, Z.; Dong, J.; Ren, R. Urban Underground Logistics System in China: Opportunities or Challenges? Undergr. Space 2017, 2, 195–208. [Google Scholar] [CrossRef]

- CST (2020). Cargo Sous Terrain. Available online: https://www.cst.ch/en/committee/ (accessed on 20 September 2023).

- Hu, W.; Dong, J.; Hwang, B.G.; Ren, R.; Chen, Z. Network Planning of Urban Underground Logistics System with Hub-and-Spoke Layout: Two Phase Cluster-Based Approach. Eng. Constr. Archit. Manag. 2020, 27, 2079–2105. [Google Scholar] [CrossRef]

- Dong, J.; Hu, W.; Yan, S.; Ren, R.; Zhao, X. Network Planning Method for Capacitated Metro-Based Underground Logistics System. Adv. Civ. Eng. 2018, 2018, 6958086. [Google Scholar] [CrossRef]

- Wang, H.W.; Peng, Z.R.; Wang, D.; Meng, Y.; Wu, T.; Sun, W.; Lu, Q.C. Evaluation and Prediction of Transportation Resilience under Extreme Weather Events: A Diffusion Graph Convolutional Approach. Transp. Res. Part. C Emerg. Technol. 2020, 115, 102619. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, J.W. A Resilience Assessment Framework for Urban Transportation Systems. Int. J. Prod. Res. 2021, 59, 2177–2192. [Google Scholar] [CrossRef]

- Miller-Hooks, E.; Zhang, X.; Faturechi, R. Measuring and Maximizing Resilience of Freight Transportation Networks. Comput. Oper. Res. 2012, 39, 1633–1643. [Google Scholar] [CrossRef]

- Govindan, K.; Fattahi, M.; Keyvanshokooh, E. Supply Chain Network Design under Uncertainty: A Comprehensive Review and Future Research Directions. Eur. J. Oper. Res. 2017, 263, 108–141. [Google Scholar] [CrossRef]

- Turkowski, M.; Szudarek, M. Pipeline System for Transporting Consumer Goods, Parcels and Mail in Capsules. Tunn. Undergr. Space Technol. 2019, 93, 103057. [Google Scholar] [CrossRef]

- Liang, H.; Yuan, G.; Han, J.; Sun, L. A Multi-Objective Location and Channel Model for ULS Network. Neural Comput. Appl. 2019, 31, 35–46. [Google Scholar] [CrossRef]

- Magway. 2019. British Company Plans Hyperloop-Inspired Network of Tunnels That Will Transport Millions of Parcels around London in Magnetic Carriages Travelling at 40 mph by 2022. Available online: https://www.dailymail.co.uk/sciencetech/article-7689241/British-company-plans-network-underground-tunnels-transport-millions-parcels.html (accessed on 23 September 2023).

- Ren, M.; Fan, Z.; Wu, J.; Zhou, L.; Du, Z. Design and Optimization of Underground Logistics Transportation Networks. IEEE Access 2019, 7, 83384–83395. [Google Scholar] [CrossRef]

- Zhao, L.; Zhou, J.; Li, H.; Yang, P.; Zhou, L. Optimizing the Design of an Intra-City Metro Logistics System Based on a Hub-and-Spoke Network Model. Tunn. Undergr. Space Technol. 2021, 116, 104086. [Google Scholar] [CrossRef]

- Hu, W.; Dong, J.; Yang, K.; Hwang, B.G.; Ren, R.; Chen, Z. Reliable Design of Urban Surface-Underground Integrated Logistics System Network with Stochastic Demand and Social-Environmental Concern. Comput. Ind. Eng. 2023, 181, 109331. [Google Scholar] [CrossRef]

- Liang, C.; Hu, X.; Shi, L.; Fu, H.; Xu, D. Joint Dispatch of Shipment Equipment Considering Underground Container Logistics. Comput. Ind. Eng. 2022, 165, 107874. [Google Scholar] [CrossRef]

- Fan, Y.; Liang, C.; Hu, X.; Li, Y. Planning Connections between Underground Logistics System and Container Ports. Comput. Ind. Eng. 2020, 139, 106199. [Google Scholar] [CrossRef]

- Gong, D.; Tian, J.; Hu, W.; Dong, J.; Chen, Y.; Ren, R.; Chen, Z. Sustainable Design and Operations Management of Metro-Based Underground Logistics Systems: A Thematic Literature Review. Buildings 2023, 13, 1888. [Google Scholar] [CrossRef]

- Ta, C.; Goodchild, A.V.; Pitera, K. Structuring a Definition of Resilience for the Freight Transportation System. Transp. Res. Rec. 2009, 2097, 19–25. [Google Scholar] [CrossRef]

- Chen, L.; Miller-Hooks, E. Resilience: An Indicator of Recovery Capability in Intermodal Freight Transport. Transp. Sci. 2012, 46, 109–123. [Google Scholar] [CrossRef]

- Gu, Y.; Fu, X.; Liu, Z.; Xu, X.; Chen, A. Performance of Transportation Network under Perturbations: Reliability, Vulnerability, and Resilience. Transp. Res. E Logist. Transp. Rev. 2020, 133, 101809. [Google Scholar] [CrossRef]

- Ganin, A.A.; Kitsak, M.; Marchese, D.; Keisler, J.M.; Seager, T.; Linkov, I. Resilience and Efficiency in Transportation Networks. Sci. Adv. 2017, 3, e1701079. [Google Scholar] [CrossRef]

- Alderson, D.L.; Brown, G.G.; Carlyle, W.M. Assessing and Improving Operational Resilience of Critical Infrastructures and Other Systems. In Bridging Data and Decisions; INFORMS: Orlando, FL, USA, 2014; pp. 180–215. [Google Scholar]

- Zhang, W.; Wang, N. Resilience-Based Risk Mitigation for Road Networks. Struct. Saf. 2016, 62, 57–65. [Google Scholar] [CrossRef]

- Balal, E.; Valdez, G.; Miramontes, J.; Cheu, R.L. Comparative Evaluation of Measures for Urban Highway Network Resilience Due to Traffic Incidents. Int. J. Transp. Sci. Technol. 2019, 8, 304–317. [Google Scholar] [CrossRef]

- Ganin, A.A.; Mersky, A.C.; Jin, A.S.; Kitsak, M.; Keisler, J.M.; Linkov, I. Resilience in Intelligent Transportation Systems (ITS). Transp. Res. Part. C Emerg. Technol. 2019, 100, 318–329. [Google Scholar] [CrossRef]

- Nogal, M.; O’Connor, A.; Caulfield, B.; Martinez-Pastor, B. Resilience of Traffic Networks: From Perturbation to Recovery via a Dynamic Restricted Equilibrium Model. Reliab. Eng. Syst. Saf. 2016, 156, 84–96. [Google Scholar] [CrossRef]

- Aydin, N.Y.; Duzgun, H.S.; Heinimann, H.R.; Wenzel, F.; Gnyawali, K.R. Framework for Improving the Resilience and Recovery of Transportation Networks under Geohazard Risks. Int. J. Disaster Risk Reduct. 2018, 31, 832–843. [Google Scholar] [CrossRef]

- Chen, M.; Lu, H. Analysis of Transportation Network Vulnerability and Resilience within an Urban Agglomeration: Case Study of the Greater Bay Area, China. Sustainability 2020, 12, 7410. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, M.; Chen, S.; Nie, R. Assessing the Resilience of China’s Natural Gas Importation under Network Disruptions. Energy 2020, 211, 118459. [Google Scholar] [CrossRef]

- Twumasi-Boakye, R.; Sobanjo, J. Civil Infrastructure Resilience: State-of-the-Art on Transportation Network Systems. Transp. A Transp. Sci. 2019, 15, 455–484. [Google Scholar] [CrossRef]

- Ransikarbum, K.; Mason, S.J. A Bi-Objective Optimisation of Post-Disaster Relief Distribution and Short-Term Network Restoration Using Hybrid NSGA-II Algorithm. Int. J. Prod. Res. 2022, 60, 5769–5793. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Population size | 60 |

| Maximum number of iterations | 400 |

| Fixed construction costs for underground nodes | 2 |

| Unit construction costs for underground pipelines | 1/km |

| Crossover rate | 0.95 |

| Mutation rate | 0.05 |

| Approach | Resilience | CPU Time (s) | |

|---|---|---|---|

| 5 | CPLEX | 1.0 | 0.148 |

| HRES | 0.9163 | 0.001 | |

| 8 | CPLEX | 0.9698 | 6.251 |

| HRES | 0.9122 | 0.003 | |

| 10 | CPLEX | 0.9108 | 31.542 |

| HRES | 0.8708 | 0.011 | |

| 12 | CPLEX | 0.9999 | 61.321 |

| HRES | 0.8855 | 0.029 | |

| 18 | CPLEX | 0.9442 | 68.406 |

| HRES | 0.8014 | 0.068 | |

| 24 | CPLEX | 0.9851 | 203.474 |

| HRES | 0.9209 | 0.112 |

| Original Network Resilience | Planned Network Resilience | Rate of Increase | |

|---|---|---|---|

| 5 | 0.5083 | 0.8917 | 75.4% |

| 8 | 0.6205 | 0.8625 | 39.0% |

| 10 | 0.6915 | 0.8655 | 25.1% |

| 12 | 0.7758 | 0.8927 | 15.0% |

| 18 | 0.7372 | 0.7837 | 6.3% |

| 24 | 0.6548 | 0.8210 | 25.4% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, Z.; Fang, Y.; Peng, W.; Chen, X. A Hybrid Heuristic Algorithm for Maximizing the Resilience of Underground Logistics Network Planning. Appl. Sci. 2023, 13, 12588. https://doi.org/10.3390/app132312588

Xue Z, Fang Y, Peng W, Chen X. A Hybrid Heuristic Algorithm for Maximizing the Resilience of Underground Logistics Network Planning. Applied Sciences. 2023; 13(23):12588. https://doi.org/10.3390/app132312588

Chicago/Turabian StyleXue, Zhaojie, Yunliang Fang, Wenxiang Peng, and Xiangsheng Chen. 2023. "A Hybrid Heuristic Algorithm for Maximizing the Resilience of Underground Logistics Network Planning" Applied Sciences 13, no. 23: 12588. https://doi.org/10.3390/app132312588