Development and Field Application of an Automated Pipe Jacking Friction Resistance Identification and Warning System in Construction

Abstract

:1. Introduction

2. Friction Resistance Analysis and Calculation

2.1. Resistance Analysis during Pipe Jacking Construction Based on a Literature Review

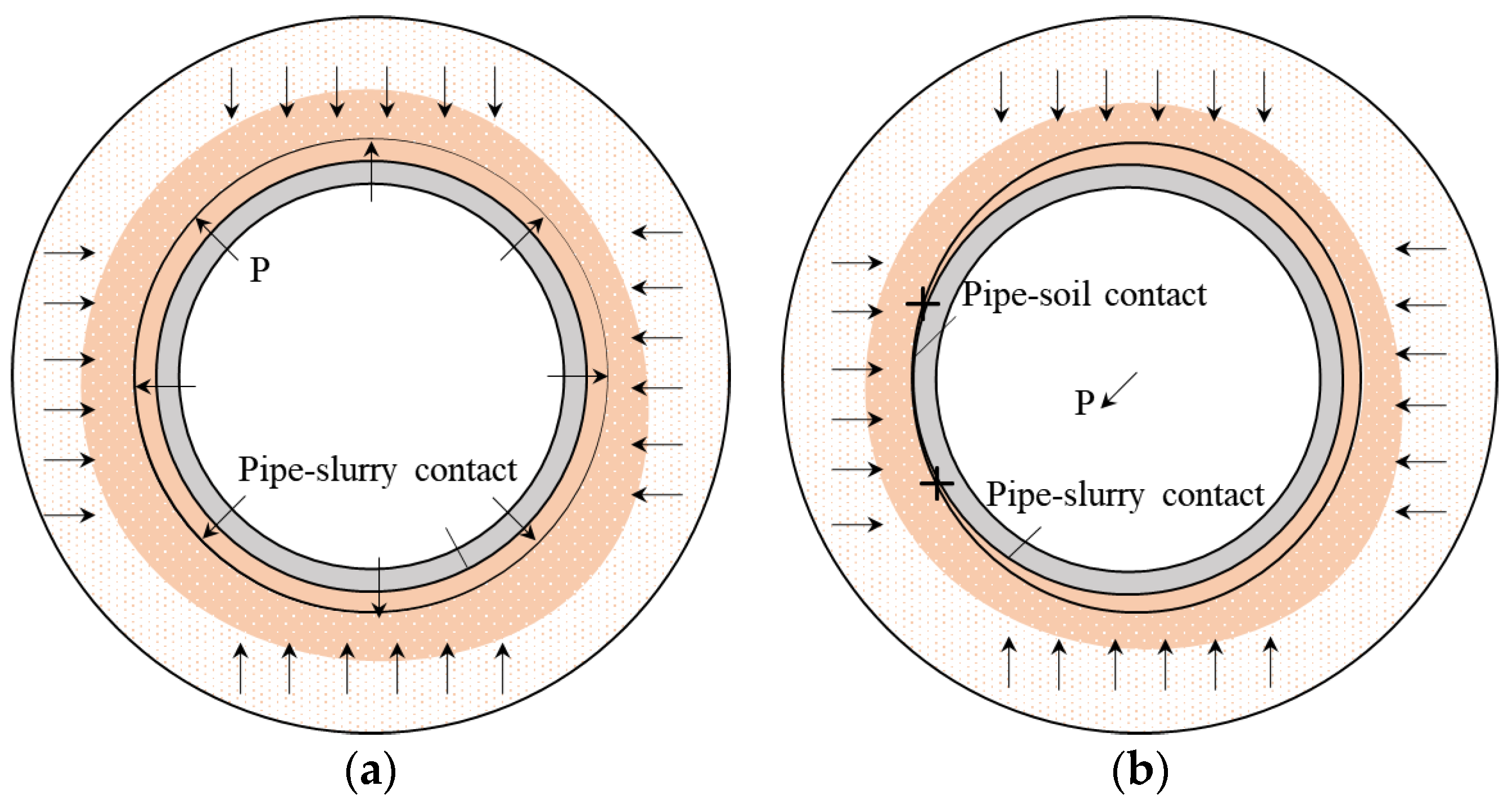

2.2. Models of Friction Resistance

3. Automated Pipe Jacking Friction Resistance Identification and Warning System

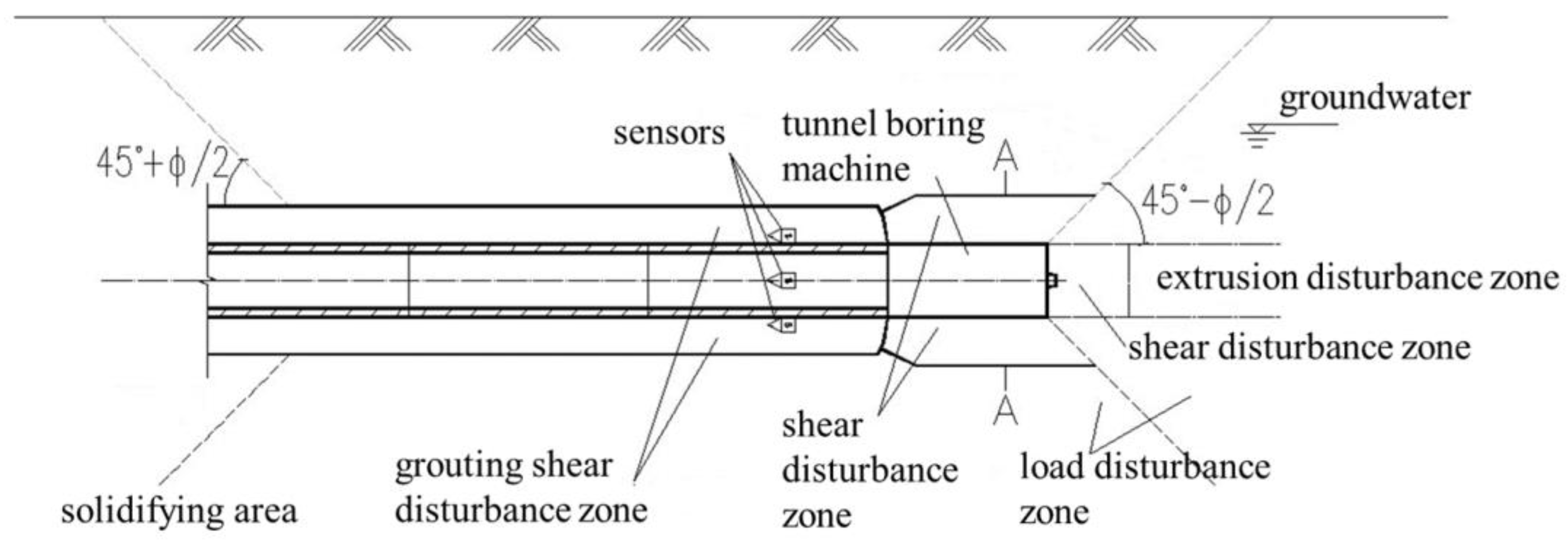

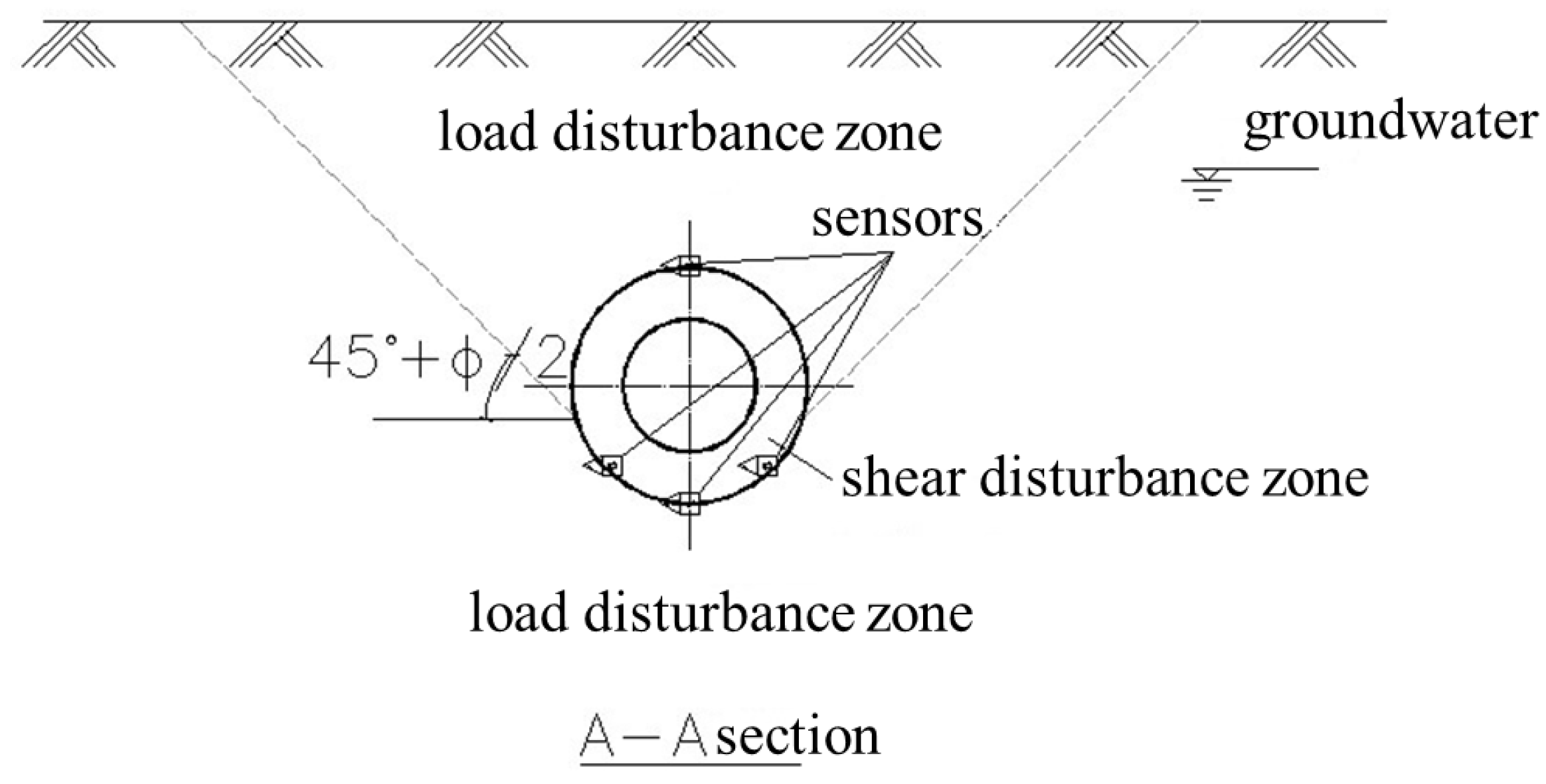

3.1. Resistance Sensor Distribution

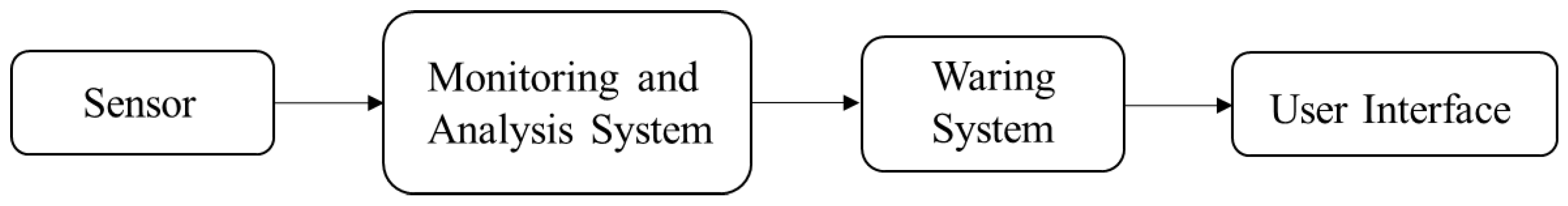

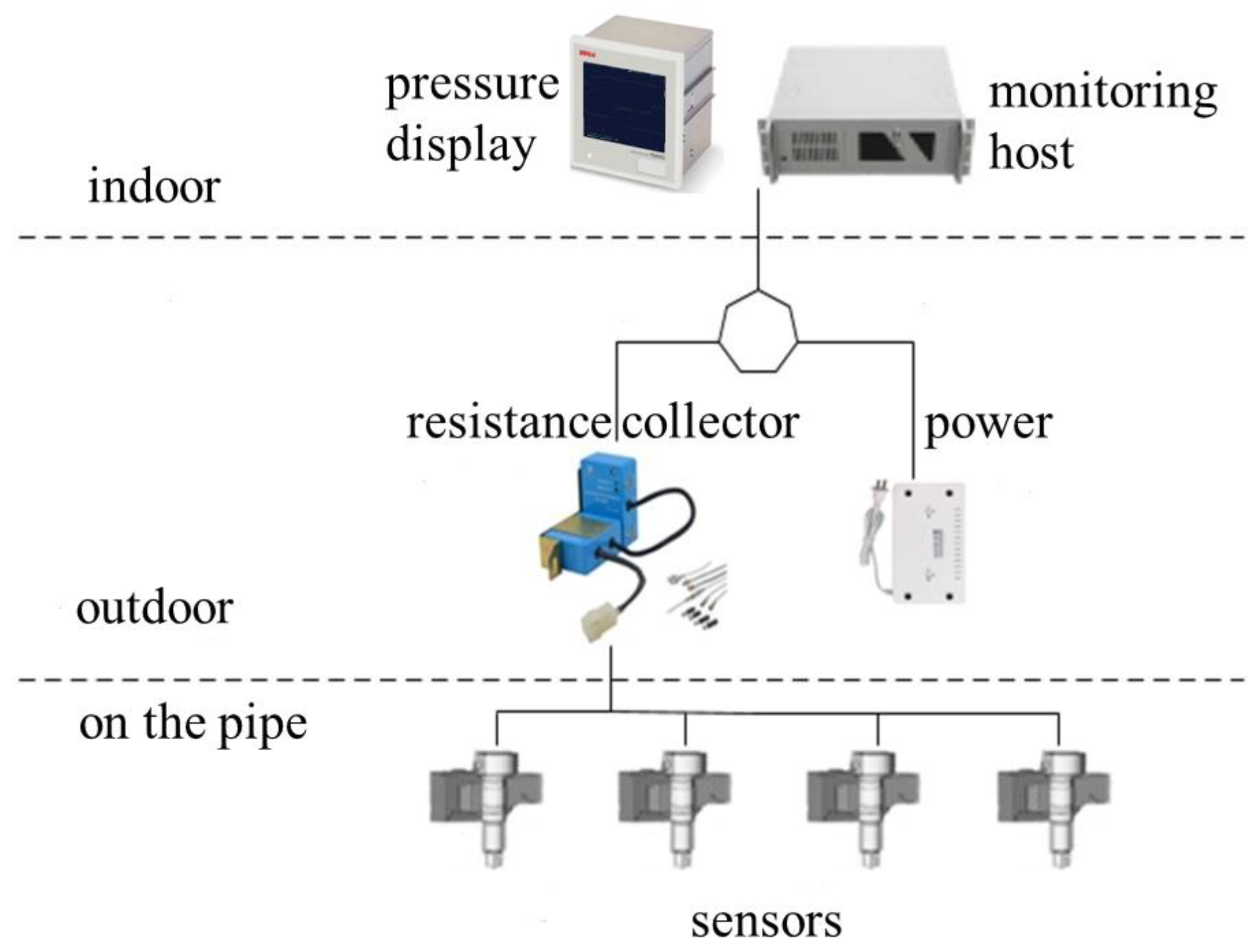

3.2. Design of an Automated Pipe Jacking Friction Resistance Identification and Warning System

3.3. Construction Methods with a Resistance Identification and Warning System

- (1)

- The installation of resistance sensors on the outer wall of the jacking pipe according to the designated positions, and their connection, with data cables, power cables, a monitoring host, and their display.

- (2)

- Near the tunnel entrance, removal of the steel sheet piles when the jacking machine is 200 mm away from the tunnel entrance wall, and quick advance of the tunneling machine into the working face.

- (3)

- Completion of the following steps: installation of guide rails—installation of infrared alignment devices—installation of reinforced backrest—fixing of jack feet and installation of jacks—connection of hydraulic cylinders—hoisting of the tunneling machine as well as pipe sections—hoisting of the crown plate—pipe jacking and other related procedures.

- (4)

- Performance of actions to ensure pressure grouting and displacement of the variable slurry. Determination of the slurry ratio based on the initial plan and determination of the grouting pressure based on the depth of the pipeline and the groundwater level.

- (5)

- The total grouting volume should not be less than 2% of the volume of the annular space outside the pipe. To consider slurry losses, continuous grouting must be performed regularly to ensure the integrity of the slurry jacket.

- (6)

- Monitor the jacking process, including preliminary, jacking, and completion measurements. Measurements must be taken every 50 cm of jacking, with frequent adjustments. The correction angle should be kept within 10’ to 20’, not exceeding 1°. Measurements should be promptly recorded and submitted for review at the end of each pipe jacking section.

- (7)

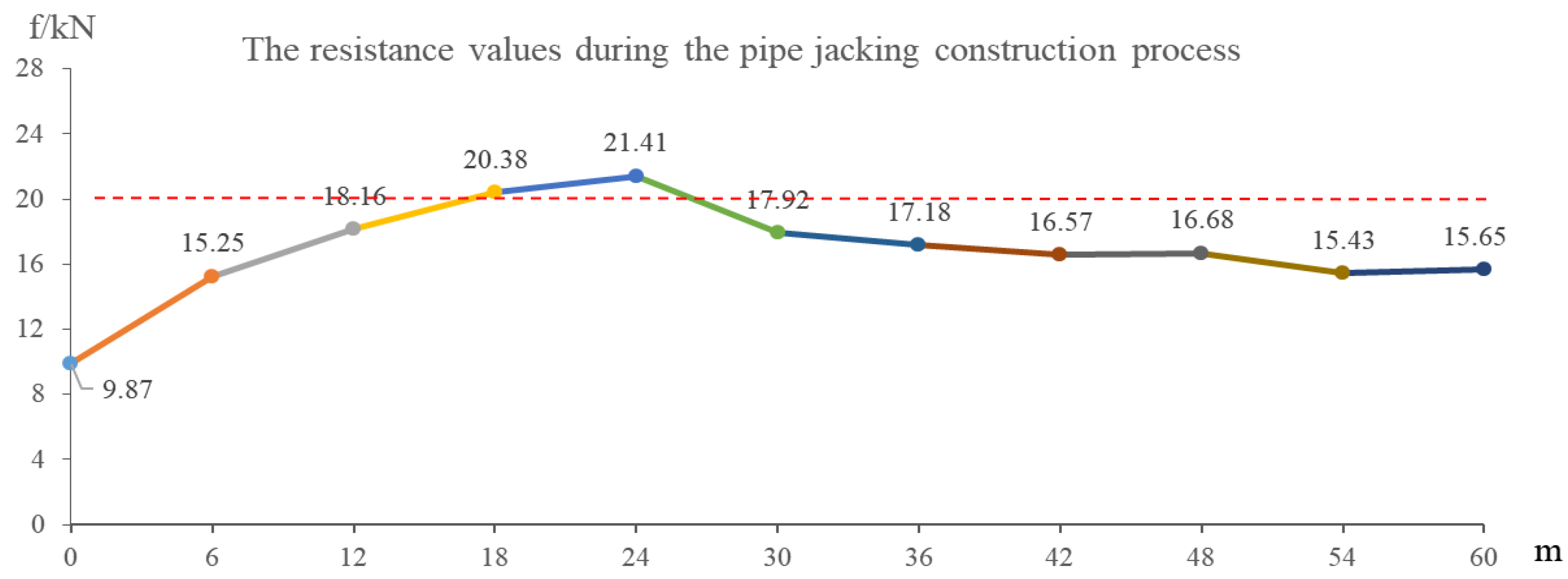

- Identification and control of jacking resistance. Sensors in the jacking process automatically identify the jacking resistance. The pressure sensor automatically detects pressure during pipe jacking construction. According to formula (4), the frictional resistance during the jacking process is calculated, resulting in the actual resistance value. When the resistance value exceeds the pre-alarm threshold, the system automatically triggers an alarm, reminding construction personnel to adjust the resistance by improving the variable slurry. At this point, soil condition analysis at the construction site is required to optimize the slurry ratio and modify it, accordingly, reducing frictional resistance to achieve smooth jacking.

4. Engineering Case

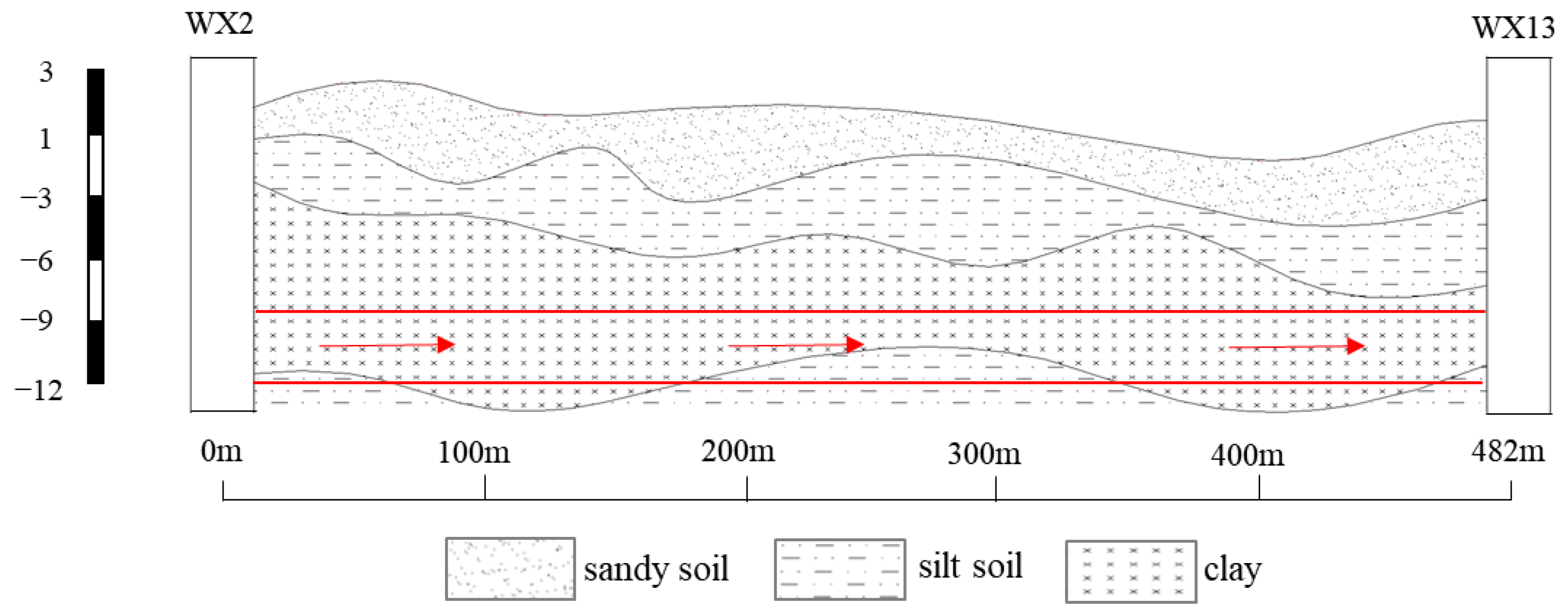

4.1. Project Background and Geological Conditions

4.2. Materials and Equipment

4.3. Calculation of Frictional Resistance and Grouting Adjustment

5. Conclusions

- (1)

- Sensor placement is strategically determined by analyzing the stress patterns in the soil surrounding the pipe jacking.

- (2)

- The foundational structure of the resistance identification and warning system is constructed.

- (3)

- The control process for the resistance warning is provided.

- (4)

- A construction approach during pipe jacking is presented, which integrates with the resistance identification and warning system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Namli, M.; Guler, E. Effect of Bentonite Slurry Pressure on Interface Friction of Pipe Jacking. J. Pipeline Syst. Eng. Pract. 2017, 8, 04016016. [Google Scholar] [CrossRef]

- Ji, X.; Ni, P.; Barla, M. Analysis of jacking forces during pipe jacking in granular materials using particle methods. Undergr. Space 2019, 4, 277–288. [Google Scholar] [CrossRef]

- Ji, X.; Zhao, W.; Ni, P.; Barla, M.; Han, J.; Jia, P.; Chen, Y.; Zhang, C. A method to estimate the jacking force for pipe jacking in sandy soils. Tunn. Undergr. Space Technol. 2019, 90, 119–130. [Google Scholar] [CrossRef]

- Wen, K.; Shimada, H.; Zeng, W.; Sasaoka, T.; Qian, D. Frictional analysis of pipe-slurry-soil interaction and jacking force prediction of rectangular pipe jacking. Eur. J. Environ. Civ. Eng. 2020, 24, 814–832. [Google Scholar] [CrossRef]

- Liu, J.; Wang, X.; Cheng, H.; Fan, H. Orthogonal Design and Microstructure Mechanism Analysis of Novel Bentonite Polymer Slurry in Pipe Jacking. Polymers 2023, 15, 1461. [Google Scholar] [CrossRef]

- Zeng, C.; Xiao, A.; Liu, K.; Ai, H.; Chen, Z.; Zhang, P. Experimental Study on the Influence of Slurry Concentration and Standing Time on the Friction Characteristics of a Steel Pipe-Soil Interface. Appl. Sci. 2022, 12, 3576. [Google Scholar] [CrossRef]

- Ma, P.; Shimada, H.; Sasaoka, T.; Hamanaka, A.; Moses, D.N.; Dintwe, T.K.M.; Matsumoto, F.; Ma, B.; Huang, S. A new method for predicting the friction resistance in rectangular pipe-jacking. Tunn. Undergr. Space Technol. 2022, 123, 104338. [Google Scholar] [CrossRef]

- Liu, K.; Xiao, A.; Zhang, P.; Zhou, H.; Chen, Z.; Xu, T.; Ma, B.; Ai, H.; Wang, Q. Study on mechanical response of steel pipe jacking considering the effect of pipe sticking. Tunn. Undergr. Space Technol. 2022, 127, 104617. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, B.; Zhang, X.; Fan, D.; Wang, H.; Yu, M. Formulation optimization and performance analysis of the thixotropic slurry for large-section rectangular pipe jacking in anhydrous sand. Constr. Build. Mater. 2022, 357, 129380. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, D.; Fang, Q.; Liu, X.; Wang, J. Analytical Solution on Ground Deformation Caused by Parallel Construction of Rectangular Pipe Jacking. Appl. Sci. 2022, 12, 3298. [Google Scholar] [CrossRef]

- Roussel, N. A thixotropy model for fresh fluid concretes: Theory, validation and applications. Cem. Concr. Res. 2006, 36, 1797–1806. [Google Scholar] [CrossRef]

- Mahaut, F.; Mokeddem, S.; Chateau, X.; Roussel, N.; Ovarlez, G. Effect of coarse particle volume fraction on the yield stress and thixotropy of cementitious materials. Cem. Concr. Res. 2008, 38, 1276–1285. [Google Scholar] [CrossRef]

- Cheng, W.-C.; Wang, L.; Xue, Z.-F.; Ni, J.C.; Rahman, M.M.; Arulrajah, A. Lubrication performance of pipejacking in soft alluvial deposits. Tunn. Undergr. Space Technol. 2019, 91, 102991. [Google Scholar] [CrossRef]

- Zhang, P.; Behbahani, S.S.; Ma, B.; Iseley, T.; Tan, L. A jacking force study of curved steel pipe roof in Gongbei tunnel: Calculation review and monitoring data analysis. Tunn. Undergr. Space Technol. 2018, 72, 305–322. [Google Scholar] [CrossRef]

- Ji, X.; Ni, P.; Barla, M.; Zhao, W.; Mei, G. Earth pressure on shield excavation face for pipe jacking considering arching effect. Tunn. Undergr. Space Technol. 2018, 72, 17–27. [Google Scholar] [CrossRef]

- Li, C.; Zhong, Z.; Liu, X.; Tu, Y.; He, G. Numerical simulation for an estimation of the jacking force of ultra-long-distance pipe jacking with frictional property testing at the rock mass-pipe interface. Tunn. Undergr. Space Technol. 2019, 89, 205–221. [Google Scholar] [CrossRef]

- Zhang, P.; Feng, X.; Zeng, C.; Ariaratnam, S.T. Field performance of steel pipes during curve jacking in Gongbei tunnel. Tunn. Undergr. Space Technol. 2022, 128, 104585. [Google Scholar] [CrossRef]

- Chen, P.; Liu, X.; Deng, Z.; Liang, N.; Du, L.; Du, H.; Huang, Y.; Deng, L.; Yang, G. Study on the pipe friction resistance in long-distance rock pipe jacking engineering. Undergr. Space 2023, 9, 173–185. [Google Scholar] [CrossRef]

- Liu, J.; Cheng, H.; Cai, H.; Wang, X. Design and Analysis of Grouting Pressure in Slurry Pipe Jacking Based on the Surrounding Soil Stability Mechanical Characteristics. Geofluids 2022, 2022, 4697730. [Google Scholar] [CrossRef]

- Guo, W.; Hong, K.; Gao, P.; Li, F.; Li, S.; Zhao, X. Status Quo and Prospects of Tunnel Intelligent Construction in China. Tunn. Constr. 2023, 43, 549–562. [Google Scholar]

- Du, J.; Zhang, J.; Hu, M.; Gan, L. Literature Review on Human Factors involved in Intelligent Shield Construction. Tunn. Constr. 2023, 8, 1269–1281. [Google Scholar]

- Chen, X.; Fu, Y.; Chen, X.; Xiao, H.; Bao, X.; Pang, X.; Wang, X. Progress in Underground Space Construction Technology and Technical Challenges of Diguital Intelligence. China J. Highw. Transp. 2022, 35, 1–12. [Google Scholar]

- Ye, Y.; Peng, L.; Zhou, Y.; Yang, W.; Shi, C.; Lin, Y. Prediction of Friction Resistance for Slurry Pipe Jacking. Appl. Sci. 2020, 10, 207. [Google Scholar] [CrossRef]

- Ye, Y.; Peng, L.; Yang, W.; Zou, Y.; Cao, C. Calculation of Friction Force for Slurry Pipe Jacking considering Soil-Slurry-Pipe Interaction. Adv. Civ. Eng. 2020, 2020, 6594306. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, Y.; Yuan, X.; Zhang, P. An Experimental Study on Frictional Properties of Concrete Pipe-Soil Interface. J. Pipeline Syst. Eng. Pract. 2022, 13, 04022004. [Google Scholar] [CrossRef]

- Cui, G.-J.; Xie, J.-S.; Sun, Y.-H.; Gao, Y.-J. Analysis and Prediction of the Factors Influencing Postconstruction Surface Deformation of Pipe-Jacking Tunnel in Soft Clay Strata in China. Adv. Civ. Eng. 2023, 2023, 6474415. [Google Scholar] [CrossRef]

- Wang, J.; Wang, K.; Zhang, T.; Wang, S. Key aspects of a DN4000 steel pipe jacking project in China: A case study of a water pipeline in the Shanghai Huangpu River. Tunn. Undergr. Space Technol. 2018, 72, 323–332. [Google Scholar] [CrossRef]

- Deng, Z.; Liu, X.; Zhou, X.; Yang, Q.; Chen, P.; de la Fuente, A.; Ren, L.; Du, L.; Han, Y.; Xiong, F.; et al. Main engineering problems and countermeasures in ultra-long-distance rock pipe jacking project: Water pipeline case study in Chongqing. Tunn. Undergr. Space Technol. 2022, 123, 104420. [Google Scholar] [CrossRef]

- Peerun, M.I.; Ong, D.E.L.; Desha, C. A strategic review on enhanced DEM simulation and advanced 3-D particle printing techniques to improve pipe-jacking force prediction. Tunn. Undergr. Space Technol. 2022, 123, 104415. [Google Scholar] [CrossRef]

- Ciavarella, M.; Decuzzi, P. The state of stress induced by the plane frictionless cylindrical contact. II. The general case (elastic dissimilarity). Int. J. Solids Struct. 2001, 38, 4525–4533. [Google Scholar] [CrossRef]

- Ciavarella, M.; Decuzzi, P. The state of stress induced by the plane frictionless cylindrical contact. I. The case of elastic similarity. Int. J. Solids Struct. 2001, 38, 4507–4523. [Google Scholar] [CrossRef]

- Zhang, P.; Ma, B.-S.; Zeng, C.; Tan, L.-X. Numerical model for jacking force based on pipe-soil contact characteristics. Chin. J. Geotech. Eng. 2017, 39, 244–249. [Google Scholar]

- Zhou, H.; Huang, S.; Zhang, P.; Ma, B.; Ma, P.; Feng, X. Prediction of jacking force using PSO-BPNN and PSO-SVR algorithm in curved pipe roof. Tunn. Undergr. Space Technol. 2023, 138, 105159. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, W.; Wang, H.; Chen, Y.; Bai, Q.; Li, S. Analysis of the influence of geometrical parameters of circular steel pipe with flange plate on the jacking force. Undergr. Space 2022, 7, 324–336. [Google Scholar] [CrossRef]

- Wu, S.; Li, X.; Jiang, P.; Xu, H.; Min, F. Dewatering characteristics of waste slurry from pipe jacking based on improved vacuum filtration method. Tunn. Undergr. Space Technol. 2022, 130, 104727. [Google Scholar] [CrossRef]

- Westgate, Z.J.; White, D.J.; Randolph, M.F. Field observations of as-laid pipeline embedment in carbonate sediments. Géotechnique 2012, 62, 787–798. [Google Scholar] [CrossRef]

| Soil | Natural Unit Weight (Kn·m−3) | Cohesion (kPa) | Internal Friction Angle (°) |

|---|---|---|---|

| Clay | 20.1 | 45.6 | 18.52 |

| Sandy soil | 19.3 | 4 | 17.15 |

| Silty soil | 19.4 | 21.1 | 18.32 |

| No. | Quantity | Equipment Name | Model and Specifications | Construction Location |

|---|---|---|---|---|

| 1 | 4 | Resistance Sensor | High-strength steel | Pipe Jacking |

| 2 | 1 | Resistance Collector | Pipe Jacking | |

| 3 | 1 | Grouting Pipe | Outlet diameter 50 mm | Grouting |

| 4 | 1 | Grout Buffer Tank | 50 L capacity | Grouting |

| 5 | 1 | Resistance Display | Control Console | |

| 6 | 1 | Monitoring Host | Control Console | |

| 7 | 1 | Slurry Balance Pipe Jacking Machine | NPD1000 | Pipe Jacking |

| 8 | 1 | Spiral Grouting Machine | Grouting | |

| 9 | 1 | Wheeled Crane | 25 T | Pipe Jacking |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, L.-H.; Wu, B.-J.; Zheng, X.-Z.; Chen, S. Development and Field Application of an Automated Pipe Jacking Friction Resistance Identification and Warning System in Construction. Appl. Sci. 2023, 13, 12814. https://doi.org/10.3390/app132312814

Jin L-H, Wu B-J, Zheng X-Z, Chen S. Development and Field Application of an Automated Pipe Jacking Friction Resistance Identification and Warning System in Construction. Applied Sciences. 2023; 13(23):12814. https://doi.org/10.3390/app132312814

Chicago/Turabian StyleJin, Liang-Hai, Bang-Jie Wu, Xia-Zhong Zheng, and Shu Chen. 2023. "Development and Field Application of an Automated Pipe Jacking Friction Resistance Identification and Warning System in Construction" Applied Sciences 13, no. 23: 12814. https://doi.org/10.3390/app132312814

APA StyleJin, L.-H., Wu, B.-J., Zheng, X.-Z., & Chen, S. (2023). Development and Field Application of an Automated Pipe Jacking Friction Resistance Identification and Warning System in Construction. Applied Sciences, 13(23), 12814. https://doi.org/10.3390/app132312814