Development of Effective Infrared Reflective Coatings

Abstract

:Featured Application

Abstract

1. Introduction

| General Description | Materials in the Coating | References |

|---|---|---|

| Metals | Aluminum, aluminum foil, metallized thin films | [13,14,15] |

| Metal oxides | TiO2, ZnO, CuO | [16,17] |

| Inorganic pigments | Fe2O3, Cr2O3 ZnS, Sb2O3, ZrO2, SrCuSi4O10, Nd2Si2O7, BiVO4 Cr2O3, BiFeO3, Ce4Si3S12 | [18] |

| Composites: oxide-metal oxide | TiO2/Ag/TiO2, ZnS/Ag/ZnS | [19] |

| Single layers and stacked polar dielectrics | SiC, GaN | [20] |

| Single and multilayers | Ag doped hafnium nitride | [21,22] |

| Small spheres | glass, glitter, crystals | [16,22,23,24,25] |

- Phase-change materials: some materials, when they change their phase from liquid to solid, absorb or release heat, regulate temperature, and reduce energy consumption in a building. Though the final effect of these materials and infrared reflective coatings are similar, the mechanisms for how they act and where they can be used are different. The application of an infrared reflective coating is more extensive [46,47].

- Two-layer system: this is the more often used technique; a top coat with infrared transparency contains the proper pigment and is deposited onto a primer. The sun’s radiation influences first the upper layer [49].

- Multilayer structure: multiple layers with different refractive properties are deposited onto each other. The interference effect between the layers increases their reflective properties. It is important to take into consideration not only the chemical properties but also the thickness of each layer [50].

2. Materials and Methods

2.1. Composition of the Paints

2.2. Characterization of Coatings with Infrared Transparent Pigments

3. Results and Discussions

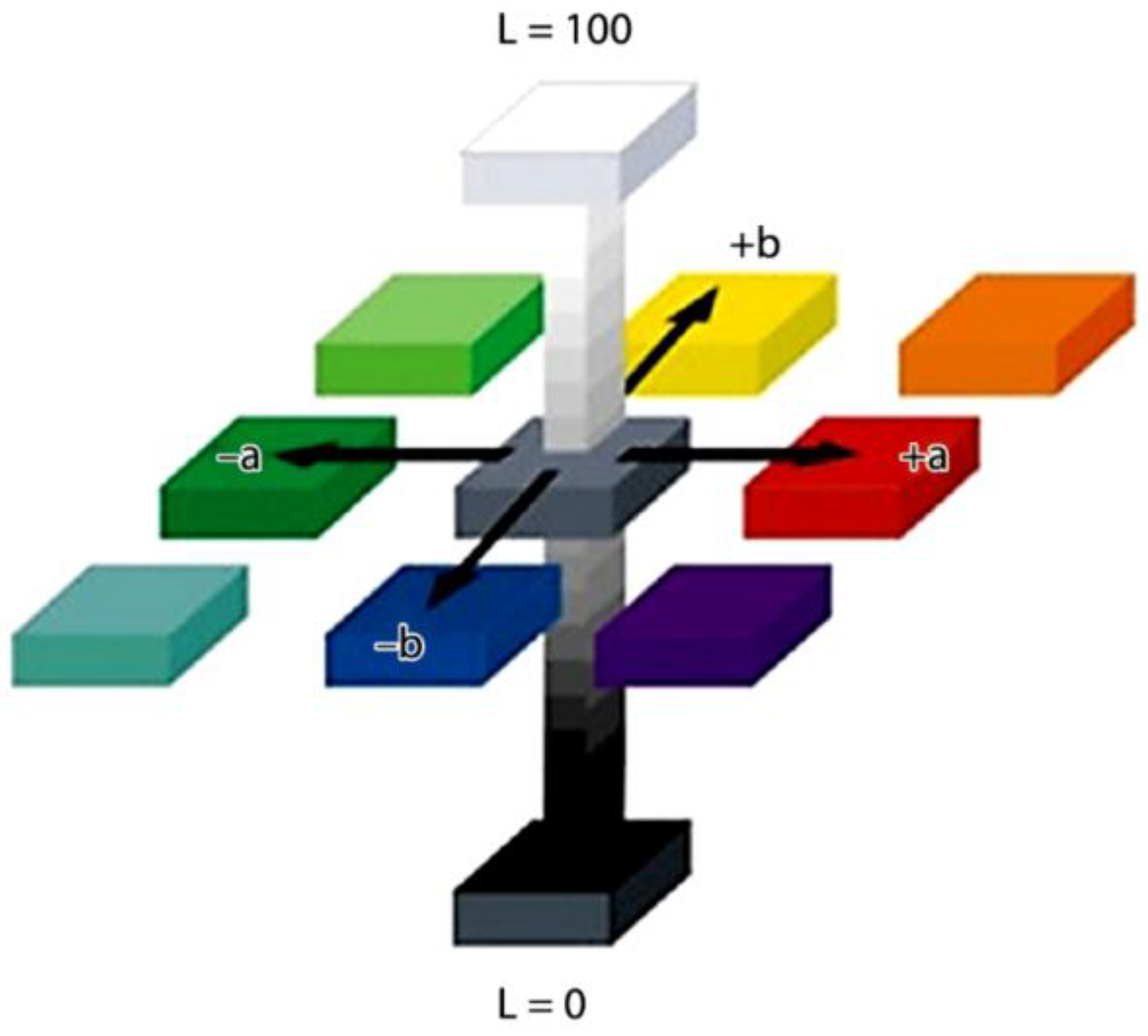

3.1. Chromatic Parameters

3.2. Reflection Behavior of Coatings

3.3. Total Solar Reflectance (TSR) and Infrared Solar Reflectance (IR-SR) Parameters

3.4. Evaluation of Heat Reflection

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bradbury, S.; Evennett, P. Absorption, transmission and reflection of light by the specimen. In Contrast Techniques in Light Microscopy; Chapter 2; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2019; ISBN 978-1-85996-085-1. [Google Scholar]

- Liu, L.; Han, A.; Ye, M.; Feng, W. The Evaluation of Thermal Performance of Cool Coatings Colored with High Near-Infrared Reflective Nano-Brown Inorganic Pigments: Magnesium Doped ZnFe2O4 Compounds. Sol. Energy 2015, 113, 48–56. [Google Scholar] [CrossRef]

- Kaur, B.; Quazi, N.; Ivanov, I.; Bhattacharya, S.N. Near-Infrared Reflective Properties of Perylene Derivatives. Dye. Pigment. 2012, 92, 1108–1113. [Google Scholar] [CrossRef]

- Kolås, T.; Røyset, A.; Grandcolas, M.; Cate, M.T.; Lacau, A. Cool Coatings with High near Infrared Transmittance for Coil Coated Aluminium. Sol. Energy Mater. Sol. Cells 2019, 196, 94–104. [Google Scholar] [CrossRef]

- Jazaeri, J.; Gordon, R.L.; Alpcan, T. Influence of Building Envelopes, Climates, and Occupancy Patterns on Residential HVAC Demand. J. Build. Eng. 2019, 22, 33–47. [Google Scholar] [CrossRef]

- Levinson, R.; Akbari, H.; Berdahl, P. Measuring Solar Reflectance—Part I: Defining a Metric That Accurately Predicts Solar Heat Gain. Sol. Energy 2010, 84, 1717–1744. [Google Scholar] [CrossRef]

- Zinzi, M.; Carnielo, E.; Agnoli, S. Characterization and Assessment of Cool Coloured Solar Protection Devices for Mediterranean Residential Buildings Application. Energy Build. 2012, 50, 111–119. [Google Scholar] [CrossRef]

- Jose, S.; Joshy, D.; Narendranath, S.B.; Periyat, P. Recent Advances in Infrared Reflective Inorganic Pigments. Sol. Energy Mater. Sol. Cells 2019, 194, 7–27. [Google Scholar] [CrossRef]

- Eastaugh, N. (Ed.) The Pigment Compendium: A Dictionary of Historical Pigments; Elsevier Butterworth-Heinemann: Amsterdam, The Netherlands; Boston, MA, USA, 2004. [Google Scholar]

- Orna, M. Historic Mineral Pigments: Colorful Benchmarks of Ancient Civilizations. In Chemical Technology in Antiquity; American Chemical Society: Washington, DC, USA, 2015; pp. 17–69. [Google Scholar] [CrossRef]

- Hund, F. Inorganic Pigments: Bases for Colored, Uncolored, and Transparent Products. Angew. Chem. Int. Ed. Engl. 1981, 20, 723–730. [Google Scholar] [CrossRef]

- Levinson, R.; Berdahl, P.; Akbari, H.; Miller, W.; Joedicke, I.; Reilly, J.; Suzuki, Y.; Vondran, M. Methods of Creating Solar-Reflective Nonwhite Surfaces and Their Application to Residential Roofing Materials. Sol. Energy Mater. Sol. Cells 2007, 91, 304–314. [Google Scholar] [CrossRef]

- Pásztory, Z.; Horváth, T.; Glass, S.V.; Zelinka, S. Experimental investigation of the influence of temperature on thermal conductivity of multilayer reflective thermal insulation. Energy Build. 2018, 174, 26–30. [Google Scholar] [CrossRef]

- Mårdalen, J.; Lein, J.E.; Bolm, H.; Hallenstvet, M.; Rekowski, V. Time and cost effective methods for testing chemical resistance of aluminium metallic pigmented powder coatings. Prog. Org. Coat. 2008, 63, 49–54. [Google Scholar] [CrossRef]

- Malewska, E.; Prociak, A.; Vevere, L.; Vanags, E.; Zemła, M.; Uram, K.; Kirpluks, M.; Cabulis, U.; Bryk, M. New Thermo-Reflective Coatings for Applications as a Layer of Heat Insulating Materials. Materials 2022, 15, 5642. [Google Scholar] [CrossRef] [PubMed]

- Lu, D.; Gao, Q.; Wu, X.; Fan, Y. ZnO Nanostructures Decorated Hollow Glass Microspheres as near Infrared Reflective Pigment. Ceram. Int. 2017, 43, 9164–9170. [Google Scholar] [CrossRef]

- You, Z.; Zhang, M.; Wang, J.; Pei, W.; Li, G. Experimental Study of Optical and Cooling Performances of CuO and TiO2 Near-Infrared Reflective Blending Coatings. Sol. Energy 2021, 225, 19–32. [Google Scholar] [CrossRef]

- Bendiganavale, A.; Malshe, V. Infrared Reflective Inorganic Pigments. Recent Pat. Chem. Eng. 2010, 1, 67–79. [Google Scholar] [CrossRef]

- Woo, H.K.; Zhou, K.; Kim, S.-K.; Manjarrez, A.; Hoque, M.J.; Seong, T.-Y.; Cai, L. Visibly Transparent and Infrared Reflective Coatings for Personal Thermal Management and Thermal Camouflage. Adv. Funct. Mater. 2022, 32, 2201432. [Google Scholar] [CrossRef]

- Hou, C.-C.; Chen, H.-M.; Zhang, J.-C.; Zhuo, N.; Huang, Y.-Q.; Hogg, R.A.; Childs, D.T.; Ning, J.-Q.; Wang, Z.-G.; Liu, F.-Q.; et al. Near-Infrared and Mid-Infrared Semiconductor Broadband Light Emitters. Light Sci. Appl. 2018, 7, 17170. [Google Scholar] [CrossRef]

- Hu, C.; Guo, K.; Li, Y.; Gu, Z.; Quan, J.; Zhang, S.; Zheng, W. Optical coatings of durability based on transition metal nitrides. Thin Solid Films 2019, 688, 137339. [Google Scholar] [CrossRef]

- Mishra, S.; Kumar, V.; Tiwari, S.; Mishra, T.; Angula, G.; Adhikari, S. Development and degradation behavior of protective multilayer coatings for aluminum reflectors for solar thermal applications. Thin Solid Films 2016, 619, 202–207. [Google Scholar] [CrossRef]

- Shi, Y.; Zhong, M.; Zhang, Z.; Wang, D. Crystal Structure and Near-Infrared Reflective Properties of Fe3+ Doped AlPO4 Pigments. Ceram. Int. 2017, 43, 5979–5983. [Google Scholar] [CrossRef]

- Gao, Q.; Wu, X.; Fan, Y.; Meng, Q. Novel near Infrared Reflective Pigments Based on Hollow Glass Microsphere/BiOCl1-xIx Composites: Optical Property and Superhydrophobicity. Sol. Energy Mater. Sol. Cells 2018, 180, 138–147. [Google Scholar] [CrossRef]

- Zheng, Q.; Xiong, S.; Wu, X.; Kuang, J.; Liu, W.; Cao, W. Near Infrared Reflection and Hydrophobic Properties of Composite Coatings Prepared from Hollow Glass Microspheres Coated with Needle-Shaped Rutile Shell. Materials 2022, 15, 8310. [Google Scholar] [CrossRef] [PubMed]

- Rosati, A.; Fedel, M.; Rossi, S. NIR Reflective Pigments for Cool Roof Applications: A Comprehensive Review. J. Clean. Prod. 2021, 313, 127826. [Google Scholar] [CrossRef]

- Mastai, Y.; Diamant, Y.; Aruna, S.; Zaban, A. TiO2 Nanocrystalline Pigmented Polyethylene Foils for Radiative Cooling Applications: Synthesis and Characterization. Langmuir 2001, 17, 7118–7123. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, J. Effect of Titanium Dioxide (TiO2) on Largely Improving Solar Reflectance and Cooling Property of High Density Polyethylene (HDPE) by Influencing Its Crystallization Behavior. J. Alloys Compd. 2014, 617, 163–169. [Google Scholar] [CrossRef]

- Yuan, L.; Han, A.; Ye, M.; Chen, X.; Ding, C.; Yao, L. Synthesis and Characterization of Novel Nontoxic BiFe1−xAlxO3/Mica-Titania Pigments with High NIR Reflectance. Ceram. Int. 2017, 43, 16488–16494. [Google Scholar] [CrossRef]

- Zou, J.; Zheng, W. TiO2@CoTiO3 Complex Green Pigments with Low Cobalt Content and Tunable Color Properties. Ceram. Int. 2016, 42, 8198–8205. [Google Scholar] [CrossRef]

- Kiomarsipour, N.; Razavi, R.; Ghani, K.; Kioumarsipour, M. Evaluation of Shape and Size Effects on Optical Properties of ZnO Pigment. Appl. Surf. Sci. 2013, 270, 33–38. [Google Scholar] [CrossRef]

- Yuan, W.; Lu, Z.; Li, C.M. Self-assembling microsized materials to fabricate multifunctional hierarchical nanostructures on macroscale substrates. J. Mater. Chem. A 2013, 1, 6416–6424. [Google Scholar] [CrossRef]

- Kumari, L.S.; Rao, P.P.; Radhakrishnan, A.N.P.; James, V.; Sameera, S.; Koshy, P. Brilliant Yellow Color and Enhanced NIR Reflectance of Monoclinic BiVO4 through Distortion in VO43− Tetrahedra. Sol. Energy Mater. Sol. Cells 2013, 112, 134–143. [Google Scholar] [CrossRef]

- Xiao, J.; Pan, Z.; Zhang, T.; Lu, Y.; Wang, Y. Preparation of High Near-Infrared Reflectance Mica/(Ni, Sb)-Co-Doped Rutile Yellow Composite Pigment via Mechanochemical Pretreatment and Sintering. Ceram. Int. 2023, 49, 6015–6029. [Google Scholar] [CrossRef]

- Meenakshi, P.; Selvaraj, M. Bismuth Titanate as an Infrared Reflective Pigment for Cool Roof Coating. Sol. Energy Mater. Sol. Cells 2018, 174, 530–537. [Google Scholar] [CrossRef]

- Radhika, S.P.; Sreeram, K.J.; Nair, B.U. Rare Earth Doped Cobalt Aluminate Blue as an Environmentally Benign Colorant. J. Adv. Ceram. 2012, 1, 301–309. [Google Scholar] [CrossRef]

- Jose, S.; Jayaprakash, A.; Laha, S.; Natarajan, S.; Nishanth, K.G.; Reddy, M.L.P. YIn0.9Mn0.1O3–ZnO Nano-Pigment Exhibiting Intense Blue Color with Impressive Solar Reflectance. Dye. Pigment. 2016, 124, 120–129. [Google Scholar] [CrossRef]

- Levinson, R.; Berdahl, P.; Akbari, H. Solar Spectral Optical Properties of Pigments—Part II: Survey of Common Colorants. Sol. Energy Mater. Sol. Cells 2005, 89, 351–389. [Google Scholar] [CrossRef]

- De Oliveira Primo, J.; Borth, K.W.; Peron, D.C.; de Carvalho Teixeira, V.; Galante, D.; Bittencourt, C.; Anaissi, F.J. Synthesis of green cool pigments (CoxZn1−xO) for application in NIR radiation reflectance. J. Alloys Compd. 2019, 780, 17–24. [Google Scholar] [CrossRef]

- Sabbagh Alvani, H.R.; Sameie, A.A.; Salimi, H.; Salimi, R.; Moosakhani, S.; Tabatabaee, F.; Zarandi, A.A. Synthesis and characterization of Co1−xZnxCr2−yAlyO4 as a near-infrared reflective color tunable nano-pigment. Dye. Pigment. 2015, 113, 588–595. [Google Scholar] [CrossRef]

- Ding, C.; Han, A.; Ye, M.; Zhang, Y.; Yao, L.; Yang, J. Synthesis and characterization of a series of new green solar heat-reflective pigments: Cr-doped BiPO4 and its effect on the aging resistance of PMMA. Sol. Energy Mater. Sol. Cells 2019, 191, 427–436. [Google Scholar] [CrossRef]

- Jelle, B.P.; Kalnæs, S.E.; Gao, T. Low-emissivity materials for building applications: A state-of-the-art review and future research perspectives. Energy Build. 2015, 96, 329–356. [Google Scholar] [CrossRef]

- Schaefer, C.; Bräuer, G.; Szczyrbowski, J. Low emissivity coatings on architectural glass. Surf. Coat. Technol. 1997, 93, 37–45. [Google Scholar] [CrossRef]

- Karlessi, T.; Santamouris, M.; Apostolakis, K.; Synnefa, A.; Livada, I. Development and testing of thermochromic coatings for buildings and urban structures. Sol. Energy 2009, 83, 538–551. [Google Scholar] [CrossRef]

- Santamouris, M. Mitigating the Local Climatic Change and Fighting Urban Vulnerability. In Minimizing Energy Consumption, Energy Poverty and Global and Local Climate Change in the Built Environment: Innovating to Zero; Chapter 8; Elsevier: Amsterdam, The Netherlands, 2019; pp. 223–307. [Google Scholar] [CrossRef]

- Lyu, X.; Heßler, A.; Wang, X.; Cao, Y.; Song, L.; Ludwig, A.; Wuttig, M.; Taubner, T. Combining Switchable Phase-Change Materials and Phase-Transition Materials for Thermally Regulated Smart Mid-Infrared Modulators. Adv. Opt. Mater. 2021, 9, 2100417. [Google Scholar] [CrossRef]

- Guo, R.; Shan, L.; Wu, Y.; Cai, Y.; Huang, R.; Ma, H.; Tang, K.; Liu, K. Phase-change materials for intelligent temperature regulation. Mater. Today Energy 2022, 23, 100888. [Google Scholar] [CrossRef]

- Coser, E.; Moritz, V.F.; Krenzinger, A.; Ferreira, C.A. Development of paints with infrared radiation reflective properties. Polímeros 2015, 25, 305–310. [Google Scholar] [CrossRef]

- Xu, S.H.; Huang, J.Y.; Fei, G.T.; Wei, Y.S.; Yuan, L.G.; Wang, B.; Gao, X.D. Preparation of double-layer two wavelength infrared antireflective coating on CdSe substrate. Colloids Surf. A Physicochem. Eng. Asp. 2021, 628, 127329. [Google Scholar] [CrossRef]

- Valiei, M.; Shaibani, P.M.; Abdizadeh, H.; Kolahdouz, M.; Soleimani, E.A.; Poursafar, J. Design and optimization of single, double and multilayer anti-reflection coatings on planar and textured surface of silicon solar cells. Mater. Today Commun. 2022, 32, 104144. [Google Scholar] [CrossRef]

- ASTM G173-03; Standard Tables for Reference Solar Spectral Irradiances: Direct Normal and Hemispherical on 37 Degree Tilted Surface. ASTM International: West Conshohocken, PA, USA, 2012.

| Name of the Coating | Short Name of Coatings | Pigment | Concentration of Pigments in Coatings | Characteristics of the Coating |

|---|---|---|---|---|

| Metallux Aqua 2k SZ RAL7016 L95/CR28 | L95/CR28 |

| 20% | infrared reflective covering coating |

| Metallux Aqua 2k SZ RAL7016 S84/CR28 | S84/CR28 |

| 17% | infrared transparent covering coating |

| Metallux Aqua 2k SZ RAL7016 S84/CR28Lacquer | S84/CR28/Lacquer |

| 6% | infrared transparent coating with optimal pigment concentration |

| Metallux Aqua 2k SZ RAL7016 TR RU/ZD | TR RU/ZD |

| 20% | infrared transparent opaque coating |

| Metallux Aqua 2k SZ RAL7016 PS/ZD | PS/ZD |

| 21% | infrared transparent opaque covering coating |

| Metallux Aqua 2k SZ RAL7016 S84/A80 | S84/A80 |

| 10% | infrared transparent opaque coating |

| Metallux Aqua 2k SZ RAL7016 | Traditional |

| 19% | Generally used in the paint industry, not infrared reflective |

| Measured ∆E* | Visual Observation |

|---|---|

| ∆E* < 1.5 | not observable |

| 1.5 < ∆E* < 3 | observable |

| 3 < ∆E* < 6 | well observable |

| 6 < ∆E* | significant |

| Short Name of Coating | Substrate | ΔE* | Δa* | Δb* | ΔL* | Brightness [%] |

|---|---|---|---|---|---|---|

| Traditional | white | 0.560 | 0.440 | 0.270 | −0.230 | 84,990 |

| black | 0.500 | 0.400 | 0.290 | −0.080 | 84,750 | |

| L95/CR28 | white | 1.300 | 1.050 | 0.020 | −0.760 | 84,750 |

| black | 1.420 | 1.100 | 0.020 | −0.900 | 84,090 | |

| S84/CR28 | white | 0.750 | −0.340 | −0.350 | −0.570 | 49,810 |

| black | 0.880 | −0.410 | −0.360 | −0.690 | 67,760 | |

| TR RU/ZD | white | 1.580 | −1.260 | 0.110 | 0.940 | 88,190 |

| black | 1.320 | −1.180 | 0.070 | 0.590 | 89,960 | |

| S84/CR28/Lacquer | white | 1.940 | 0.000 | 0.290 | −1.920 | 89,270 |

| black | 2.010 | −0.270 | 0.210 | −1.980 | 89,230 | |

| PS/ZD | white | 2.150 | −0.180 | −1.990 | −0.810 | 89,520 |

| black | 2.110 | −0.160 | −1.980 | −0.700 | 88,450 | |

| S84/A80 | white | 2.530 | −0.410 | −0.390 | −2.470 | 89,210 |

| black | 2.660 | −0.480 | −0.370 | −2.590 | 89,350 |

| Short Name of Coating | Substrate | Reflection Values Measured at Different Wavelengths [nm] | ||||||

|---|---|---|---|---|---|---|---|---|

| 335–380 | 400–540 | 480–600 | 590–720 | 700–1100 | 1000–1700 | 1700–2500 | ||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | ||

| Traditional | white | 0.061 | 0.085 | 0.082 | 0.075 | 0.067 | 0.062 | 0.062 |

| black | 0.059 | 0.085 | 0.082 | 0.075 | 0.067 | 0.063 | 0.062 | |

| L95/CR28 | white | 0.063 | 0.119 | 0.097 | 0.099 | 0.283 | 0.730 | 0.635 |

| black | 0.063 | 0.115 | 0.095 | 0.097 | 0.258 | 0.438 | 0.324 | |

| S84/CR28 | white | 0.067 | 0.2 | 0.137 | 0.175 | 0.810 | 0.813 | 0.564 |

| black | 0.066 | 0.147 | 0.113 | 0.142 | 0.489 | 0.331 | 0.136 | |

| TR RU/ZD | white | 0.058 | 0.170 | 0.122 | 0.113 | 0.544 | 0.795 | 0.589 |

| black | 0.060 | 0.147 | 0.111 | 0.103 | 0.401 | 0.395 | 0.169 | |

| S84/CR28/Lacquer | white | 0.070 | 0.192 | 0.134 | 0.180 | 0.809 | 0.795 | 0.553 |

| black | 0.068 | 0.119 | 0.100 | 0.124 | 0.334 | 0.197 | 0.085 | |

| PS/ZD | white | 0.064 | 0.167 | 0.118 | 0.104 | 0.533 | 0.790 | 0.586 |

| black | 0.060 | 0.134 | 0.103 | 0.090 | 0.318 | 0.281 | 0.112 | |

| S84/A80 | white | 0.057 | 0.184 | 0.125 | 0.135 | 0.723 | 0.788 | 0.602 |

| black | 0.056 | 0.120 | 0.096 | 0.100 | 0.332 | 0.311 | 0.223 | |

| Short Name of Coating | Primer | TSR % | IR-SR % |

|---|---|---|---|

| traditional | white | 7.2 | 6.3 |

| black | 7.2 | 6.3 | |

| L95/CR28 | white | 28.8 | 45.5 |

| black | 21.4 | 31.6 | |

| S84/CR28 | white | 48.2 | 76.6 |

| black | 26.8 | 39.1 | |

| TR RU/ZD | white | 38.6 | 61.6 |

| black | 24.9 | 36.9 | |

| S84/CR28/Lacquer | white | 47.7 | 75.9 |

| black | 18.9 | 25.7 | |

| PS/ZD | white | 37.9 | 60.8 |

| black | 19.7 | 27.8 | |

| S84/A80 | white | 44.3 | 71.4 |

| black | 21.0 | 30.6 |

| Name of the Coating | Primer | Temperature [°C] | ||

|---|---|---|---|---|

| Max | Min | Average | ||

| Traditional | white | 64.5 | 61.7 | 60.0 |

| black | 64.2 | 52.4 | 60.4 | |

| L95/CR28 | white | 59.3 | 48.6 | 54.5 |

| black | 61.5 | 51.6 | 57.1 | |

| S84/CR28 | white | 52.2 | 44.3 | 48.5 |

| black | 59.6 | 50.9 | 55.5 | |

| TR RU/ZD | white | 57.4 | 48.0 | 53.2 |

| black | 61.4 | 51.7 | 57.3 | |

| S84/CR28/Lacquer | white | 54.2 | 45.2 | 49.8 |

| black | 61.7 | 52.4 | 58.3 | |

| PS/ZD | white | 55.5 | 47.2 | 53.0 |

| black | 61.0 | 51.7 | 57.6 | |

| S84/A80 | white | 52.3 | 46.2 | 49.8 |

| black | 59.4 | 51.4 | 56.0 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mara, J.; Bodnár, A.-E.; Trif, L.; Telegdi, J. Development of Effective Infrared Reflective Coatings. Appl. Sci. 2023, 13, 12903. https://doi.org/10.3390/app132312903

Mara J, Bodnár A-E, Trif L, Telegdi J. Development of Effective Infrared Reflective Coatings. Applied Sciences. 2023; 13(23):12903. https://doi.org/10.3390/app132312903

Chicago/Turabian StyleMara, Józsefné, Attila-Ede Bodnár, László Trif, and Judit Telegdi. 2023. "Development of Effective Infrared Reflective Coatings" Applied Sciences 13, no. 23: 12903. https://doi.org/10.3390/app132312903

APA StyleMara, J., Bodnár, A.-E., Trif, L., & Telegdi, J. (2023). Development of Effective Infrared Reflective Coatings. Applied Sciences, 13(23), 12903. https://doi.org/10.3390/app132312903