Study of High Transmittance of SiO2/Nb2O5 Multilayer Thin Films Deposited by Plasma-Assisted Reactive Magnetron Sputtering

Abstract

:1. Introduction

2. Experimental Details

2.1. Fabrication

2.2. Characterization

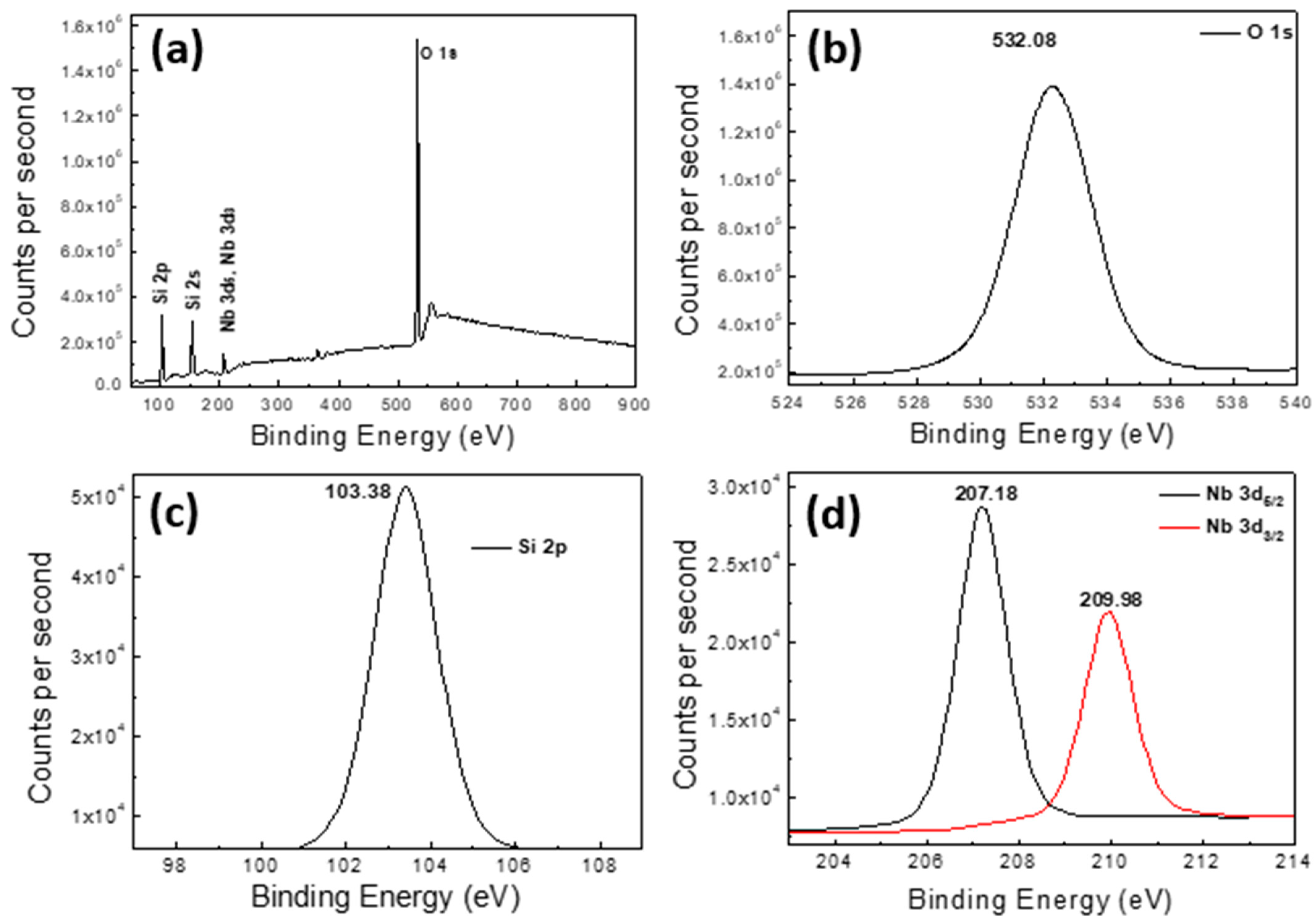

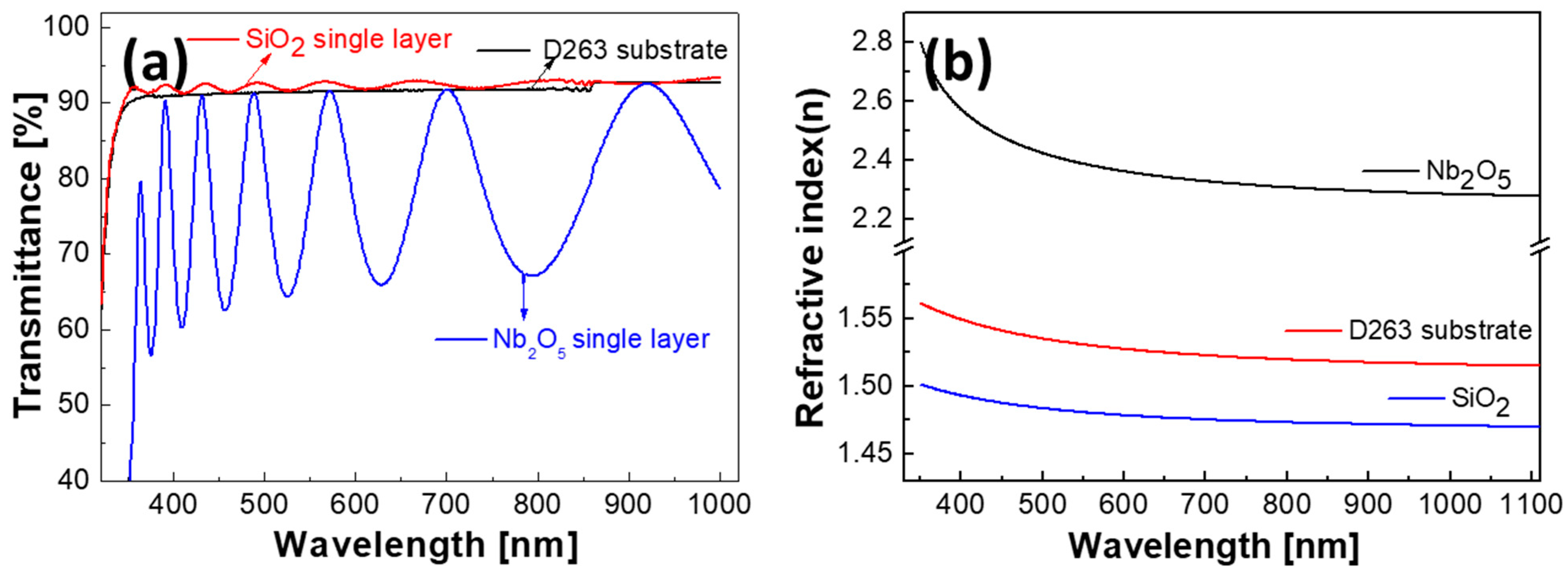

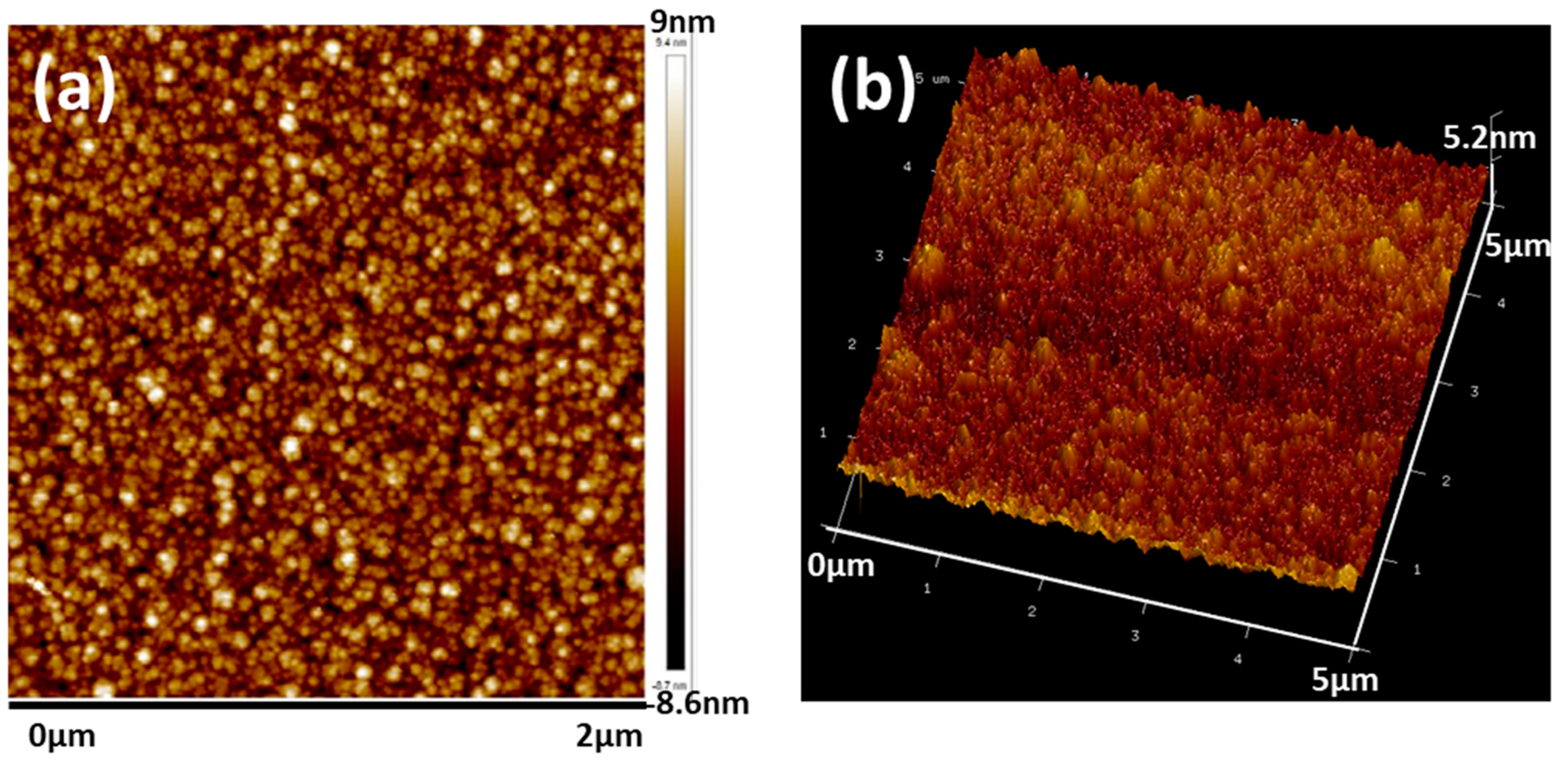

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mbam, S.O.; Nwonu, S.E.; Orelaja, O.; Nwigwe, U.S.; Gou, X.F. Thin-film coating; historical evolution, conventional deposition technologies stress state micro nano level measurement. Mater. Res. Express 2019, 6, 122001. [Google Scholar] [CrossRef]

- Sullivan, B.T.; Clarke, G.A.; Akiyama, T.; Osborne, N.; Ranger, M.; Dobrowolski, J.A.; Howe, L.; Matsumoto, A.; Song, Y.; Kikuchi, K. High-rate automated deposition system for the manufacture of complex multilayer coatings. Appl Opt. 2000, 39, 157–167. [Google Scholar] [CrossRef] [PubMed]

- ICAO (International Civil Aviation Organization). Annex 14, Standards and Aerodrome Certification; ICAO: Montreal, QC, Canada, 2022. [Google Scholar]

- Moriizumi, Y.; Honma, H.; Takai, O. Optical properties and durability performance of substance SiO2/Nb2O5 for multilayer thin films prepared by high-density plasma-assisted vapor deposition. Jpn. J. Appl. Phys. 2016, 55, 01AA23. [Google Scholar] [CrossRef]

- Thielsch, R.; Gatto, A.; Heber, J.; Kaiser, N. A comparative study of the UV optical and structural properties of SiO2, Al2O3, and HfO2 single layers deposited by reactive evaporation, ion-assisted deposition and plasma ion-assisted deposition. Thin Solid Film. 2002, 410, 86–93. [Google Scholar] [CrossRef]

- Jasapara, J.; Nampoothiri, A.V.V.; Rudolph, W.; Ristau, D.; Starke, K. Femtosecond laser pulse induced breakdown in dielectric thin films. Phys. Rev. 2001, 63, 045117. [Google Scholar] [CrossRef]

- Song, Y.; Sakurai, T.; Maruta, K.; Matusita, A.; Matsumoto, S.; Saisho, S.; Kikuchi, K. Optical and structural properties of dense SiO2, Ta2O5 and Nb2O5 thin-films deposited by indirectly reactive sputtering technique. Vacuum 2000, 59, 755–763. [Google Scholar] [CrossRef]

- Szymanowski, H.; Zabeida, O.; Klemberg-Sapieha, J.E.; Martinu, L. Optical properties and microstructure of plasma deposited Ta2O5 and Nb2O5 films. J. Vac. Sci. Technol. 2005, 23, 241–247. [Google Scholar] [CrossRef]

- Yoshimura, K.; Miki, T.; Iwama, S.; Tanemura, S. Characterization of niobium oxide electrochromic thin films prepared by reactive d.c. magnetron sputtering. Thin Solid Film. 1996, 281/282, 235–238. [Google Scholar] [CrossRef]

- Chen, K.N.; Hsu, C.M.; Liu, J.; Liou, Y.C.; Yang, C.F. Investigation of Antireflection Nb2O5 Thin films by the sputtering method under different deposition parameters. Micromachines 2016, 7, 151. [Google Scholar] [CrossRef]

- Yuan, Z.S.; Jhang, J.M.; Yu, P.H.; Jiang, C.M.; Huang, Y.C.; Wu, Y.L.; Lin, J.J.; Yang, C.F. Comparisons of theoretical and experimental results of blue light SiO2–Nb2O5 distributed bragg reflector fabricated using E-beam deposition. Vacuum 2020, 182, 109782. [Google Scholar] [CrossRef]

- Moriizumi, Y.; Honma, H.; Takai, O. Optical and mechanical properties of SiO2 and Nb2O5 thin films deposited by high-density plasma assisted vapor deposition. J. Surf. Finish. Soc. Jpn. 2015, 66, 212–218. [Google Scholar] [CrossRef]

- Chen, T.C.; Chu, C.J.; Ho, C.H.; Wu, C.C.; Lee, C.C. Determination of stress-optical and thermal-optical coefficients of Nb2O5 thin film material. J. Appl. Phys. 2007, 101, 043513. [Google Scholar] [CrossRef]

- Shaaban, K.H.; Yousef El, S.; Abdel Wahab, E.A.; Shaaban, S.A.; Mahmoud, E.R. Investigation of crystallization and mechanical characteristics of Glass and Glass-Ceramic with the Compositions xFe2O3-35SiO2-35B2O3-10Al2O3-(20x) Na2O. J. Mater. Eng. Perform 2020, 29, 4549–4558. [Google Scholar] [CrossRef]

- Alfonsetti, R.; Passacantando, M.; Lozzi, L.; Picozzi, P. XPS studies on SiOx thin films. Appl. Surf. Sci. 1993, 70/71, 222–225. [Google Scholar] [CrossRef]

- Ingo, G.M.; Riccucci, C.; Bultrini, G.; Dirè, S.; Chiozzini, G. Thermal and microchemical characterisation of sol-gel SiO2, TiO2 and x SiO2–(1–x) TiO2 ceramic materials. J. Therm. Anal. Calorim. 2001, 66, 37–46. [Google Scholar] [CrossRef]

- Zhang, W.; Wu, W.; Wang, X.; Cheng, X.; Yan, D.; Shen, C.; Peng, L.; Wang, Y.; Li, B. The investigation of NbO2 and Nb2O5 electronic structure by XPS, UPS and first principles methods. Surf. Interface Anal. 2013, 45, 1206–1210. [Google Scholar]

- King, B.R.; Patel, H.C.; Gulino, D.A.; Tatarchuk, B.J. Kinetic measurements of oxygen dissolution into niobium substrates: In situ X-ray photoelectron spectroscopy studie. Thin Solid Film. 1990, 192, 351. [Google Scholar] [CrossRef]

- Lombardo, L.; Donato, N.; Grassini, S.; Gullino, A.; Moulaee, K.; Neri, G.; Parvis, M. Nb2O5 thin film-based conductometric sensor for acetone monitoring. In Proceedings of the IEEE International Symposium on Medical Measurements and Applications (MeMeA), Istanbul, Turkey, 26–28 June 2019; pp. 1–5. [Google Scholar]

- Stenzel, O. The Physics of Thin Film Optical Spectra: An Introduction; Springer-Verlag: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Tajima, N.; Murotani, H.; Matsudaira, T. Optical multicoating using low-refractive-index SiO2 optical thin films deposited by sputtering and electron beam evaporation. Thin Solid Film. 2023, 776, 139824. [Google Scholar] [CrossRef]

- Lai, F.; Lin, L.; Huang, Z.; Gai, R.; Qu, Y. Effect of thickness on the structure, morphology and optical properties of sputter deposited Nb2O5 films. Appl. Surf. Sci. 2006, 253, 1801–1805. [Google Scholar] [CrossRef]

- Guenther, K.H. Optical thin films deposited by energetic particle processes. Thin Film. Opt. Syst. 1992, 1782, 344–355. [Google Scholar]

- Hubler, G.K.; Sprague, J.A. Energetic particles in PVD technology: Particle-surface interaction processes and energy-particle relationships in thin film deposition. Surf. Coat. Technol. 1996, 81, 29–35. [Google Scholar] [CrossRef]

- Harper, J.M.E.; Cuomo, J.J.; Gambino, R.J.; Kaufman, H.R.; Robinson, R.S. Mean free path of negative ions in diode sputtering. J. Vac. Sci. Technol. 1978, 15, 1597–1600. [Google Scholar] [CrossRef]

- Thornton, J.A. Influence of apparatus geometry and deposition conditions on the structure and topography of thick sputtered coatings. J. Vac. Sci. Technol. 1974, 11, 666–670. [Google Scholar] [CrossRef]

- Kim, D.J.; Kim, K.M.; Han, H.S.; Lee, J.H.; Ko, D.H.; Park, K.R.; Jang, K.B.; Kim, D.W.; Forrester, J.S.; Lee, S.H.; et al. TiO2/SiO2 multilayer thin films with enhanced spectral selectivity for optical narrow bandpass filters. Sci. Rep. 2022, 7, 32. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.W. The properties of multi-layered optical thin films fabricated by pulsed DC magnetron sputtering. J. Korean Inst. Surf. Eng. 2019, 52, 211–226. [Google Scholar]

- Kwon, Y.H.; Jang, G.E. Effect of SiO2 and Nb2O5 Buffer Layer on Optical Characteristics of ITO Thin Film. Trans. Electr. Electron. Mater. 2015, 16, 29–33. [Google Scholar] [CrossRef]

- Chattopadhyay, S.; Huang, Y.F.; Jen, Y.J.; Ganguly, A.; Chen, K.H.; Chen, L.C. Anti-reflecting and photonic nanostructures. Mater. Sci. Eng. 2010, 69, 1–35. [Google Scholar] [CrossRef]

- Xu, S.; Jia, H.; Wang, C.; Zhao, W.; Wang, Y.; Yang, C.; Wu, H.; Zhu, J.; Wang, B.; Wang, Q. Low-temperature preparation of SiO2/Nb2O5/TiO2–SiO2 broadband antireflective coating for the visible via acid-catalyzed sol–gel method. Coatings 2020, 10, 737. [Google Scholar] [CrossRef]

- Richter, F.; Kupfer, H.; Schlott, P.; Gessner, T.; Kaufmann, C. Optical properties and mechanical stress in SiO2/Nb2O5 multilayers. Thin Solid Film. 2001, 389, 273–283. [Google Scholar] [CrossRef]

- Zhang, W.; Li, J.; Xing, Y.; Nie, X.; Lang, F.; Yang, S.; Hou, X.; Zhao, C. Experimental study on the thickness-dependent hardness of SiO2 thin films using nanoindentation. Coatings 2021, 11, 23. [Google Scholar] [CrossRef]

- Oliver, W.; Pharr, G. An improved technique for determining hardness and elastic modulus using load and displacement-sensing indentation systems. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Sasmal, S.; Anoop, M.B. Nanoindentation for evaluation of properties of cement hydration products. In Nanotechnology in Eco-Efficient Construction; Woodhead Publishing: Sawston, UK, 2019; pp. 141–161. [Google Scholar]

- Mazur, M.; Szymańska, M.; Kaczmarek, D.; Kalisz, M.; Wojcieszak, D.; Domaradzki, J.; Placido, F. Determination of optical and mechanical properties of Nb2O5 thin films for solar cells application. Appl. Surf. Sci. 2014, 301, 63–69. [Google Scholar] [CrossRef]

| Parameters | SiO2 Film | NB2O5 Film |

|---|---|---|

| Sputtering Target | Si | Nb |

| Base Pressure (Pa) | 2.0 × 10−5 | 2.0 × 10−5 |

| Working Pressure (Pa) | 8.0~9.0 × 10−1 | 8.0~9.0 × 10−1 |

| O2 Partial Preassure (O2/Ar + O2) | 0.3~0.9 | 0.3~0.9 |

| MF Power (kW) | 8 | 8 |

| RF Power (kW) | 3 | 3 |

| Target to Substrate Spacing (mm) | 150 | 150 |

| Rotating Speed of Substrate (rpm) | 80 | 80 |

| Temp. of the substrate (°C) | 150 | 150 |

| Clean Room Temp. (°C) | 20 | 20 |

| Clean Room Relative Humidity (%) | 45 | 45 |

| Deposition Rate (Å/s) | 6.2~9.29 | 1.67~4.76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; In, J.-H.; Kim, S.H.; Han, K.; Lim, D.; Hwang, Y.S.; Lee, K.M.; Choi, J.H. Study of High Transmittance of SiO2/Nb2O5 Multilayer Thin Films Deposited by Plasma-Assisted Reactive Magnetron Sputtering. Appl. Sci. 2023, 13, 13271. https://doi.org/10.3390/app132413271

Kim S, In J-H, Kim SH, Han K, Lim D, Hwang YS, Lee KM, Choi JH. Study of High Transmittance of SiO2/Nb2O5 Multilayer Thin Films Deposited by Plasma-Assisted Reactive Magnetron Sputtering. Applied Sciences. 2023; 13(24):13271. https://doi.org/10.3390/app132413271

Chicago/Turabian StyleKim, Soyoung, Jung-Hwan In, Seon Hoon Kim, Karam Han, Dongkook Lim, Yun Sik Hwang, Kyung Min Lee, and Ju Hyeon Choi. 2023. "Study of High Transmittance of SiO2/Nb2O5 Multilayer Thin Films Deposited by Plasma-Assisted Reactive Magnetron Sputtering" Applied Sciences 13, no. 24: 13271. https://doi.org/10.3390/app132413271