Functionally Graded Additive Manufacturing: Bridging the Gap between Design and Material Extrusion

Abstract

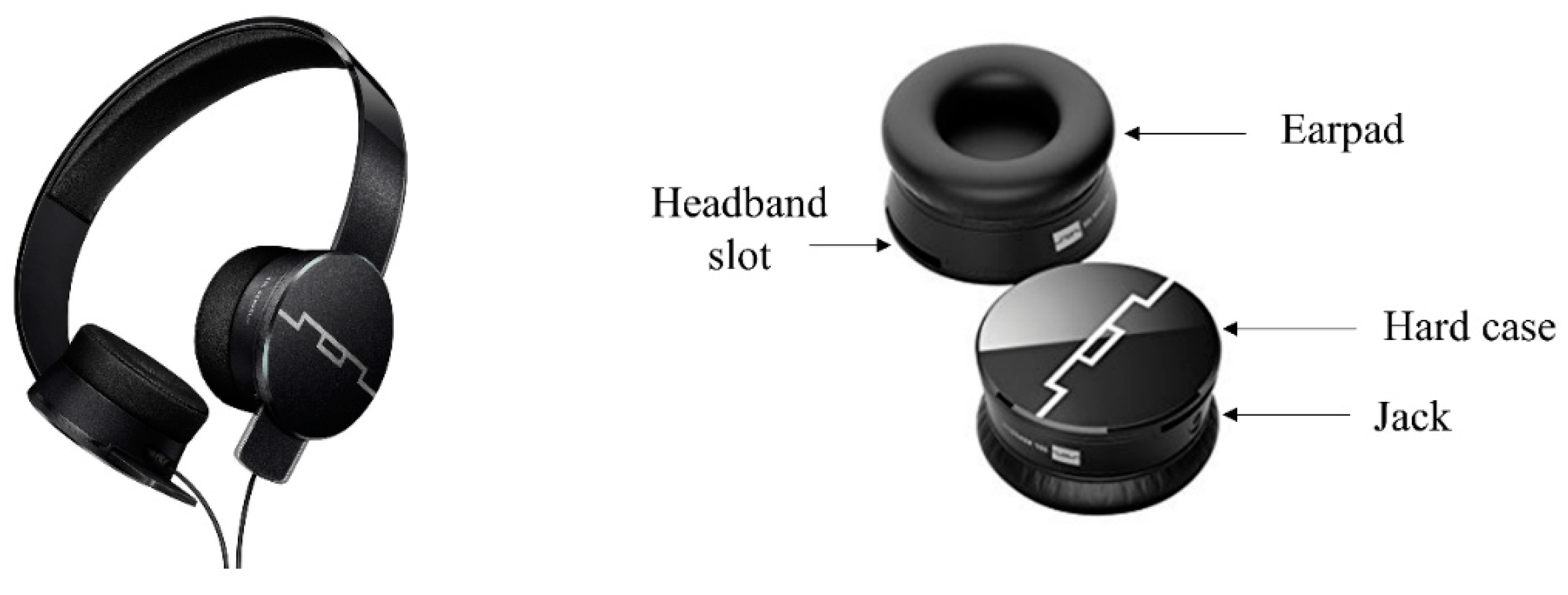

Featured Application

Abstract

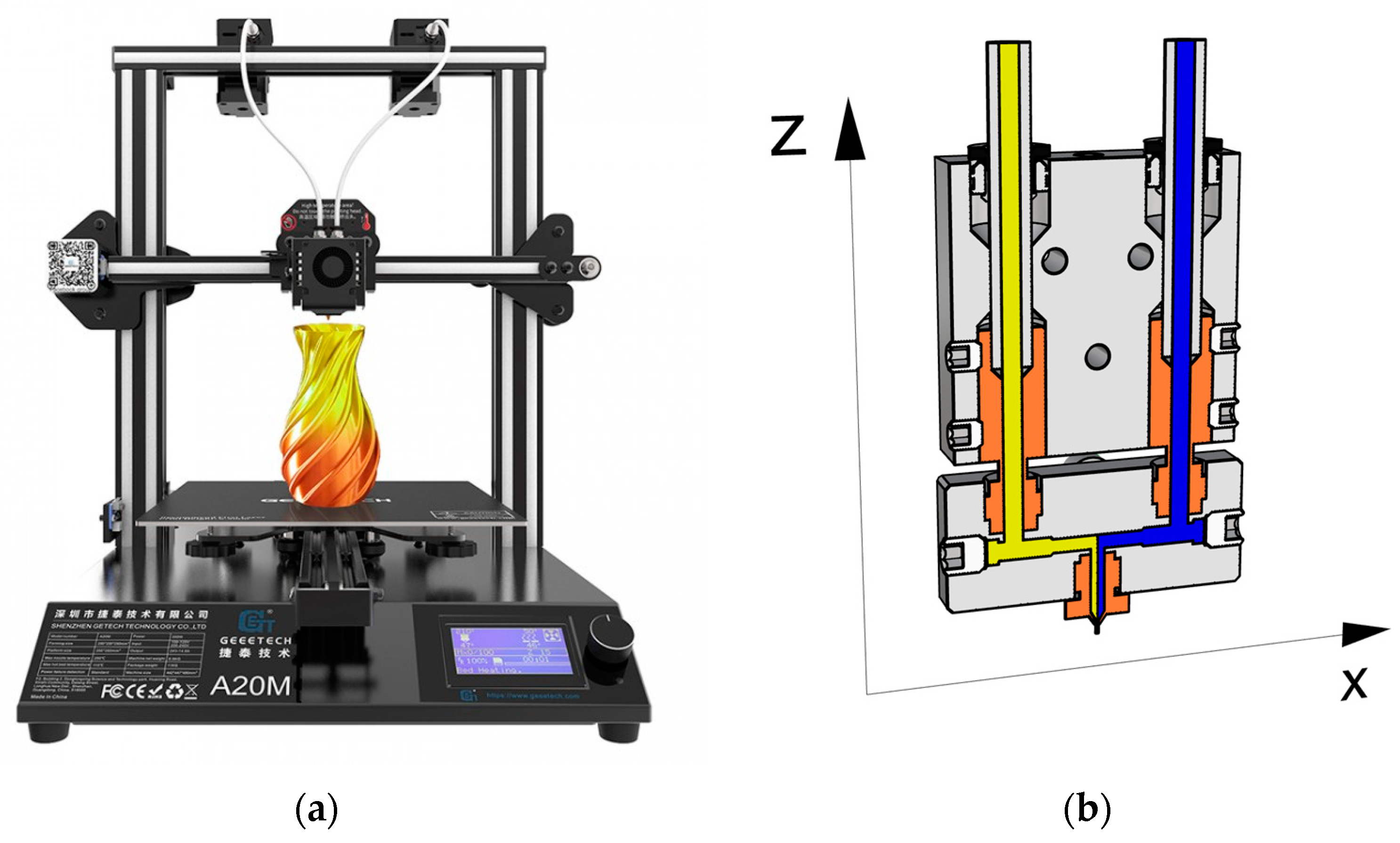

1. Introduction

Current FGAM Software Limitations

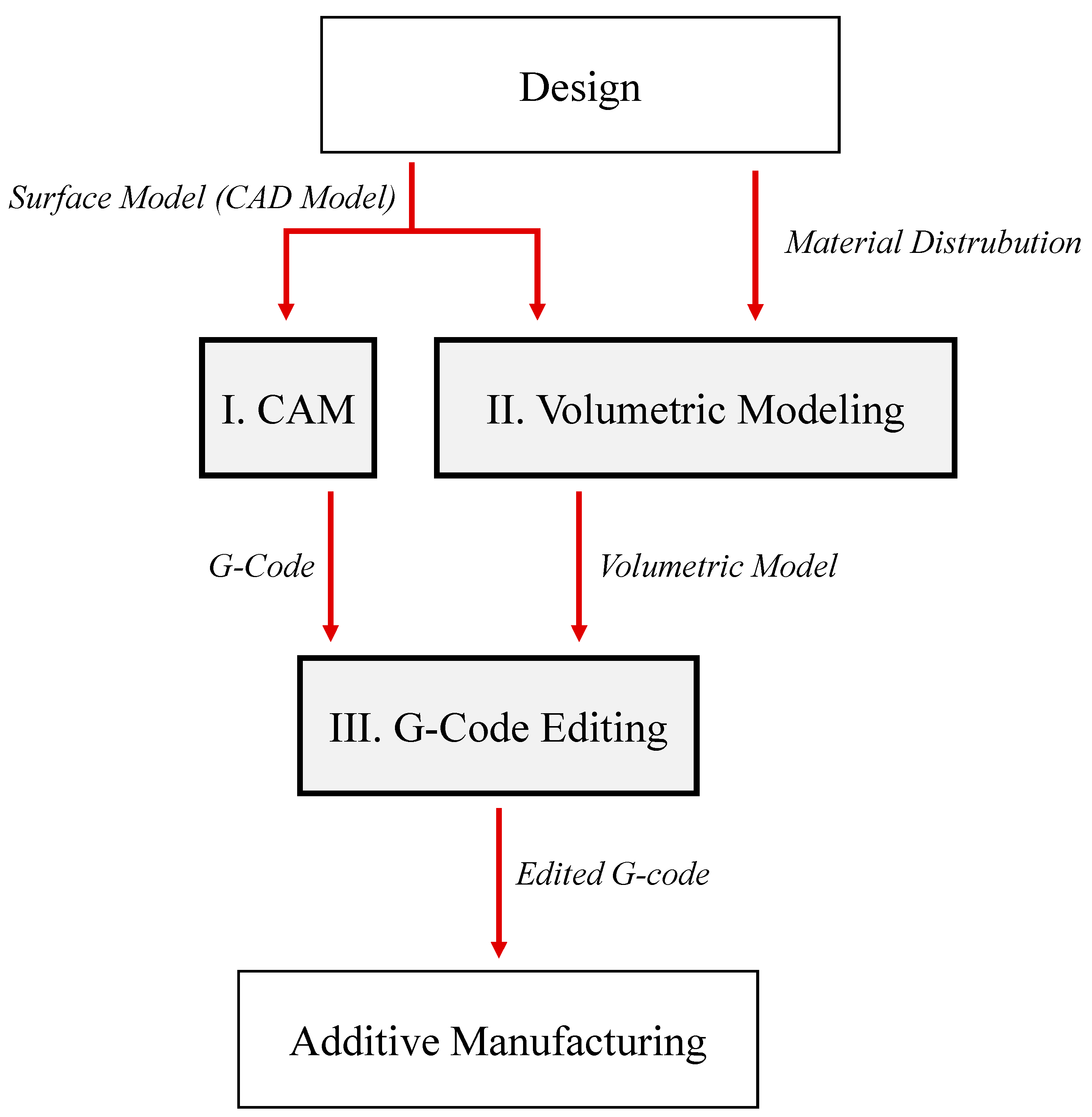

2. The Proposed Method

- G-code computing (CAM);

- volumetric modeling;

- G-code editing.

2.1. G-Code Computing

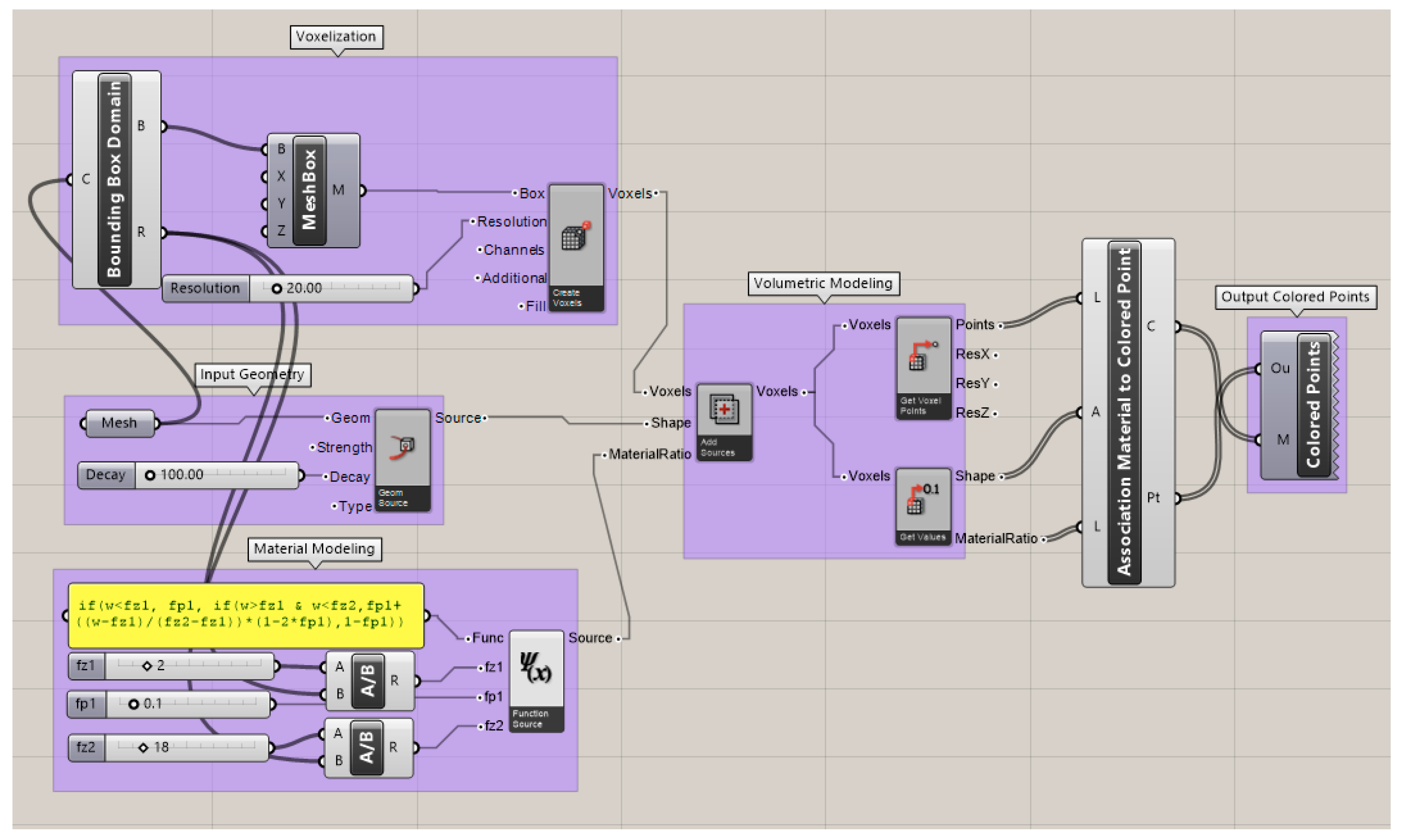

2.2. Volumetric Modeling

2.3. G-Code Editing

- M163 S0 P0.65

- S1 P0.35

- S5,

3. Results and Discussion

- Tolerance: 0.01 mm;

- Maximum aspect ratio: 6;

- Minimum edge length: 0.0001 mm;

- Maximum distance, edge to surface: 0.01 mm;

- Maximum edge length/angle and minimum initial grid quads: 0.

3.1. CAM Processing

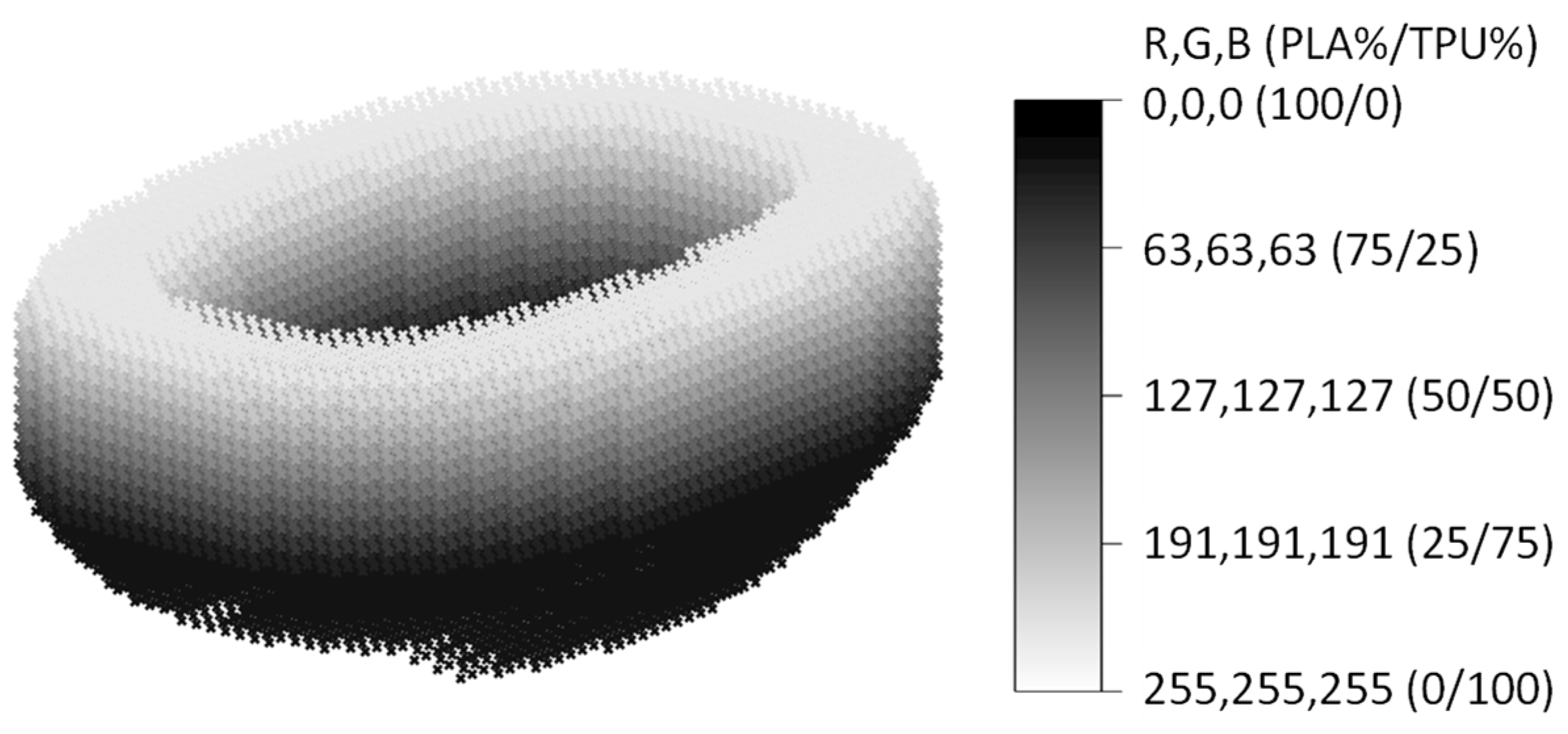

3.2. Volumetric Modeling

3.3. G-Code Editing

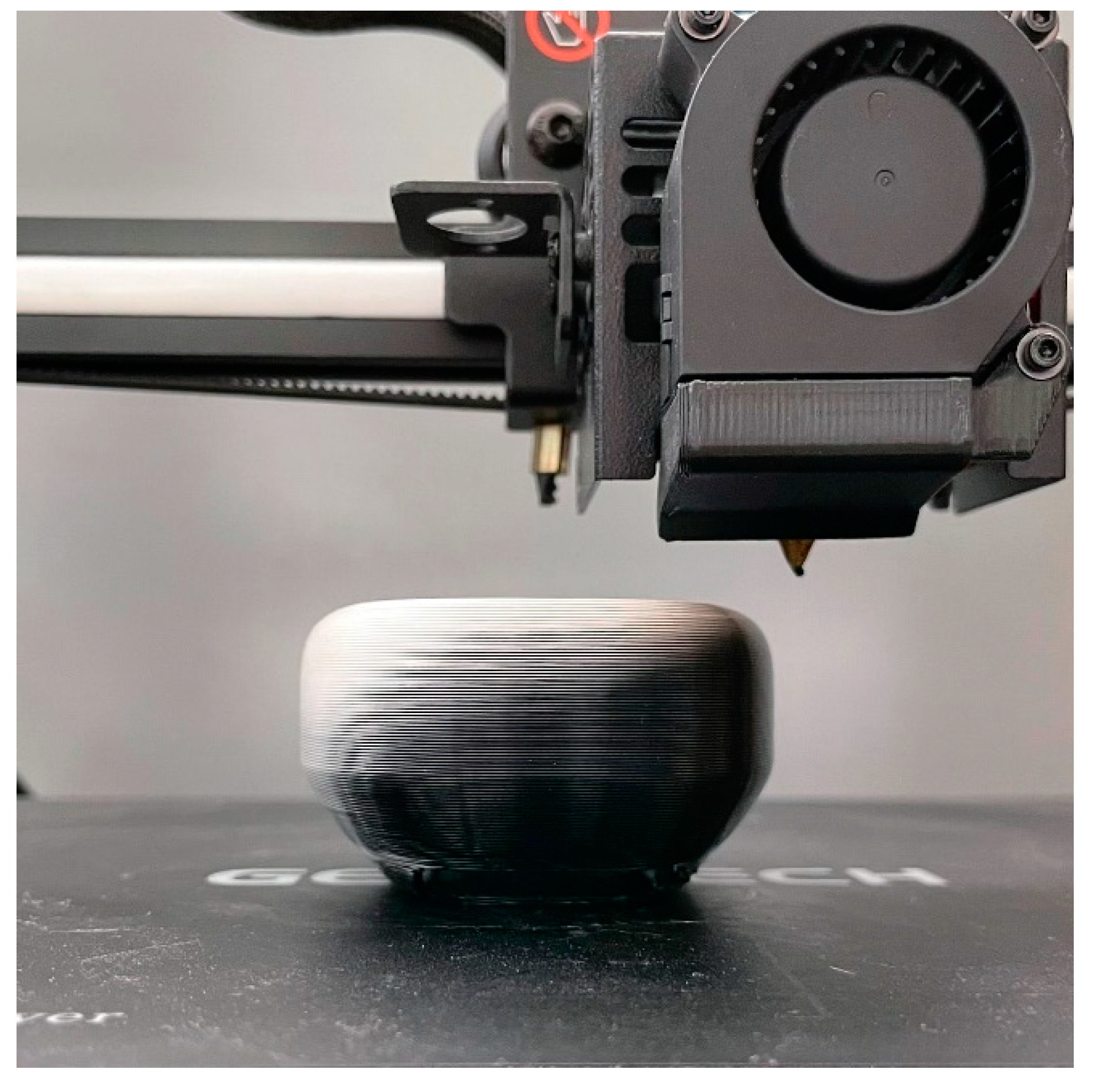

3.4. Manufacturing and Further Considerations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Loh, G.H.; Pei, E.; Harrison, D.; Monzón, M.D. An Overview of Functionally Graded Additive Manufacturing. Addit. Manuf. 2018, 23, 34–44. [Google Scholar] [CrossRef]

- Sponchiado, R.; Grigolato, L.; Filippi, S.; Concheri, G.; Meneghello, R.; Savio, G. Heterogeneous Materials Additive Manufacturing: An Overview. In Design Tools and Methods in Industrial Engineering II. ADM 2021. Lecture Notes in Mechanical Engineering; Rizzi, C., Campana, F., Bici, M., Gherardini, F., Ingrassia, T., Cicconi, P., Eds.; Springer: Cham, Switzerland, 2022; pp. 462–473. ISBN 9783030912345. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T. Introduction to Functionally Graded Materials. In Topics in Mining, Metallurgy and Materials Engineering; Springer: Cham, Switzerland, 2017; pp. 1–8. ISBN 9783319537566. [Google Scholar] [CrossRef]

- Besisa, D.H.A.; Ewais, E.M.M. Advances in Functionally Graded Ceramics–Processing, Sintering Properties and Applications. Adv. Funct. Graded Mater. Struct. 2016, 1, 32. [Google Scholar]

- Koizumi, M. FGM Activities in Japan. Compos. Part B Eng. 1997, 28, 1–4. [Google Scholar] [CrossRef]

- Müller, E.; Drašar, Č.; Schilz, J.; Kaysser, W. Functionally Graded Materials for Sensor and Energy Applications. Mater. Sci. Eng. A 2003, 362, 17–39. [Google Scholar] [CrossRef]

- Boggarapu, V.; Gujjala, R.; Ojha, S.; Acharya, S.; Venkateswara babu, P.; Chowdary, S.; kumar Gara, D. State of the Art in Functionally Graded Materials. Compos. Struct. 2021, 262, 113596. [Google Scholar] [CrossRef]

- ASTM_F42; ISO/TC_261 ISO/ASTM TR 52912: 2020 Additive Manufacturing—Design—Functionally Graded Additive Manufacturing. ISO: Geneva, Switzerland, 2020.

- Garland, A.; Fadel, G. Design and Manufacturing Functionally Gradient Material Objects with an off the Shelf Three-Dimensional Printer: Challenges and Solutions. J. Mech. Des. 2015, 137, 111407. [Google Scholar] [CrossRef]

- Khondoker, M.A.H.; Asad, A.; Sameoto, D. Printing with Mechanically Interlocked Extrudates Using a Custom Bi-Extruder for Fused Deposition Modelling. Rapid Prototyp. J. 2018, 24, 921–934. [Google Scholar] [CrossRef]

- Kennedy, Z.C.; Christ, J.F. Printing Polymer Blends through in Situ Active Mixing during Fused Filament Fabrication. Addit. Manuf. 2020, 36, 101233. [Google Scholar] [CrossRef]

- Brauer, C.; Aukes, D. Applying Graded Material Transitions with Low-Cost Additive Manufacturing. Rapid Prototyp. J. 2022; ahead-of-print. [Google Scholar]

- Lalegani Dezaki, M.; Mohd Ariffin, M.K.A.; Hatami, S. An Overview of Fused Deposition Modelling (FDM): Research, Development and Process Optimisation. Rapid Prototyp. J. 2021, 27, 562–582. [Google Scholar] [CrossRef]

- Muller, P.; Mognol, P.; Hascoet, J.Y. Functionally Graded Material (FGM) Parts: From Design to the Manufacturing Simulation. In Proceedings of the ASME 2012 11th Biennial Conference on Engineering Systems Design and Analysis, Nantes, France, 2–4 July 2012; pp. 123–131. [Google Scholar] [CrossRef]

- Savio, G.; Meneghello, R.; Rosso, S.; Concheri, G. 3D Model Representation and Data Exchange for Additive Manufacturing. In Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2019; Volume 3, pp. 412–421. ISBN 9783030123468. [Google Scholar] [CrossRef]

- Grigolato, L.; Rosso, S.; Meneghello, R.; Concheri, G.; Savio, G. Heterogeneous Objects Representation for Additive Manufacturing: A Review. Instant J. Mech. Eng. 2019, 1, 14–23. [Google Scholar] [CrossRef]

- Wang, D.; Liu, L.; Deng, G.; Deng, C.; Bai, Y.; Yang, Y.; Wu, W.; Chen, J.; Liu, Y.; Wang, Y.; et al. Recent Progress on Additive Manufacturing of Multi-Material Structures with Laser Powder Bed Fusion. Virtual Phys. Prototyp. 2022, 17, 329–365. [Google Scholar] [CrossRef]

- Richards, D.; Amos, M. Design with Gradients: Bio-Inspired Computation for Digital Fabrication. Acadia 2014, 101–110. [Google Scholar] [CrossRef]

- Steuben, J.C.; Iliopoulos, A.P.; Michopoulos, J.G. Implicit Slicing for Functionally Tailored Additive Manufacturing. Comput. Des. 2016, 77, 107–119. [Google Scholar]

- Aremu, A.K.; Adetifa, B.O. Investigating the Suitability of Different Heat Storage Media in Double Exposure Box Type Solar Cookers. J. Appl. Sci. Eng. Technol. 2016, 16, 1–9. [Google Scholar]

- Yao, X.; Moon, S.K.; Bi, G.; Wei, J. A Multi-Material Part Design Framework in Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2018, 99, 2111–2119. [Google Scholar] [CrossRef]

- Garcia, D.; Wu, Z.; Kim, J.Y.; Yu, H.Z.; Zhu, Y. Heterogeneous Materials Design in Additive Manufacturing: Model Calibration and Uncertainty-Guided Model Selection. Addit. Manuf. 2019, 27, 61–71. [Google Scholar] [CrossRef]

- Hällgren, S.; Pejryd, L.; Ekengren, J. 3D Data Export for Additive Manufacturing—Improving Geometric Accuracy. Procedia CIRP 2016, 50, 518–523. [Google Scholar] [CrossRef]

- Bader, C.; Kolb, D.; Weaver, J.C.; Sharma, S.; Hosny, A.; Costa, J.; Oxman, N. Making Data Matter: Voxel Printing for the Digital Fabrication of Data across Scales and Domains. Sci. Adv. 2018, 4, eaas8652. [Google Scholar] [CrossRef]

- Skylar-Scott, M.A.; Mueller, J.; Visser, C.W.; Lewis, J.A. Voxelated Soft Matter via Multimaterial Multinozzle 3D Printing. Nature 2019, 575, 330–335. [Google Scholar] [CrossRef]

- Bader, C.; Kolb, D.; Weaver, J.C.; Oxman, N. Data-Driven Material Modeling with Functional Advection for 3D Printing of Materially Heterogeneous Objects. 3D Print. Addit. Manuf. 2016, 3, 71–78. [Google Scholar] [CrossRef]

- Kaufman, A.; Cohen, D.; Yagel, R. Volume Graphics. Computer 1993, 26, 51–64. [Google Scholar] [CrossRef]

- Bacciaglia, A.; Ceruti, A.; Liverani, A. A Systematic Review of Voxelization Method in Additive Manufacturing. Mech. Ind. 2019, 20, 630. [Google Scholar] [CrossRef]

- Grigolato, L.; Rosso, S.; Meneghello, R.; Concheri, G.; Savio, G. Design and Manufacturing of Graded Density Components by Material Extrusion Technologies. Addit. Manuf. 2022, 57, 102950. [Google Scholar] [CrossRef]

- M163—Set Mix Factor. Available online: https://marlinfw.org/docs/gcode/M163.html (accessed on 11 October 2022).

- Select Tool. Available online: https://marlinfw.org/docs/gcode/T001-T002.html (accessed on 11 October 2022).

- Data Sheets & 3D Printing Guides. Available online: https://fillamentum.com/pages/data-sheets-and-3d-printing-guides/ (accessed on 11 October 2022).

- Brancewicz-Steinmetz, E.; Sawicki, J.; Byczkowska, P. The Influence of 3D Printing Parameters on Adhesion between Polylactic Acid (PLA) and Thermoplastic Polyurethane (TPU). Materials 2021, 14, 6464. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. 3D Printing of PLA-TPU with Different Component Ratios: Fracture Toughness, Mechanical Properties, and Morphology. J. Mater. Res. Technol. 2022, 21, 3970–3981. [Google Scholar] [CrossRef]

- Żur, A.; Żur, P.; Michalski, P.; Baier, A. Preliminary Study on Mechanical Aspects of 3D-Printed PLA-TPU Composites. Materials 2022, 15, 2364. [Google Scholar] [CrossRef]

- Ranellucci, A. Slic3r. Available online: https://slic3r.org/ (accessed on 21 January 2023).

- Michalatos, P.; Payne, A. Monolith: The Biomedical Paradigm and the Inner Complexity of Hierarchical Material Design. In Proceedings of the Complexity & Simplicity—Proceedings of the 34th eCAADe Conference, Oulu, Finland, 22–26 August 2015; Volume 1, pp. 445–454. [Google Scholar]

- Savio, G.; Meneghello, R.; Concheri, G. Design of Variable Thickness Triply Periodic Surfaces for Additive Manufacturing. Prog. Addit. Manuf. 2019, 4, 281–290. [Google Scholar] [CrossRef]

- Geeetech A20M User Manual. Available online: https://www.geeetech.com/download.html?version_id=426 (accessed on 9 December 2022).

- Marlin Firmware. Available online: https://marlinfw.org/ (accessed on 11 October 2022).

- Cyclops Drawings. Available online: https://e3d-online.zendesk.com/hc/en-us/articles/360017132577-Cyclops-Drawings (accessed on 11 October 2022).

- E3D Cyclops. Available online: https://grabcad.com/library/e3d-cyclops-1 (accessed on 11 October 2022).

- Rosso, S.; Uriati, F.; Grigolato, L.; Meneghello, R.; Concheri, G.; Savio, G. An Optimization Workflow in Design for Additive Manufacturing. Appl. Sci. 2021, 11, 2572. [Google Scholar] [CrossRef]

- Shenzhen Getech Technology Co., Ltd. Guide of Color Mixer Software. Available online: https://www.geeetech.com/download.html?version_id=85 (accessed on 11 January 2023).

- Sponchiado, R.; Rosso, S.; Fabbro, P.D.; Grigolato, L.; Elsayed, H.; Maltauro, M.; Uccheddu, F.; Meneghello, R.; Concheri, G.; Savio, G. Modeling Materials Coextrusion in Polymers Additive Manufacturing. Materials 2023, 16, 820. [Google Scholar] [CrossRef]

- Xu, T.; Shen, W.; Lin, X.; Xie, Y.M. Additively Manufactured Thermoplastic Polyurethane (TPU) Mold for Concrete Casting of Complex Structure. Rapid Prototyp. J. 2022, 28, 1717–1730. [Google Scholar] [CrossRef]

- Arifvianto, B.; Satiti, B.E.; Salim, U.A.; Suyitno; Nuryanti, A.; Mahardika, M. Mechanical Properties of the FFF Sandwich-Structured Parts Made of PLA/TPU Multi-Material. Prog. Addit. Manuf. 2022, 7, 1213–1223. [Google Scholar] [CrossRef]

- Tamburrino, F.; Graziosi, S.; Bordegoni, M. The Influence of Slicing Parameters on the Multi-Material Adhesion Mechanisms of FDM Printed Parts: An Exploratory Study. Virtual Phys. Prototyp. 2019, 14, 316–332. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Aberoumand, M.; Soltanmohammadi, K.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Zolfagharian, A.; Bodaghi, M.; Baghani, M. A New Strategy for Achieving Shape Memory Effects in 4D Printed Two-Layer Composite Structures. Polymers 2022, 14, 5446. [Google Scholar] [CrossRef] [PubMed]

- Freund, R.; Watschke, H.; Heubach, J.; Vietor, T. Determination of Influencing Factors on Interface Strength of Additively Manufactured Multi-Material Parts by Material Extrusion. Appl. Sci. 2019, 9, 1782. [Google Scholar] [CrossRef]

- Yin, J.; Lu, C.; Fu, J.; Huang, Y.; Zheng, Y. Interfacial Bonding during Multi-Material Fused Deposition Modeling (FDM) Process Due to Inter-Molecular Diffusion. Mater. Des. 2018, 150, 104–112. [Google Scholar] [CrossRef]

| Properties | PLA Extrafill | Flexfill TPU 98A |

|---|---|---|

| Density [g/cm3] | 1.24 | 1.23 |

| Ultimate tensile strength [MPa] | 60 | 53.7 |

| Elongation at break (%) | 6 | 318 |

| Elastic modulus [MPa] | 3600 | 160 * |

| Print temperature range [°C] | 190–210 | 220–240 |

| Bed temperature range [°C] | 55–60 | 50–60 |

| Nozzle temperature | 220 °C | Line width and nozzle diameter | 0.8 mm |

| Bed temperature | 60 °C | Number of perimeters | 2 |

| Infill | Cubic, 30% | Retraction enabled | False |

| Infill/perimeters overlap | 15% | Supports enabled | True |

| Initial/top/bottom print speed | 15 mm/s | Support angle | 70° |

| Travel speed | 80 mm/s | Flow | 100% |

| Print speed | 30 mm/s | Top/bottom thickness | 1.6 mm |

| Layer height | 0.4 mm | Fan speed | 100% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leoni, F.; Dal Fabbro, P.; Rosso, S.; Grigolato, L.; Meneghello, R.; Concheri, G.; Savio, G. Functionally Graded Additive Manufacturing: Bridging the Gap between Design and Material Extrusion. Appl. Sci. 2023, 13, 1467. https://doi.org/10.3390/app13031467

Leoni F, Dal Fabbro P, Rosso S, Grigolato L, Meneghello R, Concheri G, Savio G. Functionally Graded Additive Manufacturing: Bridging the Gap between Design and Material Extrusion. Applied Sciences. 2023; 13(3):1467. https://doi.org/10.3390/app13031467

Chicago/Turabian StyleLeoni, Francesco, Pierandrea Dal Fabbro, Stefano Rosso, Luca Grigolato, Roberto Meneghello, Gianmaria Concheri, and Gianpaolo Savio. 2023. "Functionally Graded Additive Manufacturing: Bridging the Gap between Design and Material Extrusion" Applied Sciences 13, no. 3: 1467. https://doi.org/10.3390/app13031467

APA StyleLeoni, F., Dal Fabbro, P., Rosso, S., Grigolato, L., Meneghello, R., Concheri, G., & Savio, G. (2023). Functionally Graded Additive Manufacturing: Bridging the Gap between Design and Material Extrusion. Applied Sciences, 13(3), 1467. https://doi.org/10.3390/app13031467