Technological Advances on Fault Diagnosis in Wind Turbines: A Patent Analysis

Abstract

:1. Introduction

2. Materials and Methods

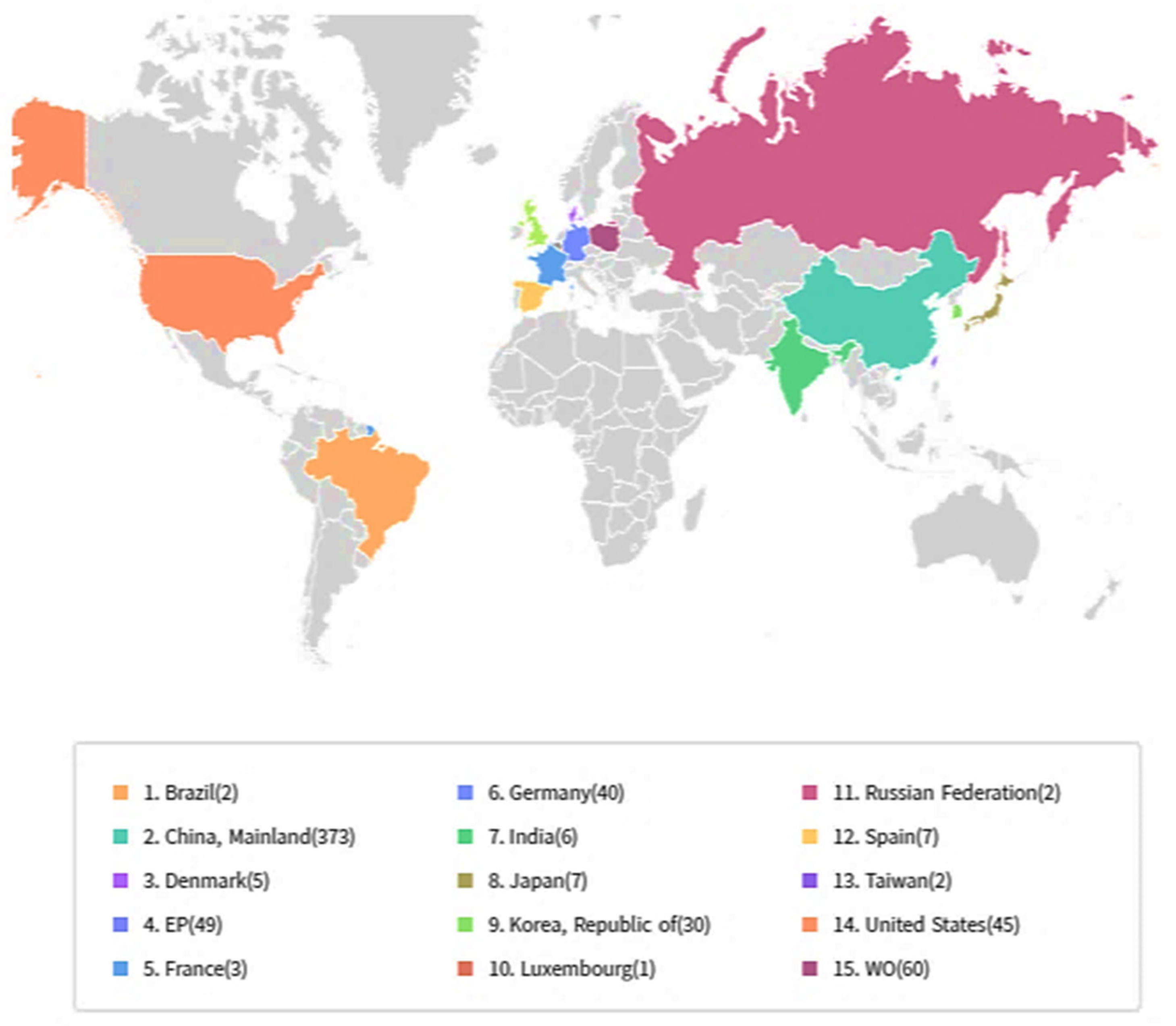

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bashir, M.; Bashir, A. Principle Parameters and Environmental Impacts that Affect the Performance of Wind Turbine: An Overview. Arab. J. Sci. Eng. 2022, 47, 7891–7909. [Google Scholar] [CrossRef] [PubMed]

- Duc Luong, N. A critical review on potential and current status of wind energy in Vietnam. Renew. Sustain. Energy Rev. 2015, 43, 440–448. [Google Scholar] [CrossRef]

- Porté-Agel, F.; Bastankhah, M.; Shamsoddin, S. Wind-Turbine and Wind-Farm Flows: A Review. Bound.-Layer Meteorol. 2020, 174, 1–59. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pachauri, R.K.; Meyer, L.A. IPCC, 2014: Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Mishnaevsky, L. Sustainable End-of-Life Management of Wind Turbine Blades: Overview of Current and Coming Solutions. Materials 2021, 14, 1124. [Google Scholar] [CrossRef] [PubMed]

- Mendonça, A.K.d.S.; Vaz, C.R.; Lezana, Á.G.R.; Anacleto, C.A.; Paladini, E.P. Comparing patent and scientific literature in airborne wind energy. Sustainability 2017, 9, 915. [Google Scholar] [CrossRef] [Green Version]

- Fazal, M.K.; Fazal, M.R. Chapter 1—Fundamentals of renewable energy systems. In Renewable Energy Conversion Systems; Academic Press Inc.: Cambridge, MA, USA, 2021; pp. 1–19. [Google Scholar] [CrossRef]

- Joo, K.; Lee, M.; Lee, G. Technology Originality and Convergence Analysis in the Wind Power Field Using Patents. Energies 2022, 15, 3316. [Google Scholar] [CrossRef]

- Costa, Á.M.; Orosa, J.A.; Vergara, D.; Fernández-Arias, P. New tendencies in wind energy operation and maintenance. Appl. Sci. 2021, 11, 1386. [Google Scholar] [CrossRef]

- Ren, Z.; Verma, A.S.; Li, Y.; Teuwen, J.J.E.; Jiang, Z. Offshore wind turbine operations and maintenance: A state-of-the-art review. Renew. Sustain. Energy Rev. 2021, 144, 110886. [Google Scholar] [CrossRef]

- Lee, J.; Zhao, F. Global Wind Report | GWEC; Global Wind Energy Council: Bonn, Germany, 2021; Volume 75. [Google Scholar]

- Global Wind Energy Council. Annual Wind Report. 2022. Available online: https://gwec.net/global-wind-report-2022/ (accessed on 28 December 2022).

- Gao, B.; He, Y.; Woo, W.L.; Tian, G.Y.; Liu, J.; Hu, Y. Multidimensional Tensor-Based Inductive Thermography with Multiple Physical Fields for Offshore Wind Turbine Gear Inspection. IEEE Trans. Ind. Electron. 2016, 63, 6305–6315. [Google Scholar] [CrossRef]

- Junginger, M.; Hittinger, E.; Williams, E.; Wiser, R. Onshore Wind Energy; Elsevier Inc.: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Sanati, H.; Wood, D.; Sun, Q. Condition monitoring of wind turbine blades using active and passive thermography. Appl. Sci. 2018, 8, 2004. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Xue, Y.; He, C.; Zhao, Y. Review of the Typical Damage and Damage-Detection Methods of Large Wind Turbine Blades. Energies 2022, 15, 5672. [Google Scholar] [CrossRef]

- Chen, I.W.; Wong, B.L.; Lin, Y.H.; Chau, S.W.; Huang, H.H. Design and analysis of jacket substructures for offshore wind turbines. Energies 2016, 9, 264. [Google Scholar] [CrossRef] [Green Version]

- Mishnaevsky, L.; Thomsen, K. Costs of repair of wind turbine blades: Influence of technology aspects. Wind Energy 2020, 23, 2247–2255. [Google Scholar] [CrossRef]

- IRENA. The Power to Change: Solar and Wind Cost Reduction Potential to 2025; IRENA: Masdar City, United Arab Emirates, 2016; ISBN 9789295111974. [Google Scholar]

- Artigao, E.; Martín-Martínez, S.; Honrubia-Escribano, A.; Gómez-Lázaro, E. Wind turbine reliability: A comprehensive review towards effective condition monitoring development. Appl. Energy 2018, 228, 1569–1583. [Google Scholar] [CrossRef]

- Agarwal, A. Wind Turbine Operations and Maintenance Market—Global Market Size, Trends, and Key Country Analysis to 2025; Technology Report; GlobalData: London, UK, 2017. [Google Scholar]

- Du, Y.; Zhou, S.; Jing, X.; Peng, Y.; Wu, H.; Kwok, N. Damage detection techniques for wind turbine blades: A review. Mech. Syst. Signal Process. 2020, 141, 106445. [Google Scholar] [CrossRef]

- Sunder Selwyn, T.; Hemalatha, S. Experimental analysis of mechanical vibration in 225 kW wind turbine gear box. Mater. Today Proc. 2021, 46, 3292–3296. [Google Scholar] [CrossRef]

- Civera, M.; Surace, C. Non-Destructive Techniques for the Condition and Structural Health Monitoring of Wind Turbines: A Literature Review of the Last 20 Years. Sensors 2022, 22, 1627. [Google Scholar] [CrossRef]

- Marquez, F.P.G.; Muñoz, C.Q.G. A new approach for fault detection, location and diagnosis by ultrasonic testing. Energies 2020, 13, 1192. [Google Scholar] [CrossRef] [Green Version]

- de Azevedo, H.D.M.; de Arruda Filho, P.H.C.; Araújo, A.M.; Bouchonneau, N.; Rohatgi, J.S.; de Souza, R.M.C. Vibration monitoring, fault detection, and bearings replacement of a real wind turbine. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 3837–3848. [Google Scholar] [CrossRef]

- Aihara, A.; Kawaguchi, T.; Miki, N.; Azami, T.; Sakamoto, H.; Okuma, M. A Vibration Estimation Method for Wind Turbine Blades. Exp. Mech. 2017, 57, 1213–1224. [Google Scholar] [CrossRef]

- Kaewniam, P.; Cao, M.; Alkayem, N.F.; Li, D.; Manoach, E. Recent advances in damage detection of wind turbine blades: A state-of-the-art review. Renew. Sustain. Energy Rev. 2022, 167, 112723. [Google Scholar] [CrossRef]

- Ciang, C.C.; Lee, J.R.; Bang, H.J. Structural health monitoring for a wind turbine system: A review of damage detection methods. Meas. Sci. Technol. 2008, 19, 122001. [Google Scholar] [CrossRef] [Green Version]

- Hwang, S.; An, Y.K.; Sohn, H. Continuous Line Laser Thermography for Damage Imaging of Rotating Wind Turbine Blades. Procedia Eng. 2017, 188, 225–232. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, L.; Zhang, W.; Ai, Y. Non-destructive testing of wind turbine blades using an infrared thermography: A review. In 2013 International Conference on Materials for Renewable Energy and Environment; IEEE: Piscataway, NJ, USA, 2014; pp. 407–410. [Google Scholar] [CrossRef]

- Glowacz, A. Thermographic Fault Diagnosis of Shaft of BLDC Motor. Sensors 2022, 22, 8537. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L. A review of failure modes, condition monitoring and fault diagnosis methods for large-scale wind turbine bearings. Measurement 2020, 149, 107002. [Google Scholar] [CrossRef]

- Fatimi, A. Exploring the Patent Landscape and Innovation of Hydrogel-based BioinksUsed for 3D Bioprinting. Recent Adv. Drug Deliv. Formul. 2022, 16, 145–163. [Google Scholar] [CrossRef]

- Liu, Z.; Jia, Z.; Vong, C.M.; Han, J.; Yan, C.; Pecht, M. A Patent Analysis of Prognostics and Health Management (PHM) Innovations for Electrical Systems. IEEE Access 2018, 6, 18088–18107. [Google Scholar] [CrossRef]

- Wu, P.T.; Park, C.; Stephen, E. Detecting Internal Abnormalities in Turbines. U.S. Patent 4,335,600, 22 June 1982. [Google Scholar]

- Nian, V.; Mignacca, B.; Locatelli, G. Policies toward net-zero: Benchmarking the economic competitiveness of nuclear against wind and solar energy. Appl. Energy 2022, 320, 119275. [Google Scholar] [CrossRef]

- Su, C.W.; Khan, K.; Umar, M.; Zhang, W. Does renewable energy redefine geopolitical risks? Energy Policy 2021, 158, 112566. [Google Scholar] [CrossRef]

- Su, C.W.; Pang, L.D.; Tao, R.; Shao, X.; Umar, M. Renewable energy and technological innovation: Which one is the winner in promoting net-zero emissions? Technol. Forecast. Soc. Chang. 2022, 182, 121798. [Google Scholar] [CrossRef]

- Qu, W.Q.; Liyan, J.W. Detecting Faults in Wind Turbines. U.S. Patent US20210108988, 11 May 2021. [Google Scholar]

- Ernst, R.; Klinge, I.S.; Enoch, C.; Hawkins, J. Handling System and Associated Methods for Conducting Tomography Scans for Defects In Manufactured Wind Turbine Blades. WO Patent WO/2021/151448, 5 August 2021. [Google Scholar]

- Li, D.D.; Zhao, Y.; Zhao, Y.; Jiang, H.T.; Zhang, K. Fault Diagnosis Method of Planetary Gear Box of Wind Turbine. Patent CN112861787A, 28 May 2021. [Google Scholar]

- Chou, J.S.; Chiu, C.K.; Huang, I.K.; Chi, K.N. Failure analysis of wind turbine blade under critical wind loads. Eng. Fail. Anal. 2013, 27, 99–118. [Google Scholar] [CrossRef]

- García Márquez, F.P.; Tobias, A.M.; Pinar Pérez, J.M.; Papaelias, M. Condition monitoring of wind turbines: Techniques and methods. Renew. Energy 2012, 46, 169–178. [Google Scholar] [CrossRef]

- Tchakoua, P.; Wamkeue, R.; Ouhrouche, M.; Slaoui-Hasnaoui, F.; Tameghe, T.A.; Ekemb, G. Wind Turbine Condition Monitoring: State-of-the-Art Review, New Trends, and Future Challenges. Energies 2014, 7, 2595–2630. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Ding, X.; Gong, Y.; Wu, N.; Yan, H. Rotor imbalance detection and quantification in wind turbines via vibration analysis. Wind Eng. 2022, 46, 3–11. [Google Scholar] [CrossRef]

- Strömbergsson, D.; Marklund, P.; Berglund, K. Increasing wind turbine drivetrain bearing vibration monitoring detectability using an artificial neural network implementation. Appl. Sci. 2021, 11, 3588. [Google Scholar] [CrossRef]

- Gholizadeh, S. A review of non-destructive testing methods of composite materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef] [Green Version]

- Park, B.; An, Y.K.; Sohn, H. Visualization of hidden delamination and debonding in composites through noncontact laser ultrasonic scanning. Compos. Sci. Technol. 2014, 100, 10–18. [Google Scholar] [CrossRef]

- Mohr, G.; Sommer, K.; Knobloch, T.; Altenburg, S.J.; Recknagel, S.; Bettge, D.; Hilgenberg, K. Process Induced Preheating in Laser Powder Bed Fusion Monitored by Thermography and Its Influence on the Microstructure of 316L Stainless Steel Parts. Metals 2021, 11, 1063. [Google Scholar] [CrossRef]

- Ishikawa, M.; Tsukagoshi, M.; Kasano, H.; Nishino, H. Influence of composition and surface discoloration of concrete on active thermographic nondestructive inspection. Measurement 2021, 168, 108395. [Google Scholar] [CrossRef]

- Mezza, S.; Vazquez, P.; Ben M’barek Jemai, M.; Fronteau, G. Infrared thermography for the investigation of physical–chemical properties and thermal durability of Tunisian limestone rocks. Constr. Build. Mater. 2022, 339, 127470. [Google Scholar] [CrossRef]

- Hwang, S.; An, Y.K.; Yang, J.; Sohn, H. Remote Inspection of Internal Delamination in Wind Turbine Blades using Continuous Line Laser Scanning Thermography. Int. J. Precis. Eng. Manuf. Green Technol. 2020, 7, 699–712. [Google Scholar] [CrossRef]

- Doroshtnasir, M.; Worzewski, T.; Krankenhagen, R.; Röllig, M.; Doroshtnasir, C.M. On-site inspection of potential defects in wind turbine rotor blades with thermography. Wind Energy 2015, 19, 1407–1422. [Google Scholar] [CrossRef]

- Oehme, F.; Gleichauf, D.; Suhr, J.; Balaresque, N.; Sorg, M.; Fischer, A. Thermographic detection of turbulent flow separation on rotor blades of wind turbines in operation. J. Wind Eng. Ind. Aerodyn. 2022, 226, 105025. [Google Scholar] [CrossRef]

- Li, C.; Sanchez, R.V.; Zurita, G.; Cerrada, M.; Cabrera, D.; Vásquez, R.E. Gearbox fault diagnosis based on deep random forest fusion of acoustic and vibratory signals. Mech. Syst. Signal Process. 2016, 76–77, 283–293. [Google Scholar] [CrossRef]

- Ma, M.; Sun, C.; Chen, X. Deep Coupling Autoencoder for Fault Diagnosis with Multimodal Sensory Data. IEEE Trans. Ind. Inform. 2018, 14, 1137–1145. [Google Scholar] [CrossRef]

- Wang, J.; Fu, P.; Zhang, L.; Gao, R.X.; Zhao, R. Multilevel Information Fusion for Induction Motor Fault Diagnosis. IEEE/ASME Trans. Mechatron. 2019, 24, 2139–2150. [Google Scholar] [CrossRef]

- Dao, P.B. Condition monitoring and fault diagnosis of wind turbines based on structural break detection in SCADA data. Renew. Energy 2022, 185, 641–654. [Google Scholar] [CrossRef]

- Mian, T.; Choudhary, A.; Fatima, S. Vibration and infrared thermography based multiple fault diagnosis of bearing using deep learning. Nondestruct. Test. Eval. 2022, 1–12. [Google Scholar] [CrossRef]

- Jiang, G.; Jia, C.; Nie, S.; Wu, X.; He, Q.; Xie, P. Multiview enhanced fault diagnosis for wind turbine gearbox bearings with fusion of vibration and current signals. Measurement 2022, 196, 111159. [Google Scholar] [CrossRef]

- de Novaes Pires Leite, G.; da Cunha, G.T.M.; dos Santos Junior, J.G.; Araújo, A.M.; Rosas, P.A.C.; Stosic, T.; Stosic, B.; Rosso, O.A. Alternative fault detection and diagnostic using information theory quantifiers based on vibration time-waveforms from condition monitoring systems: Application to operational wind turbines. Renew. Energy 2021, 164, 1183–1194. [Google Scholar] [CrossRef]

- Liu, J.; Wang, X.; Wu, S.; Wan, L.; Xie, F. Wind turbine fault detection based on deep residual networks. Expert Syst. Appl. 2023, 213, 119102. [Google Scholar] [CrossRef]

- Manno, D.; Cipriani, G.; Ciulla, G.; Di Dio, V.; Guarino, S.; Lo Brano, V. Deep learning strategies for automatic fault diagnosis in photovoltaic systems by thermographic images. Energy Convers. Manag. 2021, 241, 114315. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.; Peng, D.; Cheng, Z. Attention-guided joint learning CNN with noise robustness for bearing fault diagnosis and vibration signal denoising. ISA Trans. 2022, 128, 470–484. [Google Scholar] [CrossRef]

- This is Vestas. Available online: https://www.vestas.com/ (accessed on 6 December 2022).

- State Grid Corporation of China. Available online: https://stategrid.com.br/ (accessed on 7 December 2022).

- GE—ABOUT US. Available online: https://www.ge.com/about-us (accessed on 7 December 2022).

- Bahramian, P.; Jenkins, G.P.; Milne, F. The displacement impacts of wind power electricity generation: Costly lessons from Ontario. Energy Policy 2021, 152, 112211. [Google Scholar] [CrossRef]

- Crijns-Graus, W.; Wild, P.; Amineh, M.P.; Hu, J.; Yue, H. International Comparison of Research and Investments in New Renewable Electricity Technologies: A Focus on the European Union and China. Energies 2022, 15, 6383. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, X.; Du, S.; Li, C.; Siu, Y.L.; Rong, Y.; Yang, H. The impact of onshore wind power projects on ecological corridors and landscape connectivity in Shanxi, China. J. Clean. Prod. 2020, 254, 120075. [Google Scholar] [CrossRef]

- Wu, Z.; Zhou, M.; Li, G.; Zhao, T.; Zhang, Y.; Liu, X. Interaction between balancing market design and market behaviour of wind power producers in China. Renew. Sustain. Energy Rev. 2020, 132, 110060. [Google Scholar] [CrossRef]

- Rosales-Asensio, E.; Borge-Diez, D.; Blanes-Peiró, J.-J.; Pérez-Hoyos, A.; Comenar-Santos, A. Review of wind energy technology and associated market and economic conditions in Spain. Renew. Sustain. Energy Rev. 2019, 101, 415–427. [Google Scholar] [CrossRef]

- Wang, Q. Effective policies for renewable energy—The example of China’s wind power—Lessons for China’s photovoltaic power. Renew. Sustain. Energy Rev. 2010, 14, 702–712. [Google Scholar] [CrossRef]

- Yu-Ling Hsiao, C.; Sheng, N.; Fu, S.; Wei, X. Evaluation of contagious effects of China’s wind power industrial policies. Energy 2022, 238, 121760. [Google Scholar] [CrossRef]

- Stern, N.; Xie, C. China’s new growth story: Linking the 14th Five-Year Plan with the 2060 carbon neutrality pledge. J. Chin. Econ. Bus. Stud. 2022, 1–12. [Google Scholar] [CrossRef]

- Niu, Z.; Xiong, J.; Ding, X.; Wu, Y. Analysis of China’s Carbon Peak Achievement in 2025. Energies 2022, 15, 5041. [Google Scholar] [CrossRef]

- Jiang, Z.; Liu, Z. Policies and exploitative and exploratory innovations of the wind power industry in China: The role of technological path dependence. Technol. Forecast. Soc. Chang. 2022, 177, 121519. [Google Scholar] [CrossRef]

- Dai, J.; Xin, Y.; Li, W. Development of wind power industry in China: A comprehensive assessment. Renew. Sustain. Energy Rev. 2018, 97, 156–164. [Google Scholar] [CrossRef]

- Song, Y.; Liu, J.; Wei, Y.; Zhang, M. Study on the direct and indirect effectiveness of wind power policy: Empirical evidence from 30 provinces in China. Renew. Energy 2021, 170, 749–763. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhiying, L. Can wind power policies effectively improve the productive efficiency of Chinese wind power industry? Int. J. Green Energy 2021, 18, 1339–1351. [Google Scholar] [CrossRef]

- Jiang, Z.; Shi, J.; Liu, Z.; Gong, L. Beyond bean counting: Is the policy effective for the innovation efficiency of wind power industry in China? Res. Eval. 2022, 31, 132–144. [Google Scholar] [CrossRef]

- Wang, X.; Zhi, M. Summary of object detection based on convolutional neural network. In Eleventh International Conference on Graphics and Image Processing; SPIE: Bellingham, WA, USA, 2020; Volume 113730. [Google Scholar]

- Zhang, S.; Chen, L.; Zheng, Y.; Li, Y.; Li, Y.; Zeng, M. How policies guide and promoted wind power to market transactions in china during the 2010s. Energies 2021, 14, 4096. [Google Scholar] [CrossRef]

- Shoeib, E.A.H.; Renski, H.C.; Hamin Infield, E. Who benefits from Renewable Electricity? The differential effect of wind power development on rural counties in the United States. Energy Res. Soc. Sci. 2022, 85, 102398. [Google Scholar] [CrossRef]

- Muhammed, G.; Tekbiyik-Ersoy, N. Development of renewable energy in china, usa, and brazil: A comparative study on renewable energy policies. Sustainability 2020, 12, 9136. [Google Scholar] [CrossRef]

- Wiser, R.; Bolinger, M.; Hoen, B. Land-Based Wind Market Report: 2022 Edition; Lawrence Berkeley National Lab. (LBNL): Berkeley, CA, USA, 2022. [Google Scholar]

- Zhang, H.; Yang, J.; Ren, X.; Wu, Q.; Zhou, D.; Elahi, E. How to accommodate curtailed wind power: A comparative analysis between the US, Germany, India and China. Energy Strategy Rev. 2020, 32, 100538. [Google Scholar] [CrossRef]

- Msigwa, G.; Ighalo, J.O.; Yap, P.S. Considerations on environmental, economic, and energy impacts of wind energy generation: Projections towards sustainability initiatives. Sci. Total Environ. 2022, 849, 157755. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.-Y.; Zhou, B. Infrared Flaw Detection Robot for Wind Turbine Blades. Patent CN215979709U, 8 March 2022. [Google Scholar]

- Wei, J. Wind Power Generation Blade Defect Detection System. Patent CN217029182U, 22 July 2022. [Google Scholar]

- Ma, X. Fault Diagnosis Method and Equipment of Wind Turbine Generator Set. Patent CN108957315A, 7 December 2017. [Google Scholar]

- Liu, H.; Gao, S.Z.; Wang, J.; Zhao, L.J.; Guo, S. Wind Turbine Main Bearing Fault Diagnosis Method Based on Blind Source Separation. Patent CN104374575A, 25 February 2017. [Google Scholar]

- Ma, Y.C.; Liu, Y.Q.; Yang, Z.L.; Zhao, Y.; Zhang, L.N. Wind Turbine Generator Bearing Fault Diagnosis Method for Multi-channel Deep Convolutional Neural Network. Patent CN107560849B, 18 February 2020. [Google Scholar]

- Li, P.; Tong, R.N.; Lang, X.; Gao, L.; Zeng, J.R.; Fu, L.T.; Wang, Y.X.; Wang, H.Y. Fan Blade Icing Fault Detection Method and System Based on AWKELM. Patent CN113323823B, 31 August 2021. [Google Scholar]

- Soares-Ramos, E.P.P.; de Oliveira-Assis, L.; Sarrias-Mena, R.; Fernández-Ramírez, L.M. Current status and future trends of offshore wind power in Europe. Energy 2020, 202, 117787. [Google Scholar] [CrossRef]

- Souza, R.M.; Nascimento, E.G.S.; Miranda, U.A.; Silva, W.J.D.; Lepikson, H.A. Deep learning for diagnosis and classification of faults in industrial rotating machinery. Comput. Ind. Eng. 2021, 153, 107060. [Google Scholar] [CrossRef]

- Elyasichamazkoti, F.; Khajehpoor, A. Application of machine learning for wind energy from design to energy-Water nexus: A Survey. Energy Nexus 2021, 2, 100011. [Google Scholar] [CrossRef]

- Sudhakar, P.; Kamble, N.K.; Geetha, K.; Turukmane, A.V.; Babu, S.; Jayaraman, P. Faulty diagnostics model for wind power plant application using AI. Meas. Sens. 2023, 25, 100621. [Google Scholar] [CrossRef]

| IPC Code | Regarding |

|---|---|

| F03D | Wind Motors |

| G01H | Measurement of Mechanical Vibrations or Ultrasonic, Sonic, or Infrasonic Waves |

| G01M | Testing Static or Dynamic Balance of Machines or Structures; Testing of Structures or Apparatus, Not Otherwise Provided For |

| G01R | Measuring Electric Variables; Measuring Magnetic Variables (Indicating Correct Tuning of Resonant Circuits H03j3/12) |

| G01J | Measurement of Intensity, Velocity, Spectral Content, Polarization, Phase, or Pulse Characteristics of Infra-Red, Visible, or Ultra-Violet Light; Colorimetry, Radiation Pyrometry (Light Sources F21, H01J, H01K, H05B; Investigating Properties of Materials by Optical Means G01N) |

| G01K | Measuring Temperature; Measuring Quantity of Heat; Thermally Sensitive Elements Not Otherwise Provided For (Radiation Pyrometry G01j5/00) |

| Title | Technology | Main Findings and/or Conclusions | Reference |

|---|---|---|---|

| Multiview enhanced fault diagnosis for wind turbine gearbox bearings with fusion of vibration and current signals | Vibration Analysis + Canonical correlation analysis (CCA) | The paper undertook a novel evaluation of a multiview fault diagnosis framework enhanced to comprehend the correlated and complementary features between current and vibration signals, which were considered as two different but related views. They used an unsupervised multiview learning method based on canonical correlation analysis (CCA) to evaluate this correlation. The results have shown balanced fault characteristics and achieved higher performance in fault diagnosis, especially in composite faults, compared to methods based on unimodal signals. | [61] |

| Alternative fault detection and diagnostic using information theory quantifiers based on vibration time-waveforms from condition monitoring systems: Application to operational wind turbines | Vibration + Probability mass function | The paper analyzed information on two theory quantifiers used to monitor and detect changes in the vibration signals of two operational wind turbines of 750 kW and 2 MW. The authors evaluated the signals by power spectrum (frequency domain method), wavelet transform (time-frequency domain method), and Bandt–Pompe (time-domain method). The results demonstrated that the proposed method could distinguish (cluster) well between the states of fault. | [62] |

| Wind turbine fault detection based on deep residual networks | SCADA | In this article, researchers proposed a new depth network called deep residual network (DRN) to further analyze the raw data generated by WTs. In the method, the raw data gathered by the SCADA system are applied directly as inputs to the DRN network. Then, a convolutional residual building block (CRBB) was established by using convolutional layers and squeeze and excitation units. The results indicate that the proposed DRN achieved better performance and outperforms some published fault-detection methods. | [63] |

| Deep learning strategies for automatic fault diagnosis in photovoltaic systems by thermographic images | Deep Learning + Thermography | The authors proposed a system for the automatic classification of thermographic images using a convolutional neural network developed via open-source libraries. The results showed a 99% accuracy for a dataset of 1000 images using a multi-layer perceptron architecture and 100% accuracy for a convolutional neural network. | [64] |

| Attention-guided joint learning CNN with noise robustness for bearing fault diagnosis and vibration signal denoising | Deep Learning + Vibration | The paper reports a novel attention-driven joint learning convolutional neural network (JL-CNN) for monitoring conditions. The fault diagnosis task (FD-Task) and the signal denoising task (SD-Task) are integrated into an end-to-end CNN architecture, reaching good noise robustness through dual-task joint learning. This method allowed FD-Task and SD-Task to achieve deep cooperation and mutual learning, and the results showed outstanding fault diagnosis capacity and signal denoising ability. | [65] |

| Priority Number | Title | Refers to | Reference |

|---|---|---|---|

| US20210108988A1 | Detecting Faults in Wind Turbines | A wind turbine monitoring system for detecting faults produced by wind turbine generators and comprises a shaft rotation frequency signal that is determined from the first signal, and the first signal that is obtained from the generator of the wind turbine. | [40] |

| CN108957315A | Fault diagnosis method and equipment of wind turbine generator system | A wind turbine generator system fault diagnosing method that involves determining the testing point of fault detection of a system, detecting the testing signal of a testing point for fault detection, and determining the fault diagnosis function system. | [92] |

| CN104374575A | Wind turbine main bearing fault diagnosis method based on blind source separation | Blind source separating wind turbine main bearing fault diagnosis method involves receiving sound transmission signals and acoustic emission signals, adopting a reconstitution algorithm, and determining turbine test normal operation conditions. | [93] |

| CN107560849A | Wind turbine generator bearing fault diagnosis method for multi-channel deep convolutional neural network | Neural-network-based multi-channel depth convolution wind turbine bearing fault diagnosing method involves collecting test bearing under each state drive end and evaluating diagnosis model for obtaining application bearing to be monitored. | [94] |

| CN113323823A | Fan blade icing fault detection method and system based on AWKELM | Method for detecting fan blade icing fault that involves inputting supervisory control and data acquisition (SCADA) data of wind generating set to be tested and performing maintenance decisions according to the detection results. | [95] |

| IPC Code | Related to |

|---|---|

| F03D 17/00 | Monitoring or testing of wind motors, e.g., diagnostics (testing during the commissioning of wind motors F03D13/30) |

| G01M 13/00 | Testing of machine parts |

| F03D 11/00 | Details, parts, and accessories not included in or pertinent to the other groups of this subclass |

| G01R 31/34 | Testing dynamo-electric machines |

| F03D 1/06 | Rotors |

| F03D 80/50 | Maintenance or repair |

| F03D 80/00 | Details, components, or accessories not provided for in groups F03D1/00—F03D17/00 |

| F03D 7/00 | Controlling wind motors |

| G01R 31/00 | Arrangements for testing electric properties; arrangements for locating electrical faults; arrangements for electrical testing characterized by what is being tested not provided for elsewhere |

| F03D 7/02 | The wind motors have a rotation axis substantially parallel to the air flow entering the rotor |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barbosa, N.B.; Nunes, D.D.G.; Santos, A.Á.B.; Machado, B.A.S. Technological Advances on Fault Diagnosis in Wind Turbines: A Patent Analysis. Appl. Sci. 2023, 13, 1721. https://doi.org/10.3390/app13031721

Barbosa NB, Nunes DDG, Santos AÁB, Machado BAS. Technological Advances on Fault Diagnosis in Wind Turbines: A Patent Analysis. Applied Sciences. 2023; 13(3):1721. https://doi.org/10.3390/app13031721

Chicago/Turabian StyleBarbosa, Natasha Benjamim, Danielle Devequi Gomes Nunes, Alex Álisson Bandeira Santos, and Bruna Aparecida Souza Machado. 2023. "Technological Advances on Fault Diagnosis in Wind Turbines: A Patent Analysis" Applied Sciences 13, no. 3: 1721. https://doi.org/10.3390/app13031721

APA StyleBarbosa, N. B., Nunes, D. D. G., Santos, A. Á. B., & Machado, B. A. S. (2023). Technological Advances on Fault Diagnosis in Wind Turbines: A Patent Analysis. Applied Sciences, 13(3), 1721. https://doi.org/10.3390/app13031721