Method for Prevention of Liquefaction Caused by Earthquakes Using Grouting Applicable to Existing Structures

Abstract

:1. Introduction

2. Materials and Methods

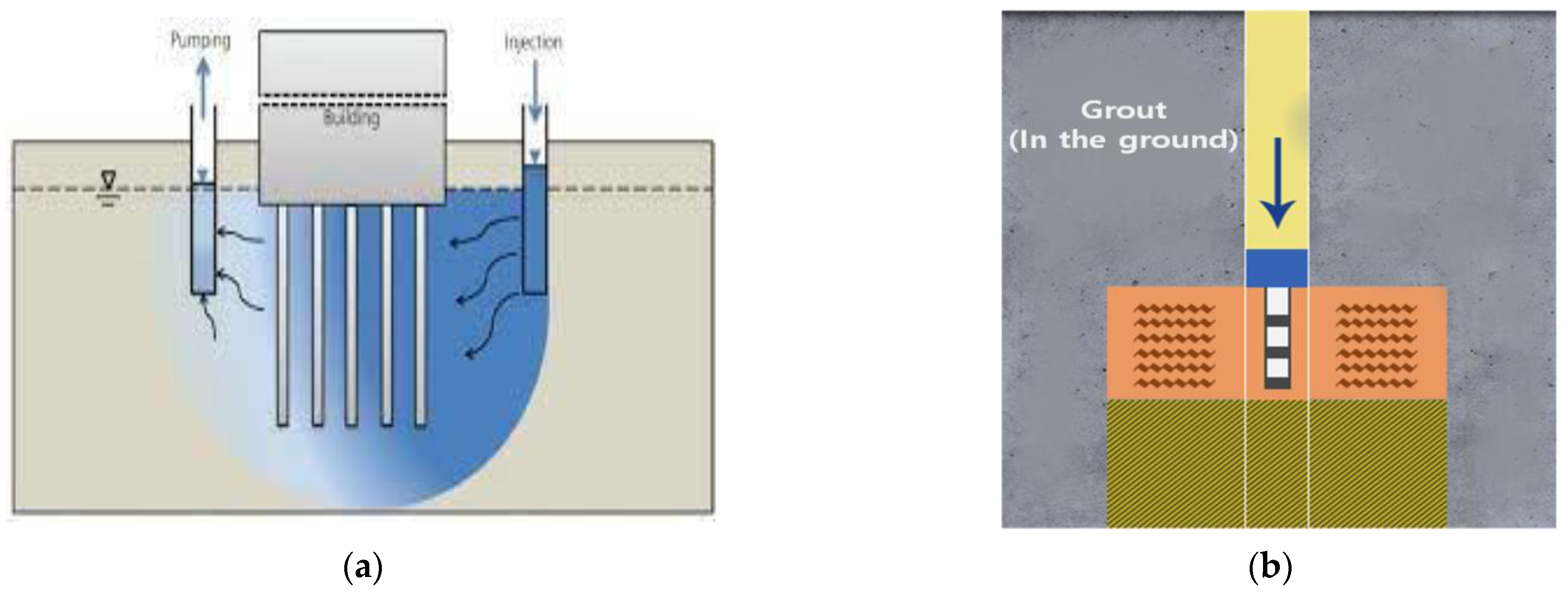

2.1. Penetration Grouting

2.2. Preparation

2.2.1. Vibration Testing Table

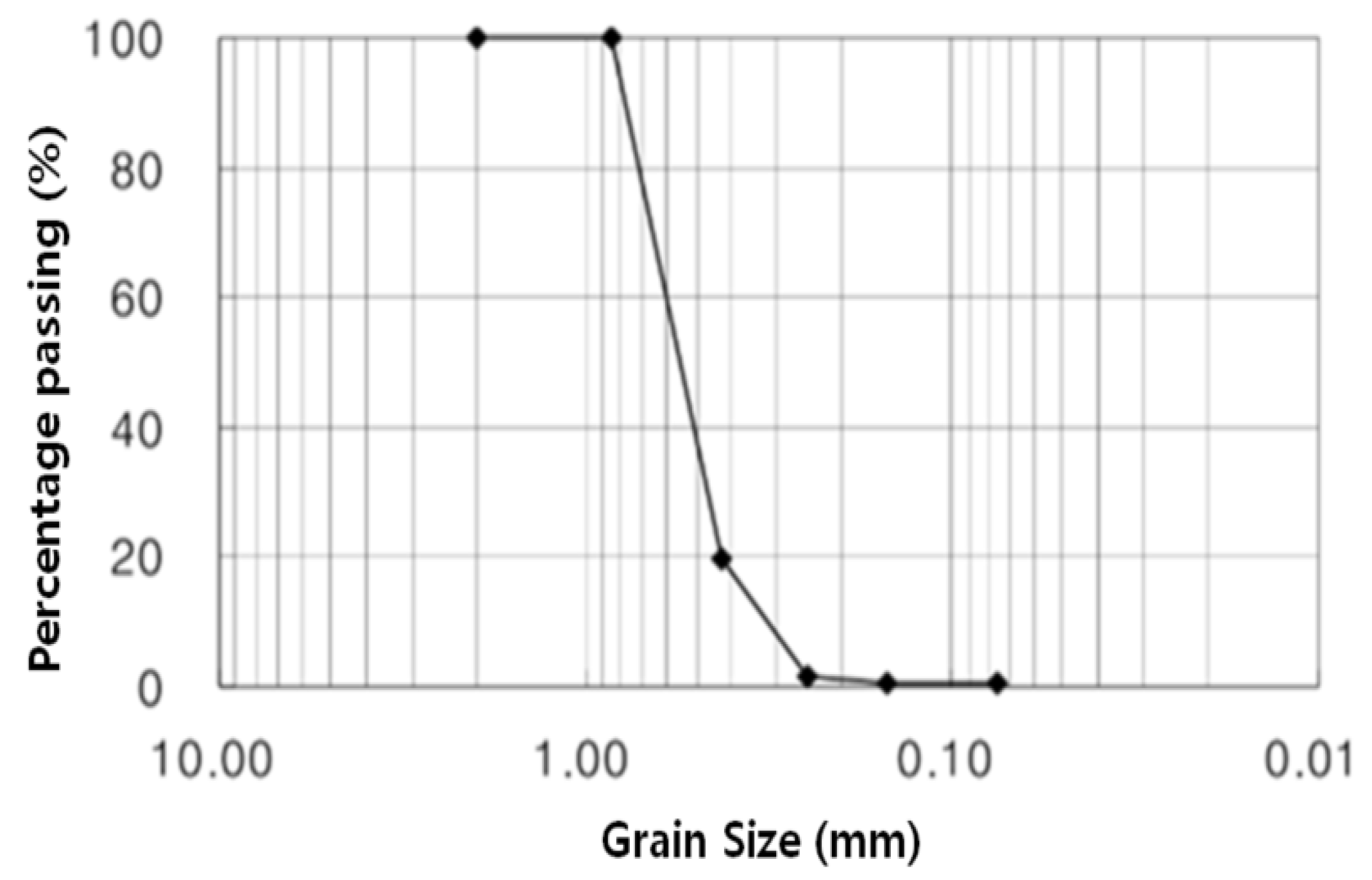

2.2.2. Ground Construction and Installation of Instrumentation Sensor

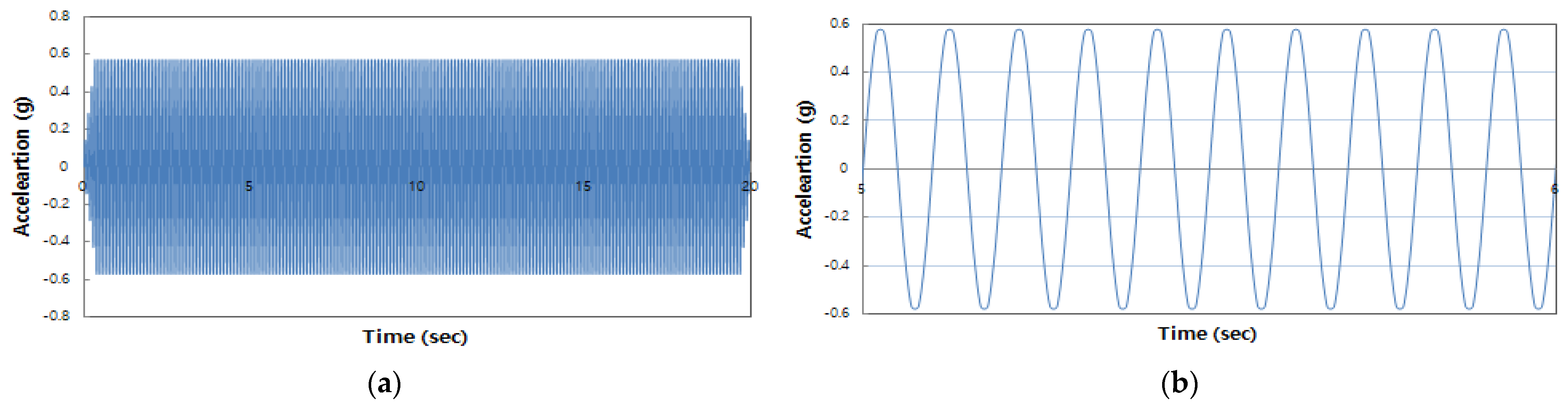

2.2.3. Input Earthquake Wave and Experimental Program

2.2.4. Model Experiment Similarity Ratio

3. Results and Discussion

3.1. Cement Water Mixing Ratio and Separation Distance

3.2. Settlement and Pore Water Pressure

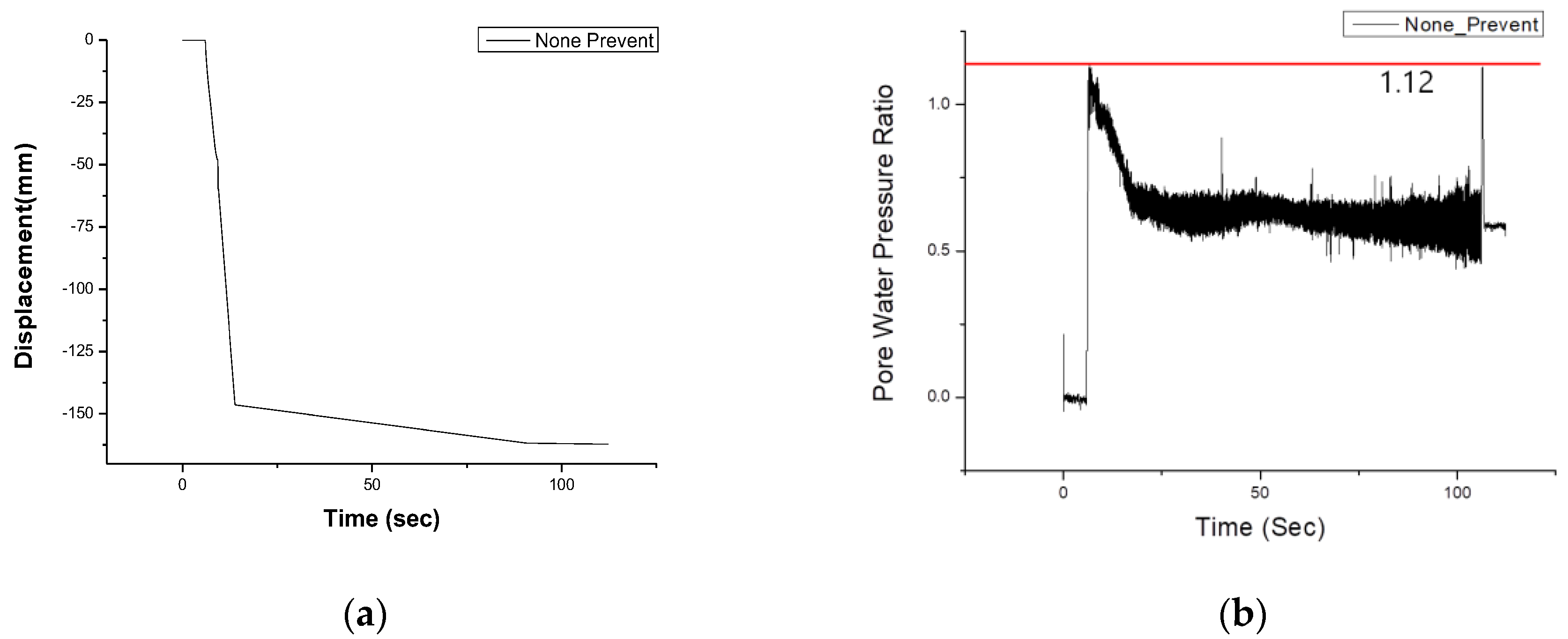

3.3. Non-Reinforcement

3.4. Reinforcement

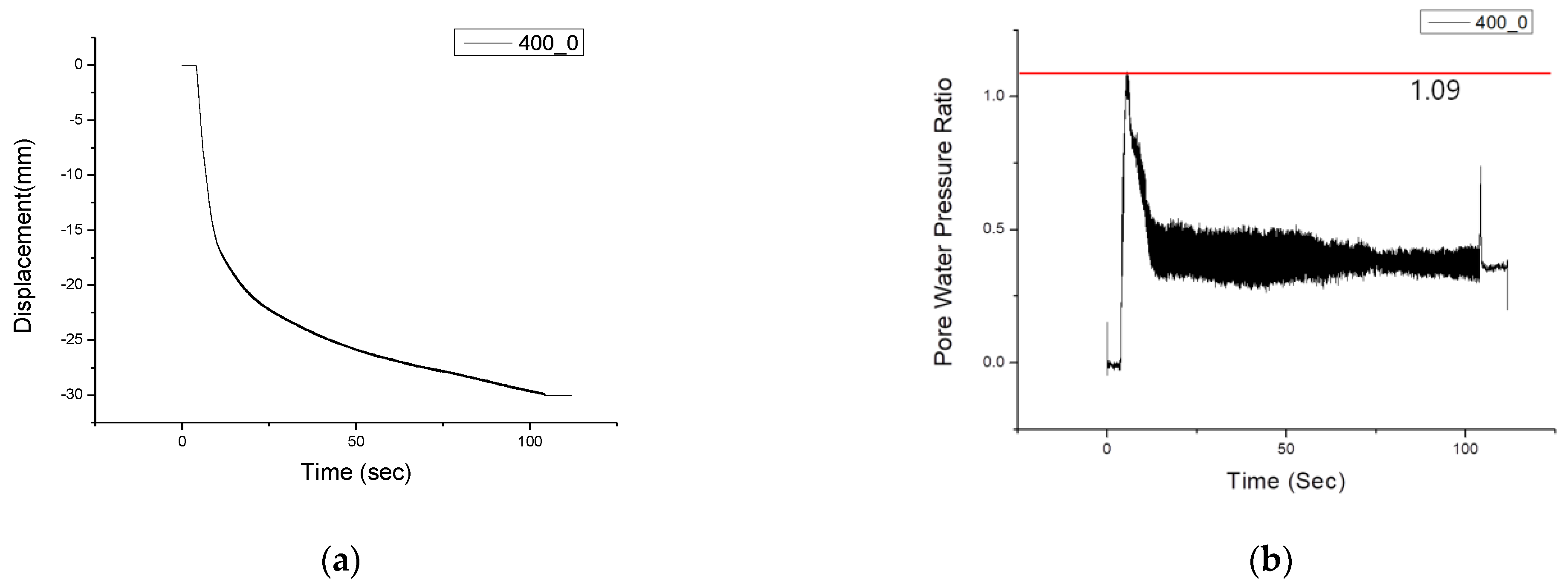

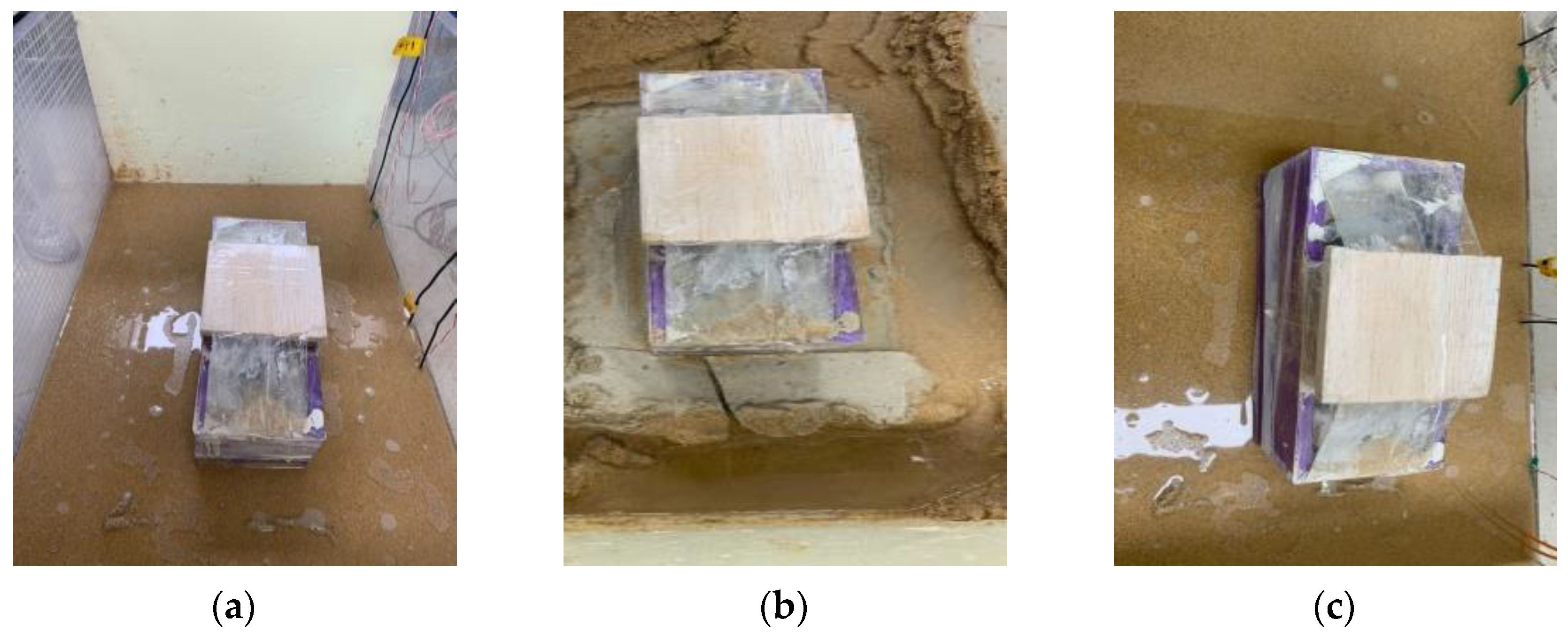

3.4.1. Mixing Ratio 0.4—Separation Distance 0 cm

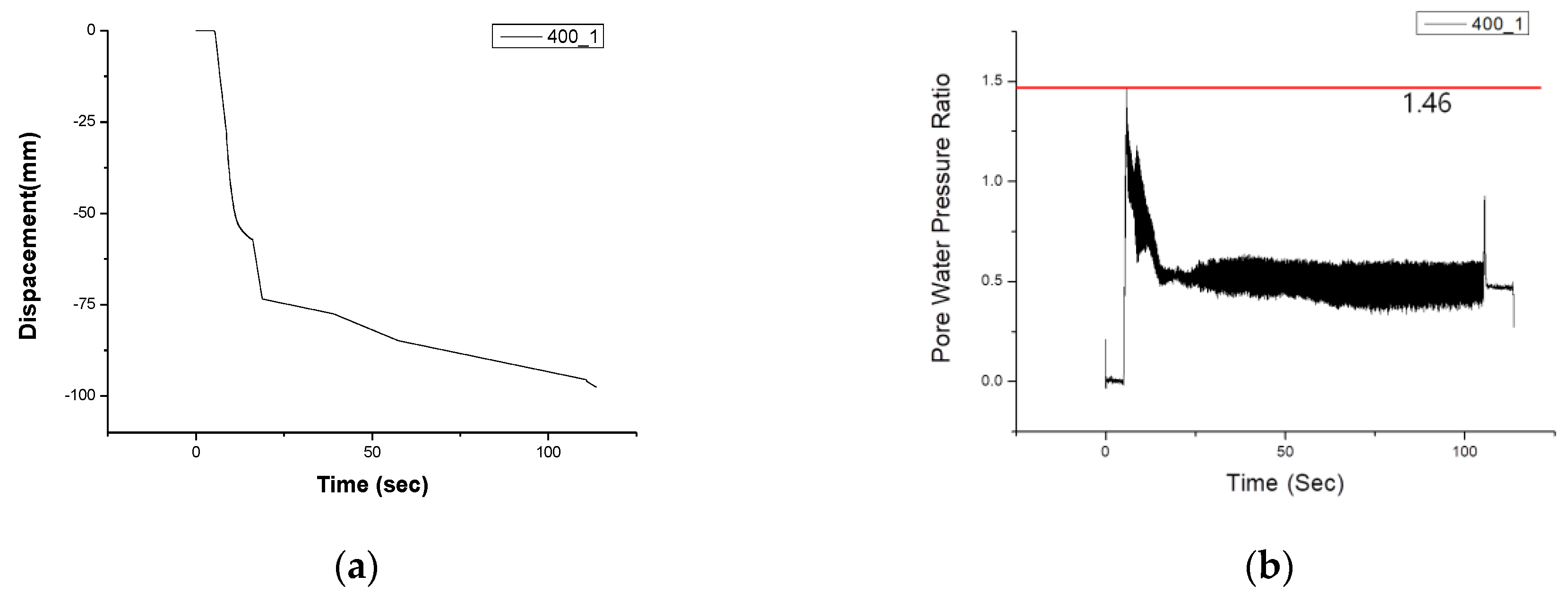

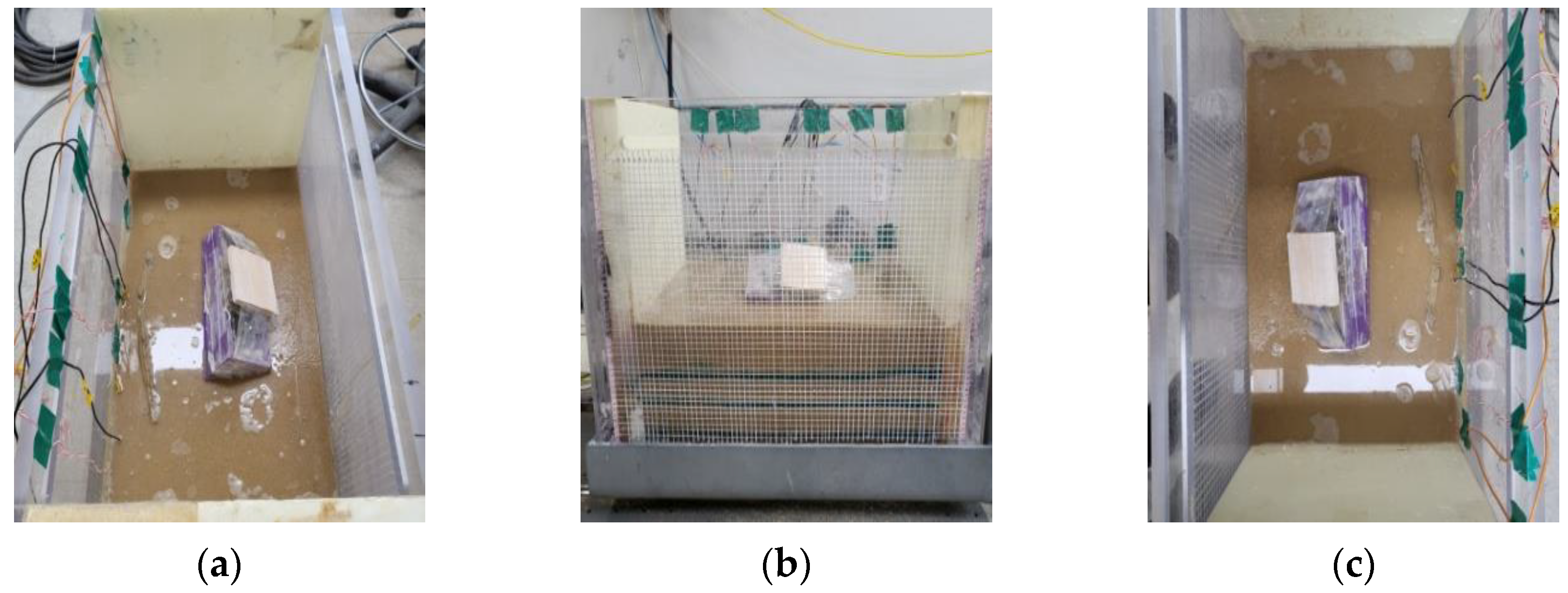

3.4.2. Mixing Ratio 0.4—Separation Distance 1 cm

3.4.3. Mixing Ratio 0.45—Separation Distance 0 cm

3.4.4. Mixing Ratio 0.475—Separation Distance 0 cm

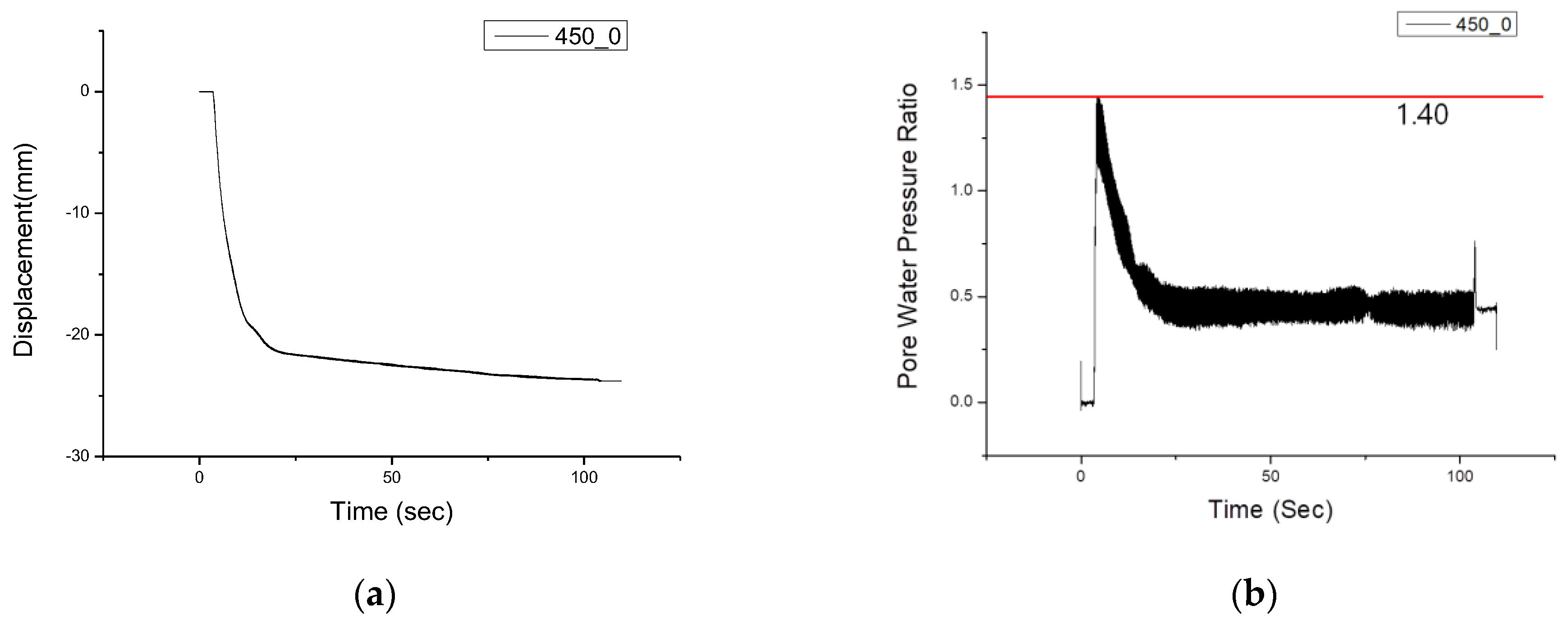

3.4.5. Mixing Ratio 0.5—Separation Distance 0 cm

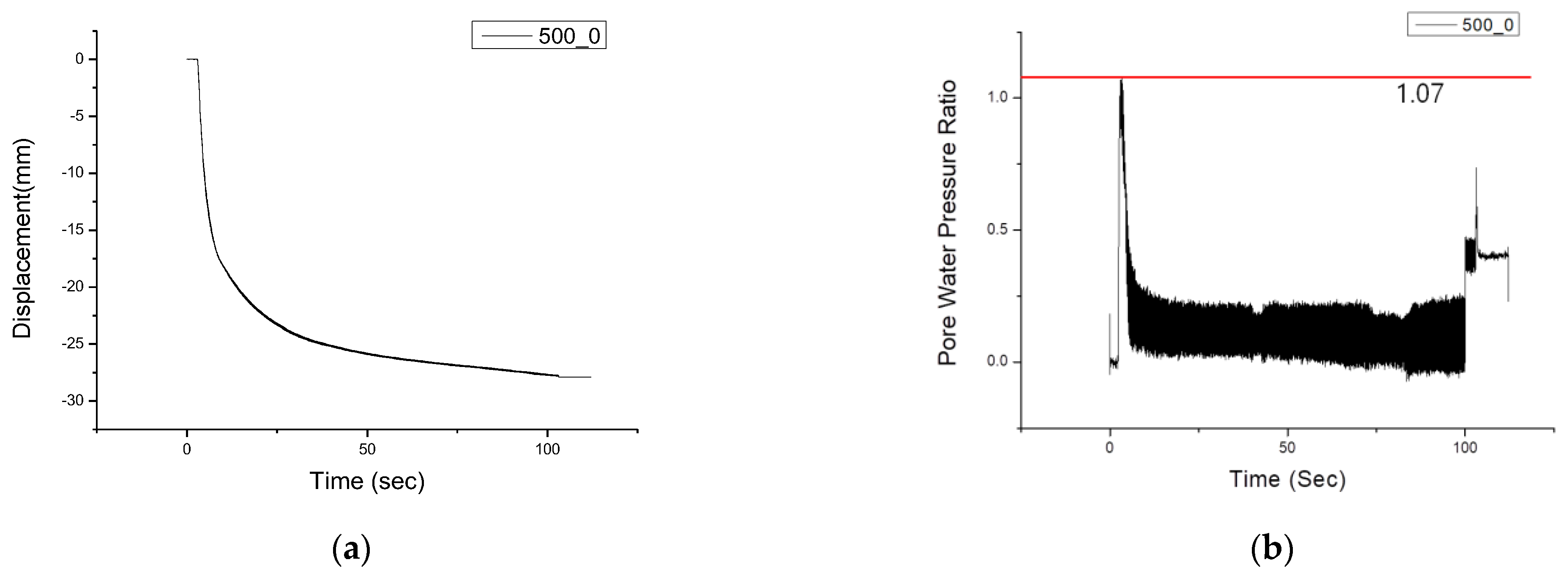

3.4.6. Mixing Ratio 0.5—Separation Distance 1 cm

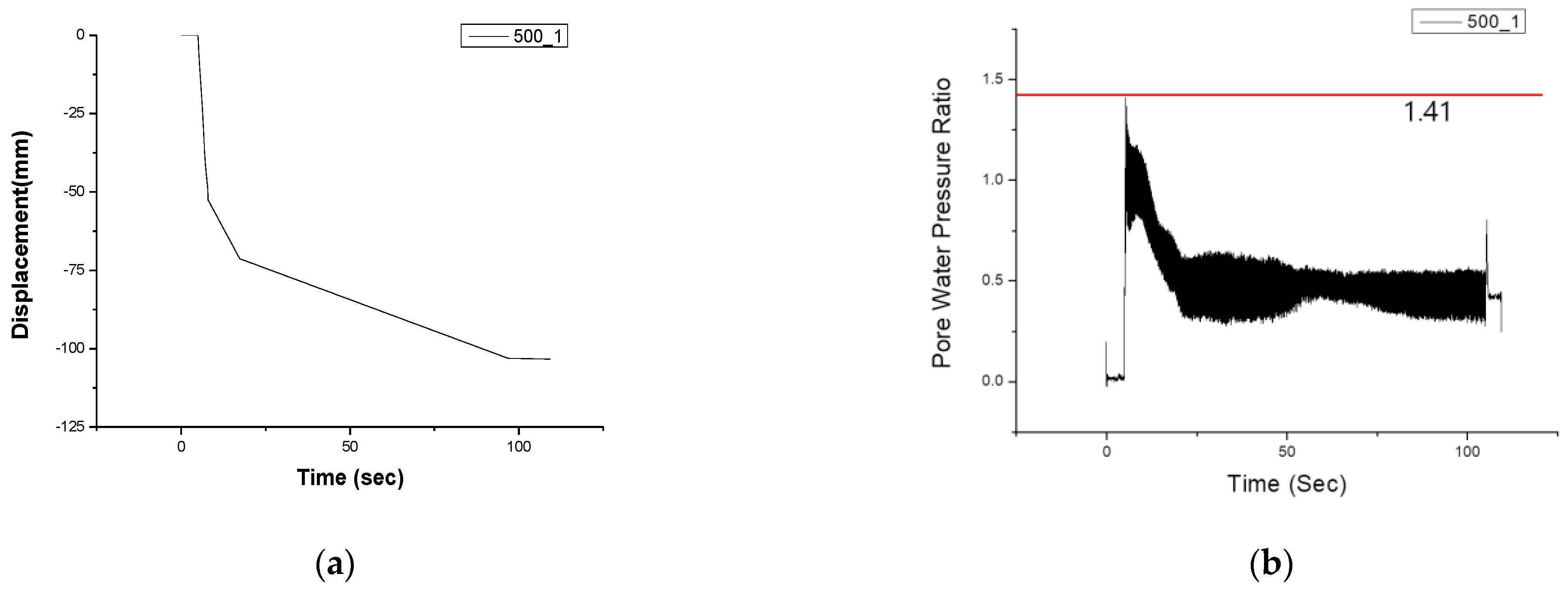

3.4.7. Mixing Ratio 0.55—Separation Distance 0 cm

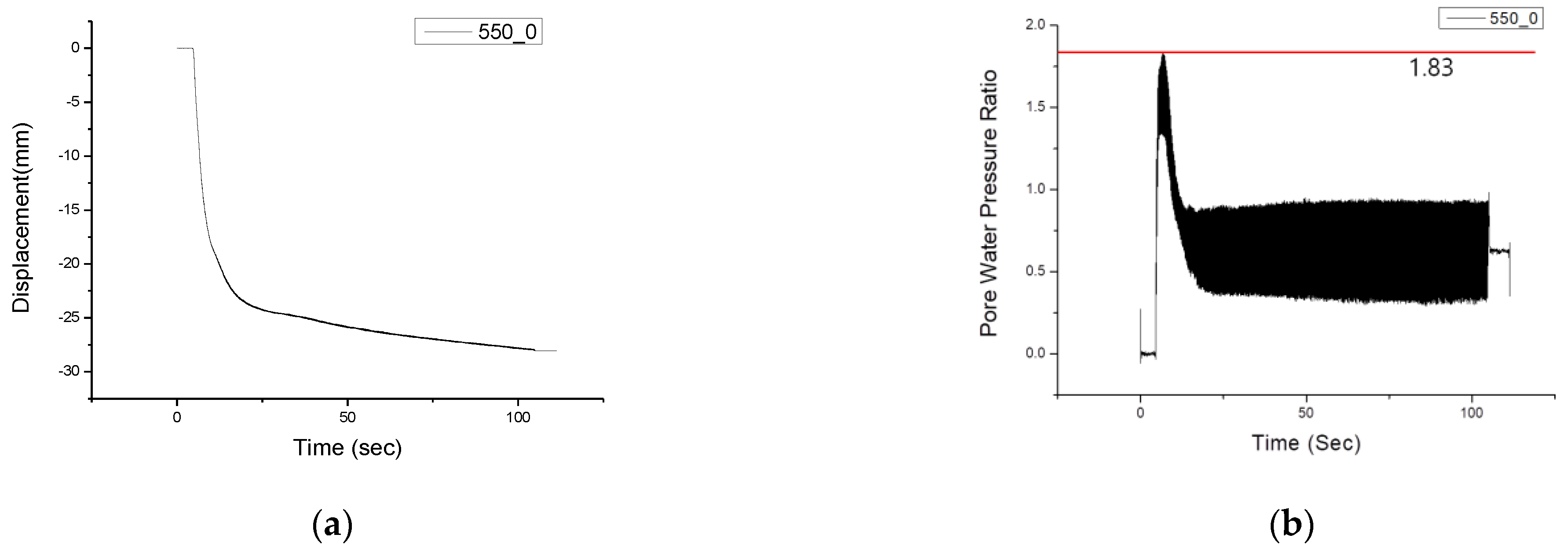

3.5. Comparison of Settlement Amount Based on Grouting Mixing Ratio

4. Conclusions

- The ground reinforcement effect, using grouting, significantly affected the amount of structural subsidence. While the settlement amount of the structure, due to liquefaction, was measured at approximately 8.5 m on the ground without reinforcement, when ground reinforcement was performed through grouting, the smallest value of the structure was measured at approximately 1.15 m, which reduced the amount of settlement by approximately 84%.

- A comparison of the reinforcement effect of the separation distance, between the grouting injection part and the structure, showed that the structure subsided up to 5.2 and 1.65 m when there was or was not a separation distance between the grouting injection part and the structure, respectively. The amount of structural subsidence decreased by approximately 73% when there was no separation distance between the grouting injection part and the structure.

- When there is no separation distance between the grouting injection part and the structure, the grouting chemical penetrates and hardens the ground due to the decrease in the structure settlement amount; this combines with the structure foundation and thus expands the cross-sectional area. As a result, it is thought that the structure’s own load is dispersed and the buoyancy against the excess pore water pressure is increased, thereby reducing structure settlement. Based on these results, it is considered that the absence of a separation distance between the grouting injection part and the structure is more effective in suppressing structure settlement.

- The amount of structure settlement tended to decrease as the grouting mixing ratio increased; however, when the grouting mixing ratio exceeded a certain value, the amount of structure settlement slightly increased. An increase in the grouting, which acted as an additional load on the structure, and the grouting mixing ratio, were considered to increase the amount of settlement in the structure.

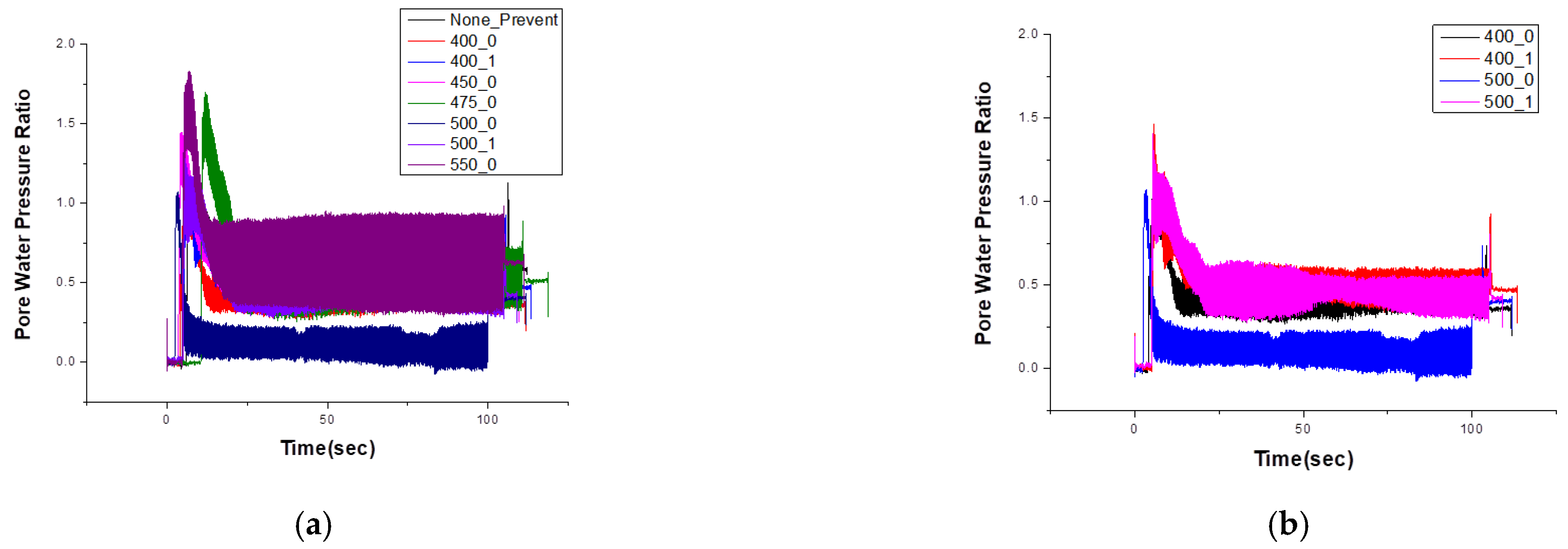

- By comparing the pore water pressure change, according to the grouting chemical mixing ratio and the separation distance between the grouting injection part and the structure, it was confirmed that penetrating the grouting did not significantly affect the suppression of the increase in the pore water pressure. In general, when the ground is reinforced through a high-pressure injection grouting method, the ground is hardened to a deep position in the ground, due to the injected grouting chemical; this suppresses an increase in the pore water pressure during an earthquake. However, unlike the general high-pressure injection grouting method, this study lowers the grouting chemical injection pressure and allows the grouting chemical to penetrate the ground; therefore, the penetration depth of the grouting chemical is smaller than that of the general high-pressure injection grouting method. This seems to cause difficulty in penetrating the grouting chemical into the deep position in the ground, making it difficult to harden the deep ground; for this reason, reinforcing the ground with the penetrating grouting method does not have a significant impact on suppressing the increase in the pore water pressure in the ground.

- No significant difference was found between the input and the ground acceleration, based on the grouting mixing ratio and the separation distance between the grouting injection point and the structure; therefore, we concluded that there is no significant increase or attenuation in the ground acceleration due to penetration grouting.

- The rapidly increasing pore water pressure during an earthquake causes ground liquefaction. The pore water pressure, which increased rapidly in this study, tends to decrease again after reaching the maximum pore water pressure and dissipates. The dissipation rate of such pore water pressure can be seen as one of the important factors in determining the time it takes to recover ground strength. Therefore, the effect of ground reinforcement, via penetrating grouting, on the dissipation of pore water pressure is considered an important process to understand in this study. Accordingly, the change in pore water pressure was confirmed after a certain period of time after liquefaction occurred; as a result, the penetrating grouting method showed no tendency to interfere with or suppress the dissipation of pore water pressure after liquefaction occurred. This is considered to be the case because the grouting chemical does not penetrate to a deep position in the ground, so it does not affect the dissipation of the pore water pressure.

- Considering the effect of grouting on ground reinforcement in the event of liquefaction, it is considered that the optimal grouting mixing ratio is 0.45; this has the smallest structure settlement, has excellent grouting strength, and ensures economic feasibility.

- Based on the results of this study, the correlation equation between the grouting mixing ratio and the structure settlement amount was proposed. This relational equation is expected to enable the effective and efficient calculation of the grouting mixing ratio when the penetrating grouting method is applied on-site in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Korea Meteorological Administration Weather Nuri. Available online: https://www.weather.go.kr/w/eqk-vol/archive/stat/trend.do (accessed on 11 October 2022).

- Seed, H.B.; Idriss, I.M. A Simplified Procedure for Evaluating Soil Liquefaction Potential. J. Soil Mech. Found. Div. 1971, 97, 1249–1273. [Google Scholar] [CrossRef]

- Mejia, L.H.; Boulanger, R.W. A Long-Term Test of Compaction Grouting for Liquefaction Mitigation. In Earthquake-Induced Movements and Seismic Remediation of Existing Foundations and Abutments; Soil Dynamics Committer of the Geotechnical Engineering: San Diego, CA, USA, 1995. [Google Scholar]

- Andrus, D.; Chung, M. Ground Improvement Techniques for Liquefaction Remediation near Existing Lifelines; NISTIR 5714; US National Institute of Standards and Technology: Gaithersburg, MD, USA, 1995.

- Hausler, E.; Sitar, N. Performance of Improved Ground. In Proceedings of the Annual Meeting Research Digest, 2002–16; The Pacific Earthquake Engineering Research Center: Oackland, CA, USA, 2002. [Google Scholar]

- Hausler, E. Influence of Ground Improvement on Settlement and Liquefaction: A Study Based on Field Case History Evidence and Dynamic Geotechnical Centrifuge Tests. Ph.D. Thesis, University of California, Berkeley, CA, USA, 2002. [Google Scholar]

- Kawamura, K.; Yamazaki, H.; Sugano, T.; Hayashi, K. Proof Experiment Using Artificial Earthquake Concerning Effect Of Permeable Grouting Method As Measures Against Liquefaction. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004. [Google Scholar]

- Yasuda, S. Remediation methods against liquefaction which can be applied to existing structures. Earthq. Geotech. Eng. 2007, 6, 385–406. [Google Scholar]

- Caballero, F.L.; Razavi, A.M.F. Numerical simulation of liquefaction effects on seismic SSI. Soil Dyn. Earthq. Eng. 2008, 28, 85–98. [Google Scholar] [CrossRef] [Green Version]

- Sitar, N.; Hausler, E. Influence of Ground Improvement on Liquefaction Induced Settlement: Observations from Case Histories and Centrifuge Experiments. Invited Lecture Presented to the Korean Geotechnical Society Seoul, Korea. Int. J. Geo-Eng. 2012, 4, 5–15. [Google Scholar]

- Rasouli, R.; Hayashi, K. Liquefaction resistance and residual shear strength of soil improved by permeable grouting method. In Proceedings of the Conference of Japanese Geothechnical Society Symposium on Practical Design of Chemical Grouting, Tokyo, Japan, 5 June 2015. [Google Scholar]

- Bray, J.D.; Boulanger, R.W.; Cubrinovski, M.; Tokimatsu, K.; Kramer, S.L.; O’Rourke, T.; Rathje, E.; Green, R.A.; Robertson, P.K.; Beyzaei, C.Z. Liquefaction-Induced Ground Movements Effects. In Proceedings of the U.S.–New Zealand–Japan International Workshop, Berkeley, CA, USA, 2–4 November 2016. [Google Scholar]

- Rasouli, R.; Hayashi, K.; Zen, K. Controlled permeation grouting method for mitigation of liquefaction. J. Geotech. Geoenviron. Eng. 2016, 142, 04016052. [Google Scholar] [CrossRef]

- Park, S.Y.; Shim, H.G.; Kang, H.J.; Lim, O.B.; Kim, Y.S. Grouting injection effectiveness of a permeable compacting grout using permeable compaction type packer. J. Korean Geosynth. Soc. 2017, 16, 149–158. [Google Scholar]

- Nabeshima, Y. Permeation of Ultra-Fine Particle Cement to Sandy Ground and Cement Stabilization. In Proceedings of the International Ocean and Pore Engineering Conference, Shanghai, China, 11–16 October 2020. [Google Scholar]

- Duan, W.; Congress, S.S.C.; Cai, G.; Liu, S.; Dong, X.; Chen, R.; Liu, X. A Hybrid GMDH neural networks and Logistic Regression Framework for State Parameter-Based Liquefaction Evaluation. J. Can. Geotech. 2021, 99, 1801–1811. [Google Scholar] [CrossRef]

- Hasheminezhad, A.; Farazalizadeh, R.; Rahimi, H.; Bahadori, H. Seismic Performance Assessment of Wall-type Gravel and Rubber Drains in Liquefaction Mitigation of Sands. Bull. Earthq. Eng. 2022, 20, 3699–3714. [Google Scholar] [CrossRef]

- Kobayashi, M.; Zen, K.; Chen, G.; Kasama, K. Shaking Table Test on the Improvement Dimension Of Permeable Grouting Method For Liquefaction Countermeasure. In Proceedings of the ASME 2009 28th International Conference on Ocean, Offshore and Arctic Engineering OMAE2009, Honolulu, HI, USA, 31 May–6 June 2009. [Google Scholar]

- Mitrani, H.; Madabhushi, S.P.G. Cementation liquefaction remediation for existing buildings. Ground Improv. 2010, 163, 81–94. [Google Scholar] [CrossRef]

- Wang, W.; Hashimoto, K.; Hyodo, T.; Tsukamoto, Y.; Oji, S.; Nishihara, S.; Kanazawa, T. Examining efficient assisting geotechnology for permeation grouting of ultra microfine cement for soil liquefaction countermeasure. In Proceedings of the 6th Japan-Korea Geotechnical Workshop, Okayama, Japan, 12 September 2016. [Google Scholar]

- Salvatore, E.; Modoni, G.; Mascolo, M.C.; Grassi, D.; Spagnoli, G. Experiment Evidence of the Effectiveness and Applicability of Colloidal Nanosilica Grouting for Liquefaction Mitigation. J. Geotech. Geoenviron. Eng. 2020, 146, 04020108. [Google Scholar] [CrossRef]

- Arpit, J.; Satyendra, M.; Tshering, C. Liquefaction Mitigation Measures of Fine Sand Using Cement Grout Under Cyclic Loading. ISET J. Earthq. Tech. 2020, 57, 555. [Google Scholar]

- Ciardi, G.; Vannucchi, G.; Madial, C. Effects of colloidal silica grouting on geotechnical properties of liquefiable soils: A review. Geotechnics 2021, 1, 460–491. [Google Scholar] [CrossRef]

- Nabeshima, Y. Permeation of ultra-fine particle cement grout into sandy ground. Int. J. Struct. Civ. Eng. 2021, 10, 3. [Google Scholar] [CrossRef]

| (mm) | (mm) | ||||

|---|---|---|---|---|---|

| 2.63 | 0.937 | 0.65 | 0.331 | 0.586 | 1.93 |

| No. | Cement Past/Water | Acceleration (g) | Frequency (Hz) |

|---|---|---|---|

| 1 | 0 | 0.6 | 10 |

| 2 | 0.45 (0 cm) | 0.6 | 10 |

| 3 | 0.45 (1 cm) | 0.6 | 10 |

| 4 | 0.475 | 0.6 | 10 |

| 5 | 0.5 (0 cm) | 0.6 | 10 |

| 6 | 0.5 (1 cm) | 0.6 | 10 |

| 7 | 0.55 | 0.6 | 10 |

| Scale Factor (λ = 50) | ||

|---|---|---|

| Parameter | Prototype/Experiment | |

| Length | λ | 50 |

| Stress and Pressure | λ | 50 |

| Acceleration | 1 | 1 |

| Time | 7.07 | |

| Stiffness | λ | 50 |

| Grouting Mixing Ratio (a Separation Distance) | Non-Reinforced | 0.40 (0) | 0.40 (1 cm) | 0.45 (0) | 0.475 (0) | 0.50 (0) | 0.50 (1 cm) | 0.55 (0) |

|---|---|---|---|---|---|---|---|---|

| Maximum amount of settlement (cm) | 8.5 | 1.65 | 4.9 | 1.15 | 1.3 | 1.5 | 5.2 | 1.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, J.C.; Son, S.W.; Kim, J.M. Method for Prevention of Liquefaction Caused by Earthquakes Using Grouting Applicable to Existing Structures. Appl. Sci. 2023, 13, 1871. https://doi.org/10.3390/app13031871

Yoon JC, Son SW, Kim JM. Method for Prevention of Liquefaction Caused by Earthquakes Using Grouting Applicable to Existing Structures. Applied Sciences. 2023; 13(3):1871. https://doi.org/10.3390/app13031871

Chicago/Turabian StyleYoon, Jong Chan, Su Won Son, and Jin Man Kim. 2023. "Method for Prevention of Liquefaction Caused by Earthquakes Using Grouting Applicable to Existing Structures" Applied Sciences 13, no. 3: 1871. https://doi.org/10.3390/app13031871

APA StyleYoon, J. C., Son, S. W., & Kim, J. M. (2023). Method for Prevention of Liquefaction Caused by Earthquakes Using Grouting Applicable to Existing Structures. Applied Sciences, 13(3), 1871. https://doi.org/10.3390/app13031871