High Brightness Diode Laser Based on V-Shaped External Cavity and Beam-Waist Splitting Polarization Combining

Abstract

1. Introduction

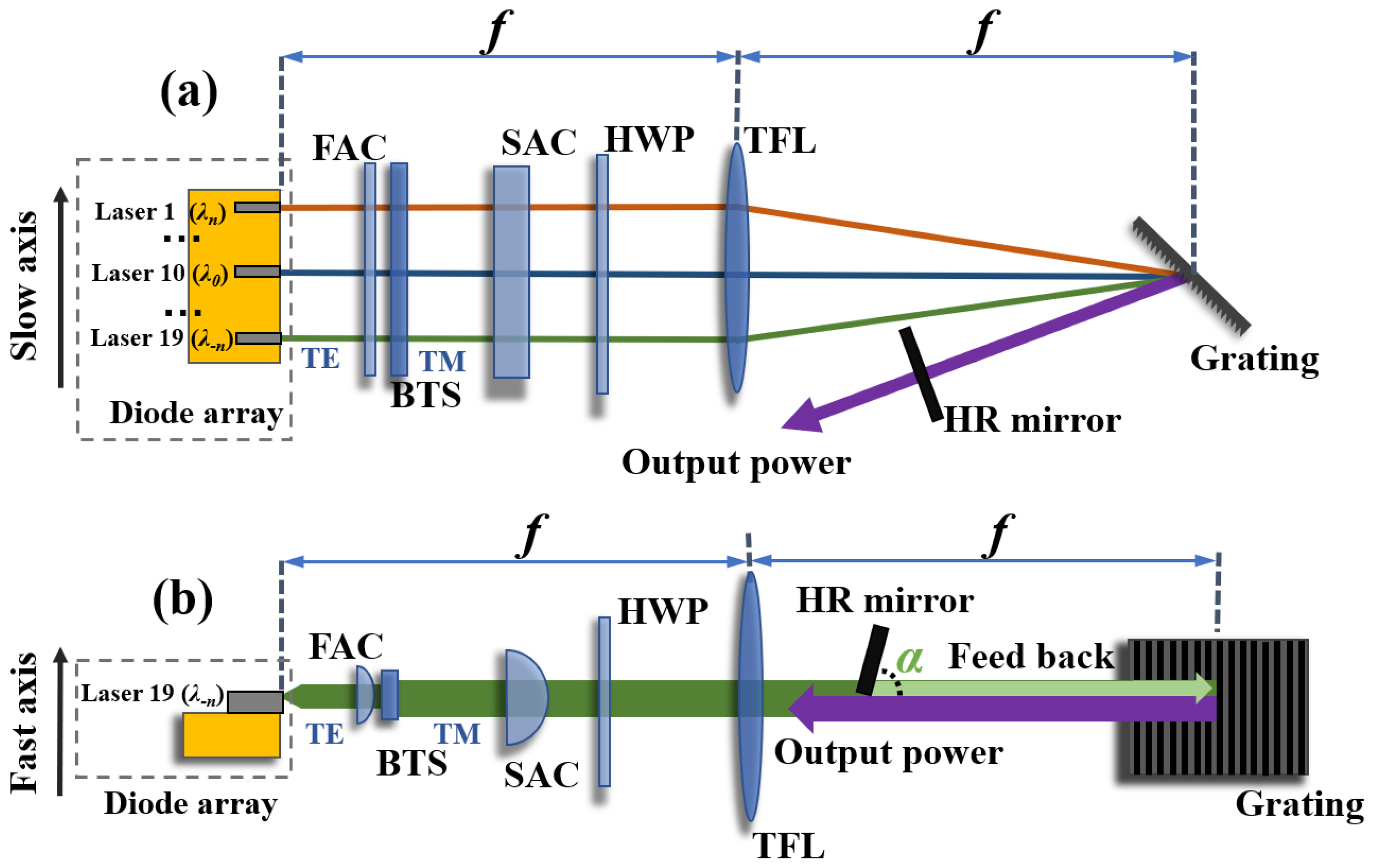

2. Materials and Methods

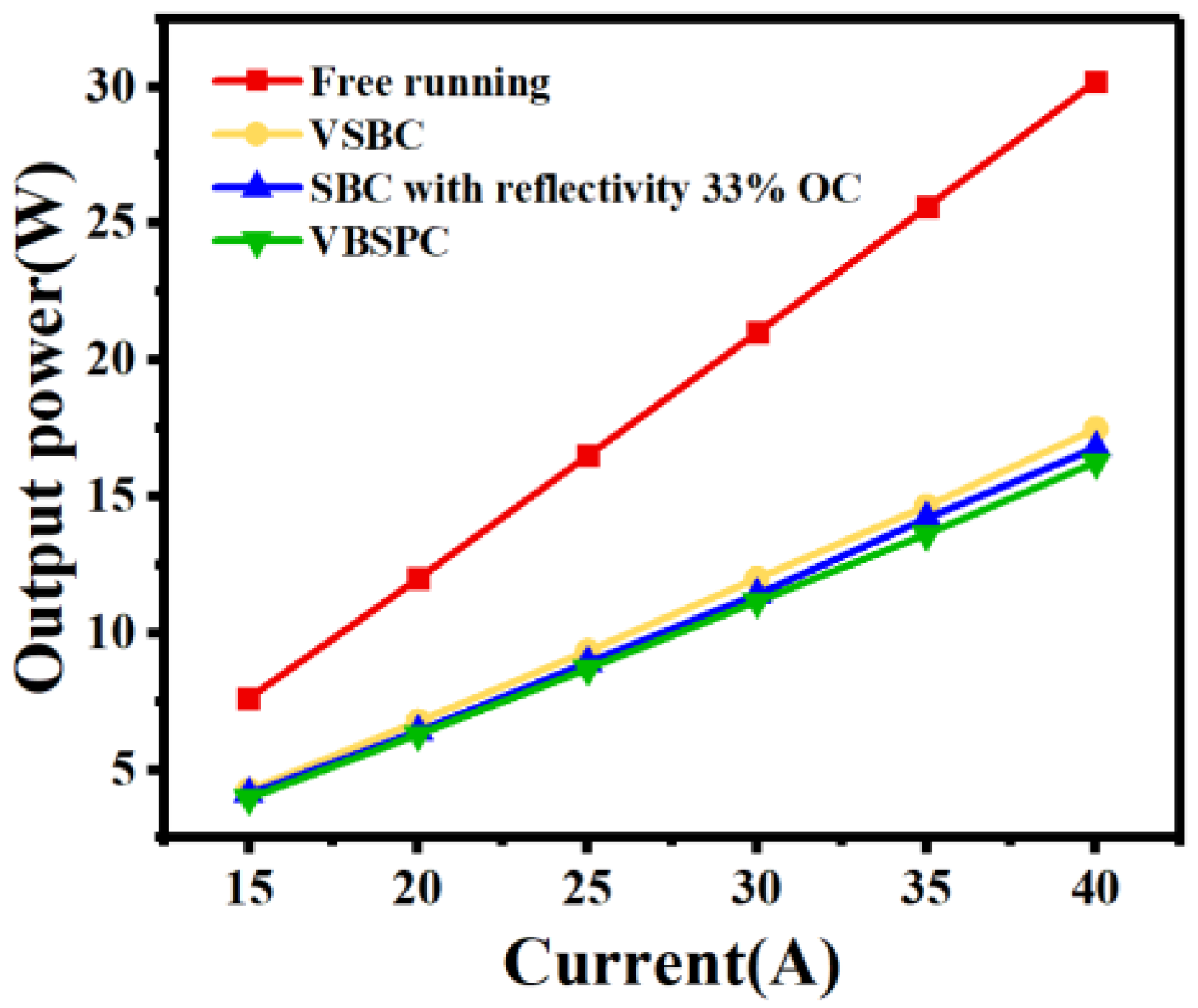

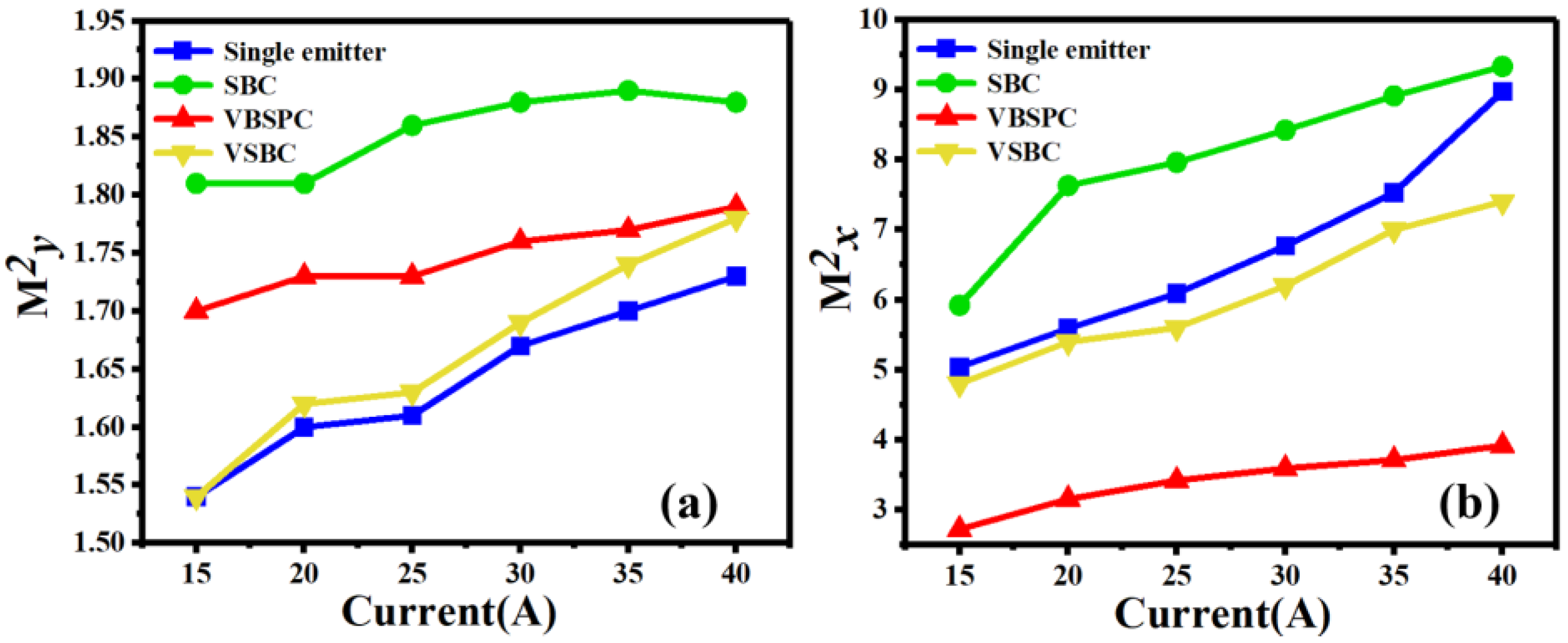

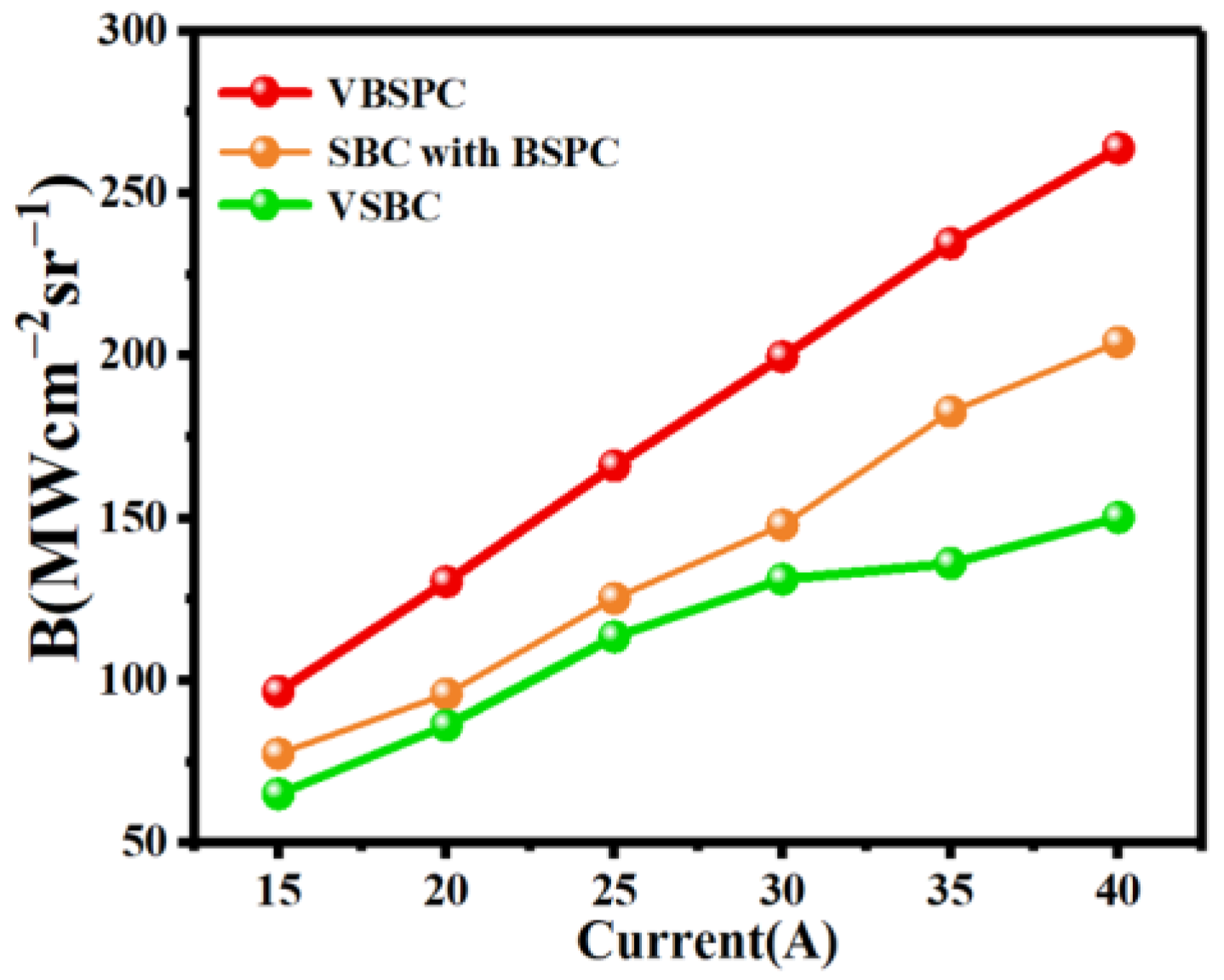

3. Results

4. Discussion

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yu, H.; Tan, S.; Pan, H. High-brightness fiber-coupled diode module using dense wavelength beam combining technology based on single emitter for material processing and fiber amplifier pumping. Proc. SPIE 2022, 11983, 72–78. [Google Scholar] [CrossRef]

- Eyal, S.; Yaniv, V.; Benayahu, U. 16kW single mode CW laser with dynamic beam for material processing. Proc. SPIE 2020, 11260, 267–272. [Google Scholar] [CrossRef]

- Strohmaier, S.G.; Erbert, G.; Meissner-Schenk, A.H. kW-class diode laser bars. Proc. SPIE 2017, 10086, 77–82. [Google Scholar] [CrossRef]

- Daming, L.; Serge, C.; Xu, J. Power scaling of mini-bar-based high-power 780–980 nm pump modules at Spectra Physics. Proc. SPIE 2009, 7198, 453–458. [Google Scholar] [CrossRef]

- Wang, L.; Qu, H.; Qi, A. High-power laser diode at 9xx nm with 81.10% efficiency. Opt. Lett. 2022, 47, 3231–3234. [Google Scholar] [CrossRef]

- Sakaev, I.; Ishaaya, A.A. Diode laser assisted oxygen cutting of thick mild steel with off-axis beam delivery. Opt. Laser Technol. 2021, 138, 106876. [Google Scholar] [CrossRef]

- Polat, B.; Ozay, Y.; Kucukkara, I.; Dizge, N. A new method for membrane manufacturing from polyamide with semiconductor diode laser. J. Mem. Sci. 2022, 641, 119807. [Google Scholar] [CrossRef]

- Yihan, X.; Ching-long, J.; Ayesha, J. Advances in 976 nm single emitter broad area semiconductor diode lasers for 300W+ fiber laser pump module applications. Proc. SPIE 2022, 641, 119807. [Google Scholar] [CrossRef]

- Talla Mbé, J.H.; Woafo, P. Modulation of distributed feedback (DFB) laser diode with the autonomous Chua’s circuit: Theory and experiment. Opt. Laser Technol. 2018, 100, 145–152. [Google Scholar] [CrossRef]

- Patil, D. Semiconductor Laser Diode Technology and Applications; Books on Demand: Norderstedt, Germany, 2012; Chapter 5. [Google Scholar]

- Tünnermann, H.; Pöld, J.H.; Neumann, J. Beam quality and noise properties of coherently combined ytterbium doped single frequency fiber amplifiers. Opt. Express 2011, 1920, 19600–19606. [Google Scholar] [CrossRef]

- Yu, C.X.; Augst, S.J.; Redmond, S. Coherent combining of a 4 kW, eight-element fiber amplifier array. Opt. Lett. 2011, 3614, 2686–2688. [Google Scholar] [CrossRef]

- Redmond, S.M.; Ripin, D.J.; Charles, X.Y. Diffractive coherent combining of a 2.5 kW fiber laser array into a 1.9 kW Gaussian beam. Opt. Lett. 2012, 3714, 2832–2834. [Google Scholar] [CrossRef]

- Yang, G.; Liu, L.; Jiang, Z. Incoherent beam combining based on the momentum SPGD algorithm. Opt. Laser Technol. 2018, 101, 372–378. [Google Scholar] [CrossRef]

- Daneu, V.; Sanchez, A.; Fan, T.Y. Spectral beam combining of a broad-stripe diode laser array in an external cavity. Opt. Lett. 2000, 256, 405–407. [Google Scholar] [CrossRef]

- Cook, C.C.; Fan, T.Y. Spectral beam combining of Yb-doped fiber lasers in an external cavity. In Advanced Solid State Lasers; Optica Publishing Group: Washington, DC, USA, 1999; p. PD5. [Google Scholar]

- Huang, R.K.; Chann, B.; Missaggia, L.J. High-brightness wavelength beam combined semiconductor laser diode arrays. IEEE Photon-Technol. Lett. 2007, 194, 209–211. [Google Scholar] [CrossRef]

- Zhang, J.; Peng, H.; Liu, Y. Hundred-watt diode laser source by spectral beam combining. Laser Phys. Lett. 2014, 1112, 125803. [Google Scholar] [CrossRef]

- Meng, H.; Sun, T. High-brightness spectral beam combining of diode laser array stack in an external cavity. Opt. Express 2015, 2317, 21819–21824. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, Y.; Wang, J. 10.8 kW spectral beam combination of eight all-fiber super fluorescent sources and their dispersion compensation. Opt. Express 2016, 2411, 12063–12071. [Google Scholar] [CrossRef]

- Lin, X.; Lin, G.; Zhao, P. Generation of high brightness diode laser by using spectral and polarization beam combination. Opt. Laser Technol. 2019, 116, 219–223. [Google Scholar] [CrossRef]

- Huang, R.K.; Samson, B.; Chann, B.; Lochman, B.; Tayebati, P. Recent progress on high-brightness kW-class direct diode lasers. In Proceedings of the 2015 IEEE High Power Diode Lasers and Systems Conference (HPD), Coventry, UK, 14–15 October 2015. [Google Scholar]

- Platz, R.; Erbert, G.; Pittroff, W.; Malchus, M.; Vogel, K.; Tränkle, G. 400 μm stripe lasers for high-power fiber coupled pump modules. High Power Laser Sci. Eng. 2013, 1, 60–67. [Google Scholar] [CrossRef]

- Su, J.; Tong, C.; Wang, L.; Wang, Y.; Lu, H.; Zhao, Z.; Wang, J.; Tan, S.; Shu, S.; Wang, L. Beam waist shrinkage of high-power broad-area diode lasers by mode tailoring. Opt. Express 2020, 28, 13131–13140. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Tong, C.; Shu, S.; Tian, S.; Sun, F.; Zhao, Y.; Lu, H.; Zhang, X.; Hou, G.; Wang, L. Loss tailoring of high-power broad-area diode lasers. Opt. Lett. 2019, 44, 3562–3565. [Google Scholar] [CrossRef] [PubMed]

- Vijayakumar, D.; Jensen, O.B.; Ostendorf, R. Spectral beam combining of a 980 nm tapered diode laser bar. Opt. Express 2010, 182, 893–898. [Google Scholar] [CrossRef] [PubMed]

- Müller, A.; Vijayakumar, D.; Jensen, O.B.; Hasler, K.-H.; Sumpf, B.; Erbert, G.; Andersen, P.E.; Petersen, P.M. 16 W output power by high-efficient spectral beam combining of DBR-tapered diode lasers. Opt. Express 2011, 192, 1228–1235. [Google Scholar] [CrossRef] [PubMed]

- Chann, B.; Huang, R.K.; Missaggia, L.J.; Harris, C.T.; Liau, Z.L.; Goyal, A.K.; Donnelly, J.P.; Fan, T.Y.; Sanchez-Rubio, A.; Turner, G.W. Near-diffraction-limited diode laser arrays by wavelength beam combining. Opt. Lett. 2005, 3016, 2104–2106. [Google Scholar] [CrossRef]

- Jensen, O.B.; Thestrup, B.; Andersen, P.E. Near-diffraction-limited segmented broad area diode laser based on off-axis spectral beam combining. App. Phy. B 2006, 832, 225–228. [Google Scholar] [CrossRef]

- Vijayakumar, D.; Jensen, O.B.; Thestrup, B. 980 nm high brightness external cavity broad area diode laser bar. Opt. Express 2009, 177, 5684–5690. [Google Scholar] [CrossRef]

- Sun, F.; Shu, S.; Zhao, Y. High-brightness diode lasers obtained via off-axis spectral beam combining with selective feedback. Opt. Express 2018, 2617, 21813–21818. [Google Scholar] [CrossRef]

- Jechow, A.; Raab, V. High cw power using an external cavity for spectral beam combining of diode laser-bar emission. Appl. Opt. 2006, 4515, 3545–3547. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, F.; Tong, C. Going beyond the beam quality limit of spectral beam combining of diode lasers in a V-shaped external cavity. Opt. Express 2018, 2611, 14058–14065. [Google Scholar] [CrossRef]

- Zhao, Y.; Tong, C.; Wang, L.; Wang, Y.; Lu, H.; Zhang, X.; Wei, Z.; Wang, L. High Brightness Diode Lasers Based on Beam Splitting and Polarization Combining. App. Sci. 2022, 1216, 7980. [Google Scholar] [CrossRef]

- Witte, U.; Schneider, F.; Traub, M.; Hoffmann, D.; Drovs, S.; Brand, T.; Unger, A. kW-class direct diode laser for sheet metal cutting based on DWDM of pump modules by use of ultra-steep dielectric filters. Opt. Express 2016, 24, 22917–22929. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Gou, L.; Jiang, M.; Hui, Y.; Lei, H.; Li, Q. High beam quality in two directions and high efficiency output of a diode laser array by spectral-beam-combining. Opt. Express 2014, 22, 17804–17809. [Google Scholar] [CrossRef]

- Winterfeldt, M.; Crump, P.; Knigge, S. High beam quality in broad area lasers via suppression of lateral carrier accumulation. IEEE Photon-Technol. Lett. 2015, 2717, 1809–1812. [Google Scholar] [CrossRef]

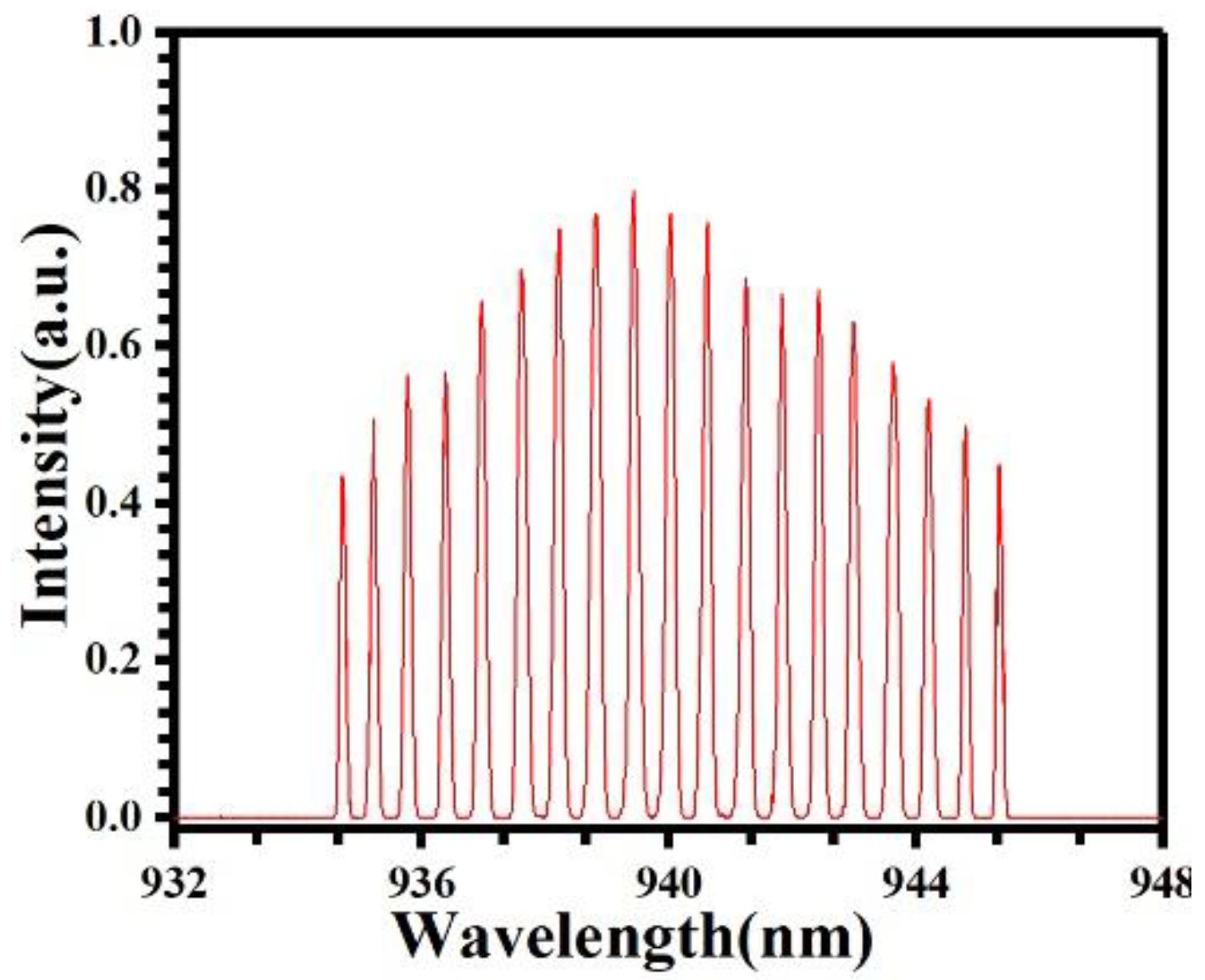

| Parameters | Value |

|---|---|

| Wavelength/nm | 940 |

| Chip width/mm | 10 |

| Cavity length/mm | 1.5 |

| Number of emitters | 19 |

| Emitter pitch/μm | 500 |

| Emitter width/μm | 100 |

| Cavity length/mm | 1.5 |

| The thickness of the waveguide/μm | 1 |

| θfast 95%power content/(°) | 45 |

| θslow 95%power content/(°) | 7 |

| Polarization | TE |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Tong, C.; Wei, Z.; Feng, J.; Wang, L. High Brightness Diode Laser Based on V-Shaped External Cavity and Beam-Waist Splitting Polarization Combining. Appl. Sci. 2023, 13, 2125. https://doi.org/10.3390/app13042125

Zhao Y, Tong C, Wei Z, Feng J, Wang L. High Brightness Diode Laser Based on V-Shaped External Cavity and Beam-Waist Splitting Polarization Combining. Applied Sciences. 2023; 13(4):2125. https://doi.org/10.3390/app13042125

Chicago/Turabian StyleZhao, Yufei, Cunzhu Tong, Zhipeng Wei, Jian Feng, and Lijie Wang. 2023. "High Brightness Diode Laser Based on V-Shaped External Cavity and Beam-Waist Splitting Polarization Combining" Applied Sciences 13, no. 4: 2125. https://doi.org/10.3390/app13042125

APA StyleZhao, Y., Tong, C., Wei, Z., Feng, J., & Wang, L. (2023). High Brightness Diode Laser Based on V-Shaped External Cavity and Beam-Waist Splitting Polarization Combining. Applied Sciences, 13(4), 2125. https://doi.org/10.3390/app13042125