Dynamic Characteristics Analysis of an Assembly Robot for a Wine Box Base Considering Radial and Axial Clearances in a 3D Revolute Joint

Abstract

:1. Introduction

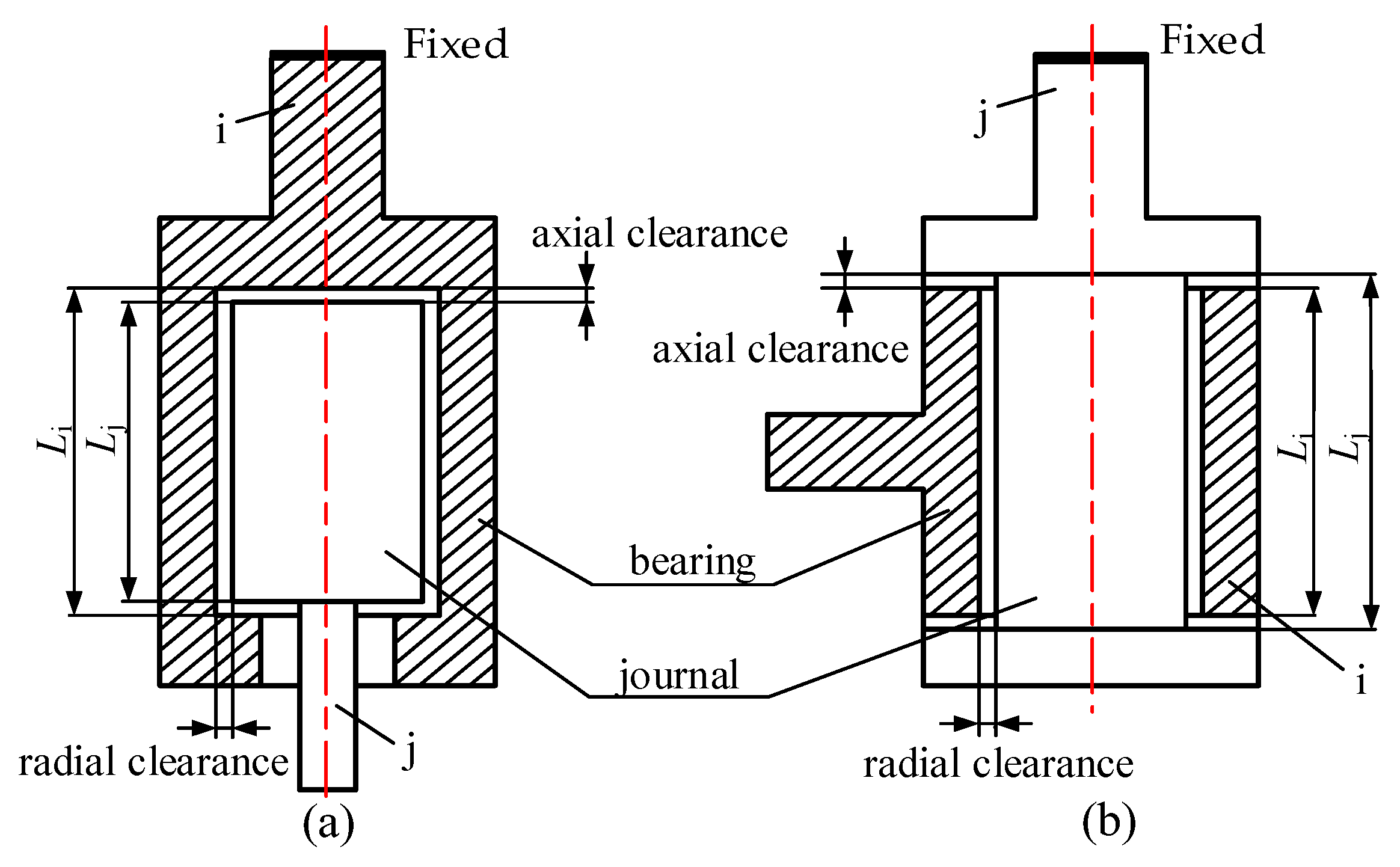

2. Modeling of Revolute Joint with Clearances

2.1. Combination of Bearing and Journal

2.2. Contact Conditions of Journal and Bearing

3. Contact Force Analysis

3.1. Normal Contact Force Model

3.2. Tangential Contact Force Model

4. Dynamic Modeling of Assembly Robot with Joint Clearance

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Marques, F.; Isaac, F.; Dourado, N.; Flores, P. 3D formulation for revolute clearance joints. In New Trends in Mechanism and Machine Science; Springer: Cham, Switzerland, 2017; pp. 183–191. [Google Scholar]

- Vocetka, M.; Bobovský, Z.; Babjak, J.; Suder, J.; Grushko, S.; Mlotek, J.; Krys, V.; Hagara, M. Influence of Drift on Robot Repeatability and Its Compensation. Appl. Sci. 2021, 11, 10813. [Google Scholar] [CrossRef]

- Pollák, M.; Kočiško, M.; Paulišin, D.; Baron, P. Measurement of unidirectional pose accuracy and repeatability of the collaborative robot UR5. Adv. Mech. 2014, 12, 1687814020972893. [Google Scholar] [CrossRef]

- Wang, Y.; Pessi, P.; Wu, H.; Handroos, H. Accuracy analysis of hybrid parallel robot for the assembling of ITER. Fus. Eng. Des. 2009, 84, 1964–1968. [Google Scholar] [CrossRef]

- Qian, W.; Song, S.; Zhao, J.; Hou, J.; Wang, L.; Yin, X. A Study of the Effect of a Kinematic Pair Containing Clearance on the Dynamic Characteristics of a Tool-Changing Robot. Appl. Sci. 2022, 12, 11041. [Google Scholar] [CrossRef]

- Flores, P.; Ambrósio, J.; Claro, J.C.P.; Lankarani, H.M. Dynamics of Multibody Systems with Spherical Clearance Joints. J. Comput. Nonlinear Dyn. 2006, 1, 240–247. [Google Scholar] [CrossRef]

- Flores, P.; Ambrósio, J.; Claro, J.C.P.; Lankarani, H.M.; Koshy, C.S. A study on dynamics of mechanical systems including joints with clearance and lubrication. Mech. Mach. Theory 2006, 41, 247–261. [Google Scholar] [CrossRef]

- Flores, P.; Ambrósio, J.; Claro, J.C.P.; Lankarani, H.M. Translational Joints with Clearance in Rigid Multibody Systems. J. Comput. Nonlinear Dyn. 2008, 3, 011007. [Google Scholar] [CrossRef]

- Liu, C.-S.; Zhang, K.; Yang, R. The FEM analysis and approximate model for cylindrical joints with clearances. Mech. Mach. Theory 2007, 42, 183–197. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, X. Minimizing the influence of revolute joint clearance using the planar redundantly actuated mechanism. Robot. Comput-Int. Manuf. 2017, 46, 104–113. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, X.; Chen, Z. Dynamic analysis of a 3-RRR parallel mechanism with multiple clearance joints. Mech. Mach. Theory 2014, 78, 105–115. [Google Scholar] [CrossRef]

- Erkaya, S. Investigation of joint clearance effects on welding robot manipulators. Robot. Comput.-Int. Manuf. 2012, 28, 449–457. [Google Scholar] [CrossRef]

- Zhao, B.; Zhou, K.; Xie, Y.-B. A new numerical method for planar multibody system with mixed lubricated revolute joint. Int. J. Mech. Sci. 2016, 113, 105–119. [Google Scholar] [CrossRef]

- Xiang, W.; Yan, S. Dynamic analysis of space robot manipulator considering clearance joint and parameter uncertainty: Modeling, analysis and quantification. Acta Astronaut. 2020, 169, 158–169. [Google Scholar] [CrossRef]

- Marques, F.; Isaac, F.; Dourado, N.; Flores, P. An enhanced formulation to model spatial revolute joints with radial and axial clearances. Mech. Mach. Theory 2017, 116, 123–144. [Google Scholar] [CrossRef]

- Marques, F.; Roupa, I.; Silva, M.T.; Flores, P.; Lankarani, H.M. Examination and comparison of different methods to model closed loop kinematic chains using Lagrangian formulation with cut joint, clearance joint constraint and elastic joint approaches. Mech. Mach. Theory 2021, 160, 104294. [Google Scholar] [CrossRef]

- Zhao, Y.; Bai, Z.F. Dynamics analysis of space robot manipulator with joint clearance. Acta Astronaut. 2011, 68, 1147–1155. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, X.; Zhang, X.; Mo, J. Dynamic analysis of a 3-PRR parallel mechanism by considering joint clearances. Nonlinear Dyn. 2017, 90, 405–423. [Google Scholar] [CrossRef]

- Askari, E.; Flores, P. Coupling multi-body dynamics and fluid dynamics to model lubricated spherical joints. Arch. Appl. Mech. 2020, 90, 2091–2111. [Google Scholar] [CrossRef]

- Yan, S.; Xiang, W.; Zhang, L. A comprehensive model for 3D revolute joints with clearances in mechanical systems. Nonlinear Dyn. 2015, 80, 309–328. [Google Scholar] [CrossRef]

- Akhadkar, N.; Acary, V.; Brogliato, B. 3D revolute joint with clearance in multibody systems. In Computational Kinematics; Springer: Cham, Switzerland, 2018; pp. 11–18. [Google Scholar]

- Bai, Z.F.; Jiang, X.; Li, J.Y.; Zhao, J.J.; Zhao, Y. Dynamic analysis of mechanical system considering radial and axial clearances in 3D revolute clearance joints. J. Vib. Control 2021, 27, 1893–1909. [Google Scholar] [CrossRef]

- Bai, Z.F.; Zhao, Y. Dynamic behaviour analysis of planar mechanical systems with clearance in revolute joints using a new hybrid contact force model. Int. J. Mech. Sci. 2012, 54, 190–205. [Google Scholar] [CrossRef]

- Flores, P. A parametric study on the dynamic response of planar multibody systems with multiple clearance joints. Nonlinear Dyn. 2010, 61, 633–653. [Google Scholar] [CrossRef]

- Flores, P.; Leine, R.; Glocker, C. Modeling and Analysis of Rigid Multibody Systems with Translational Clearance Joints Based on the Nonsmooth Dynamics Approach. In Multibody Dynamics: Computational Methods and Applications; Arczewski, K., Blajer, W., Fraczek, J., Wojtyra, M., Eds.; Springer: Dordrecht, The Netherlands, 2011; pp. 107–130. [Google Scholar]

- Ting, K.-L.; Hsu, K.-L.; Wang, J. Clearance-Induced Position Uncertainty of Planar Linkages and Parallel Manipulators. J. Mech. Robot. 2017, 9, 061001. [Google Scholar] [CrossRef]

- Zhan, Z.; Zhang, X.; Zhang, H.; Chen, G. Unified motion reliability analysis and comparison study of planar parallel manipulators with interval joint clearance variables. Mech. Mach. Theory 2019, 138, 58–75. [Google Scholar] [CrossRef]

- Qi, Z.; Luo, X.; Huang, Z. Frictional contact analysis of spatial prismatic joints in multibody systems. Multibody Syst. Dyn. 2011, 26, 441–468. [Google Scholar] [CrossRef]

- Flores, P.; Lankarani, H.M. Dynamic Response of Multibody Systems with Multiple Clearance Joints. J. Comput. Nonlinear Dyn. 2012, 7, 031003. [Google Scholar] [CrossRef]

- Ravn, P. A Continuous Analysis Method for Planar Multibody Systems with Joint Clearance. Multibody Syst. Dyn. 1998, 2, 1–24. [Google Scholar] [CrossRef]

- Hunt, K.H.; Crossley, F.R.E. Coefficient of Restitution Interpreted as Damping in Vibroimpact. J. ASME Appl. Mech. 1975, 42, 440–445. [Google Scholar] [CrossRef]

- Lankarani, H.M.; Nikravesh, P.E. A contact force model with hysteresis damping for impact analysis of multibody systems. J. Mech. Des. 1990, 112, 369–376. [Google Scholar] [CrossRef]

- Kakizaki, T.; Deck, J.F.; Dubowsky, S. Modeling the Spatial Dynamics of Robotic Manipulators with Flexible Links and Joint Clearances. J. Mech. Des. 1993, 115, 839–847. [Google Scholar] [CrossRef]

| Contact Mode | Radial Minimum Distance | Axial Minimum Distance |

|---|---|---|

| free flight mode | ||

| continuous contact mode | ||

| pseudo penetration mode | ||

| Arms | Length [mm] | Mass [kg] | Characteristics of Inertia [kg m2] | |||||

|---|---|---|---|---|---|---|---|---|

| Jxx | Jyy | Jzz | Jxy | Jxz | Jyz | |||

| Arm 1 | 329 | 5.78 | 2.569 | 3.080 | 2.537 | 2.002 × 10−5 | 2.384 | 0.007 × 10−5 |

| Arm 2 | 275 | 4.35 | 1.346 | 0.981 | 1.298 | 4.871 × 10−4 | −2.258 × 10−4 | −4.22 × 10−4 |

| Arm 3 | 350 | 3.03 | 2.087 × 10−2 | 2.087 × 10−2 | 4.726 × 10−5 | 1.005 × 10−6 | 3.307 × 10−6 | 0.489 × 10−6 |

| Parameter | Value |

|---|---|

| Coefficient of friction | 0.1 |

| Integration step size | 1 × 10−5 s |

| Young’s modulus | 207 GPa |

| Integration tolerance | 1 × 10−7 |

| Coefficient of restitution | 0.9 |

| Poisson’s ratio | 0.3 |

| Case | Clearance Dimension (mm) |

|---|---|

| Case 1 | Ca = Cr = 0.2 |

| Case 2 | Ca = Cr = 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Li, R.; Liu, J.; Jia, Z.; Liang, H. Dynamic Characteristics Analysis of an Assembly Robot for a Wine Box Base Considering Radial and Axial Clearances in a 3D Revolute Joint. Appl. Sci. 2023, 13, 2211. https://doi.org/10.3390/app13042211

Wang Y, Li R, Liu J, Jia Z, Liang H. Dynamic Characteristics Analysis of an Assembly Robot for a Wine Box Base Considering Radial and Axial Clearances in a 3D Revolute Joint. Applied Sciences. 2023; 13(4):2211. https://doi.org/10.3390/app13042211

Chicago/Turabian StyleWang, Yuan, Ruiqin Li, Juan Liu, Zengyu Jia, and Hailong Liang. 2023. "Dynamic Characteristics Analysis of an Assembly Robot for a Wine Box Base Considering Radial and Axial Clearances in a 3D Revolute Joint" Applied Sciences 13, no. 4: 2211. https://doi.org/10.3390/app13042211

APA StyleWang, Y., Li, R., Liu, J., Jia, Z., & Liang, H. (2023). Dynamic Characteristics Analysis of an Assembly Robot for a Wine Box Base Considering Radial and Axial Clearances in a 3D Revolute Joint. Applied Sciences, 13(4), 2211. https://doi.org/10.3390/app13042211