Application of Thermoelectric Generators for Low-Temperature-Gradient Energy Harvesting

Abstract

:1. Introduction

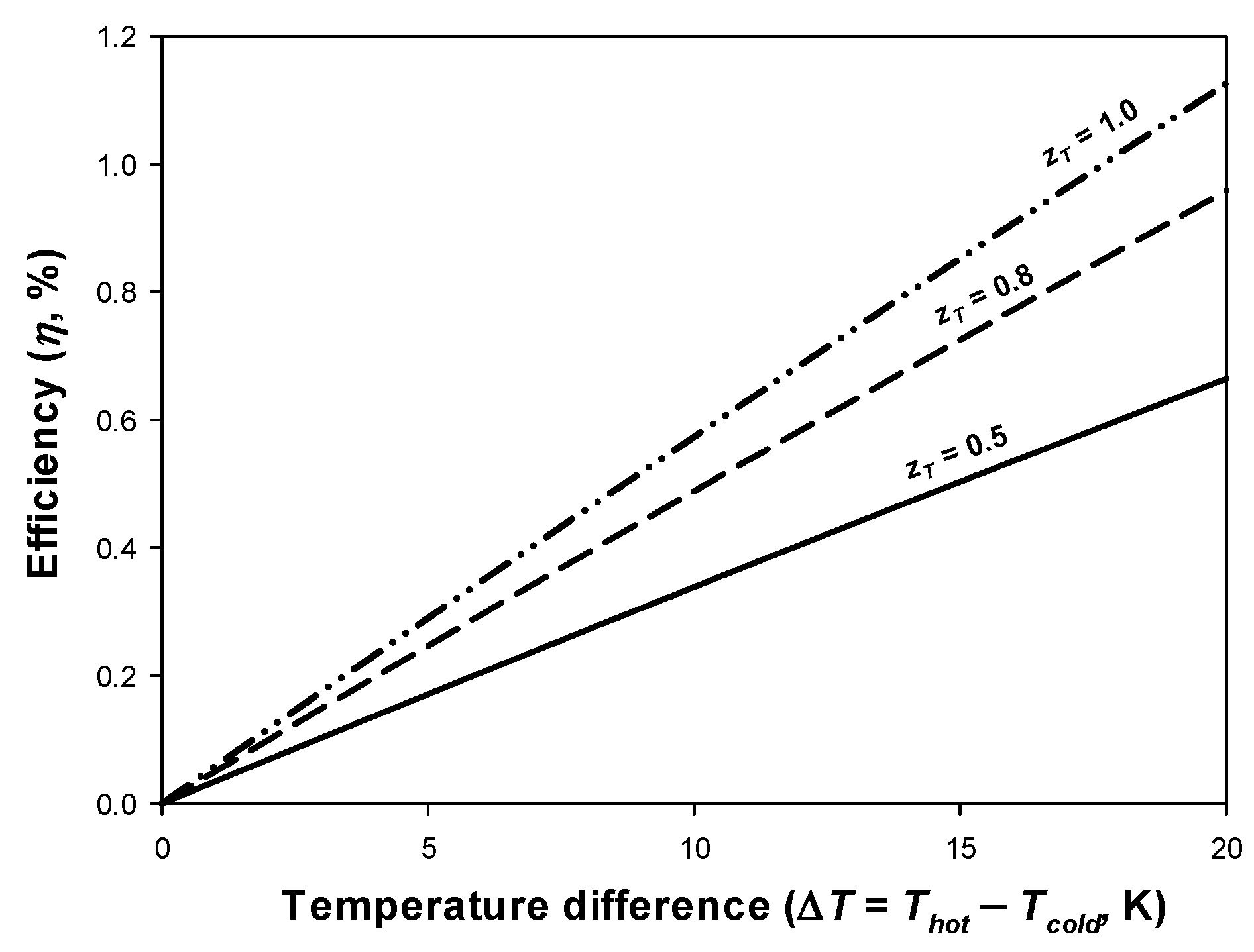

2. Basic Principles of Thermoelectric Generators

2.1. The Seebeck Effect

2.2. The Seebeck Coefficient

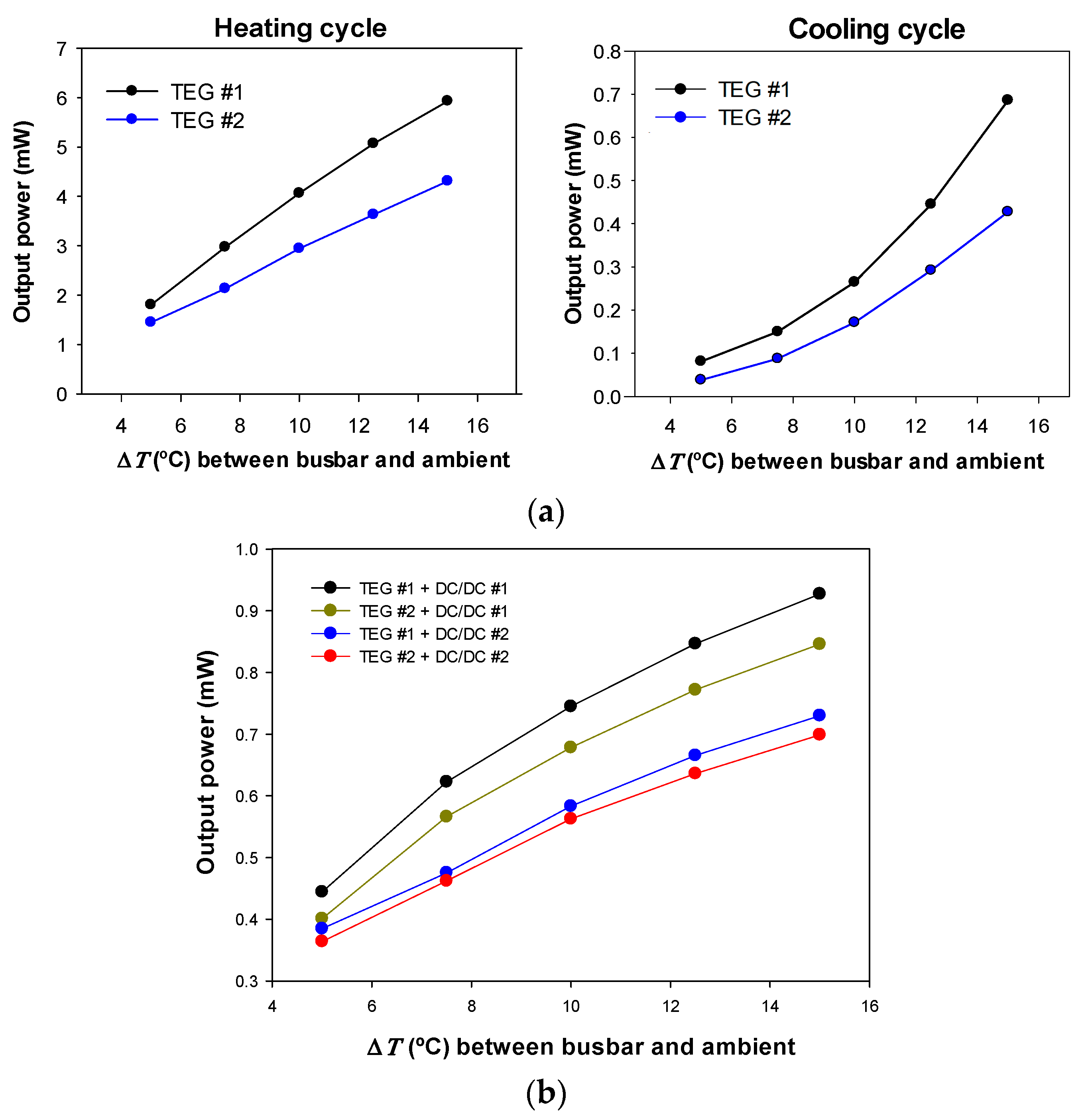

3. Selection of the Best TEG + DC/DC Converter Combination

3.1. Experimental Setup

3.2. Experimental Tests

3.3. Characterization of TEG #1

4. Efficiency Determination of the Best Combination of TEG + DC/DC Converter

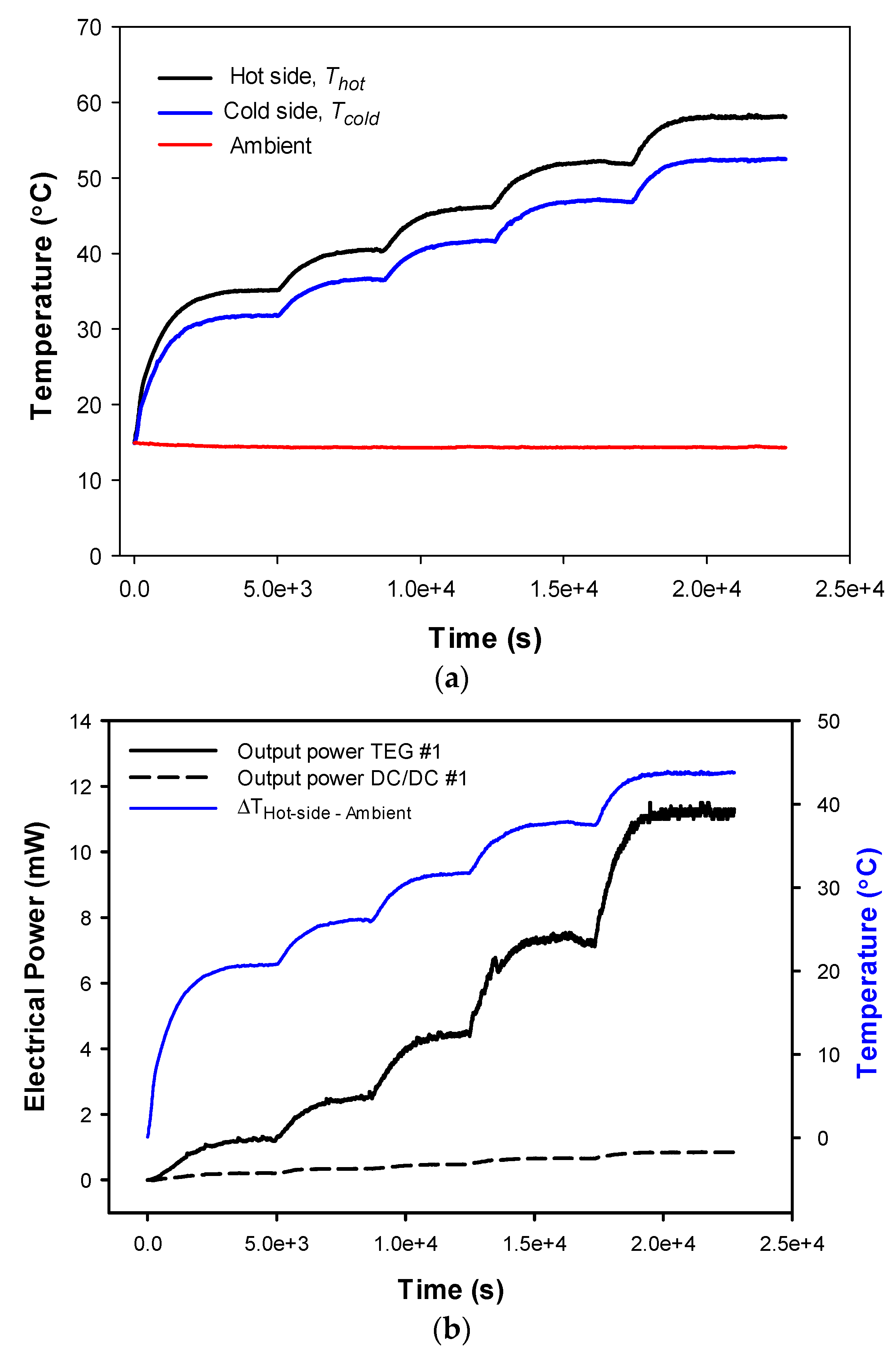

4.1. Steady State Performance of TEG #1

4.2. Cold Starting

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, X.; Sun, L.; Zhu, H.; Zhen, Y.; Chen, H. Application of Internet of Things in Power-Line Monitoring. In Proceedings of the 2012 International Conference on Cyber-Enabled Distributed Computing and Knowledge Discovery, Sanya, China, 10–12 October 2012; pp. 423–426. [Google Scholar] [CrossRef]

- Eunice Akin-Ponnle, A.; Borges Carvalho, N.; Poniszewska-Maranda, A.; Maranda, W. Energy Harvesting Mechanisms in a Smart City—A Review. Smart Cities 2021, 4, 476–498. [Google Scholar] [CrossRef]

- Liu, Y.; Khanbareh, H.; Halim, M.A.; Feeney, A.; Zhang, X.; Heidari, H.; Ghannam, R.; Correspondence, R.; Ghannam, J. Piezoelectric energy harvesting for self-powered wearable upper limb applications. Nano Sel. 2021, 2, 1459–1479. [Google Scholar] [CrossRef]

- Prajwal, K.T.; Manickavasagam, K.; Suresh, R. A review on vibration energy harvesting technologies: Analysis and technologies. Eur. Phys. J. Spéc. Top. 2022, 231, 1359–1371. [Google Scholar] [CrossRef]

- Verma, G.; Sharma, V. A Novel RF Energy Harvester for Event-Based Environmental Monitoring in Wireless Sensor Networks. IEEE Internet Things J. 2022, 9, 3189–3203. [Google Scholar] [CrossRef]

- Mohd Zainuddin, N.; Abd Rahman, M.S.; Ab Kadir, M.Z.A.; Nik Ali, N.H.; Ali, Z.; Osman, M.; Mansor, M.; Mohd Ariffin, A.; Syahmi, M.; Nor, S.F.M.; et al. Review of Thermal Stress and Condition Monitoring Technologies for Overhead Transmission Lines: Issues and Challenges. IEEE Access 2020, 8, 120053–120081. [Google Scholar] [CrossRef]

- Liu, Y.; Riba, J.-R.; Moreno-Eguilaz, M.; Sanllehí, J. Analysis of a Smart Sensor Based Solution for Smart Grids Real-Time Dynamic Thermal Line Rating. Sensors 2021, 21, 7388. [Google Scholar] [CrossRef]

- Risdiyanto, A.; Arifin, M.; Khayam, U. Suwarno Study on temperature distribution at busbar connection based on contact resistance of different plating contact surface. In Proceedings of the 2013 Joint International Conference on Rural Information & Communication Technology and Electric-Vehicle Technology (rICT & ICeV-T), Bandung, Indonesia, 26–28 November 2013. [Google Scholar] [CrossRef]

- Kadechkar, A.; Capelli, F.; Riba, J.-R.; Moreno-Eguilaz, M. Feasibility Study on Thermal Energy Harvesting for Low Powered Electronics in High-Voltage Substations. In Proceedings of the IECON 2018—44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 4224–4229. [Google Scholar] [CrossRef]

- Bellini, P.; Nesi, P.; Pantaleo, G. IoT-Enabled Smart Cities: A Review of Concepts, Frameworks and Key Technologies. Appl. Sci. 2022, 12, 1607. [Google Scholar] [CrossRef]

- Al Mamun, A.; Yuce, M.R. Sensors and Systems for Wearable Environmental Monitoring Toward IoT-Enabled Applications: A Review. IEEE Sens. J. 2019, 19, 7771–7788. [Google Scholar] [CrossRef]

- Kadechkar, A.; Riba, J.-R.; Moreno-Eguilaz, M.; Perez, J. SmartConnector: A Self-Powered IoT Solution to Ease Predictive Maintenance in Substations. IEEE Sens. J. 2020, 20, 11632–11641. [Google Scholar] [CrossRef]

- Kadechkar, A.; Moreno-Eguilaz, M.; Riba, J.-R.; Capelli, F. Low-Cost Online Contact Resistance Measurement of Power Connectors to Ease Predictive Maintenance. IEEE Trans. Instrum. Meas. 2019, 68, 4825–4833. [Google Scholar] [CrossRef] [Green Version]

- Vitolo, P.; De Vita, A.; Di Benedetto, L.; Pau, D.; Licciardo, G.D. Low-Power Detection and Classification for In-Sensor Predictive Maintenance Based on Vibration Monitoring. IEEE Sens. J. 2022, 22, 6942–6951. [Google Scholar] [CrossRef]

- Riba, J.-R.; Moreno-Eguilaz, M.; Bogarra, S. Energy Harvesting Methods for Transmission Lines: A Comprehensive Review. Appl. Sci. 2022, 12, 10699. [Google Scholar] [CrossRef]

- Schlechter, T. Energy Harvesting Approaches for Wireless Sensor Nodes In High Voltage Direct Current Systems. In Proceedings of the 2019 IEEE 5th World Forum on Internet of Things (WF-IoT), Limerick, Ireland, 15–18 April 2019; pp. 243–246. [Google Scholar] [CrossRef]

- Moghe, R.; Yang, Y.; Lambert, F.; Divan, D. A scoping study of electric and magnetic field energy harvesting for wireless sensor networks in power system applications. In Proceedings of the 2009 IEEE Energy Conversion Congress and Exposition, San Jose, CA, USA, 20–24 September 2009; pp. 3550–3557. [Google Scholar]

- Sudevalayam, S.; Kulkarni, P. Energy Harvesting Sensor Nodes: Survey and Implications. IEEE Commun. Surv. Tutorials 2011, 13, 443–461. [Google Scholar] [CrossRef] [Green Version]

- Cetinkaya, O.; Akan, O.B. Electric-Field Energy Harvesting in Wireless Networks. IEEE Wirel. Commun. 2017, 24, 34–41. [Google Scholar] [CrossRef] [Green Version]

- Guo, F.; Hayat, H.; Wang, J. Energy harvesting devices for high voltage transmission line monitoring. In Proceedings of the 2011 IEEE Power and Energy Society General Meeting, Detroit, MI, USA, 24–28 July 2011; Volume 43210, pp. 1–8. [Google Scholar] [CrossRef]

- Jouhara, H.; Żabnieńska-Góra, A.; Khordehgah, N.; Doraghi, Q.; Ahmad, L.; Norman, L.; Axcell, B.; Wrobel, L.; Dai, S. Thermoelectric generator (TEG) technologies and applications. Int. J. Thermofluids 2021, 9, 100063. [Google Scholar] [CrossRef]

- Becker, T.; Kluge, M.; Schalk, J.; Otterpohl, T.; Hilleringmann, U. Power management for thermal energy harvesting in aircrafts. In Proceedings of the IEEE Sensors Conference, IEEE, Lecce, IT, USA, 26–29 October 2008; pp. 681–684. [Google Scholar] [CrossRef]

- Jouhara, H.; Khordehgah, N.; Almahmoud, S.; Delpech, B.; Chauhan, A.; Tassou, S.A. Waste heat recovery technologies and applications. Therm. Sci. Eng. Prog. 2018, 6, 268–289. [Google Scholar] [CrossRef]

- Moultif, N.; Divay, A.; Joubert, E.; Latry, O. Reliability Study of High-Power Mechatronic Components by Spectral Photoemission Microscopy. In Reliability of High-Power Mechatronic Systems 2; Elsevier: Amsterdam, The Netherlands, 2017; pp. 241–271. [Google Scholar] [CrossRef]

- How Thermoelectric Generators Work—Applied Thermoelectric Solutions LLC. Available online: https://thermoelectricsolutions.com/how-thermoelectric-generators-work/ (accessed on 5 October 2022).

- Thermoelectricity Using Semiconductor Thermocouples. Available online: https://www.mpoweruk.com/thermoelectricity.htm (accessed on 5 October 2022).

- Di Stefano, V.; Muscato, O. Seebeck Effect in Silicon Semiconductors. Acta Appl. Math. 2012, 122, 225–238. [Google Scholar] [CrossRef]

- Cai, J.; Mahan, G.D. Effective Seebeck coefficient for semiconductors. Phys. Rev. B—Condens. Matter Mater. Phys. 2006, 74, 075201. [Google Scholar] [CrossRef]

- Goldsmid, H.J. Bismuth Telluride and Its Alloys as Materials for Thermoelectric Generation. Materials 2014, 7, 2577–2592. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.S.; Liu, W.; Chen, G.; Chu, C.-W.; Ren, Z. Relationship between thermoelectric figure of merit and energy conversion efficiency. Proc. Natl. Acad. Sci. USA 2015, 112, 8205–8210. [Google Scholar] [CrossRef] [Green Version]

- Stobart, R.; Milner, D. The Potential for Thermo-Electric Regeneration of Energy in Vehicles. SAE Tech. Pap. 2009, 14. [Google Scholar] [CrossRef]

- Remeli, M.F.; Date, A.; Orr, B.; Ding, L.C.; Singh, B.; Affandi, N.D.N.; Akbarzadeh, A. Experimental investigation of combined heat recovery and power generation using a heat pipe assisted thermoelectric generator system. Energy Convers. Manag. 2016, 111, 147–157. [Google Scholar] [CrossRef]

- Angrist, S.W. Direct Energy Conversion; Allyn and Bacon: Boston, MA, USA, 1982; ISBN 0205077587. [Google Scholar]

- Orr, B.; Singh, B.; Tan, L.; Akbarzadeh, A. Electricity generation from an exhaust heat recovery system utilising thermoelectric cells and heat pipes. Appl. Therm. Eng. 2014, 73, 588–597. [Google Scholar] [CrossRef]

- Orr, B.; Taglieri, J.; Ding, L.C.; Akbarzadeh, A. Validating an alternative method to predict thermoelectric generator performance. Energy Convers. Manag. 2016, 116, 134–141. [Google Scholar] [CrossRef]

- Shuai, J.; Kim, H.S.; Lan, Y.; Chen, S.; Liu, Y.; Zhao, H.; Sui, J.; Ren, Z. Study on thermoelectric performance by Na doping in nanostructured Mg1-Na Ag0.97Sb0.99. Nano Energy 2015, 11, 640–646. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Zuo, L.; Chen, J.; Klein, J.A. A model to analyze the device level performance of thermoelectric generator. Energy 2016, 115, 591–603. [Google Scholar] [CrossRef] [Green Version]

- Champier, D. Thermoelectric generators: A review of applications. Energy Convers. Manag. 2017, 140, 167–181. [Google Scholar] [CrossRef]

- Rare Earth Elements—Critical Resources for High Technology|USGS Fact Sheet 087-02. Available online: https://pubs.usgs.gov/fs/2002/fs087-02/ (accessed on 5 October 2022).

- Meng, J.-H.; Zhang, X.-X.; Wang, X.-D. Dynamic response characteristics of thermoelectric generator predicted by a three-dimensional heat-electricity coupled model. J. Power Sources 2014, 245, 262–269. [Google Scholar] [CrossRef]

- IEEE. IEEE Std 605-2008 Guide for Bus Design in Air Insulated Substations; IEEE: Piscataway, NJ, USA, 2010; ISBN 9780738158570. [Google Scholar]

- Sabovic, A.; Delgado, C.; Subotic, D.; Jooris, B.; De Poorter, E.; Famaey, J. Energy-Aware Sensing on Battery-Less LoRaWAN Devices with Energy Harvesting. Electronics 2020, 9, 904. [Google Scholar] [CrossRef]

- Kang, J.; Yan, F.; Zhang, P.; Du, C. Comparison of comprehensive properties of Ni-MH (nickel-metal hydride) and Li-ion (lithium-ion) batteries in terms of energy efficiency. Energy 2014, 70, 618–625. [Google Scholar] [CrossRef]

| Combination | Devices Involved |

|---|---|

| 1 | TEG #1 + DC/DC converter #1 |

| 2 | TEG #1 + DC/DC converter #2 |

| 3 | TEG #2 + DC/DC converter #1 |

| 4 | TEG #2 + DC/DC converter #2 |

| TEG Modules | TEG #1 | TEG #2 |

|---|---|---|

| Model | GM250-157-14-16 | TG12-8 |

| Manufacturer | European Thermodynamics | Marlow Industries |

| Dimensions (mm) | 40 × 40 | 40 × 40 |

| Thickness (mm) | 4.1 | 3.6 |

| Matched load resistance (Ω) | 3.65 | 3.46 |

| Hot side temperature (℃) | 250 | 230 |

| Cold side temperature (℃) | 30 | 50 |

| Optimum output voltage (V) | 5.05 | 5.25 |

| Optimum output power (W) | 6.99 | 7.95 |

| DC/DC Converters | DC/DC #1 | DC/DC #2 |

|---|---|---|

| Model | LTC3108 | LTC3109 |

| Manufacturer | Analog devices | Analog devices |

| Harvesting board | Adaptive ADEH | Demo circuit 1664 A |

| Input voltage range | 50−400 mV | 30−500 mV |

| Voltage regulation | 2.35−5.00 V | 2.30−5.10 V |

| MPPT technology * | Yes | No |

| Parameters | Measured Values |

|---|---|

| Ambient temperature (°C) | 21.5 |

| Cold side temperature (°C) | 57.8 |

| Hot side temperature (°C) | 67.7 |

| Open circuit voltage (V) | 0.79 |

| Short-circuit current (mA) | 99.56 |

| Maximum power point voltage (V) | 0.40 |

| Maximum power point current (mA) | 50.39 |

| Resistance at the maximum power point (Ω) | 6.00 |

| Maximum power (mW) | 20.25 |

| T (°C) | ∆V1m (VRMS) | Current (ARMS) | cosφ | rac (µΩ/m) |

|---|---|---|---|---|

| 25 | 1.4735 | 280 | 0.9997 | 5267 |

| 30 | 1.4845 | 279 | 0.9997 | 5319 |

| 35 | 1.4913 | 277 | 0.9997 | 5378 |

| 40 | 1.5085 | 277 | 0.9997 | 5441 |

| 45 | 1.5148 | 275 | 0.9997 | 5501 |

| 50 | 1.5200 | 274 | 0.9997 | 5545 |

| 55 | 1.5290 | 273 | 0.9997 | 5591 |

| 60 | 1.5313 | 271 | 0.9997 | 5635 |

| 65 | 1.5353 | 271 | 0.9997 | 5657 |

| Current (Arms) | rac (µΩ/m) | ∆THot-Ambient (°C) | ∆THot-Cold (°C) | pJoule,conductor (W/m) | PJoule,TEG-area (W) | Pelectric,TEG (mW) | PDC/DC (mW) | RTEG (°C/W) | ηTEG (%) | ηTEG+DC/DC (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| 136 | 5380 | 20.7 | 3.4 | 99.5 | 0.85 | 1.24 | 0.21 | 3.964 | 0.15 | 0.025 |

| 169 | 5448 | 26.1 | 3.9 | 155.6 | 1.32 | 2.50 | 0.34 | 2.914 | 0.19 | 0.026 |

| 194 | 5512 | 31.7 | 4.5 | 207.5 | 1.76 | 4.47 | 0.48 | 2.534 | 0.25 | 0.027 |

| 226 | 5560 | 37.7 | 5.1 | 284.0 | 2.41 | 7.34 | 0.66 | 2.095 | 0.30 | 0.027 |

| 254 | 5622 | 43.7 | 5.7 | 362.7 | 3.08 | 11.2 | 0.84 | 1.841 | 0.36 | 0.027 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Riba, J.-R.; Moreno-Eguilaz, M.; Sanllehí, J. Application of Thermoelectric Generators for Low-Temperature-Gradient Energy Harvesting. Appl. Sci. 2023, 13, 2603. https://doi.org/10.3390/app13042603

Liu Y, Riba J-R, Moreno-Eguilaz M, Sanllehí J. Application of Thermoelectric Generators for Low-Temperature-Gradient Energy Harvesting. Applied Sciences. 2023; 13(4):2603. https://doi.org/10.3390/app13042603

Chicago/Turabian StyleLiu, Yuming, Jordi-Roger Riba, Manuel Moreno-Eguilaz, and Josep Sanllehí. 2023. "Application of Thermoelectric Generators for Low-Temperature-Gradient Energy Harvesting" Applied Sciences 13, no. 4: 2603. https://doi.org/10.3390/app13042603

APA StyleLiu, Y., Riba, J.-R., Moreno-Eguilaz, M., & Sanllehí, J. (2023). Application of Thermoelectric Generators for Low-Temperature-Gradient Energy Harvesting. Applied Sciences, 13(4), 2603. https://doi.org/10.3390/app13042603