1. Introduction

Currently, more than 1.1 billion people are not accessible to the electrical grid. Most of these people live in rural areas or offshore islands, and expanding the power grid to these remote areas is neither economical nor effective [

1]. A stand-alone wind energy generating system is a perspective method of providing electricity to regional grids and effectively solving the above-mentioned issues. Among all wind generators, the permanent magnet (PM) generator, with its high torque density and efficiency, is the most favored electrical generator. However, as the wind speed is not constant, the output voltage would remain constant if no control is introduced. For conventional PM generator, a fully rated matrix converter may be needed, which may be expensive and complex to control. To effectively control the output voltage, flux-weakening control is widely used for PM machines. Numerous methods of flux weakening have been proposed in the past 20 years, which can mainly be classified into two categories: Electrical and mechanical techniques.

For electrical flux-weakening techniques, the most conventional method is to inject a negative d-axis current, which produces a field that opposes the original PM field. This technique is relatively suitable for machines with a high saliency ratio, i.e., the difference between the d-axis and q-axis inductance is significant [

2,

3,

4]. However, additional external inductors are required for a machine with a small saliency ratio if the negative d-axis current injection flux-weakening technique is used [

5], which adds more complexity to the system. In addition, over-injection of negative d-axis current may cause the demagnetization of the PMs. Moreover, for the generating system, using this method requires two sets of windings, and the coupling effect between two windings needs further consideration. Another electrical flux-weakening technique uses the variable flux method, which can be further categorized into hybrid excitation type and mnemonic material type. Hybrid excitation type machines generally need an extra set of DC excitation winding, which could enhance or weaken the field by injecting positive or negative DC. Typically, the DC excitation flux path is parallel to the PMs to prevent demagnetization of the PMs [

6,

7,

8,

9]. Nevertheless, two sets of windings are needed for this type of machine. The mnemonic material type machine, also known as a memory machine, uses the Alnico PM for parts or all excitations of the machine. The Alnico PM has low coercivity; therefore, its magnetization direction can be easily adjusted using excitation pulses in the d-axis direction of Alnico PMs [

10,

11,

12]. Nevertheless, the structure of the memory machine needs to be specially designed to prevent the interaction between the field generated by the armature and Alnico PMs, which is relatively complex. Otherwise, the unwanted demagnetization of Alnico PMs may occur.

With the electrical methods, considerable amounts of current would have to be consumed to weaken the strong flux from the PMs or maintain the excitation flux, which results in an efficiency decrease, while also having the risk of PM demagnetization. Conversely, mechanical methods adjust the linked flux by manipulating the position of certain machine parts, which avoids the current consumption. Therefore, mechanical methods might be more suitable for the application of a stand-alone generator, where a wide speed range and constant working condition is required. Mechanical flux-weakening techniques can be categorized into two categories: Self-actuated type and actively controlled type [

13]. The self-actuated type generally uses the rotating speed-related force and the spring system to realize the movement of flux-adjusting elements by themselves. In [

14], a spoke IPM machine with movable ferromagnetic yokes connected with the spring system is proposed. The yoke provides a leakage path that can move closer to the inner rotor rim when the centrifugal force is large, thus achieving flux regulation by itself. In [

15], a double-rotor PM machine is proposed in which one rotor is directly connected to the shaft, and another rotor rotates with displacement relative to the shaft by the spring system. Depending on the rotational speed, two rotors will have a corresponding displacement angle. Therefore, the total flux linkage, which is the vector sum of two flux linkages, is adjustable. However, all the self-actuated mechanical flux-weakening methods cannot be controlled manually, which may be problematic when emergencies occur. Moreover, the spring system is difficult to calibrate and requires regular maintenance. The actively controlled mechanical flux-weakening method uses an external force to control the flux-adjusting elements. A switched flux machine with movable iron pieces outside of the stator that is controlled independently is introduced in [

16]. When the iron piece is moved to the closed position, the PM flux is short-circuited, reducing 60% of the flux linkage compared to the conventional switched flux machine. An actively controlled version of the axial-flux PM machine in [

15] is proposed in [

17], and a radial-flux version is presented in [

18], which has the minimum flux linkage in the equilibrium position and the maximum flux linkage in the aligned position.

In [

19], a dual-rotor PM machine based on bidirectional flux modulation is proposed for the standalone DC power supply. This design requires a conventional winding whose pole pair number is equal to the outer rotor, and a modulation winding. Two sets of windings are connected in series as their frequencies are the same. The inner rotor is connected to the servo motor. Therefore, the inner PM flux linkage vector is adjustable and the sum of modulated vector and the outer PM vector, namely the total flux linkage, is controllable. This active-controlled mechanical flux-weakening method suits the machine with a small saliency ratio. Nevertheless, two sets of windings are needed, which have the following shortcomings: First, two pairs of windings have different coil pitches, which are relatively complex to manufacture; second, the turn numbers of two pairs of windings are different for reaching the maximized flux controlling range.

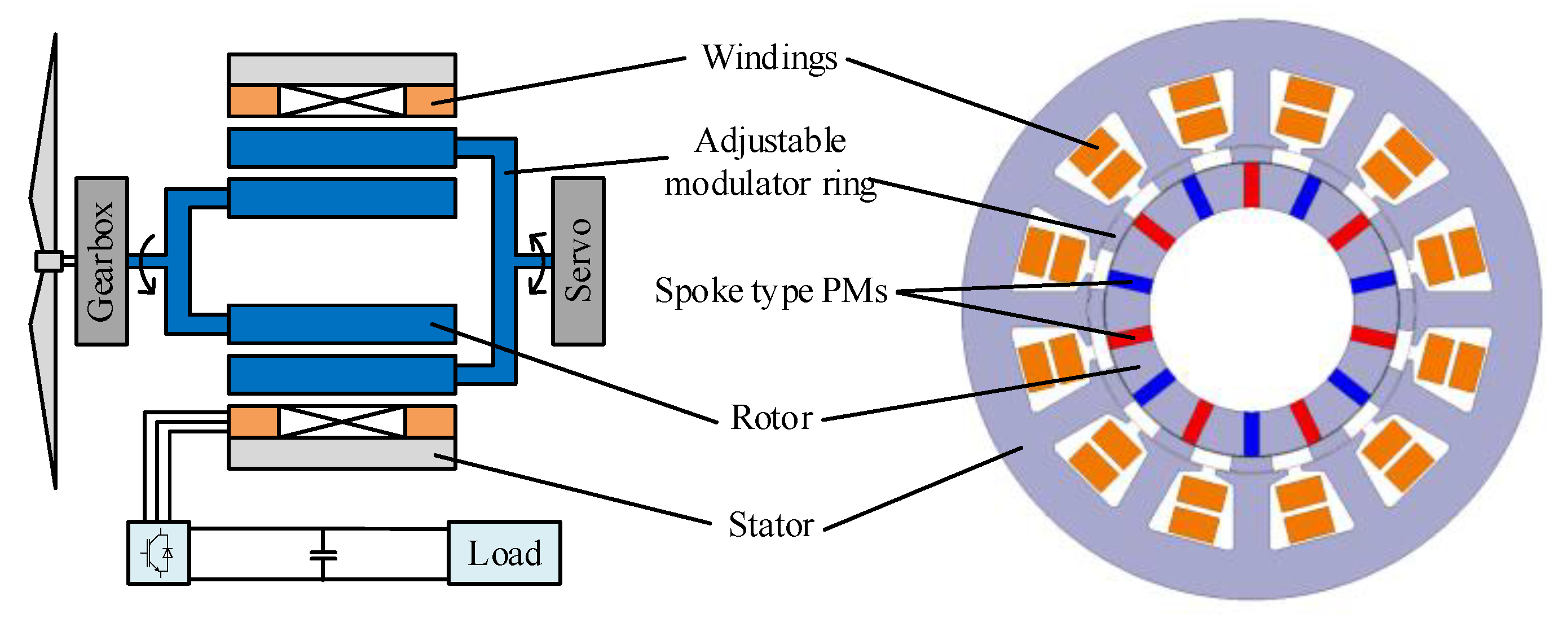

This paper proposes a novel mechanical flux-weakening spoke-type PM generator. In only one set of windings, all three working harmonics have the same frequency, which can be added as vectors based on the flux modulation principle. By adjusting the modulator ring within a certain angle, the flux can be effectively controlled without the risk of PM demagnetization, and the variable-speed constant-amplitude voltage control (VSCAVC) can be achieved. A commercial servo system using the position control mode is sufficient for dynamic performance, which is also cost-efficient, robust, and easy to control. The principles of flux controlling and working harmonic selection are introduced. To investigate the influence of the pole pair number and the performance of the novel design, four cases with different rotor poles and winding configurations, i.e., 12/7, 12/8, 12/10, and 12/11 stator/rotor pole pair combinations, have been designed, optimized, and compared. Finally, the 12/7 design is selected, and its VSCAVC characteristics are analyzed.