Abstract

The impact of replacing the sunflower oil in a typical muffin formulation with different protein-based emulsions was investigated. Fundamental rheological measurements indicated significant differences between emulsions prepared with soy, lupin, and yeast proteins. The highest viscosity of 2.04 Pa·s was registered for the lupin protein-based emulsion, whereas the yeast protein-based emulsion exhibited the narrowest linear viscoelastic region. The influence of the protein-based emulsions on the thermo-mechanical properties of wheat flour dough was further investigated using the Mixolab device and Chopin+ protocol. Oil substitution with emulsion resulted in better starch gelatinization with the C3 torque of 0.46 Nm being registered for doughs with soy and lupin protein emulsions. Significant differences in terms of moisture, color, porosity, and texture were observed between muffins prepared with protein-based emulsions and control. The lower fat baked products retained higher amounts of water (25.05–26.00%) and exhibited slightly more vivid color (color intensity of 46.34–46.81) and harder texture (firmness of 5.64–5.86 N). The sensory analysis confirmed that soy, lupin, and yeast protein emulsions can be used for obtaining muffin samples with acceptable taste and flavor, and overall quality comparable to the control. These results indicate that the protein based-emulsions are promising oil replacers in muffin formulations.

1. Introduction

Sweet baked food products, such as cakes, muffins, and biscuits, are convenient and affordable tasty snacks appreciated by many consumers of all ages. However, this category of food products is usually incriminated for its high sugar and fat contents. Nutrition related diseases, together with the increase in consumer concern and demand for healthier foods, led to a high interest in developing new formulations with less fat and/or sugar content. However, considering the contribution of the main ingredients to the technological behavior and sensorial perception, finding solutions for low calorie, sweet, baked products still represents a great challenge.

Fat is the energetic component with the highest calorific value and therefore, its reduction by substitution with other ingredients is highly appealing. Reducing the fat content of different types of baked foods represents a great challenge, as fats exert a high contribution to the sensorial characteristics like texture, softness, high volume, mouthfeel, and flavor [1,2,3]. Muffins are popular breakfast bakery products, mainly obtained from flour, sugar, fats, and eggs, and are usually known to contain up to 24% of fat in the final product or 40% fat relative to the flour content [3], both of animal or vegetable origin. There are many studies focusing on fat reduction in muffin cakes by substitution with different fat mimetics. The most tested in this respect are carbohydrate-based ingredients [2]. Different studies report the use of starch [4], chia seed mucilage [5], inulin [6], cocoa fibers [7], gums, polydextrose [2], and legume/fruit purees [1] for replacing various amounts of fats in typical muffin formulations. The use of oleogels is a rather new approach for fat replacement in muffins. In addition to reducing the total fat content, the use of oleogels represents a new healthier alternative for shortenings and saturated fats [8,9]. Regardless of the ingredient used to substitute fats in the muffin or cake formulations, different quality changes were observed, such as volume decrease or increase in crumb density and overall hardness, with negative consequences on the sensorial perception of the final product [6,10].

The use of protein-based ingredients for reducing the content of fats in bakery applications received less attention compared to other fat-based replacers. Protein-based fat replacers used so far for obtaining reduced fat baked products with improved porosity and pore area included animal protein sources, such as whey, milk, or egg white [11]. These protein sources are not considered sustainable ingredients to be used to feed the next generation of people, thus, alternative environmentally friendly sources need to be explored. Legume proteins are acknowledged as sustainable ingredients with high nutritional value and good functional properties [12].

The functional properties of proteins, such as high-water binding and retention capacity as well as foaming and emulsifying capacities, may contribute to the volume and mouthfeel of muffin cakes with a promising potential to imitate the fat function [3]. Azmoon et al. [3] incorporated a hydrocolloid-protein emulsion in a muffin cake recipe as an oil substitute. Authors obtained O/W emulsions using a mixture of guar and konjac gums as stabilizers together with soy protein isolate and achieved a 63% oil substitution rate in relation to the control sample’s oil content, with no significant differences on quality characteristics of the final product. Using emulsions as fat substitutes in cakes was also studied by Grossi Bovi Karatay et al. [13] who substituted palm oil from pound cakes with emulsions obtained from canola oil and chickpea aquafaba (the viscous liquid formed when boiling legumes used by vegans as an egg replacement). The maximum rate of total fat reduction, in this case, was 25%, with no significant effect on quality characteristics of the final product.

Another interesting sustainable protein source, which was not previously considered as an ingredient for reducing the fat content of muffins, is the brewer’s spent yeast extract. Although yeast extracts are rich in proteins, minerals, B vitamins, and many other biologically active compounds, their use in various food products is mostly related to flavoring properties [14,15]. However, taking into account their high protein content, the yeast extracts have good potential as emulsifiers and emulsion-stabilizing agents rich in essential amino acids for several applications in nutraceuticals and the food industry.

The objective of the study was to investigate the rheological properties of soy, lupin, and yeast protein-based emulsions and to evaluate the influence of oil substitution with these emulsions on the thermo-mechanical behavior of the dough and the baking performance of muffin formulations.

2. Materials and Methods

2.1. Materials

The following protein derivatives were considered in the experiment: soy protein isolate (Ubimedia S.R.L., Galati, Romania; 84.6% protein and 9.1% moisture), lupin concentrate (Lupipro 550, Luprodin; protein content of 57.8% and 9.4% moisture), and powdered yeast extract (69.1% protein and 4.9% moisture), obtained from Saccharomyces cerevisiae biomass through autolysis for 48 h at 55 °C, followed by centrifugation at 9000 rpm for 15 min to remove the yeast cell and freeze-drying (CHRIST Alpha 1–4 LD plus, Germany) the resulting liquid portion.

Superior white wheat flour (11.5% protein, 11.3% moisture and 0.4% ash) used for preparing muffin samples was purchased from Dobrogea Grup SA, Constanta, Romania. Other ingredients used for preparing the muffins, such as refined white sugar, fresh white eggs, sunflower oil (Spornic, Prutul SA, Galati, Romania), whole milk, and refined salt, were purchased from a local market (Galati, Romania).

2.2. Chemical Composition

The chemical compositions of the protein powders, wheat flour, and muffin samples were assessed using the following official methods: SR ISO 712:2005 [16] was used to determine the moisture content by air-drying the samples with a LabTech oven (Daihan Labtech Co., LTD, Kyungki-Do, Republic of Korea). The Kjeldahl method AACC 46–11.02 [17] (Raypa Trade, R. Espinar, S.L., Barcelona, Spain) and a nitrogen-to-protein conversion factor of 6.25 were used to determine the crude protein content and the SR ISO 2171:2002 [16] was employed to quantify the ash content.

2.3. Preparation of Emulsions

Suspensions with protein concentrations of 6% (w/v) were prepared by allowing the powders to well hydrate at room temperature, with over four hours of mixing at 600 rpm on a Cimarec i Poly magnetic stirrer (Thermo Fisher Scientific, Waltham, MA, USA). The protein suspensions were then mixed with sunflower oil (1:1 ratio, w/v) and further homogenized for 5 min at a speed of 15,000× g, using an Ultra Turrax ® IKA T18 basic homogenizer and the S18N-19G dispersing tool (IKA-Werke GmbH and Co. KG, Staufen, Germany).

2.4. Fundamental Rheological Measurements on Emulsions

The rheological characterization of the protein-based emulsions was performed by using a controlled-stress rheometer (AR2000ex, TA Instruments Ltd., New Castle, DE, USA). All measurements were performed at 20 °C with a cone–plate geometry (40 mm in diameter, 2° cone angle) and a closing gap of 1000 μm. The excess sample resulting when lowering the cone geometry towards the plate was trimmed off and the exposed edges of the sample were covered with a tinny layer of mineral oil, such as to limit the moisture loss during the measurements.

The emulsion samples were first subjected to a strain sweep test at a constant frequency of 1 Hz by increasing the oscillating strain in the 0.1–100% domain for checking the linear viscoelastic region (LVR).

Further frequency sweep testing was applied at constant strain within the LVR. The storage modulus (G′) and loss modulus (G″) of the protein-based emulsions were recorded while oscillating the frequency from 0.1 to 100 Hz.

The steady shear viscosities were finally recorded while running a stepped flow test at increasing shear rate values from 0.1 to 100 s−1.

The TA Rheology Advantage Data Analysis Software V 4.8.3. (TA Instruments, New Castle, DE, USA) was used to analyze the results of the triplicate measurements.

2.5. Thermo-Mechanical Behavior

The Mixolab Chopin (Tripette & Renaud Chopin, Villeneuve La Garenne, France) device was used to estimate the influence of sunflower oil or proteins-based emulsion addition on the rheological properties of the white wheat flour dough. The amount of water required to prepare the wheat flour dough with standard torque value of 1.1 Nm (C1) at the initial mixing step was considered for all investigated samples. The empirical rheological measurements were performed on model doughs, prepared by well mixing in the Mixolab tank the white wheat flour with oil or protein-based emulsion (4% in respect to the flour) and water to reach water absorption (WA) of the flour. The volume fraction of the oil or protein-based emulsion added to prepare the model doughs was decided upon running preliminary tests (results not shown) in such a manner to allow for measuring of the torque while mixing at 30 °C in the first stage of the Mixolab protocol. At a higher volume oil fraction, the doughs were sticky, no appropriate contact with the mixing blades was ensured, and therefore, the dough resistance could not be correctly recorded by Mixolab. The torque of the resulting doughs was monitored over the 45 min long Chopin+ protocol, involving mixing coupled with thermal treatment. The typical Mixolab parameters were registered for estimating the influence of oil or emulsions addition on the properties of the main wheat flour constituents: C2 (Nm) torque providing information on the protein weakening under constant mixing and temperature (it was not possible to register the C2 for the doughs prepared with oil or soy and lupin protein emulsions), C3 (Nm) torque related to starch gelatinization, C4 (Nm) torque which is a measure of the starch gel stability at high temperature, and C5 (Nm) torque related to starch retrogradation upon cooling at 50 °C.

2.6. Preparation of the Muffins

Protein-based emulsions were further used to prepare muffins, following the procedure proposed by Martínez-Cervera et al. [18] with slight modifications. The muffin formulations included white wheat flour (100 g), sugar (100 g), fresh eggs (80 g), 50 mL emulsion, 50 mL of whole milk, 4 g of baking powder, and 1.5 g NaCl, as indicated in Table 1. The muffin samples prepared with emulsions based on soy protein, lupin protein, and yeast extract were coded M1, M2, and M3, respectively. The control sample (M) was prepared with sunflower oil instead of protein-based emulsion.

Table 1.

Formulation of the muffin samples.

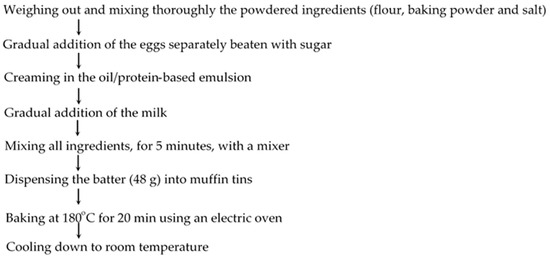

The batters were prepared by beating the ingredients with a Braun mixer (De’Longhi, Neu Isenburg, Hessen, Germany) for 3 min at the highest speed (4), followed by 2 min at a lower speed (2). The procedure for the preparation of the muffins is presented in Figure 1. For each type of emulsion, 12 paper cups were placed in the muffin baking trays and filled with 48 g of batter. The muffins were baked at 180 °C for 20 min using an electric oven (Electrolux, Stockholm, Sweden) with top and bottom heat. The oven was preliminarily heated to the desired temperature. The samples were then left for 1 h in the paper cups to cool down to room temperature.

Figure 1.

Flow diagram for muffin preparation.

2.7. Characterization of the Muffins

The muffins prepared with different types of protein-based emulsions to replace the oil were characterized by determining the moisture content, height, texture, color, and porosity. All measurements were performed within 12 h after baking.

Weight loss (WL) during baking was calculated, upon weighing the batter poured in the muffin cups (m0) and the final baked products upon cooling (m1), using the following equation:

WL = (m0 − m1) × 100/m0

For each muffin formulation used in the study, five different samples were used to measure the highest point in respect to the flat base, using a caliper.

The firmness of the muffins’ crumb was measured using the MLFTA apparatus (Guss, Strand, South Africa). The upper and bottom parts of the muffins were discarded and a probe with a diameter of 7.9 mm was used to penetrate the samples for 25 mm with a speed of 5 mm/s. The trigger threshold force was 20 g [19]. Each muffin sample was penetrated in three different points and the maximum force was registered as an indicator of crumb firmness.

The Chroma Meter CR-410 (Konica Minolta Business Solutions Europe GmbH) colorimeter was used to measure the brightness (L*), redness (a*), and yellowness (b*) of the muffin crumb. In order to estimate the impact of oil substitution by protein-based emulsion in the muffin formulation, the total color difference (ΔE) was calculated as:

ΔE = ((L*sample − L*control)2 + (a*sample − a*control)2 + (b*sample − b*control)2)1/2

Moreover, chroma (C*), which gives indications on color intensity, was calculated using Equation (3):

C* = (a*2 + b*2)1/2

The porosity of the muffin samples was assessed by image analysis, using the procedure described by Aprodu and Banu [20]. The muffins were prepared for pores’ measurement through cutting them into halves. The scanned images with a resolution of 300 dpi (Canon Lide 210, Canon Inc., Tokyo, Japan) of the resulting sections were first gray-scaled and used for further analysis of porosity characteristics using the Image J software.

2.8. Sensory Analysis Test

The sensory analysis of the muffin samples was performed in agreement with the IFST Guidelines for Ethical and Professional Practices for the Sensory Analysis of Foods by 12 consumers. The consumer panel consisted of 7 women and 5 men aged between 23 and 50 years. The recruiting criteria of the consumer panel was the regular consumption of sweet baked food products, such as muffins, at least once every two days. Written informed consent was obtained from all participants to the sensory evaluation test, according to the decision of the Dunarea de Jos University Ethics Commission no. 28/19 October 2022. A pretest session was organized to instruct the members of the sensory panel on the use of the attributes selected for characterization of the muffins. The sensory evaluation was performed in a room that had the proper environmental controls and was sufficient in size to handle the panelists and products. Each consumer was asked to evaluate the sensory attributes of all muffin samples, placed on individual small white plates and codified with three-digit random numbers. The panelists were asked to use water for cleaning the palate before tasting each muffin sample. The products were submitted to a sensory acceptance test. The nine-point hedonic scale was used to rate the appearance, flavor, taste, color, texture, and overall quality of the muffins (1—“dislike extremely” to 9—“like extremely”).

2.9. Statistical Analysis

The results are presented as average values ± standard deviation of triplicate measurements. The Minitab 19 (Minitab LLC, State College, PA, USA) software was used to perform statistical analysis of the results. Significant differences between samples were identified through the ANOVA method and the post hoc test, based on the Tukey method, when p < 0.05.

3. Results and Discussion

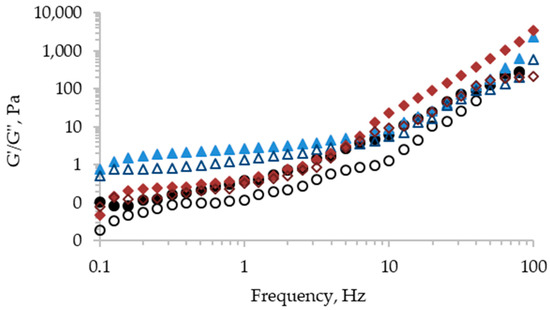

3.1. Rheological Properties of the Emulsions

Proteins are natural ingredients commonly used as emulsifying agents in the food industry [21]. Protein-based emulsions were used to reduce the fat content of the muffin formulations. Three different protein sources (soy, lupin, and spent brewery yeast) were used to stabilize the emulsions by forming a viscoelastic layer on the oil droplets [21]. Emulsions were prepared by mixing the 6% protein suspensions with sunflower oil in a 1:1 ratio (w/v), decided such as not to exceed the emulsifying capacity of the protein sources used in the study. The influence of the protein source on the rheological behavior of the emulsions was assessed by running low oscillatory and stepped flow tests.

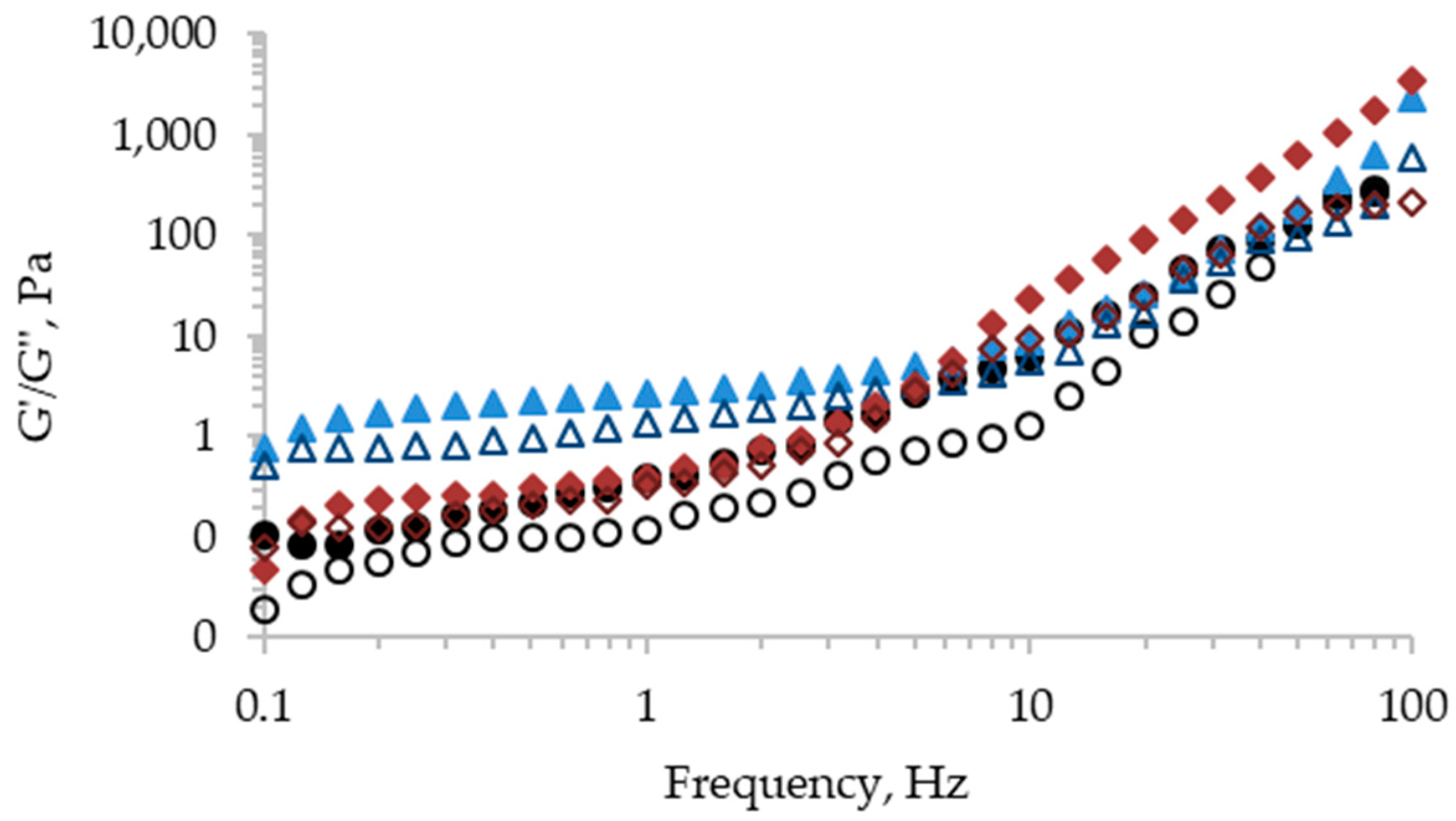

The viscoelastic behavior of the emulsions was characterized through dynamic oscillation measurements within the LVR. The results of the frequency sweep test are presented in Figure 2. For all tested emulsions, both storage and loss moduli progressively increased with frequency. In agreement with the observations of Manoi & Rizvi [22] and Liu & Tang [23], these phenomena may be attributed to the solid-like behavior of the samples, exhibiting permanent interactions. Over the entire frequency domain considered in the experiment, the samples exhibited slightly higher G’ compared to G’’ values, suggesting the formation of weak elastic gel-like emulsions.

Figure 2.

Evolution of the storage (G′—full symbol) and loss (G″—empty symbol) moduli with frequency for the emulsions prepared with soy proteins (circle), lupin proteins (triangle), and yeast proteins (diamonds).

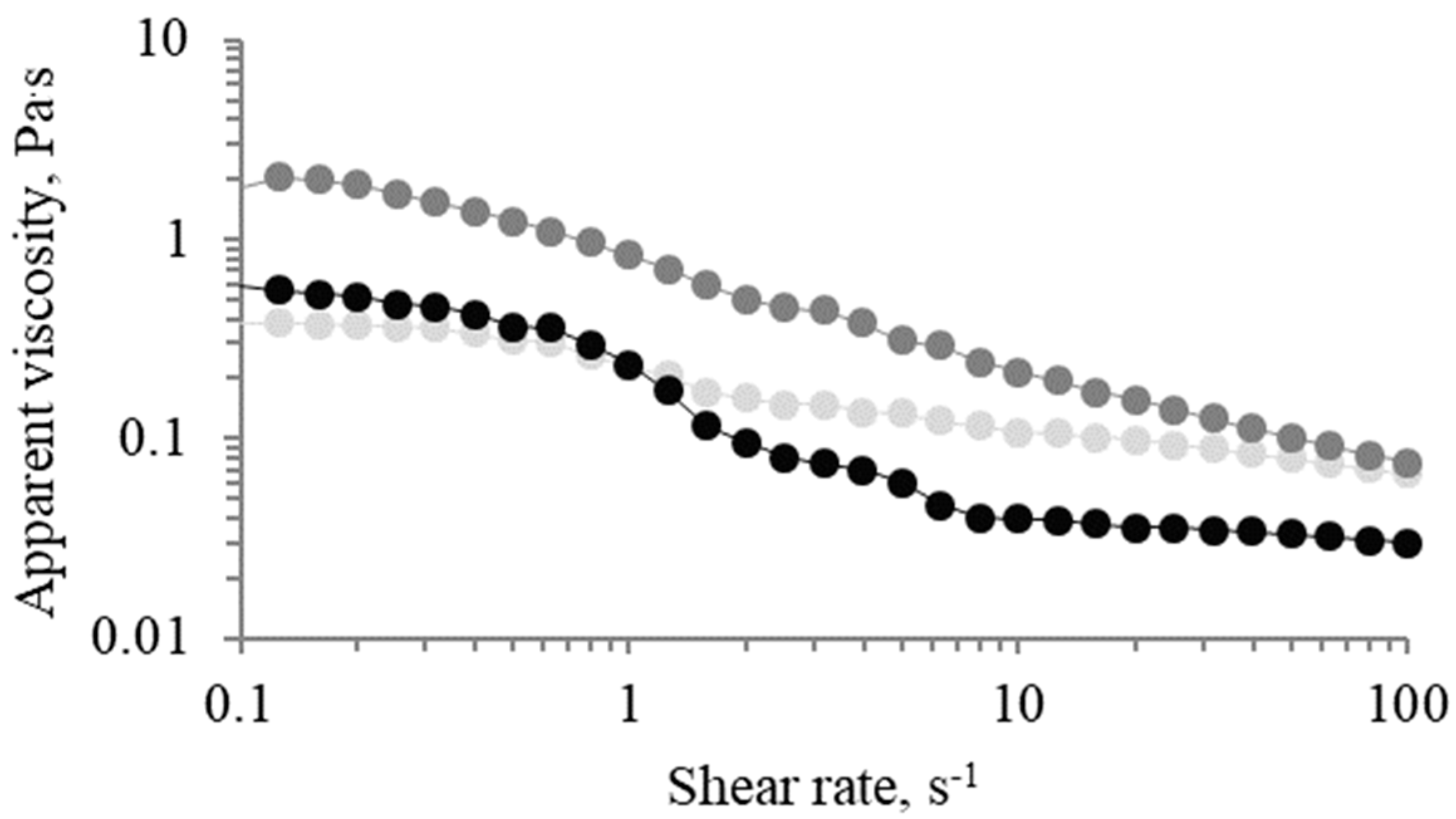

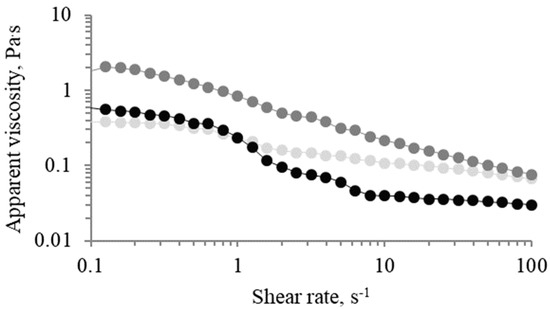

The rheological behavior of the protein-based emulsions under flow conditions is presented in Figure 3. as apparent viscosity vs. shear rate rheograms. Regardless of the protein source, the emulsion samples presented shear-thinning behavior, which has been previously reported for protein-stabilized emulsions [22,23]. Liu and Tang [23] explained the shear-thinning behavior through the flocculation of the emulsion droplets. In addition, Berli et al. [24] suggested that the high shear-induced gradual disruption of the droplet aggregates might contribute to the shear-thinning behavior of the emulsions. The disruption of the droplets usually occurs at high flow rates when the hydrodynamic forces overcome the interfacial forces responsible for droplets aggregation [25].

Figure 3.

Evolution of the apparent viscosities as a function of shear rate for the emulsions prepared with soy proteins (light gray), lupin proteins (dark gray), and yeast proteins (black).

In the case of all tested samples, the shear stress increased, and the apparent viscosity decreased in the whole shear rate range of 0.1–100 s−1. The highest values of apparent viscosity were registered for the lupin protein-based emulsion (Figure 3). At low shear rates, the soy protein-based emulsion had the lowest shear stress and viscosities values. For shear rates over 1 s−1, the yeast protein-based emulsion was overtaken by the soy protein-based one (Figure 3). The slightly different shape of the yeast protein-based emulsion, with a more evident plateau of apparent viscosity values, might be due to the rather high content of minerals in the sample, which might weaken the attractive interaction between droplets [24].

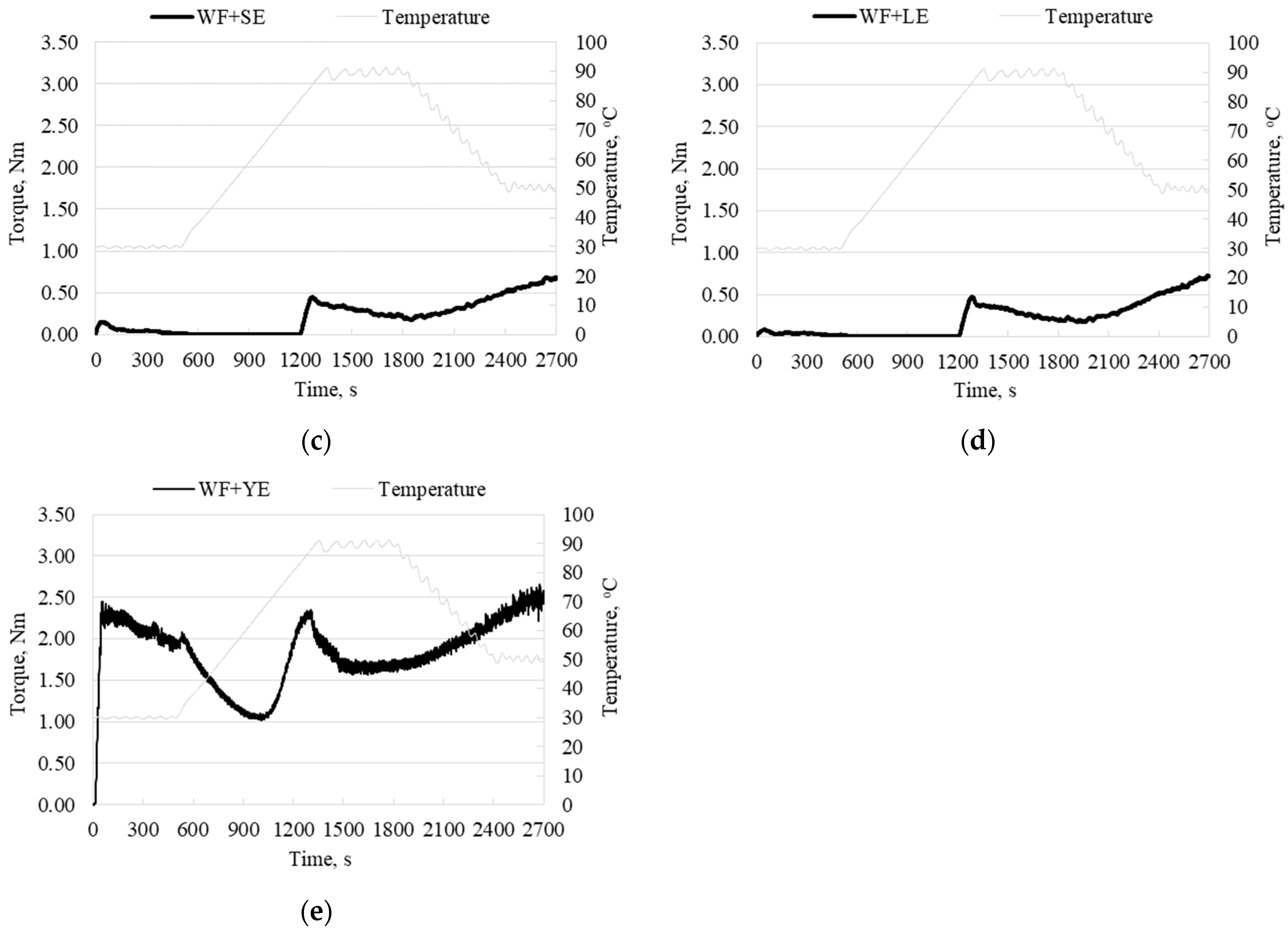

3.2. Rheological Properties of the Doughs

The influence of oil addition and further substitution by emulsion on the thermo-mechanical behavior of the white wheat flour used to prepare the muffin samples was investigated by means of the Mixolab device, which allows for registering the torque of the dough while subjecting it to dual mixing and thermal constraints.

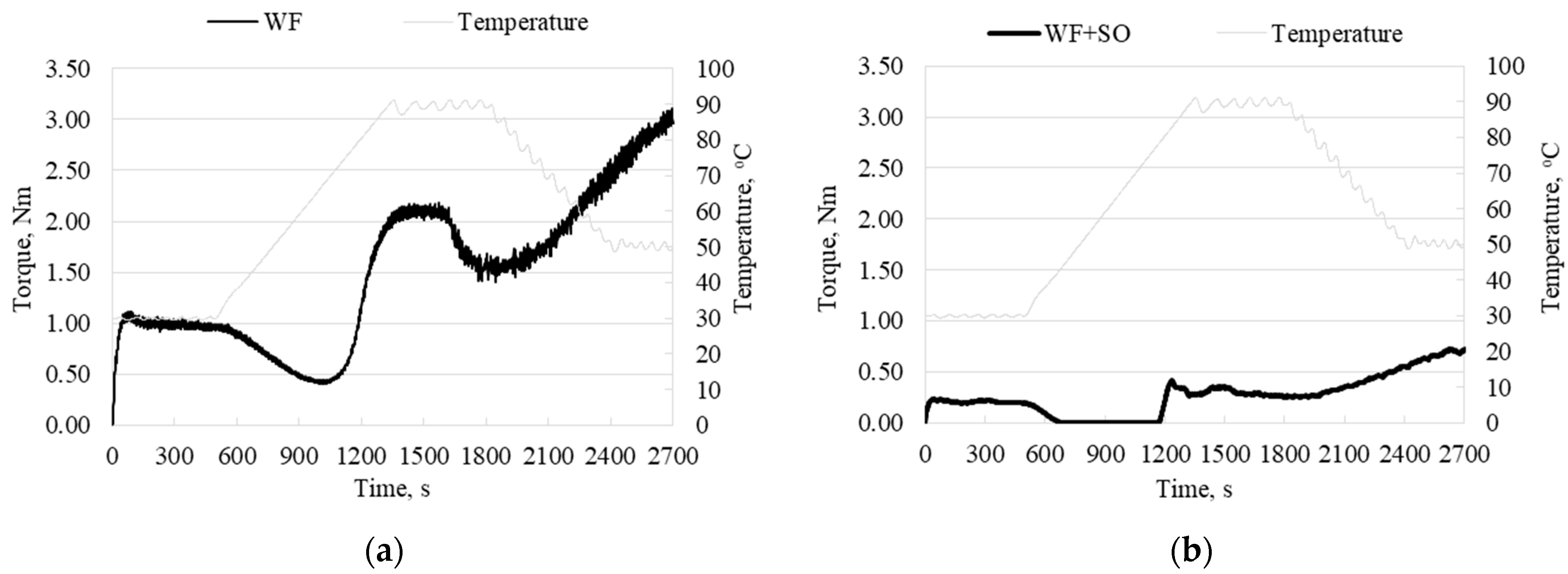

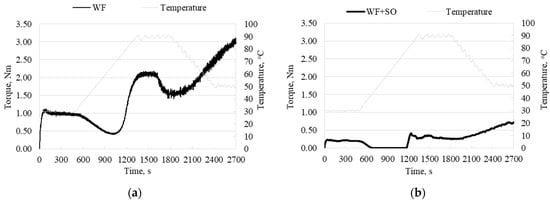

The typical Mixolab curve showing the thermo-mechanical behavior of the white wheat flour, used as a basis in the batter formulations, is presented in Figure 4a. The WA of 59.3% was used to get the target torque value C1 of 1.1 Nm. The addition of sunflower oil caused some important changes to the thermo-mechanical behavior of the dough (Figure 4b). The main consistency values were significantly lower (p < 0.05) compared to those measured for wheat flour with no oil addition (Table 2). The reduction of the torque values registered by Mixolab on the dough with the addition of sunflower oil was previously reported by Moreira et al. [26]. Moreover, they showed that oil addition resulted in lower WA values required to reach the target C1 of 1.1 Nm. In the case of our experiment, in order to actually measure the effect of oil and emulsion addition on the thermo-mechanical behavior of the dough, the optimum WA level of 59.3% measured for the white wheat flour was used for preparing all the dough samples. Thanks to the lubricating effect of the oil, softer consistency of the dough is obtained even at low water addition levels [27]. It is generally accepted that, when starch gelatinization occurs in the presence of lipids, the amylose-starch complexes have lower viscosity [28]. The maximum consistency registered for the oil-containing dough sample at 30 °C (C1) was 0.23 Nm, significantly lower compared with C1 of 1.08 Nm (p < 0.05) obtained for the white wheat flour sample. The increase of the temperature up to 45 °C resulted in the rapid drop of the torque measured on the oil-containing sample, indicating the impossibility to record the dough resistance by Mixolab, most probably occurring as a consequence of dough sliding on the mixing paddles when adhesion ceased. A similar rapid torque falling to zero was recently reported by Berceli et al. [29] when registering the Mixolab curve of the wheat dough with high oil content. This behavior of the dough suggests that oil addition might interfere with gluten proteins interaction, resulting in softer networks. Further increase of the temperature up to 80 °C caused the rise of the dough consistency up to C3 of 0.42 Nm, which is five times lower compared with the C3 measured on the wheat flour, therefore suggesting limited gelatinization of the starch. Our observation is in agreement with the previous findings of Ai et al. [30] and Dun et al. [28], who showed that the formation of the starch-lipid complex might interfere with starch swelling, resulting in the reduction of peak viscosity. Finally, the C4 and C5 torque values registered on the oil-containing dough, when heating at 90 °C and further cooling to 50 °C, were significantly lower (p < 0.05) compared with the white wheat flour (Figure 4a,b). The lower values of the C3-C4 parameter suggest the improvement of the hot starch paste stability upon oil addition (Table 2). An additional distinctive characteristic of the oil-supplemented dough consists of the low C5-C4 value, suggesting increased resistance to starch retrogradation. Amylose-lipid complexes, formed when starch gelatinization occurs in the presence of lipids, are known to inhibit the retrogradation phenomenon [28].

Figure 4.

Mixolab curves of the dough samples prepared with: (a) white wheat flour (WF); (b) WF supplemented with sunflower oil (SO); (c) WF supplemented with soy protein-based emulsion (SE); (d) WF supplemented with lupin protein-based emulsion (LE); (e) WF supplemented with yeast protein-based emulsion (YE).

Table 2.

Effect of supplementation with sunflower oil (SO), soy proteins (SE), lupin proteins (LE), and yeast proteins-based (YE) emulsion on the Mixolab parameters of the wheat flour dough (WF).

The thermo-mechanical behavior of the doughs prepared with emulsion instead of oil varied with the type of proteins used to prepare the emulsion. The maximum torque of the doughs prepared with soy and lupin proteins registered during mixing at a constant temperature of 30 °C were 0.15 Nm and 0.06 Nm, respectively. In the case of both samples, the gradual drop of the torque to zero was noticed during the initial mixing at 30 °C (Figure 4c,d). The more rapid decrease of the torque, compared with the dough sample prepared with sunflower oil, might be due to the fact that the lipids in the fine oil drops within the emulsion are more easily available for interacting with the macromolecular components of the wheat flour, resulting in faster termination of the adhesion between the mixing paddles and dough. A sharp increase of the torques was noticed when the temperature increased to 85–87 °C, the maximum C3 value of 0.46 Nm, registered for doughs with soy and lupin protein emulsions, being higher compared with the oil-based dough. These results suggest a better gelatinization of the starch as a consequence of a lower volume fraction of oil when emulsions are used to prepare the doughs. The lower C4 values registered for doughs prepared with soy and lupin proteins-based emulsions suggest the lower hot paste stability compared with the oil-based sample. Cooling the doughs to 50 °C in the final Mixolab stage resulted in the C5 values of 0.69–0.71 Nm, close to the one registered for the oil-based sample. These results indicate higher starch retrogradation in the case of the samples prepared with soy or lupin proteins emulsion (C5-C4 of 0.52–0.53 Nm) compared with the oil-based dough (C5-C4 of 0.47 Nm). In addition to oil, which exerts a major influence on the starch-related thermo-mechanical behavior of the doughs, the starch swelling and gelatinization are hampered by the interactions established by the proteins originating from the emulsion. Yang et al. [31] explained this phenomenon by the perturbation occurring in the hydrogen bonding network. Furthermore, the non-covalent interactions established between the gelatinized starch and the proteins are prone to alter the retrogradation behavior of the starch [28].

A different trend was observed in the case of the sample containing yeast proteins emulsion (Figure 4e). Analyzing the results presented in Table 2, one can see that, except for C5, all torque values were higher compared with the wheat flour dough. This particular rheological behavior is a consequence of the higher amount of water needed to prepare the dough of a specific work input (corresponding in this case to C1 of 1.1 Nm), which is due to the particular composition of the yeast extract used to prepare the emulsion. In addition to the high protein content, the yeast extract is particularly rich in minerals and B-complex vitamins. Vieira et al. [14] obtained lyophilized yeast extract with a protein content of 64% and high levels of macrominerals, trace elements (1.76 mg Fe/100 g dw and 11.9 mg Zn/100 g dw), and vitamins like nicotinic acid (77.2 mg/100 mg dw) and folic acid (3.01 mg/100 g dw). Moreover, Tomé [15] indicated that yeast extract is a good source of minerals (such as Ca over 130 mg/100 g dw and Fe over 5 mg/100 g dw) and group B vitamins (such as thiamine 10–12 mg/100 g dw, riboflavine 8–12 mg/100 g dw, niacine 90–110 mg/100 g dw, and pantothenic acid 12–20 mg/100 g dw). The human body needs all these micronutrients, and their adequate intake and availability are particularly important for a healthy lifestyle. Considering that over two billion people suffer from deficiencies of various nutrients worldwide, many programs and studies proposed the fortification of staple foods [32]. The influence of wheat flour supplementation with different levels of iron (30–90 ppm) or calcium (800–1600 ppm) alone or as micronutrient premix, additionally including different levels of vitamins like riboflavin (0.038–0.113 ppm), thiamine (0.033–0.098 ppm), niacin (0.25–0.75 ppm), and folic acid (0.008–0.023 ppm) on the rheological behavior of the dough and bread-making quality was investigated by Sudha and Leelavathi [32]. They indicated no alteration of the bread-making quality of the wheat flour, but the addition of iron resulted in the increase of WA by 1–2%, whereas the vitamins-minerals mixture raised the WA from 57.9 to 58.9%. Moreover, Aktar et al. [33] showed that wheat flour fortification with elemental iron and ZnO significantly increased the WA.

In the zones of the Mixolab curves where starch behavior prevails over proteins, smaller differences were found between C3 and C4 torques registered for the control dough and the samples with yeast proteins emulsion (Table 2). Finally, the lower C5 value suggests better starch retrogradation behavior of the dough upon yeast proteins emulsion addition.

3.3. Muffin Characterization

The influence of oil replacement by protein-based emulsion on the quality of muffins was established by assessing the physical properties of the muffins. Oil replacement by protein-based emulsion resulted in a significant increase of the protein and ash contents (p < 0.05) and significantly affected (p < 0.05) the height of the samples (Table 3). Our results are in line with the observations from previous studies reporting the height-reducing effect of partial oil replacement in muffin formulations with cocoa fiber [7], resistant dextrins obtained from wheat or maize starch [34], or cellulose ether emulsions [18]. Due to the higher amount of water used in the batter preparation when replacing the oil, the moisture content of the emulsion-based muffin samples was significantly higher (p < 0.05) compared with the control (Table 3). Among all investigated muffin samples, those prepared with soy proteins-based emulsion exhibited the lowest weight loss during baking, whereas no significant changes were noticed between muffins prepared with lupin or yeast protein emulsions and the control. These results indicate that the emulsion-based muffins have high water-holding capacity, and from an economic standpoint, the production process is advantageous.

Table 3.

Quality characteristics of the muffin samples prepared with different types of emulsion (M—control prepared with sunflower oil, M1—muffins prepared with soy protein-based emulsion, M2—muffins prepared with lupin protein-based emulsion, M3—muffins prepared with yeast protein-based emulsion).

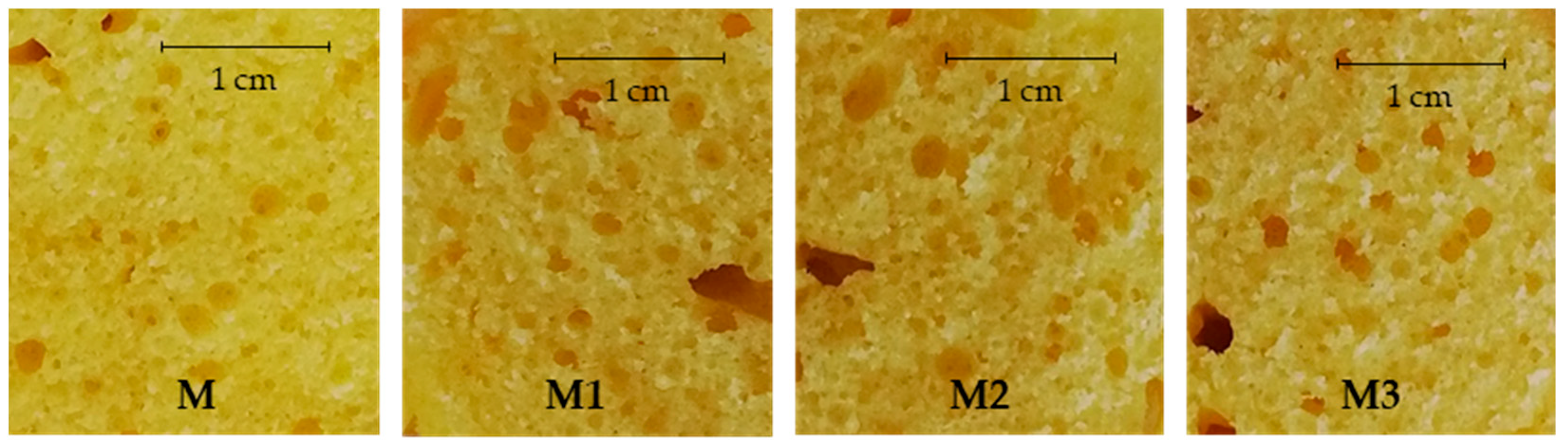

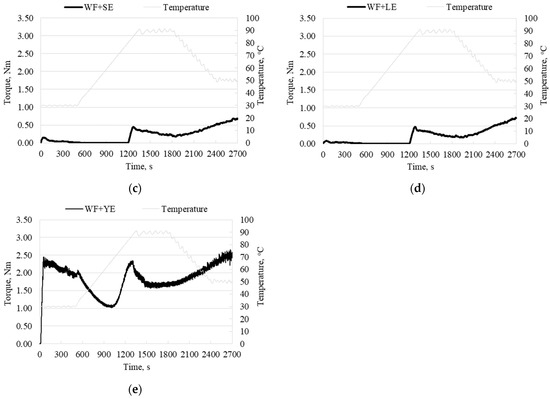

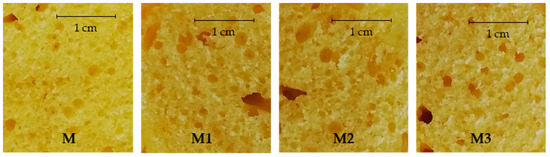

The characteristics of the pores of the four types of muffins (Figure 5) considered in the study were determined through image analysis and the results are presented in Table 4. The porosity-related characteristic provides indication of the ability of the batter to retain the CO2 released by baking powder during heating. As one can see in Figure 5, the pore size and homogeneity of the pore structure varied with the muffin samples. The average pore size was significantly higher in the case of the muffin samples prepared with emulsions (p < 0.05). On the other hand, the control muffin sample had a higher number of uniformly distributed smaller pores (Figure 5). Considering that the same processing conditions were applied for preparing the batters and muffin samples, the observed differences could be attributed to the lower viscosity of the samples prepared with emulsions as the result of the higher amount of water in respect to the binding ability of the dry mixture. No important differences were noticed between the investigated samples in terms of the cell-total area ratio (Table 4).

Figure 5.

Structure of the crumb of muffin samples with different types of emulsion (M—control prepared with sunflower oil, M1—muffins prepared with soy protein-based emulsion, M2—muffins prepared with lupin protein-based emulsion, M3—muffins prepared with yeast protein-based emulsion). Images were captured using a Canon PowerShot G16 digital camera (Canon Inc., Tokyo, Japan).

Table 4.

Porosity and texture characteristics of the muffin samples prepared with different types of emulsion (M—control prepared with sunflower oil, M1—muffins prepared with soy protein-based emulsion, M2—muffins prepared with lupin protein-based emulsion, M3—muffins prepared with yeast protein-based emulsion).

The crumb cell structure exerts a major influence on how the texture and freshness of the product is perceived [20]. The firmness of the muffins was measured at 12 h after baking. Analyzing the results presented in Table 4, one can see that oil substitution by emulsion in the batter formulations resulted in a significant increase of firmness. Our results comply with the observations of Martinez-Cervera et al. [18] who reported a significant hardness increase when using cellulose ether emulsions in the muffins formulation instead of oil.

Color is an important attribute of food products which might influence the consumers’ choice in a decisive manner. The color usually depends on the type and amount of ingredients used for the preparation of different foods, as well as on their interaction and transformation during processing. The difference in color (ΔE) between the control sample and muffins prepared with different types of protein-based emulsions is presented in Table 5. For all emulsion-based muffin samples, the ΔE fell within the 1.5–3.0 range, which, in agreement with Goyeneche et al. [35], suggests noticeable differences in respect to the sample prepared with sunflower oil. As all the samples exhibited similar a* values, the ΔE variations are mainly due to brightness (L*) and yellow (b*) chromaticity. The color intensity (C*) varied significantly with the source of fats (p < 0.05), being more vivid in the emulsion-based muffins (Table 5).

Table 5.

Color characteristics of the muffin samples prepared with different types of emulsion (M—control prepared with sunflower oil, M1—muffins prepared with soy protein-based emulsion, M2—muffins prepared with lupin protein-based emulsion, M3—muffins prepared with yeast protein-based emulsion).

The scoring method was applied for the sensory analysis of the muffin samples and the sensory scores for the main attributes are shown in Table 6. Oil replacement by protein-based emulsions resulted in no significant differences in color, flavor, taste, and appearance of the muffin samples. In agreement with the results of the instrumental analysis, showing that among all investigated samples, those with lupin and yeast protein-based emulsions had the highest firmness values (Table 4), the textures of these muffins were rated with the lowest scores (Table 6). However, no important differences between control and emulsion-based muffins were observed in terms of overall quality.

Table 6.

Sensory evaluation data of muffin samples prepared with different types of emulsion (M—control prepared with sunflower oil, M1—muffins prepared with soy protein-based emulsion, M2—muffins prepared with lupin protein-based emulsion, M3—muffins prepared with yeast protein-based emulsion).

4. Conclusions

Fundamental and empirical rheological measurements were applied to assess the properties of the soy, lupin, and yeast protein-based emulsions and batters, respectively. The protein-based emulsions exhibited a weak elastic gel-like behavior with moderate frequency dependence on the storage and loss moduli. The stepped flow tests revealed the shear-thinning behavior of the samples. Among all investigated emulsions, the lupin proteins-based one exhibited the highest apparent viscosity over the entirety of the tested shear rate range. The results of the Mixolab test indicated that emulsion addition influences, in a different manner, the thermo-mechanical behavior of the white wheat flour doughs, depending on the protein source. The reduction of the volume fraction of fats added to the dough, when replacing sunflower oil with the soy or lupin proteins emulsion, ensured a better gelatinization of the starch. Higher torque values were registered for the dough prepared with yeast proteins emulsion in all stages of the Mixolab curve.

Oil substitution by emulsion resulted in muffins with higher moisture and firmness values. The structure of the muffins was assessed by analyzing the porosity of their cores. All samples exhibited a good ability to retain the CO2 released during baking, the pore size being slightly higher in the case of the muffins with lower fat content. The chromatic parameters indicated that the samples prepared with protein emulsion have a more vivid color. In conclusion, the results reported herein confirm that protein-based emulsions considered in this study are sustainable ingredients for obtaining muffins with reduced fat content with acceptable quality characteristics.

Author Contributions

Conceptualization, I.A. and I.B.; methodology, L.D., I.V. and L.P.; software, I.A. and L.D.; validation, I.B., I.V. and L.P.; formal analysis, L.D. and L.P.; investigation, I.B., I.A., L.D., I.V. and L.P.; resources, I.A.; data curation, I.B.; writing—original draft preparation, I.A., I.B. and L.P.; writing—review and editing, I.A. and L.D.; supervision, I.A. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by a grant of the Ministry of Research, Innovation and Digitization, CNCS—UEFISCDI, project number PN-III-P1-1.1-TE-2021-0459, within PNCDI III.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Written informed consent was obtained from all subjects (patients) in this study, according to the decision of the Dunarea de Jos University Ethics Commission no. 28/19 October 2022.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hussien, H.A. Using vegetable puree as a fat substitute in cakes. Int. J. Nutr. Food Sci. 2016, 5, 284–292. [Google Scholar] [CrossRef]

- Colla, K.; Costanzo, A.; Gamlath, S. Fat replacers in baked food products. Foods 2018, 7, 192. [Google Scholar] [CrossRef] [PubMed]

- Azmoon, E.; Saberi, F.; Kouhsari, F.; Akbari, M.; Kieliszek, M.; Vakilinezam, A. The effects of hydrocolloids-protein mixture as a fat replacer on physicochemical characteristics of sugar-free muffin cake: Modeling and optimization. Foods 2021, 10, 1549. [Google Scholar] [CrossRef]

- Rodriguez-Sandoval, E.; Prasca-Sierra, I.; Hernandez, V. Effect of modified cassava starch as a fat replacer on the texture and quality characteristics of muffins. J. Food Meas. Charact. 2017, 11, 1630–1639. [Google Scholar] [CrossRef]

- Fernandes, S.S.; de las Mercedes Salas-Mellado, M. Addition of chia seed mucilage for reduction of fat content in bread and cakes. Food Chem. 2017, 227, 237–244. [Google Scholar] [CrossRef]

- Zahn, S.; Pepke, F.; Rohm, H. Effect of inulin as a fat replacer on texture and sensory properties of muffins. Int. J. Food Sci. Technol. 2010, 45, 2531–2537. [Google Scholar] [CrossRef]

- Martínez-Cervera, S.; Salvador, A.; Muguerza, B.; Moulay, L.; Fiszman, S.M. Cocoa fibre and its application as a fat replacer in chocolate muffins. LWT-Food Sci. Technol. 2011, 44, 729–736. [Google Scholar] [CrossRef]

- Jeong, S.; Lee, S.; Oh, I. Development of antioxidant-fortified oleogel and its application as a solid fat replacer to muffin. Foods 2021, 10, 3059. [Google Scholar] [CrossRef]

- Manzoor, S.; Masoodi, F.A.; Naqash, F.; Rashid, R. Oleogels: Promising alternatives to solid fats for food applications. Food Hydrocoll. Health 2022, 2, 100058. [Google Scholar] [CrossRef]

- Pehlivanoglu, H.; Ozulku, G.; Yildirim, R.M.; Demirci, M.; Toker, O.S.; Sagdic, O. Investigating the usage of unsaturated fatty acid-rich and low-calorie oleogels as a shortening mimetics in cake. J. Food Process. Pres. 2018, 42, e13621. [Google Scholar] [CrossRef]

- Therdthai, N. Sugar, salt and fat reduction of bakery products. Adv. Food Nutr. Res. 2022, 99, 283–327. [Google Scholar]

- Boye, J.I.; Zare, F.; Pletch, A. Pulse proteins: Processing, characterization, functional properties and applications in food and feed. Food Res. Int. 2010, 43, 414–431. [Google Scholar] [CrossRef]

- Grossi Bovi Karatay, G.; Rebellato, A.P.; Joy Steel, C.; Dupas Hubinger, M. Chickpea aquafaba-based emulsions as a fat replacer in pound cake: Impact on cake properties and sensory analysis. Foods 2022, 11, 2484. [Google Scholar] [CrossRef]

- Vieira, E.F.; Carvalho, J.; Pinto, E.; Cunha, S.; Almeida, A.A.; Ferreira, I.M. Nutritive value, antioxidant activity and phenolic compounds profile of brewer’s spent yeast extract. J. Food Compos. Anal. 2016, 52, 44–51. [Google Scholar] [CrossRef]

- Tomé, D. Yeast extracts: Nutritional and flavoring food ingredients. ACS Food Sci. Technol. 2021, 1, 487–494. [Google Scholar] [CrossRef]

- SR ISO 712:2005; SR ISO 2171:2002; Romanian Standards Catalog for Cereal and Milling Products Analysis. ASRO: Bucharest, Romania, 2008.

- AACC International. Approved Methods of Analysis, 11th ed.; Method 46-11.02; American Association of Cereal Chemists International: Saint Paul, MN, USA, 2000. [Google Scholar]

- Martínez-Cervera, S.; Salvador, A.; Sanz, T. Cellulose ether emulsions as fat replacers in muffins: Rheological, thermal and textural properties. LWT-Food Sci. Technol. 2015, 63, 1083–1090. [Google Scholar] [CrossRef]

- Banu, I.; Aprodu, I. Investigation on functional, thermo-mechanical and bread-making properties of some white and black rice flours. Appl. Sci. 2022, 12, 4544. [Google Scholar] [CrossRef]

- Aprodu, I.; Banu, I. Rheological, thermo-mechanical, and baking properties of wheat-millet flour blends. Food Sci. Technol. Int. 2015, 21, 342–353. [Google Scholar] [CrossRef] [PubMed]

- Wilde, P.; Mackie, A.; Husband, F.; Gunning, P.; Morris, V. Proteins and emulsifiers at liquid interfaces. Adv. Colloid Interface Sci. 2004, 108, 63–71. [Google Scholar] [CrossRef]

- Manoi, K.; Rizvi, S.S. Emulsification mechanisms and characterizations of cold, gel-like emulsions produced from texturized whey protein concentrate. Food Hydrocoll. 2009, 23, 1837–1847. [Google Scholar] [CrossRef]

- Liu, F.; Tang, C.H. Cold, gel-like whey protein emulsions by microfluidisation emulsification: Rheological properties and microstructures. Food Chem. 2011, 127, 1641–1647. [Google Scholar] [CrossRef]

- Berli, C.L.; Quemada, D.; Parker, A. Modelling the viscosity of depletion flocculated emulsions. Colloid. Surf. A-Physicochem. Eng. Asp. 2002, 203, 11–20. [Google Scholar] [CrossRef]

- McClements, D.J. Emulsion Rheology. In Food Emulsions: Principles, Practices, and Techniques, 2nd ed.; McClements, D.J., Ed.; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Moreira, R.; Chenlo, F.; Torres, M.D. Effect of shortenings on the rheology of gluten-free doughs: Study of chestnut flour with chia flour, olive and sunflower oils. J. Texture Stud. 2012, 43, 375–383. [Google Scholar] [CrossRef]

- Zoulias, E.I.; Oreopoulou, V.; Tzia, C. Textural properties of low-fat cookies containing carbohydrate-or protein-based fat replacers. J. Food Eng. 2002, 55, 337–342. [Google Scholar] [CrossRef]

- Dun, H.; Liang, H.; Zhan, F.; Wei, X.; Chen, Y.; Wan, J.; Ren, Y.; Hu, L.; Li, B. Influence of O/W emulsion on gelatinization and retrogradation properties of rice starch. Food Hydrocoll. 2020, 103, 105652. [Google Scholar] [CrossRef]

- Berceli, M.B.; Izsó, E.; Gergely, S.; Salgó, A. Effects of special additives in wheat dough system measured by Mixolab technique. Czech J. Food Sci. 2021, 39, 460–468. [Google Scholar] [CrossRef]

- Ai, Y.; Hasjim, J.; Jane, J.L. Effects of lipids on enzymatic hydrolysis and physical properties of starch. Carboh. Polym. 2013, 92, 120–127. [Google Scholar] [CrossRef]

- Yang, C.; Zhong, F.; Goff, H.D.; Li, Y. Study on starch-protein interactions and their effects on physicochemical and digestible properties of the blends. Food Chem. 2019, 280, 51–58. [Google Scholar] [CrossRef]

- Sudha, M.L.; Leelavathi, K. Influence of micronutrients on rheological characteristics and bread-making quality of flour. Int. J. Food Sci. Nutr. 2008, 59, 105–115. [Google Scholar] [CrossRef]

- Akhtar, S.; Anjum, F.M.; Rehman, S.U.; Sheikh, M.A. Effect of mineral fortification on rheological properties of whole wheat flour. J. Texture Stud. 2009, 40, 51–65. [Google Scholar] [CrossRef]

- Martínez-Cervera, S.; de la Hera, E.; Sanz, T.; Gómez, M.; Salvador, A. Effect of nutriose on rheological, textural and sensorial characteristics of Spanish muffins. Food Bioprocess Technol. 2013, 6, 1990–1999. [Google Scholar] [CrossRef]

- Goyeneche, R.; Agüero, M.V.; Roura, S.; Di Scala, K. Application of citric acid and mild heat shock to minimally processed sliced radish: Color evaluation. Postharvest Biol. Technol. 2014, 93, 106–113. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).