Numerical Analysis of Shield Tunnelling Breakthrough Working Shaft by Artificial Ground Freezing Method under Extreme Conditions Considering Phase Change Latent Heat

Abstract

:1. Introduction

2. Numerical Modeling of the AGF Process including Phase Transition Conditions

2.1. Heat Conduction Governing Equation

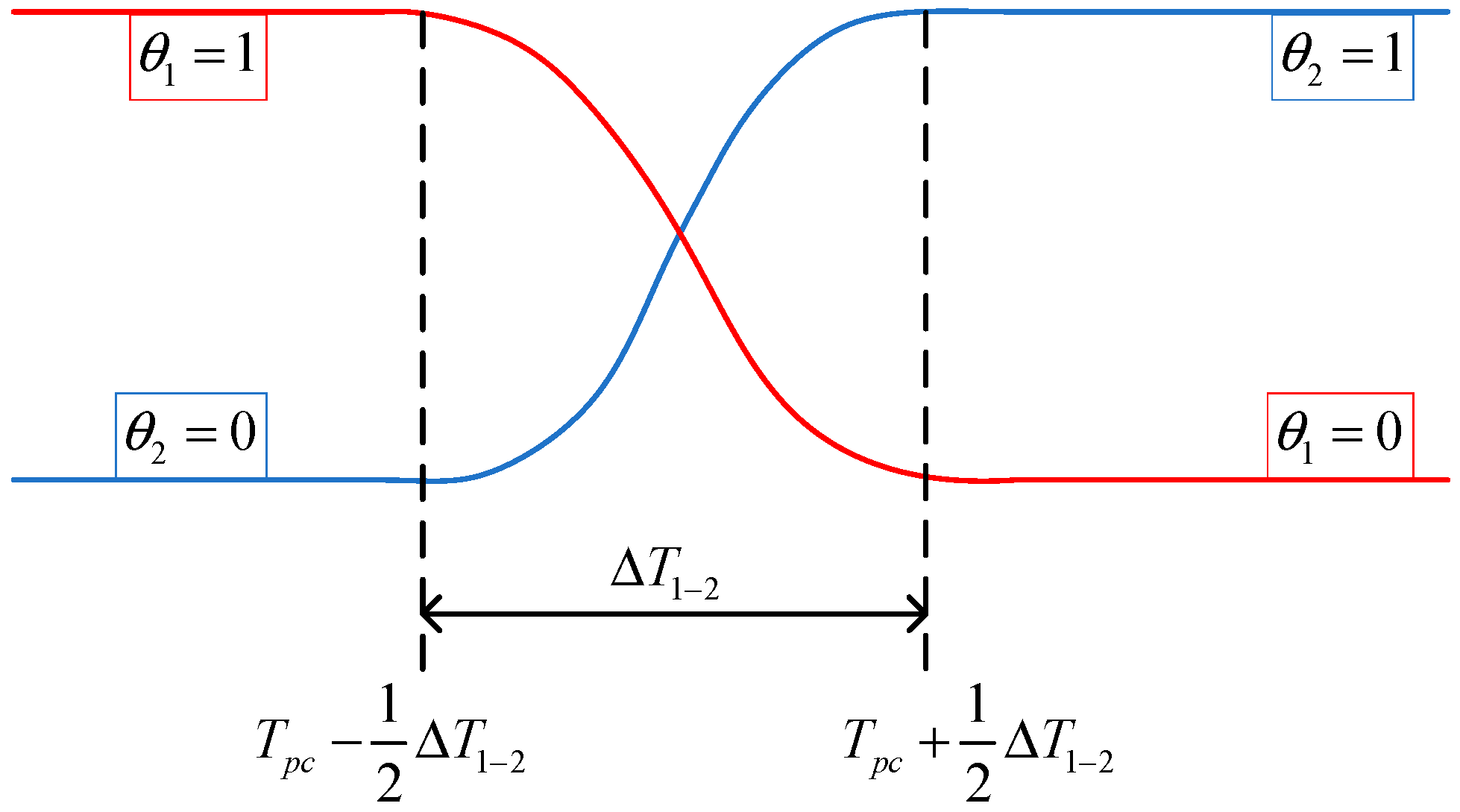

2.2. Coupling Calculation Model of Shield Machine Heating and Freezing Cooling

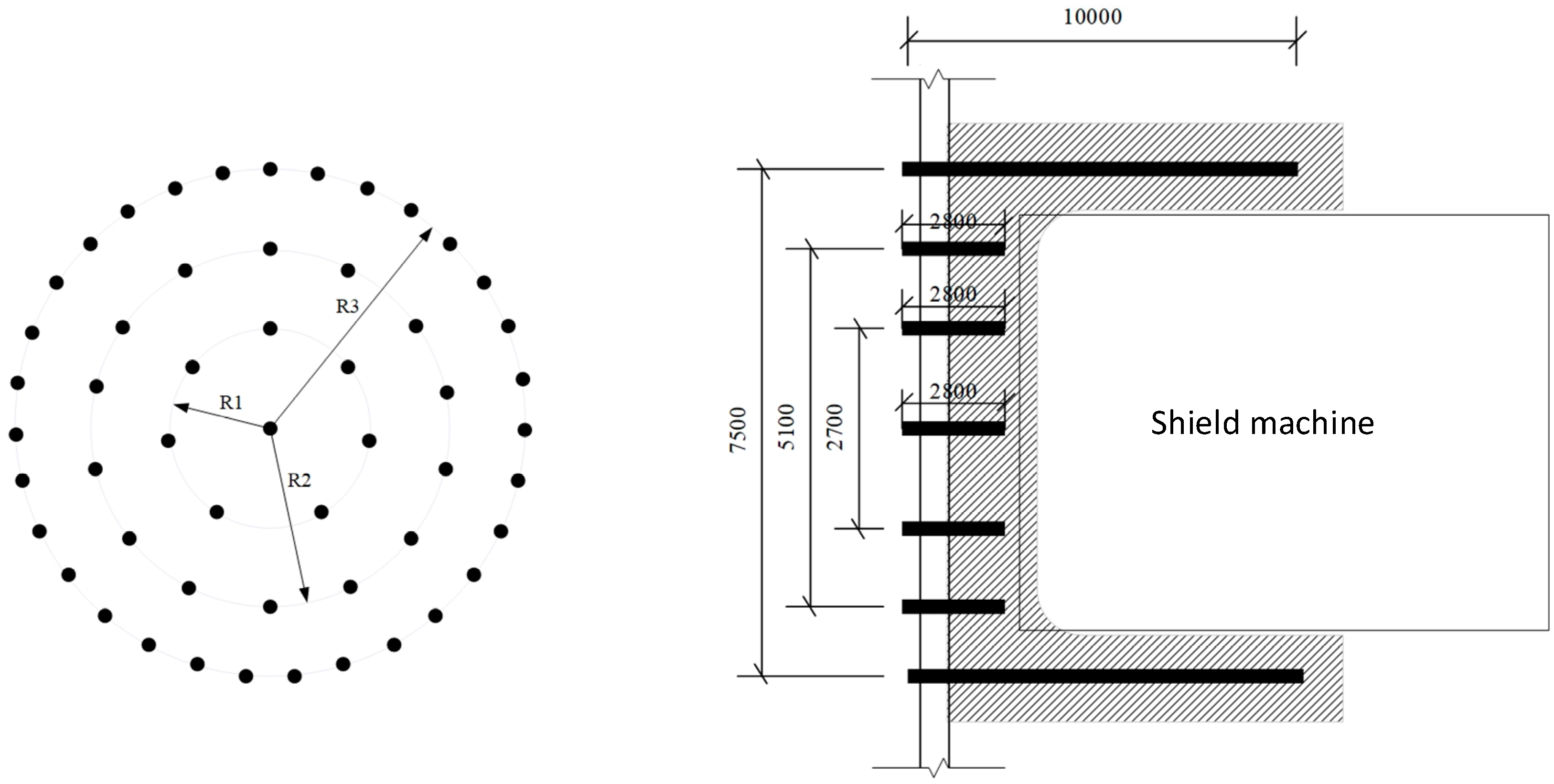

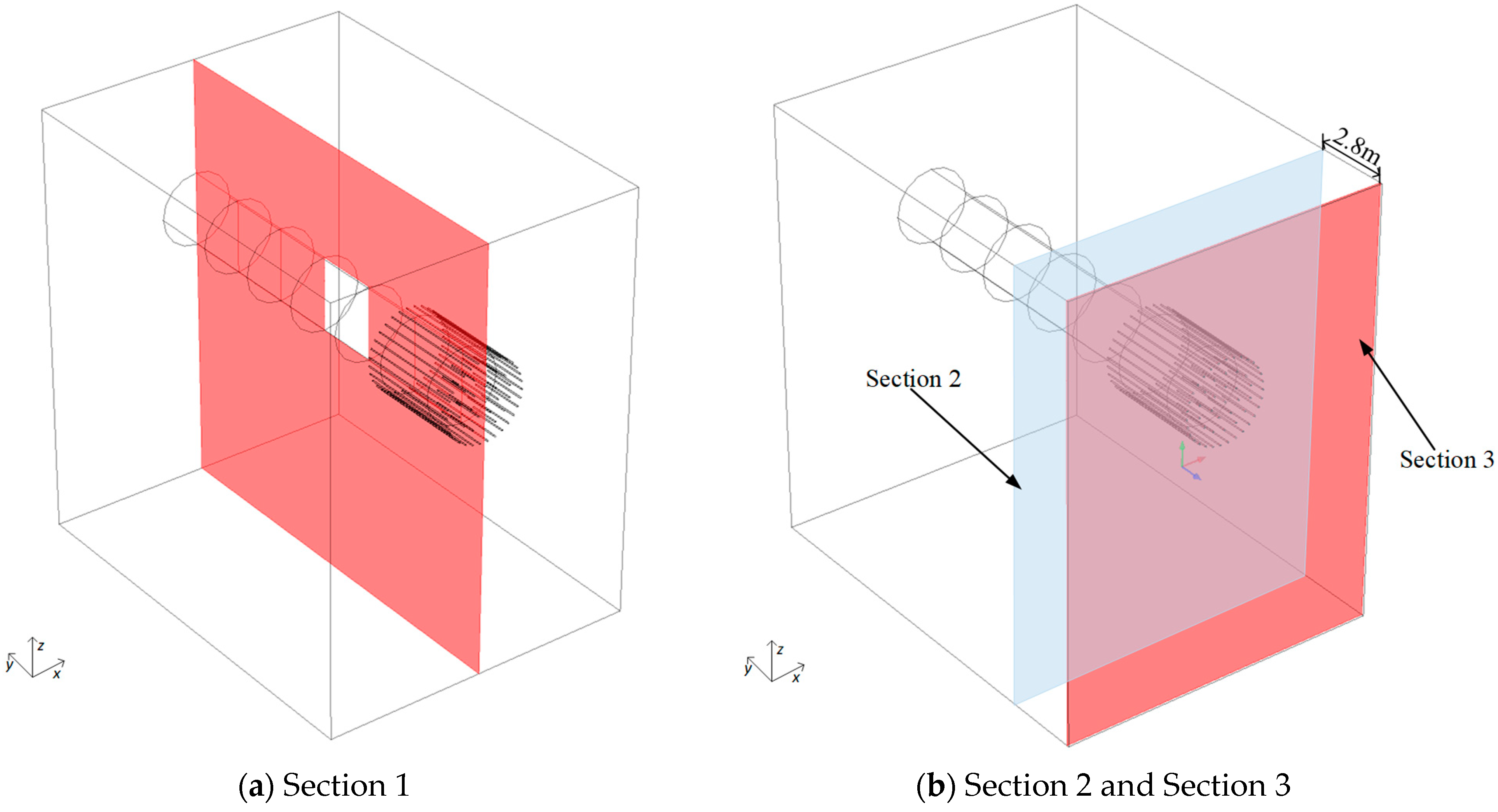

2.2.1. Layout Scheme of Freezing System

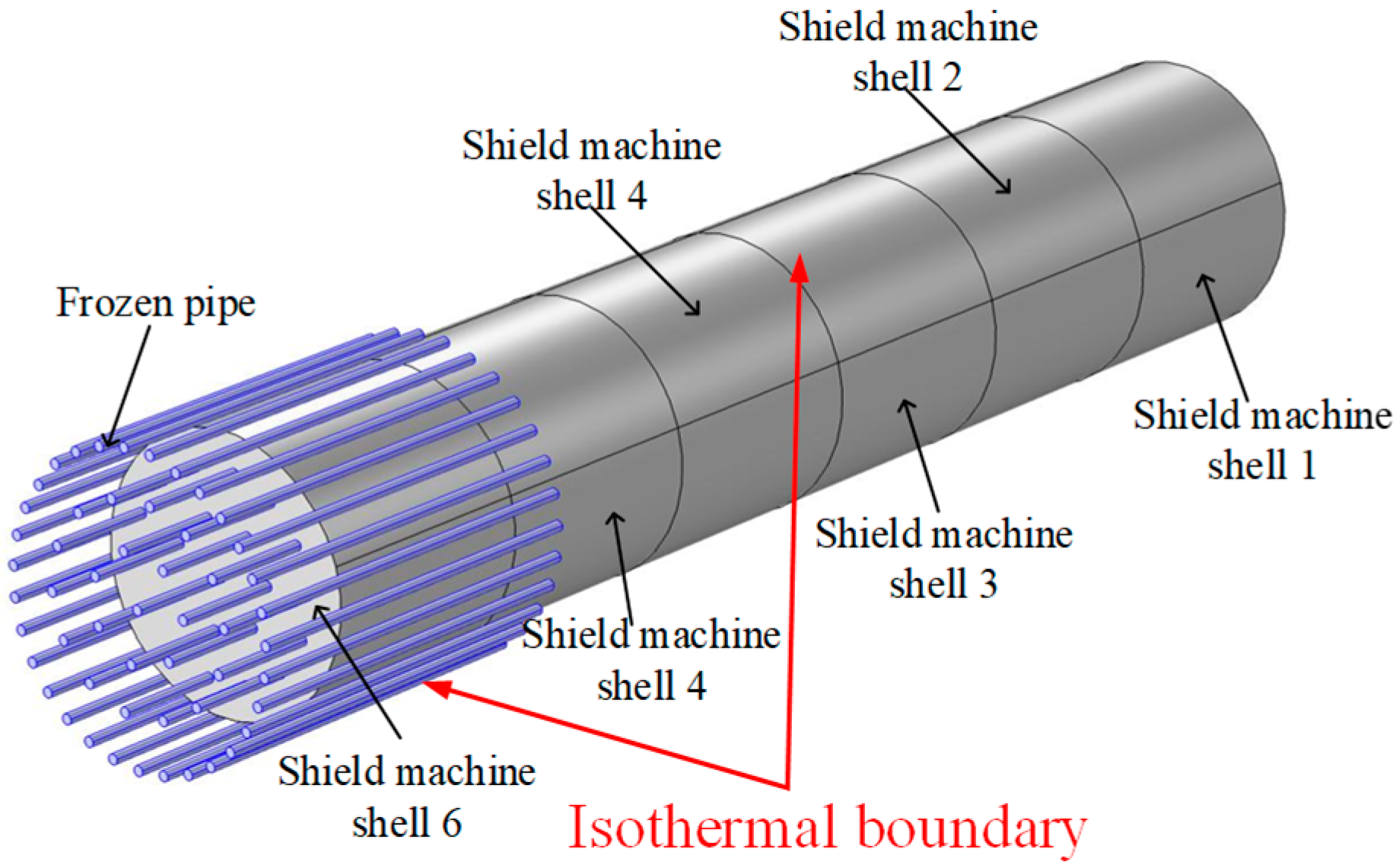

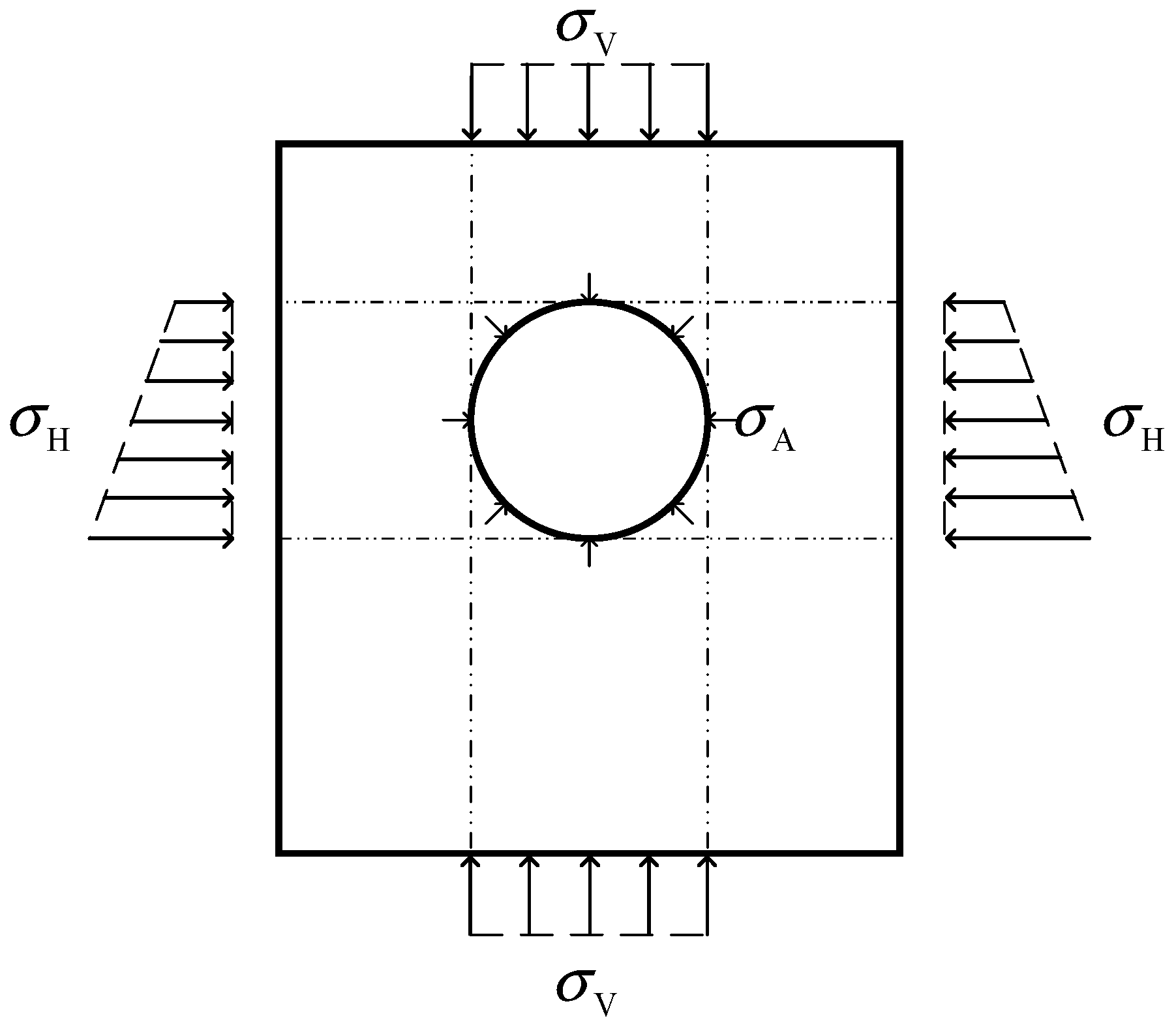

2.2.2. The Finite Element Model

2.2.3. Parameters of the Model

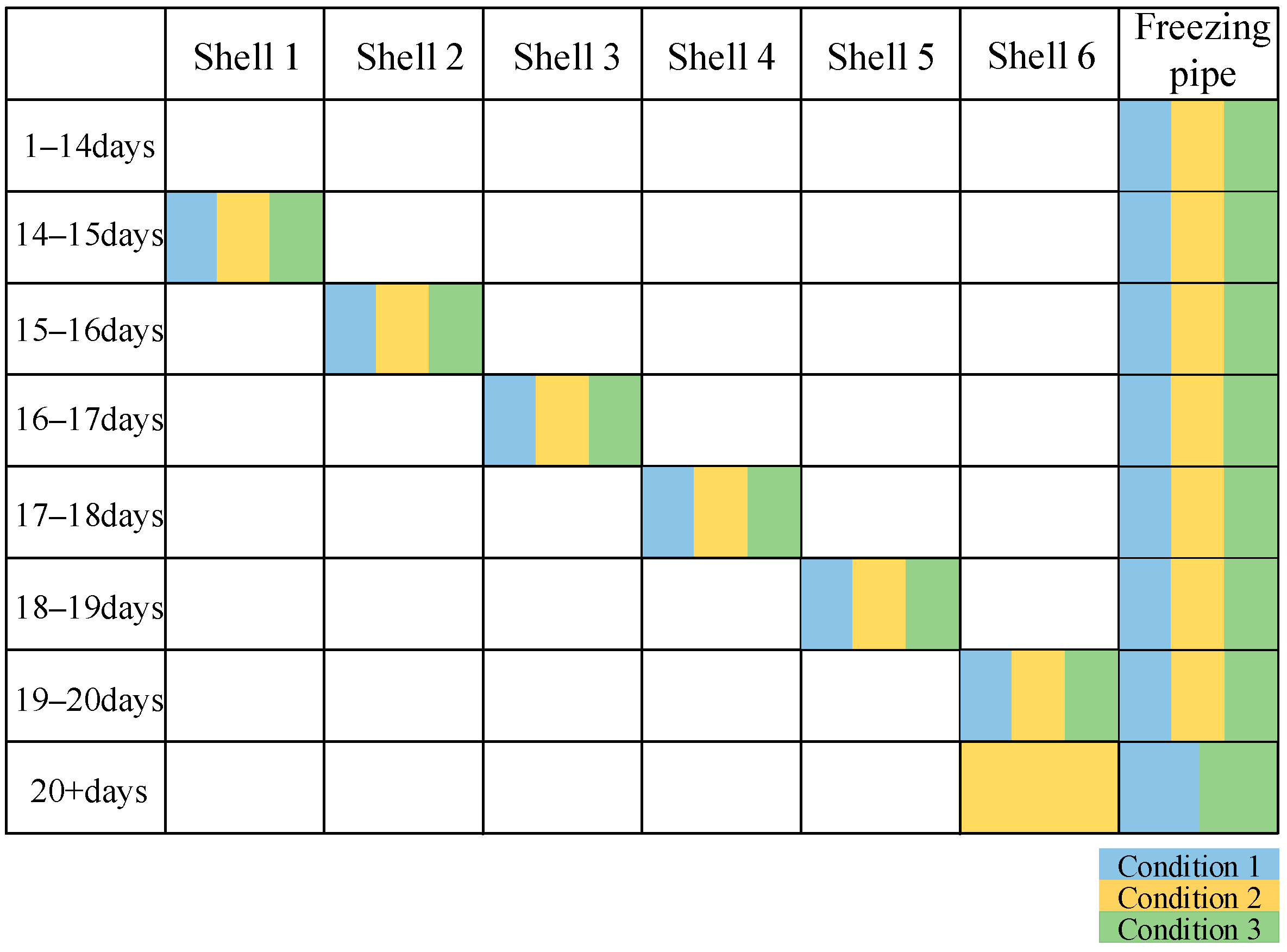

2.3. Simulated Working Conditions

3. Modelling Results

3.1. Model Verification

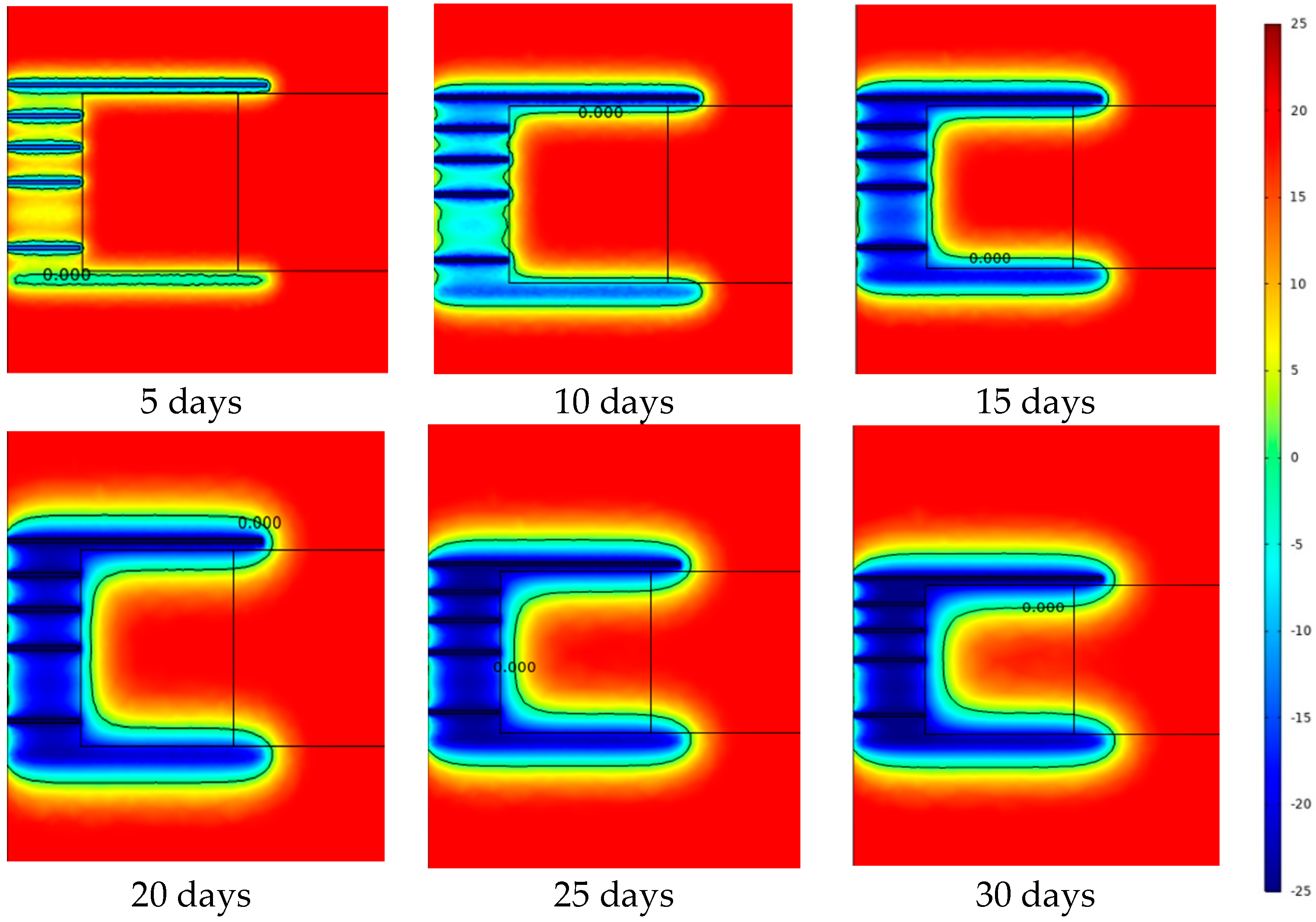

3.2. The Shield Tunneling Considering Heating Effect of Shield Machine

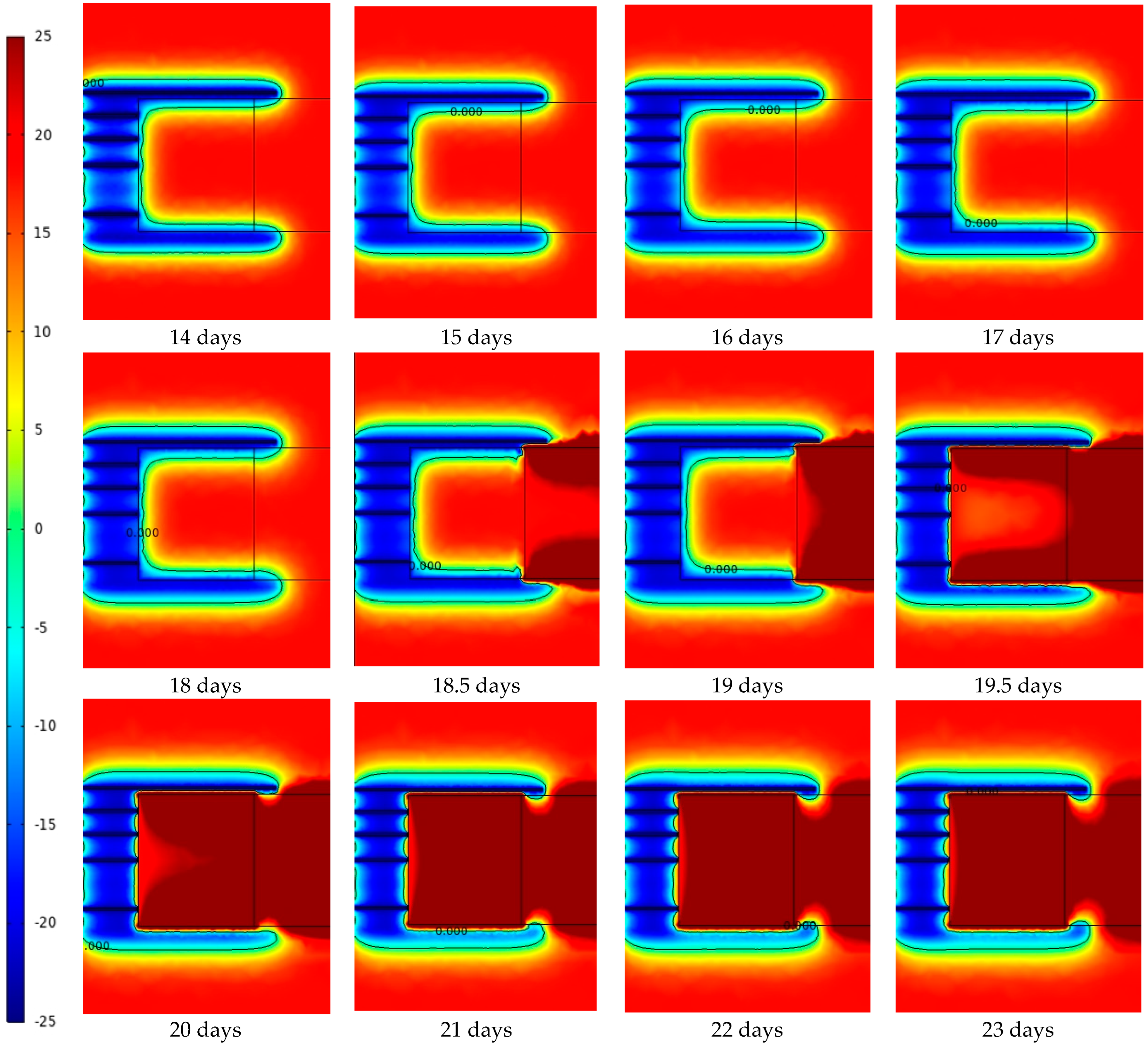

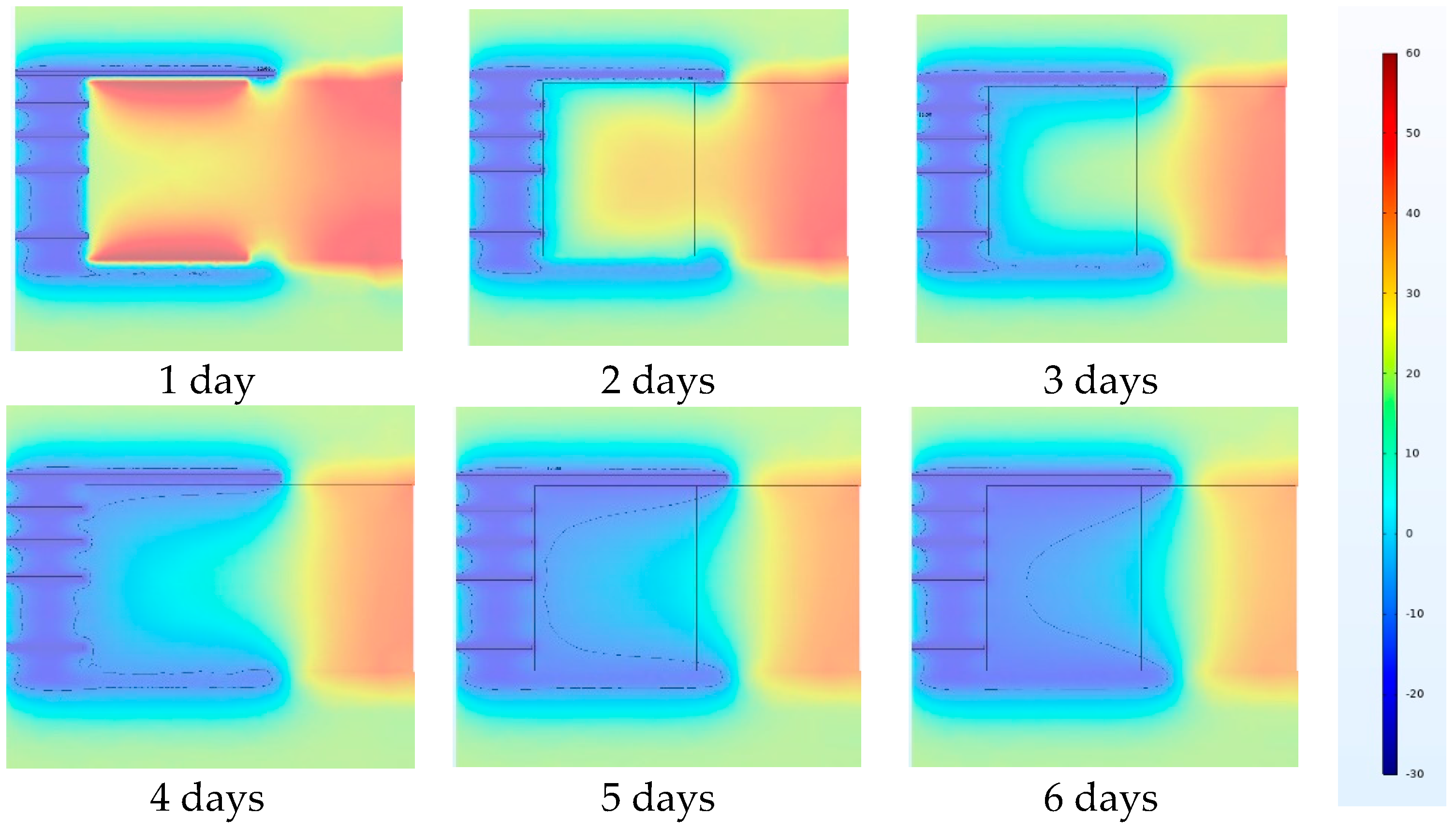

3.3. The Continuous Rotation Working Condition

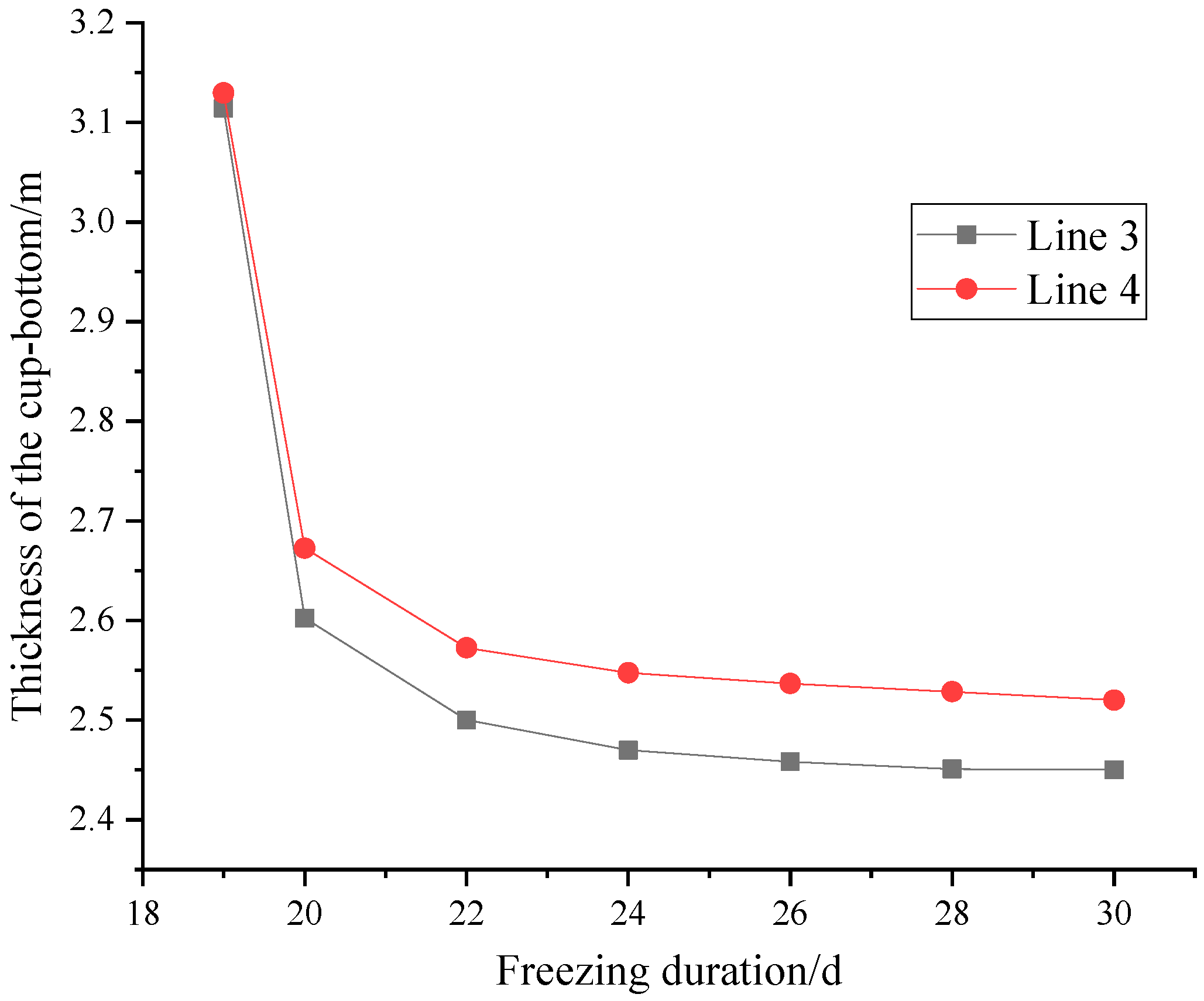

3.4. The Temporary Shutdown Condition

4. Conclusions

- (1)

- The heat generated by the tunneling of the shield machine will cause a certain melting of the frozen soil curtain that originally met the design requirements. After melting, the thickness of the frozen soil curtain cannot reach the initial design, but it is still within the safe range and can meet the tunneling requirements. It is recommended to add a switchable enhancing freezing tube arranged in the outer ring to deal with the melting in extreme conditions.

- (2)

- When the shield tunneling encounters harsh geological conditions, such as hard rock strata, the heat emitted by the in-situ operation of the shield machine will continue to cause the melting of the frozen soil curtain under the condition that the cutter head needs to be cut at the same position for a long time. In the early 6 day stay of the shield machine, the bottom and sides of the cup-shaped frozen soil curtain are partially melted. Then, the thickness is reduced to a relatively stable value, of approximately 0.8 m, and the bottom part continues to melt at a small rate. If proper measures are not taken to enhance the freezing effect, it will lead to water flow channels, leading to engineering disasters.

- (3)

- In a temporary shutdown working condition, when the contact surface temperature between the shield machine shell and the frozen soil drops to −12 °C, after almost 4 days of shutdown, the shield machine may not keep tunneling forward due to the freezing effect.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, S.Y.; Lai, J.X.; Wang, L.X.; Wang, K. A literature review on properties and applications of grouts for shield tunnel. Constr. Build. Mater. 2019, 239, 2–17. [Google Scholar] [CrossRef]

- Hong, K.R. Development and prospects of tunnels and underground works in China in recent two years. Tunn. Constr. 2017, 2, 14–25. [Google Scholar]

- Li, J.; Li, J.K.; Cai, Y.C.; Wu, D.Y.; Guo, C.X.; Zhao, W.C.; Tang, K.J.; Liu, Y.H. Application of Artificial Freezing Method in Deformation Control of Subway Tunnel. Adv. Mater. Sci. Eng. 2022, 2022, 3251318. [Google Scholar] [CrossRef]

- Tang, S.H.; Zhang, X.P.; Liu, H.; Zhang, L.L.; Zhang, J.; Chen, P.; Bai, K.; Wu, K. Engineering difficulties and key technologies for underwater shield tunnel in complex ground. J. Eng. Geol. 2021, 5, 1477–1487. [Google Scholar]

- Fu, Y.; Hu, J.; Wu, Y.W. Finite element study on temperature field of subway connection aisle construction via artificial ground freezing method. Cold Reg. Sci. Technol. 2021, 189, 103327. [Google Scholar] [CrossRef]

- Qi, Y.; Zhang, J.X.; Yang, H.; Song, Y.W. Application of Artificial Ground Freezing Technology in Modern Urban Underground Engineering. Adv. Mater. Sci. Eng. 2020, 2020, 1619721. [Google Scholar] [CrossRef]

- Zhan, Z.X.; Cui, Z.D.; Yang, P.; Zhang, T. In situ monitoring of temperature and deformation fields of a tunnel cross passage in Changzhou Metro constructed by AGF. Arab. J. Geosci. 2020, 2020, 310. [Google Scholar] [CrossRef]

- Hu, X.D.; Fang, T.; Chen, J.; Ren, H.; Guo, W. A large-scale physical model test on frozen status in freeze-sealing pipe roof method for tunnel construction. Tunn. Undergr. Space Technol. 2018, 72, 55–63. [Google Scholar] [CrossRef]

- Alzoubi, M.A.; Aurelien, N.R.; Agus, P.S. Conjugate heat transfer in artificial ground freezing using enthalpy-porosity method: Experiments and model validation. Int. J. Heat Mass Transf. 2018, 126, 740–752. [Google Scholar] [CrossRef]

- Ahmad, Z.; Aurelien, N.R.; Mahmoud, A.A.; Agus, P.S. Thermal and hydraulic analysis of selective artificial ground freezing using air insulation: Experiment and modeling. Comput. Geotech. 2020, 120, 103416. [Google Scholar]

- Li, W.; Zhang, C.P.; Tan, Z.B.; Ma, M.S. Effect of the seepage flow on the face stability of a shield tunnel. Tunn. Undergr. Space Technol. 2021, 112, 103900. [Google Scholar] [CrossRef]

- Alessandro, M.; Gennaro, N.; Filippo, C.; Pasquale, M.; Nicola, M. Modeling Artificial Ground Freezing for Construction of Two Tunnels of a Metro Station in Napoli (Italy). Energies 2020, 13, 1272. [Google Scholar]

- Fu, Y.; Hu, J.; Liu, J.; Hu, S.B.; Yuan, Y.H.; Zeng, H. Finite Element Analysis of Natural Thawing Heat Transfer of Artificial Frozen Soil in Shield-Driven Tunnelling. Adv. Civ. Eng. 2020, 2020, 2769064. [Google Scholar] [CrossRef]

- Alzoubi, M.A.; Xu, M.H.; Hassani, F.P.; Poncet, S.; Sasmito, A.P. Artificial ground freezing: A review of thermal and hydraulic aspects. Tunn. Undergr. Space Technol. 2020, 104, 103534. [Google Scholar] [CrossRef]

- Ou, C.Y.; Kao, C.C.; Chen, C.L. Performance and Analysis of Artificial Ground Freezing in the Shield Tunneling. J. GeoEngineering 2009, 4, 29–40. [Google Scholar]

- Hu, J.; Liu, Y.; Li, Y.P.; Kai, Y. Artificial ground freezing in tunnelling through aquifer soil layers: A case study in Nanjing Metro Line 2. KSCE J. Civ. Eng. 2018, 22, 4136–4142. [Google Scholar] [CrossRef]

- Hu, J.; Liu, W.B.; Pan, Y.T.; Zeng, H. Site Measurement and Study of Vertical Freezing Wall Temperatures of a Large-Diameter Shield Tunnel. Adv. Civ. Eng. 2019, 2019, 8231458. [Google Scholar] [CrossRef]

- Yang, S.M.; Tao, W.Q. Heat Transfer, 4th ed.; Higher Education Press: Beijing, China, 2006; pp. 112–138. [Google Scholar]

- Pan, A.G.; Wang, J.B.; Zhang, X.J. Numerical Analysis of Phase-Change Heat Transfer Characteristics Using Effective Heat Capacity Method and Enthalpy Method. Comput. Simul. 2014, 31, 315–319. [Google Scholar]

- Luo, T.; Hu, J.; Wei, H. Numerical Optimization Analysis of Temperature Field with Shield Tunnelling Cup-shaped Freezing Wall. Forest Eng. 2017, 33, 83–88. [Google Scholar]

- Liu, D.Y.; Zhang, N.C. Calculation and Analysis of Heat Balance of Boring of Shield TBMs. Tunn. Constr. 2006, 26, 82–86. [Google Scholar]

- Sun, H.C.; Ma, A.Q.; Yang, P.; Zhang, F. Comparative Analysis of Monotonic Shearing Test and Numerical Simulation for Interface Layer of Frozen Soil. For. Eng. 2022, 38, 133–139. [Google Scholar]

- Deng, L.J.; Liu, C.G.; Dang, J.F. Research on method of calculating torque of cutter head of shield machine and thrust of shield. Min. Process. Equip. 2010, 38, 13–16. [Google Scholar]

| Position | Temperature/°C |

|---|---|

| Ambient temperature | 20 |

| Initial soil temperature | 20 |

| Shield cutterhead | 20 |

| Shield shell | 60 |

| Freezing pipes | According to simulated conditions |

| Frozen Soil | Unfrozen Soil | Air | |

|---|---|---|---|

| Thermal conductivity/(W/(m∙K)) | 1.79 | 1.18 | 0.023 |

| Specific heat capacity/(J/(kg∙K)) | 1610 | 1530 | 1003 |

| Density/(kg/m3) | 1880 | 1880 | 1.29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, S.; He, Y.; Yang, M.; Zhou, F.; Liu, H.; Zhu, R.; Wan, Z. Numerical Analysis of Shield Tunnelling Breakthrough Working Shaft by Artificial Ground Freezing Method under Extreme Conditions Considering Phase Change Latent Heat. Appl. Sci. 2023, 13, 3651. https://doi.org/10.3390/app13063651

Deng S, He Y, Yang M, Zhou F, Liu H, Zhu R, Wan Z. Numerical Analysis of Shield Tunnelling Breakthrough Working Shaft by Artificial Ground Freezing Method under Extreme Conditions Considering Phase Change Latent Heat. Applied Sciences. 2023; 13(6):3651. https://doi.org/10.3390/app13063651

Chicago/Turabian StyleDeng, Shengjun, Yang He, Mingqi Yang, Feng Zhou, Heng Liu, Rui Zhu, and Zhihui Wan. 2023. "Numerical Analysis of Shield Tunnelling Breakthrough Working Shaft by Artificial Ground Freezing Method under Extreme Conditions Considering Phase Change Latent Heat" Applied Sciences 13, no. 6: 3651. https://doi.org/10.3390/app13063651