Analysis of the Thermodynamic Characteristics of a Hyper-Compressor through Numerical Simulation and Experimental Investigation

Abstract

1. Introduction

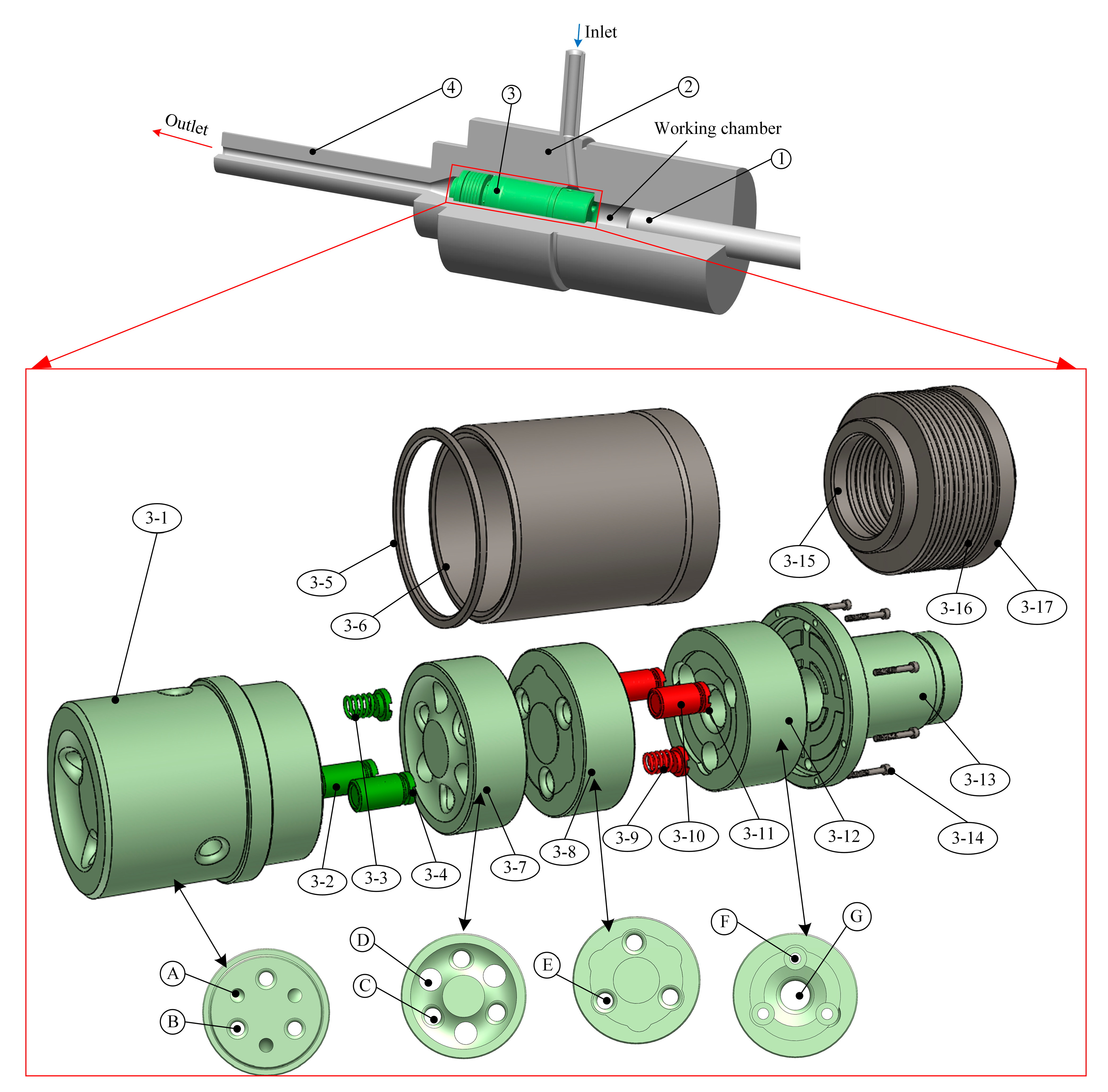

2. Numerical Calculation Model

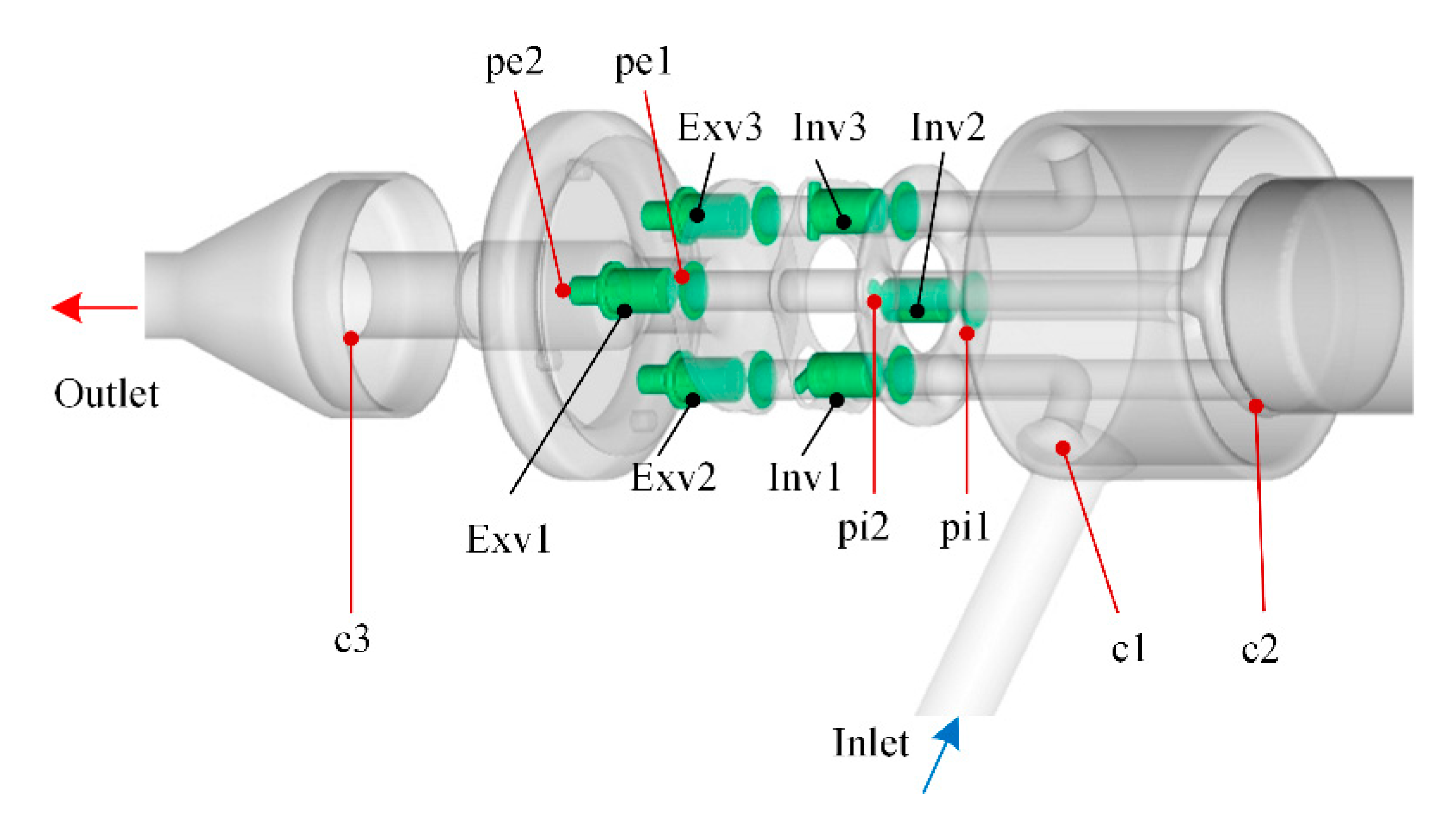

2.1. Physical and Numerical Model

2.2. Numerical Methodology and Boundary Conditions

- Leakage was disregarded;

- The heat exchange during the operating cycle was neglected;

- The pressure pulsation in the piping in front of the inlet buffer tank was not considered.

2.3. Real Gas Model

2.4. Mesh Independence Check

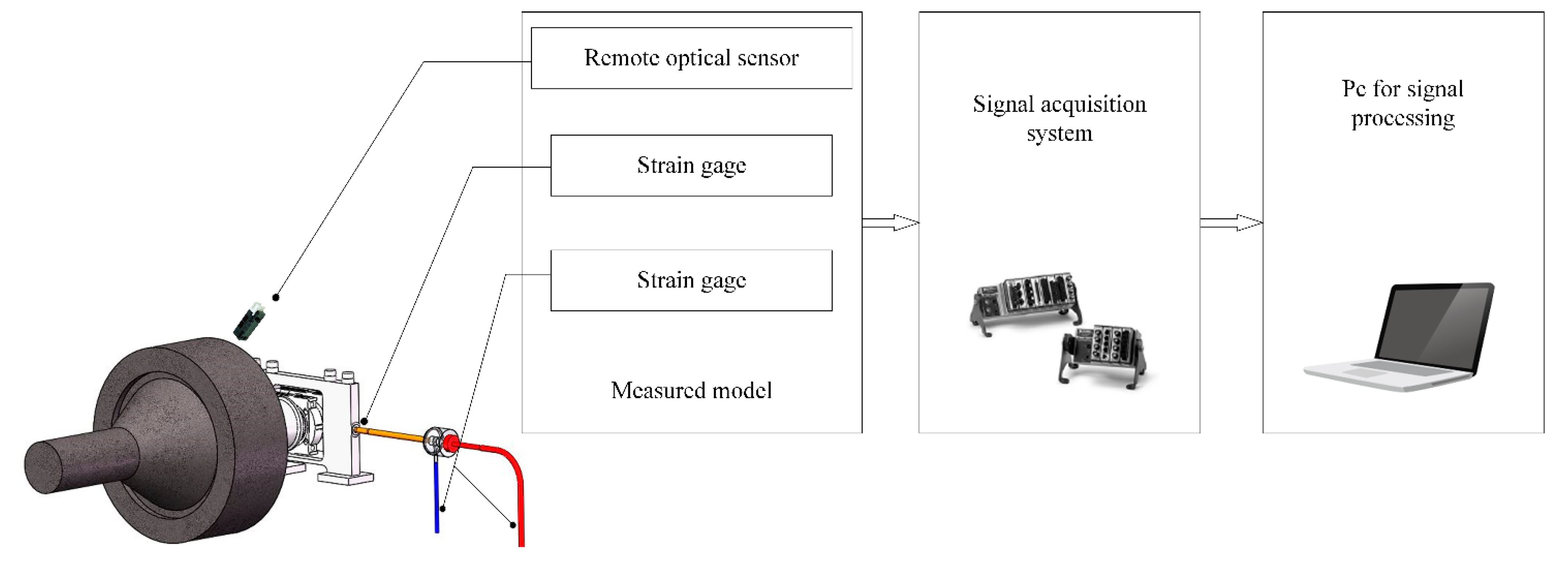

3. Experimental Verification

3.1. Measurement of the TDC Signal

3.2. Measurement and Construction of the Diagram

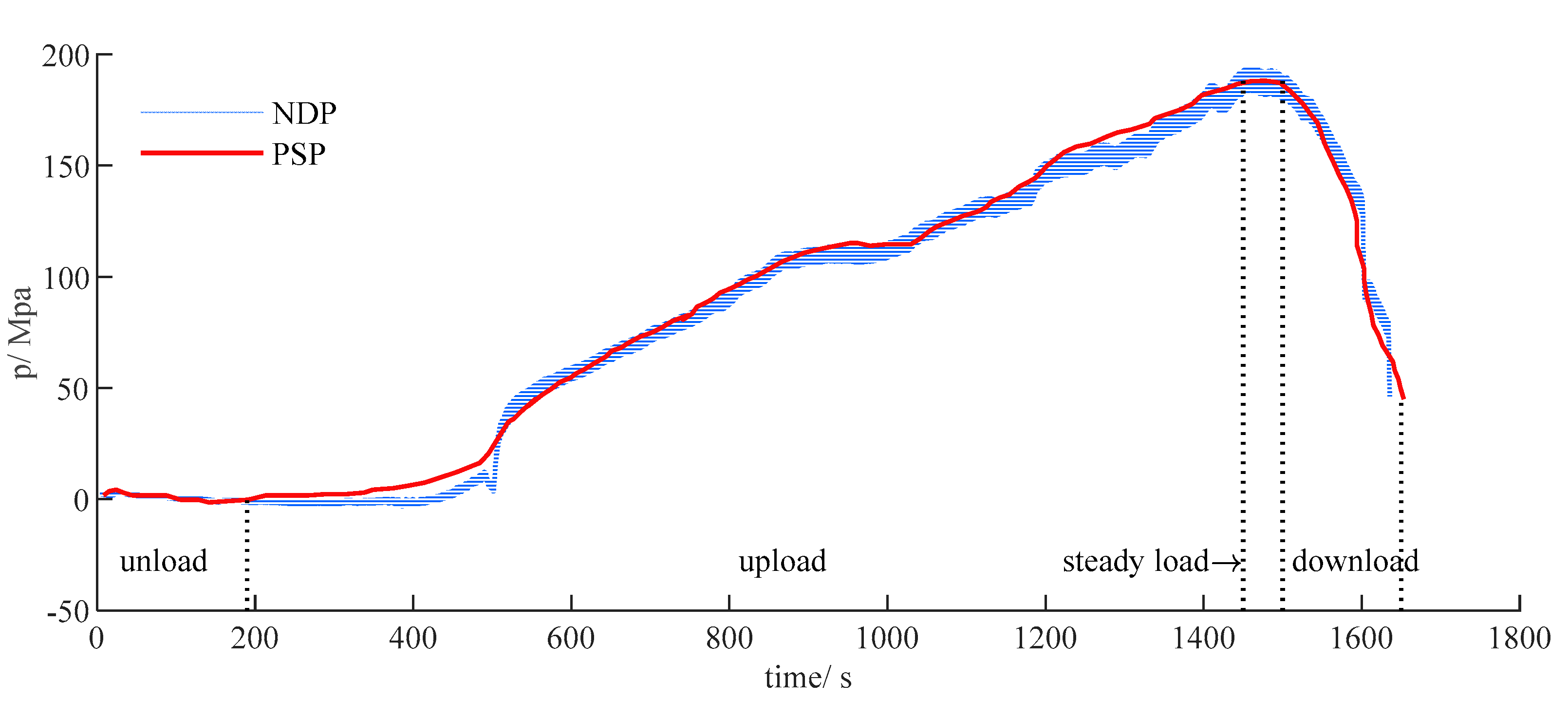

3.3. Measurement and Reconstruction of the Pressure Pulsation in the Pipe

3.4. Validation of the NDT

4. Discussion

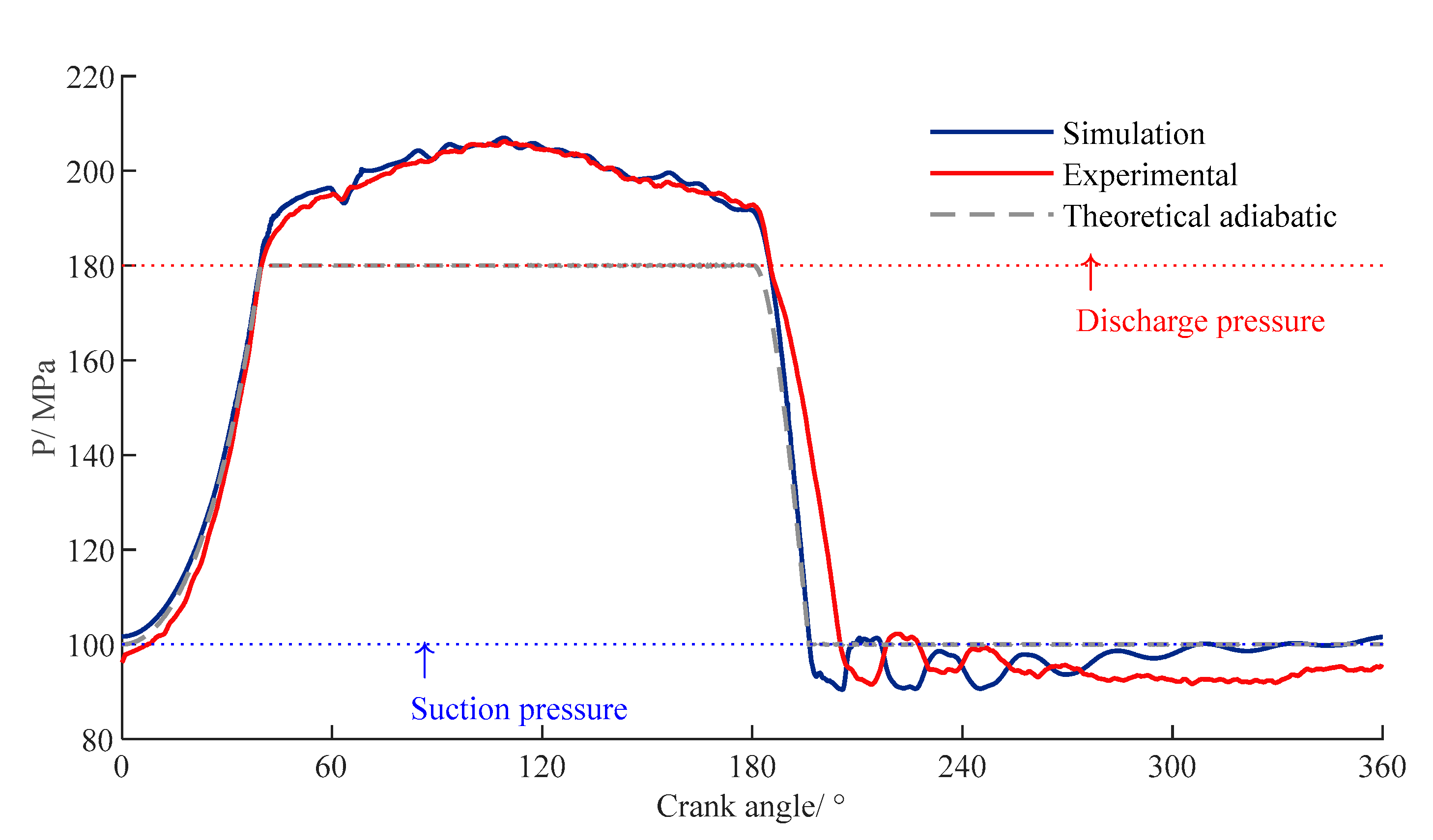

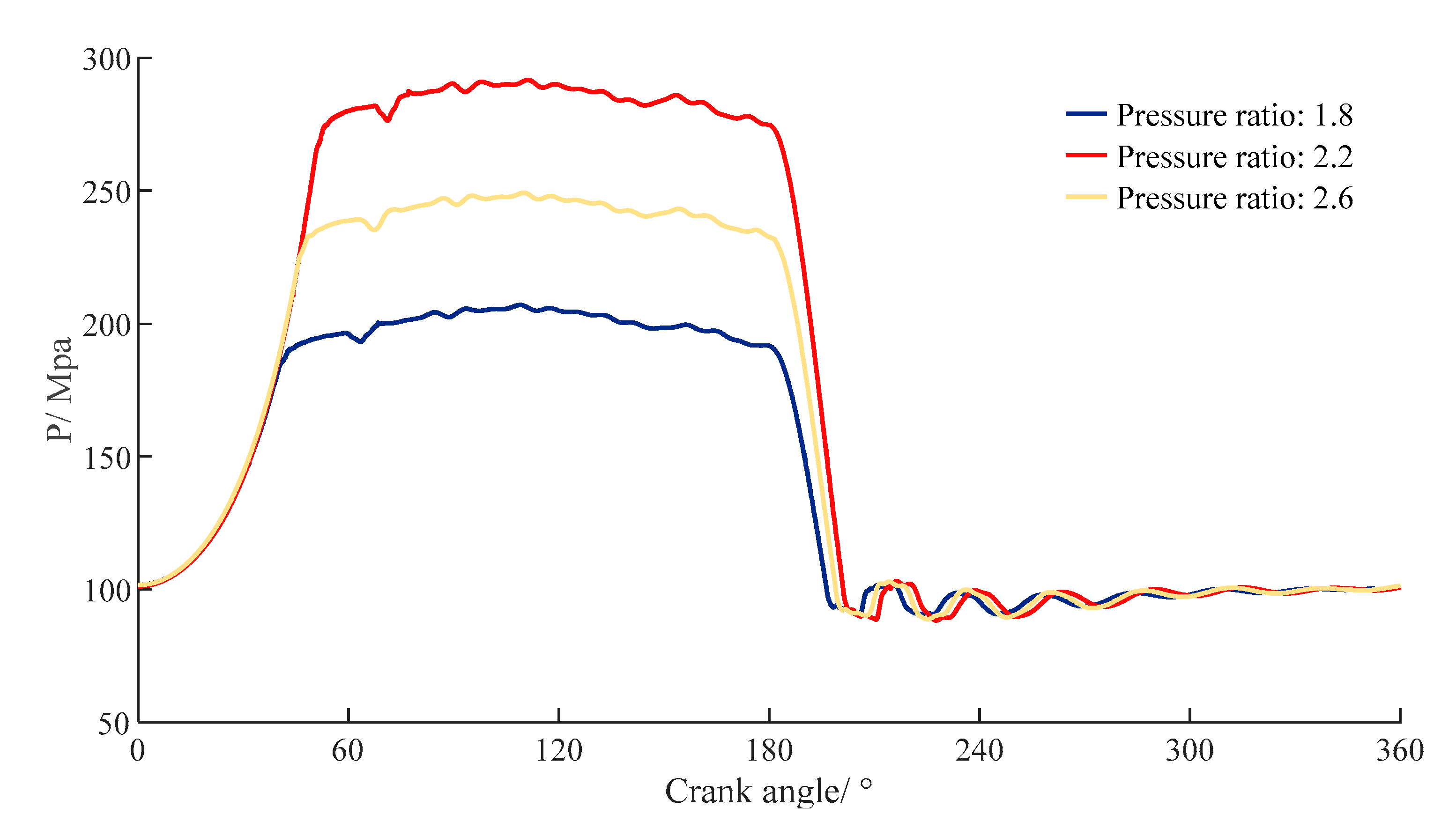

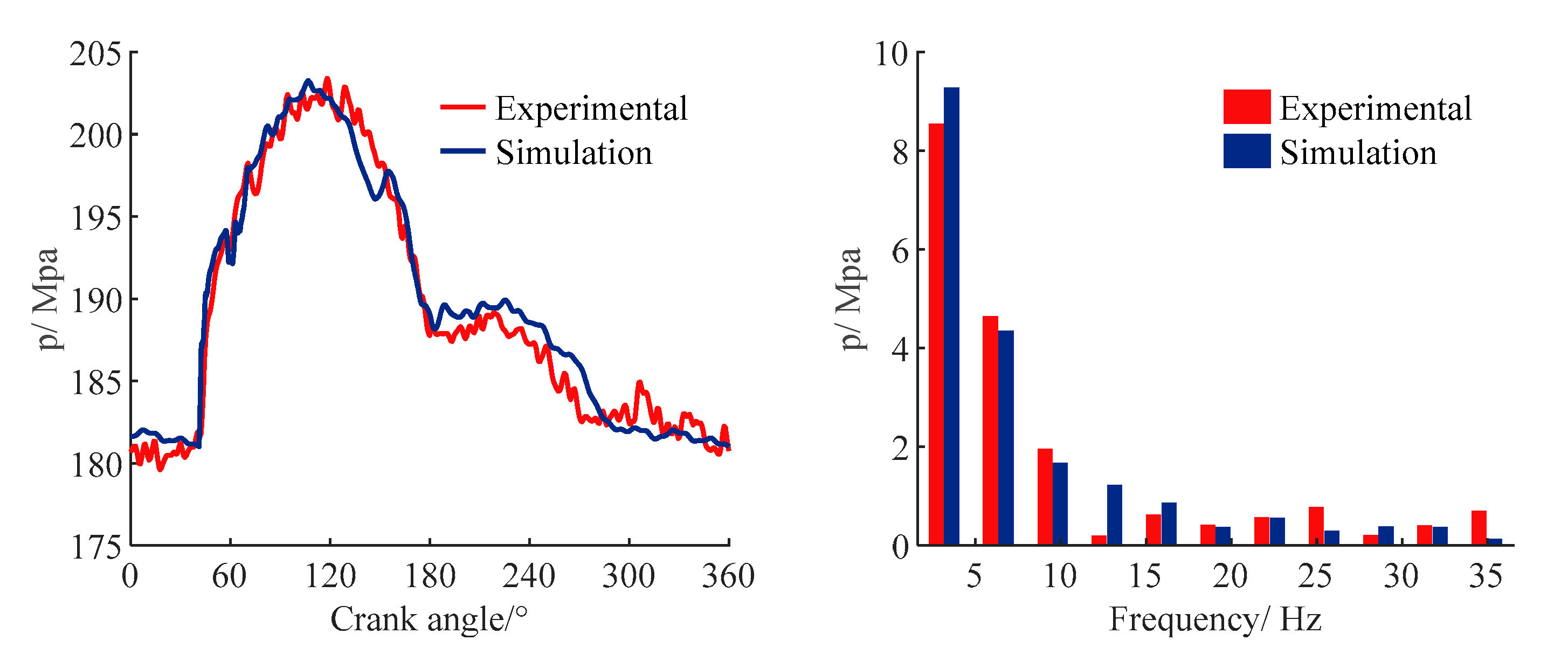

4.1. Dynamic Pressure in the Working Chamber

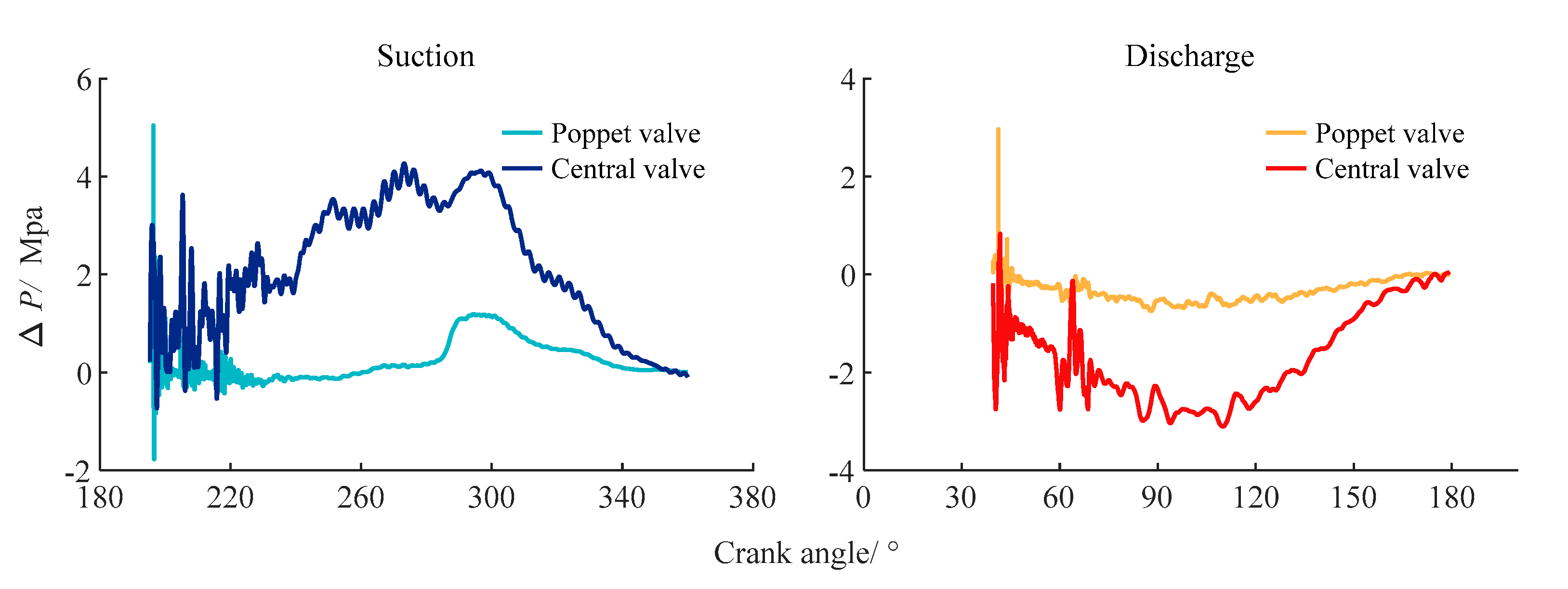

4.2. The Performance of the Central Valve

4.2.1. Poppet Valve Motion

4.2.2. Valve Power Loss

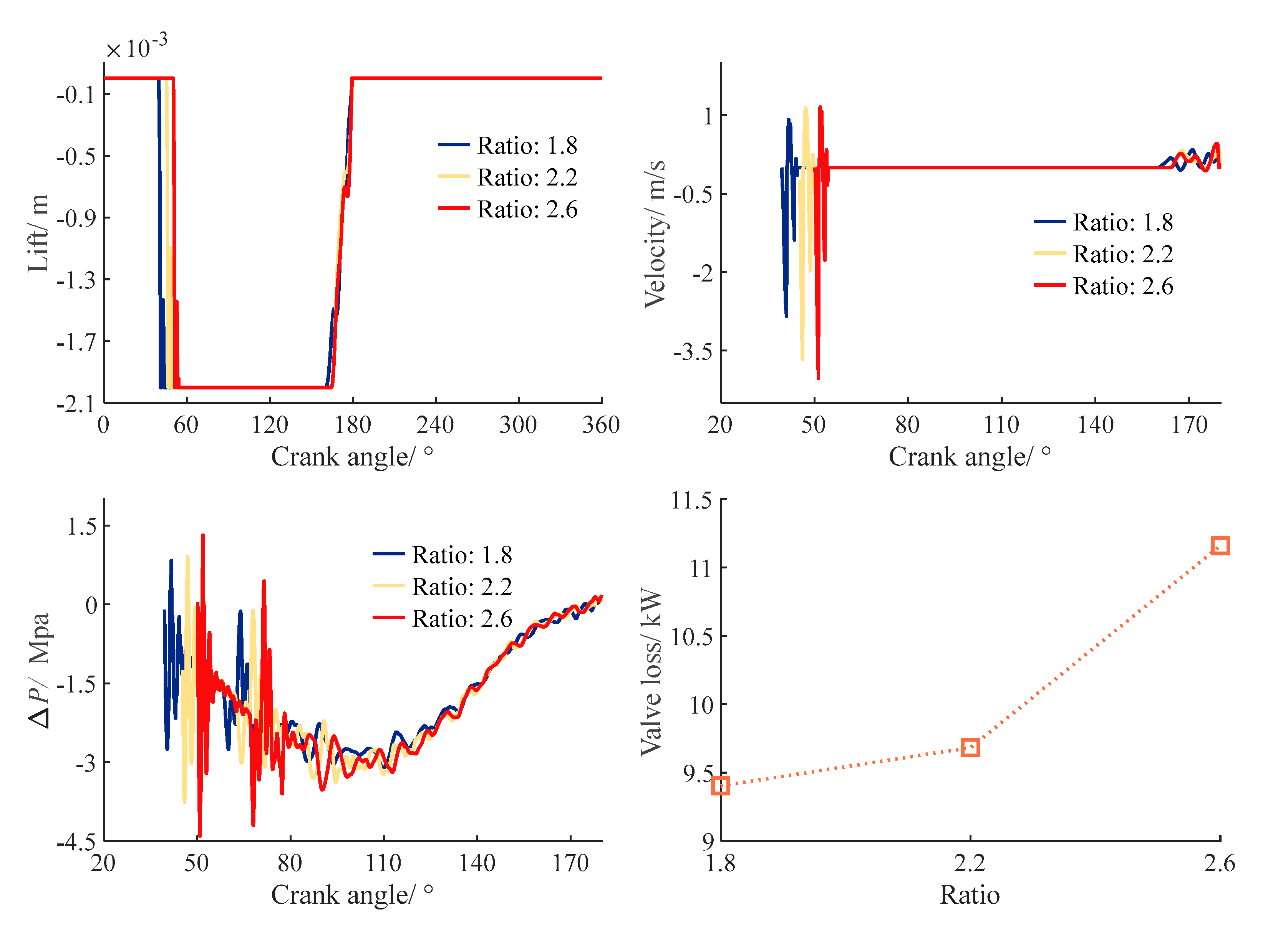

4.2.3. Effect of the Pressure Ratio

4.3. The Effect of the Dis-Pipe Pressure Pulsation

5. Conclusions

- A non-destructive method based on material stress was proposed to measure and construct a diagram of a hyper-compressor and the pressure of an internal pipe, which demonstrated good agreement with the directly measured pressure;

- The 3D-CFD model considering piston and valve motions could predict the thermodynamic performance and pressure pulsation of the hyper-compressor with reasonable precision compared to the experimental results;

- The RGM was of great importance for the simulated results;

- The valve loss was produced primarily by the complex geometric structure, while the structure and movement of the poppet valve had little impact on the power loss;

- The poppet valve closest to the inlet was fastest-closing and the valve farthest from the inlet had obvious flutter;

- The valve loss represented a small amount of power loss in an operating cycle, and the major power loss was due to pressure pulsation in the discharge process;

- A pulsation attenuator should be installed in both the suction and discharge pipe near the hyper-compressor.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Notation | |

| Valve sleeve equivalent mass | |

| Stiffness of valve spring | |

| Acceleration of valve sleeve | |

| Velocity of valve sleeve Displacement of valve sleeve | |

| Damping coefficient | |

| Force | |

| Pressure | |

| Area of valve | |

| velocity | |

| Stroke | |

| Rotational speed | |

| Molar gas constant Specific Helmholtz energy | |

| Temperature | |

| Isobaric heat capacity | |

| Isochoric heat capacity Second viral coefficient Third viral coefficient Specific enthalpy Specific internal energy Speed of sound Specific entropy Indicated power Mass flow rate | |

| Gravitational acceleration | |

| Reciprocating inertial mass | |

| Crank radius | |

| Young’s modulus | |

| Diameter | |

| Greek letters | |

| Ratio of crank radius to connecting rod | |

| Crank angle | |

| Dimensionless Helmholtz energy | |

| Reduced density | |

| Inverse reduced temperature | |

| Density | |

| Difference | |

| Dynamic friction coefficient | |

| Stress | |

| Angular velocity of crankshaft rotation | |

| Strain | |

| Poisson’s ratio | |

| Subscripts | |

| Piston rod | |

| At the critical point | |

| Suction | |

| Discharge | |

| Friction | |

| Gas | |

| Reciprocating inertia Internal External | |

| Circumferential | |

| Axial | |

| Superscripts | |

| Ideal gas part | |

| Residual part | |

| Saturated liquid state | |

| Saturated vapor state |

References

- Giacomelli, E.; Battagli, P.; Lumachi, F.; Gimignani, L. Safety Aspects of Design of Cylinders and Hyper-Compressors for LDPE; ASME: San Diego, CA, USA, 2004. [Google Scholar]

- Passeri, M.; Generosi, S.; Bagagli, R.; Maggi, C. Preliminary Piping Sizing and Pressure Pulsation Evaluation; ASME: Anaheim, CA, USA, 2014. [Google Scholar]

- Tuhovcak, J.; Hejcik, J.; Jicha, M. Comparison of Heat Transfer Models for Reciprocating Compressor. Appl. Therm. Eng. 2016, 103, 607–615. [Google Scholar] [CrossRef]

- Anderson, J.D.; Wendt, J. Computational Fluid Dynamics; Springer: New York, NY, USA; McGraw-Hill: New York, NY, USA, 1995; Volume 206, ISBN 978–3-540-85055-7. [Google Scholar]

- Bhavikatti, S.S. Finite Element Analysis; New Age International: New Delhi, India, 2005; ISBN 81-224-1589-X. [Google Scholar]

- Costagliola, M. The Theory of Spring-Loaded Valves for Reciprocating Compressors. J. Appl. Mech. 1950, 17, 415–420. [Google Scholar] [CrossRef]

- Sun, X.; Wang, Y.; Zhang, J.; Lei, F.; Zhao, D.; Hong, H. Multi-Objective Optimization Design of Key Parameters of a Stepless Flow Control System with Multi-System Coupling Characteristics. Appl. Sci. 2022, 12, 1301. [Google Scholar] [CrossRef]

- Mohammadi-Amin, M.; Jahangiri, A.R.; Bustanchy, M. Thermodynamic Modeling, CFD Analysis and Parametric Study of a near-Isothermal Reciprocating Compressor. Therm. Sci. Eng. Prog. 2020, 19, 100624. [Google Scholar] [CrossRef]

- Giacomelli, E.; Shi, J.-X.; Manfrone, F. Considerations on Design, Operation and Performance of Hypercompressors; American Society of Mechanical Engineers Digital Collection: Bellevue, DC, USA, 2010; pp. 31–40. [Google Scholar]

- Grover, S.S. Analysis of Pressure Pulsations in Reciprocating Compressor Piping Systems. J. Eng. Ind. 1966, 88, 164–168. [Google Scholar] [CrossRef]

- Giacomelli, E.; Passeri, M.; Zagli, F.; Generosi, S. Control of Pulsations and Vibrations in Hypercompressors for LDPE Plants; American Society of Mechanical Engineers Digital Collection: San Diego, CA, USA, 2004; Volume 46687, pp. 73–79. [Google Scholar]

- Liu, B.; Feng, J.; Wang, Z.; Peng, X. Attenuation of Gas Pulsation in a Reciprocating Compressor Piping System by Using a Volume-Choke-Volume Filter. J. Vib. Acoust. 2012, 134, 051002. [Google Scholar] [CrossRef]

- Mlynarczyk, P.; Cyklis, P. The Estimation of the Pressure Pulsation Damping Coefficient of a Nozzle. J. Sound Vib. 2020, 464, 115002. [Google Scholar] [CrossRef]

- Liu, Z.; Jia, W.; Liang, L.; Duan, Z. Analysis of Pressure Pulsation Influence on Compressed Natural Gas (CNG) Compressor Performance for Ideal and Real Gas Models. Appl. Sci. 2019, 9, 946. [Google Scholar] [CrossRef]

- Balduzzi, F.; Tanganelli, A.; Ferrara, G.; Babbini, A. Two-Dimensional Approach for the Numerical Simulation of Large Bore Reciprocating Compressors Thermodynamic Cycle. Appl. Therm. Eng. 2018, 129, 490–501. [Google Scholar] [CrossRef]

- Giacomelli, E.; Schiavone, M.; Manfrone, F.; Raggi, A. Flow Coefficient Evaluation of Poppet Valves Used in Reciprocating Compressors for LDPE; American Society of Mechanical Engineers Digital Collection: Chicago, IL, USA, 2008; Volume 5, pp. 123–129. [Google Scholar]

- Wu, W.; Guo, T.; Peng, C.; Li, X.; Li, X.; Zhang, Z.; Xu, L.; He, Z. FSI Simulation of the Suction Valve on the Piston for Reciprocating Compressors. Int. J. Refrig. 2022, 137, 14–21. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, J.; Wang, Y.; Wang, J.; Qi, Z. Optimization of Capacity Control of Reciprocating Compressor Using Multi-System Coupling Model. Appl. Therm. Eng. 2021, 195, 117175. [Google Scholar] [CrossRef]

- Townsend, J.; Badar, M.A.; Szekerces, J. Updating Temperature Monitoring on Reciprocating Compressor Connecting Rods to Improve Reliability. Eng. Sci. Technol. Int. J. 2016, 19, 566–573. [Google Scholar] [CrossRef]

- Cerrada, M.; Macancela, J.-C.; Cabrera, D.; Estupiñan, E.; Sánchez, R.-V.; Medina, R. Reciprocating Compressor Multi-Fault Classification Using Symbolic Dynamics and Complex Correlation Measure. Appl. Sci. 2020, 10, 2512. [Google Scholar] [CrossRef]

- Zhao, B.; Jia, X.; Sun, S.; Wen, J.; Peng, X. FSI Model of Valve Motion and Pressure Pulsation for Investigating Thermodynamic Process and Internal Flow inside a Reciprocating Compressor. Appl. Therm. Eng. 2018, 131, 998–1007. [Google Scholar] [CrossRef]

- Young, W.C.; Budynas, R.G.; Sadegh, A.M. Roark’s Formulas for Stress and Strain, 8th ed.; The McGraw-Hill Companies, Inc.: New York, NY, USA, 2012. [Google Scholar]

- Li, X.; Peng, X.; Zhang, Z.; Jia, X.; Wang, Z. A New Method for Nondestructive Fault Diagnosis of Reciprocating Compressor by Means of Strain-Based p–V Diagram. Mech. Syst. Signal Process. 2019, 133, 106268. [Google Scholar] [CrossRef]

- Carcasci, C.; Sacco, M.; Landucci, M.; Fiaschi, M. From Piping Deformation to Pressure Pulsation Measurements to Solve LDPE Plants Vibration Issues; American Society of Mechanical Engineers Digital Collection: Prague, Czech Republic, 2018; Volume 5. [Google Scholar]

- Sun, S.-Y.; Ren, T.-R. New Method of Thermodynamic Computation for a Reciprocating Compressor: Computer Simulation of Working Process. Int. J. Mech. Sci. 1995, 37, 343–353. [Google Scholar] [CrossRef]

- Nowak, P.; Kleinrahm, R.; Wagner, W. Measurement and Correlation of the (p, ρ,T) Relation of Ethylene II. Saturated-Liquid and Saturated-Vapour Densities and Vapour Pressures along the Entire Coexistence Curve. J. Chem. Thermodyn. 1996, 28, 1441–1460. [Google Scholar] [CrossRef]

- Smukala, J.; Span, R.; Wagner, W. New Equation of State for Ethylene Covering the Fluid Region for Temperatures From the Melting Line to 450 K at Pressures up to 300 MPa. J. Phys. Chem. Ref. Data 2000, 29, 1053–1121. [Google Scholar] [CrossRef]

- Holland, P.M.; Eaton, B.E.; Hanley, H.J.M. A Correlation of the Viscosity and Thermal Conductivity Data of Gaseous and Liquid Ethylene. J. Phys. Chem. Ref. Data 1983, 12, 917–932. [Google Scholar] [CrossRef]

- Klein, S.A.; McLinden, M.O.; Laesecke, A. An Improved Extended Corresponding States Method for Estimation of Viscosity of Pure Refrigerants and Mixtures. Int. J. Refrig. 1997, 20, 208–217. [Google Scholar] [CrossRef]

- Assael, M.J.; Koutian, A.; Huber, M.L.; Perkins, R.A. Reference Correlations of the Thermal Conductivity of Ethene and Propene. J. Phys. Chem. Ref. Data 2016, 45, 033104. [Google Scholar] [CrossRef] [PubMed]

- Fusi, A.; Cappelli, L.; Carcasci, C.; Sacco, M. Tuning of the Acoustical Analysis Model for Hypercompressors through Strain Gage Pulsation Measurements; American Society of Mechanical Engineers Digital Collection: San Antonio, TX, USA, 2019; Volume 5. [Google Scholar]

| Item | 1 | 2(Ref) | 3 |

|---|---|---|---|

| No of mesh /106 | 1.27 | 1.73 | 2.05 |

| 0.9844 | 1 | 1.00045 | |

| 0.9817 | 1 | 1.0034 |

| Parameters | Unit | |

|---|---|---|

| Crank radius | mm | 170 |

| Connecting rod length | mm | 800 |

| Speed | rpm | 200 |

| Piston diameter | mm | 80 |

| Clearance volume | % | 31 |

| Substance | - | Ethylene |

| Suction/discharge pressure | MPa | 100/180 |

| Suction/discharge temperature | K | 294/317 |

| Pressure Ratio | 1.8 | 2.2 | 2.6 |

|---|---|---|---|

| Indicated power/kW | 557.73 | 763.14 | 960.78 |

| Suction loss/kW | 20.09 | 21.04 | 20.35 |

| Discharge loss/kW | 108.33 | 116.66 | 124.10 |

| Valve Power Loss/kW | Poppet Valve | Central Valve |

|---|---|---|

| Suction | 1.23 | 14.50 |

| Discharge | 2.07 | 10.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Jia, X.; Peng, X. Analysis of the Thermodynamic Characteristics of a Hyper-Compressor through Numerical Simulation and Experimental Investigation. Appl. Sci. 2023, 13, 4478. https://doi.org/10.3390/app13074478

Yang L, Jia X, Peng X. Analysis of the Thermodynamic Characteristics of a Hyper-Compressor through Numerical Simulation and Experimental Investigation. Applied Sciences. 2023; 13(7):4478. https://doi.org/10.3390/app13074478

Chicago/Turabian StyleYang, Lanlan, Xiaohan Jia, and Xueyuan Peng. 2023. "Analysis of the Thermodynamic Characteristics of a Hyper-Compressor through Numerical Simulation and Experimental Investigation" Applied Sciences 13, no. 7: 4478. https://doi.org/10.3390/app13074478

APA StyleYang, L., Jia, X., & Peng, X. (2023). Analysis of the Thermodynamic Characteristics of a Hyper-Compressor through Numerical Simulation and Experimental Investigation. Applied Sciences, 13(7), 4478. https://doi.org/10.3390/app13074478