Analysis of Fire Resistance of Prestressed Concrete T-Beam Based on ABAQUS Numerical Simulation

Abstract

:1. Introduction

2. Finite Element Model Building and Verification

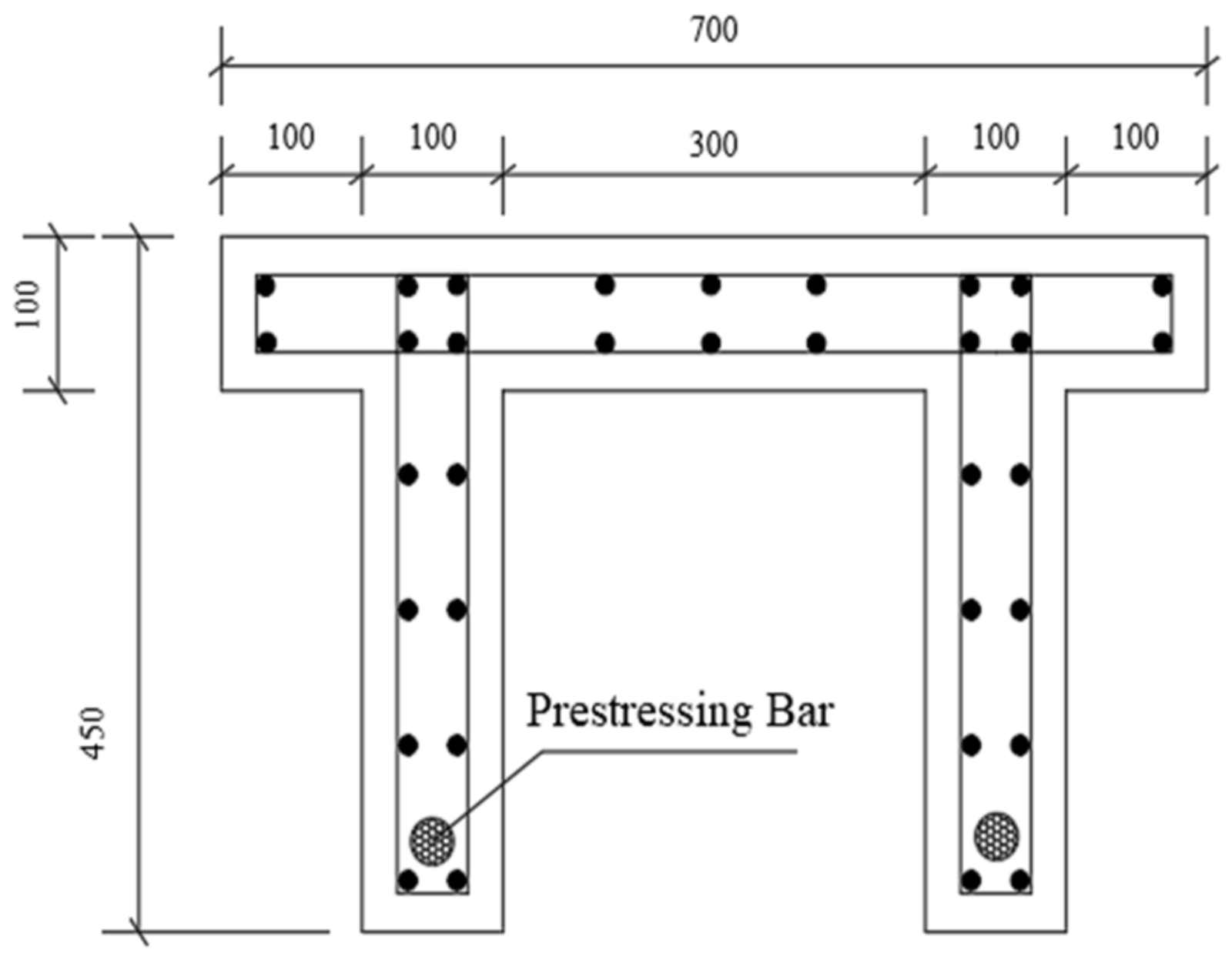

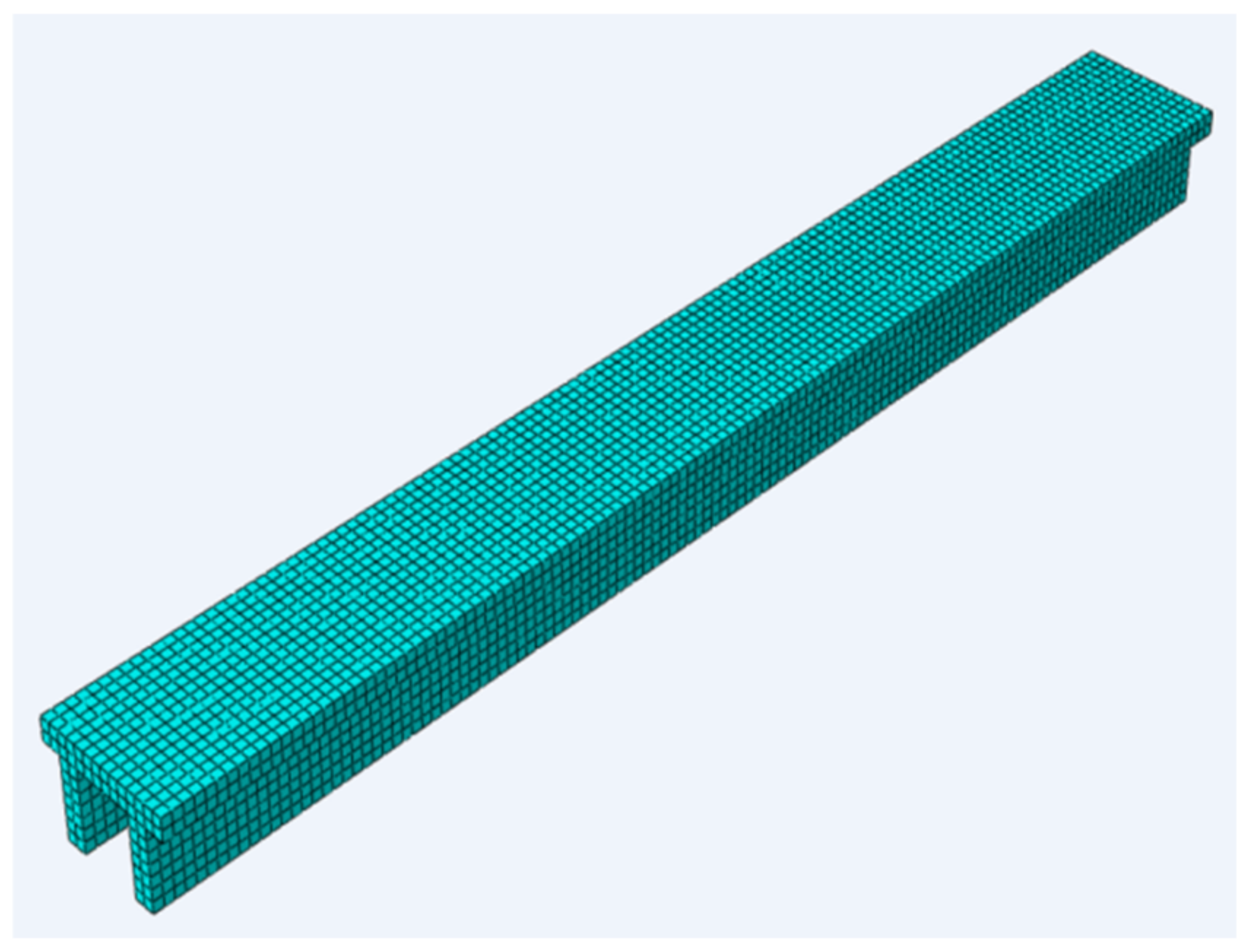

2.1. Finite Element Model and Simulation

2.1.1. Temperature Field Calculation Model

2.1.2. Calculation Model of Fire Resistance Analysis

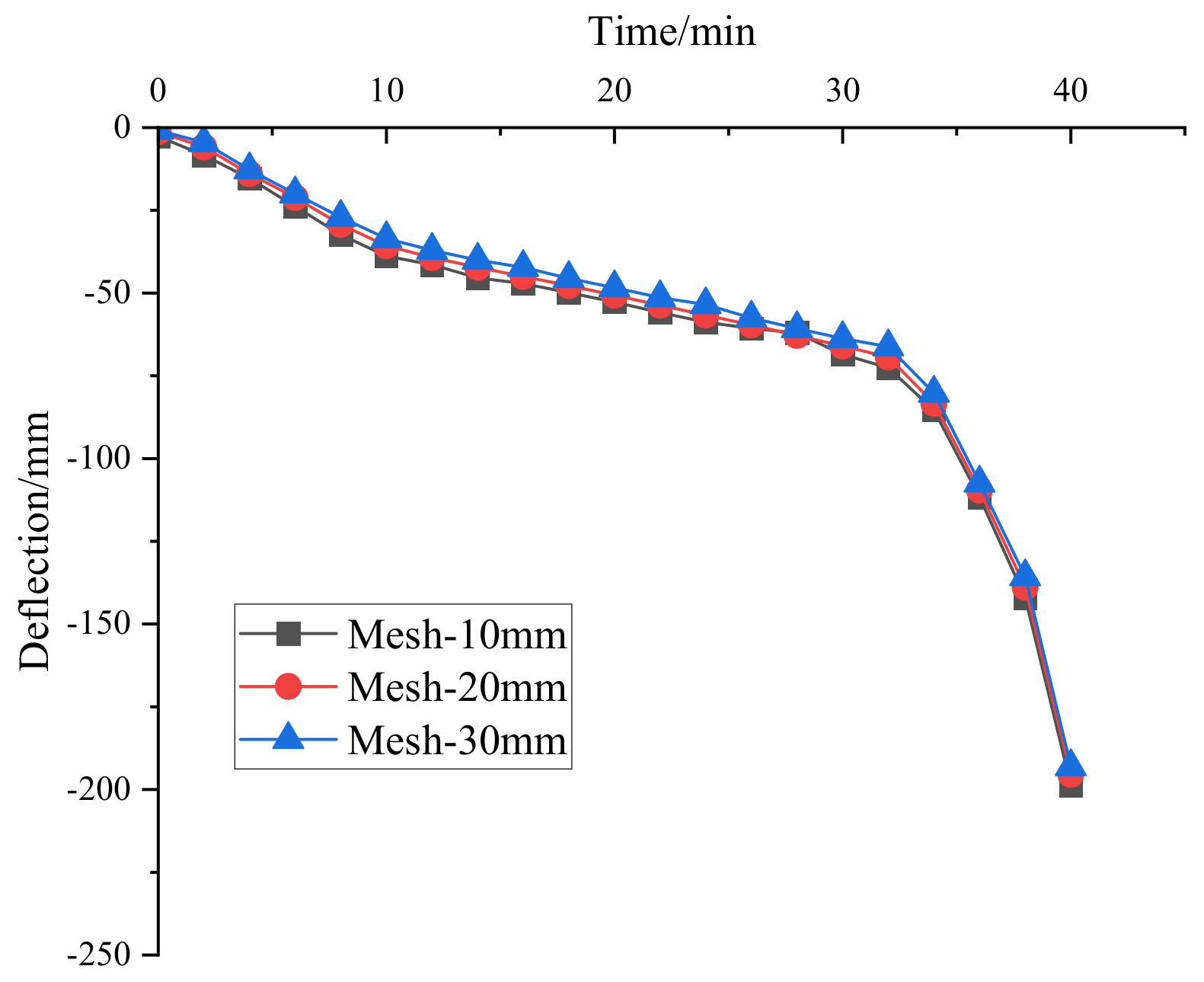

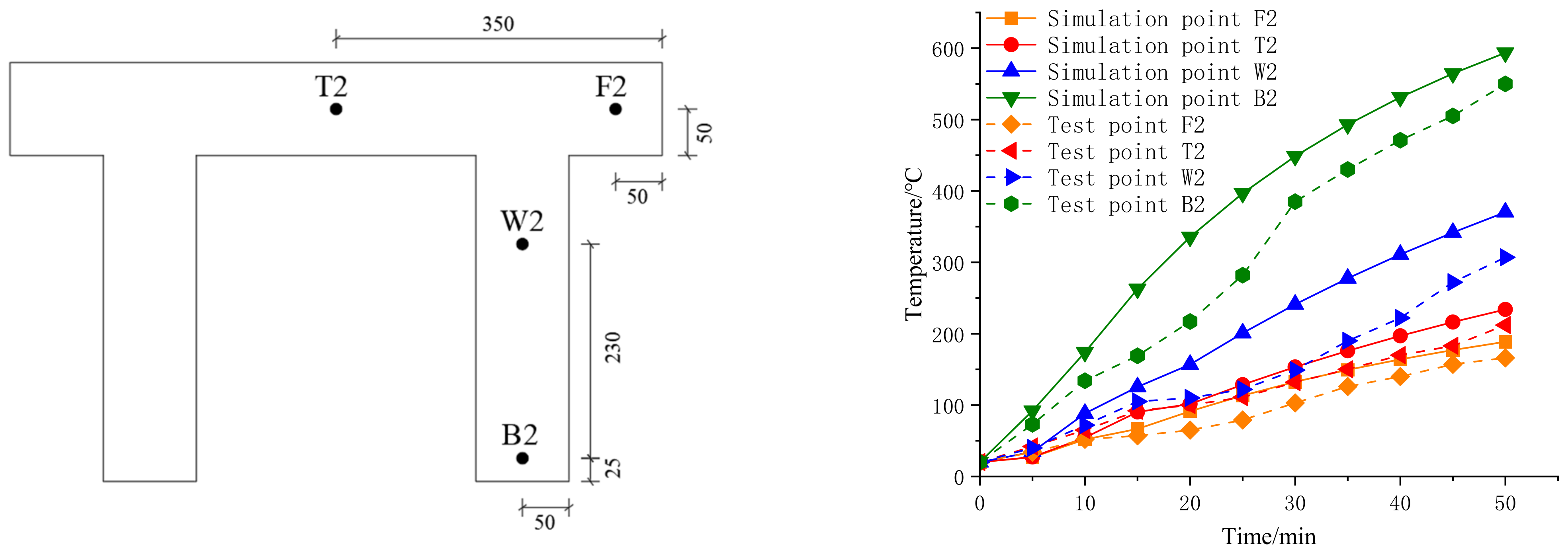

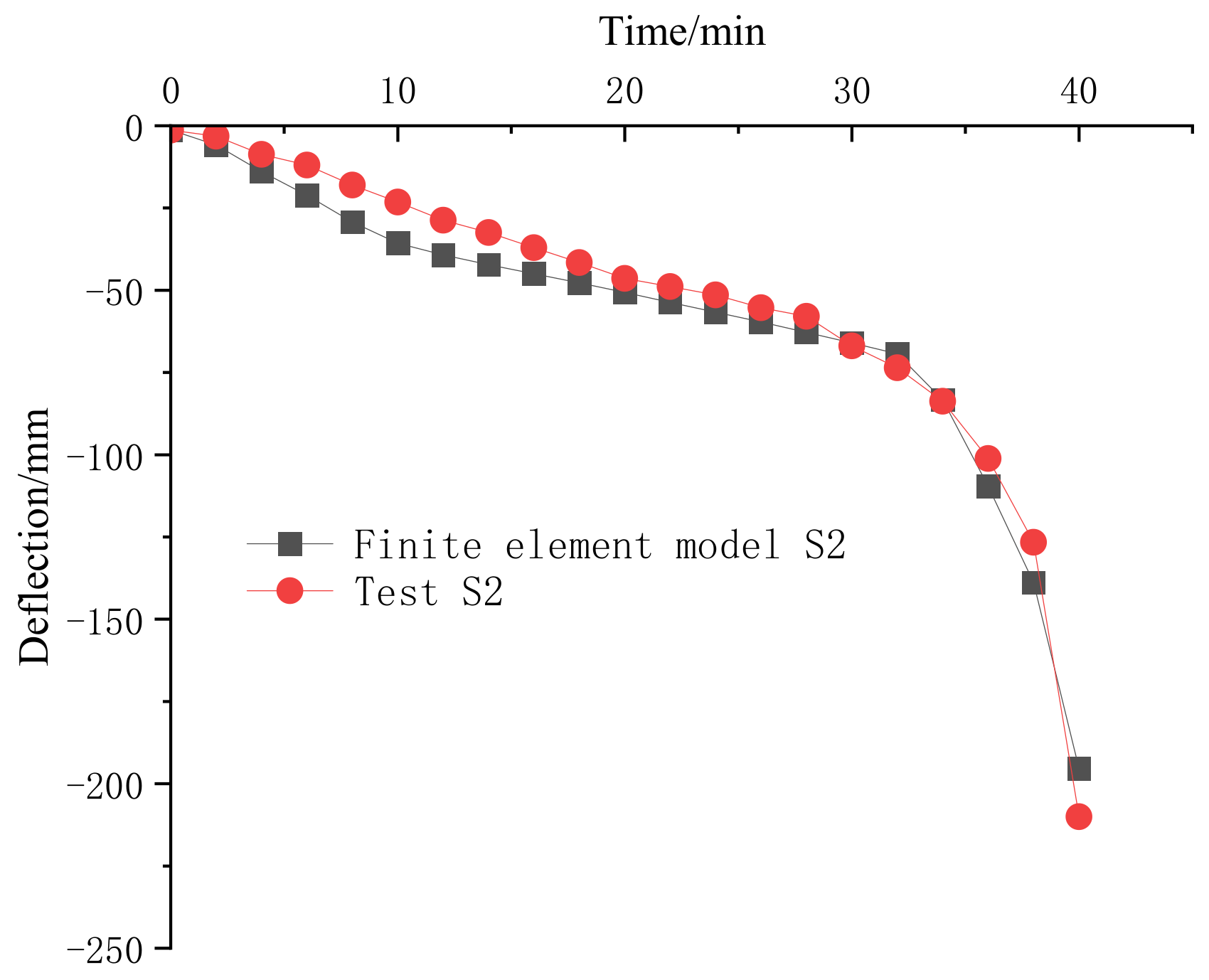

2.2. Finite Element Model Calibration Based on Existing Experimental Results

3. Calculation Results and Parameter Analysis of Fire Resistance of Prestressed Concrete T-Beam

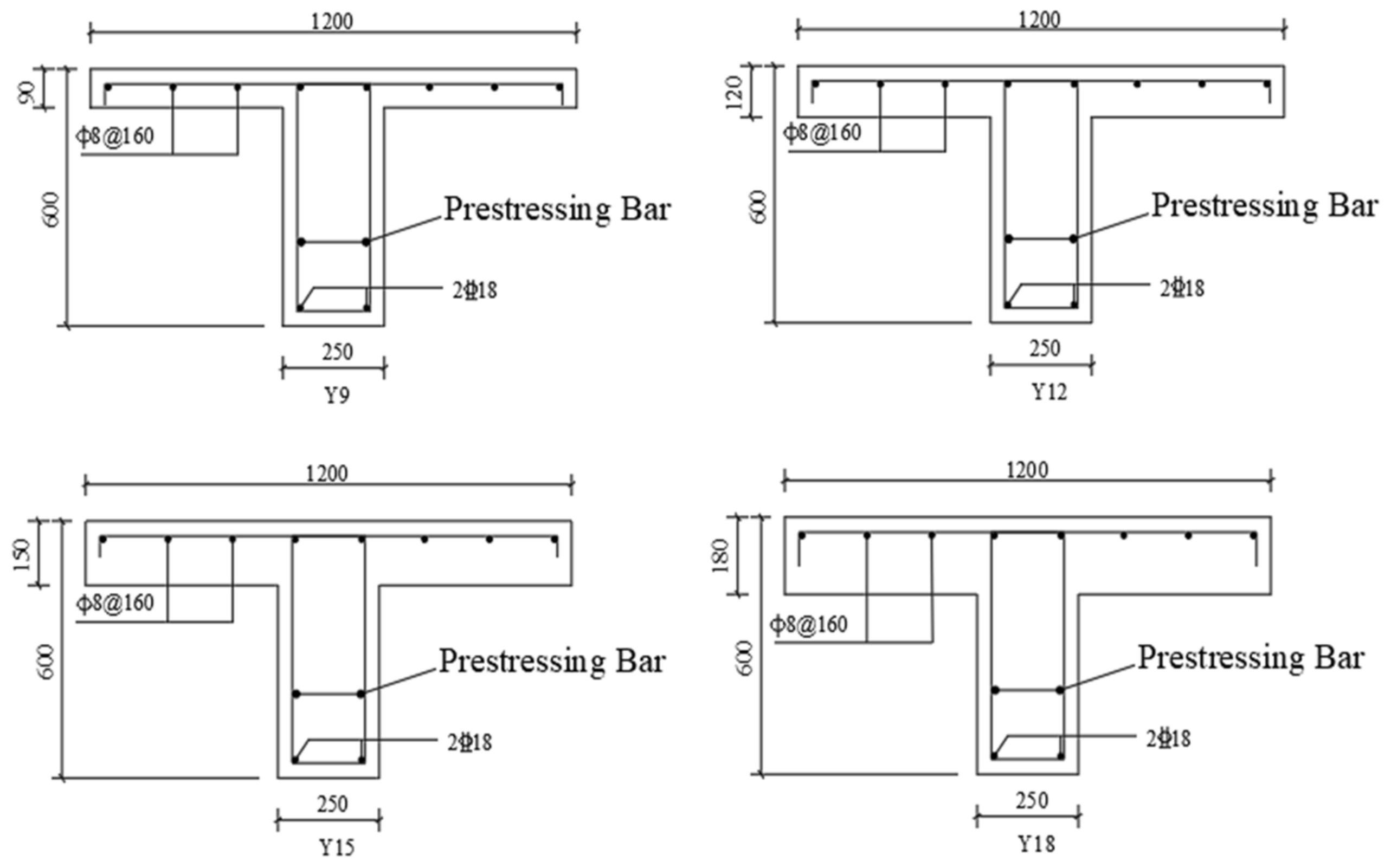

3.1. Determination of Finite Element Model and Analysis Parameters

3.2. Finite Element Model Calculation Results

3.2.1. Definition of Fire Resistance

3.2.2. Fire Resistance Calculation Results

3.3. Analysis of Parameters Affecting the Fire Resistance of Prestressed Concrete T-Beams

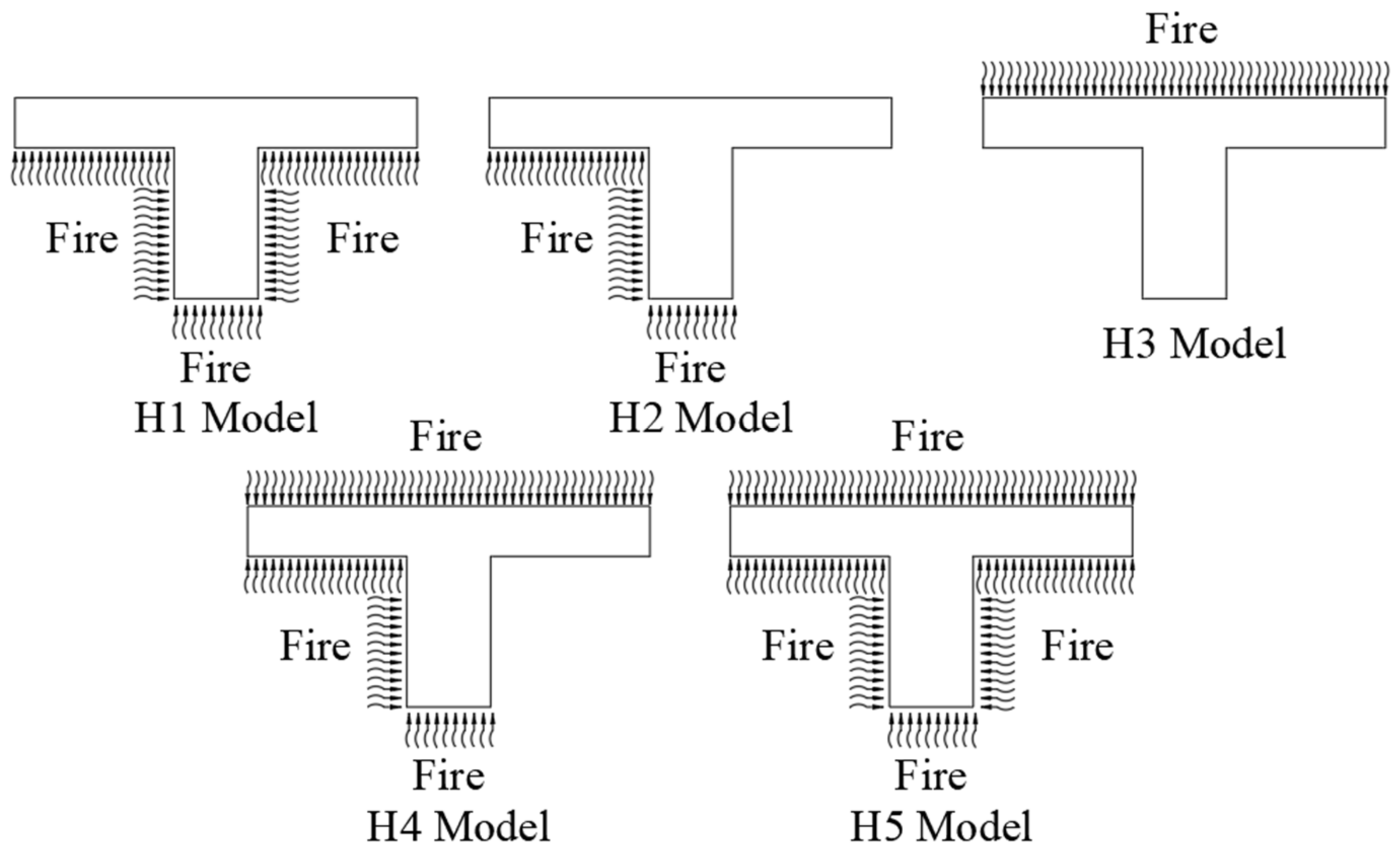

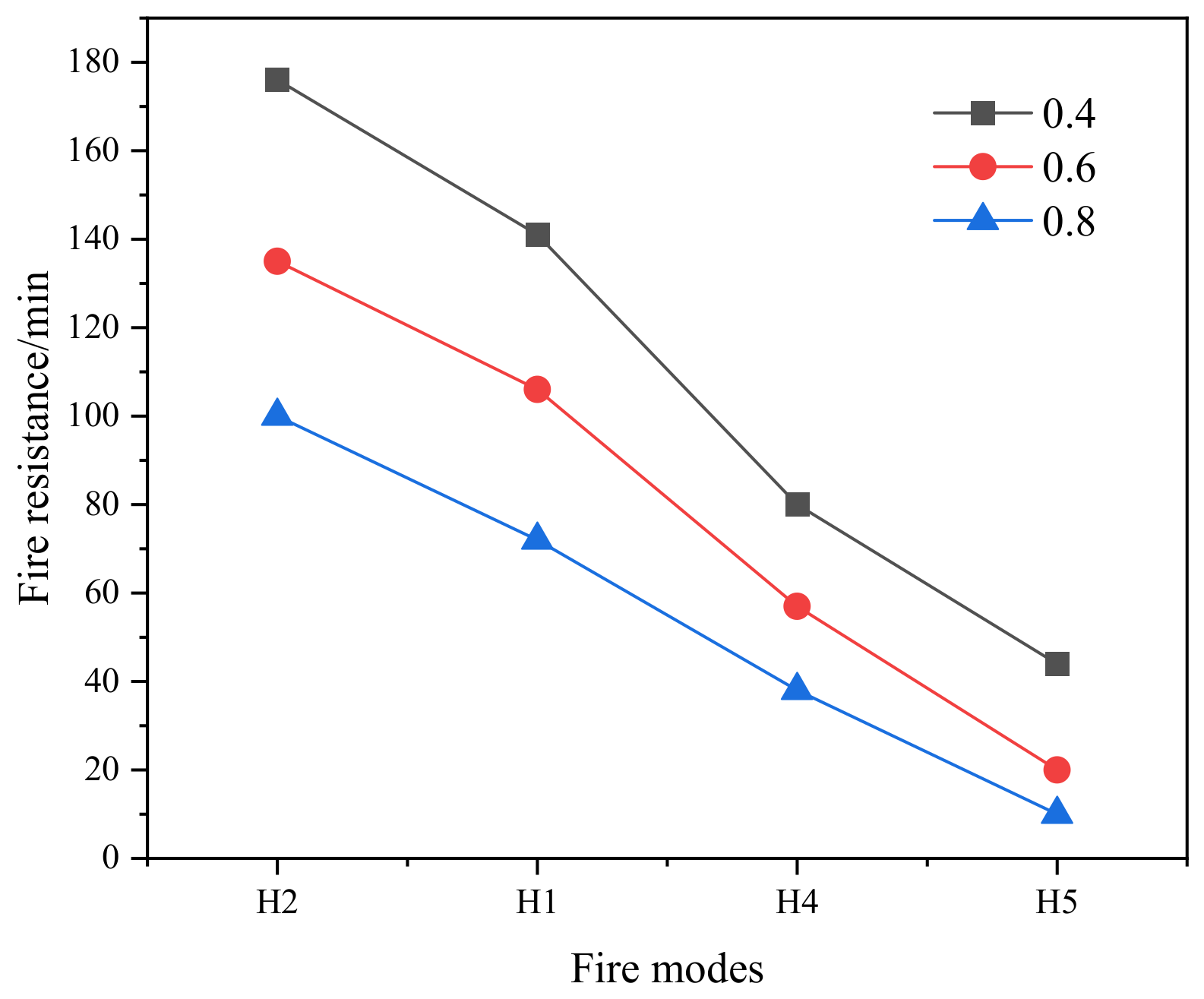

3.3.1. Effect of Different Fire Modes on Fire Resistance

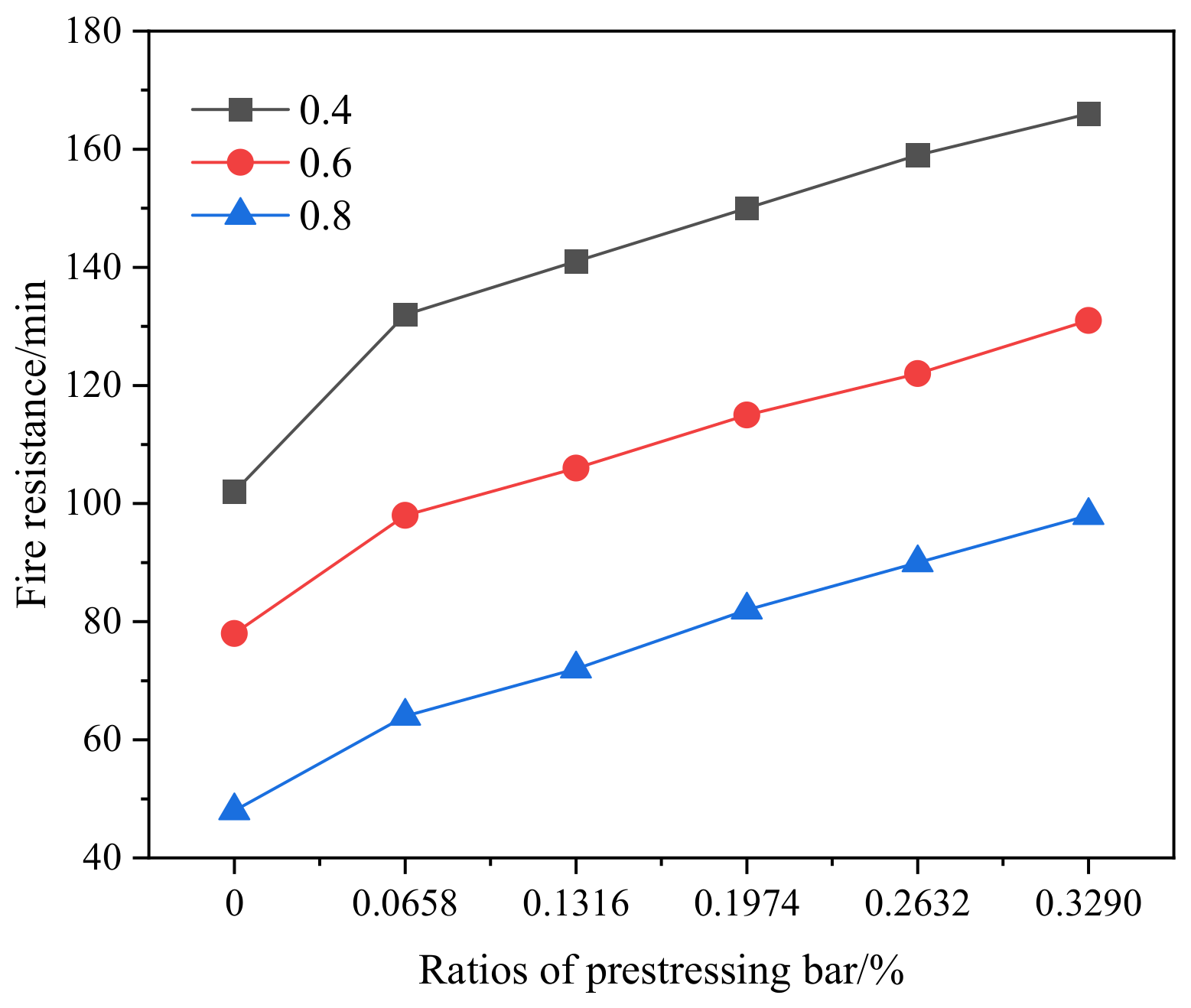

3.3.2. Effect of Different Ratios of Prestressing Bar on Fire Resistance

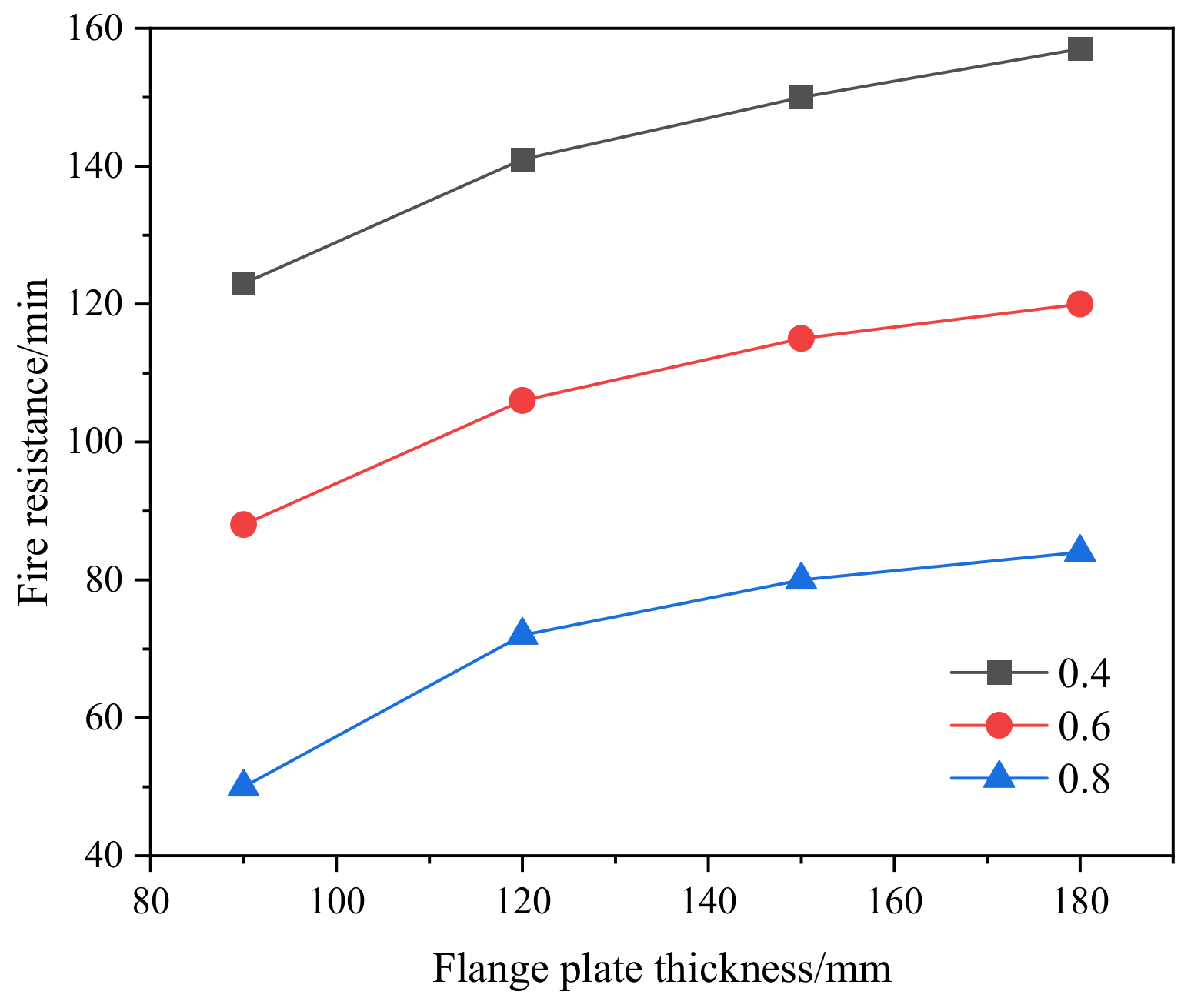

3.3.3. Effect of Different Flange Plate Thicknesses on Fire Resistance

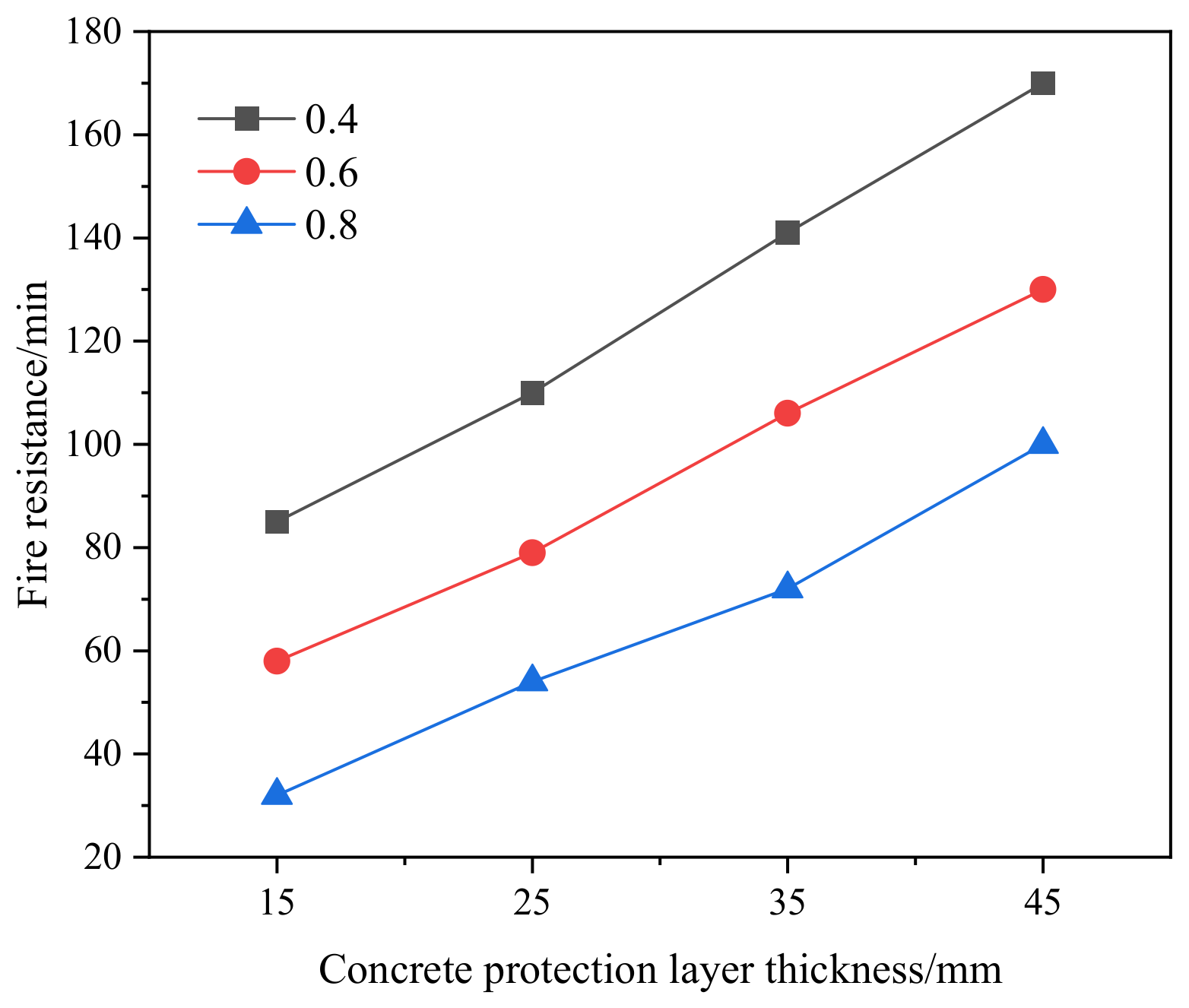

3.3.4. Effect of Different Concrete Protection Layer Thicknesses on Fire Resistance

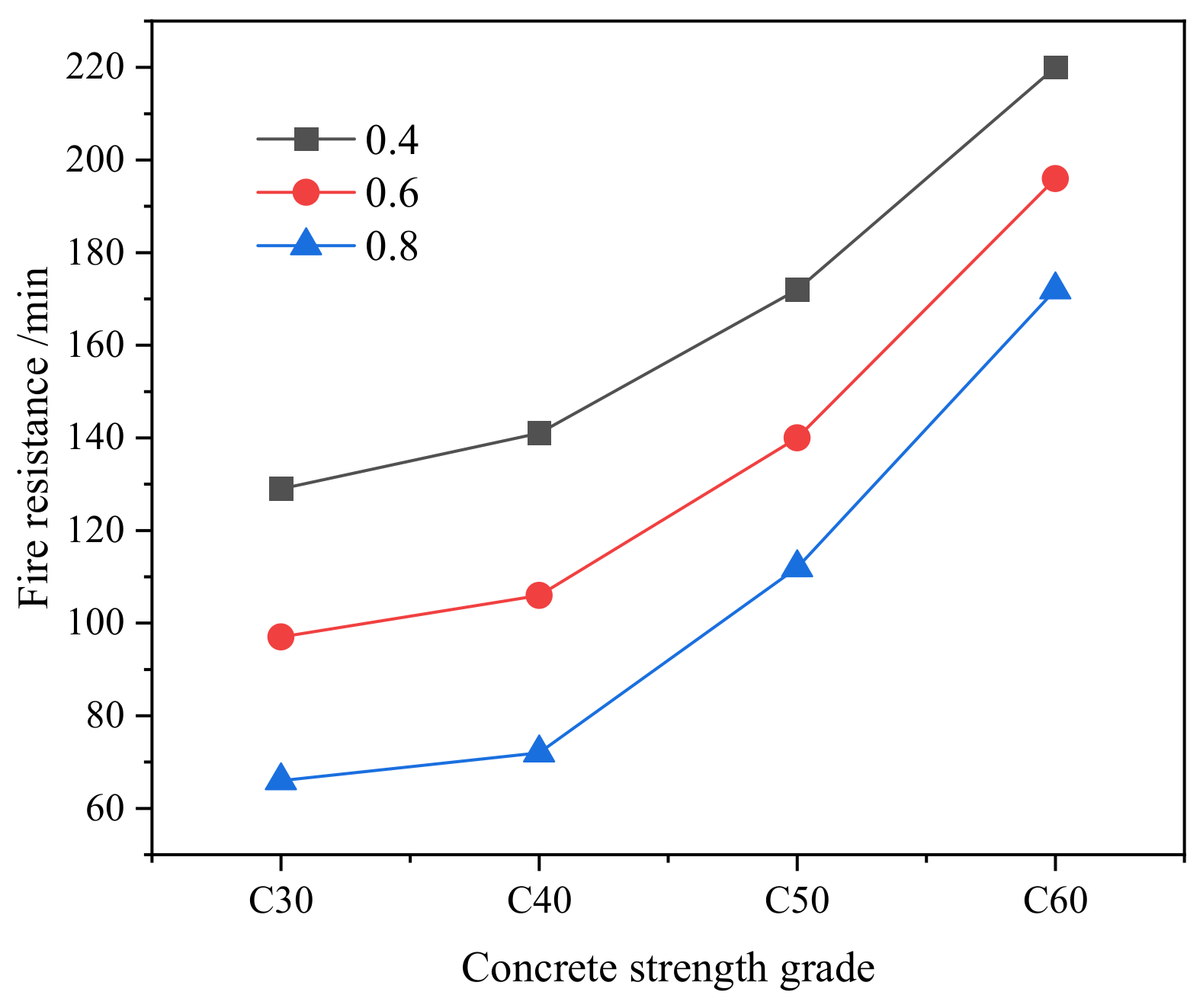

3.3.5. Effect of Different Concrete Strengths on Fire Resistance

4. Regression Prediction Formula for Fire Resistance of Prestressed Concrete T-Beams

5. Conclusions

- The fire resistance of prestressed concrete T-beams under different fire modes shows a large variability. Under the action of high temperature, the load will make the damage of the prestressed concrete T-beam aggravated, leading to a faster decrease of the fire resistance. The fire resistance mode should be considered in the fire resistance design.

- The ratio of prestressing bar shows an approximately linear increase in the fire resistance of prestressed concrete T-beam, and an appropriate increase in the ratio of prestressing bar can improve the fire resistance of the beam. In practical applications, an appropriate increase in the ratio of prestressing bar can be considered under the premise that the code allows and the economy is reasonable.

- Concrete protective layer thickness, and concrete strength can significantly improve the fire resistance of prestressed concrete T-beams. For the fire resistance design of practical projects, the addition of these two parameters is effective in obtaining higher fire resistance limits.

- For the fire mode H1, a formula for calculating the fire resistance of prestressed concrete T-beam considering several influencing parameters of load ratio, the ratio of the prestressing bar, flange plate thickness, concrete protective layer thickness, and concrete strength is proposed. The predicted results of the Equation are in good agreement with the numerical simulation results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, W.Z.; Hou, X.M.; Wang, Y. Progress and prospect of fire resisitance of reinforced concrete and prestressed concrete structures. J. Harbin Inst. Technol. 2016, 48, 1–18. [Google Scholar]

- Garlock, M.; Paya-Zaforteza, I.; Kodur, V. Fire hazard in bridges: Review, assessment and repair strategies. Eng. Struct. 2012, 35, 89–98. [Google Scholar] [CrossRef]

- Zhang, G.; He, S.H.; Hou, W. Review on fire resistance of prestressed-concrete bridge. J. Chang. Univ. 2018, 38, 1–10. [Google Scholar]

- Han, C.Q.; Xu, Q.F.; Liu, Q. Experimental research and FEA of fire resistance of RC continuous T-beam. J. Build. Struct. 2015, 36, 142–150. [Google Scholar]

- Wang, Y.Z.; Qiu, H.; Xiu, T.G. Change law of failure mode of reinforce concrete two-end consolidation beam in fire. J. Disaster Prev. Mitig. Eng. 2023, 2023, 1–10. [Google Scholar]

- Kodur, V.K.R.; Dwaikat, M.B. Design equation for predicting fire resistance of reinforced concrete beams. Eng. Struct. 2011, 33, 602–614. [Google Scholar] [CrossRef]

- Liu, Q.; Han, C.Q.; Xu, Q.F. Experimental research and numerical analysis of the flexural behavior of RC continuous T-beam with high-strength bar after fire. Eng. Mech. 2015, 32, 179–187. [Google Scholar]

- Yan, K.; Cai, H.; Zhang, Y. Experimental study on fire resistance of prestressed reactive powder concrete beams. J. Build. Struct. 2020, 41, 105–115. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Xu, Z.W. Experimental research on unbonded prestressed concrete flat beams under high temperature. J. Build. Struct. 2011, 32, 98–106. [Google Scholar]

- Zhang, G.; Song, C.J.; Li, X.Y. Experimental study on fire resistance of prestressed concrete girders under fuel fire exposure. China J. Highw. Transp. 2022, 35, 210–221. [Google Scholar]

- Yan, K.; Qin, H.; Hu, Y. Experimental and numerical studies on the fire resistance of prestressed reactive powder concrete beams. Structures 2022, 45, 1814–1832. [Google Scholar] [CrossRef]

- Yu, Y.; Hang, Z.; Zhao, W. Fire-resistance mechanism and residual bearing capacity of prestressed concrete beams after fire exposure. J. Struct. Eng. 2021, 147, 04021109. [Google Scholar] [CrossRef]

- Guo, Z.H.; Shi, X.D. Experiment and Calculation of Reinforced Concrete at Elevated Temperatures; Tsinghua University Press: Beijing, China, 2011. [Google Scholar]

- EN 1992-1-2 (2004); Eurocode2: Design of Concrete Structures: Part 1–2: General Rules-Structural Fire Design. European Committee for Standardization: Brussels, Belgium, 2004.

- EN 1993-1-2 (2005); Eurocode 3: Design of Steel Structures, Part 1–2: General Rules-Structural Fire Design. European Committee for Standardization: Brussels, Belgium, 2005.

- Li, Y.Q.; Ma, D.Z.; Xu, J. Fire Protection Design Calculation and Construction Treatment of Building Structures; Architecture & Building Press: Beijing, China, 1991. [Google Scholar]

- Li, W.; Guo, Z.H. Experimental Study on the strength and deformation properties of concrete at high temperature. J. Build. Struct. 1993, 14, 8–16. [Google Scholar]

- Zhu, B.L.; Lu, Z.D. Ontogenetic relationship between concrete and reinforcement under high temperature (fire). Sichuan Build. Sci. 1990, 16, 37–43. [Google Scholar]

- Yang, H.; Han, L.H.; Wang, Y.C. Effects of heating and loading histories on post-fire cooling behaviour of concrete-filled steel tubular columns. J. Constr. Steel Res. 2008, 64, 556–570. [Google Scholar] [CrossRef]

- Lie, T.T. Fire Resistance of Circular Steel Columns Filled with Bar-reinforced Concrete. J. Struct. Eng. 1994, 120, 1489–1509. [Google Scholar] [CrossRef]

- Saafi, M. Effect of fire on FRP reinforced concrete members. Compos. Struct. 2002, 58, 11–20. [Google Scholar] [CrossRef]

- Hou, X.M. Research on Fire Resistance and Fire Safety Design Method of Prestressed Concrete Beam and Slab. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2009. [Google Scholar]

- Hua, Y.J. Research on Fire Response and Fire Resistance of Prestressed Concrete Structures. Ph.D. Thesis, Tongji University, Shanghai, China, 2000. [Google Scholar]

- Zhang, B. The Numerical Analysis of Temperature Field and Mechanical Properties for Prestressed Concrete Slab at High Temperature (In Fire). Ph.D. Thesis, Hefei University of Technology, Hefei, China, 2010. [Google Scholar]

- Fan, J.; Lv, Z.T. Experimental research on pretressed steel strand at high temperature. J. Build. Struct. 2002, 32, 50–63. [Google Scholar]

- JGJ/369-2016; Code for Design of Prestressed Concrete Structures. China Architecture & Building Press: Beijing, China, 2016.

- GB/T9978-2008; Fire-Resistance Test Elements Building Construction. Standards Press of China: Beijing, China, 2008.

| Thermal Parameters | Formula | References |

|---|---|---|

| Heat transfer coefficient | (Gou et al. [13]) | |

| Heat capacity | (Eurocode2 [14]) | |

| Density |

| Thermal Parameters | Formula | References |

|---|---|---|

| Heat transfer coefficient | (Eurocode3 [15]) | |

| Heat capacity | (Li et al. [16]) | |

| Density |

| Mechanical Properties | Formula | References |

|---|---|---|

| Stress–strain principal structure relationship | (Guo et al. [13]) | |

| Tensile–compressive strength | (Guo et al. [13]) | |

| Thermal expansion | (Li et al. [17]) | |

| Elasticity | (Zhu et al. [18]) |

| Mechanical Properties | Formula | References |

|---|---|---|

| Stress–strain principal structure relationship | (Yang et al. [19]) | |

| Tensile–compressive strength | (Guo et al. [13]) | |

| Thermal expansion | (Lie et al. [20]) | |

| Elasticity | (Saafi et al. [21]) |

| Mechanical Properties | Formula | References |

|---|---|---|

| Stress–strain principal structure relationship | (Hou et al. [22]) | |

| Tensile–compressive strength | (Hua et al. [23]) | |

| Thermal expansion | (Zhang et al. [24]) | |

| Elasticity | (Fan et al. [25]) |

| Groups | Fire Modes | Flange Plate Thickness Y/mm | Prestressing Bar Ratio P% | Concrete Thickness a/mm | Concrete Strength C | load Rate n | Fire Resistance/min |

|---|---|---|---|---|---|---|---|

| D1 | H1 | 120 | 0.1316 | 35 | 40 | 0.4 | 141 |

| H2 | 120 | 0.1316 | 35 | 40 | 0.4 | 176 | |

| H3 | 120 | 0.1316 | 35 | 40 | 0.4 | \ | |

| H4 | 120 | 0.1316 | 35 | 40 | 0.4 | 80 | |

| H5 | 120 | 0.1316 | 35 | 40 | 0.4 | 44 | |

| H1 | 120 | 0.1316 | 35 | 40 | 0.6 | 106 | |

| H2 | 120 | 0.1316 | 35 | 40 | 0.6 | 135 | |

| H3 | 120 | 0.1316 | 35 | 40 | 0.6 | \ | |

| H4 | 120 | 0.1316 | 35 | 40 | 0.6 | 57 | |

| H5 | 120 | 0.1316 | 35 | 40 | 0.6 | 20 | |

| H1 | 120 | 0.1316 | 35 | 40 | 0.8 | 72 | |

| H2 | 120 | 0.1316 | 35 | 40 | 0.8 | 100 | |

| H3 | 120 | 0.1316 | 35 | 40 | 0.8 | \ | |

| H4 | 120 | 0.1316 | 35 | 40 | 0.8 | 38 | |

| H5 | 120 | 0.1316 | 35 | 40 | 0.8 | 10 | |

| D2 | H1 | 120 | 0.0000 | 35 | 40 | 0.4 | 102 |

| H1 | 120 | 0.0658 | 35 | 40 | 0.4 | 132 | |

| H1 | 120 | 0.1316 | 35 | 40 | 0.4 | 141 | |

| H1 | 120 | 0.1974 | 35 | 40 | 0.4 | 150 | |

| H1 | 120 | 0.2632 | 35 | 40 | 0.4 | 159 | |

| H1 | 120 | 0.3290 | 35 | 40 | 0.4 | 166 | |

| H1 | 120 | 0.0000 | 35 | 40 | 0.6 | 78 | |

| H1 | 120 | 0.0658 | 35 | 40 | 0.6 | 98 | |

| H1 | 120 | 0.1316 | 35 | 40 | 0.6 | 106 | |

| H1 | 120 | 0.1974 | 35 | 40 | 0.6 | 115 | |

| H1 | 120 | 0.2632 | 35 | 40 | 0.6 | 122 | |

| H1 | 120 | 0.3290 | 35 | 40 | 0.6 | 131 | |

| H1 | 120 | 0.0000 | 35 | 40 | 0.8 | 48 | |

| H1 | 120 | 0.0658 | 35 | 40 | 0.8 | 64 | |

| H1 | 120 | 0.1316 | 35 | 40 | 0.8 | 72 | |

| H1 | 120 | 0.1974 | 35 | 40 | 0.8 | 82 | |

| H1 | 120 | 0.2632 | 35 | 40 | 0.8 | 90 | |

| H1 | 120 | 0.3290 | 35 | 40 | 0.8 | 98 | |

| D3 | H1 | 90 | 0.1316 | 35 | 40 | 0.4 | 123 |

| H1 | 120 | 0.1316 | 35 | 40 | 0.4 | 141 | |

| H1 | 150 | 0.1316 | 35 | 40 | 0.4 | 150 | |

| H1 | 180 | 0.1316 | 35 | 40 | 0.4 | 157 | |

| H1 | 90 | 0.1316 | 35 | 40 | 0.6 | 88 | |

| H1 | 120 | 0.1316 | 35 | 40 | 0.6 | 106 | |

| H1 | 150 | 0.1316 | 35 | 40 | 0.6 | 115 | |

| H1 | 180 | 0.1316 | 35 | 40 | 0.6 | 120 | |

| H1 | 90 | 0.1316 | 35 | 40 | 0.8 | 50 | |

| H1 | 120 | 0.1316 | 35 | 40 | 0.8 | 72 | |

| H1 | 150 | 0.1316 | 35 | 40 | 0.8 | 80 | |

| H1 | 180 | 0.1316 | 35 | 40 | 0.8 | 84 | |

| D4 | H1 | 120 | 0.1316 | 35 | 30 | 0.4 | 129 |

| H1 | 120 | 0.1316 | 35 | 40 | 0.4 | 141 | |

| H1 | 120 | 0.1316 | 35 | 50 | 0.4 | 172 | |

| H1 | 120 | 0.1316 | 35 | 60 | 0.4 | 220 | |

| H1 | 120 | 0.1316 | 35 | 30 | 0.6 | 97 | |

| H1 | 120 | 0.1316 | 35 | 40 | 0.6 | 106 | |

| H1 | 120 | 0.1316 | 35 | 50 | 0.6 | 140 | |

| H1 | 120 | 0.1316 | 35 | 60 | 0.6 | 196 | |

| H1 | 120 | 0.1316 | 35 | 30 | 0.8 | 66 | |

| H1 | 120 | 0.1316 | 35 | 40 | 0.8 | 72 | |

| H1 | 120 | 0.1316 | 35 | 50 | 0.8 | 112 | |

| H1 | 120 | 0.1316 | 35 | 60 | 0.8 | 172 | |

| D5 | H1 | 120 | 0.1316 | 15 | 40 | 0.4 | 85 |

| H1 | 120 | 0.1316 | 25 | 40 | 0.4 | 110 | |

| H1 | 120 | 0.1316 | 35 | 40 | 0.4 | 141 | |

| H1 | 120 | 0.1316 | 45 | 40 | 0.4 | 170 | |

| H1 | 120 | 0.1316 | 15 | 40 | 0.6 | 58 | |

| H1 | 120 | 0.1316 | 25 | 40 | 0.6 | 79 | |

| H1 | 120 | 0.1316 | 35 | 40 | 0.6 | 106 | |

| H1 | 120 | 0.1316 | 45 | 40 | 0.6 | 130 | |

| H1 | 120 | 0.1316 | 15 | 40 | 0.8 | 32 | |

| H1 | 120 | 0.1316 | 25 | 40 | 0.8 | 54 | |

| H1 | 120 | 0.1316 | 35 | 40 | 0.8 | 72 | |

| H1 | 120 | 0.1316 | 45 | 40 | 0.8 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Chen, M.; Liao, Y. Analysis of Fire Resistance of Prestressed Concrete T-Beam Based on ABAQUS Numerical Simulation. Appl. Sci. 2023, 13, 4683. https://doi.org/10.3390/app13084683

Wang Z, Chen M, Liao Y. Analysis of Fire Resistance of Prestressed Concrete T-Beam Based on ABAQUS Numerical Simulation. Applied Sciences. 2023; 13(8):4683. https://doi.org/10.3390/app13084683

Chicago/Turabian StyleWang, Zhongqiang, Miao Chen, and Yong Liao. 2023. "Analysis of Fire Resistance of Prestressed Concrete T-Beam Based on ABAQUS Numerical Simulation" Applied Sciences 13, no. 8: 4683. https://doi.org/10.3390/app13084683

APA StyleWang, Z., Chen, M., & Liao, Y. (2023). Analysis of Fire Resistance of Prestressed Concrete T-Beam Based on ABAQUS Numerical Simulation. Applied Sciences, 13(8), 4683. https://doi.org/10.3390/app13084683