In-Service Performance Evaluation of Flexible Pavement with Lightweight Cellular Concrete Subbase

Abstract

1. Introduction

2. Literature Review

3. Methodology

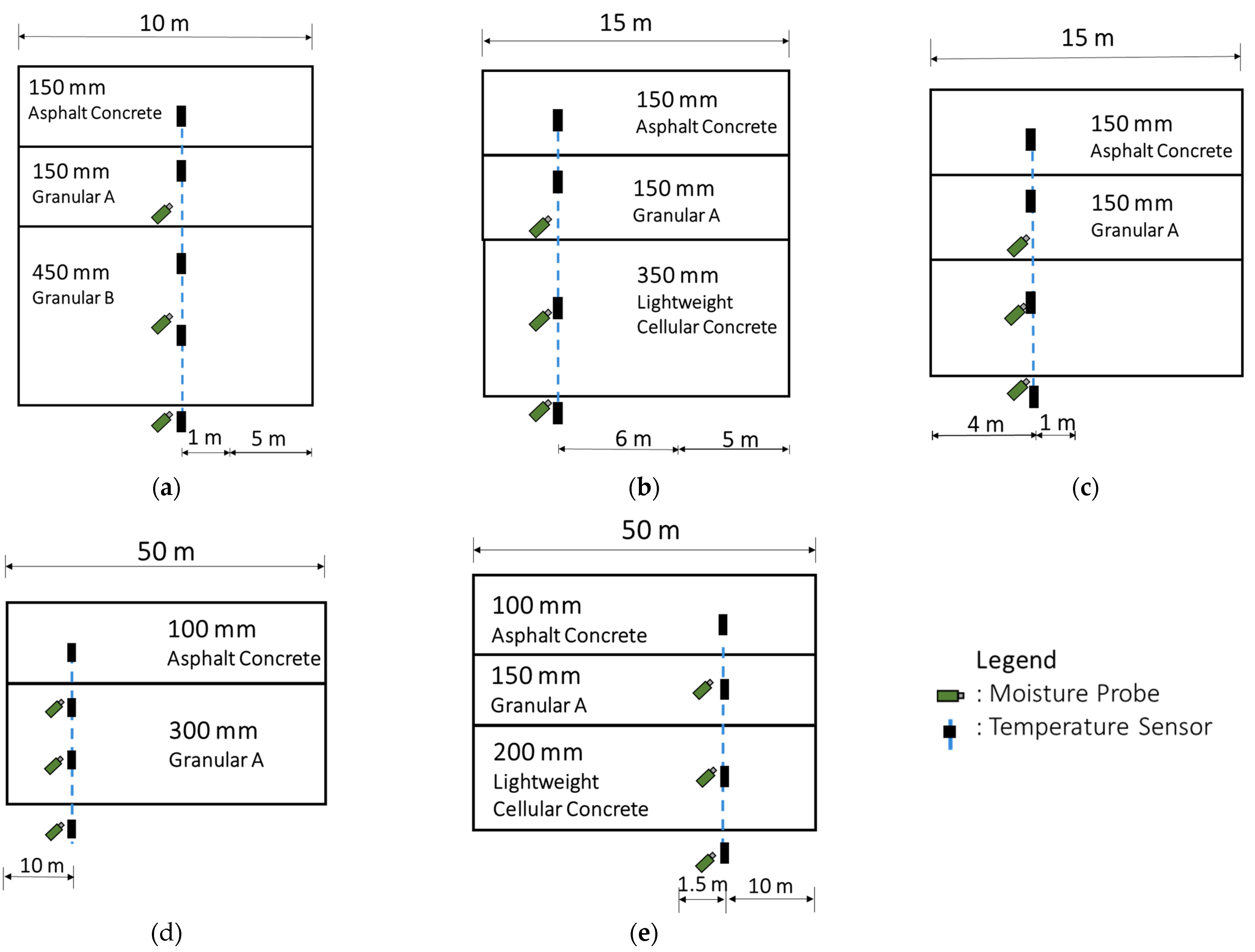

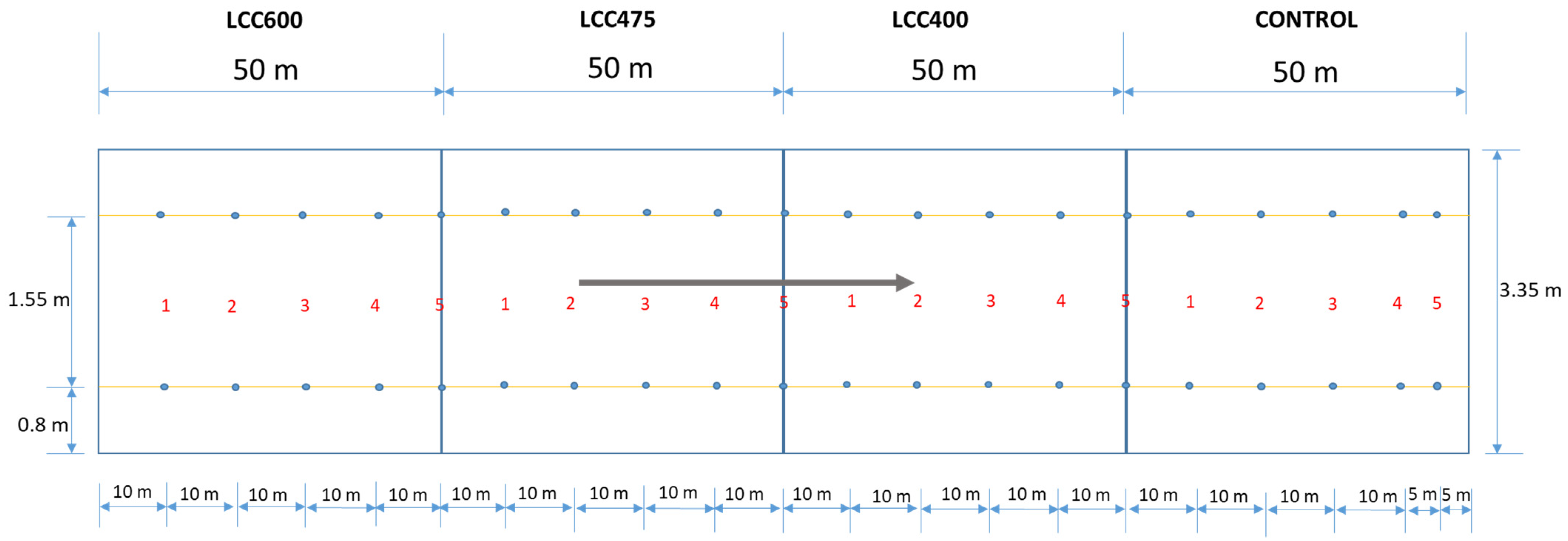

3.1. Test Sections

3.2. Pavement Layer Material Properties

3.3. Test Methods

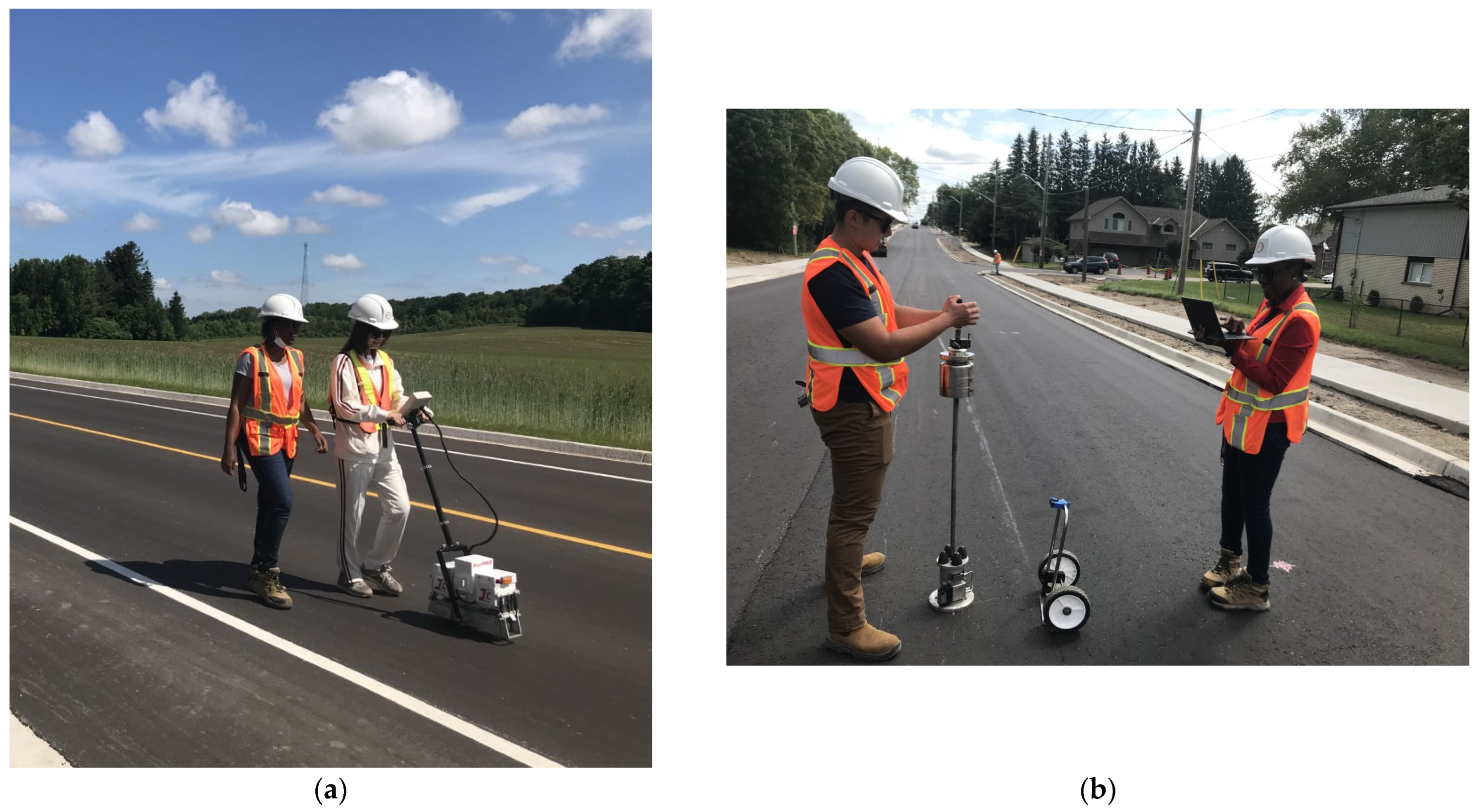

3.3.1. Lightweight Deflectometer

3.3.2. SurPro

4. Results

4.1. Pavement Stiffness

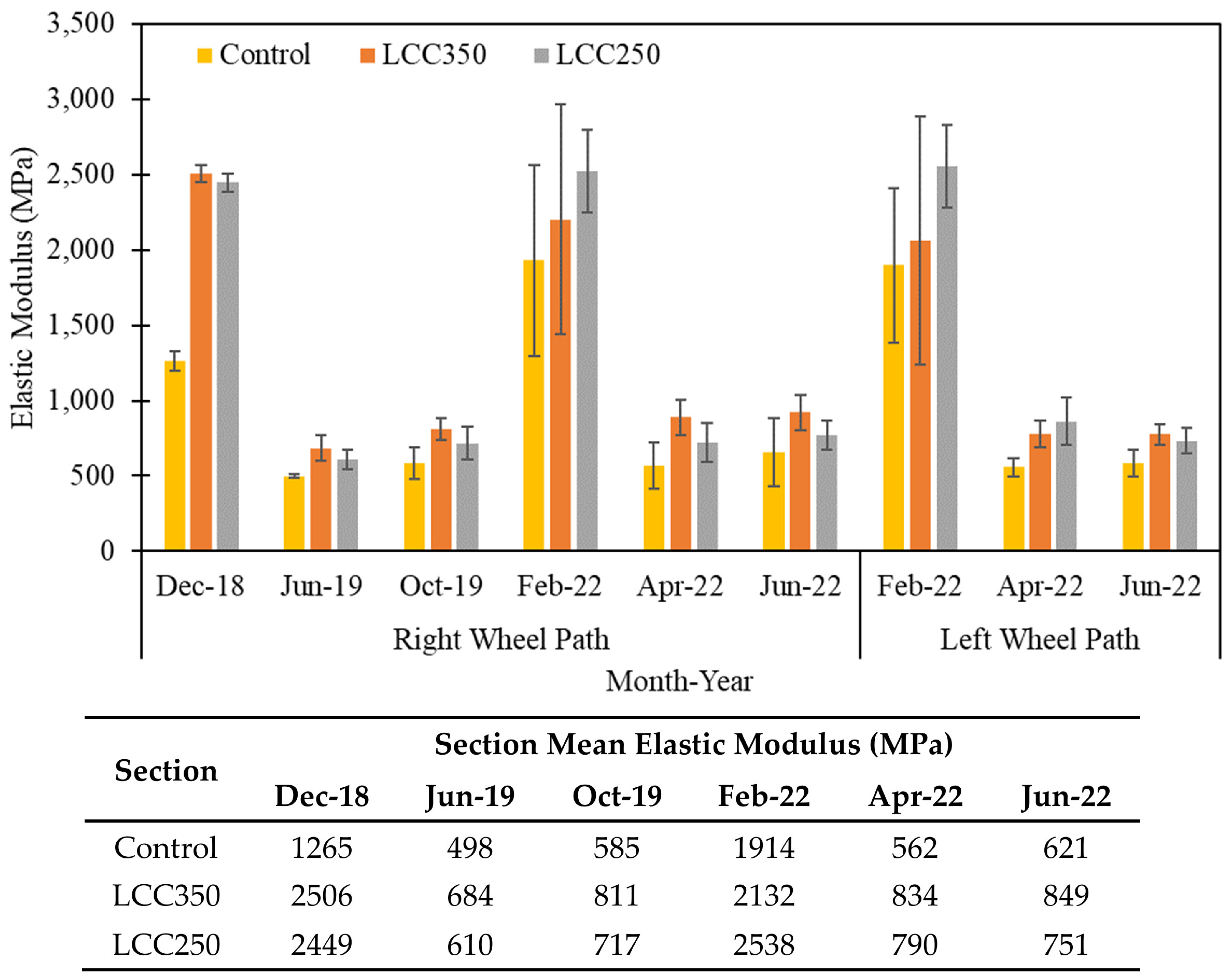

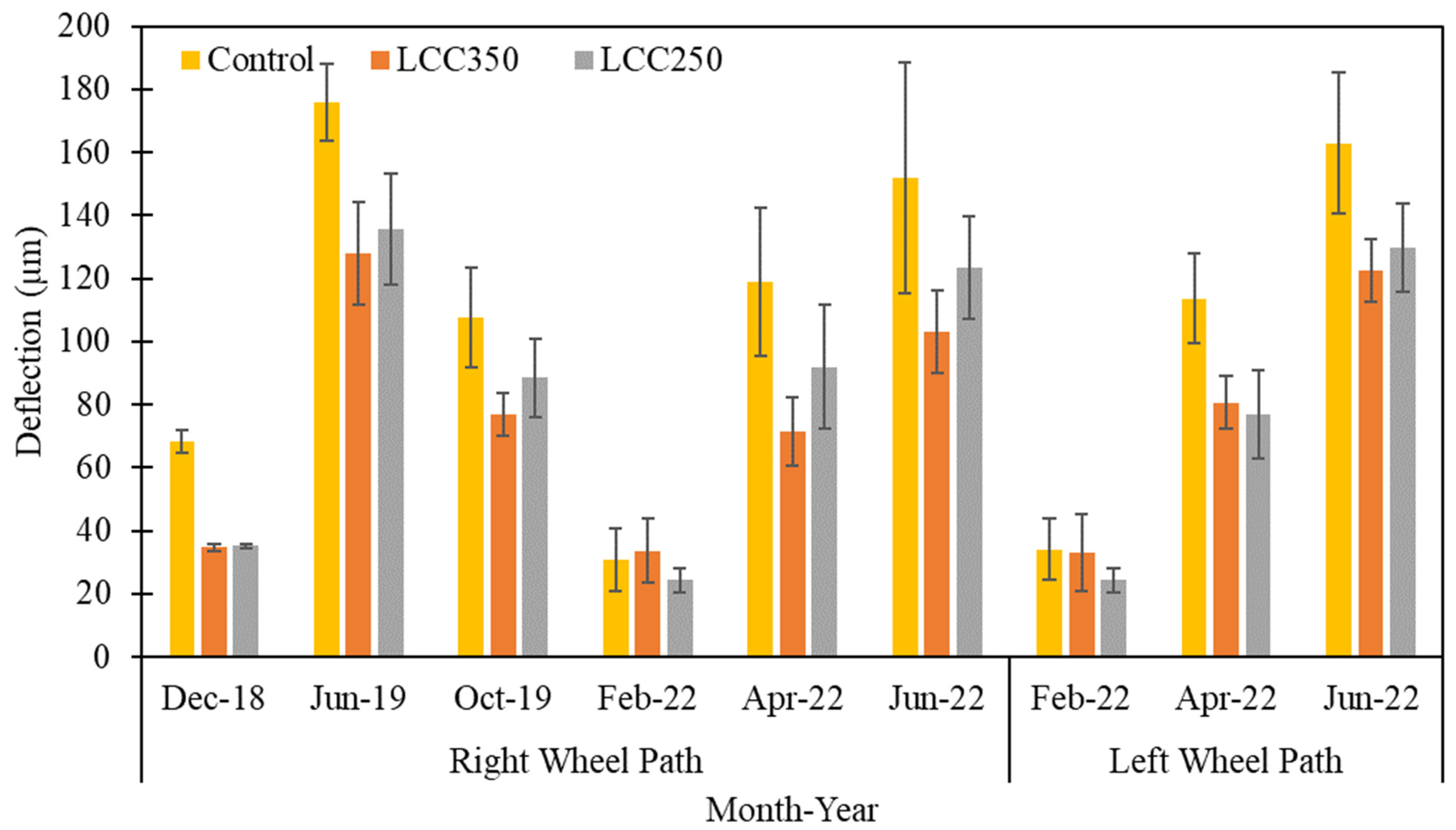

4.1.1. Erbsville

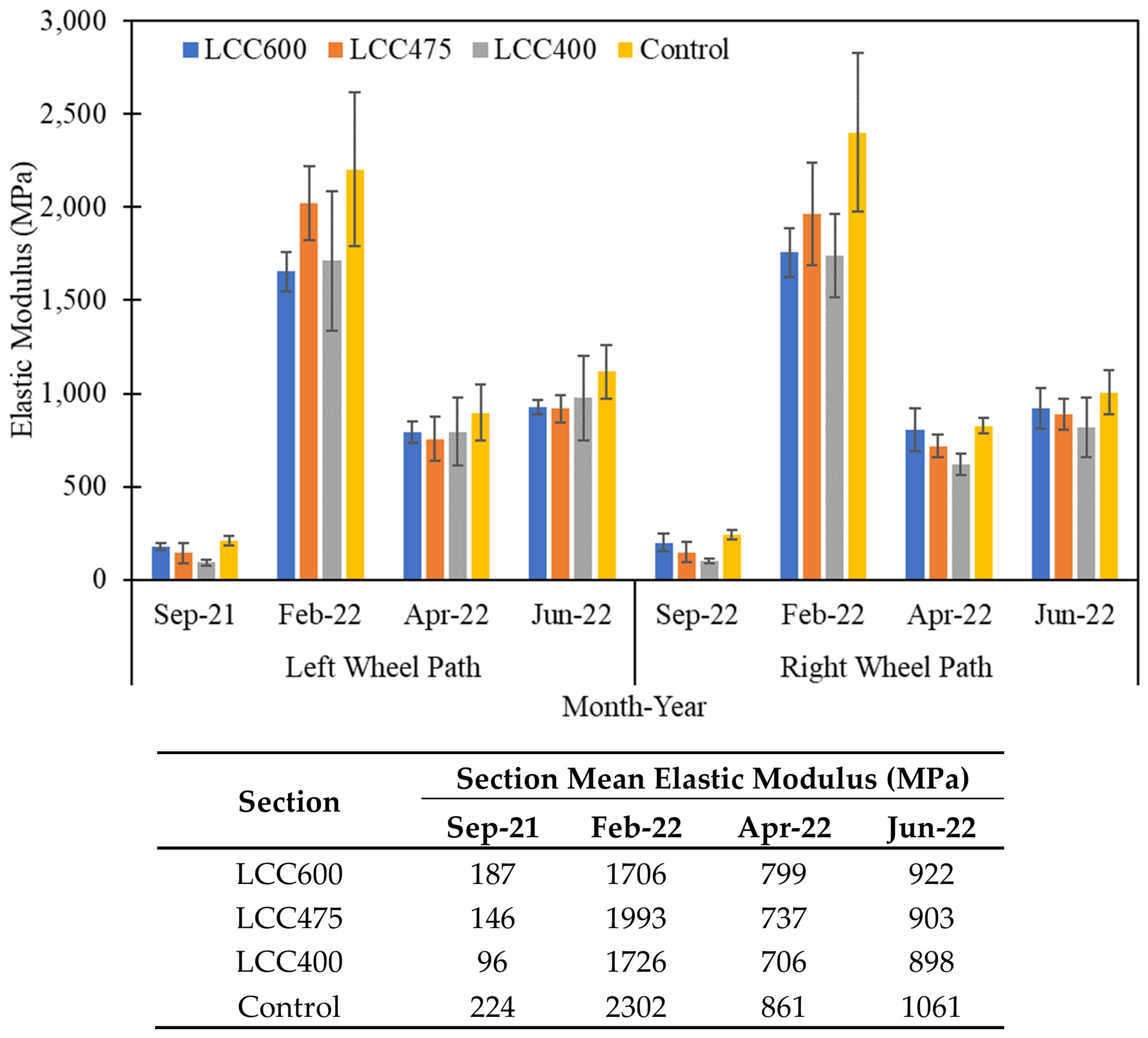

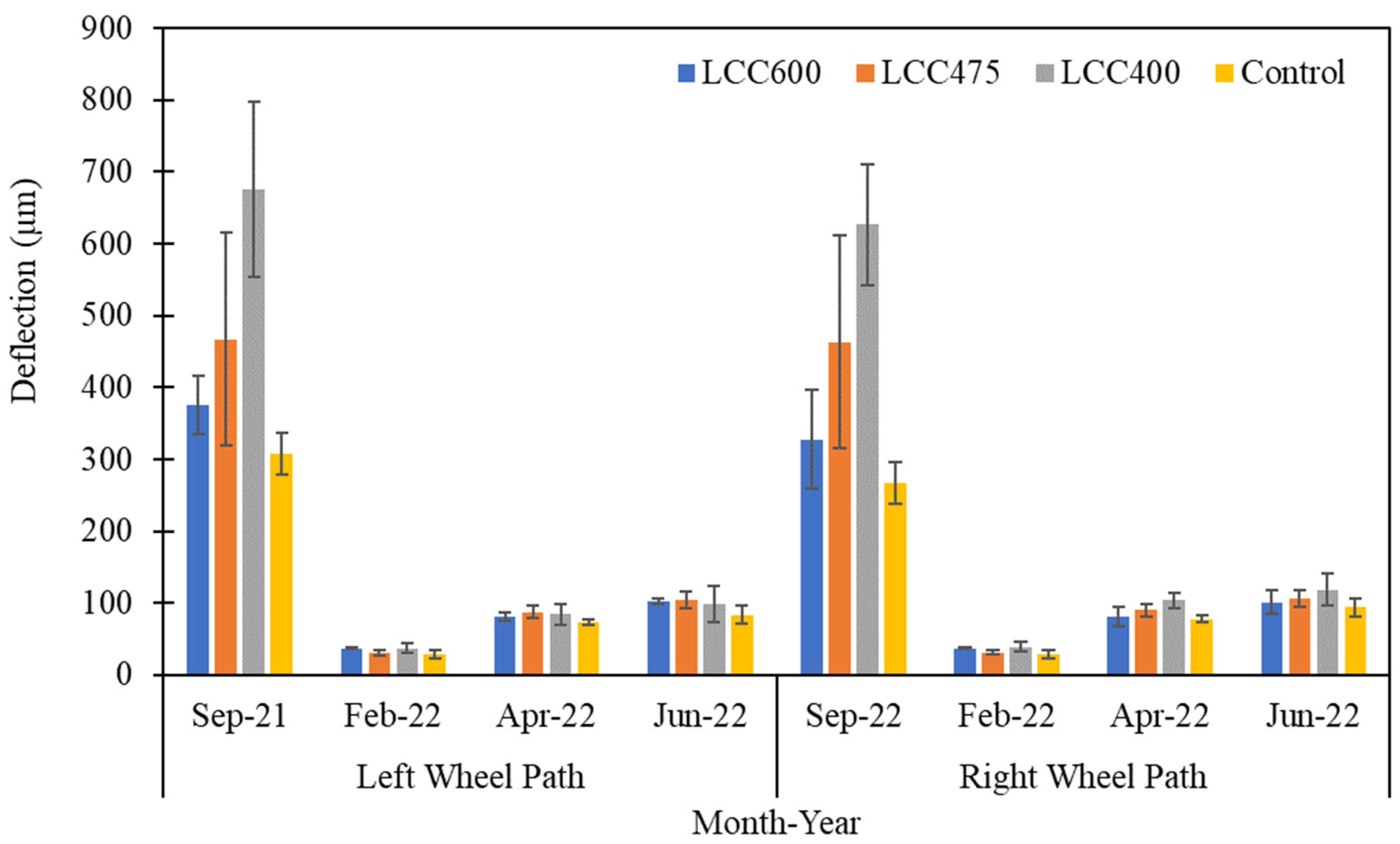

4.1.2. Notre Dame Drive

4.2. Pavement Roughness

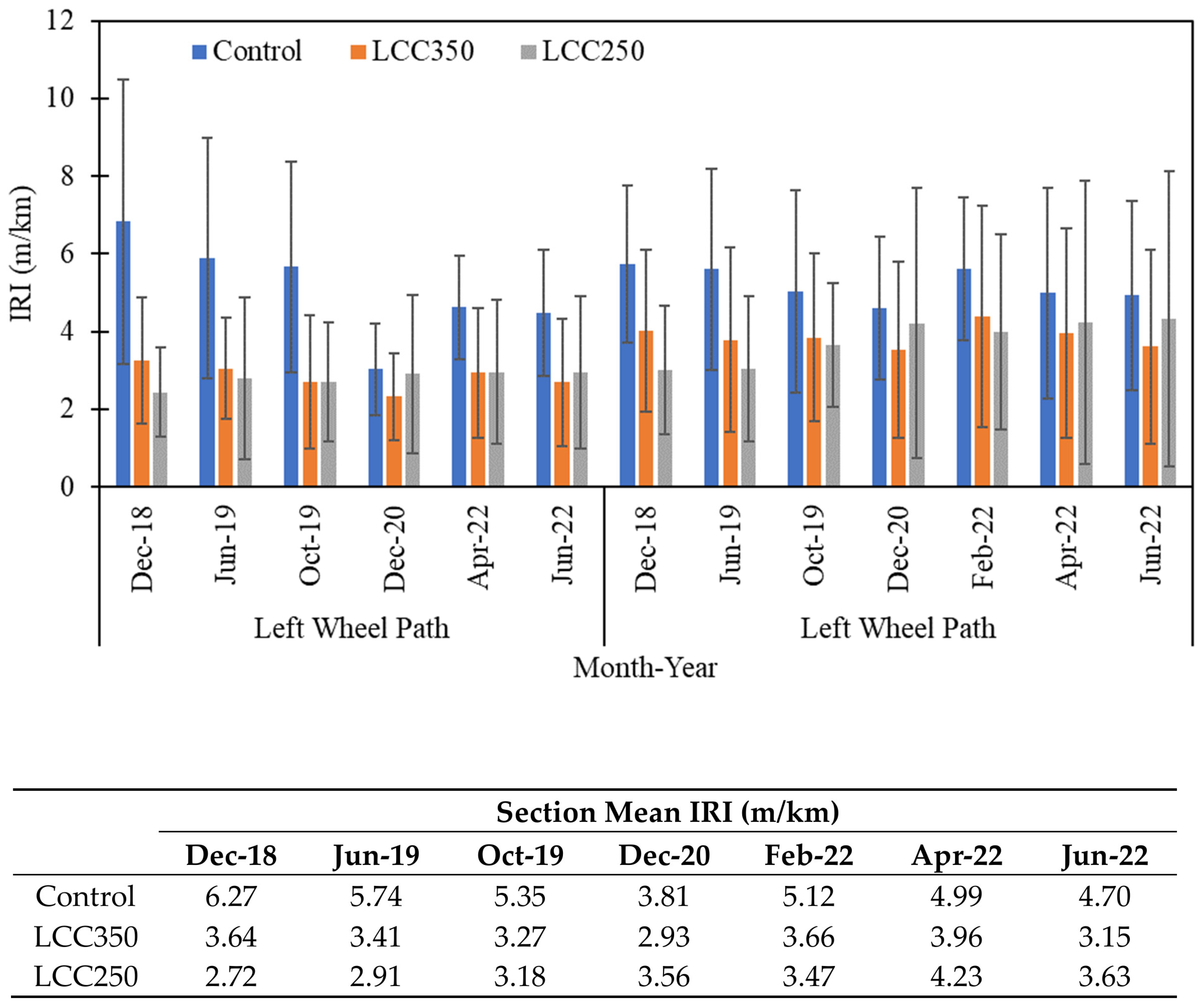

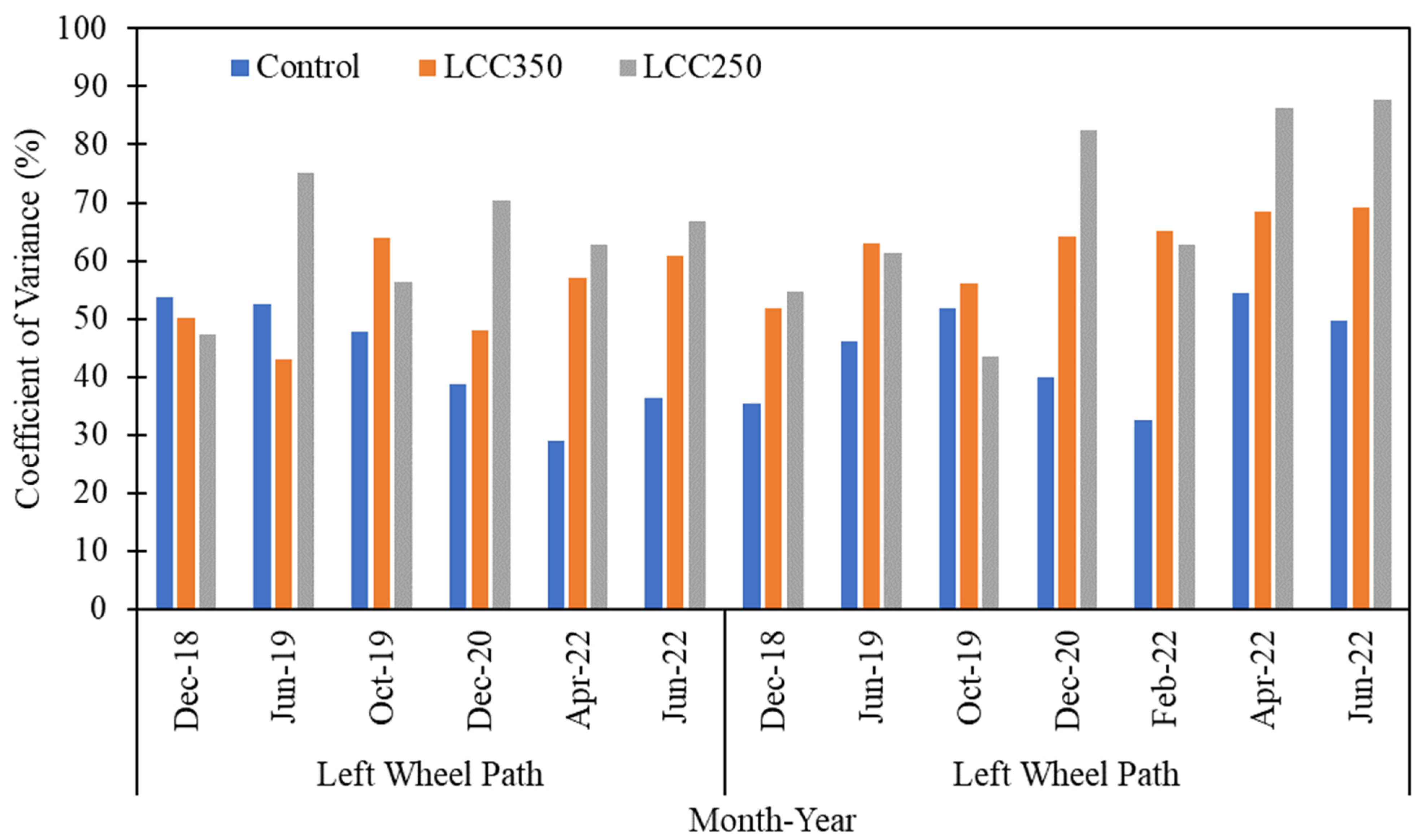

4.2.1. Erbsville

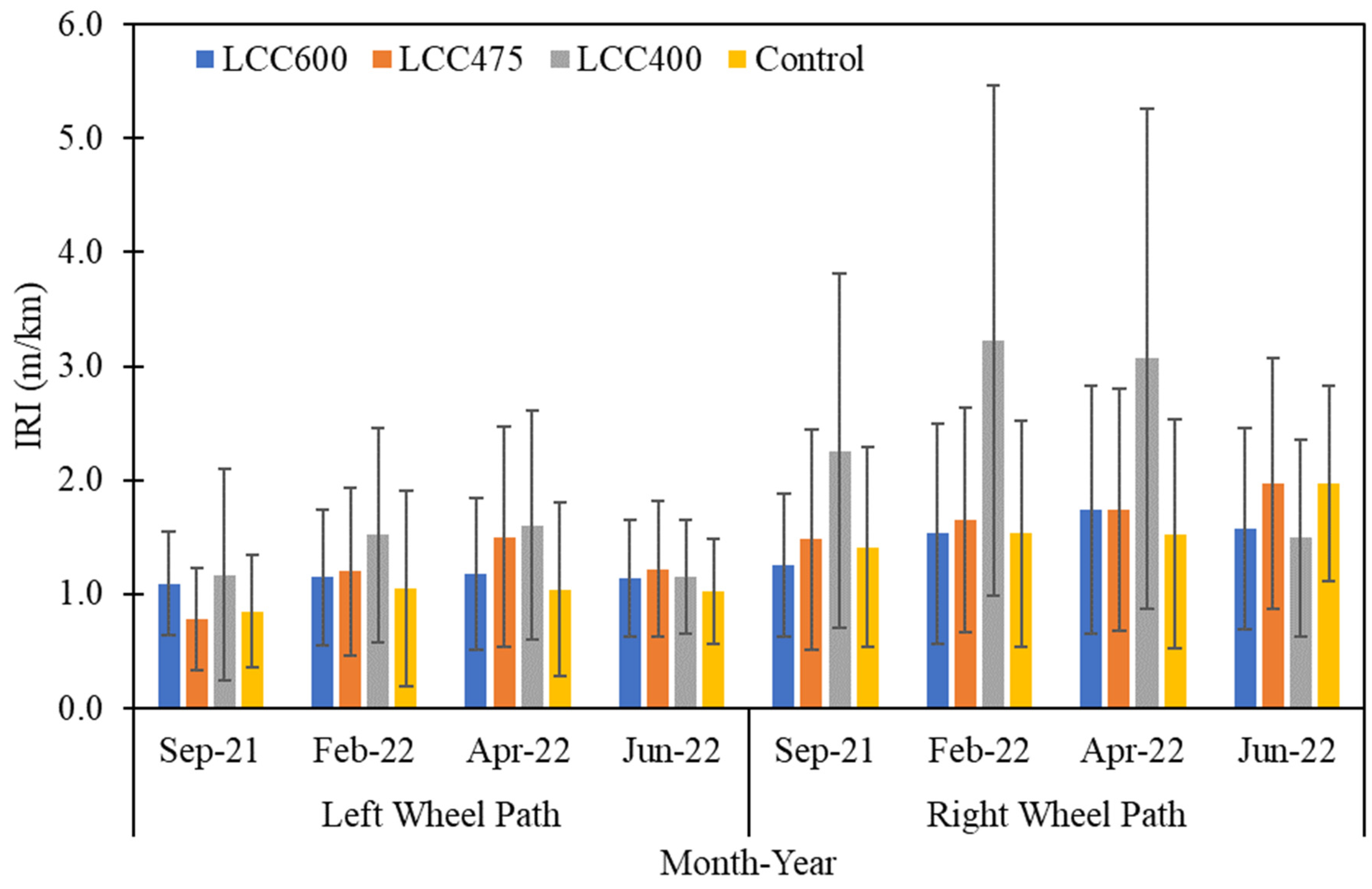

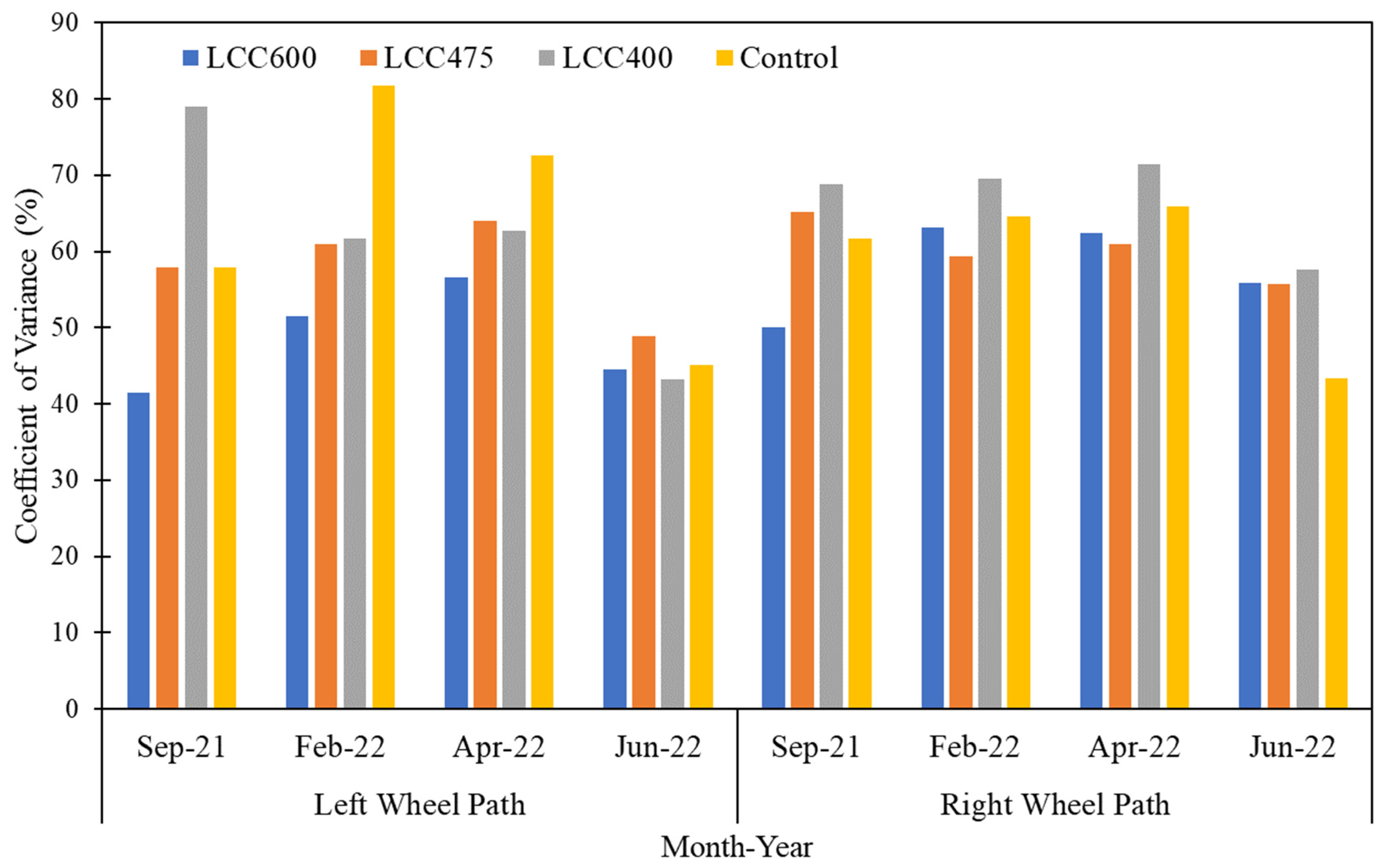

4.2.2. Notre Dame Drive

5. Conclusions

- The field experiment was carried out to investigate the in-service pavement stiffness and roughness of lightweight cellular concrete subbase pavements and compare them with traditional unbound materials subbase pavements. This was done by examining the deflections induced by a lightweight deflectometer to measure the pavement stiffness and a Surpro walking profiler to measure the pavement roughness over varying seasons. Based on these evaluations, the following conclusions have been made.

- The findings show that flexible pavements with LCC subbase thicknesses ≥ 250 mm could produce a 21% stiffer pavement structure compared with twice as thick unbound granular B subbase pavements. An increase of 36% in stiffness can occur when LCC thickness increases by 100 mm. Pavement stiffness was also noted to increase with LCC layer density and over time. LCC subbase thickness ≥ 250 mm can produce over 22% smoother riding surfaces than unbound granular pavements. Time of testing, pavement temperature during testing, construction method, insufficient compaction, excessive truck traffic on LCC pavements before AC placement, and road gradient could influence LCC pavement stiffness.

- LCC thickness equal to 200 mm could yield over 20% smoother pavements for a 600 kg/m³ LCC subbase. While varying results were seen for 400 kg/m³ and 475 kg/m³ LCC subbase pavements compared to unbound subbase materials due to varying reasons discussed, it was evident that they may function comparably or better than conventional pavements. Factors influencing roughness progression in LCC pavements include environmental conditions, seasonal variations, road class, road function, road gradient, subgrade conditions, initial construction process, and practices (compaction, early vehicular traffic).

- It is recommended that pavement sections be monitored over a longer period and that a correlation between LWD and FWD testing be performed to further assess the pavement sections’ performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miller, H.; Cabral, C.; Kestler, M.; Berg, R.; Eaton, R. Calibration of a Freeze-Thaw Prediction Model for Spring Load Restriction Timing in Northern New England. In Proceedings of the 15th International Conference on Cold Regions Engineering, Quebec City, QC, Canada, 19–22 August 2012. [Google Scholar]

- Miller, H.J.; Cabral, C.; Kestler, M.A.; Berg, R. Aurora SPR-3 (042) Phase 1: Review of Seasonal Weight Restriction Models for Comparison and Demonstration Project. In Proceedings of the 94th Annual Meeting of the Transportation Research Board, Washington, DC, USA, 11–15 January 2015. [Google Scholar]

- Salour, F.A. Moisture Influence on Structural Behaviour of Pavements. Ph.D. Thesis, School of Architecture and the Built Environment, Royal Institute of Technology, Stockholm, Sweden, 2015. [Google Scholar]

- Tighe, S.L.; Cowe Falls, L.; Haas, R.; MacLeod, D. Climate Impacts and Adaptations on Roads in Northern Canada. In Proceedings of the 85th Annual Meeting of the Transportation Research Board, Washington, DC, USA, 22–26 January 2006. [Google Scholar]

- Huang, Y.; Molavi Nojumi, M.; Hashemian, L.; Bayat, A. Performance evaluation of different insulating materials using field temperature and moisture data. Transp. Res. Rec. 2021, 2675, 595–607. [Google Scholar] [CrossRef]

- Penner, E. Experimental pavement structures insulated with a polyurethane and extruded polystyrene foam. Phys. Snow Proc. 1967, 1, 1311–1322. [Google Scholar]

- Zhuo, Z. Design and Analysis of Flexible Insulated Pavement for Cold Region Applications. Ph.D. Thesis, Rowan University, Glassboro, NJ, USA, 2021. [Google Scholar]

- Ullah, S.; Jamal, A.; Almoshaogeh, M.; Alharbi, F.; Hussain, J. Investigation of Resilience Characteristics of Unbound Granular Materials for Sustainable Pavements. Sustainability 2022, 14, 6874. [Google Scholar] [CrossRef]

- Li, J.; Zhang, J.; Yang, X.; Zhang, A.; Yu, M. Monte Carlo simulations of deformation behaviour of unbound granular materials based on a real aggregate library. Int. J. Pavement Eng. 2023, 24, 2165650. [Google Scholar] [CrossRef]

- Oyeyi, A.G.; Ni, F.M.; Pickel, D.; Tighe, S. Lightweight Cellular Concrete as a Subbase Alternative in Pavements: Instrumentation Plan, Installation and Preliminary Results. In Proceedings of the Transportation Association of Canada and ITS Canada 2019 Joint Conference and Exhibition, Halifax, NS, Canada, 22–25 September 2019. [Google Scholar]

- Oyeyi, A.G. Lightweight Cellular Concrete as Flexible Pavement Subbase Material: Field Performance and Sustainability Study. Ph.D. Thesis, University of Waterloo, Waterloo, ON, Canada, 2022. [Google Scholar]

- Ni, F.M. Lightweight Cellular Concrete: Applicability of Pavement Subbase Layer Materials. Ph.D. Thesis, University of Waterloo, Waterloo, ON, Canada, 2021. [Google Scholar]

- Jones, M.R.; McCarthy, A. Preliminary views on the potential of foamed concrete as a structural material. Mag. Concr. Res. 2005, 57, 21–31. [Google Scholar] [CrossRef]

- Dolton, B.; Witchard, M.; Smith, T.J. Application of Lightweight Cellular Concrete to Reconstruction of Settlement Prone Roadways in Victoria. In Proceedings of the GEOVancouver 2016, Vancouver, BC, Canada, 20–23 September 2016. [Google Scholar]

- Jones, R.; Zheng, L.; Yerramala, A.; Rao, K.S. Use of recycled and secondary aggregates in foamed concretes. Mag. Concr. Res. 2012, 64, 513–525. [Google Scholar] [CrossRef]

- Jones, M.R.; McCarthy, A. Heat of hydration in foamed concrete: Effect of mix constituents and plastic density. Cem. Concr. Res. 2006, 36, 1032–1041. [Google Scholar] [CrossRef]

- Jones, M.R.; McCarthy, M.J.; McCarthy, A. Moving fly ash utilisation in concrete forward: A UK perspective. In Proceedings of the 2003 International Ash Utilization Symposium, Lexington, KY, USA, 20–22 October 2003. [Google Scholar]

- Gannakou, M.; Jones, M.R. Potential of foamed concrete to enhance the thermal performance of low-rise dwellings. In Innovations and Developments In Concrete Materials and Construction: Proceedings of the International Conference Held at the University of Dundee, Scotland, UK, 9–11 September 2002; Thomas Telford Publishing: London, UK, 2002; pp. 533–544. [Google Scholar]

- Kearsley, E.P.; Wainwright, P.J. The effect of high fly ash content on the compressive strength of foamed concrete. Cem. Concr. Res. 2001, 31, 105–112. [Google Scholar] [CrossRef]

- Ministry of Transportation Ontario (MTO). Pavement Design and Rehabilitation Manual, 2nd ed.; Materials Engineering and Research Office, Ministry of Transportation: North York, ON, Canada, 2013. [Google Scholar]

- Perera, R.W.; Al-Rawashdeh, A. Investigation of Increase in Roughness Due to Environmental Factors in Flexible Pavements Using Profile Data from Long-Term Pavement Performance Studies 1 Experiment; Publication FHWA-HRT-17-049. FHWA; U.S. Department of Transportation: Washington, DC, USA, 2017.

- Chatti, K.; Buch, N.; Haider, S.W.; Pulipaka, A.S.; Lyles, R.W.; Gilliland, D.; Deasaraju, P. LTPP Data Analysis, Influence of Design and Construction Features on the Response and Performance of New Flexible and Rigid Pavements; Web Document 74; National Cooperative Highway Research Program: Washington, DC, USA, 2005. [Google Scholar]

- Stoffels, S.M.; Lee, S.W.; Bae, A. Observed Effects of Subgrade Moisture on Longitudinal Profile. In Proceedings of the 85th Annual Meeting of the Transportation Research Board, Washington, DC, USA, 22–26 January 2006. [Google Scholar]

- Tighe, S.; Haas, R.; Li, N. Overlay Performance in the Canadian Strategic Highway Program LTPP Study. Transp. Res. Rec. J. Transp. Res. Board 2001, 1778, 191–200. [Google Scholar] [CrossRef]

- Lu, P.; Tolliver, D. Pavement Pre- and Post-Treatment Performance Models Using LTPP Data. J. Transp. Res. Forum 2012, 51, 67–81. [Google Scholar]

- Von Quintus, H.L.; Eltahan, A.; Yau, A. Smoothness Models for Hot-Mix Asphalt-Surfaced Pavements: Developed from Long-Term Pavement Performance Program Data. Transp. Res. Rec. J. Transp. Res. Board 2001, 1764, 139–156. [Google Scholar] [CrossRef]

- Pickel, D.J. Precast Concrete Inlay Panels: Rehabilitation Strategy for High-Volume Highways in Ontario. Ph.D. Thesis, University of Waterloo, Waterloo, ON, USA, 2018. [Google Scholar]

- Sayers, M.W.; Gillespie, T.D.; Paterson, W.D. Guidelines for Conducting and Calibrating Road Roughness Measurements; The World Bank Technical Report 46; Transportation Research Institute: Washington, DC, USA, 1986. [Google Scholar]

- El Khoury, J.; Akle, B.; Katicha, S.; Ghaddar, A.; Daou, M. A microscale evaluation of pavement roughness effects for asset management. Int. J. Pavement Eng. 2014, 15, 323–333. [Google Scholar] [CrossRef]

- Li, Q.; Qiao, F. Clustering Pavement Roughness Based on the Impacts on Vehicle Emissions and Public Health. J. Ergon. 2016, 6, 1000146. [Google Scholar] [CrossRef]

- Li, Q.; Qiao, F.; Yu, L. Impacts of pavement types on in-vehicle noise and human health. J. Air Waste Manag. Assoc. 2016, 66, 87–96. [Google Scholar] [CrossRef] [PubMed]

- Zaabar, I.; Chatti, K. Estimating vehicle operating costs caused by pavement surface conditions. Transp. Res. Rec. J. Transp. Res. Board 2014, 2414, 63–76. [Google Scholar] [CrossRef]

- Hettiarachchi, C.; Yuan, J.; Amirkhanian, S.; Xiao, F. Measurement of Pavement Unevenness and Evaluation Through the IRI Parameter—An Overview. Measurement 2022, 206, 112284. [Google Scholar] [CrossRef]

- Sayers, M.W.; Karamihas, S.M. The Little Book of Profiling: Basic Information About Measuring and Interpreting Road Profiles; Transportation Research Institute, University of Michigan: Ann Arbor, MI, USA, 1998; Available online: https://deepblue.lib.umich.edu/bitstream/handle/2027.42/21605/90151.pdf (accessed on 3 July 2022).

- Ministry of Transportation Ontario (MTO). Ontario’s Default Parameters for AASHTOWare Pavement ME Design. Interim Report; 2019. Available online: https://www.library.mto.gov.on.ca/SydneyPLUS/Sydney/Portal/default.aspx?component=AAAAIY&record=89a3febc-f471-4f73-8f3b-4a5c52068874 (accessed on 1 August 2022).

- Taha, M.; Hardwiyono, S.; Yusoff, N.; Hainin, M.; Wu, J.; Nayan, K. Study of the Effect of Temperature Changes on the Elastic Modulus of Flexible Pavement Layers. Res. J. Appl. Sci. Eng. Technol. 2013, 5, 1661–1667. [Google Scholar] [CrossRef]

- Zakaria, N.M.; Yusoff, N.I.M.; Hardwiyono, S.; Mohd Nayan, K.A.; El-Shafie, A. Measurements of the stiffness and thickness of the pavement asphalt layer using the enhanced resonance search method. Sci. World J. 2014, 2014, 195960. [Google Scholar] [CrossRef]

- Jiang, X.; Gabrielson, J.; Huang, B.; Bai, Y.; Polaczyk, P.; Zhang, M.; Hu, W.; Xiao, R. Evaluation of inverted pavement by structural condition indicators from falling weight deflectometer. Constr. Build. Mater. 2022, 319, 125991. [Google Scholar] [CrossRef]

- Stehlik, D.; Hyzl, P.; Dasek, O.; Malis, L.; Kaderka, R.; Komenda, R.; Varaus, M. Comparison of Unbound Granular Materials’ Resilient Moduli Determined by Cyclic Triaxial Test and Innovative FWD Device. Appl. Sci. 2022, 12, 5673. [Google Scholar] [CrossRef]

- Mallick, R.B.; El-Korchi, T. Pavement Engineering: Principles and Practice, 1st ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- American Association of State Highway and Transportation Officials. AASHTO TP 62-07 Standard Method of Test for Determining Dynamic Modulus of Hot Mix Asphalt (HMA); American Association of State and Highway Transportation Officials: Washington, DC, USA, 2007. [Google Scholar]

- ASTM D 1883; Standard Test Methods for California Bearing Ratio (CBR) of Laboratory-Compacted Soils. ASTM International: West Conshohocken, PA, USA, 2021.

- American Association of State Highway and Transportation Officials (AASHTO). Mechanistic-Empirical Pavement Design Guide: A Manual Practice; AASHTO: Washington, DC, USA, 2008. [Google Scholar]

- ASTM C469/C469M; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2014.

- TAC. Pavement Asset Design and Management Guide; Transportation Association of Canada: Ottawa, ON, Canada, 2013. [Google Scholar]

- Federal Highway Authority (FHWA). Bridges and Structures; U.S Department of Transportation: Washington, DC, USA, 2022. Available online: https://www.fhwa.dot.gov/engineering/geotech/pubs/05037/05b.cfm (accessed on 22 July 2022).

- Perera, R.W.; Kohn, S.D.; Rada, G.R. LTPP Manual for Profile Measurements and Processing; FHWA-HRT-08-056; U.S. Department of Transportation: Washington, DC, USA, 2008.

- Hossain, M.S.; Apeagyei, A.K. Evaluation of the Lightweight Deflectometer for In-Situ Determination of Pavement Layer Moduli; No. VTRC 10-R6; Virginia Transportation Research Council: East Liberty, OH, USA, 2010. [Google Scholar]

- Oyeyi, A.G.; Ni, F.M.; Tighe, S. In-situ structural analysis of lightweight cellular concrete subbase flexible pavements. Road Mater. Pavement Des. 2023. [Google Scholar] [CrossRef]

- Ni, F.M.; Oyeyi, A.G.; Tighe, S. Structural capacity evaluation of lightweight cellular concrete for flexible pavement subbase. Road Mater. Pavement Des. 2021, 23, 1–17. [Google Scholar] [CrossRef]

- Zuo, G.; Drumm, E.C.; Meier, R.W. Environmental effects on the predicted service life of flexible pavements. J. Transp. Eng. 2007, 133, 47–56. [Google Scholar] [CrossRef]

| Location | Material | Modulus (MPa) | Poisson’s Ratio | ||

|---|---|---|---|---|---|

| Average | Std Dev | Average | Std. Dev | ||

| Erbsville | HL3 (21 °C, 5 Hz) | 5716 | 310 | - | - |

| HL4 (21 °C, 5 Hz) | 5545 | 228 | - | - | |

| Granular A | 226 | 34 | - | - | |

| Granular B | 145 | 37 | - | - | |

| 475 kg/m³ | 1207 | 117 | 0.24 | 0 | |

| Subgrade | 72 | 15 | |||

| Notre Dame | SP 19.0 | 3511 | 87 | - | - |

| Granular A | 387 | 53 | - | - | |

| 400 kg/m³ | 888 | 107 | 0.21 | 5 | |

| 475 kg/m³ | 1188 | 241 | 0.3 | 14 | |

| 600 kg/m³ | 1391 | 44 | 0.26 | 24 | |

| Subgrade | 43 | 3 | - | - | |

| Section Relationship | Section Mean Difference | |||||||

|---|---|---|---|---|---|---|---|---|

| Sep-21 | Feb-22 | Apr-22 | Jun-22 | |||||

| RWP | LWP | RWP | LWP | RWP | LWP | RWP | LWP | |

| Control-LCC400 | 490 | 103 | 186 | 141 | ||||

| Control-LCC475 | 92 | 441 | 179 | 108 | 142 | 117 | 199 | |

| Control-LCC600 | 42 | 26 | 645 | 20 | 105 | 88 | 191 | |

| LCC400-LCC475 | 48 | 51 | 222 | 311 | 101 | 39 | 69 | 59 |

| LCC400-LCC600 | 18 | 58 | 2 | 98 | 50 | |||

| LCC475-LCC600 | 50 | 32 | 204 | 369 | 88 | 37 | 29 | 8 |

| LSD Criteria | 70 | 54 | 504 | 563 | 133 | - | - | - |

| p-value | 0.000 | 0.000 | 0.007 | 0.041 | 0.002 | 0.415 | 0.153 | 0.134 |

| Section | Southbound Section Mean IRI (m/km) | |||

|---|---|---|---|---|

| Sept 21 | Feb 22 | April 22 | June 22 (Baseline IRI) | |

| LCC600 | 1.17 | 1.34 | 1.46 | 1.36 |

| LCC475 | 1.13 | 1.43 | 1.62 | 1.60 |

| LCC400 | 1.71 | 2.37 | 2.34 | 1.33 |

| Control | 1.13 | 1.29 | 1.28 | 1.50 |

| Northbound Section Mean IRI (m/km) | ||||

| LCC600 | 1.23 | 2.00 | 1.28 | |

| LCC475 | 1.26 | 1.78 | 1.23 | |

| LCC400 | 1.50 | 1.50 | 1.82 | |

| Control | 1.33 | 1.18 | 1.68 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oyeyi, A.G.; Ni, F.M.-W.; Tighe, S. In-Service Performance Evaluation of Flexible Pavement with Lightweight Cellular Concrete Subbase. Appl. Sci. 2023, 13, 4757. https://doi.org/10.3390/app13084757

Oyeyi AG, Ni FM-W, Tighe S. In-Service Performance Evaluation of Flexible Pavement with Lightweight Cellular Concrete Subbase. Applied Sciences. 2023; 13(8):4757. https://doi.org/10.3390/app13084757

Chicago/Turabian StyleOyeyi, Abimbola Grace, Frank Mi-Way Ni, and Susan Tighe. 2023. "In-Service Performance Evaluation of Flexible Pavement with Lightweight Cellular Concrete Subbase" Applied Sciences 13, no. 8: 4757. https://doi.org/10.3390/app13084757

APA StyleOyeyi, A. G., Ni, F. M.-W., & Tighe, S. (2023). In-Service Performance Evaluation of Flexible Pavement with Lightweight Cellular Concrete Subbase. Applied Sciences, 13(8), 4757. https://doi.org/10.3390/app13084757