The Combined Effect of Calcium Chloride and Cement on Expansive Soil Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. General

2.1.2. Al-Qatif Clay

2.1.3. Calcium Chloride

2.1.4. Cement

2.2. Testing Methods

2.2.1. Selecting Cement Dose and Sample Preparation

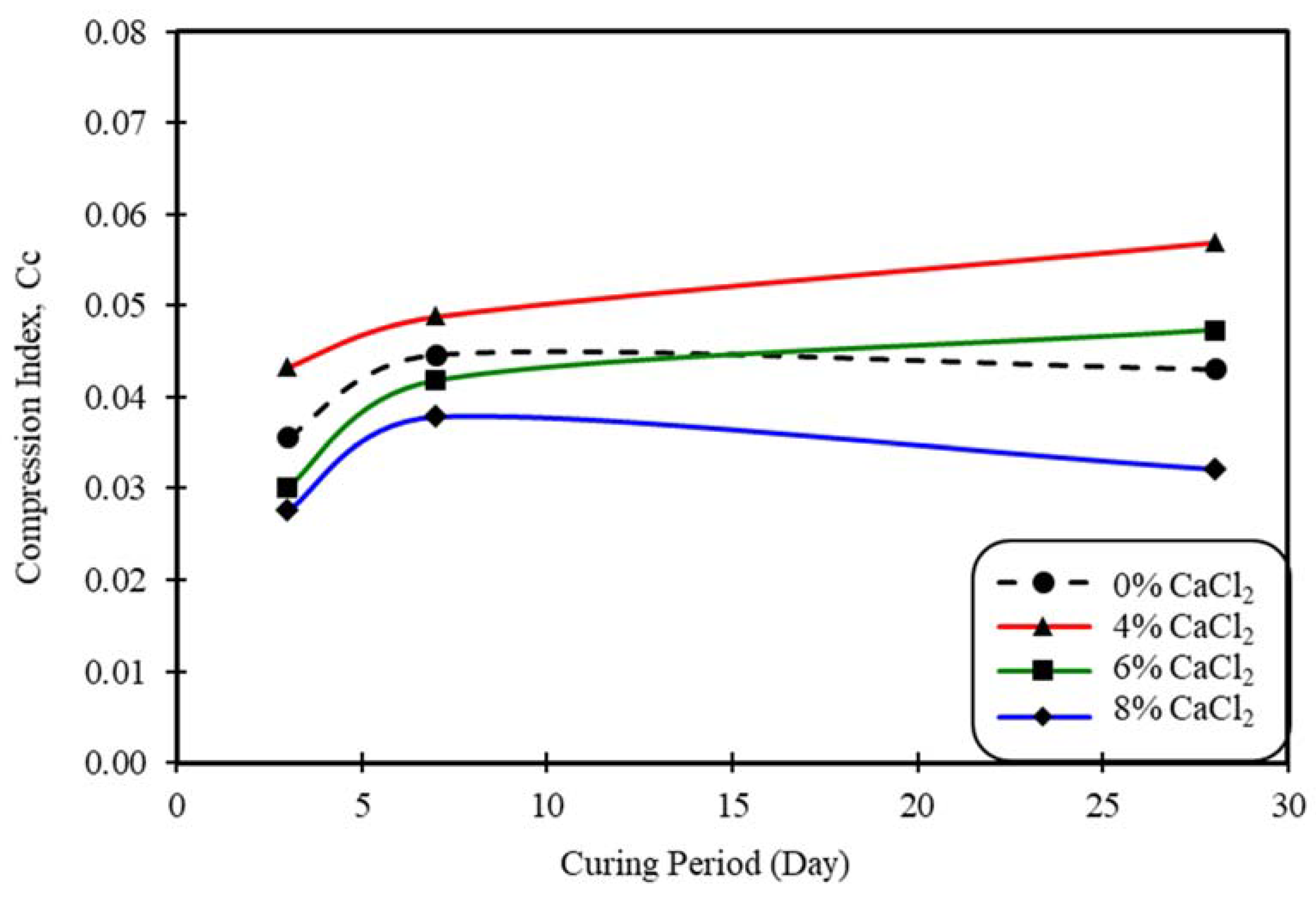

2.2.2. Oedometer Tests

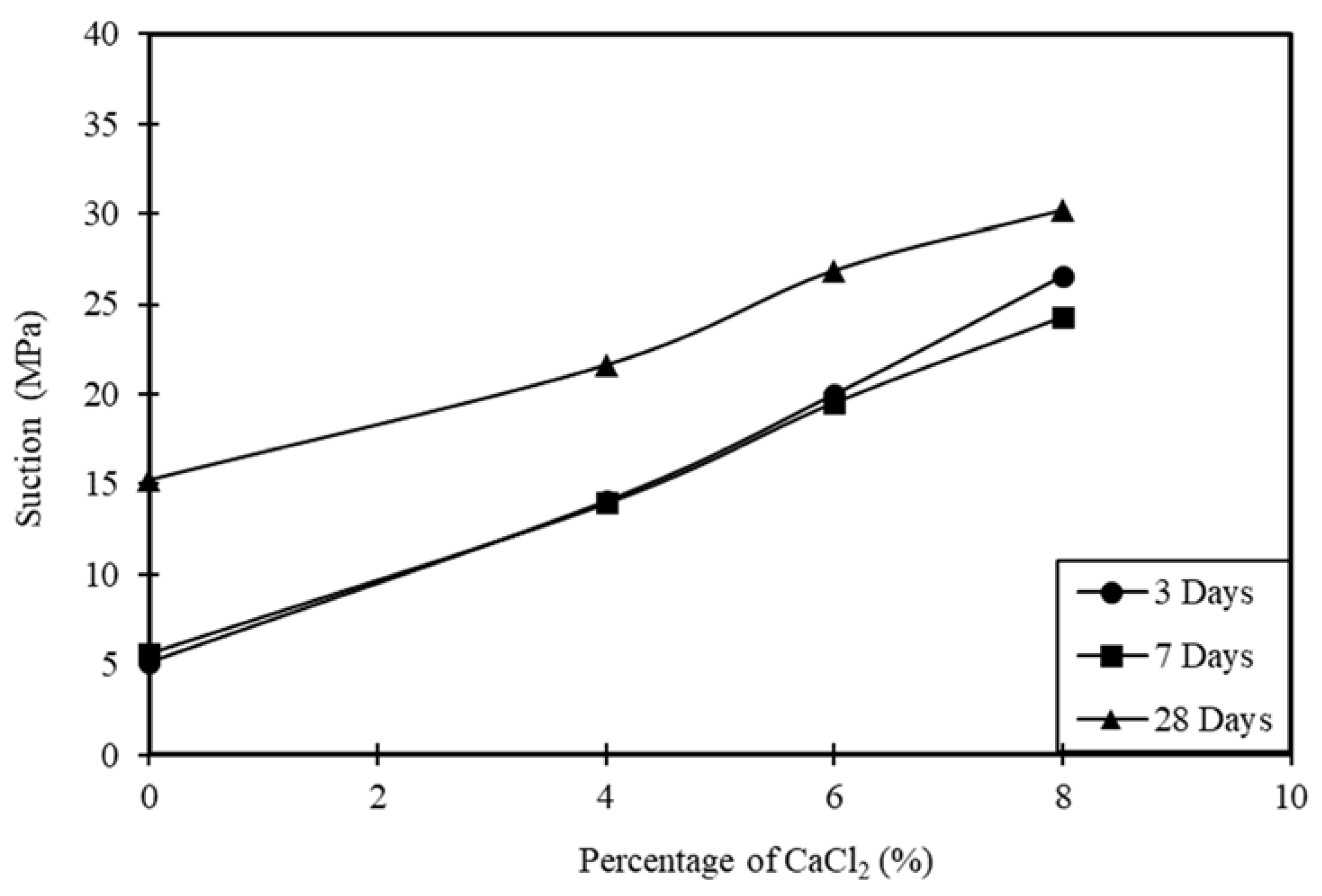

2.2.3. Soil Suction

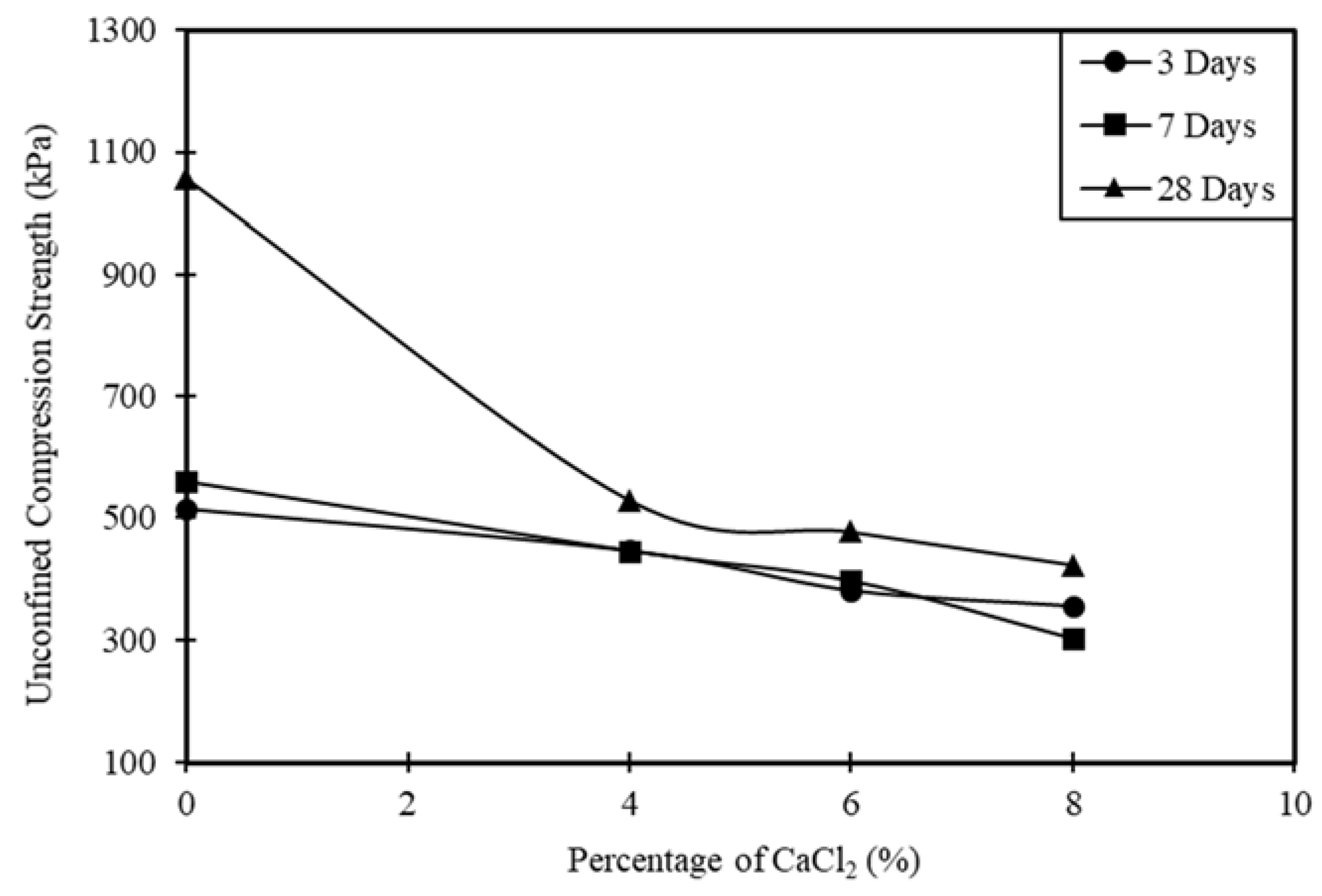

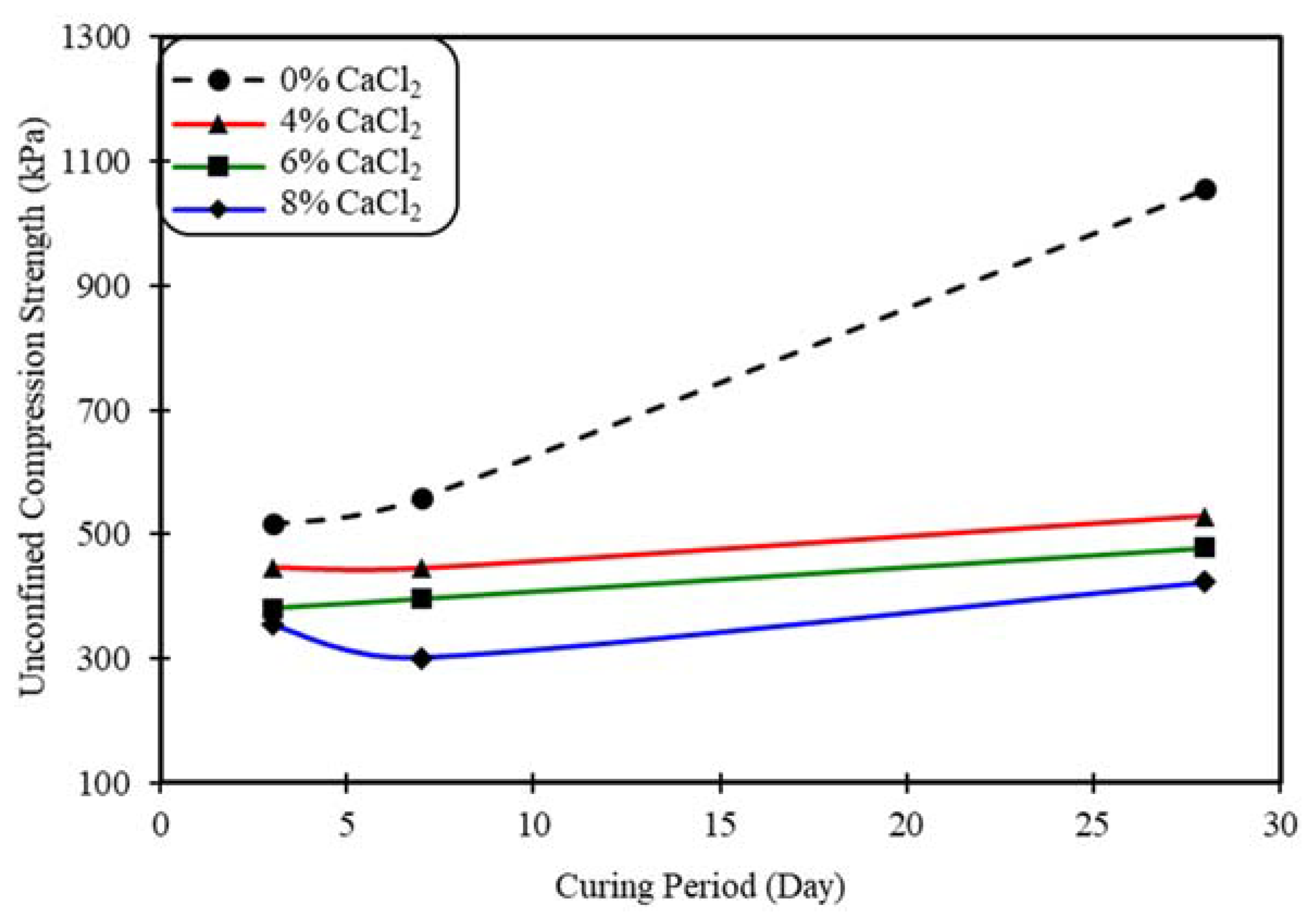

2.2.4. Unconfined Compression

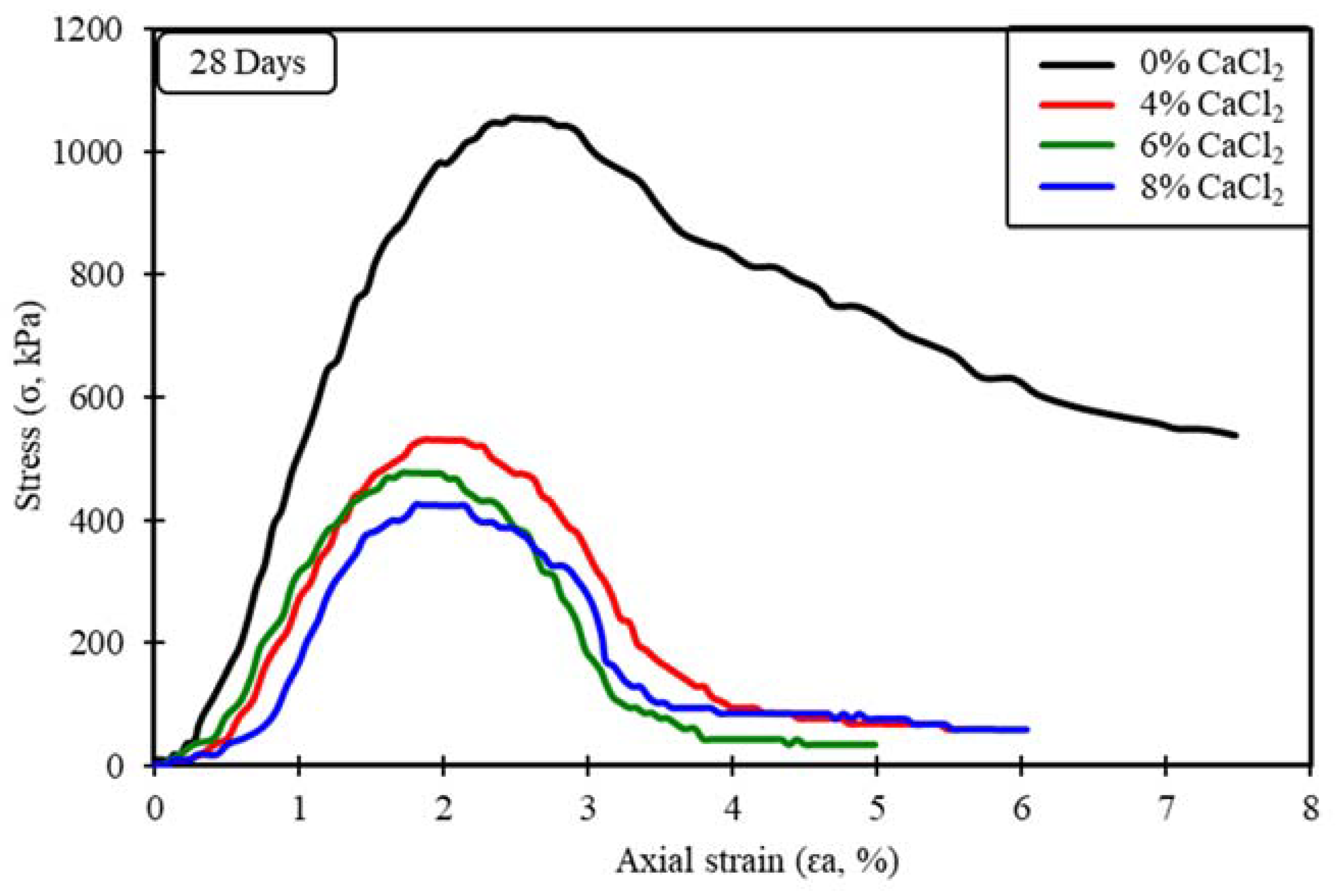

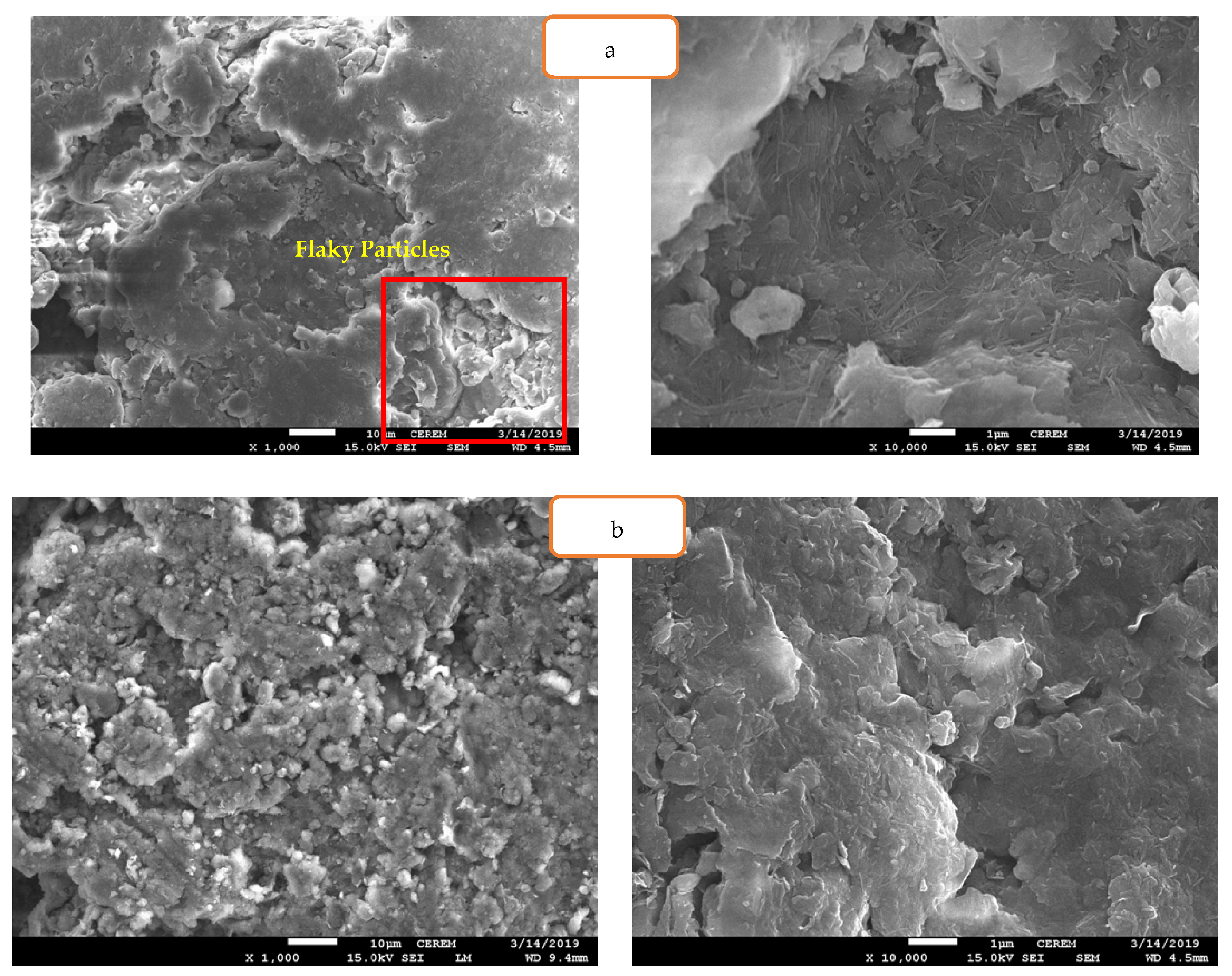

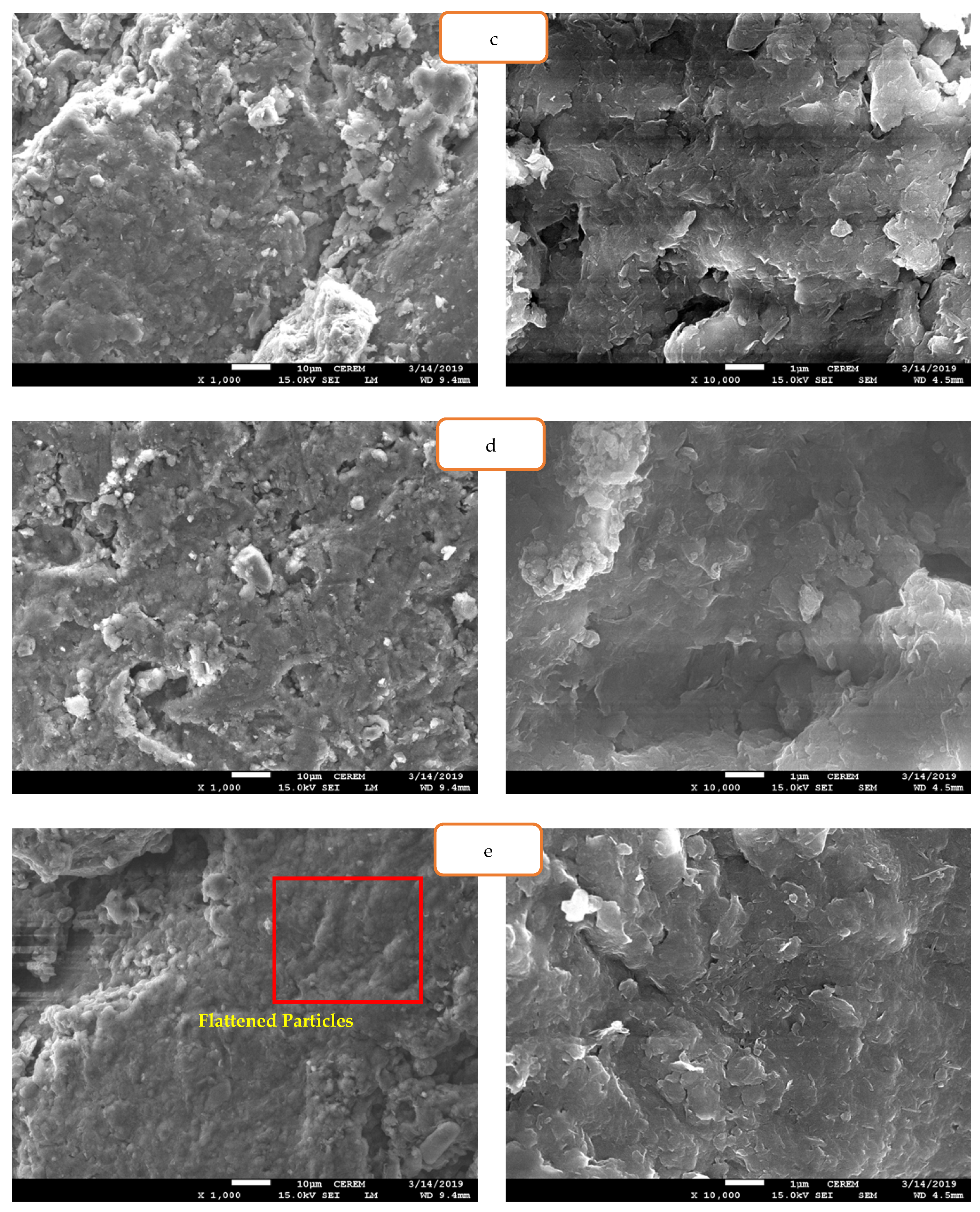

2.2.5. Scanning Electron Microscope

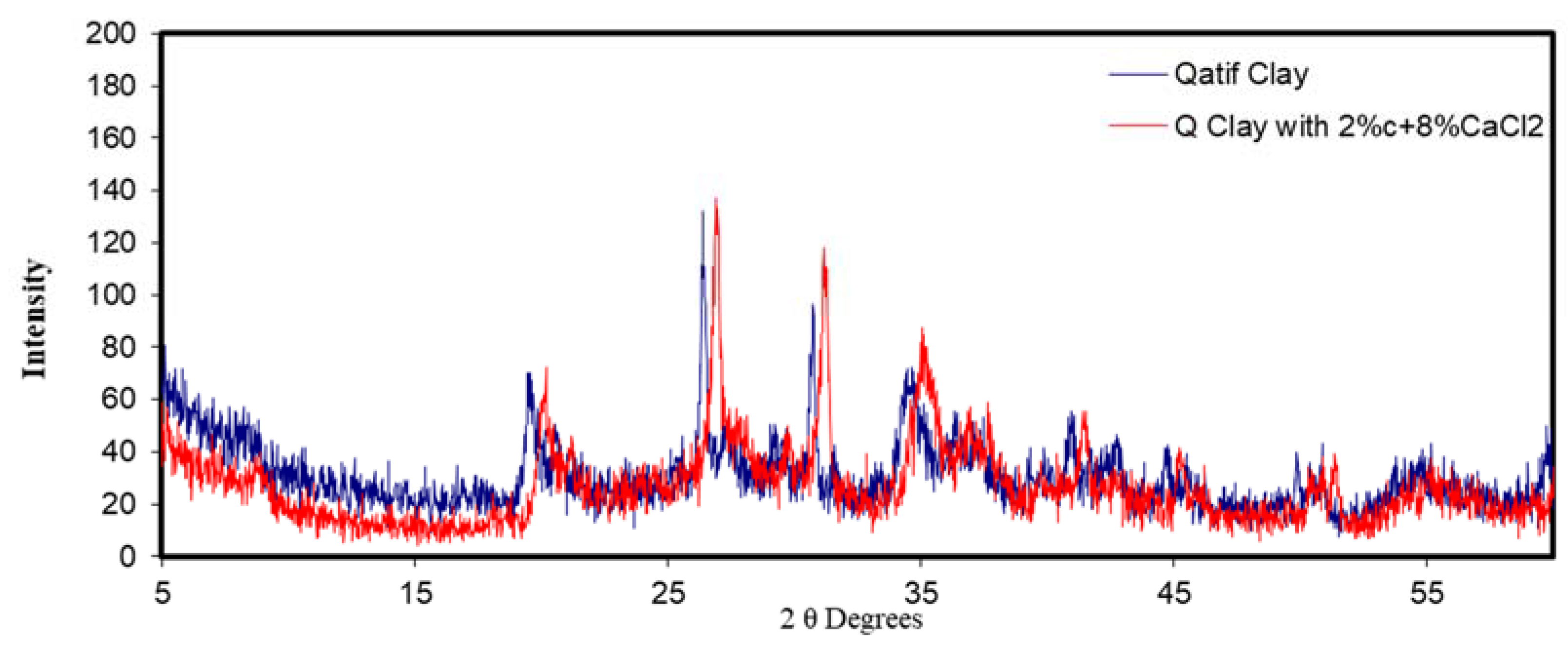

2.2.6. X-ray Diffraction

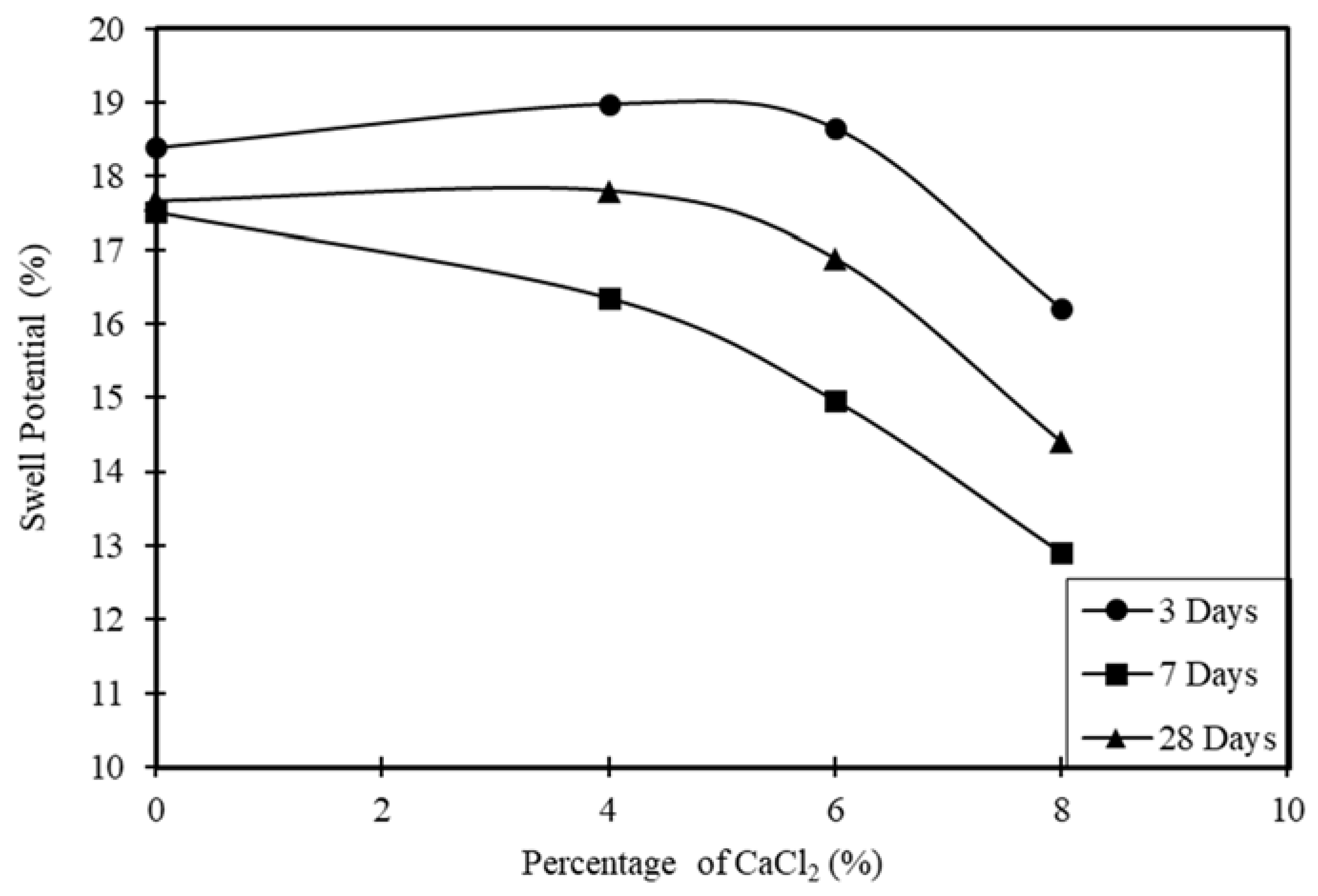

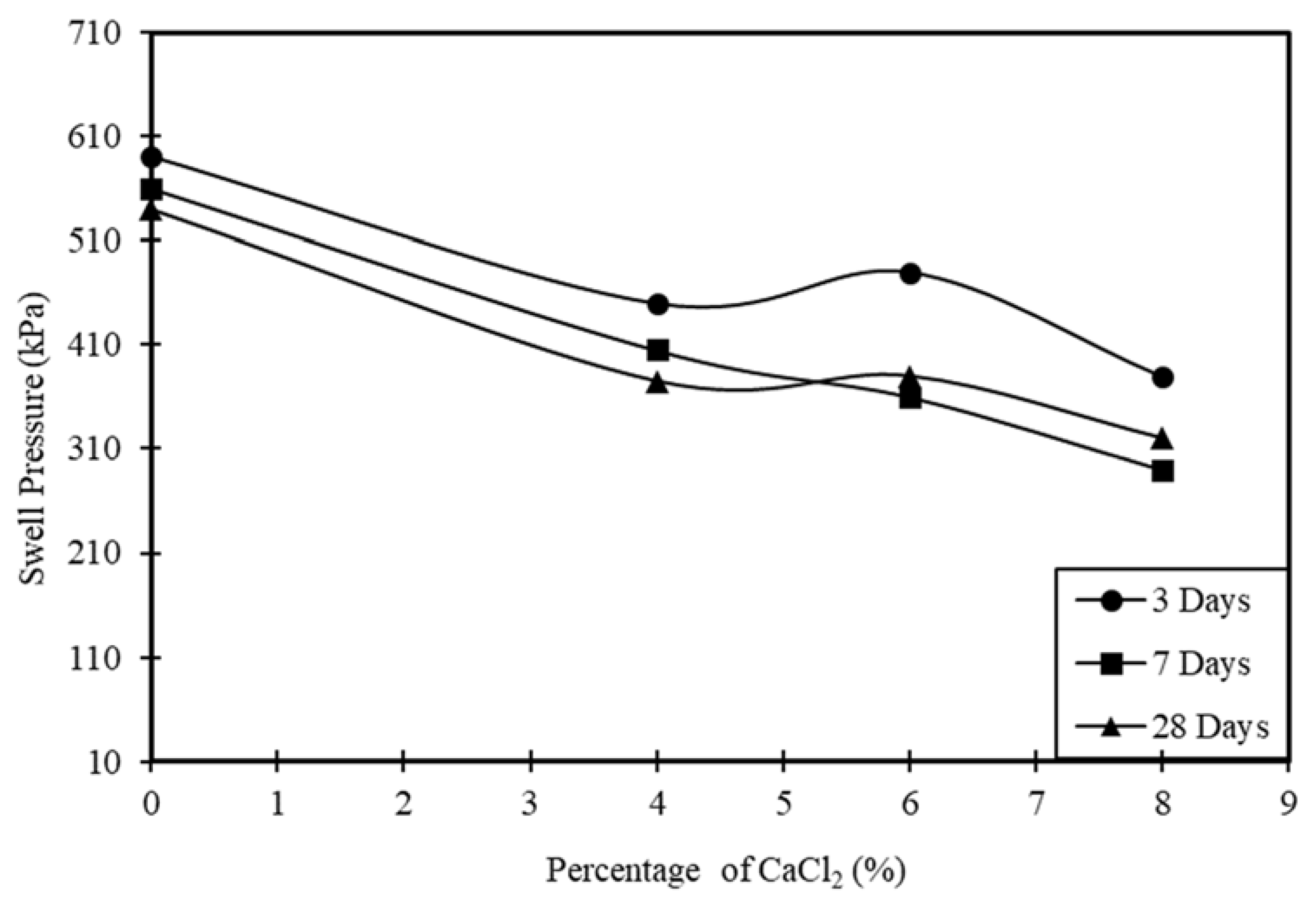

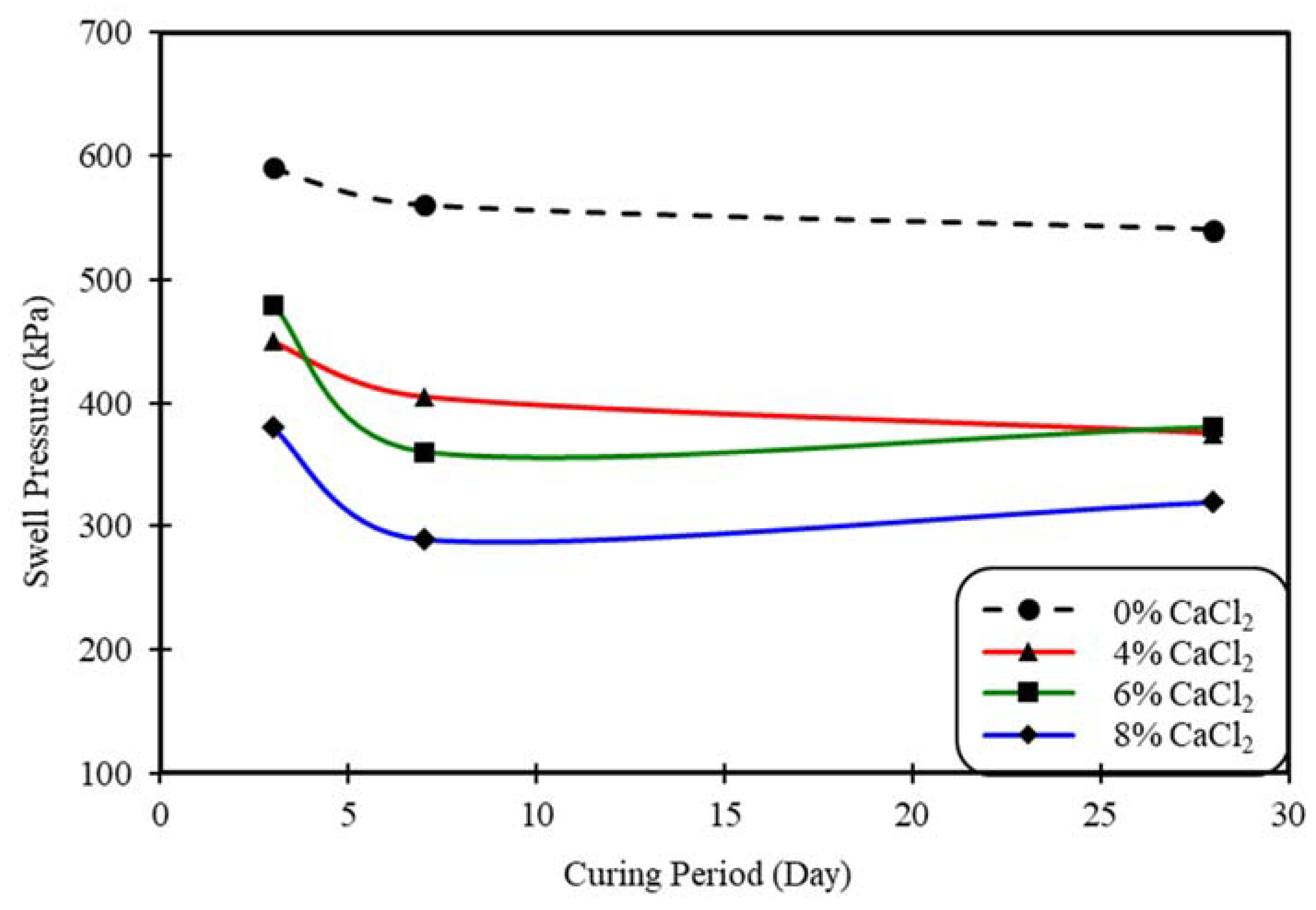

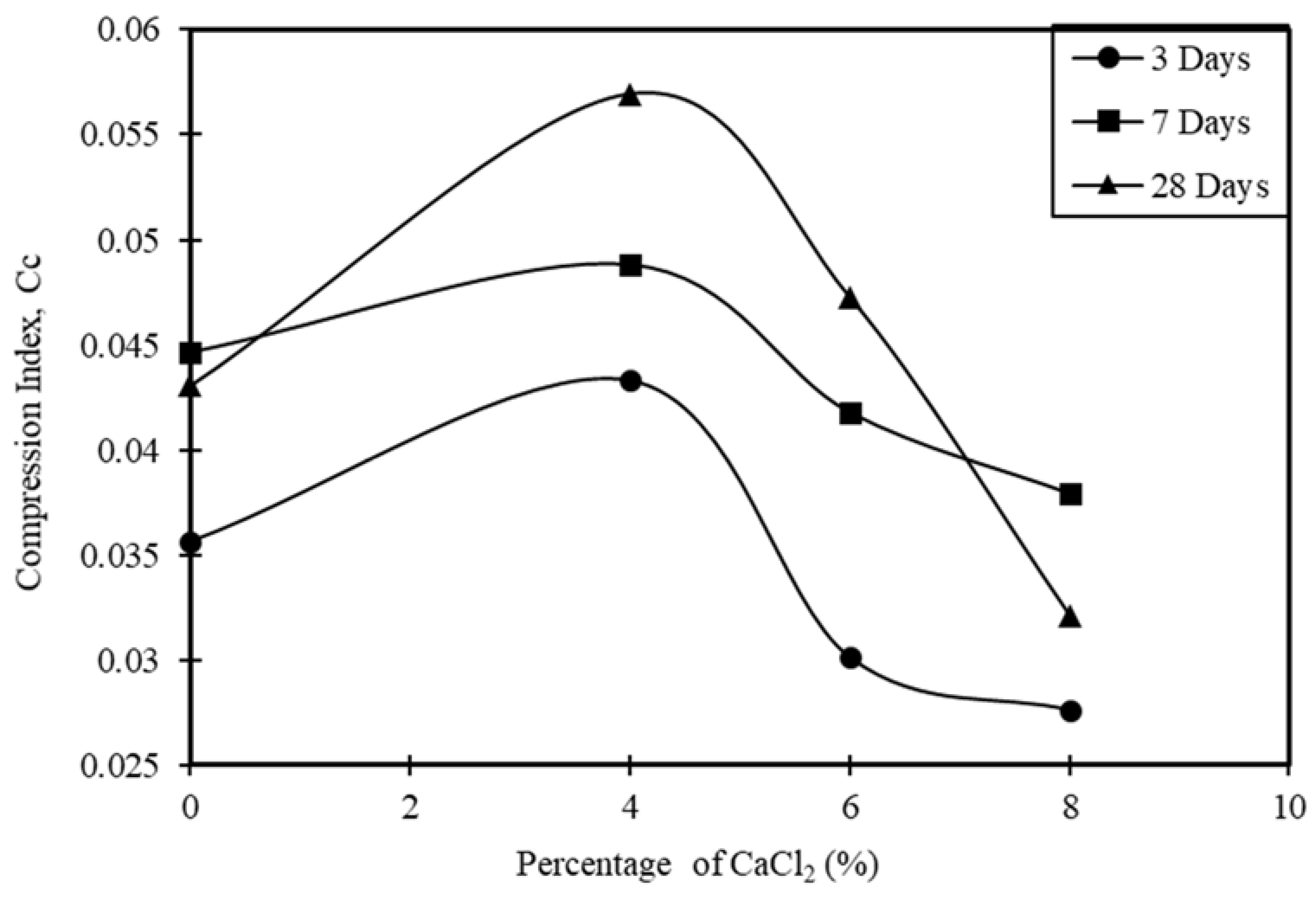

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- McDowell, C. Stabilization of soils with lime, lime-fly ash, and other lime reactive materials. High. Res. Board Bull. 1959, 231, 60–66. [Google Scholar]

- Sherwood, P. Soil Stabilization with Cement and Lime. State of the Art Review; Transport Research Laboratory, HMSO: London, UK, 1993. [Google Scholar]

- Liu, Z.Y.; Xue, Y.G.; Wang, X.J. Experimental study on mechanical behaviours of lime-stabilized soils with small lime content. Adv. Mater. Res. 2012, 374, 1823–1826. [Google Scholar]

- Wang, D.; Abriak, N.E.; Zentar, R. Strength and deformation properties of Dunkirk marine sediments solidified with cement, lime and fly ash. Eng. Geol. 2013, 166, 90–99. [Google Scholar] [CrossRef]

- Barman, D.; Dash, S.K. Stabilization of expansive soils using chemical additives: A review. J. Rock Mech. Geotech. Eng. 2022, 14, 1319–1342. [Google Scholar] [CrossRef]

- Eades, J.L.; Grim, R.E. A Quick Test to Determine Lime Requirements for Lime Stabilization. Highw. Res. Rec. 1966, 139, 61–72. [Google Scholar]

- U.S. Army Corps of Engineers. Soil Stabilization for Pavements; Technical Manual, TM 5-822-14; Department of the Army and Air Force of United States: Washington, DC, USA, 1994. Available online: https://wbdg.org/ffc/army-coe/technical-manuals-tm/tm-5-822-14 (accessed on 1 April 2023).

- Bell, F.G. Lime stabilization of clay minerals and soils. Eng. Geol. 1996, 42, 223–237. [Google Scholar] [CrossRef]

- Puppala, A.J.; Mohammad, L.N.; Allen, A. Engineering behavior of lime-treated Louisiana subgrade soil. Transp. Res. Rec. 1996, 1546, 24–31. [Google Scholar] [CrossRef]

- Puppala, A.J.; Wattanasanticharoen, E.; Hoyos, L.R. Ranking of four chemical and mechanical stabilization methods to treat low-volume road subgrades in Texas. Transp. Res. Rec. 2003, 1819, 63–71. [Google Scholar] [CrossRef]

- Puppala, A.J.; Talluri, N.S.; Chittoori, B.S.; Gaily, A. Lessons learned from sulfate induced heaving studies in chemically treated soils. In Proceedings of the Proceedings of the international conference on ground improvement and ground control. Res. Publ. 2012, 1, 85–98. [Google Scholar]

- Miller, G.A.; Zaman, M. Field and laboratory evaluation of cement kiln dust as a soil stabilizer. Transp. Res. Rec. 2000, 1714, 25–32. [Google Scholar] [CrossRef]

- Morse, J.W.; Arvidson, R.S.; Lüttge, A. Calcium carbonate formation, and dissolution. Chem. Rev. 2007, 107, 342–381. [Google Scholar] [CrossRef] [PubMed]

- Shon, C.-S.; Saylak, D.; Mishra, S.K. Combined use of calcium chloride and fly ash in road base stabilization. Transp. Res. Rec. 2010, 2186, 120–129. [Google Scholar] [CrossRef]

- Belabbaci, Z.; Mamoune, S.M.A.; Bekkouche, A. Laboratory Study of the Influence of Mineral Salts on Swelling (KCl, MgCl2). Earth Sci. Res. 2013, 2, 135. [Google Scholar] [CrossRef]

- Sasanian, S.; Newson, T.A. Basic parameters governing the behaviour of cement-treated clays. Soils Found. 2014, 54, 209–224. [Google Scholar] [CrossRef]

- Moghal, A.A.B.; Dafalla, M.A.; Elkady, T.Y.; Al-Shamrani, M.A. Lime leachability studies on stabilized expansive semi-arid soil. GEOMATE J. 2015, 9, 1467–1471. [Google Scholar]

- Zumrawi, M.M.E.; Mahjoub, A.M.M.; Alnour, I.M. Effect of some chloride salts on swelling properties of expansive soil. Univ. Khartoum Eng. J 2016, 6, 35–41. [Google Scholar]

- Zumrawi, M.M.E.; Eltayeb, K.A. Laboratory investigation of expansive soil stabilized with calcium chloride. Int. J. Environ. Chem. Ecol. Geol. Geophys. Eng. 2016, 10, 223–227. [Google Scholar]

- Saylak, D.; Mishra, S.K.; Mejeoumov, G.G.; Shon, C.-S. Fly ash-calcium chloride stabilization in road construction. Transp. Res. Rec. 2008, 2053, 23–29. [Google Scholar] [CrossRef]

- Murty, V.R.; Hari, K.P. Stabilisation of expansive clay bed using calcium chloride solution. Proc. Inst. Civ. Eng. Ground Improv. 2008, 10, 39–46. [Google Scholar] [CrossRef]

- Suresh, R.; Murugaiyan, V. Microstructural behavior of expansive soil using calcium chloride and alccofine. Mater. Today Proc. 2021, 46, 8397–8403. [Google Scholar] [CrossRef]

- Legas, S.K. Stabilization of Expansive Soil Using Cement Blended Pumice. Master’s Thesis, Addis Ababa Science and Technology University, Addis Ababa, Ethiopia, 2020. [Google Scholar]

- Al-Jabban, W.J. Soil Modification by Adding Small Amounts of Binders a Laboratory Study. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2019. [Google Scholar]

- Abduljauwad, S.N. Characteristics and chemical treatment of expansive clay in Al-Qatif, Saudi Arabia. Eng. Geol. 1991, 31, 143–158. [Google Scholar] [CrossRef]

- Azam, S. Influence of mineralogy on swelling and consolidation of soils in eastern Saudi Arabia. Can. Geotech. J. 2003, 40, 964–975. [Google Scholar] [CrossRef]

- Shamrani, M.A.; Mutaz, E.; Puppala, A.J.; Dafalla, M.A. Characterization of problematic expansive soils from mineralogical and swell characterization studies. In GeoFlorida 2010: Advances in Analysis, Modeling & Design; Fratta, D.O., Puppala, A.J., Muhunthan, B., Eds.; American Society of Civil Engineers: Reston, VA, USA, 2010; pp. 793–802. ISBN 9780784410950. [Google Scholar]

- Moghal, A.A.B.; Abbas, M.F.; Al-Mahbashi, A.M.; Shaker, A.A. Effect of structure anisotropy and compaction method on the swelling behavior of Al-qatif soil. Int. J. Geomate 2016, 11, 2600–2605. [Google Scholar] [CrossRef]

- Dafalla, M.A. The compressibility and swell of mixtures for sand-clay liners. Adv. Mater. Sci. Eng. 2017, 2017, 3181794. [Google Scholar] [CrossRef]

- Elkady, T.Y.; Shaker, A.A. Role of Cementation and Suction in the Swelling Behavior of Lime-Treated Expansive Soils. J. Mater. Civ. Eng. 2018, 30, 04018073. [Google Scholar] [CrossRef]

- Abbas, M.F.; Elkady, T.Y.; Aldrees, A.A.; Shaker, A.A. Impact of stress path on hydraulic and mechanical behavior of compacted Al-Qatif clay. Transp. Geotech. 2021, 26, 100417. [Google Scholar] [CrossRef]

- C150/C150M–16; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2015.

- Azmee, N.; Abbas, Y.M.; Shafiq, N.; Fares, G.; Osman, M.; Iqbal Khan, M. Enhancing the Microstructure and Sustainability of Ultra-High-Performance Concrete Using Ultrafine Calcium Carbonate and High-Volume Fly Ash under Different Curing Regimes. Sustainability 2021, 13, 3900. [Google Scholar] [CrossRef]

- Mutaz, E.; Dafalla, M.A.; Shamrani, M.A. Stabilization of Al-Ghatt Clay Shale by Using a Mixture of Lime and Cement. In Road Materials and New Innovations in Pavement Engineering, Proceedings of the GeoHunan International Conference 2011, Changsha, China, 9–11 June 2011; American Society of Civil Engineers: Reston, VA, USA, 2011. [Google Scholar] [CrossRef]

- D 4546–03; Standard Test Methods for One-Dimensional Swell or Settlement Potential of Cohesive Soils. ASTM International: West Conshohocken, PA, USA, 2003.

- Fathih, E.; Ali, M.; Muawia, A.D.; Elturabi. Comparison of Two Methods for the Measurement of Swelling Pressure. Barton, ACT. 1984. Available online: https://search.informit.org/doi/10.3316/informit.826800240387612 (accessed on 1 April 2023).

- Hunter, R.D. The Geochemistry of Lime-Induced Heave in Sulfate-Bearing Clay Soils; University of Nevada: Reno, NV, USA, 1989; ISBN 9798207684307. [Google Scholar]

- Ren, J.; Xue, Y.; Zhang, J.; Liu, B.; Luo, S.; Xu, S.; Xing, F.; Liu, M. Pre-treatment of reclaimed concrete slurry waste for substituting cementitious materials: Effect of treatment approach and substitution content. J. Clean. Prod. 2022, 380, 134987. [Google Scholar] [CrossRef]

- Ren, J.; Zhou, Q.-Z.; Yang, C.-H.; Bai, Y. Performance and interaction of sodium silicate activated slag with lignosulfonate superplasticizer added at different mixing stages. Cem. Concr. Compos. 2023, 136, 104900. [Google Scholar] [CrossRef]

- Dafalla, M. Effect of Fluid Chemistry on the Consolidation and Hydraulic Conductivity of Sand-Clay Liners. Sustainability 2021, 13, 11213. [Google Scholar] [CrossRef]

- Mutaz, D.E.; Shamrani, M.A.; Puppala, A.J.; Dafalla, M.A. Evaluation of chemical stabilization of a highly expansive clayey soil. Transp. Res. Rec. 2011, 2204, 148–157. [Google Scholar] [CrossRef]

- Muawia, D.; Mutaz, E.; Al-Shamrani, M. Compressive strength variations of lime-treated expansive soils. IFCEE 2015, 2015, 1402–1409. [Google Scholar]

- Choi, H.J. Soil Stabilization Using Optimum Quantity of Calcium Chloride with Class F Fly Ash. Master’s Thesis, Texas A&M University, College Station, TX, USA, 2005. [Google Scholar]

| Property | Range |

|---|---|

| Material passing sieve number 200 | >90% |

| Liquid Limit % | 130–150 |

| Plastic Limit % | 60–70 |

| Plasticity Index | 70–80 |

| Maximum Dry Density (kN/m3) | 11.5–12 |

| Optimum Moisture Content | 32–40% |

| Swell percent (ASTM D4546) | 16–18% |

| Swelling pressure (ASTM D4546) | 500–800 kN/m2 (γ = 12 kN/m3) |

| K+ (%) | K2O (%) | Al (%) | Al2O3 (%) | Si (%) | SiO2 (%) | Ca2+ (%) | CaO (%) |

|---|---|---|---|---|---|---|---|

| 1.8 | 2.2 | 3.3 | 6.3 | 8.1 | 17.3 | 0.7 | 0.9 |

| Oxides | Percentages |

|---|---|

| SiO2 | 19.97 |

| Al2O3 | 5.55 |

| Fe2O3 | 3.96 |

| TiO2 | 0.36 |

| MnO | 0.06 |

| MgO | 0.75 |

| CaO | 65.98 |

| Na2O | 0.08 |

| K2O | 0.13 |

| P2O5 | 0.05 |

| SO3 | 3.08 |

| L.O.I. | 4.00 |

| Chemical Compound | MgO (%) | Al2O3 (%) | SiO2 (%) | KCI (%) | CaSiO3 (%) | FeS2 (%) | Fe2O3 (%) | CaCO3 (%) |

|---|---|---|---|---|---|---|---|---|

| 0% CaCl2 | 4.23 | 6.79 | 22.8 | 0.31 | 5.91 | 0.6 | 5.63 | - |

| 4% CaCl2 | 3.65 | 6.48 | 22.07 | 2.27 | 6.04 | 0.86 | 4.72 | 3.16 |

| 6% CaCl2 | 3.92 | 6.43 | 21.53 | 2.97 | 6.48 | 0.9 | 5.21 | - |

| 8% CaCl2 | 3.63 | 5.83 | 19.5 | 3.6 | 6.21 | 0.67 | 4.58 | - |

| Item | Unit | Unit Price for Cement per Ton in USD | Unit Price for Calcium Chloride per Ton in USD | Estimated Cost of the Stabilizer in USD |

|---|---|---|---|---|

| Quantity of road volume to be stabilized | 1000 m3 | 150 | 110 | - |

| Weight of cement required for 2% stabilizer | 36,698 kg | 5504.7 | ||

| Weight of cement required for 4% dose | 73,396 kg | 11,009.4 | ||

| Weight of cement required for 6% dose | 110,094 kg | 16,514.1 | ||

| Weight of calcium chloride for 4% dose | 73,396 kg | 8073.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almajed, A.; Dafalla, M.; Shaker, A.A. The Combined Effect of Calcium Chloride and Cement on Expansive Soil Materials. Appl. Sci. 2023, 13, 4811. https://doi.org/10.3390/app13084811

Almajed A, Dafalla M, Shaker AA. The Combined Effect of Calcium Chloride and Cement on Expansive Soil Materials. Applied Sciences. 2023; 13(8):4811. https://doi.org/10.3390/app13084811

Chicago/Turabian StyleAlmajed, Abdullah, Muawia Dafalla, and Abdullah A. Shaker. 2023. "The Combined Effect of Calcium Chloride and Cement on Expansive Soil Materials" Applied Sciences 13, no. 8: 4811. https://doi.org/10.3390/app13084811

APA StyleAlmajed, A., Dafalla, M., & Shaker, A. A. (2023). The Combined Effect of Calcium Chloride and Cement on Expansive Soil Materials. Applied Sciences, 13(8), 4811. https://doi.org/10.3390/app13084811