Evaluation of Heating Inserts in Active Protective Clothing for Mountain Rescuers—Preliminary Tests

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Textile Materials

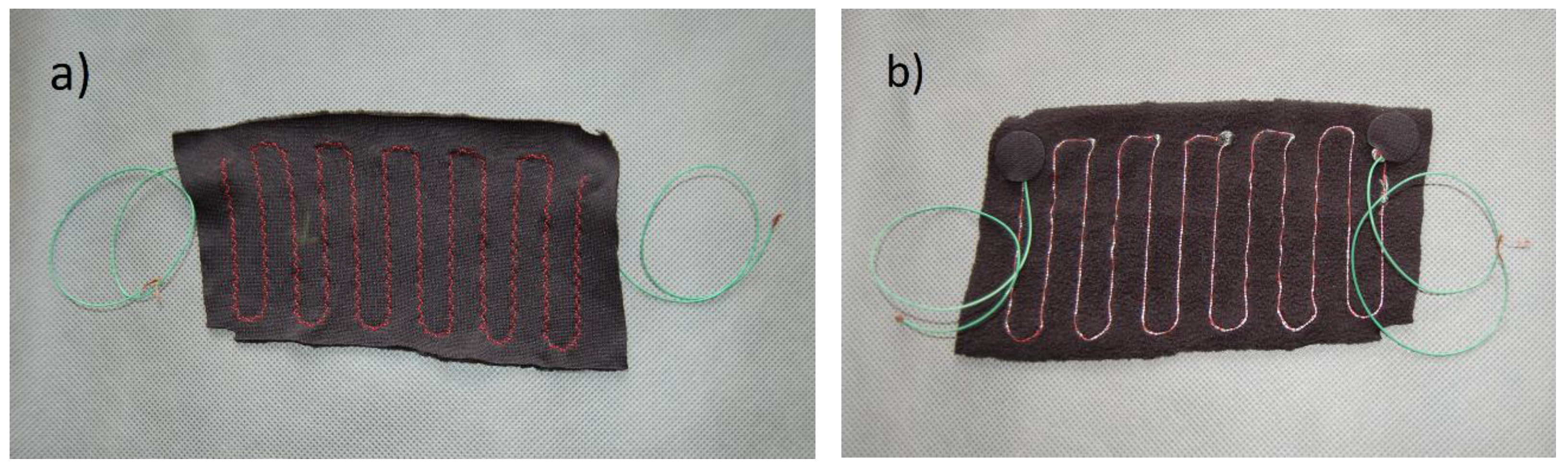

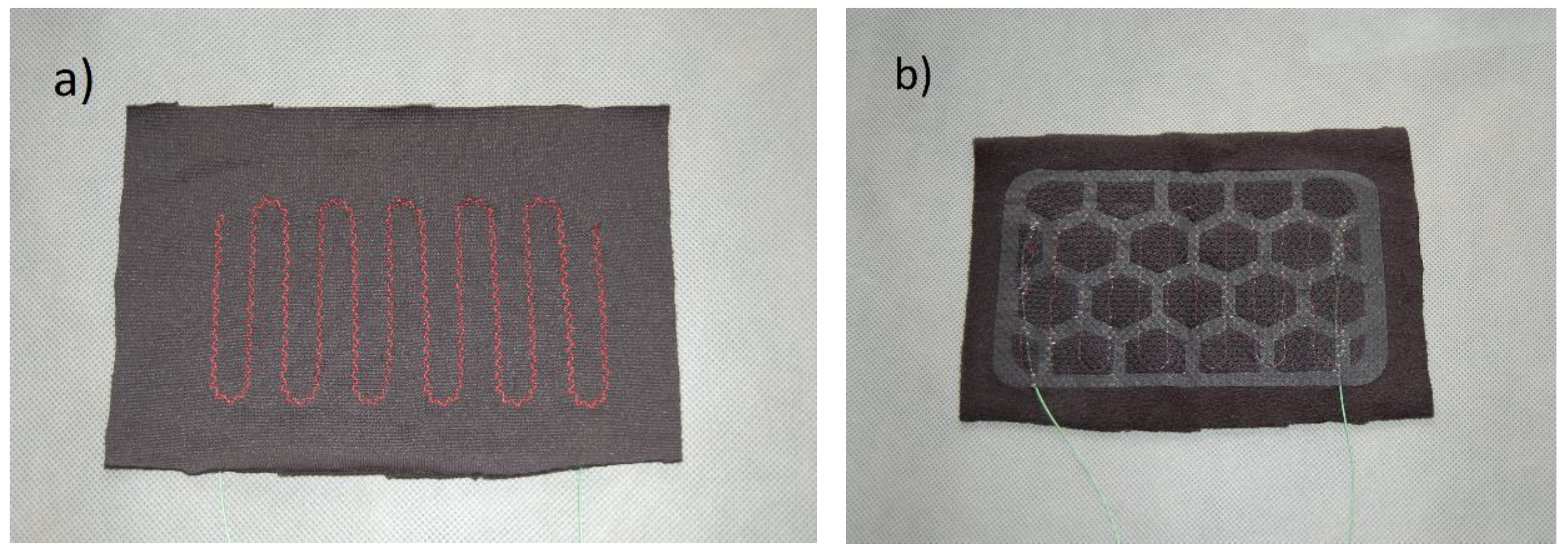

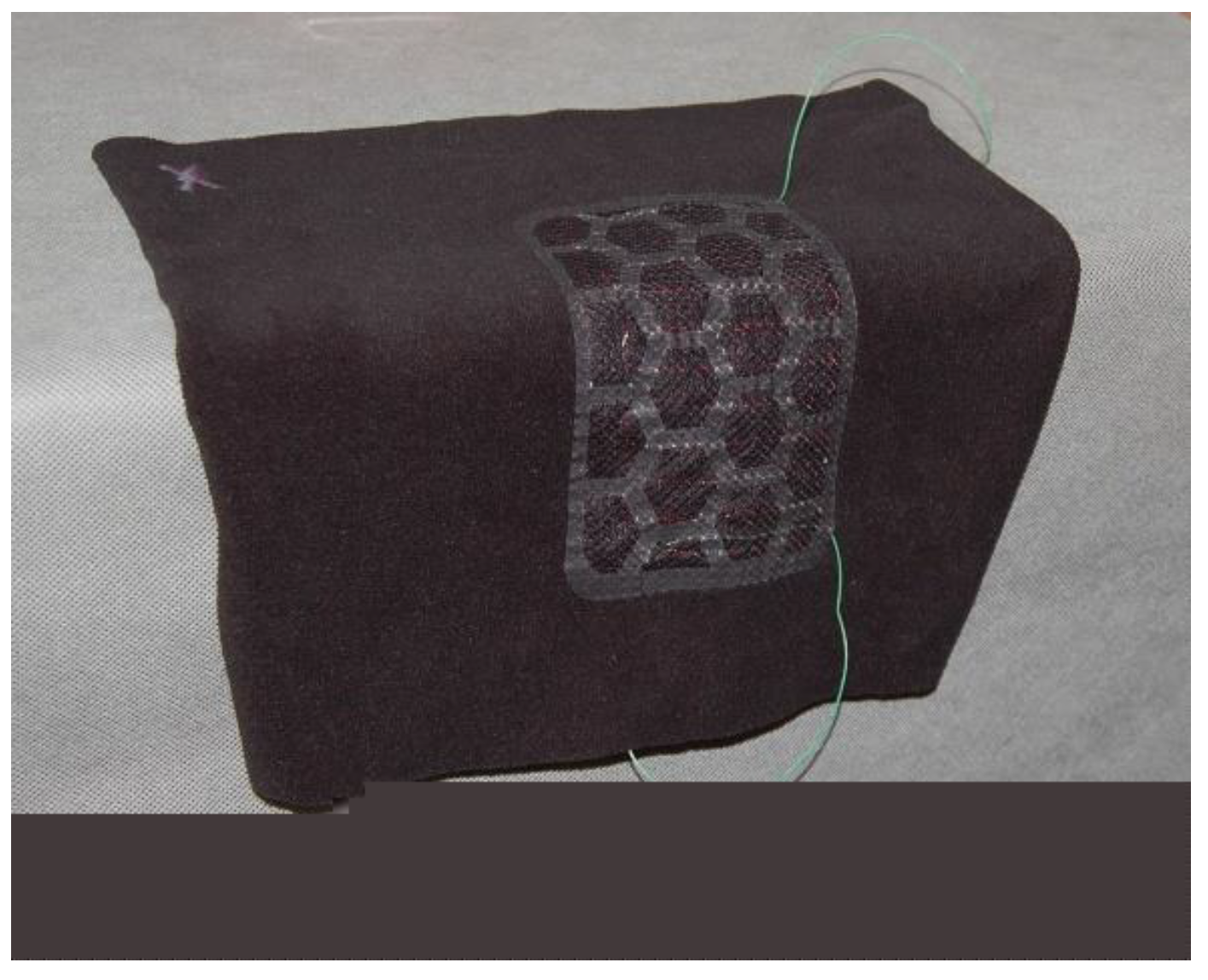

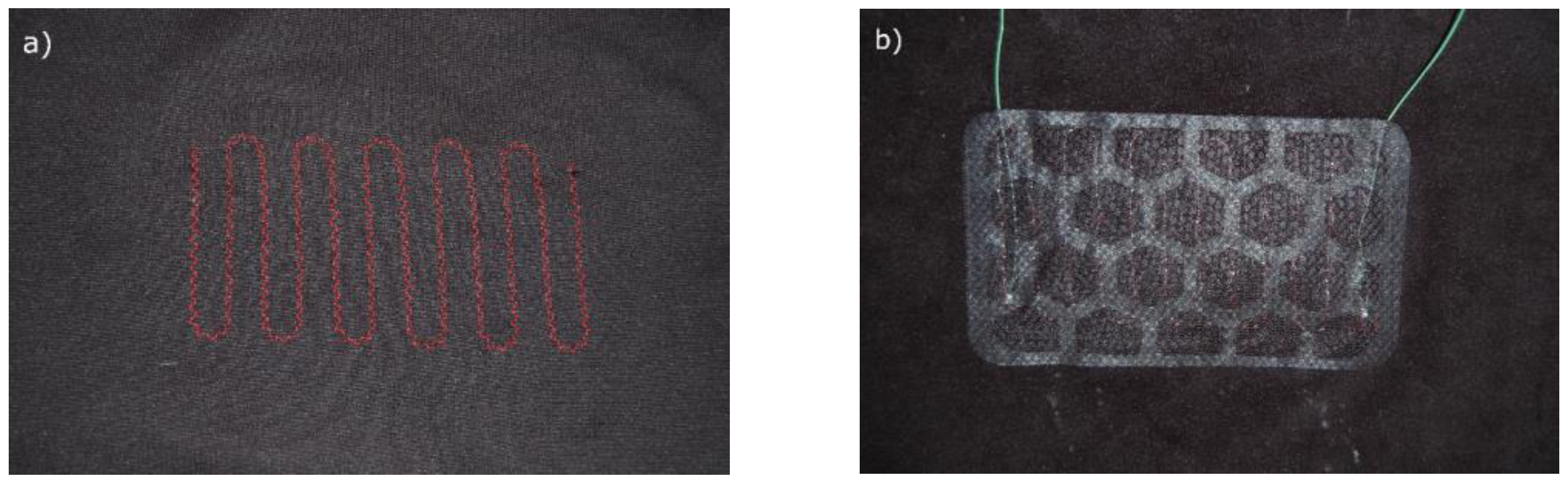

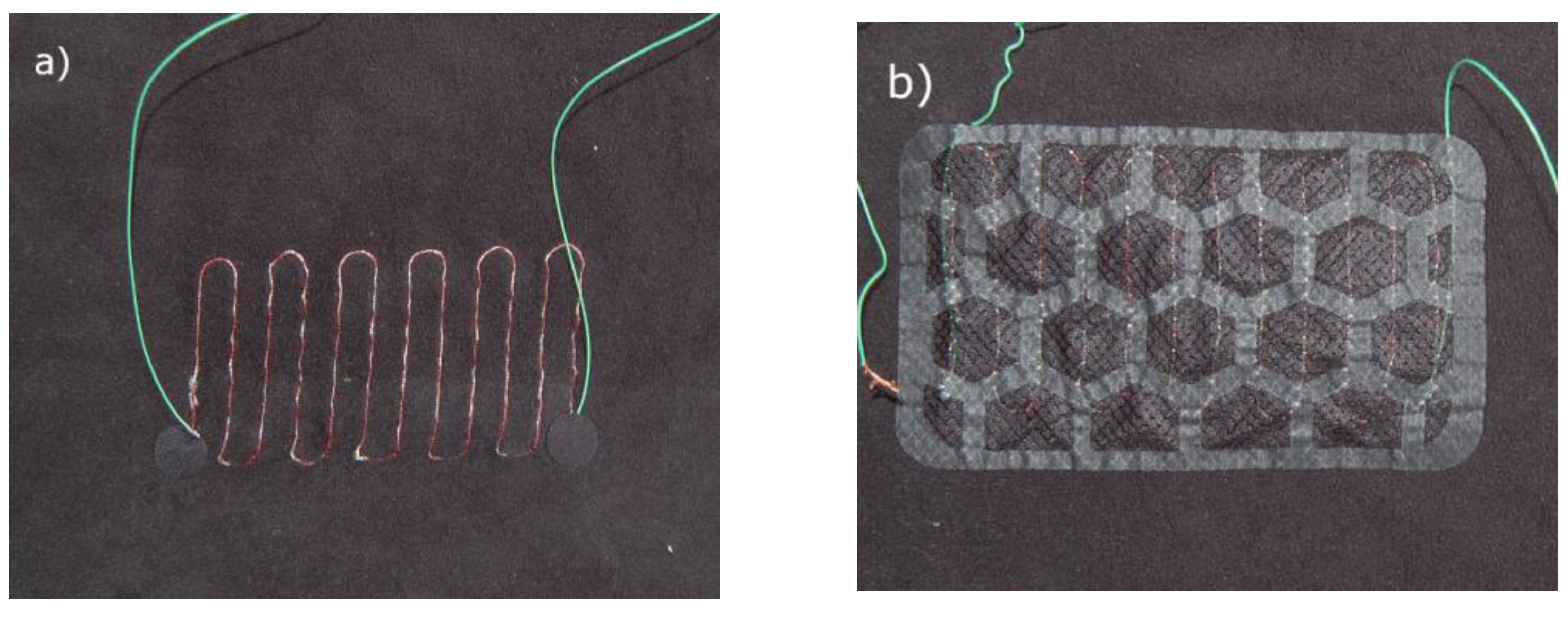

2.1.2. Preparation of Samples of Heating Inserts

2.2. Test Methods

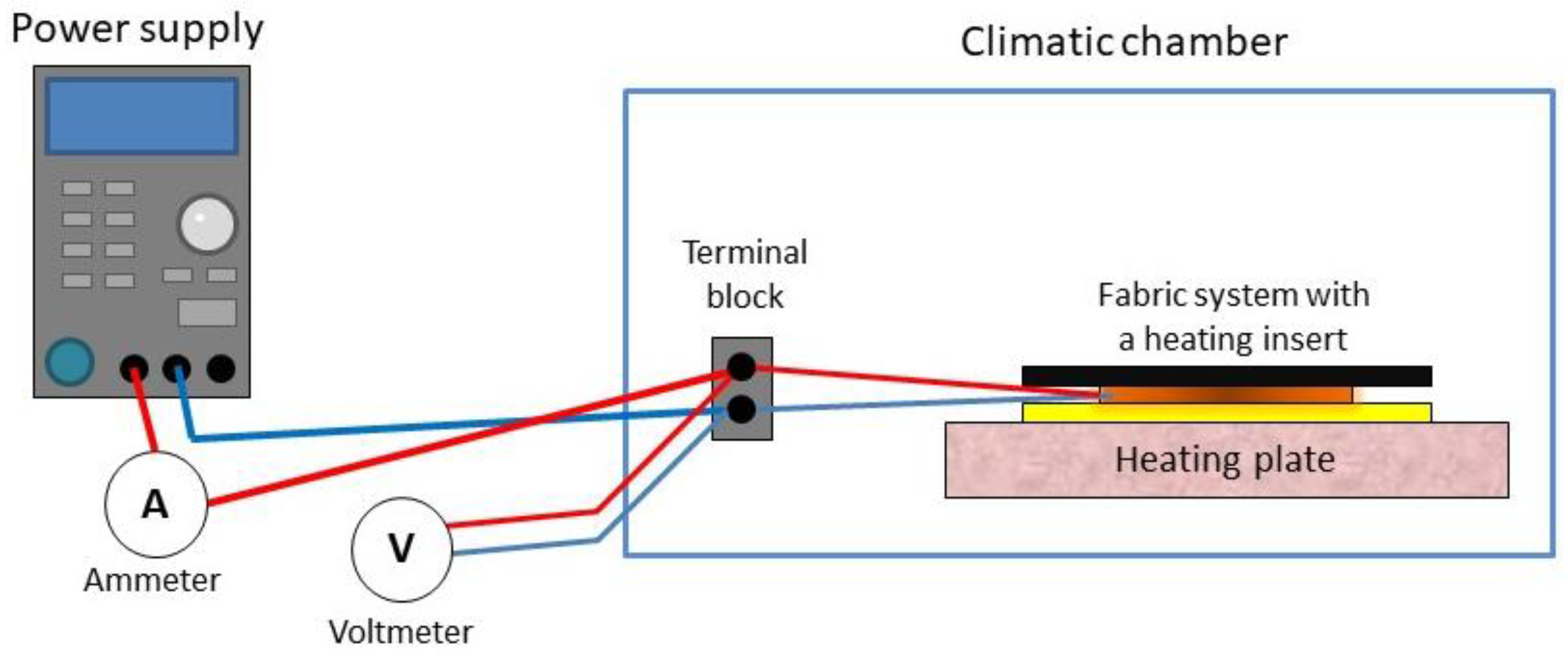

2.2.1. Thermal Resistance of the System of Materials with a Heating Insert and Electrical Parameters of the Heating Insert

2.2.2. Durability after Repeated Bending and Twisting

2.2.3. Durability against Multiple Washing

2.2.4. Durability against Artificial Sweat

2.2.5. Temperature between the Layers of the Material System with a Heating Insert

3. Results and Discussion

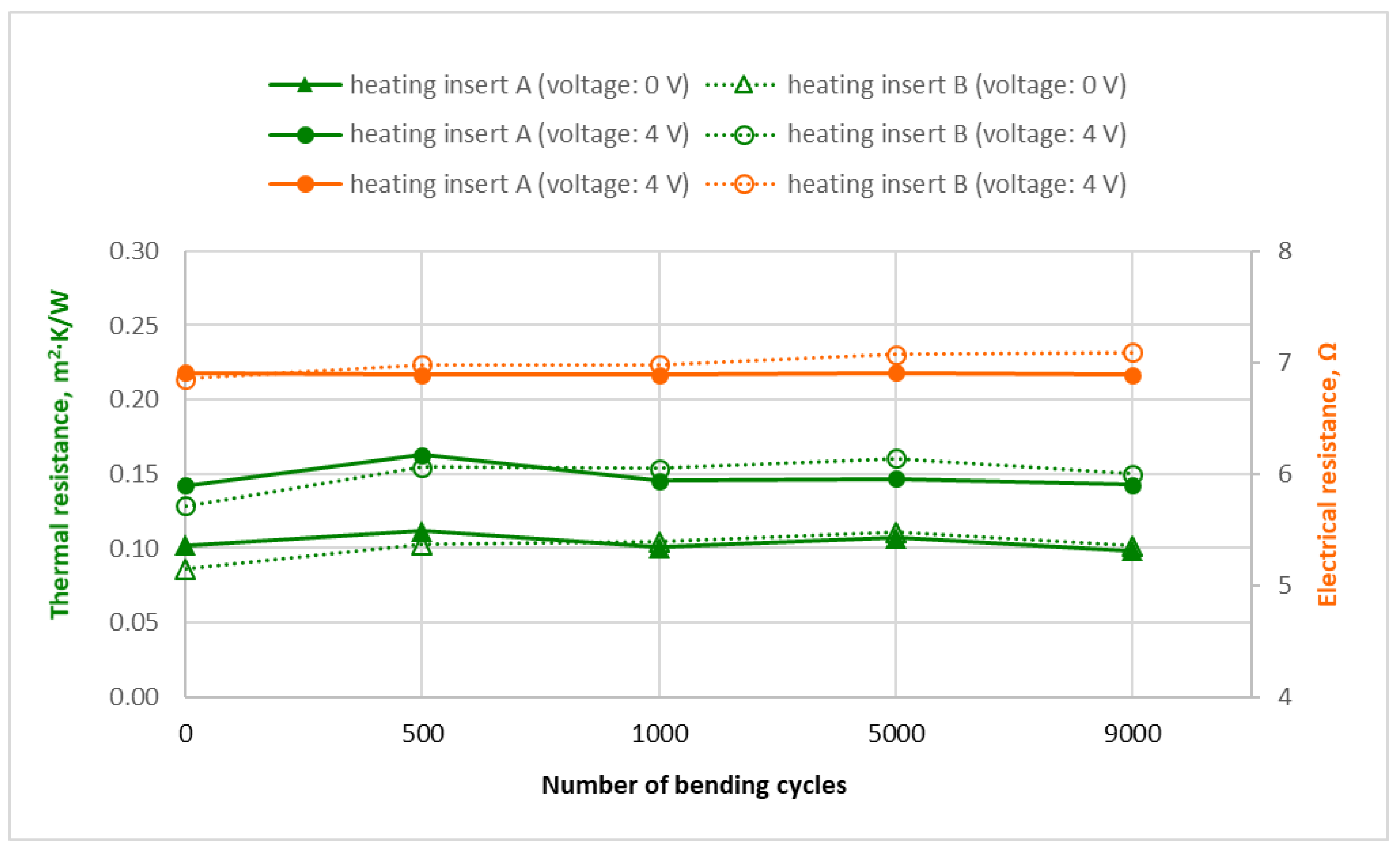

3.1. Resistance to Multiple Bending and Twisting

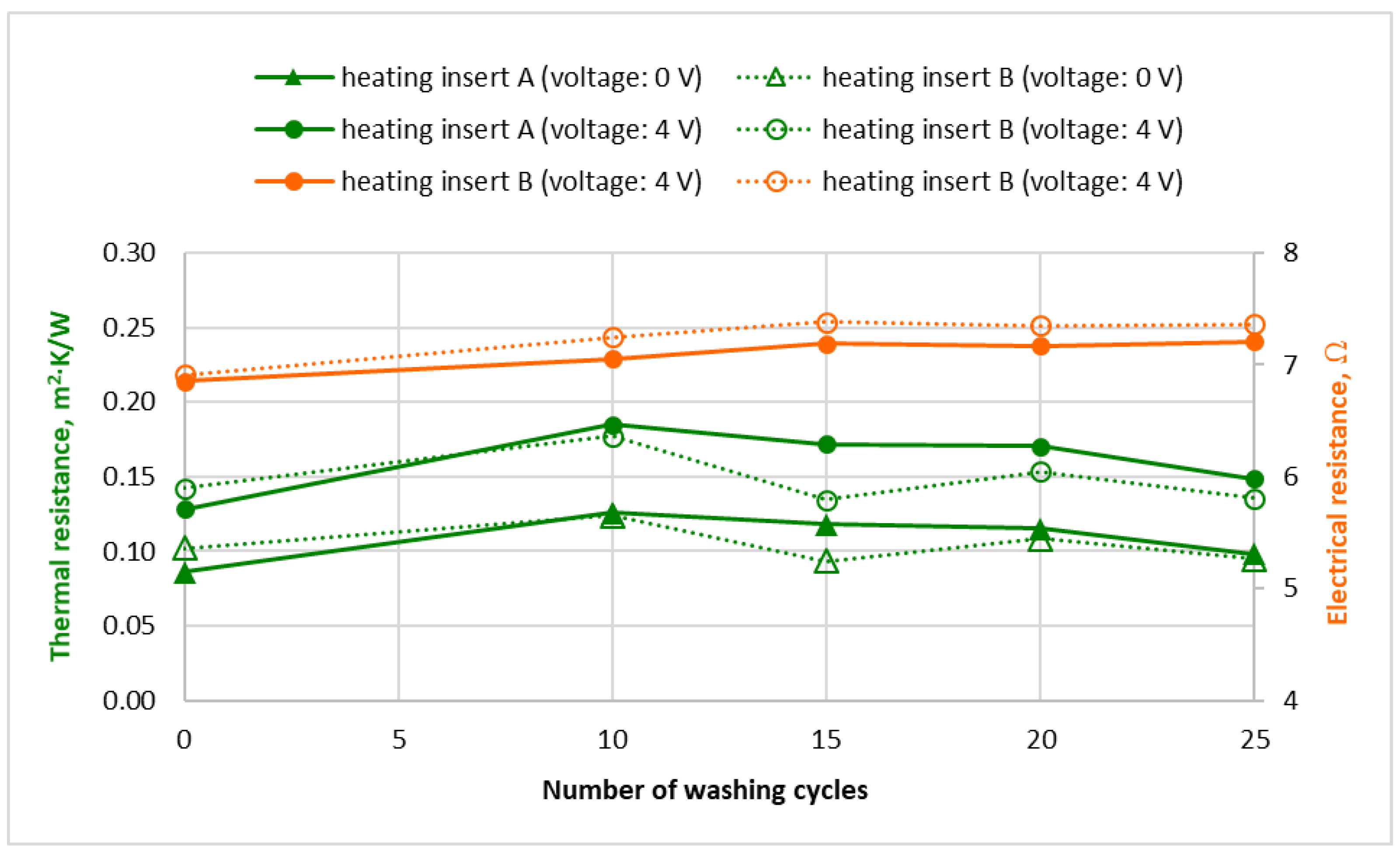

3.2. Resistance to Multiple Washing Cycles

3.3. Resistance to Sweat Exposure

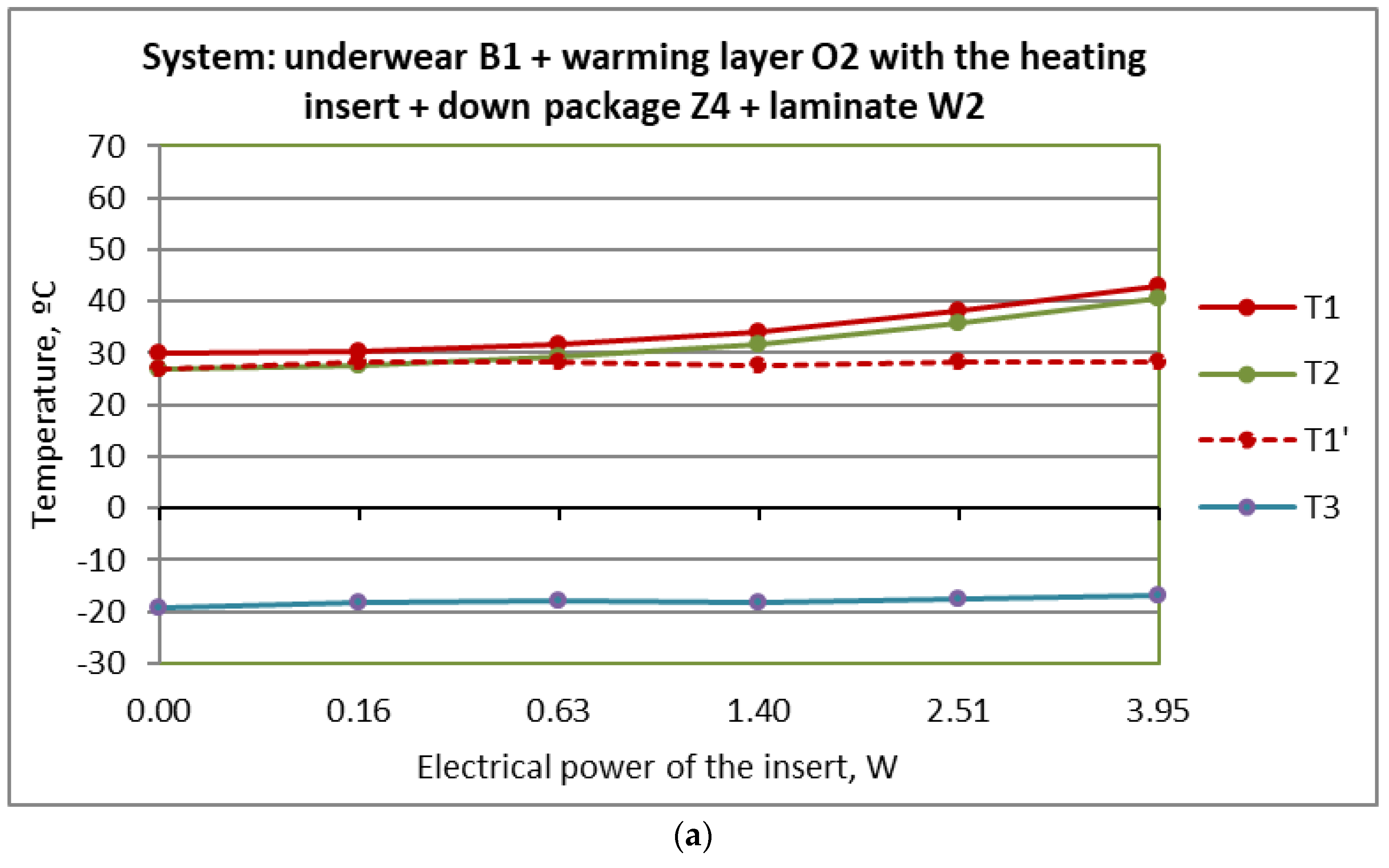

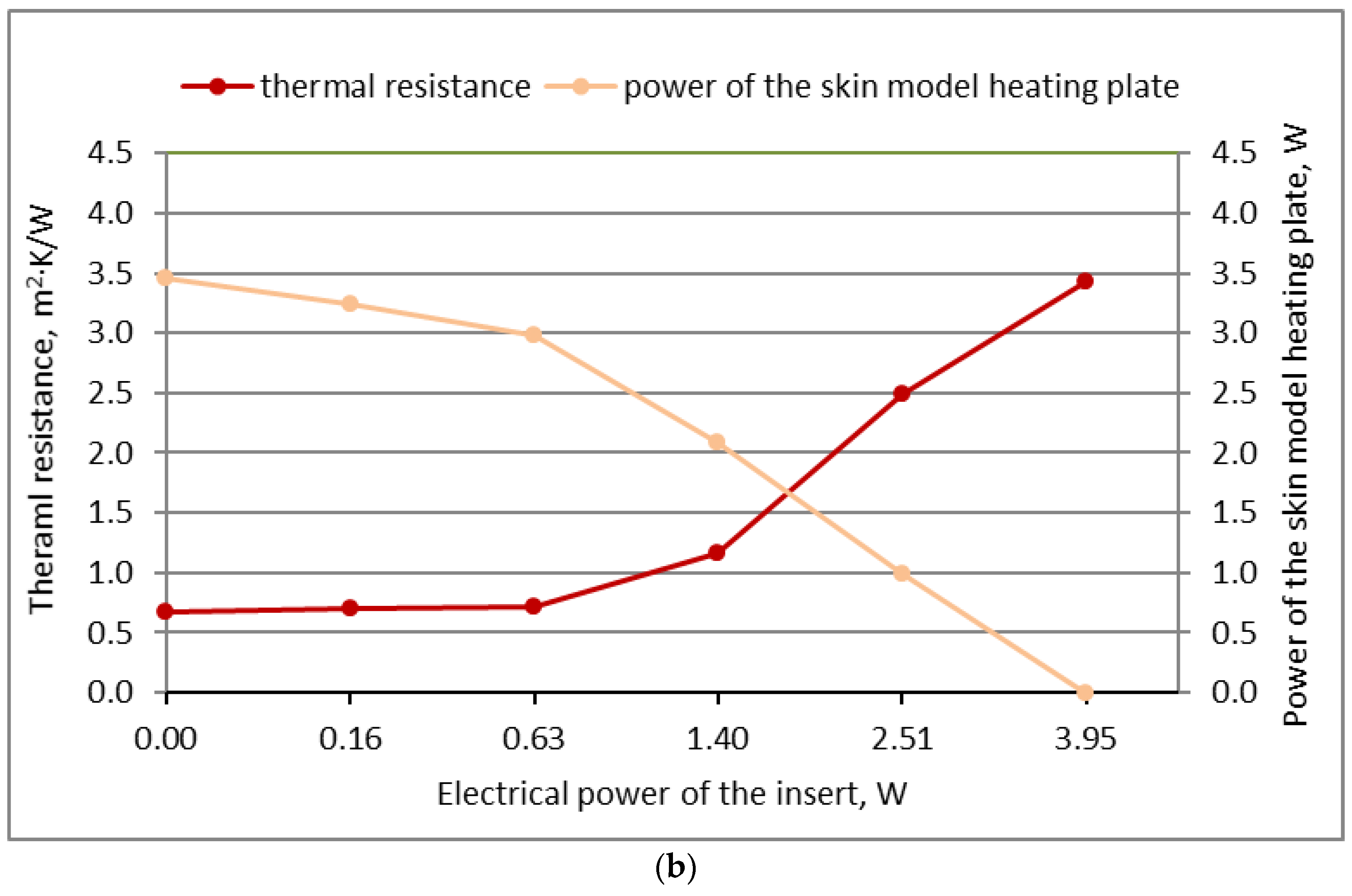

3.4. Temperature Test Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mäkinen, H.; Jussila, K. Cold-protective clothing: Types, design and standards, protective clothing managing thermal stress. In Protective Clothing, 1st ed.; Wang, F., Gao, C., Eds.; Woodhead Publishing (An Important of Elsevier): Sawston, UK, 2014; pp. 3–38. [Google Scholar]

- Wang, L.; Xu, D.-H.; Cheng, J.-X.; Zhou, X.-H. A Model of Heat and Moisture Transfer through Parallel Pore Textiles. J. Fiber Bioeng. Inform. 2011, 3, 250–255. [Google Scholar] [CrossRef]

- Sampatth, M.; Aruputharaj, A.; Senthilkumar, M.; Nalankilli, G. Analysis of thermal comfort characteristics of Moisture management finished knitted fabrics from different yerns. J. Ind. Text. 2012, 42, 19–22. [Google Scholar] [CrossRef]

- Shah, M.A.; Pirzada, B.M.; Price, G.; Shibiru, A.L.; Qurashi, A. Applications of nanotechnology in smart textile industry: A critical review. J. Adv. Res. 2022, 38, 55–75. [Google Scholar] [CrossRef] [PubMed]

- Bahadir, S.K.; Sahin, U.K. A wearable heating system with a controllable e-textile-based thermal panel. In Wearable Technologies; Ortiz, J.H., Ed.; InTech. Publishing: London, UK, 2018. [Google Scholar]

- Ueng, T.; Cheng, K. Friction core-spun yarns for electrical properties of woven fabrics. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1491–1496. [Google Scholar] [CrossRef]

- Fang, S.; Wang, R.; Ni, H.; Liu, H.; Liu, L. A review of flexible electric heating element and electric heating garments. J. Ind. Text. 2022, 51, 101S–136S. [Google Scholar] [CrossRef]

- Wang, F.; Gao, C.; Kuklane, K.; Holmér, I. A Review of Technology of Personal Heating Garments. Int. J. Occup. Saf. Ergon. 2010, 16, 387–404. [Google Scholar] [CrossRef]

- Jussila, K.; Sormunen, E.; Remes, J. Case study: Perceived usability of emergency communication equipment with and without protective gloves in the cold. J. Search Rescue 2013, 1, 1–15. [Google Scholar]

- Jussila, K.; Valkama, A.; Remes, J.; Anttonen, H.; Peitso, A. The Effect of Cold Protective Clothing on Comfort and Perception of Performance. Int. J. Occup. Saf. Ergon. 2010, 16, 185–197. [Google Scholar] [CrossRef]

- Wang, F.; Lee, H. Evaluation of an Electrically Heated Vest (EHV) Using a Thermal Manikin in Cold Environments. Ann. Occup. Hyg. 2010, 54, 117–124. [Google Scholar] [CrossRef]

- Kempson, G.E.; Clark, R.P.; Goff, M.R. The design, development and assessment of electrically heated gloves used for protecting cold extremities. Ergonomics 1988, 31, 1083–1091. [Google Scholar] [CrossRef]

- Chiu, C.-C.; Shyr, T.-W.; Chu, H.-C.; Chung, Y.-C.; Lan, C.-Y. A wearable e-health system with multi-functional physiological measurement. In Proceedings of the World Congress on Medical Physics and Biomedical Engineering, Berlin, Germany, 27 August–1 September 2006. [Google Scholar]

- Repon, M.R.; Mikučionienė, D. Progress in flexible electronic textile for heating application: A critical review. Materials 2021, 14, 6540. [Google Scholar] [CrossRef] [PubMed]

- Holmér, I.; Gao, C.; Wang, F. Adaptive strategies to preserve comfort in cold rooms-is personal warming an alternative. In Proceedings of the 6th International Conference on Cold Climate-Heating, Ventilating and Air-Conditioning (Cold Climate HVAC 2009), Sisimiut, Greenland, 16–19 March 2009. [Google Scholar]

- Rantanen, J.; Impio¨, J.; Karinsalo, T.; Malmivaara, M.; Reho, A.; Tasanen, M.; Vanhala, J. Smart Clothing Prototype for the Arctic Environment. Pers. Ubiquitous Comput. 2002, 6, 3–16. [Google Scholar] [CrossRef]

- Bahadir, S.K.; Jevsnik, S.; Fakin, D.; Sahin, U.K. Color and electrical resistance evaluation of cotton fabrics composed of stainless steel yarns treated with direct and reactive dyes. Text. Res. J. 2016, 86, 1356–1371. [Google Scholar] [CrossRef]

- Tabaczyńska, A.; Dąbrowska, A.; Słoma, M. Printed Graphene, Nanotubes and Silver Electrodes Comparison for Textile and Structural Electronics Applications. Sensors 2021, 21, 4038. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Li, H.; Zhu, X.; Peng, Z.; Zhang, G.; Yang, J.; Wang, F.; Zhang, Y.; Sun, L.; Wang, R.; et al. Directly Printed Embedded Metal Mesh for Flexible Transparent Electrode via Liquid Substrate Electric-Field-Driven Jet. Adv. Sci. 2022, 9, 2105331. [Google Scholar] [CrossRef]

- Zhu, X.; Liu, M.; Qi, X.; Li, H.; Zhang, Y.-F.; Li, Z.; Peng, Z.; Yang, J.; Qian, L.; Xu, Q.; et al. Templateless, Plating-Free Fabrication of Flexible Transparent Electrodes with Embedded Silver Mesh by Electric-Field-Driven Microscale 3D Printing and Hybrid Hot Embossing. Adv. Sci. 2021, 33, 2007772. [Google Scholar] [CrossRef]

- Li, H.; Li, Z.; Li, N.; Zhu, X.; Zhang, Y.; Sun, L.; Wang, R.; Zhang, J.; Yang, Z.; Yi, H.; et al. 3D Printed High Performance Silver Mesh for Transparent Glass Heaters through Liquid Sacrificial Substrate Electric-Field-Driven Jet. Small 2022, 18, 2107811. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Xu, Q.; Li, H.; Liu, M.; Li, Z.; Yang, K.; Zhao, J.; Qian, L.; Peng, Z.; Zhang, G.; et al. Fabrication of High-Performance Silver Mesh for Transparent Glass Heaters via Electric-Field-Driven Microscale 3D Printing and UV-Assisted Microtransfer. Adv. Mater. 2019, 31, 1902479. [Google Scholar] [CrossRef] [PubMed]

- Greszta, A.; Bartkowiak, G.; Dąbrowska, A.; Gliścińska, E.; Machnowski, W.; Kozikowski, P. Multilayer Nonwoven Inserts with Aerogel/PCMs for the Improvement of Thermophysiological Comfort in Protective Clothing against the Cold. Materials 2022, 15, 2307. [Google Scholar] [CrossRef]

- Tylman, W.; Kotas, R.; Kamiński, M.; Woźniak, S.; Dąbrowska, A. A Thermal Model for Processing Data from Undergarment Sensors in Automatic Control of Actively Heated Clothing. Energies 2022, 15, 169. [Google Scholar] [CrossRef]

- Pękosławski, B.; Marciniak, P.; Starzak, Ł; Stawiński, A.; Bartkowiak, G. Power Supply and Control Unit for Actively Heated Protective Clothing with Photovoltaic Energy Harvesting. Energies 2022, 15, 5656. [Google Scholar] [CrossRef]

- Tylman, W.; Kotas, R.; Kamiński, M.; Dąbrowska, A.; Młynarczyk, M. Modeling and Experimental Verification of the Required Power for Electrically Heated Clothing. Energies 2022, 15, 7713. [Google Scholar] [CrossRef]

- EN ISO 5084:1996; Textiles—Determination of Thickness of Textiles and Textile Products. European Committee for Standarization: Brussels, Belgium, 1996.

- EN 12127:1997; Textile Fabrics—Determination of Mass Per Unit Area Using Small Samples. European Committee for Standarization: Brussels, Belgium, 1997.

- EN ISO 11092:2014; Textiles—Physiological Effects—Measurement of Thermal and Water-Vapour Resistance under Steady-State Conditions (Sweating Guarded-Hotplate Test). European Committee for Standarization: Brussels, Belgium, 2014.

- EN ISO 7854:1997; Rubber or Plastics-Coated Fabrics—Determination of Resistance to Damage by Flexing. European Committee for Standarization: Brussels, Belgium, 1997.

- EN ISO 6330:2012; Washing and Drying Procedures for Textile Testing. European Committee for Standarization: Brussels, Belgium, 2012.

- EN ISO 105-E04:2013-06; Textiles—Tests for Colour Fastness—Part E04: Colour Fastness to Perspiration. European Committee for Standarization: Brussels, Belgium, 2013.

- Hamdani, S.T.A.; Fernando, A.; Maqsood, M. Thermo-mechanical behavior of stainless steel knitted structures. Heat Mass Transf. 2016, 52, 1861–1870. [Google Scholar] [CrossRef]

- Islam, R.; Khair, N.; Ahmed, D.M.; Shahariar, H. Fabrication of low cost and scalable carbon-based conductive ink for E-textile applications. Mater. Today Commun. 2019, 19, 32–38. [Google Scholar] [CrossRef]

- Rotzler, S.; von Krshiwoblozki, M.; Schneider-Ramelow, M. Washability of e-textiles: Current testing practices and the need for standardization. Text. Res. J. 2021, 91, 2401–2417. [Google Scholar] [CrossRef]

- Gaubert, V.; Gidik, H.; Bodart, N.; Koncar, V. Investigating the Impact of Washing Cycles on Silver-Plated Textile Electrodes: A Complete Study. Sensors 2020, 20, 1739. [Google Scholar] [CrossRef]

- Hirman, M.; Navratil, J.; Radouchova, M.; Stulik, J.; Soukup, R. Influence of Sweat on Joint and Sensor Reliability of E-Textiles. Energies 2022, 15, 506. [Google Scholar] [CrossRef]

- EN 60335-2-17: 2013/A11:2019; Household and Similar Electrical Appliances—Safety—Part 2–17: Particular Requirements for Blankets, Pads, Clothing and Similar Flexible Heating Appliances. European Committee for Standarization: Brussels, Belgium, 2019.

- Stygienė, L.; Varnaitė-Žuravliova, S.; Abraitienė, A.; Padleckienė, I.; Krauledas, S. Investigation of textile heating element in simulated wearing conditions. Autex Res. J. 2021, 21, 207–215. [Google Scholar] [CrossRef]

| No. | Symbol | Fabric Composition | Mass per Unit Area, g/m2 | Thickness, mm | Thermal Resistance, m2·K/W |

|---|---|---|---|---|---|

| knitted fleece fabric | B1 | 100% PES | 131.3 ± 0.9 | 0.83 ± 0.01 | 0.024 ± 0.001 |

| openwork knitted fabric | S1 | 100% PES | 71.0 ± 3.5 | 0.35 ± 0.00 | not tested |

| Symbol | Thickness 1, mm | Mass 2, g | Area, mm2 |

|---|---|---|---|

| A | 1.82 ± 0.04 | 5.2 | 16,500 |

| B | 2.21 ± 0.06 | 5.8 | 16,500 |

| No. | Designation of the System | Arrangement of Layers in the Material System |

|---|---|---|

| 1 | U1 + insert A | Layer I (underwear fabric): knitted fabric U1 (100% PES), 131 g/m2 layer II: heating insert A |

| 2 | U1 + insert B | layer I (underwear fabric): knitted fabric U1 (100% PES), 131 g/m2 layer II: heating insert B |

| Chemical Composition (Formula) | Acidic Solution pH = 5.5 ± 0.2 |

|---|---|

| Amount | |

| L-histidine monohydrochloride monohydrate (C6H9O2N3 HCL H2O) | 0.5 g |

| Sodium chloride (NaCl) | 5.0 g |

| Disodium hydrogen orthophosphate dihydrate (NaH2PO4 2H2O) | 2.2 g |

| Total volume | 1000 mL |

| No. | Designation of the System | Arrangement of Layers in the Material System |

|---|---|---|

| 1 | U1 + insert B + Z4 + W2 | layer I (underwear fabric): knitted fabric U1 (100% PES), 131 g/m2 layer II: heating insert B layer II (for down jacket): down package made of Z4 fabric (100% PA, 131 g/m2) with filling: 92% goose down, 8% feathers layer III (for outer jacket): vapor-permeable laminate W2 (fabric: 100% PES, membrane: 100% PU) |

| Number of Bending Cycles | Applied Voltage, V | Power, W | Electrical Resistance, Ω | ||

|---|---|---|---|---|---|

| Variant A | Variant B | Variant A | Variant B | ||

| 0 | 4 V | 2.09 | 2.15 | 6.91 | 6.86 |

| 500 | 2.08 | 2.11 | 6.89 | 6.98 | |

| 1000 | 2.08 | 2.04 | 6.89 | 6.98 | |

| 5000 | 2.09 | 2.06 | 6.91 | 7.07 | |

| 9000 | 2.08 | 2.07 | 6.89 | 7.09 | |

| Number of Washing Cycles | Applied Voltage, V | Power, W | Electrical Resistance, Ω |

|---|---|---|---|

| 0 | 4 V | 2.15 | 6.86 |

| 10 | 2.06 | 7.06 | |

| 15 | 2.02 | 7.19 | |

| 20 | 2.01 | 7.17 | |

| 25 | 2.02 | 7.21 |

| Variant | Applied Voltage, V | Power, W | Electrical Resistance, Ω |

|---|---|---|---|

| New | 4 V | 1.95 | 6.92 |

| after exposure to sweat (wet, 5 min) | 2.00 | 6.87 | |

| after exposure to sweat (dry, 24 h) | 1.89 | 6.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krzemińska, S.; Greszta, A.; Bartkowiak, G.; Dąbrowska, A.; Kotas, R.; Pękosławski, B.; Małachowski, B.; Miśkiewicz, P. Evaluation of Heating Inserts in Active Protective Clothing for Mountain Rescuers—Preliminary Tests. Appl. Sci. 2023, 13, 4879. https://doi.org/10.3390/app13084879

Krzemińska S, Greszta A, Bartkowiak G, Dąbrowska A, Kotas R, Pękosławski B, Małachowski B, Miśkiewicz P. Evaluation of Heating Inserts in Active Protective Clothing for Mountain Rescuers—Preliminary Tests. Applied Sciences. 2023; 13(8):4879. https://doi.org/10.3390/app13084879

Chicago/Turabian StyleKrzemińska, Sylwia, Agnieszka Greszta, Grażyna Bartkowiak, Anna Dąbrowska, Rafał Kotas, Bartosz Pękosławski, Bartosz Małachowski, and Pamela Miśkiewicz. 2023. "Evaluation of Heating Inserts in Active Protective Clothing for Mountain Rescuers—Preliminary Tests" Applied Sciences 13, no. 8: 4879. https://doi.org/10.3390/app13084879

APA StyleKrzemińska, S., Greszta, A., Bartkowiak, G., Dąbrowska, A., Kotas, R., Pękosławski, B., Małachowski, B., & Miśkiewicz, P. (2023). Evaluation of Heating Inserts in Active Protective Clothing for Mountain Rescuers—Preliminary Tests. Applied Sciences, 13(8), 4879. https://doi.org/10.3390/app13084879