A Numerical Study of Blast Resistance of Carbon Fiber Reinforced Aluminum Alloy Laminates

Abstract

:1. Introduction

2. Problem Description

2.1. Geometry Description

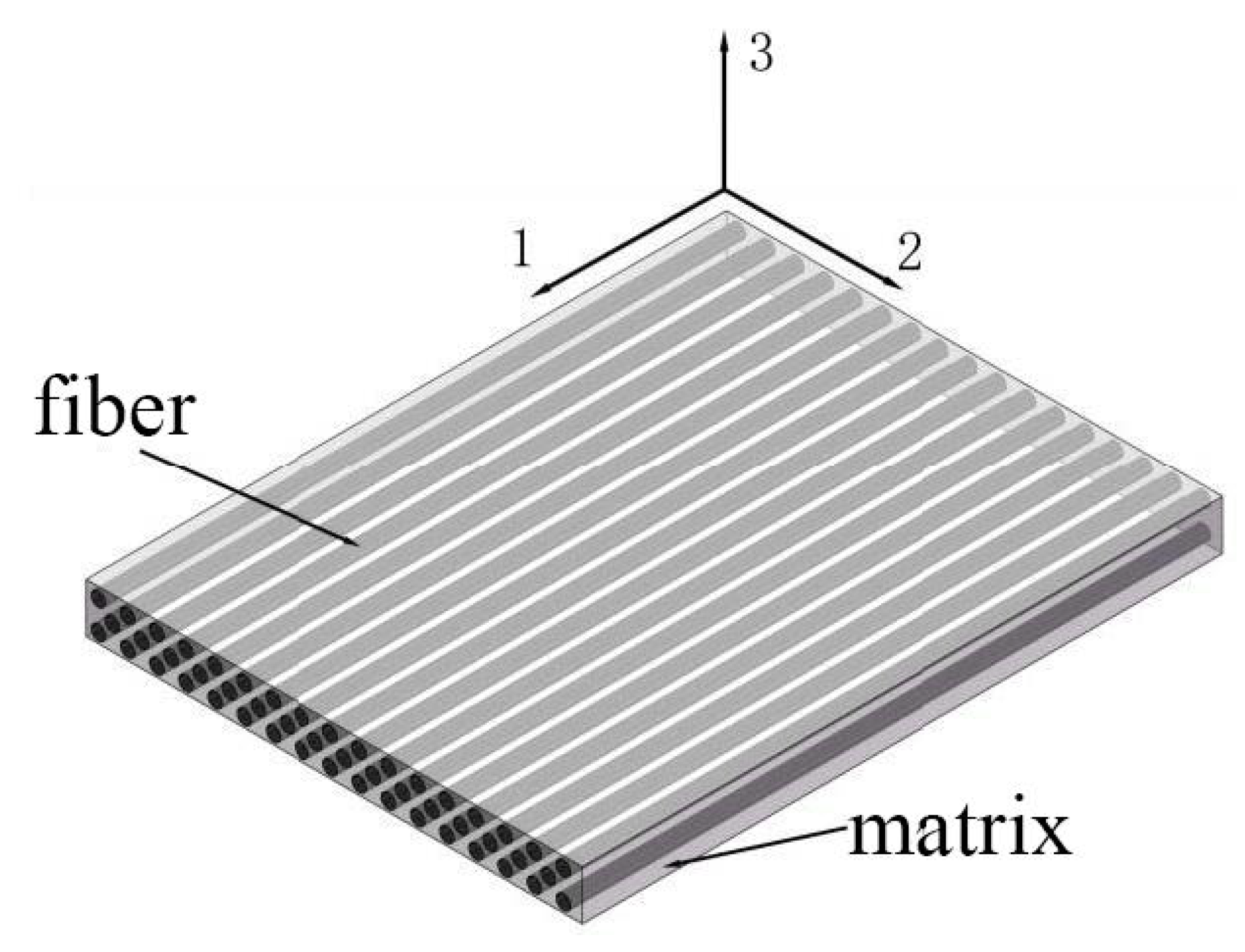

2.2. FML Structure Design

3. Finite Element Modeling

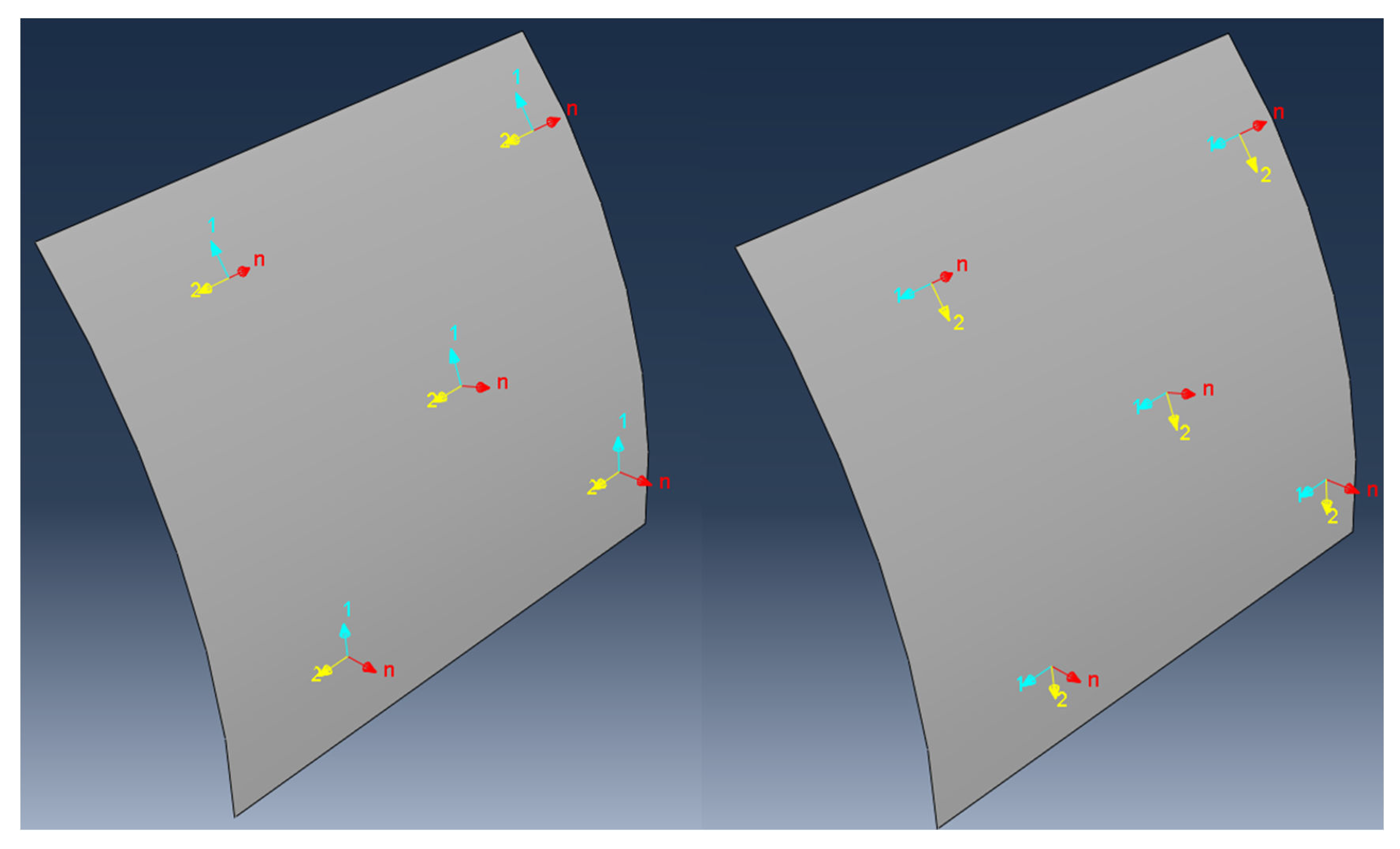

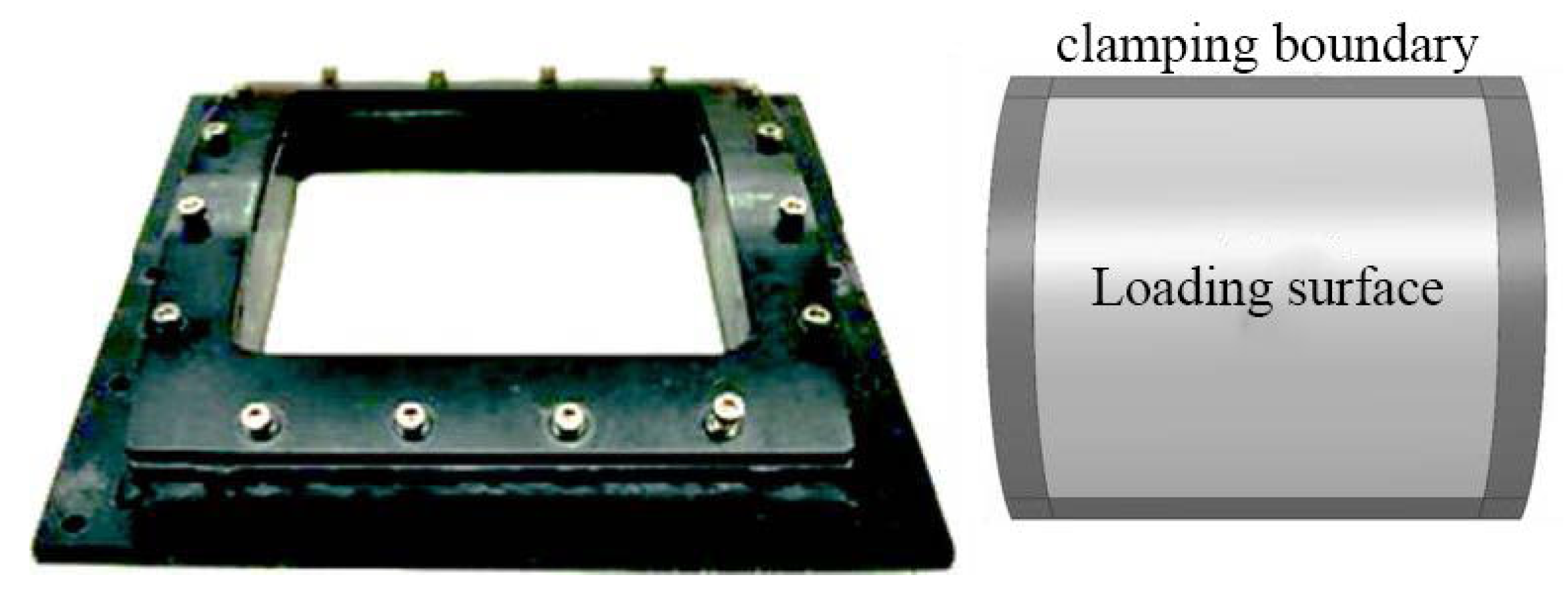

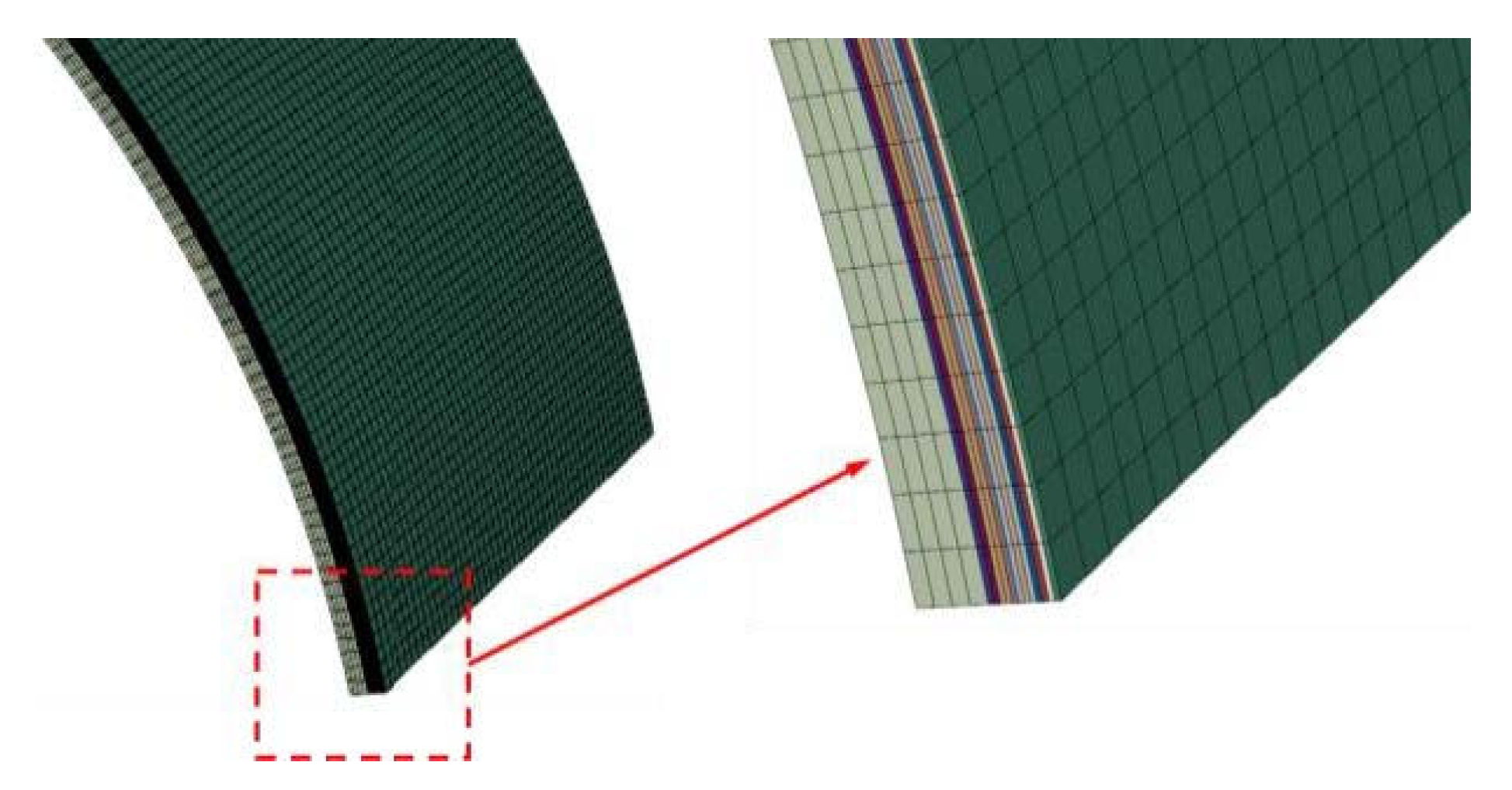

3.1. Geometry, Boundary Conditions, and Contact Modeling

3.2. Material Properties and Modeling

3.3. Damage Model of Composite Material

3.4. Blast Load Modeling

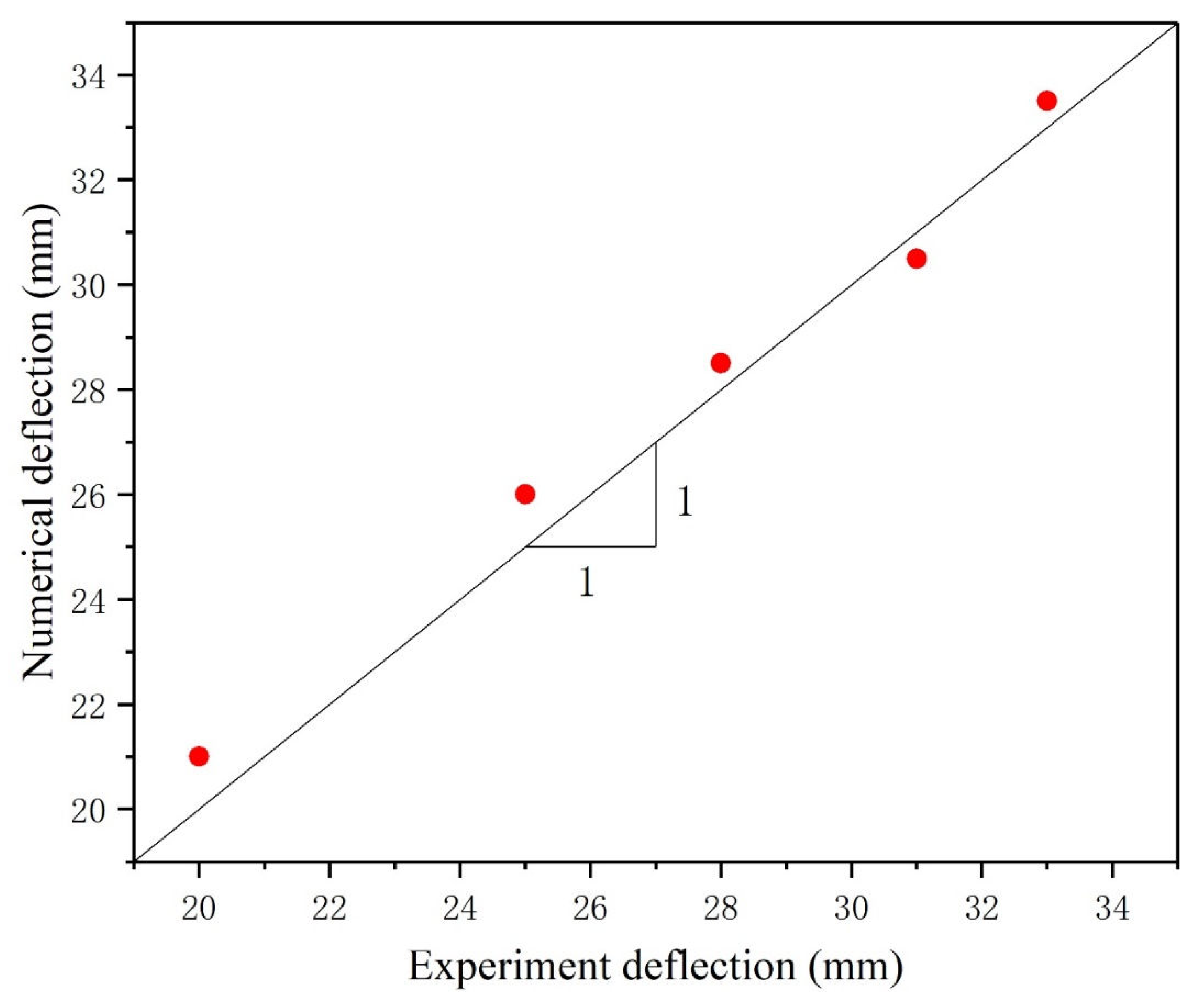

3.5. Validation of FE Model

3.5.1. Validation of Carbon Composite Panels

3.5.2. Validation of Aluminum Panels

4. Results and Discussion

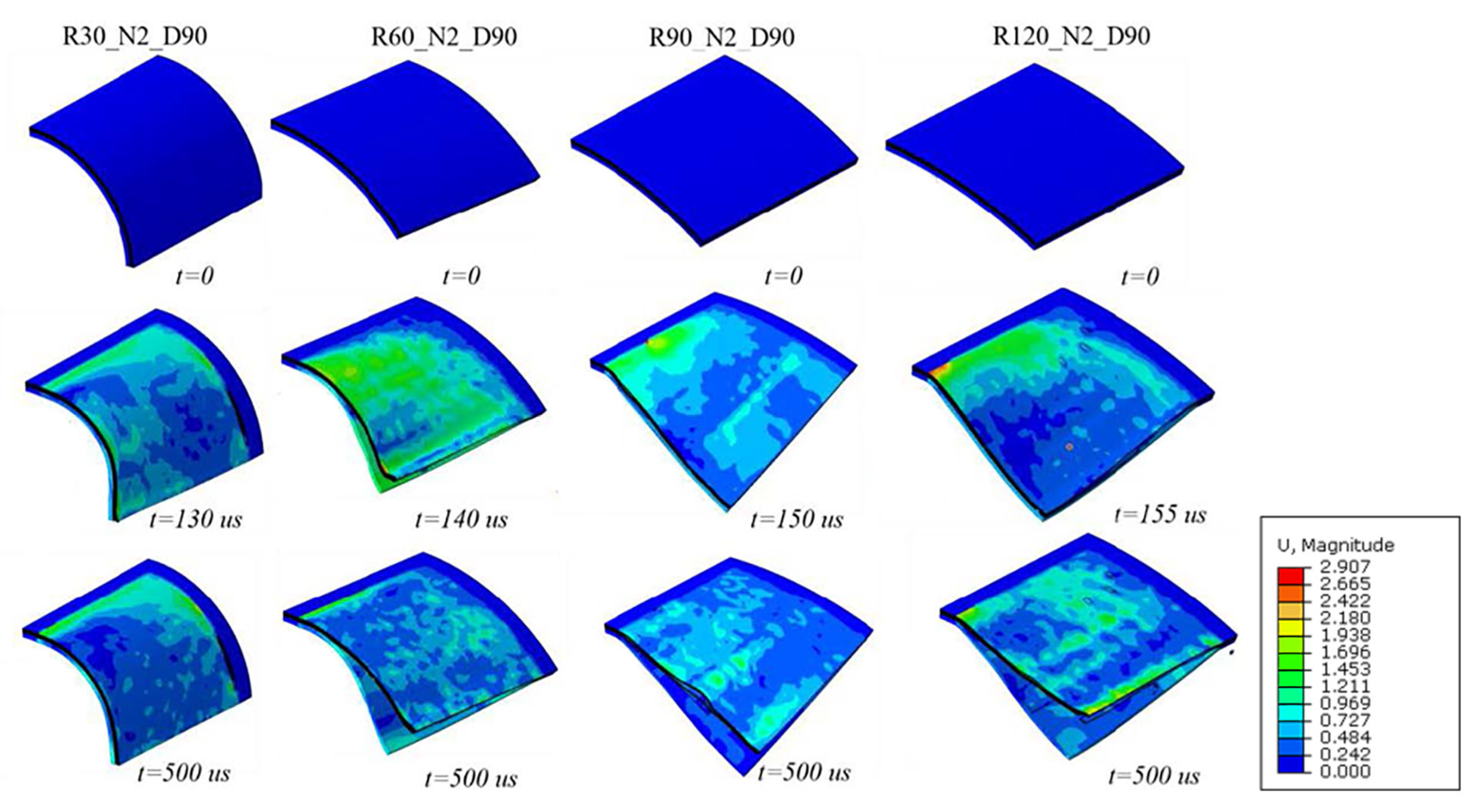

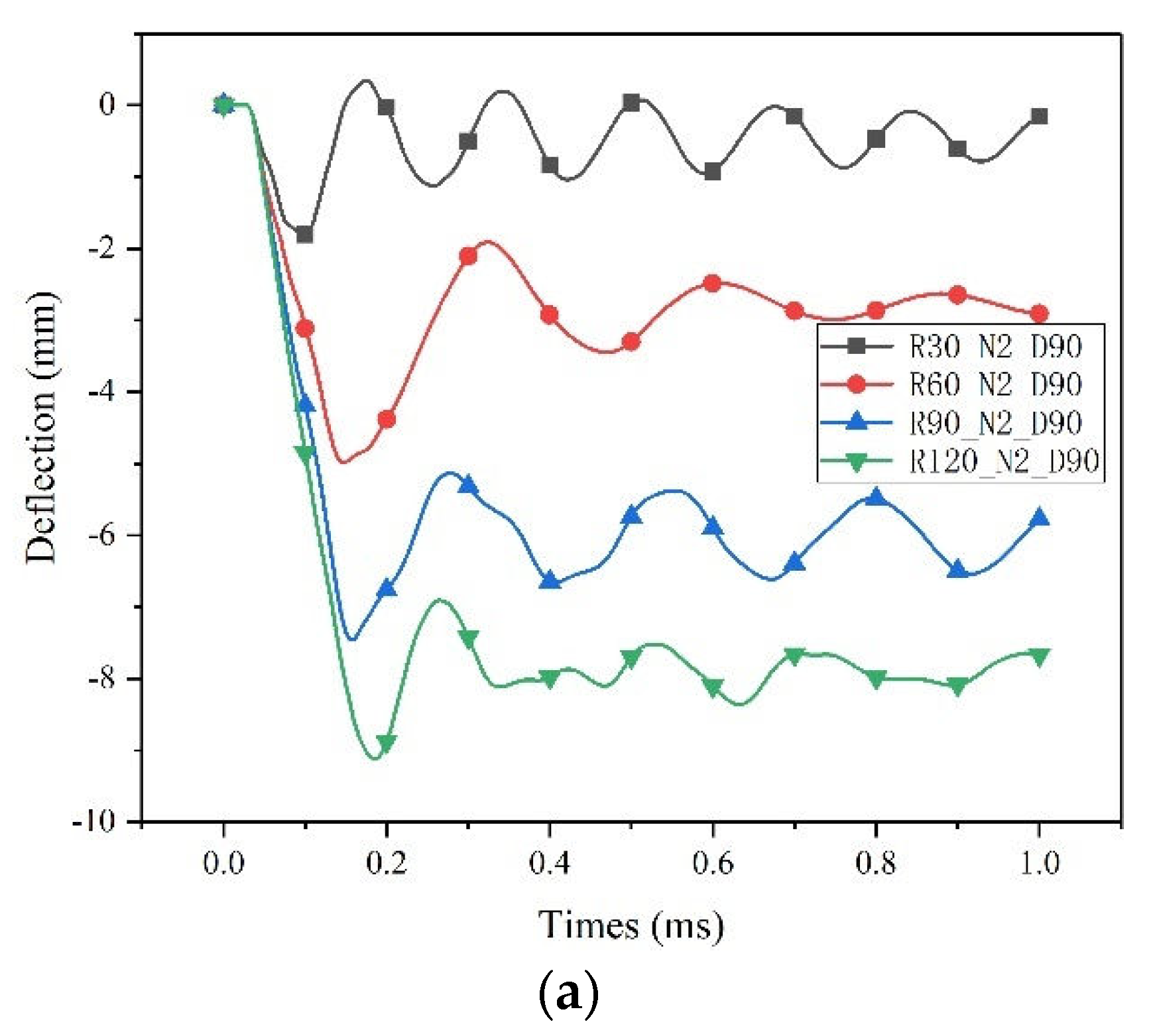

4.1. Influence of Curvature on CARALL Impact Response

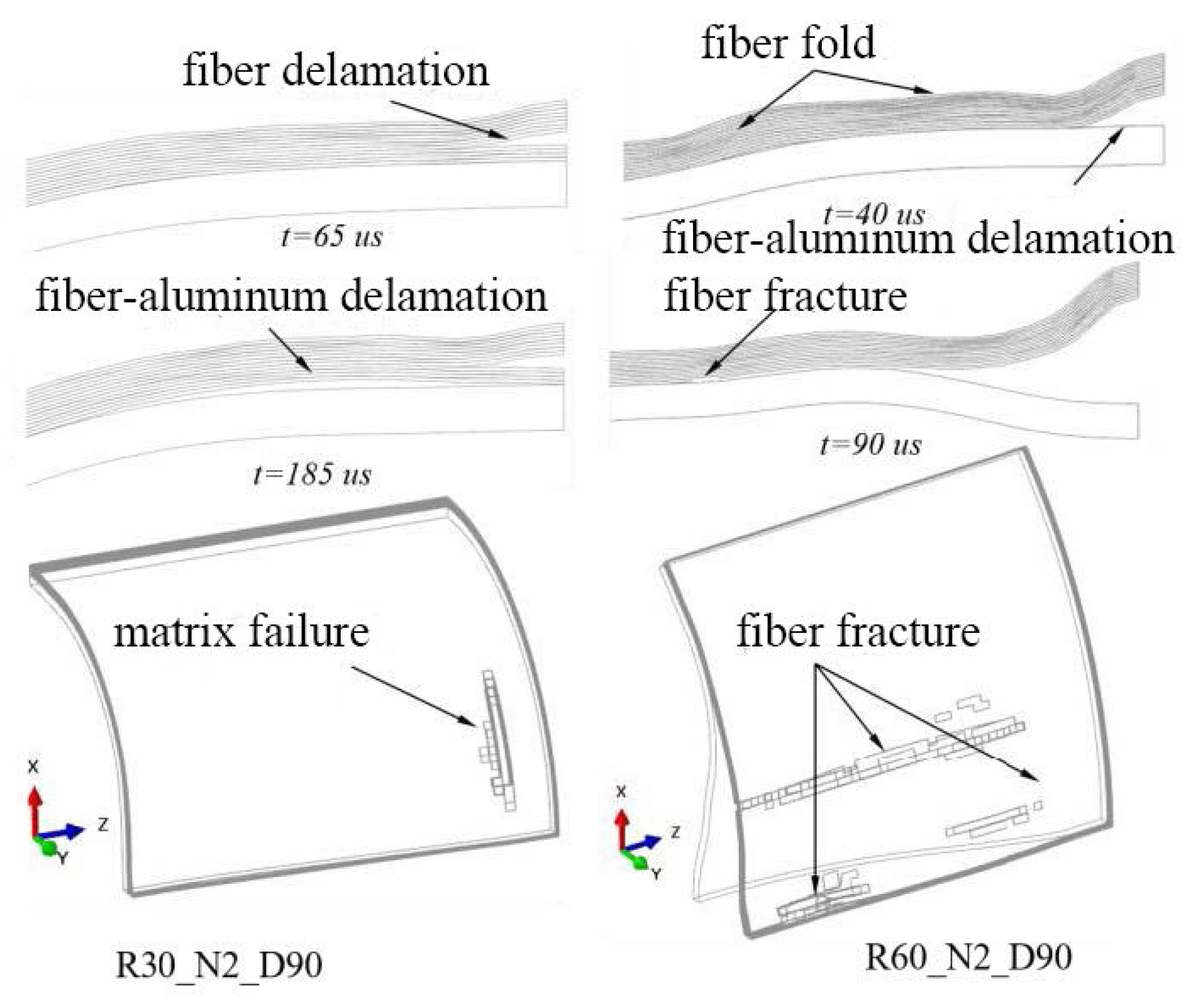

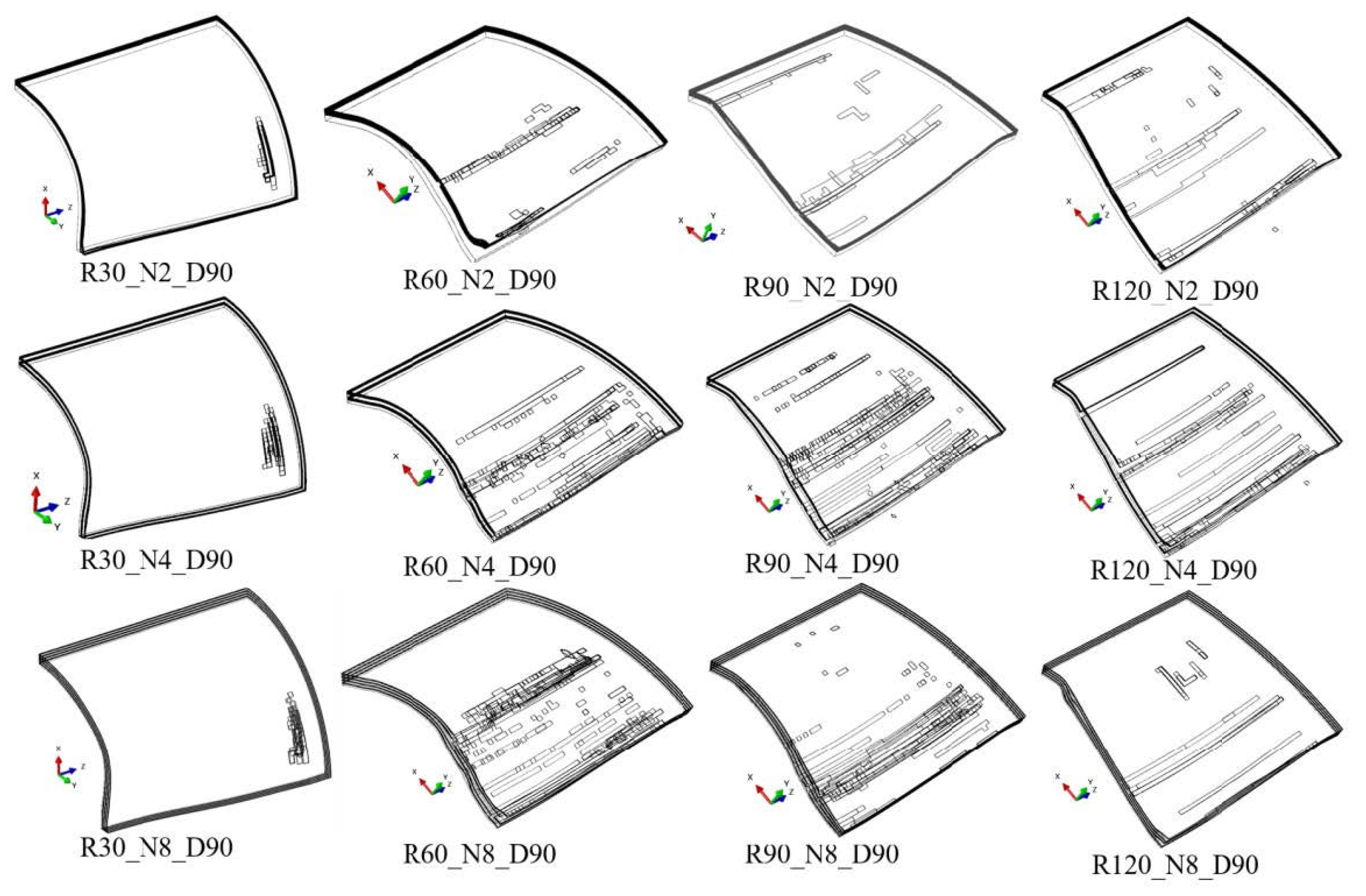

4.1.1. Influence of Curvature on Failure Modes of CARALL Deformation

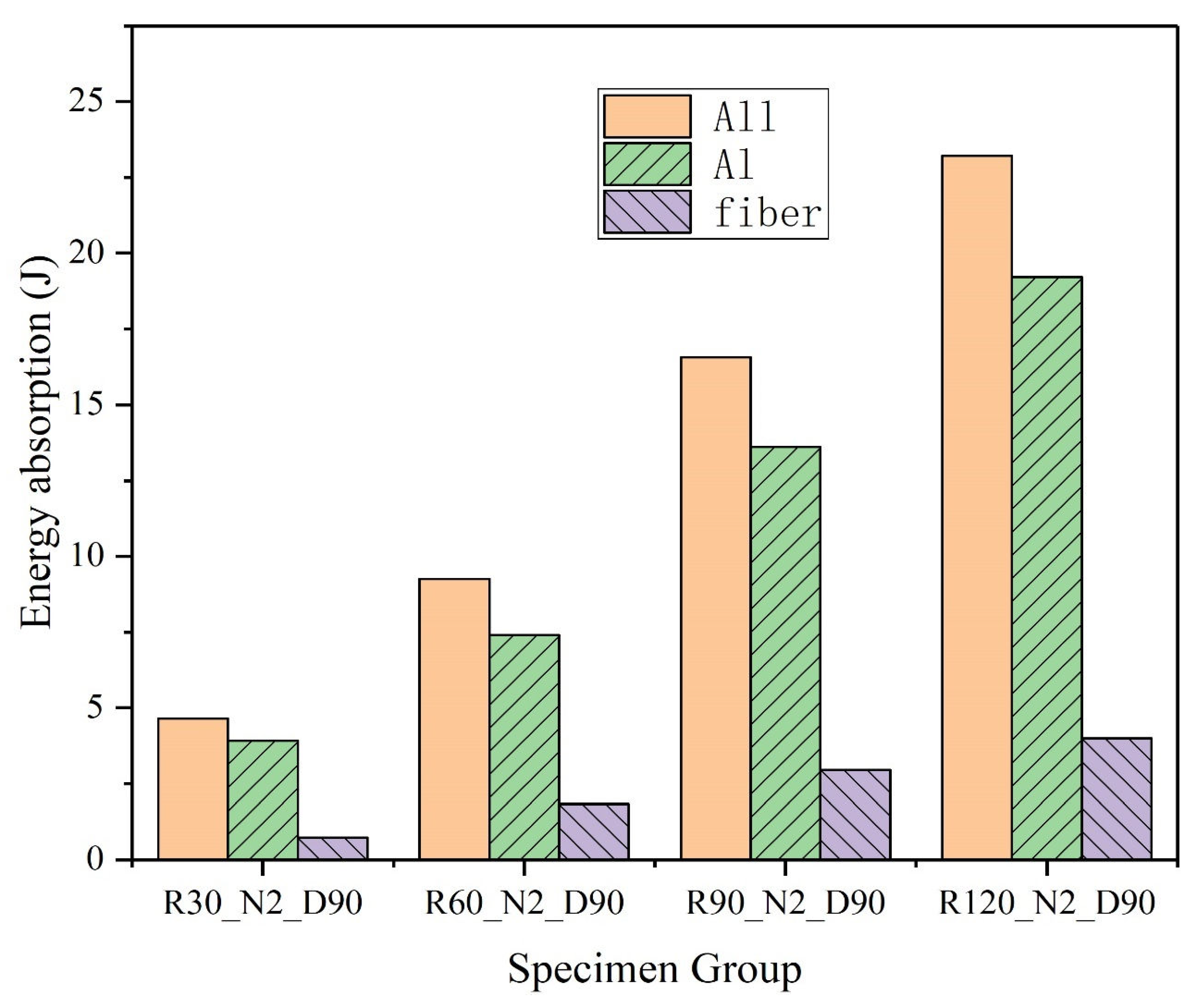

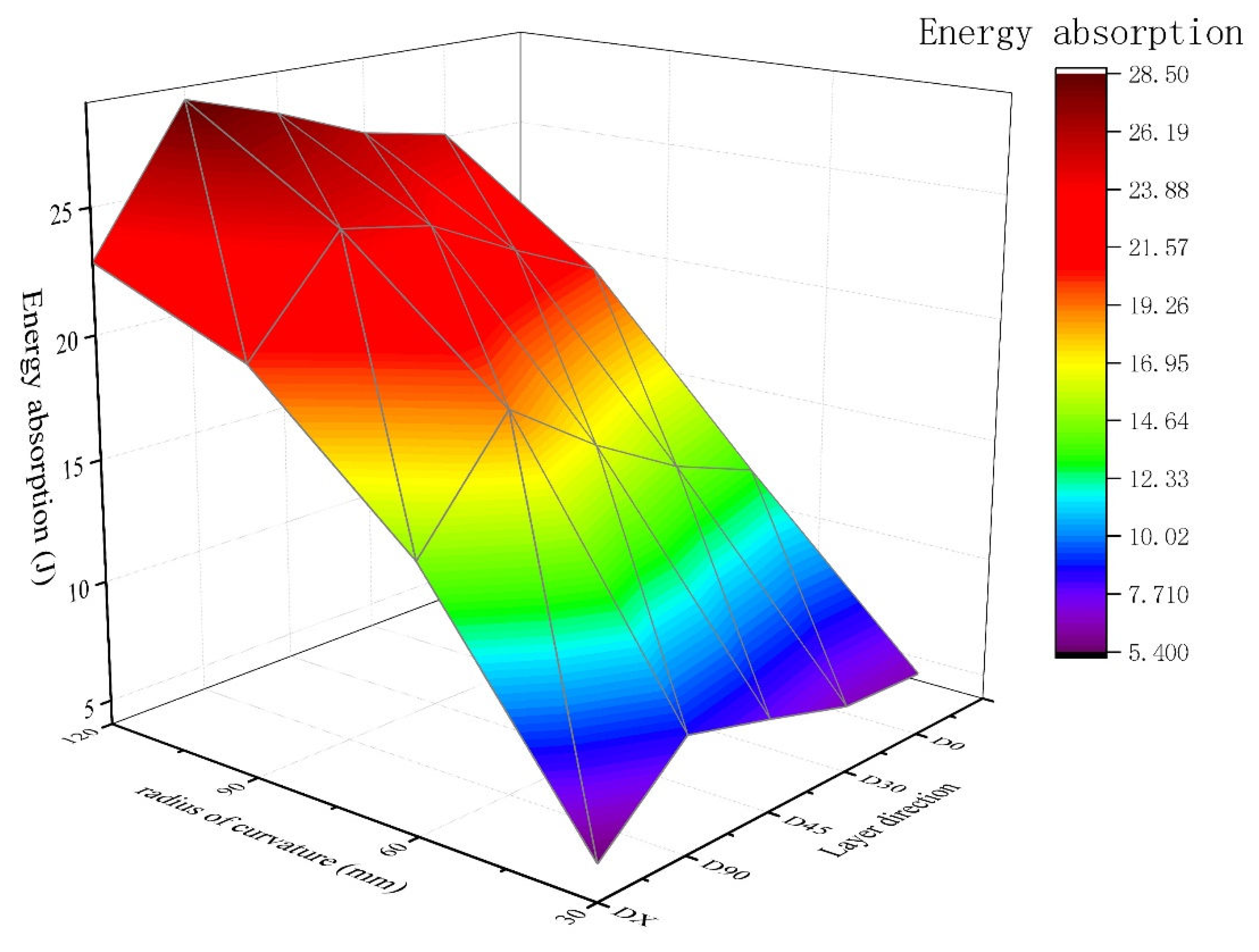

4.1.2. Influence of Curvature on CARALL Energy Absorption

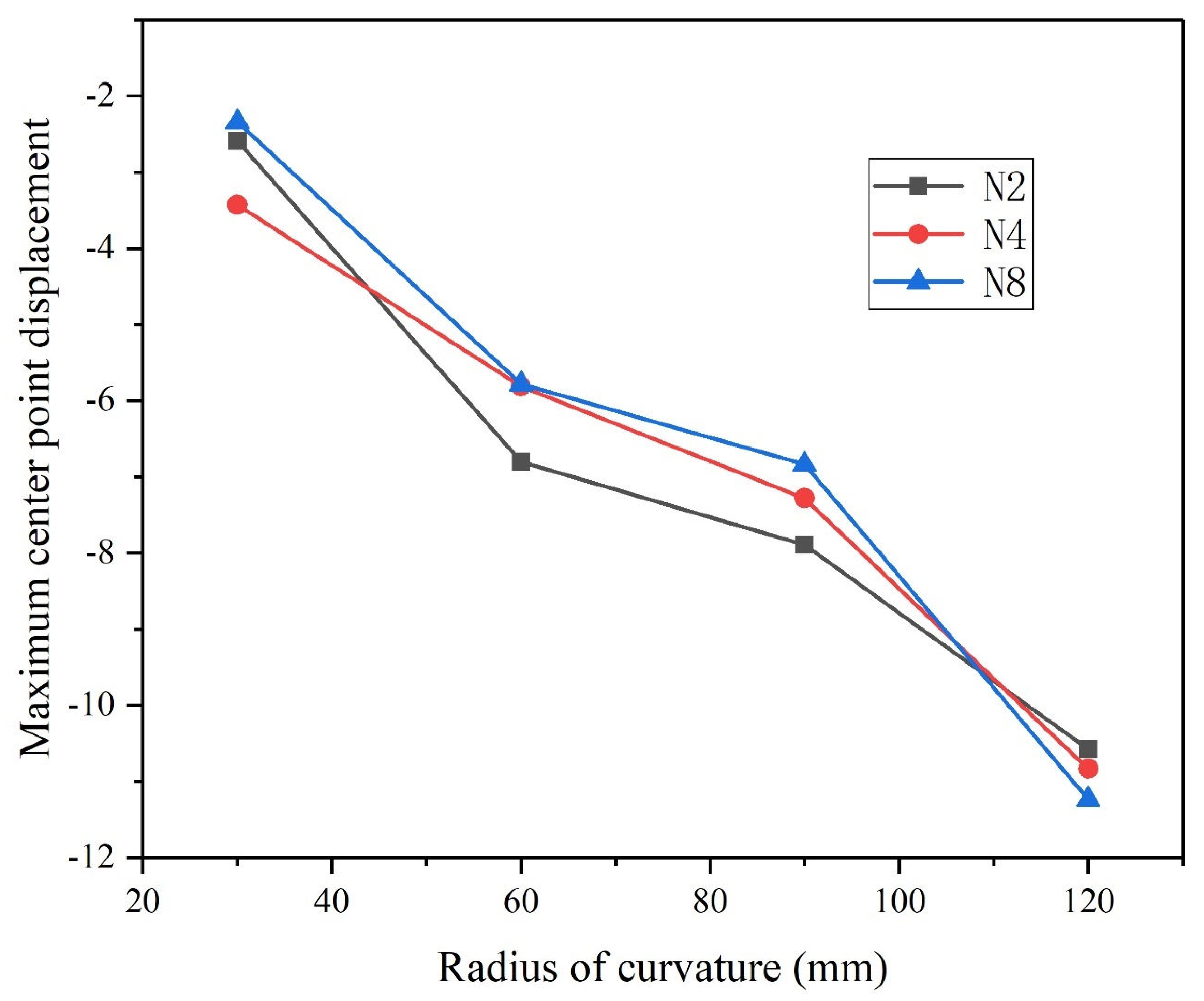

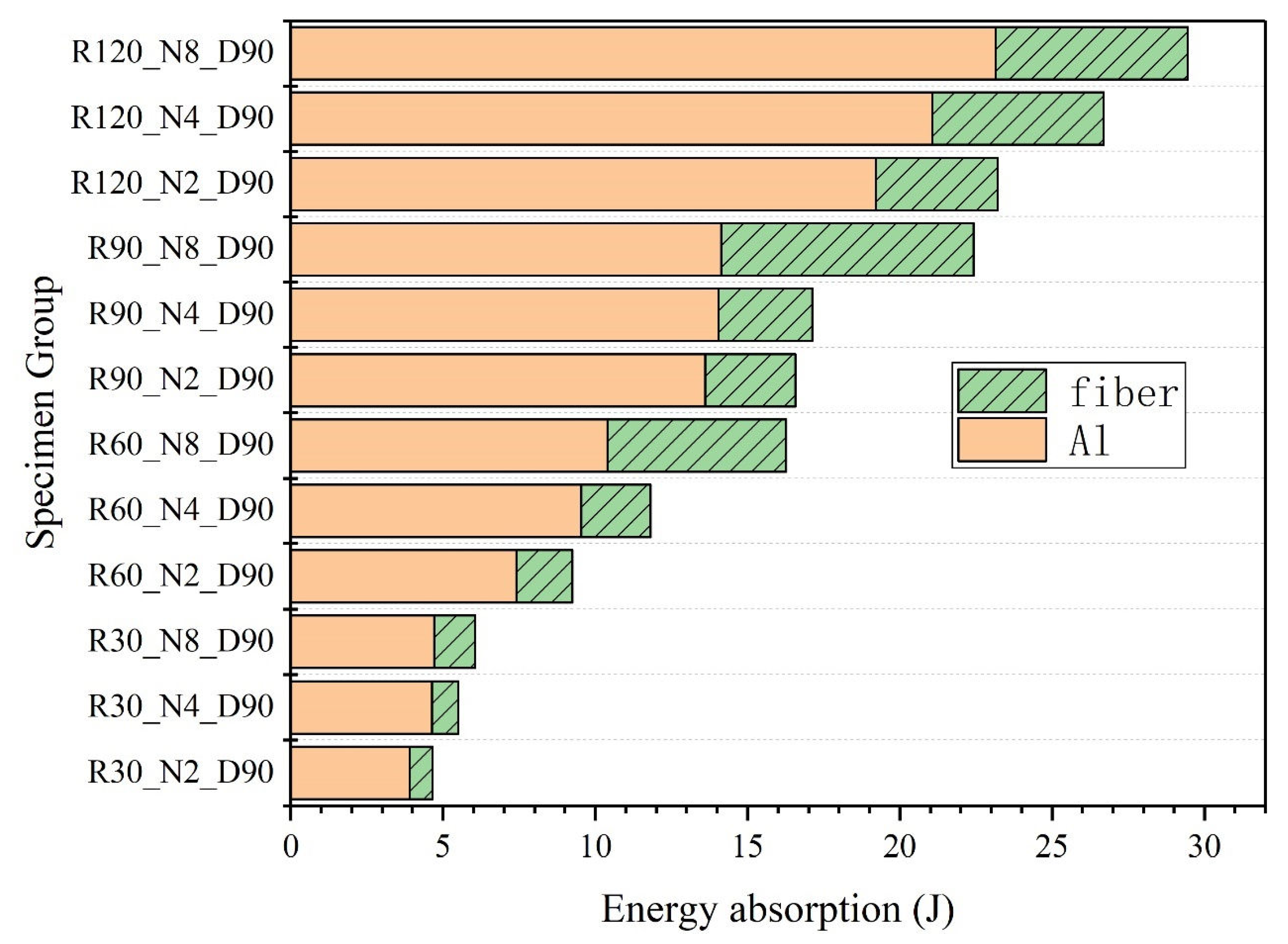

4.2. Influence of Layers on CARALL Impact Response of Curved Surface

4.3. Influence of Fiber Layering Direction on CARALL Impact Response of Curved Surfaces

5. Conclusions

- (1)

- The results show that the curvature radius has the most direct effect on the structural deformation failure. With the decrease in the curvature radius, the displacement of the center point of the backplane decreases, but the energy absorption of the shock wave also decreases. With the increase in the radius of curvature, the absorption energy of the aluminum alloy layer increases significantly and plays a major role.

- (2)

- Parametric study shows that the layered structure has little effect on the deformation of the structure. In contrast, the increase in the number of layered structures will significantly improve the energy absorption of the shock wave. With the increase in the radius of curvature, the influence will be more significant. In the multilayer fiber energy absorption, the outer fiber has more energy absorption, and the difference increases with the increase in curvature radius.

- (3)

- The fiber layering mode determines the failure mode and impact resistance of the fiber. Under the same curvature radius, the 0° and orthogonal arrangements of the fiber layer have the minimum deformation, and the 45° arrangement has the maximum deformation. With the increase in curvature radius, the difference in the deformation of different arrangement modes increases. The energy absorption of the shock wave shows the opposite rule.

Author Contributions

Funding

Conflicts of Interest

References

- Sadeghi, M.; Alderliesten, R.C.; Benedictus, R. Impact resistance of fiber-metal laminates: A review. Int. J. Impact Eng. 2012, 49, 77–90. [Google Scholar] [CrossRef]

- Zarei, H.; Fallah, M.; Minak, G.; Bisadi, H.; Daneshmehr, A. Low velocity impact analysis of Fiber Metal Laminates (FMLs) in thermal environments with various boundary conditions. Compos. Struct. 2016, 149, 170–183. [Google Scholar] [CrossRef]

- Li, X.; Yahya, M.Y.; Bassiri Nia, A.; Wang, Z.; Lu, G. Dynamic failure of fibre-metal laminates under impact loading–experimental observations. J. Reinf. Plast. Compos. 2016, 35, 305–319. [Google Scholar] [CrossRef]

- Hinton, M. Failure Criteria in Fibre-Reinforced-Polymer Composites; Elsevier Science: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Wang, B.; Wu, L.Z.; Ma, L. Low-velocity impact characteristics and residual tensile strength of carbon fiber composite lattice core sandwich structures. Compos. Part B Eng. 2011, 42, 891–897. [Google Scholar] [CrossRef]

- Wang, S.X.; Wu, L.Z.; Ma, L. Low-velocity impact and residual tensile strength analysis to carbon fiber composite laminates. Mater. Des. 2010, 31, 118–125. [Google Scholar] [CrossRef]

- Chai, G.B.; Manikandan, P. Low velocity impact response of fibre-metal laminates–A review. Compos. Struct. 2014, 107, 363–381. [Google Scholar] [CrossRef]

- Su, X.; Yang, Z.; Liu, G. Finite element modelling of complex 3d static and dynamic crack propagation by embedding cohesive elements in abaqus. Acta Mech. Solida Sin. 2010, 23, 271–282. [Google Scholar] [CrossRef]

- Xu, M.M.; Huang, G.Y.; Feng, S.S.; McShane, G.J.; Stronge, W.J. Perforation resistance of aluminum/polyethylene sandwich structure. Mater. Des. 2016, 100, 92–101. [Google Scholar] [CrossRef] [Green Version]

- Che, L.; Fang, G.; Wu, Z.; Ma, Y.; Zhang, J.; Zhou, Z. Investigation of curing deformation behavior of curved fiber metal laminates. Compos. Struct. 2020, 232, 111570. [Google Scholar] [CrossRef]

- Sinmazçelik, T.; Avcu, E.; Bora, M.Ö.; Çoban, O. A review: Fibre metal laminates, background, bonding types and applied test methods. Mater. Des. 2011, 32, 3671–3685. [Google Scholar] [CrossRef]

- Song, S.H.; Byun, Y.S.; Ku, T.W.; Song, W.J.; Kim, J.; Kang, B.S. Experimental and Numerical Investigation on Impact Performance of Carbon Reinforced Aluminum Laminates. J. Mater. Sci. Technol. 2010, 26, 327–332. [Google Scholar] [CrossRef]

- Rahmani, H.; Eslami-Farsani, R.; Ebrahimnezhad-Khaljiri, H. High velocity impact response of aluminum-carbon fibers-epoxy laminated composites toughened by nano silica and zirconia. Fibers Polym. 2020, 21, 170–178. [Google Scholar] [CrossRef]

- Bahari-Sambran, F.; Eslami-Farsani, R.; Arbab Chirani, S. The flexural and impact behavior of the laminated aluminum-epoxy/basalt fibers composites containing nanoclay: An experimental investigation. J. Sandw. Struct. Mater. 2020, 22, 1931–1951. [Google Scholar] [CrossRef]

- Najafi, M.; Ansari, R.; Darvizeh, A. Influence of thermal aging on mechanical properties of fiber metal laminates hybridized with nanoclay. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 7003–7018. [Google Scholar] [CrossRef]

- Najafi, M.; Ansari, R.; Darvizeh, A. Effect of cryogenic aging on nanophased fiber metal laminates and glass/epoxy composites. Polym. Compos. 2019, 40, 2523–2533. [Google Scholar] [CrossRef]

- Askin, M.Y.; Turen, Y. The effect of GNP addition on mechanical and residual stress properties of 2024-T3 aluminum and carbon fiber reinforced FML. Mater. Res. Express 2019, 6, 126546. [Google Scholar] [CrossRef]

- Majerski, K.; Surowska, B.; Bienias, J. The comparison of effects of hygrothermal conditioning on mechanical properties of fibre metal laminates and fibre reinforced polymers. Compos. Part B Eng. 2018, 142, 108–116. [Google Scholar] [CrossRef]

- Ebrahimnezhad-Khaljiri, H.; Eslami-Farsani, R.; Akbarzadeh, E. Effect of interlayer hybridization of carbon, Kevlar, and glass fibers with oxidized polyacrylonitrile fibers on the mechanical behaviors of hybrid composites. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 234, 1823–1835. [Google Scholar] [CrossRef]

- Eslami-Farsani, R.; Aghamohammadi, H.; Khalili, S.; Ebrahimnezhad-Khaljiri, H.; Jalali, H. Recent trend in developing advanced fiber metal laminates reinforced with nanoparticles: A review study. J. Ind. Text. 2020, 51, 7374S–7408S. [Google Scholar] [CrossRef]

- Xu, M.M. Velocity High Impact Resistance of Carbon Fiber-Reinforced Metal Laminates; Beijing Insititute of Technology: Beijing, China, 2016. [Google Scholar]

- Yao, L.; Sun, G.; He, W.; Meng, X.; Xie, D. Investigation on impact behavior of FMLs under multiple impacts with the same total energy: Experimental characterization and numerical simulation. Compos. Struct. 2019, 226, 111218. [Google Scholar] [CrossRef]

- Lin, X.H. Study on Impact Resistance of Fiber-Metal Laminates; Huazhong University of Science and Technology: Wuhan, China, 2012. [Google Scholar]

- Lee, D.W.; Park, B.J.; Park, S.Y.; Choi, C.-H.; Song, J. Fabrication of High-Stiffness Fiber-Metal Laminates and Study of Their Behavior Under Low-Velocity Impact Loadings. Compos. Struct. 2018, 189, 61–69. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, Y.; Fu, X.; Hao, G.; Jiang, W. Mechanical properties of Ti/CF/PMR polyimide fiber metal laminates with various layup configurations. Compos. Struct. 2019, 229, 111408. [Google Scholar] [CrossRef]

- Anisimov, A.G.; Müller, B.; Sinke, J.; Groves, R.M. Analysis of thermal strains and stresses in heated fibre metal laminates. Strain 2018, 54, e12260. [Google Scholar] [CrossRef]

- Ebrahimnezhad-Khaljiri, H.; Eslami-Farsani, R. Experimental investigation of flexural properties of glass fiber–epoxy self-healable composite structures containing capsulated epoxy healing agent and NiCl2(imidazole)4 catalyst. J. Ind. Text. 2019, 51, 788–805. [Google Scholar] [CrossRef]

- Prasad, E.; Sivateja, C.; Sahu, S. Effect of nanoalumina on fatigue characteristics of fiber metal laminates. Polym. Test. 2020, 85, 106441. [Google Scholar] [CrossRef]

| Parameter Name | Value |

|---|---|

| Radius of curvature R(mm) | 30, 60, 90, 120 |

| The layer number N | 2,4,8 |

| Fiber direction D (°) | unidirectional [0, 30, 45, 90] orthogonal (X) |

| Knn (GPa) | Kss (GPa) | Ktt (GPa) | (MPa) | (MPa) | (MPa) | |

|---|---|---|---|---|---|---|

| fiber-fiber | 5.2 | 3.91 | 3.91 | 71 | 30 | 30 |

| fiber-alloy | 3.5 | 3.5 | 3.5 | 35 | 39 | 39 |

| Density (kg/m3) | Young’s Modulus (GPa) | Yield Stress (MPa) | Poisson’s Ratio | Tangent Modulus (GPa) | |

|---|---|---|---|---|---|

| Al-2024 | 2680 | 72 | 75.8 | 0.33 | 0.737 |

| Value | |

|---|---|

| ρ (kg/m3) | 1750 |

| E11 (GPa) | 134 |

| E22 = E33 (GPa) | 5.2 |

| 𝜈12 = 𝜈31 | 0.25 |

| 𝜈23 | 0.38 |

| G12 = G13 = G23 (GPa) | 3.1 |

| Xt (MPa) | 2160 |

| Xc (MPa) | 1470 |

| Yt = Zt (MPa) | 71 |

| Yc = Zc (MPa) | 1030 |

| S12 (MPa) | 450 |

| S31 = S32 (MPa) | 325 |

| Failure Mode | E11 | E22 | E33 | G12 | G13 | G23 | ν12 | ν13 | ν23 |

|---|---|---|---|---|---|---|---|---|---|

| Fiber tensile failure | 0.07 | 0.07 | 0.07 | 0.07 | 0.07 | 0.07 | 0.07 | 0.07 | 0.07 |

| Fiber compression failure | 0.14 | 0.14 | 0.14 | 0.14 | 0.14 | 0.14 | 0.14 | 0.14 | 0.14 |

| Matrix tensile failure | 1 | 0.2 | 0.20 | 0.2 | 0.2 | 0.2 | 1 | 1 | 1 |

| Matrix compression failure | 1 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 1 | 1 | 1 |

| In-plane shear failure | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 |

| Out-of-plane shear failure | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Feng, S. A Numerical Study of Blast Resistance of Carbon Fiber Reinforced Aluminum Alloy Laminates. Appl. Sci. 2023, 13, 4906. https://doi.org/10.3390/app13084906

Zhang B, Feng S. A Numerical Study of Blast Resistance of Carbon Fiber Reinforced Aluminum Alloy Laminates. Applied Sciences. 2023; 13(8):4906. https://doi.org/10.3390/app13084906

Chicago/Turabian StyleZhang, Bo, and Shunshan Feng. 2023. "A Numerical Study of Blast Resistance of Carbon Fiber Reinforced Aluminum Alloy Laminates" Applied Sciences 13, no. 8: 4906. https://doi.org/10.3390/app13084906

APA StyleZhang, B., & Feng, S. (2023). A Numerical Study of Blast Resistance of Carbon Fiber Reinforced Aluminum Alloy Laminates. Applied Sciences, 13(8), 4906. https://doi.org/10.3390/app13084906