On the Use of Microstructure Characteristics to Predict Metal Matrix Composites’ Macroscopic Mechanical Behavior

Abstract

:1. Introduction

2. Materials and Methods

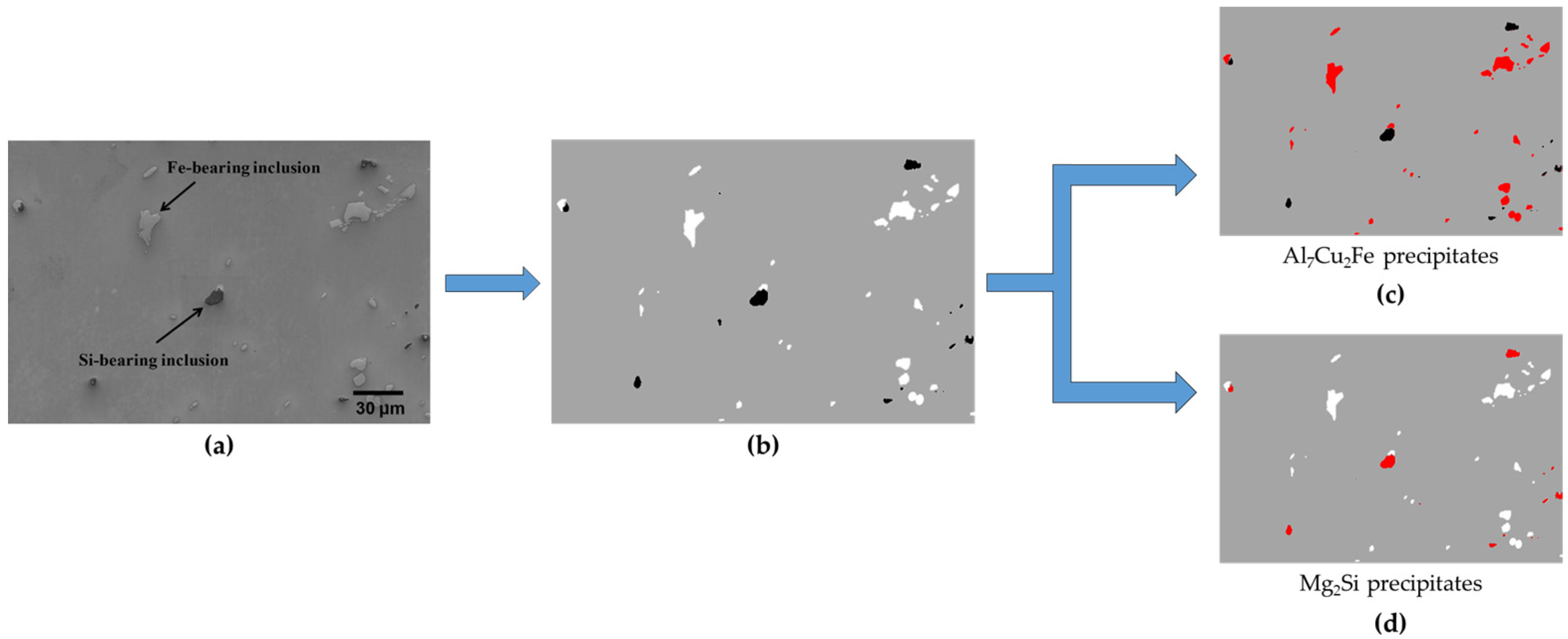

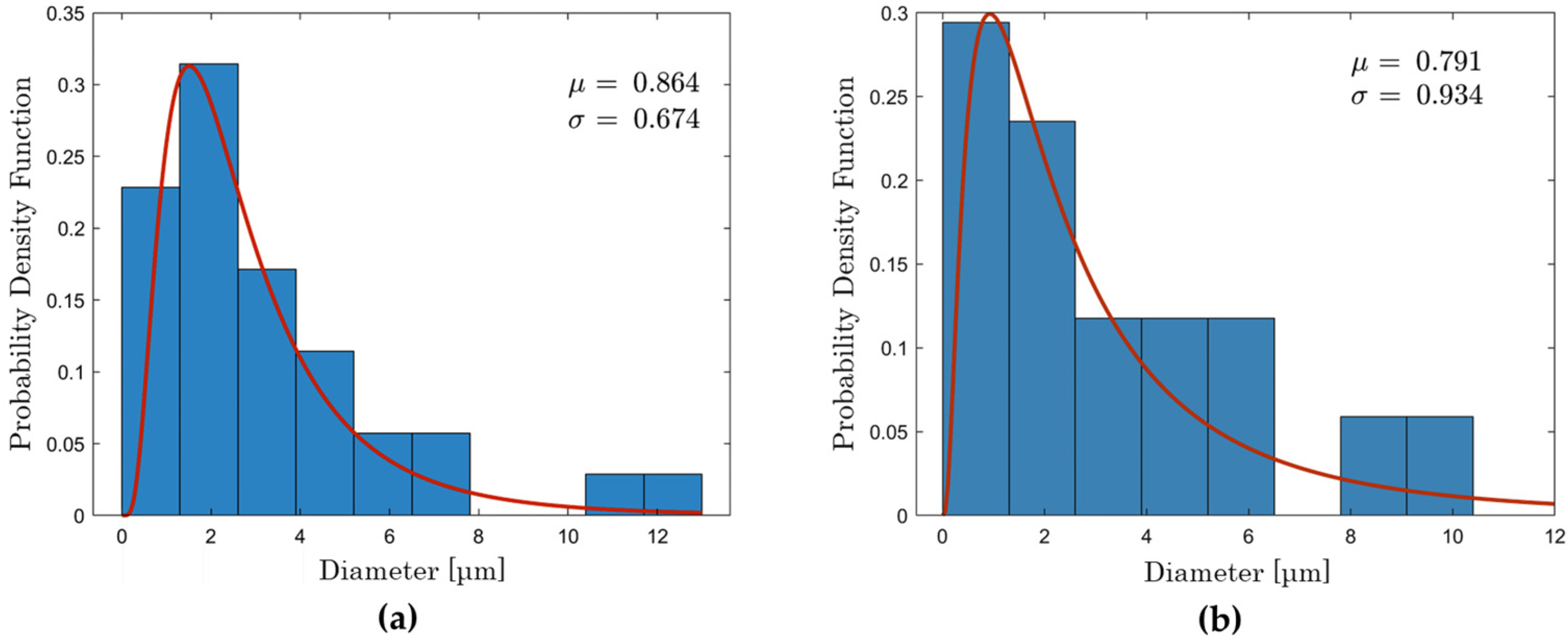

2.1. Material Statistics

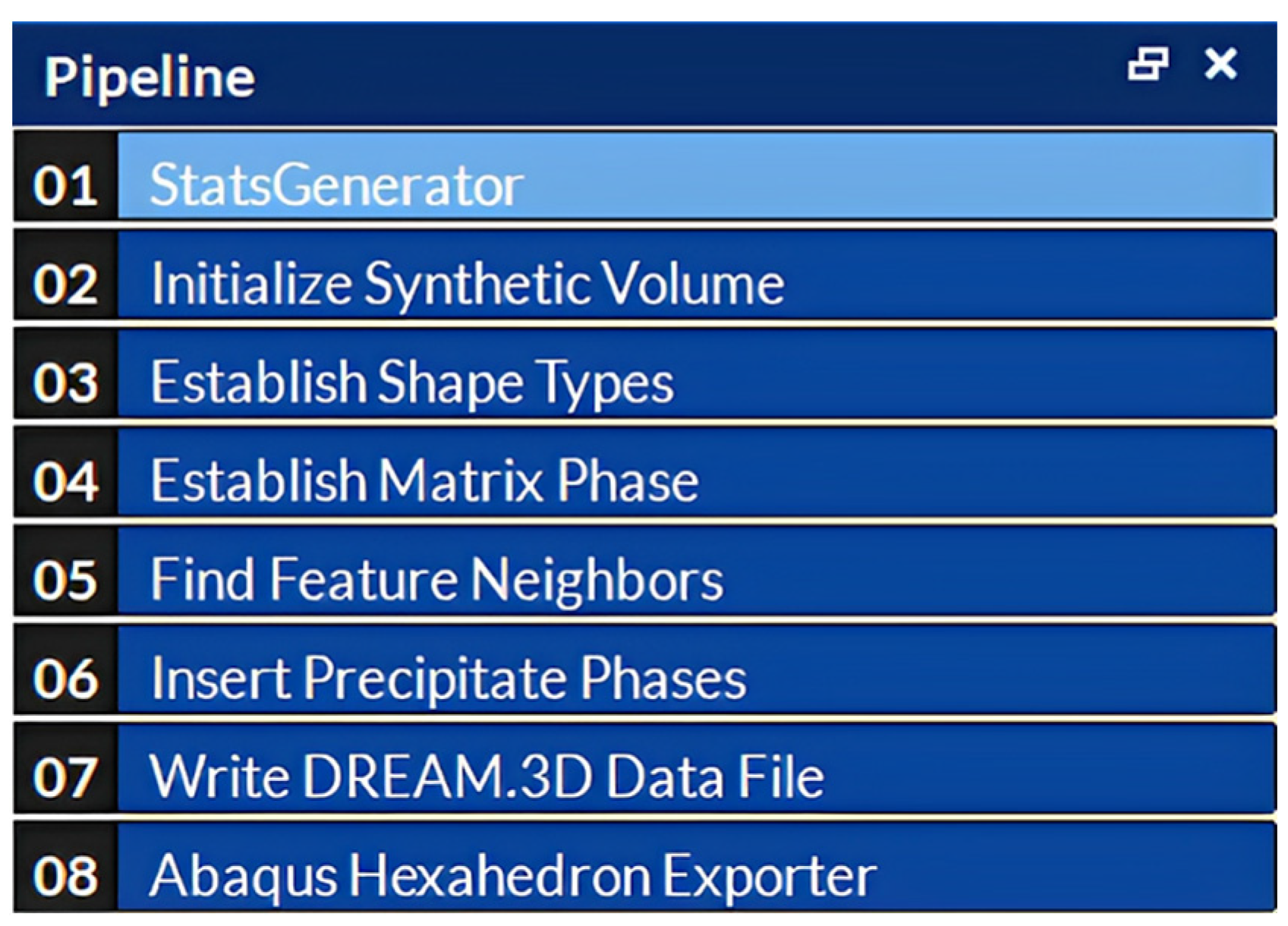

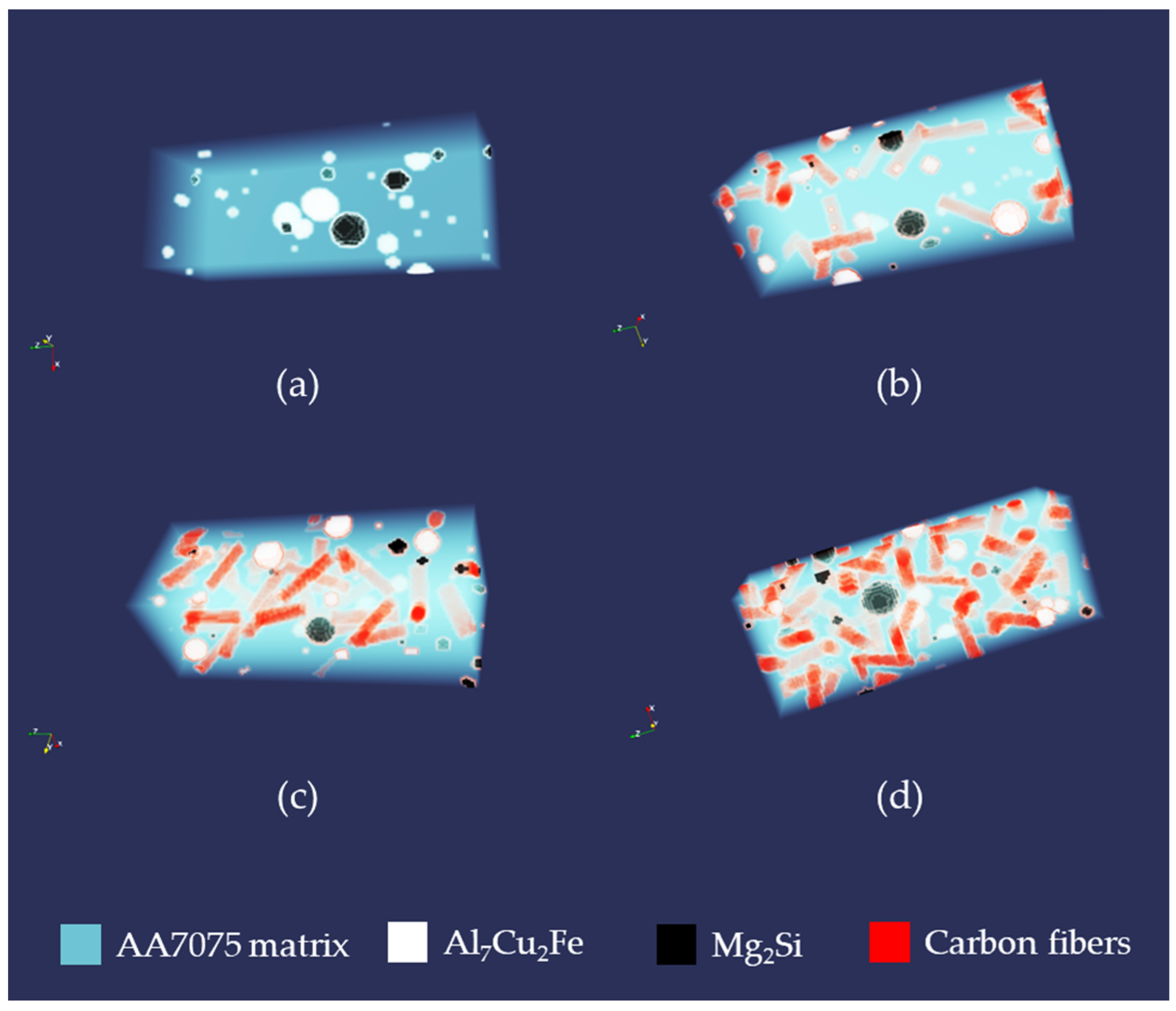

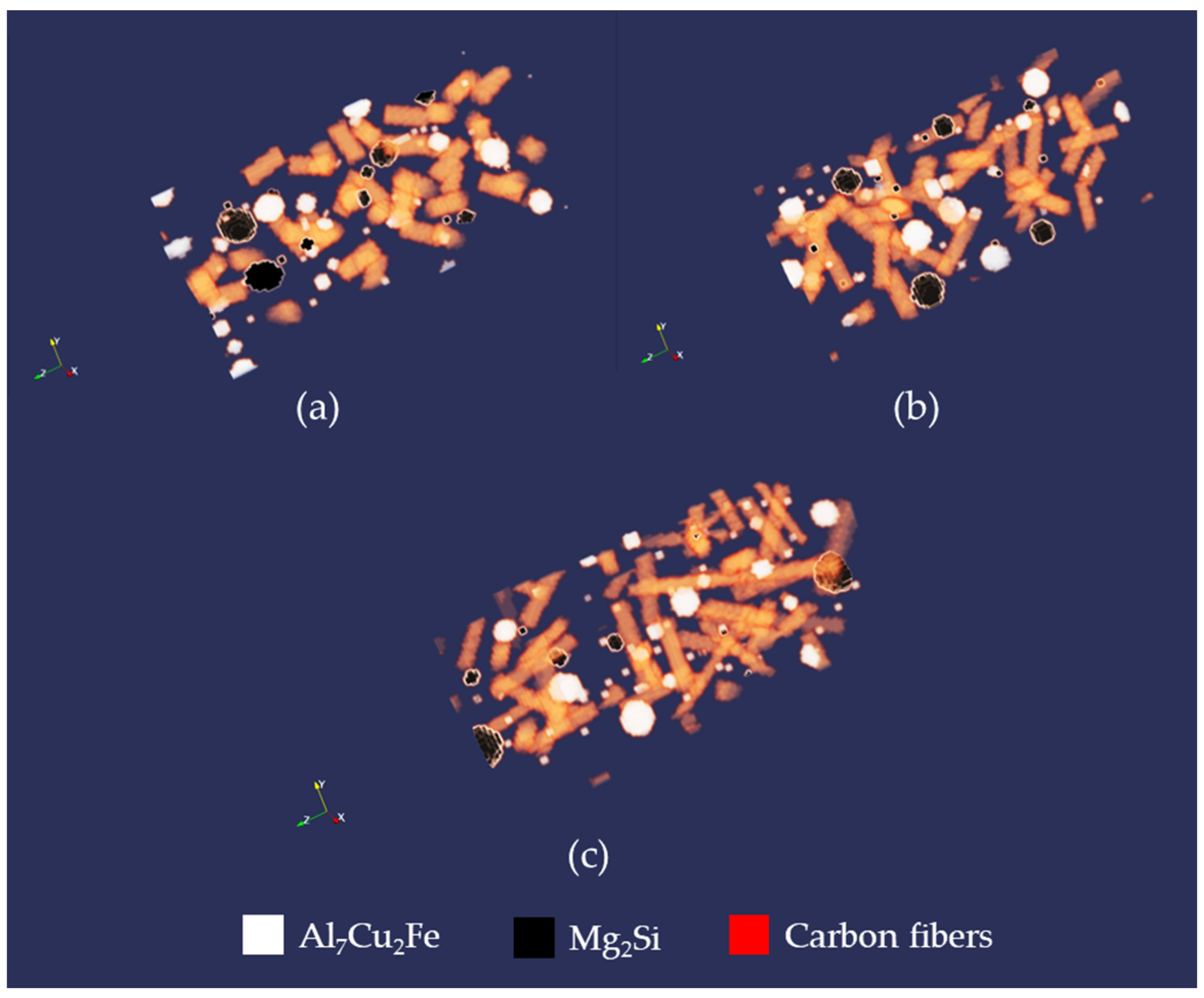

2.2. 3D Elements Building

2.3. Finite Element Analysis Simulations

3. Results

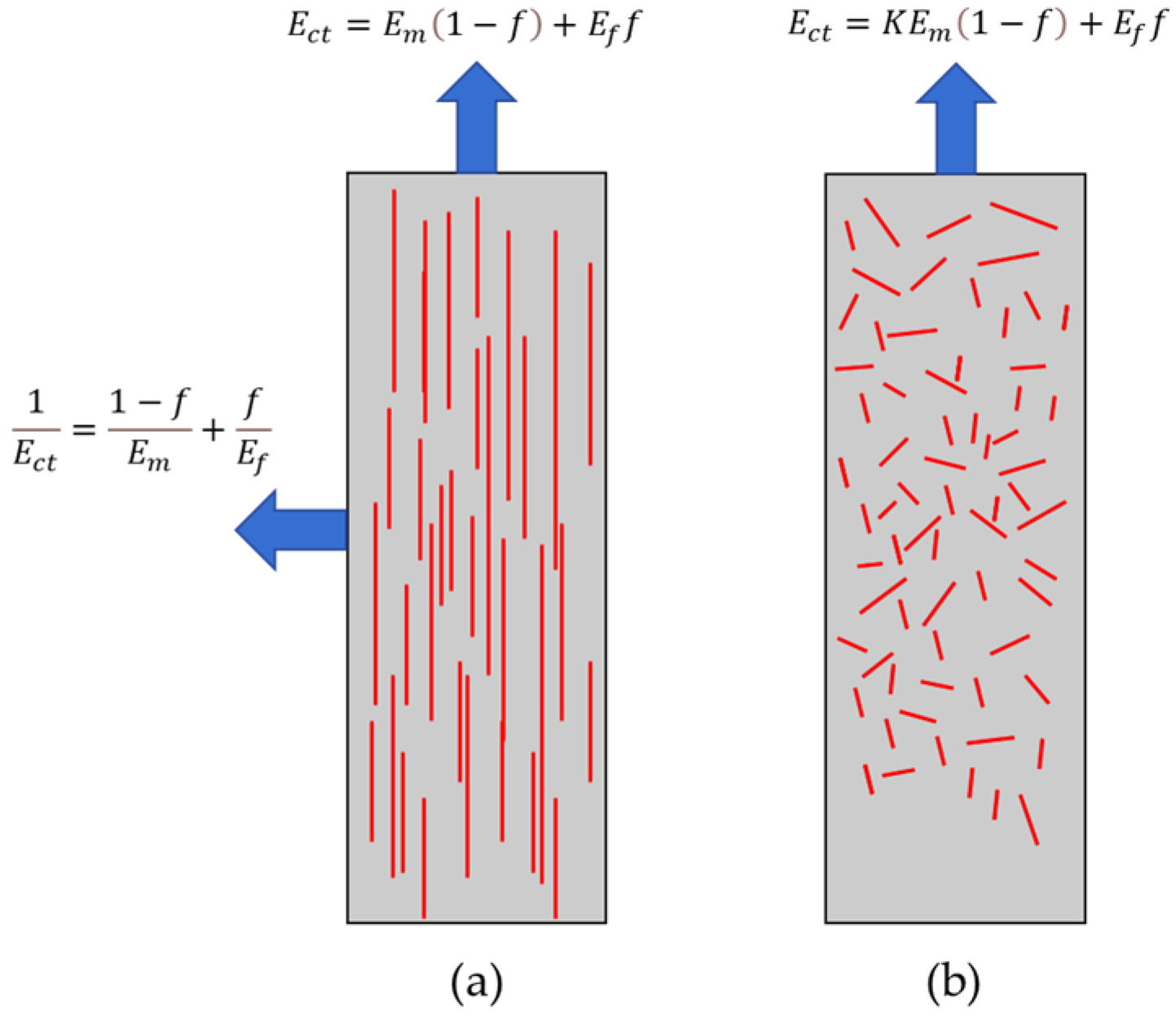

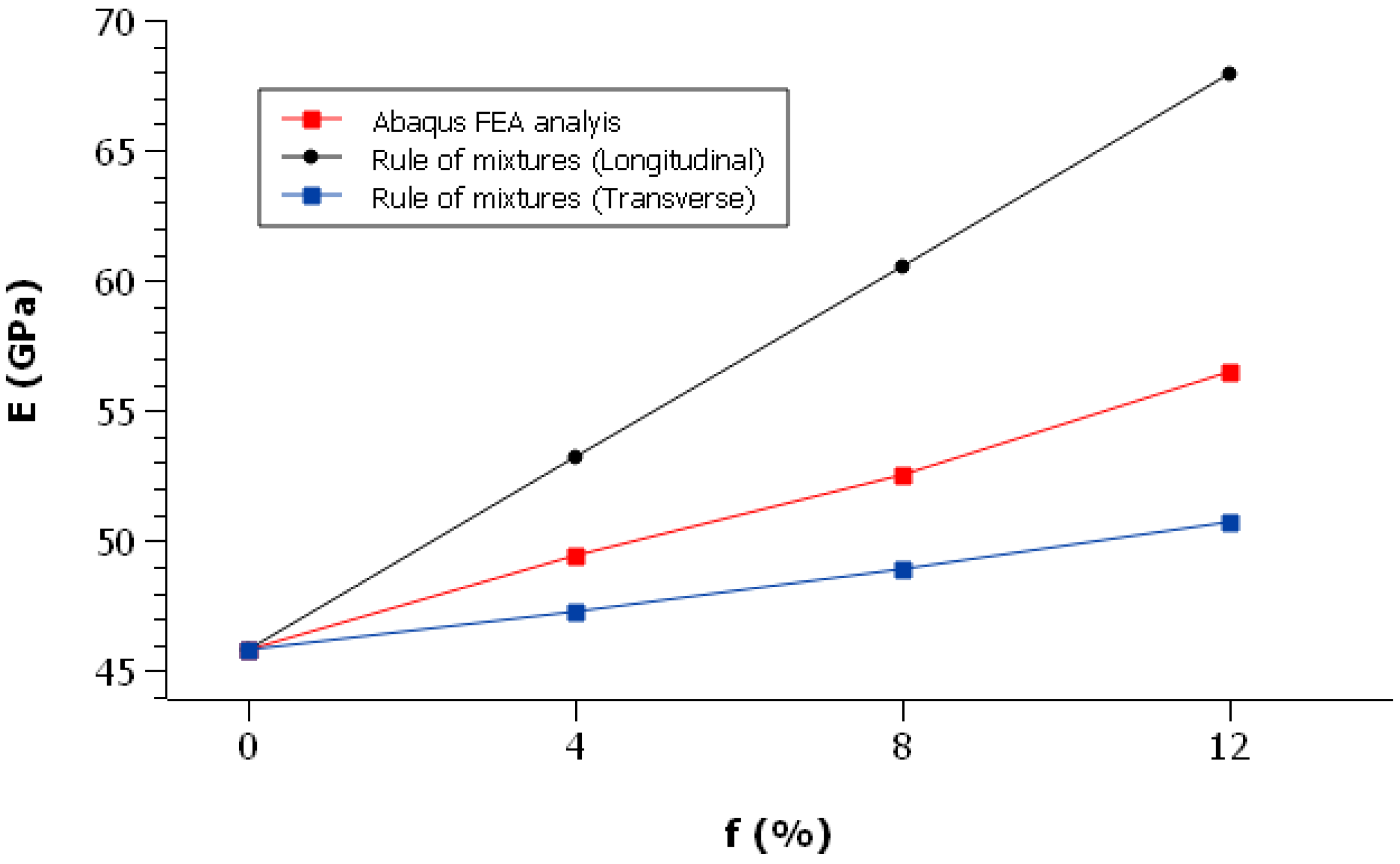

3.1. Elastic Moduli Dependence on CF Content

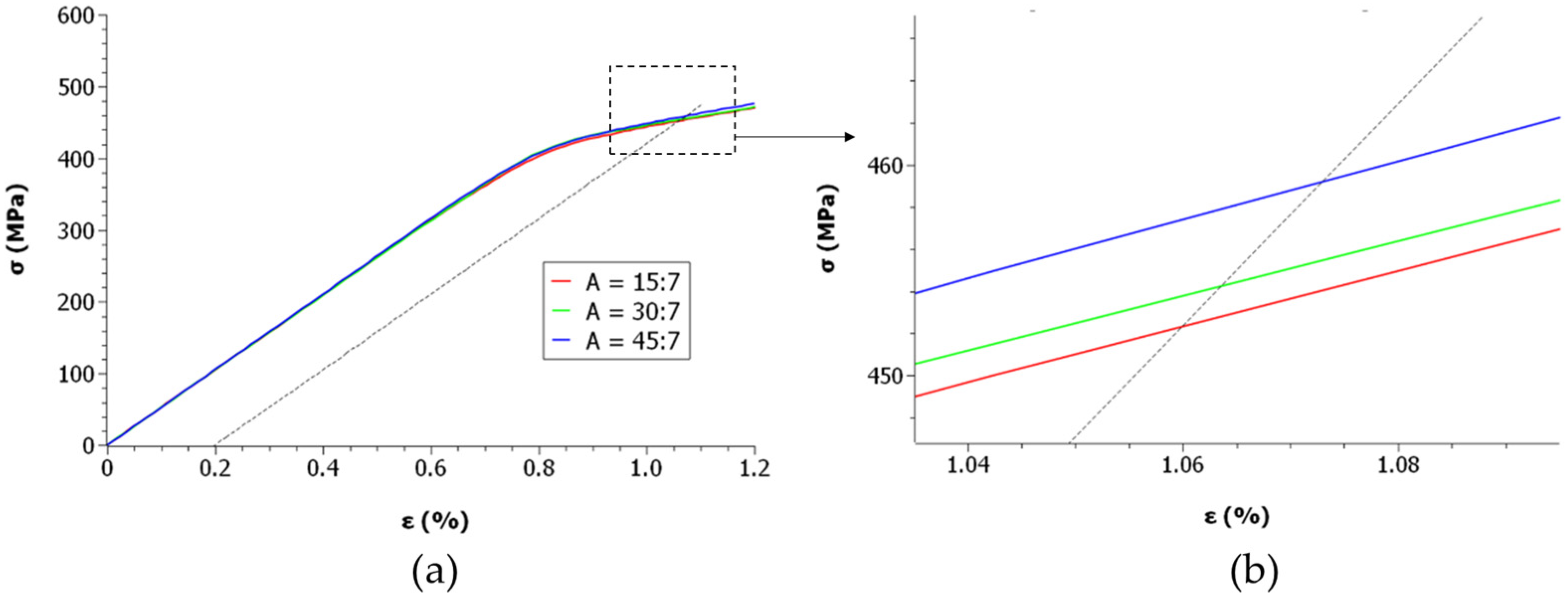

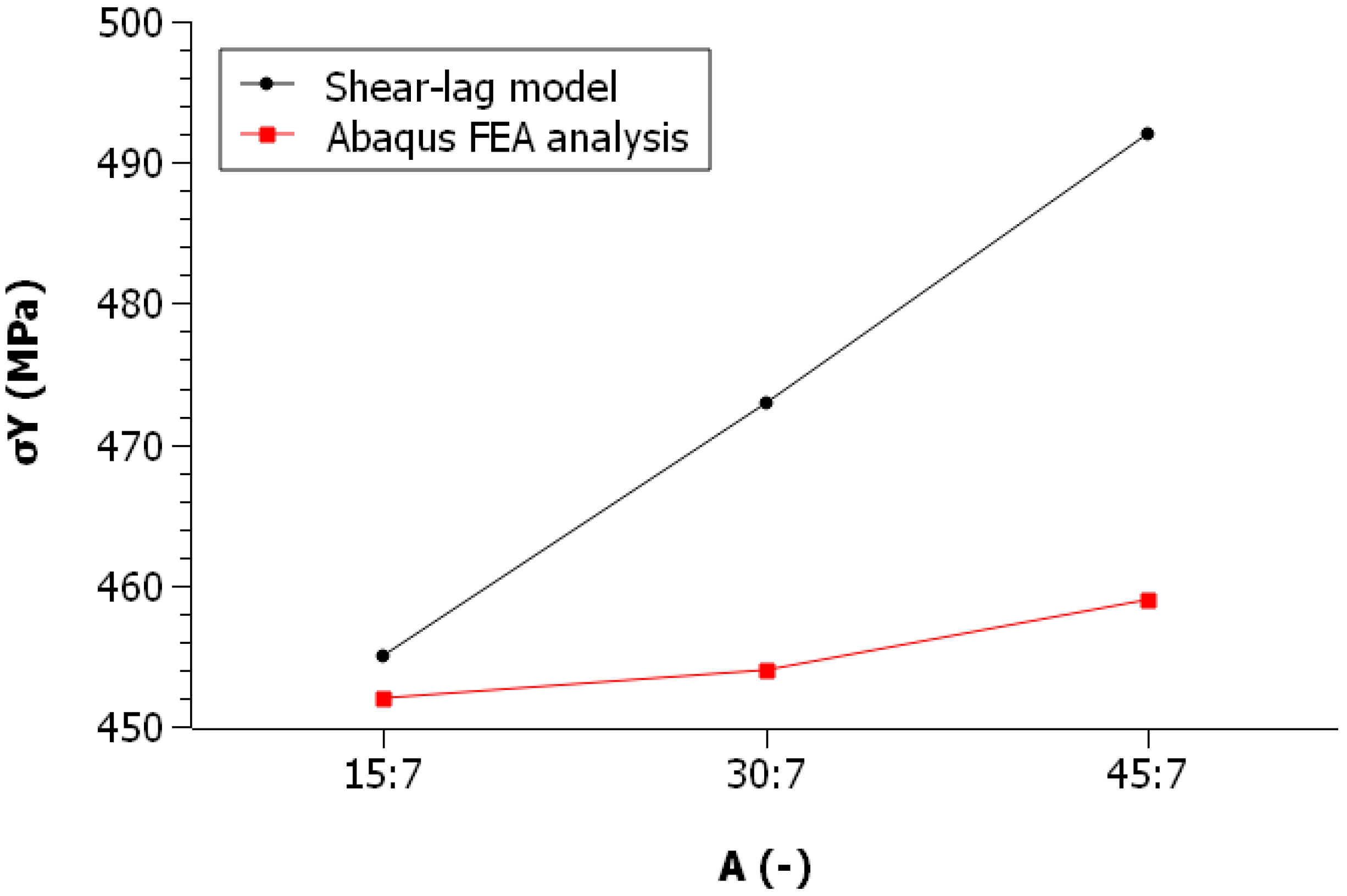

3.2. Yield Stress Dependence on CF Content and Aspect Ratio

4. Conclusions

- Extract statistical data describing the microstructure of AA7075 alloy and match the extracted surface fraction with the volume fraction of each phase;

- Build 3D SSRVEs by employing the DREAM.3D package, representing the two precipitate phases present in the alloy;

- Insert carbon fibers with the desired volume fraction and shape morphology, to mimic the microstructure of a randomly oriented MMC with discontinuous fibers;

- Perform tensile testing simulations with Abaqus FEA to these SSRVEs having appropriately adjusted the mechanical properties of each phase;

- Assess the macroscopic mechanical behavior of MMCs with respect to the volume fraction and the aspect ratio of CF by comparing this performance with that theoretically expected from fiber composite mechanics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, B.; Jansenss, K.; Dunne, F.P.E. Role of Geometrically Necessary Dislocation Density in Multiaxial and Non-Proportional Fatigue Crack Nucleation. Int. J. Fatigue 2020, 135, 105517. [Google Scholar] [CrossRef]

- Pinz, M.; Weber, G.; Lenthe, W.C.; Uchic, M.D.; Pollock, T.M.; Ghosh, S. Microstructure and Property Based Statistically Equivalent RVEs for Intragranular Γ−γ’ Microstructures of Ni-Based Superalloys. Acta Mater. 2018, 157, 245–258. [Google Scholar] [CrossRef]

- Lane, R.J.; Momen, A.M.; Kesler, M.S.; Brechtl, J.; Rios, O.; Nawaz, K.; Mirzaeifar, R. Developing an Experimental-Computational Framework to Investigate the Deformation Mechanisms and Mechanical Properties of Al-8Ce-10Mg Alloys at Micro and Macroscales. Mater. Today Commun. 2021, 28, 102674. [Google Scholar] [CrossRef]

- Tu, X.; Shahba, A.; Shen, J.; Ghosh, S. Microstructure and Property Based Statistically Equivalent RVEs for Polycrystalline-Polyphase Aluminum Alloys. Int. J. Plast. 2019, 115, 268–292. [Google Scholar] [CrossRef]

- Zhang, X.X.; Andrä, H. Crystal Plasticity Simulation of the Macroscale and Microscale Stress–Strain Relations of Additively Manufactured AlSi10Mg Alloy. Comput. Mater. Sci. 2021, 200, 110832. [Google Scholar] [CrossRef]

- Hajizad, O.; Kumar, A.; Petrov, R.H.; Sietsma, J.; Dollevoet, R.; Li, Z. Strain Partitioning and Damage Initiation in a Continuously Cooled Carbide Free Bainitic Steel. Comput. Mater. Sci. 2022, 202, 110965. [Google Scholar] [CrossRef]

- Diehl, M.; Groeber, M.; Haase, C.; Molodov, D.A.; Roters, F.; Raabe, D. Identifying Structure–Property Relationships Through DREAM.3D Representative Volume Elements and DAMASK Crystal Plasticity Simulations: An Integrated Computational Materials Engineering Approach. Jom 2017, 69, 848–855. [Google Scholar] [CrossRef]

- Bonifaz, E.A.; Baus, J.; Czekanski, A. Finite Element Modelling of Dual-Phase Polycrystalline Nickel-Base Alloys. Mech. Mater. 2016, 98, 134–141. [Google Scholar] [CrossRef]

- Bonifaz, E.A.; Alban, A.; Czekanski, A. Finite Element Analysis of Cylindrical Inclusions in Polycrystalline Nickel Alloys. J. Multiscale Model. 2018, 9, 1850003. [Google Scholar] [CrossRef]

- Carneiro, P.M.C.; Gamboa, P.V.; Baudín, C.; Silva, A.P. Modelling of Elastic Modulus of a Biphasic Ceramic Microstructure Using 3D Representative Volume Elements. J. Eur. Ceram. Soc. 2020, 40, 901–910. [Google Scholar] [CrossRef]

- Mermigkis, P.G.; Mavrantzas, V.G. Geometric Analysis of Clusters of Free Volume Accessible to Small Penetrants and Their Connectivity in Polymer Nanocomposites Containing Carbon Nanotubes. Macromolecules 2020, 53, 9563–9583. [Google Scholar] [CrossRef]

- Parashar, A.; Mertiny, P. Representative Volume Element to Estimate Buckling Behavior of Graphene/Polymer Nanocomposite. Nanoscale Res. Lett. 2012, 7, 1–6. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.K.; Ansari, R.; Darvizeh, A. Micromechanical Modeling of Thermal Expansion Coefficients for Unidirectional Glass Fiber-Reinforced Polyimide Composites Containing Silica Nanoparticles. Compos. Part A Appl. Sci. Manuf. 2017, 96, 110–121. [Google Scholar] [CrossRef]

- Yarali, E.; Baniassadi, M.; Baghani, M. Numerical Homogenization of Coiled Carbon Nanotube Reinforced Shape Memory Polymer Nanocomposites. Smart Mater. Struct. 2019, 28, 035026. [Google Scholar] [CrossRef]

- Qayyum, F.; Guk, S.; Kawalla, R.; Prahl, U. On Attempting to Create a Virtual Laboratory for Application-Oriented Microstructural Optimization of Multi-Phase Materials. Appl. Sci. 2021, 11, 1506. [Google Scholar] [CrossRef]

- Schneider, Y.; Weber, U.; Wasserbäch, W.; Zielke, R.; Schmauder, S.; Tillmann, W. A Numerical Method for the Generation of Hierarchical Poisson Voronoi Microstructures Applied in Micromechanical Finite Element Simulations—Part I: Method. Comput. Mech. 2020, 66, 651–667. [Google Scholar] [CrossRef]

- Fritzen, F.; Böhlke, T. Periodic Three-Dimensional Mesh Generation for Particle Reinforced Composites with Application to Metal Matrix Composites. Int. J. Solids Struct. 2011, 48, 706–718. [Google Scholar] [CrossRef]

- Sreeranganathan, A.; Gokhale, A.M.; Young, P. Realistic Micromechanical Modeling of Discontinuously Reinforced Composites. Comput. Mater. Sci. 2010, 49, 407–413. [Google Scholar] [CrossRef]

- Zhang, J.F.; Andrä, H.; Zhang, X.X.; Wang, Q.Z.; Xiao, B.L.; Ma, Z.Y. An Enhanced Finite Element Model Considering Multi Strengthening and Damage Mechanisms in Particle Reinforced Metal Matrix Composites. Compos. Struct. 2019, 226, 111281. [Google Scholar] [CrossRef]

- Sun, Z.; Zhao, J. Nano-Graphene Toughened Al2O3 Ceramic Materials: 3D Simulation of the Fracture Behaviour. Ceram. Int. 2020, 46, 28569–28577. [Google Scholar] [CrossRef]

- Shan, Z.; Gokhale, A.M. Representative Volume Element for Non-Uniform Micro-Structure. Comput. Mater. Sci. 2002, 24, 361–379. [Google Scholar] [CrossRef]

- Prosuntsov, P.V.; Taraskin, N.Y. Theoretical and Numerical Characterization of the Thermal Physical Properties of Carbon Ceramic Material. MATEC Web Conf. 2016, 72, 01092. [Google Scholar] [CrossRef]

- Tang, C.; Sheikh, M.A.; Hayhurst, D.R. Finite Element Modeling of Transverse Deformation in Representative Volume Elements of Ceramic Matrix Composites. J. Multiscale Model. 2010, 2, 107–126. [Google Scholar] [CrossRef]

- Brands, D.; Balzani, D.; Scheunemann, L.; Schröder, J.; Richter, H.; Raabe, D. Computational Modeling of Dual-Phase Steels Based on Representative Three-Dimensional Microstructures Obtained from EBSD Data. Arch. Appl. Mech. 2016, 86, 575–598. [Google Scholar] [CrossRef]

- Vittorietti, M.; Hidalgo, J.; López, J.G.; Sietsma, J.; Jongbloed, G. A Data-Driven Approach for Studying the Influence of Carbides on Work Hardening of Steel. Materials 2022, 15, 892. [Google Scholar] [CrossRef]

- Critchfield, T.R.; Johnson, O.K. Representative and Statistical Volume Elements for Grain Boundary Networks: A Stereological Approach. Acta Mater. 2020, 188, 166–180. [Google Scholar] [CrossRef]

- Mitić, V.V.; Paunović, V.; Janković, S.; Pavlović, V.; Antolović, I.; Rančić, D. Electronic Ceramic Structure within the Voronoi Cells Model and Microstructure Fractals Contacts Surfaces New Frontier Applications. Sci. Sinter. 2013, 45, 223–232. [Google Scholar] [CrossRef]

- Scheunemann, L.; Balzani, D.; Brands, D.; Schröder, J. Construction of Statistically Similar RVEs. In Analysis and Computation of Microstructure in Finite Plasticity; Conti, S., Hackl, K., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 219–256. ISBN 978-3-319-18242-1. [Google Scholar]

- Rauch, L.; Kuziak, R.; Pietrzyk, M. From High Accuracy to High Efficiency in Simulations of Processing of Dual-Phase Steels. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2014, 45, 497–506. [Google Scholar] [CrossRef]

- Sowrabh, B.S.; Gurumurthy, B.M.; Shivaprakash, Y.M.; Sharma, S.S. Reinforcements, Production Techniques and Property Analysis of AA7075 Matrix Composites-a Critical Review. Manuf. Rev. 2021, 8, 31. [Google Scholar] [CrossRef]

- Davis, J.R. Aluminum and Aluminum Alloys. In Alloying: Understanding the Basics; ASM International: Materials Park, OH, USA, 2001; pp. 351–416. ISBN 978-1-62708-297-6. [Google Scholar]

- Bhujangrao, T.; Veiga, F.; Froustey, C.; Guérard, S.; Iriondo, E.; Darnis, P.; Mata, F.G. Experimental Characterization of the AA7075 Aluminum Alloy Using Hot Shear Compression Test. Arch. Civ. Mech. Eng. 2021, 21, 45. [Google Scholar] [CrossRef]

- Zhu, Y.; Sun, K.; Frankel, G.S. Intermetallic Phases in Aluminum Alloys and Their Roles in Localized Corrosion. J. Electrochem. Soc. 2018, 165, C807–C820. [Google Scholar] [CrossRef]

- Zou, X.; Yan, H.; Chen, X.H. Evolution of Second Phases and Mechanical Properties of 7075 Al Alloy Processed by Solution Heat Treatment. Trans. Nonferrous Met. Soc. China 2017, 27, 2146–2155. (In English) [Google Scholar] [CrossRef]

- Aliyah, A.N.; Anawati, A. Effect of Heat Treatment on Microstructure and Mechanical Hardness of Aluminum Alloy AA7075. IOP Conf. Ser. Mater. Sci. Eng. 2019, 541, 1–6. [Google Scholar] [CrossRef]

- Kainer, K.U. Metal Matrix Composites: Custom-Made Materials for Automotive and Aerospace Engineering; Wiley-VCH Verlag GmbH & Co.: Weinheim, Germany, 2006; ISBN 3527313600. [Google Scholar]

- Seetharaman, S.; Gupta, M. Fundamentals of Metal Matrix Composites. In Encyclopedia of Materials: Composites; Elsevier: Oxford, UK, 2021; pp. 11–29. ISBN 9780128035818. [Google Scholar]

- Wu, J.; Zhang, C.; Meng, Q.; Liu, B.; Sun, Y.; Wen, M.; Ma, S.; He, L. Study on Tensile Properties of Carbon Fiber Reinforced AA7075 Composite at High Temperatures. Mater. Sci. Eng. A 2021, 825, 141931. [Google Scholar] [CrossRef]

- Singh, S.S.; Schwartzstein, C.; Williams, J.J.; Xiao, X.; De Carlo, F.; Chawla, N. 3D Microstructural Characterization and Mechanical Properties of Constituent Particles in Al 7075 Alloys Using X-Ray Synchrotron Tomography and Nanoindentation. J. Alloys Compd. 2014, 602, 163–174. [Google Scholar] [CrossRef]

- Singh, S.S.; Guo, E.; Xie, H.; Chawla, N. Mechanical Properties of Intermetallic Inclusions in Al 7075 Alloys by Micropillar Compression. Intermetallics 2015, 62, 69–75. [Google Scholar] [CrossRef]

- Torbati-Sarraf, H.; Stannard, T.J.; La Plante, E.C.; Sant, G.N.; Chawla, N. Direct Observations of Microstructure-Resolved Corrosion Initiation in AA7075-T651 at the Nanoscale Using Vertical Scanning Interferometry (VSI). Mater. Charact. 2020, 161, 110166. [Google Scholar] [CrossRef]

- Gharbi, O.; Kumar Kairy, S.; De Lima, P.R.; Jiang, D.; Nicklaus, J.; Birbilis, N. Microstructure and Corrosion Evolution of Additively Manufactured Aluminium Alloy AA7075 as a Function of Ageing. NPJ Mater. Degrad. 2019, 3, 40. [Google Scholar] [CrossRef]

- Jin, Y.; Cai, P.; Wen, W.; Nagaumi, H.; Xu, B.; Zhang, Y.; Zhai, T. The Anisotropy of Fatigue Crack Nucleation in an AA7075 T651 Al Alloy Plate. Mater. Sci. Eng. A 2015, 622, 7–15. [Google Scholar] [CrossRef]

- Mason, S.F. Crystal Structure Determinations; Springer: Berlin/Heidelberg, Germany, 1979; Volume 282, ISBN 9783642072710. [Google Scholar]

- Fátima Vaz, M.; Fortes, M.A. Grain Size Distribution: The Lognormal and the Gamma Distribution Functions. Scr. Metall. 1988, 22, 35–40. [Google Scholar] [CrossRef]

- Deschamps, A. Microstructure—Properties Relationships In Metal-Based Alloys. In Mechanical Properties of Complex Intermetallics; Belin-Ferré, E., Ed.; World Scientific Publishing Company: Paris, France, 2010; pp. 73–124. [Google Scholar]

- Chang, K.-H. Reliability Analysis. In E-Design; Elsevier: Amsterdam, The Netherlands, 2015; pp. 523–595. [Google Scholar]

- Groeber, M.A.; Jackson, M.A. DREAM.3D: A Digital Representation Environment for the Analysis of Microstructure in 3D. Integr. Mater. Manuf. Innov. 2014, 3, 56–72. [Google Scholar] [CrossRef]

- Dassault Systèmes Simulia Inc. Abaqus 6.14. Analysis User’s Manual. Available online: https://classes.engineering.wustl.edu/2009/spring/mase5513/abaqus/docs/v6.6/books/usb/default.htm?startat=pt05ch17s02abm02.html (accessed on 15 February 2023).

- Toray T700SC-12K Data Sheet. Available online: https://www.toraycma.com/wp-content/uploads/T700S-Technical-Data-Sheet-1.pdf.pdf (accessed on 14 February 2023).

- Langston, T. The Tensile Behavior of High-Strength Carbon Fibers. Microsc. Microanal. 2016, 22, 841–844. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering: An Introduction, 10th ed.; Wiley: Hoboken, NJ, USA, 2018; ISBN 9781119321590. [Google Scholar]

- Quadros, J.D.; Suhas, P.; Vaishak, N.L. Evaluation of Mechanical Properties of Aluminium Alloy 7075 Reinforced with SiC and Al2O3 Hybrid Metal Matrix Composites. Am. J. Mater. Sci. 2017, 7, 102–107. [Google Scholar] [CrossRef]

- Bargmann, S.; Klusemann, B.; Markmann, J.; Schnabel, J.E.; Schneider, K.; Soyarslan, C.; Wilmers, J. Generation of 3D Representative Volume Elements for Heterogeneous Materials: A Review. Prog. Mater. Sci. 2018, 96, 322–384. [Google Scholar] [CrossRef]

- Sanaty-Zadeh, A. Comparison between Current Models for the Strength of Particulate-Reinforced Metal Matrix Nanocomposites with Emphasis on Consideration of Hall-Petch Effect. Mater. Sci. Eng. A 2012, 531, 112–118. [Google Scholar] [CrossRef]

| ImageJ Analysis Surface Fraction | Literature Volume Fraction [39,43] | Differences (%) | |

|---|---|---|---|

| 1.19% | 1.29% | 8 | |

| 0.54% | 0.34% | 59 | |

| + | 1.73% | 1.63% | 6 |

| 0.69% | 0.79% | 13 |

| Elastic Modulus (GPa) | Poisson’s Ratio | Yield Stress (MPa) | Strain Hardening Modulus (MPa) | |

|---|---|---|---|---|

| Matrix | 44 | 0.3 | 400 | 0 |

| 500 | 0.011 | |||

| 600 | 0.036 | |||

| Mg2Si | 102 | 0.3 | 1650 | 0 |

| 1950 | 0.036 | |||

| Al7Cu2Fe | 132 | 0.3 | 2500 | 0 |

| CF | 230 | 0.3 | 4900 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markopoulos, I.; Kouris, L.-A.; Konstantinidis, A. On the Use of Microstructure Characteristics to Predict Metal Matrix Composites’ Macroscopic Mechanical Behavior. Appl. Sci. 2023, 13, 4989. https://doi.org/10.3390/app13084989

Markopoulos I, Kouris L-A, Konstantinidis A. On the Use of Microstructure Characteristics to Predict Metal Matrix Composites’ Macroscopic Mechanical Behavior. Applied Sciences. 2023; 13(8):4989. https://doi.org/10.3390/app13084989

Chicago/Turabian StyleMarkopoulos, Ioannis, Leonidas-Alexandros Kouris, and Avraam Konstantinidis. 2023. "On the Use of Microstructure Characteristics to Predict Metal Matrix Composites’ Macroscopic Mechanical Behavior" Applied Sciences 13, no. 8: 4989. https://doi.org/10.3390/app13084989