Multi-Location Assortment Optimization with Drone and Human Courier Joint Delivery

Abstract

:1. Introduction

- To the best of our knowledge, this paper is the first one to consider the assortment optimization problem under cooperative delivery by drone and human courier.

- The drone and human courier joint delivery mode is proposed, and the load constraint of the drone, delivery distance settings, and storage capacity are concluded in the model. The MMNL model is used to characterize customer purchase behavior.

- The MIP model is converted into MILP, and an accurate Conic + MC algorithm is designed to accelerate calculation.

- In the numerical study, we first verify the effectiveness of our Conic + MC algorithm, then we conduct two cases to give some advice on product distribution optimization and delivery setting optimization.

2. Literature Review

3. Model Description

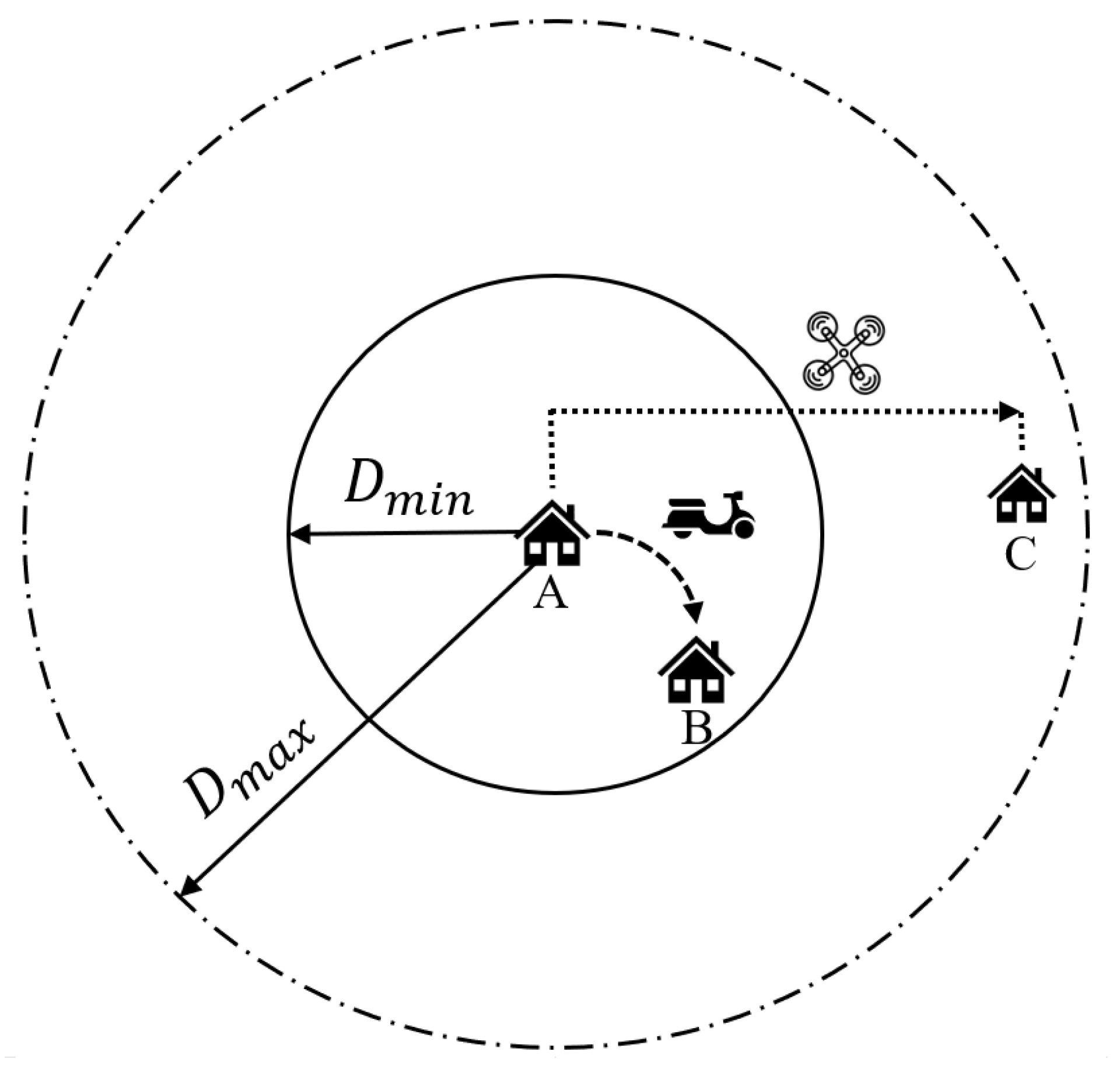

3.1. Problem Definition

3.2. Complexity

4. Mixed-Integer Linear Programming Formulation

4.1. MILP Formulation

4.2. Conic Formulation

4.3. McCormick Inequalities

5. Numerical Study

5.1. Effectiveness of MILP and Conic + MC

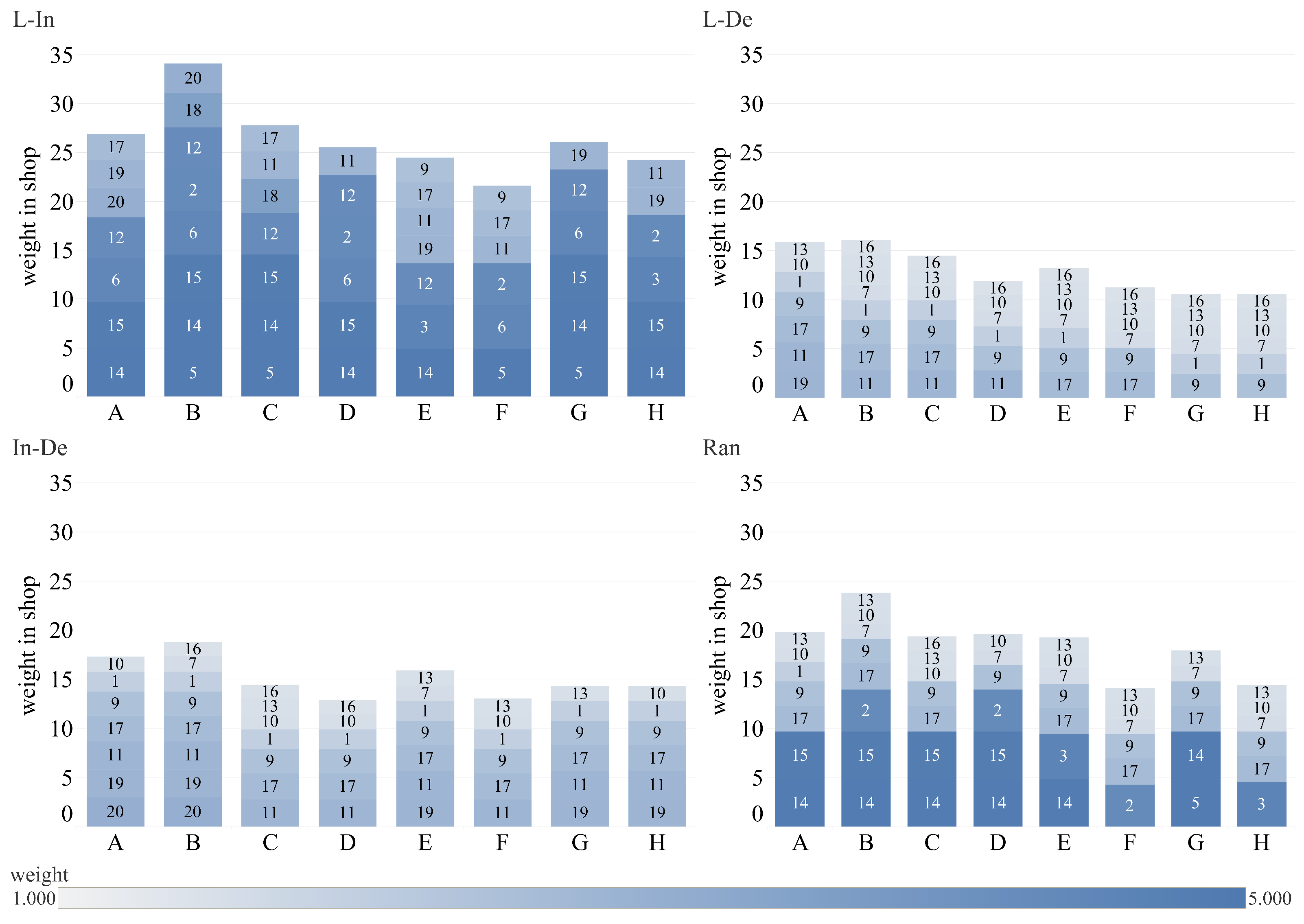

5.2. The Influence of Marginal Revenue Varying by Weight

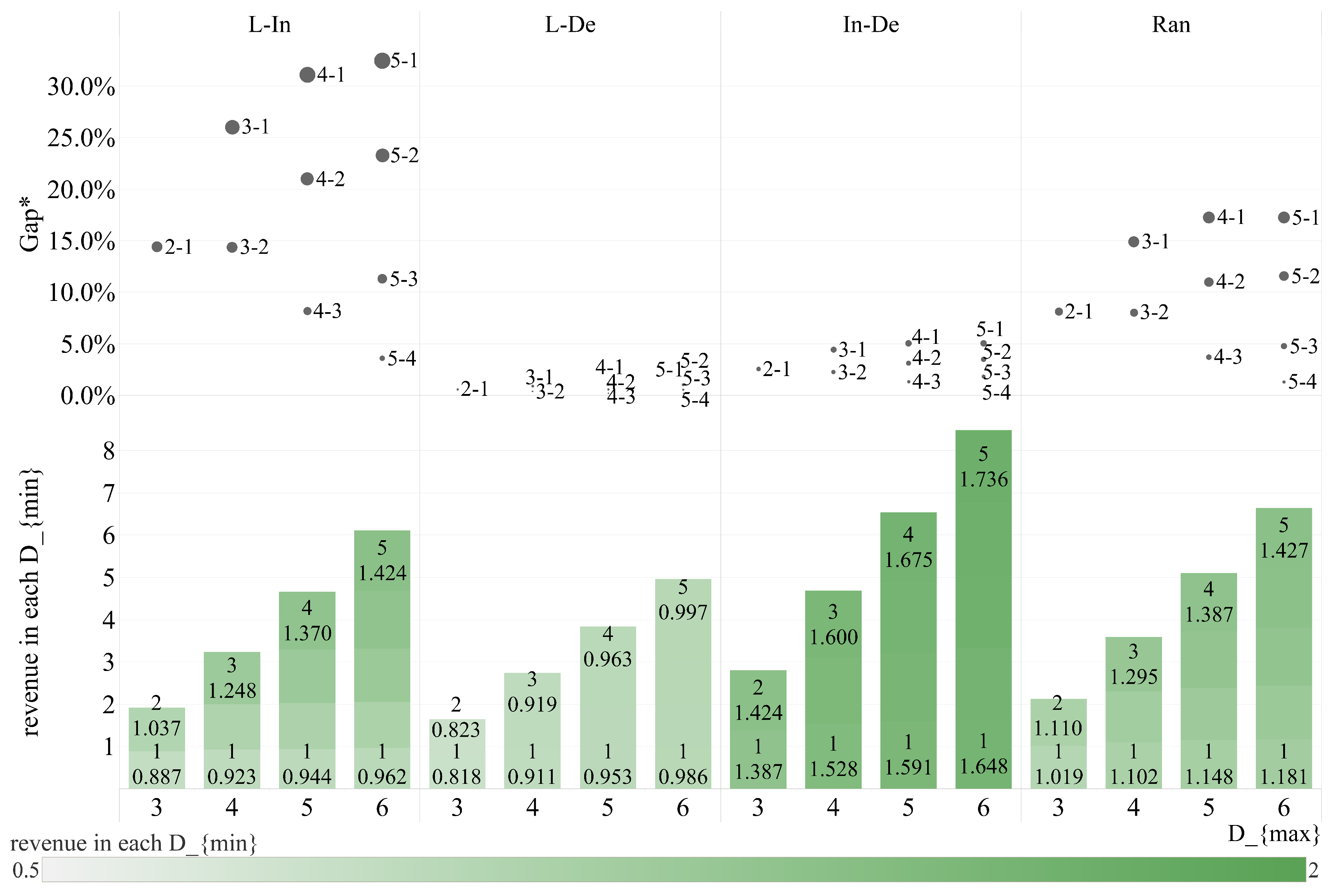

5.3. The Influence of Delivery Distance on Revenue

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| MIP | Mixed-integer program |

| MILP | Mixed-integer linear program |

| Conic + MC | Conic quadratic mixed-integer formulation with McCormick inequalities |

| MNL | Multinomial Logit model |

| NL | Nested Logit model |

| MMNL | Mixture of Multinomial Logit model |

| IIA | Independence of Irrelevant Alternatives |

| MADH | Multi-location assortment problem under the cooperative delivery by drone and human courier |

Appendix A

| A | B | C | D | E | F | G | H | Capacity List | |

|---|---|---|---|---|---|---|---|---|---|

| A | 0.000 | 18.063 | 10.890 | 14.064 | 18.900 | 19.174 | 5.693 | 14.105 | 7 |

| B | 18.063 | 0.000 | 15.143 | 1.864 | 3.705 | 11.626 | 1.066 | 8.683 | 8 |

| C | 10.890 | 15.143 | 0.000 | 19.600 | 16.926 | 5.179 | 4.944 | 6.794 | 7 |

| D | 14.064 | 1.864 | 19.600 | 0.000 | 9.494 | 16.088 | 9.502 | 17.944 | 6 |

| E | 18.900 | 3.705 | 16.926 | 9.494 | 0.000 | 7.001 | 9.586 | 5.640 | 7 |

| F | 19.174 | 11.626 | 5.179 | 16.088 | 7.001 | 0.000 | 18.664 | 5.622 | 6 |

| G | 5.693 | 1.066 | 4.944 | 9.502 | 9.586 | 18.664 | 0.000 | 1.447 | 6 |

| H | 14.105 | 8.683 | 6.794 | 17.944 | 5.640 | 5.622 | 1.447 | 0.000 | 6 |

| Product | Weight | L–In | L–De | In–De | Ran | Product | Weight | L–In | L–De | In–De | Ran |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.987 | 1.987 | 3.013 | 4.743 | 2.069 | 11 | 2.828 | 2.828 | 2.172 | 4.894 | 1.064 |

| 2 | 4.317 | 4.317 | 0.683 | 2.079 | 3.592 | 12 | 4.241 | 4.241 | 0.759 | 2.296 | 1.262 |

| 3 | 4.586 | 4.586 | 0.414 | 1.284 | 4.964 | 13 | 1.528 | 1.528 | 3.472 | 4.097 | 3.888 |

| 4 | 3.112 | 3.112 | 1.888 | 4.635 | 4.163 | 14 | 4.849 | 4.849 | 0.151 | 0.474 | 4.152 |

| 5 | 4.856 | 4.856 | 0.144 | 0.453 | 3.586 | 15 | 4.831 | 4.831 | 0.169 | 0.531 | 3.680 |

| 6 | 4.471 | 4.471 | 0.529 | 1.633 | 2.572 | 16 | 1.462 | 1.462 | 3.538 | 3.974 | 2.651 |

| 7 | 1.600 | 1.600 | 3.400 | 4.222 | 4.422 | 17 | 2.646 | 2.646 | 2.354 | 4.979 | 4.486 |

| 8 | 3.105 | 3.105 | 1.895 | 4.643 | 1.248 | 18 | 3.523 | 3.523 | 1.477 | 4.002 | 3.295 |

| 9 | 2.462 | 2.462 | 2.538 | 4.999 | 4.629 | 19 | 2.841 | 2.841 | 2.159 | 4.886 | 2.113 |

| 10 | 1.564 | 1.564 | 3.436 | 4.161 | 3.490 | 20 | 3.003 | 3.003 | 1.997 | 4.753 | 1.639 |

References

- Jin. Meituan Drones: In 2022, More Than 100,000 Orders Were Delivered between Shanghai and Shenzhen, with an Average of 12 Minutes per Order. 2023. Available online: https://finance.sina.com.cn/jjxw/2023-01-16/doc-imyakpnk9115299.shtml (accessed on 16 January 2023).

- Kirschstein, T. Comparison of energy demands of drone-based and ground-based parcel delivery services. Transp. Res. Part Transp. Environ. 2020, 78, 102209. [Google Scholar] [CrossRef]

- Kim, S.H. Choice model based analysis of consumer preference for drone delivery service. J. Air Transp. Manag. 2020, 84, 101785. [Google Scholar] [CrossRef]

- Borghetti, F.; Caballini, C.; Carboni, A.; Grossato, G.; Maja, R.; Barabino, B. The use of drones for last-mile delivery: A numerical case study in milan, italy. Sustainability 2022, 14, 1766. [Google Scholar] [CrossRef]

- Lyu, G.; Teo, C.-P. Last mile innovation: The case of the locker alliance network. Manuf. Serv. Oper. Manag. 2022, 24, 2425–2443. [Google Scholar] [CrossRef]

- Clothier, R.A.; Greer, D.A.; Greer, D.G.; Mehta, A.M. Risk perception and the public acceptance of drones. Risk Anal. 2015, 35, 1167–1183. [Google Scholar] [CrossRef]

- Waris, I.; Ali, R.; Nayyar, A.; Baz, M.; Liu, R.; Hameed, I. An empirical evaluation of customers’ adoption of drone food delivery services: An extended technology acceptance model. Sustainability 2022, 14, 2922. [Google Scholar] [CrossRef]

- Aydin, B. Public acceptance of drones: Knowledge, attitudes, and practice. Technol. Soc. 2019, 59, 101180. [Google Scholar] [CrossRef]

- Park, J.; Kim, S.; Suh, K. A comparative analysis of the environmental benefits of drone-based delivery services in urban and rural areas. Sustainability 2018, 10, 888. [Google Scholar] [CrossRef]

- Baldisseri, A.; Siragusa, C.; Seghezzi, A.; Mangiaracina, R.; Tumino, A. Truck-based drone delivery system: An economic and environmental assessment. Transp. Res. Part Transp. Environ. 2022, 107, 103296. [Google Scholar] [CrossRef]

- Chauhan, D.; Unnikrishnan, A.; Figliozzi, M. Maximum coverage capacitated facility location problem with range constrained drones. Transp. Res. Part Emerg. Technol. 2019, 99, 1–18. [Google Scholar] [CrossRef]

- Cicek, C.T.; Gultekin, H.; Tavli, B. The location-allocation problem of drone base stations. Comput. Oper. Res. 2019, 111, 155–176. [Google Scholar] [CrossRef]

- Aurambout, J.-P.; Gkoumas, K.; Ciuffo, B. Last mile delivery by drones: An estimation of viable market potential and access to citizens across european cities. Eur. Transp. Res. Rev. 2019, 11, 30. [Google Scholar] [CrossRef]

- Salama, M.; Srinivas, S. Joint optimization of customer location clustering and drone-based routing for last-mile deliveries. Transp. Res. Part Emerg. Technol. 2020, 114, 620–642. [Google Scholar] [CrossRef]

- Poikonen; S; Golden; B Multi-visit drone routing problem. Comput. Oper. Res. 2020, 113, 104802. [CrossRef]

- Wang, Z.; Sheu, J.-B. Vehicle routing problem with drones. Transp. Res. Part Methodol. 2019, 122, 350–364. [Google Scholar] [CrossRef]

- Sadiq, O.B.; Salawudeen, A. Fanet optimization: A destination path flow model. Int. J. Electr. Comput. Eng. (IJECE) 2020, 10, 4381–4389. [Google Scholar] [CrossRef]

- Poikonen, S.; Golden, B. The mothership and drone routing problem. Informs J. Comput. 2020, 32, 249–262. [Google Scholar] [CrossRef]

- Leon-Blanco, J.M.; Gonzalez-R, P.L.; Andrade-Pineda, J.L.; Canca, D.; Calle, M. A multi-agent approach to the truck multi-drone routing problem. Expert Syst. Appl. 2022, 195, 116604. [Google Scholar] [CrossRef]

- Chung, S.H.; Sah, B.; Lee, J. Optimization for drone and drone-truck combined operations: A review of the state of the art and future directions. Comput. Oper. Res. 2020, 123, 105004. [Google Scholar] [CrossRef]

- Talluri, K.; Van Ryzin, G. Revenue management under a general discrete choice model of consumer behavior. Manag. Sci. 2004, 5, 15–33. [Google Scholar] [CrossRef]

- Rusmevichientong, P.; Shen, Z.-J.M.; Shmoys, D.B. Dynamic assortment optimization with a multinomial logit choice model and capacity constraint. Oper. Res. 2010, 58, 1666–1680. [Google Scholar] [CrossRef]

- Davis, J.; Gallego, G.; Topaloglu, H. Assortment planning under the multinomial logit model with totally unimodular constraint structures. In Work in Progress; Department of IEOR, Columbia University: Palisades, NY, USA, 2013. [Google Scholar]

- Feldman, J.; Paul, A. Relating the approximability of the fixed cost and space constrained assortment problems. Prod. Oper. Manag. 2019, 28, 1238–1255. [Google Scholar] [CrossRef]

- Davis, J.M.; Gallego, G.; Topaloglu, H. Assortment optimization under variants of the nested logit model. Oper. Res. 2014, 62, 250–273. [Google Scholar] [CrossRef]

- Gallego, G.; Topaloglu, H. Constrained assortment optimization for the nested logit model. Manag. Sci. 2014, 60, 2583–2601. [Google Scholar] [CrossRef]

- Feldman, J.; Topaloglu, H. Capacitated assortment optimization under the multinomial logit model with nested consideration sets. Oper. Res. 2018, 66, 380–391. [Google Scholar] [CrossRef]

- Rusmevichientong, P.; Shmoys, D.; Topaloglu, H. Assortment optimization with mixtures of logits. In Technical Report; School of IEOR, Cornell University: Ithaca, NY, USA, 2010. [Google Scholar]

- Mittal, S.; Schulz, A.S. A general framework for designing approximation schemes for combinatorial optimization problems with many objectives combined into one. Oper. Res. 2013, 61, 386–397. [Google Scholar] [CrossRef]

- Désir, A.; Goyal, V.; Zhang, J. Near-optimal algorithms for capacity constrained assortment optimization. SSRN 2014, 2543309. [Google Scholar] [CrossRef]

- Bront, J.J.M.; Méndez-Díaz, I.; Vulcano, G. A column generation algorithm for choice-based network revenue management. Oper. Res. 2009, 57, 769–784. [Google Scholar] [CrossRef]

- Méndez-Díaz, I.; Miranda-Bront, J.J.; Vulcano, G.; Zabala, P. A branch-and-cut algorithm for the latent-class logit assortment problem. Discret. Appl. Math. 2014, 164, 246–263. [Google Scholar] [CrossRef]

- Bebitoğlu, B. Multi-Location Assortment Optimization under Capacity Constraints. Ph.D. Thesis, Bilkent Universitesi, Ankara, Turkey, 2016. [Google Scholar]

- Sen, A.; Atamturk, A.; Kaminsky, P. A conic integer optimization approach to the constrained assortment problem under the mixed multinomial logit model. Oper. Res. 2018, 66, 994–1003. [Google Scholar] [CrossRef]

- Chen, J.; Liang, Y.; Shen, H.; Shen, Z.-J.M.; Xue, M. Offline-channel planning in smart omnichannel retailing. Manuf. Serv. Oper. Manag. 2022, 24, 2444–2462. [Google Scholar] [CrossRef]

- Akçay, Y.; Tan, B. On the benefits of assortment-based cooperation among independent producers. Prod. Oper. Manag. 2008, 17, 626–640. [Google Scholar] [CrossRef]

- Besbes, O.; Sauré, D. Product assortment and price competition under multinomial logit demand. Prod. Oper. Manag. 2016, 25, 114–127. [Google Scholar] [CrossRef]

- Rodríguez, B.; Aydın, G. Pricing and assortment decisions for a manufacturer selling through dual channels. Eur. J. Oper. Res. 2015, 242, 901–909. [Google Scholar] [CrossRef]

- Gallego, G.; Li, A.; Truong, V.-A.; Wang, X. Approximation algorithms for product framing and pricing. Oper. Res. 2020, 68, 134–160. [Google Scholar] [CrossRef]

- Lin, Y.H.; Wang, Y.; He, D.; Lee, L.H. Last-mile delivery: Optimal locker location under multinomial logit choice model. Transp. Res. Part Logist. Transp. Rev. 2020, 142, 102059. [Google Scholar] [CrossRef]

- Désir, A.; Goyal, V.; Zhang, J. Capacitated assortment optimization: Hardness and approximation. Oper. Res. 2022, 70, 893–904. [Google Scholar] [CrossRef]

| Reference | Topic | Constraint | Choice Model | Comments |

|---|---|---|---|---|

| Akçay and Tan (2008) [36] | Assortment-based cooperation among independent producers | Cooperation constraint | Assortment-based substitution | An analytical model to determine the characteristics of firms and products, explore what firms should cooperate with and set the parameters of it |

| Rusmevichientong et al. (2010b) [28] | Assortment optimization problem with a mixture of logits | Unconstrained | MMNL | Given the first PTAS for the assortment problem under MMNL model |

| Rusmevichientong et al. (2010a) [22] | Dynamic assortment optimization problem | Capacity constraint | MNL | An adaptive policy for joint parameter estimation and assortment optimization |

| Rodríguez and Aydın (2015) [38] | Pricing and assortment problem through dual channels | Cardinality constraint | NL | Give optimal pricing strategies and characterize scenarios in which the assortment preferences are in conflict |

| Besbes and Sauré (2016) [37] | Assortment and Price Competition | Cardinality constraint | MNL | Equilibrium retailers when prices are fixed, and retailers compete or retailers compete jointly in assortment and prices |

| Bebitoğlu (2016) [33] | Multi-Location assortment problem | Cardinality constraint | MMNL | A conic quadratic mixed-integer programming formulation and valid inequalities to strengthen |

| Sen et al. (2018) [34] | Geographical relationship between distribution centers and customers | Spatial constraint | MMNL | Conic quadratic mixed-integer formulation with McCormick inequalities |

| Gallego et al. (2018) [39] | “Product framing” and pricing problem | Cardinality constraint | MMNL | Approximation algorithms with guaranteed performance under reasonable assumptions |

| Feldman and Topaloglu (2017) [27] | Assortment problem where customers choose with nested consideration sets | Spatial constraint | MMNL | FPTAS based on dynamic programming formulation |

| Lin et al. (2022) [40] | Assortment and Location problem of locker | Cardinality constraint | MMNL | MILP with McCormick estimators and two embedded algorithms for large scale problem |

| Chen et al. (2021) [35] | Store location and location-dependent assortment problems | Cardinality constraint | MMNL | Mixed-integer second-order conic programming (MISOCP) reformulation and structural properties |

| This work | Multi-location assortment problem under drone and human courier delivery | Cardinality/Drone load capacity | MMNL | Conic quadratic mixed-integer formulation with McCormick inequalities, marginal revenue and delivery distance |

| Notation | Description |

|---|---|

| 1 if products j is provided in the online store i and 0 otherwise | |

| 1 if product j can be delivered from spot i to k by drone and 0 otherwise | |

| 1 if product j can be delivered from spot i to k by human courier and 0 otherwise | |

| Probability of demand for spot i | |

| Decision variable be 1 if product j can be delivered from spot i to k and 0 otherwise | |

| Preference associated with product j in assortment for demand from spot k | |

| No-purchase preference of spot i | |

| Marginal revenue of product j in spot i | |

| W | Drone load capacity |

| The cardinality capacity of products in spot i | |

| The weight of product j | |

| Maximum delivery distance of the drone | |

| Maximum delivery distance of the human courier |

| M | N | MILP | Conic + MC | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Value | CPU/s | Gap | Value | CPU/s | |||||

| 10 | 200 | [10, 12] | 20 | [0, 1] | 2.416 | 600 | 5.57 × 10 | 2.416 | 13.086 |

| 15 | 2.758 | 600 | 3.36 × 10 | 2.758 | 57.993 | ||||

| 20 | 2.968 | 600 | 6.78 × 10 | 2.968 | 161.322 | ||||

| 25 | 3.199 | 600 | 2.57 × 10 | 3.199 | 310.179 | ||||

| 30 | 3.352 | 600 | 5.03 × 10 | 3.352 | 372.597 | ||||

| 20 | 100 | [10, 12] | 20 | [0, 1] | 2.869 | 600 | 5.08 × 10 | 2.869 | 42.040 |

| 120 | 2.837 | 600 | 1.92 × 10 | 2.837 | 65.766 | ||||

| 140 | 2.939 | 600 | 7.33 × 10 | 2.939 | 80.716 | ||||

| 160 | 2.929 | 600 | 3.77 × 10 | 2.929 | 88.233 | ||||

| 180 | 2.956 | 600 | 3.21 × 10 | 2.956 | 113.929 | ||||

| 200 | 2.969 | 600 | 1.72 × 10 | 2.969 | 127.364 | ||||

| 20 | 200 | [4, 6] | 20 | [0, 1] | 2.272 | 600 | 6.10 × 10 | 2.272 | 29.100 |

| [6, 8] | 2.507 | 600 | 6.32 × 10 | 2.507 | 52.958 | ||||

| [8, 10] | 2.800 | 600 | 9.89 × 10 | 2.800 | 64.435 | ||||

| [10, 12] | 3.014 | 600 | 5.82 × 10 | 3.014 | 140.901 | ||||

| [12, 14] | 3.137 | 600 | 2.91 × 10 | 3.137 | 259.235 | ||||

| [14, 16] | 3.254 | 600 | 4.20 × 10 | 3.254 | 343.928 | ||||

| 20 | 200 | [10, 12] | 10 | [0, 1] | 3.611 | 600 | 1.18 × 10 | 3.611 | 220.315 |

| 20 | 2.804 | 600 | 6.77 × 10 | 2.804 | 108.650 | ||||

| 30 | 2.499 | 600 | 7.72 × 10 | 2.499 | 83.416 | ||||

| 40 | 2.274 | 600 | 2.02 × 10 | 2.274 | 74.115 | ||||

| 50 | 1.962 | 600 | 9.75 × 10 | 1.962 | 65.058 | ||||

| 20 | 200 | [10, 12] | 20 | [0, 1] | 2.820 | 600 | 5.84 × 10 | 2.820 | 116.823 |

| [1, 2] | 3.885 | 600 | 2.69 × 10 | 3.885 | 209.405 | ||||

| [2, 3] | 4.294 | 600 | 5.33 × 10 | 4.294 | 170.582 | ||||

| [3, 4] | 4.408 | 600 | 1.31 × 10 | 4.408 | 95.440 | ||||

| [4, 5] | 4.492 | 600 | 8.11 × 10 | 4.492 | 178.419 | ||||

| 3 | 4 | 5 | 6 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 1 | 2 | 3 | 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 | 5 | |

| L–In | 0.887 | 1.037 | 0.923 | 1.068 | 1.248 | 0.944 | 1.083 | 1.258 | 1.370 | 0.962 | 1.092 | 1.263 | 1.373 | 1.424 |

| L–De | 0.818 | 0.823 | 0.911 | 0.916 | 0.919 | 0.953 | 0.958 | 0.961 | 0.963 | 0.986 | 0.991 | 0.994 | 0.997 | 0.997 |

| In–De | 1.387 | 1.424 | 1.528 | 1.564 | 1.600 | 1.591 | 1.623 | 1.653 | 1.675 | 1.648 | 1.676 | 1.704 | 1.725 | 1.736 |

| Ran | 1.019 | 1.110 | 1.102 | 1.190 | 1.295 | 1.148 | 1.234 | 1.335 | 1.387 | 1.181 | 1.262 | 1.359 | 1.408 | 1.427 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, M.; Pei, Z. Multi-Location Assortment Optimization with Drone and Human Courier Joint Delivery. Appl. Sci. 2023, 13, 5441. https://doi.org/10.3390/app13095441

Wu M, Pei Z. Multi-Location Assortment Optimization with Drone and Human Courier Joint Delivery. Applied Sciences. 2023; 13(9):5441. https://doi.org/10.3390/app13095441

Chicago/Turabian StyleWu, Mengting, and Zhi Pei. 2023. "Multi-Location Assortment Optimization with Drone and Human Courier Joint Delivery" Applied Sciences 13, no. 9: 5441. https://doi.org/10.3390/app13095441