Abstract

Production scheduling in a knitting workshop is an important method to improve production efficiency, reduce costs and improve service. In order to achieve a reasonable allocation of parallel machines as well as cooperation between different machines within the workshop, thereby ensuring the optimal scheduling of production plans, this paper proposes a scheduling method using an improved genetic algorithm (IGA) based on tabu search. Firstly, the production scheduling model of a knitting workshop is established. Secondly, an IGA based on the minimum processing time rule, the priority idle machine rule and the production order ranking code is used to optimize the solution. Finally, an experiment platform for knitting workshop production is built to verify the proposed scheduling method. The experimental results show that the proposed IGA based on tabu search performs well in terms of preconvergence speed, global search capability and local search capability. The IGA converges faster than the traditional genetic algorithm by about 25%, reduces the redundancy time of scheduling, meets the production requirements of the knitting intelligent workshop and has a good reference value for promoting the intelligent development of knitting production.

1. Introduction

At present, the textile industry is one of the pillar industries of China’s national economy, but it is also a labor-intensive industry, facing the problems of low productivity and high human resource costs [1]. In the whole knitting industry, the processes of cutting, dropping and transporting fabric are still mainly performed manually. Manual production not only has a high labor cost but is also not conducive to intelligent and large-scale production [2]. With the application and development of intelligent scheduling theory and robotics, intelligent manufacturing has become the main direction of the current strategic transformation of the textile industry [3,4], while the impact of the pandemic and the development of the Internet have also greatly promoted the transformation of intelligent production in the textile industry [5].

Automated production in the knitting workshop is achieved by assigning production orders to the circular knitting machines through the workshop management system. After the orders are completed, robots, Automated Guided Vehicles(AGVs) and other equipment are dispatched to complete the processes of cutting, dropping and transporting fabrics to achieve continuous automatic production in the knitting workshop. There are multiple parallel machines in the production and processing equipment, and the processes of cutting, falling and transporting fabrics are completed by the corresponding processing and production equipment assigned by the workshop management system according to the process flow. Therefore, the production scheduling problem in the knitting shop is a typical hybrid shop scheduling problem (HFSP), which is a generalization of the traditional flow shop scheduling problem (FSP), characterized by the existence of multiple parallel machines that can process at least one process at the same time, and it has been proven to be an NP-hard problem [6]. In order to improve the automatic production efficiency of the knitting workshop and reduce production costs, the scheduling of equipment in the workshop is optimized. Therefore, a more efficient solution to HFSP is proposed, which has practical reference value for promoting the intelligent development of the whole process of knitting production.

Precise optimization algorithms, such as dynamic programming and integer linear programming, are usually not applicable to large-scale shop scheduling problems. A common approach to solve flow shop scheduling problems is to use swarm intelligence algorithms, and some of the most commonly used algorithms include the genetic algorithm (GA), particle swarm optimization (PSO) algorithm, artificial fish school (AFS) algorithm, gray wolf optimization (GWO) algorithm [6,7], etc. Among these alogorithms, GA has been successfully applied to many combinatorial optimization problems, such as machine scheduling problems and workshop scheduling problems [8]. However, GA needs to be improved to enhance the algorithm performance for problems with a higher complexity. Moreover, improved genetic algorithms based on local search algorithms are one of the most common forms of improvement [9].

In this paper, the knitting workshop scheduling problem is considered as a combinatorial optimization problem, which focuses on the optimal arrangement of production schedules to meet the requirements of specific objectives through the rational allocation of parallel equipment and the cooperation between equipment. For this reason, this paper constructs a knitting workshop production scheduling model and proposes an IGA based on tabu search, following the arrangement coding of normal shop scheduling in decoding according to various rules to obtain a feasible solution to the problem in order to reduce the production time and production cost by scheduling.

The sections of this paper are organized as follows: Section 2 describes the work related to the hybrid flow shop. Section 3 describes the mathematical model of production scheduling in the knitting shop. Section 4 proposes an IGA based on tabu search. Section 5 builds an experimental platform for knitting workshop production to validate the algorithm. Section 6 concludes with a summary.

2. Related Works

In the hybrid flow shop scheduling problem, HFSP can be divided into three categories according to the type of parallel machines [10,11]: parallel same-speed HFSP, where the processing time of the workpiece is the same on each machine at each stage; parallel different-speed HFSP, where the parallel machines at a certain stage have the same function but different processing speeds, and the processing time of the workpiece is different on each machine at that stage; and unrelated parallel HFSP, where each machine at a certain stage has different functions and different machining times [7]. Currently, more than 70% of the literature focuses on parallel same-speed machine HFSP research, while parallel different-speed machine HFSP and unrelated parallel machine HFSP account for less than 30% of the literature research.

Early work on HFSP focused on small-scale problems and used some precise methods to find optimal solutions. Brah and Hunsucker [12] proposed a branch-and-bound algorithm to solve the flow shop scheduling problem with identical machines. Carlier and Néron [13] improved the branch-and-bound algorithm for solving the flow shop scheduling problem. The problems mentioned in the above literature can be considered as the prototype of HFSP. However, due to the NP-hardness of HFSP, when the problem size grows, it is difficult for the precise optimization algorithms proposed by many later scholars to find the optimal solution in a reasonable computation time. Therefore, heuristic and metaheuristic algorithms emerged to solve HFSP [14].

Intelligent optimization algorithms can obtain the optimal solution with high probability in a reasonable time, and several common intelligent algorithms such as the evolutionary algorithm [9,15,16], artificial bee colony algorithm [17,18], rider optimization algorithm [19], GWO [20,21] and GA [22,23,24] have been widely applied. Pang, X. L [25] et al. optimized the fireworks algorithm by introducing strategies such as non-linear radius and detecting the minimum explosion magnitude, Cauchy–Gaussian mixture operator and elite population selection. Wang, Z. Q [26] proposed a genetic algorithm for optimal scheduling of the flow shop, and the algorithm outperformed the traditional flowing shop. Ombuki, Beatrice M [27] proposed a local search genetic algorithm (LSGA) to improve the genetic algorithm by tabu search and this was one of the first works to incorporate a more refined local search strategy. Asadzadeh [28] combined local search algorithms with crossover and mutation operators to develop multi-agent systems containing multiple agents with special behaviors to improve the local search capability of the algorithm.

Kong, L [29] proposed a sustainable HFSP model considering machine characteristics. The matching distances between parallel machines and the weights of the optimization objective were introduced to improve the genetic algorithm, and the effectiveness of the algorithm was verified. To overcome the premature convergence of the metaheuristic algorithm and the concentration of the population in the local optimization region, Viana, M. S [24] proposed a new method to determine individual genetic quality using genetic frequency analysis to improve the population quality of the algorithm, thus enhancing the effectiveness of the algorithm. Ni, F [30] proposed a multi-graph attributed reinforcement learning-based optimization algorithm (MGRO), which incorporates the reinforcement learning-based policy search approach with classic search operators and powerful multi-graph-based representation. MGRO is capable of adjusting the search paradigm according to specific instances and enhancing the search efficiency.

Currently, most of the coding methods for shop scheduling use the first-come-first-processing rule and priority idle machine rules to facilitate the operation of intelligent optimization algorithms, and the optimal solution of the problem can be obtained quickly after the decoding of various rules, so the related decoding methods are widely used [6,31,32].

Within the literature, the HFSP has attracted the attention of several researchers. More efforts have been made in applying heuristic and metaheuristic algorithms to solve HFSP. The combination and improvement of algorithms to address the search capability and search speed of the algorithm is an effective way to solve the HFSP [33]. However, there is still a shortage of research in the application area of knitting shops, and the efforts of related scholars are still required.

3. Formulation of the Knitting Workshop Production Scheduling Problem

In this section, we classify the knitting shop production scheduling problem as an HFSP, which can be described as follows: there are n production orders , which are processed by m machines and require z processes in sequence, there are several parallel processing machines for at least one process, and the production orders are not necessarily processed at the same time at each processing station. There is a buffer zone between two adjacent processes. The processing order of the workpieces and assignment of processes to parallel machines need to be determined so that the model meets the actual production requirements. To better describe the problem, the following assumptions are considered [8]:

- Each machine can only process at most one production order at a given time;

- Each production order can only be processed by one machine at a given time for a given process;

- Production orders cannot be interrupted when they begin to be processed, which means that production orders are considered non-preemptive;

- The processing time for each process of each production order is deterministic;

- No priority constraints exist between operations of different production orders;

- When scheduling starts (i.e., the initial state), all equipment is available until processing is complete, regardless of equipment failure.

In the knitting shop production scheduling problem, the processing time, which is the total time required to complete all production operations, is used as a measure of the merit of the scheduling algorithm. In the hybrid flow shop scheduling problem, as the objective function of the model, the algorithm is guided to search for the optimal solution by heuristic rules. Mathematically, we define the knitting shop production scheduling problem as consisting of the following components:

- is the production order set.

- is the order process set.

- is the processing machines set.

- is the processing sequence set, which defines the processing sequence for processing the production order set in the processing machines set , where indicates the machines assigned in each process of order .

- is the start time when the production order is processed according to the processing sequence defined in .

- is the end time when the production order is processed according to the processing sequence defined in .

- is the parallel equipment for the process, where .

- is the number of available processing machines for production order process , where .

- is a binary decision variable that equals one if production order is assigned to machine equipment ; otherwise, it is zero.

For the purpose of explaining several components of the model, as an example, there are five processing machines and four orders in the knitting shop. Each order needs to be completed by two processes . Process 1 can be processed by machines , and process 2 can be processed by machines , so and . is the first processing machine for process 1, i.e., . If the two processes of production order are produced by and , respectively, then .

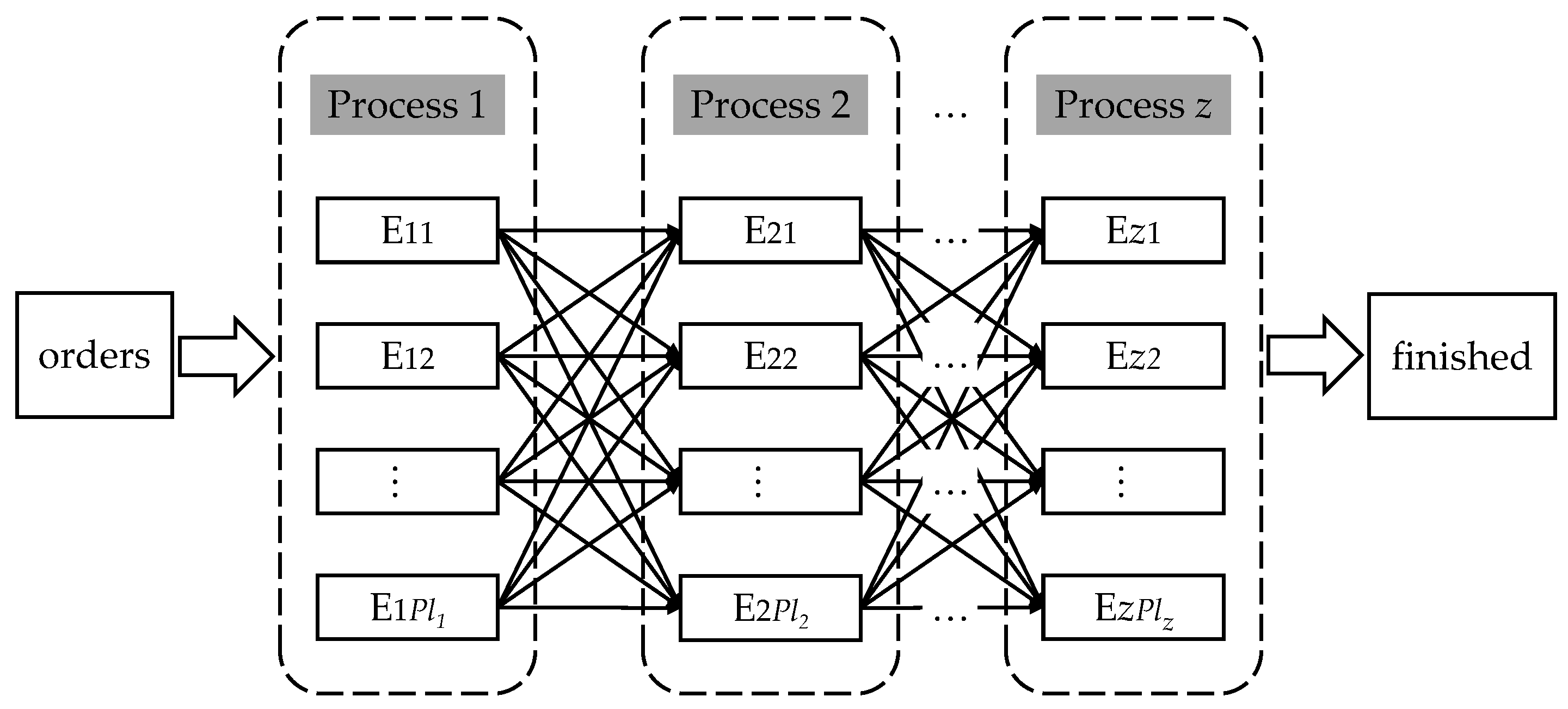

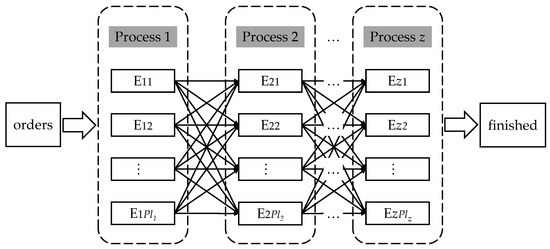

In this paper, the shop production scheduling model is illustrated in Figure 1. The optimization objective of the model is to minimize the maximum completion time , which is the end time when the last production order is processed and completed, as shown in Equation (1).

Figure 1.

The schematic diagram of production scheduling model of knitting workshop.

At the same time, the shop production scheduling model also needs to satisfy the fol-lowing constraints to ensure the integrity of the optimization process:

where constraint (2) represents the number of machines; constraint (3) constrains the number of parallel machines; constraint (4) indicates that any processing process of a production order can be completed by only one mechanical equipment; constraints (5) and (6) represent the production order processing constraints; and constraint (7) states that the processing machine can perform one operation at a time and can be used for other operations only after the previous operation is completed.

4. An IGA Design Based on Tabu Search Applied to HFSP

GA is an evolutionary algorithm born with reference to the law of evolution of superiority and inferiority in nature, and it has an excellent performance in global and parallel searches. It often has a good solution effect for large and complex problems. GAs have been successfully applied to many combinatorial problems, but for more complex problems, GAs need to be knitted together with specific algorithms in order for the method to be truly effective. The tabu search algorithm is a metaheuristic stochastic search algorithm that uses a domain-selective search method and has the advantages of strong local search capability and fast convergence. Combining the GA and tabu search algorithm is a common way to improve genetic algorithms [28].

Therefore, an IGA is designed to solve the HFSP inspired by the tabu search algorithm, combining the tabu search algorithm to improve the population diversity and avoid the GA from entering the local optimum solution. At the same time, the convergence of the GA is improved. The improved algorithm proposed in this paper consists of four main stages: (a) population initialization, (b) gene evolution, (c) tabu search and (d) gene selection.

4.1. Genetic Representation

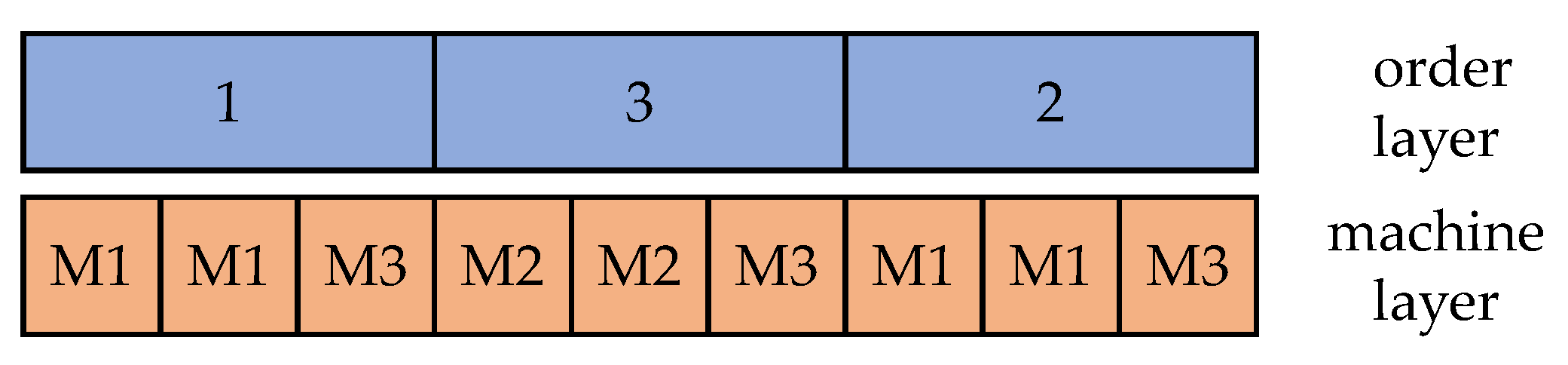

The genetic encoding representation of optimization problem variables are the basis of GA. In this paper, the coding method based on production order arrangement is used to solve the knitting shop production scheduling problem. Based on the characteristics of the knitting shop production scheduling model, the chromosome encoding consists of the production order layer and the machine layer.

The production order layer can be represented by an n-dimensional array , where the machine layer corresponding to is represented by a z-dimensional array . Therefore, the sequence of production machines for the knitting shop scheduling model is an array , as shown in Equation (8).

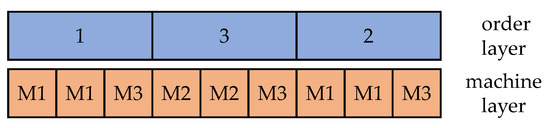

For example, the knitting shop has three production orders, three machines, two parallel machines and three production processes. The coding is shown in Figure 2. The coding sequence at the production order layer in the figure indicates the production order sequence in which the production orders are assigned. The coding sequence at the machine layer indicates that the three production processes of the first order need to be processed by machines in sequence, where are parallel machines.

Figure 2.

Chromosome encoding.

4.2. Fitness Function

The objective function is used to evaluate each chromosome, and the fitness function is used to represent the fitness of a single chromosome. In this paper, by minimizing the maximum completion time as the objective function of the algorithm, the genetic coding naturally defines the fitness function of the problem as the completion time according to the order production array . The fitness function is set as shown in Equation (9).

In this way, the production orders are sequentially assigned to processing production through the genetic coding method based on production order alignment, and then a metaheuristic algorithm is used to find the order production sequence with the smallest possible completion time.

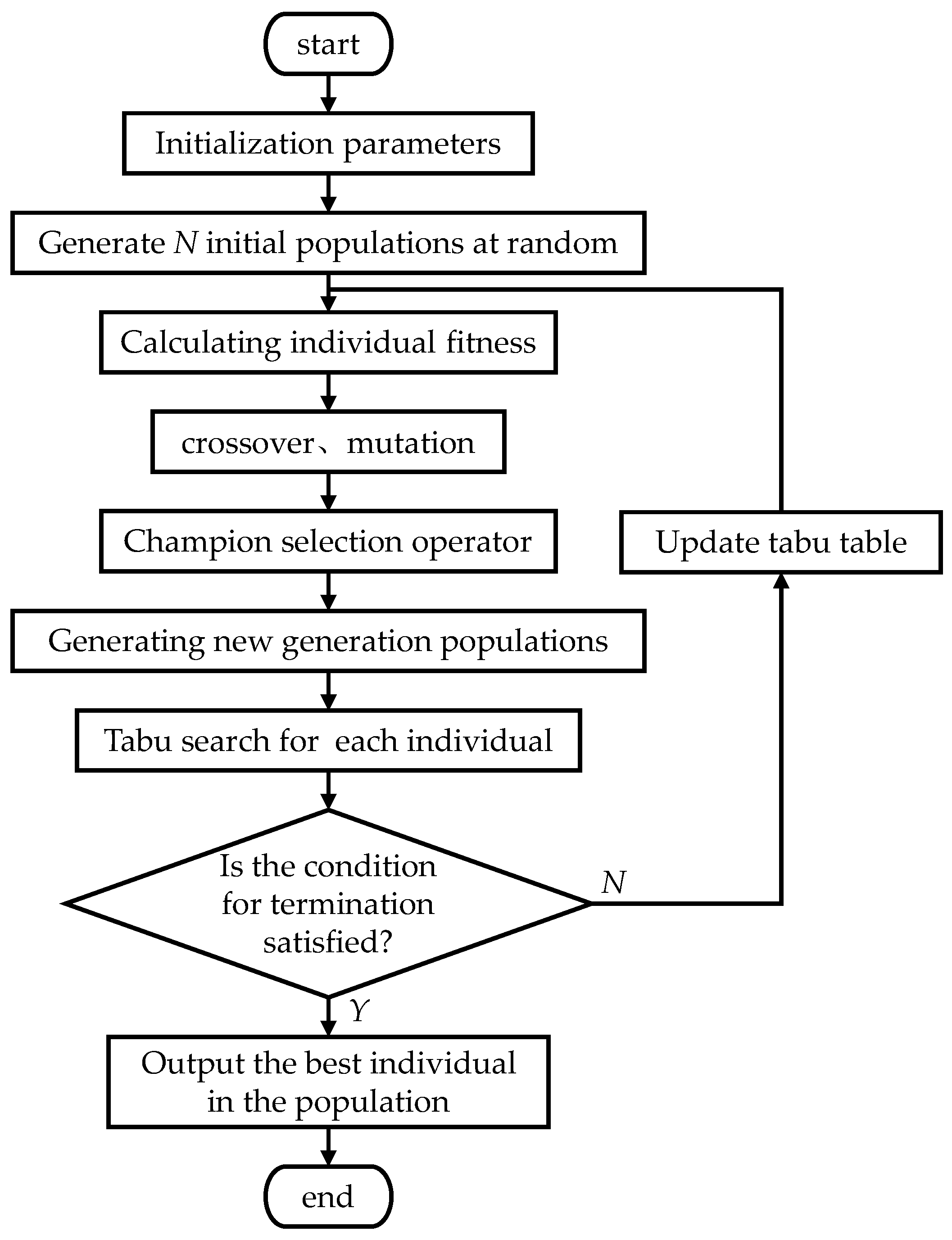

4.3. Proposed IGA Based on Tabu Search

In this work, according to the algorithmic characteristics of GA and tabu search algorithms, an IGA based on tabu search is proposed to achieve a better search ability and convergence speed. Meanwhile, it avoids the problem that genetic algorithms are prone to local optima.

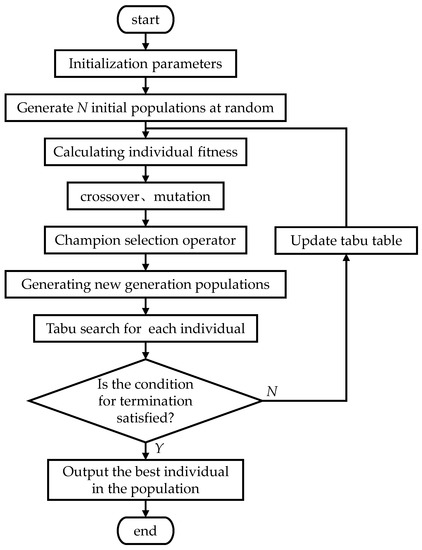

The traditional GA maintains population diversity only by the mutation operator, while the selection operator gradually eliminates solutions with low population fitness, which is less efficient in solving large and complex problems. The IGA introduces a tabu search table in each generation of the population, which improves the search ability of the selection operator in the GA and improves the solution efficiency of the algorithm while ensuring population diversity. The IGA flow is shown in Figure 3.

Figure 3.

The IGA flow chart.

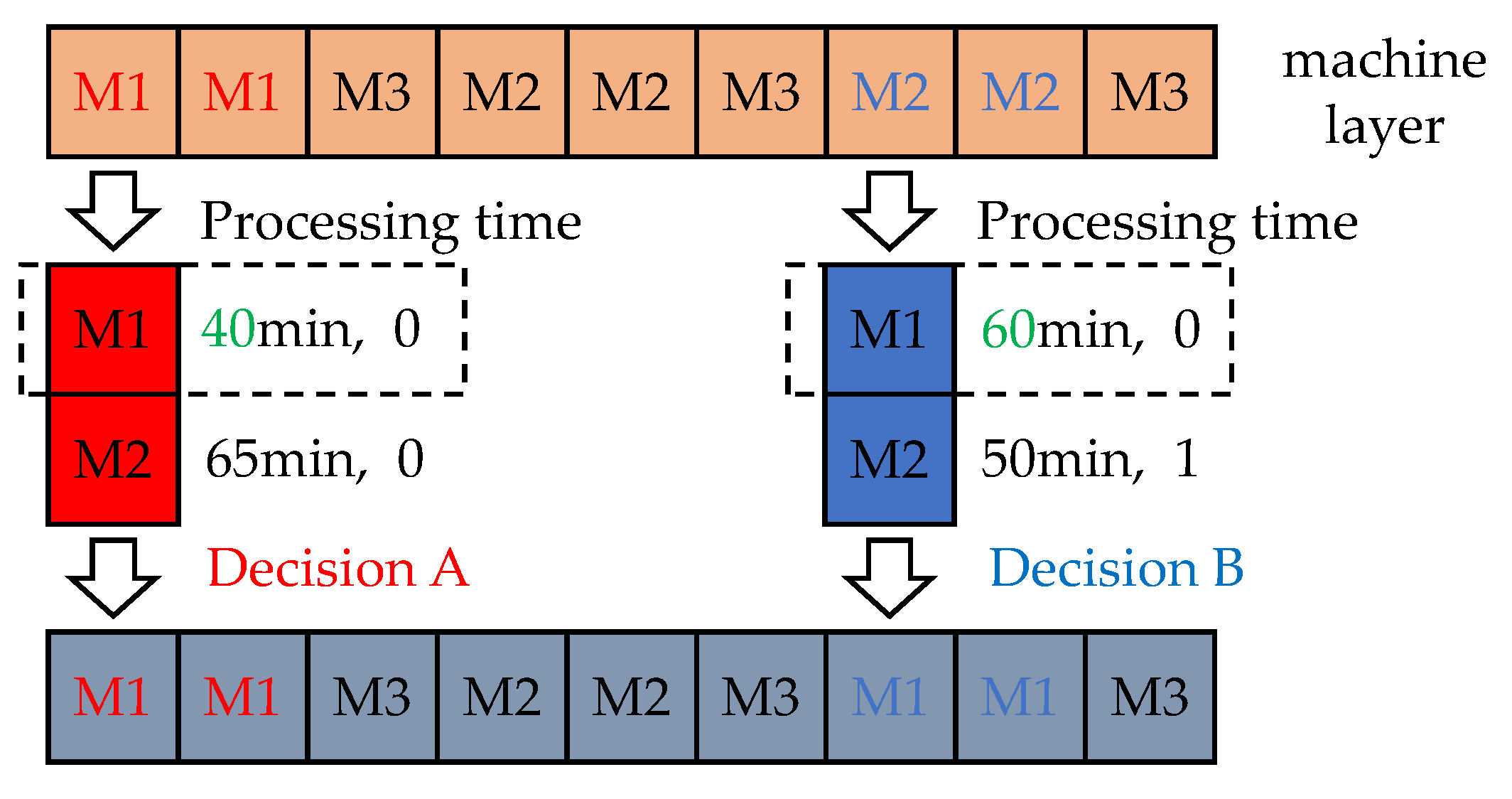

4.3.1. Heuristic Decision on Equipment Selection

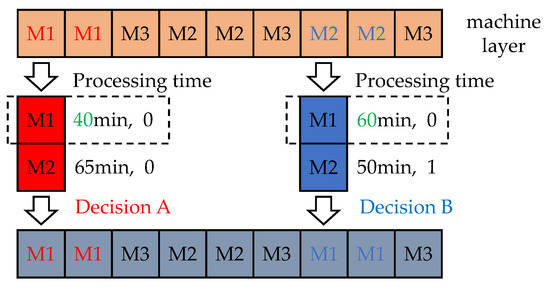

The algorithm uses both the minimum processing time rule and the priority idle machine rule to schedule the processing equipment selection. The equipment selection decision is mainly focused on the second layer, which is illustrated by the same example as above, as shown in Figure 4. Process 1 and process 2 of order are processed by the same machine, i.e., processing time , where indicates the processing time of process 1 and indicates the processing time of process 2. Decision A represents the minimum processing time rule. When assigning parallel machines to process 1 and process 2 of order , the equipment with the least processing time is given priority, that is, the equipment with the shortest processing time is selected. Decision B indicates the priority idle machines rule. When process 1 and process 2 of order are assigned parallel machines, equipment is occupied, so equipment is selected first.

Figure 4.

Heuristic equipment selection decisions.

4.3.2. Tabu Search Operator

The tabu algorithm also belongs to an optimization algorithm that simulates human intelligence, which avoids roundabout searches by blocking the searched areas through the tabu table. At the same time, some good states in the tabu areas are pardoned, thereby ensuring the diversity of searches, so as to achieve global optimality and improve search efficiency. In this paper, on the basis of the GA, the tabu search is performed randomly on each generation of chromosomes, and a tabu table is established to store the optimal solution of each generation. We update the tabu table according to the optimal solution of the tabu search and the optimal solution in the global tabu table, and use the chromosome processed by the tabu search as the object of genetic manipulation for genetic algorithm processing. The algorithm description is shown in Algorithm 1.

| Algorithm 1 Tabu Search Operator |

| 1: Input: H A empty tabu list; 2: i Optimal generation of genetic algorithm; 3: s Optimal solution s = i; 4: begin 5: Generate the neighbors of solution i A = N(i,H); 6: for gen =1 to len(i) 7: i = The best solution in the neighbors; 8: if f(i) < f(s) 9: s=i; 10: H(gen) = f(s); 11: end if 12: end for 13: end 14: Output: Optimal solution s |

4.3.3. Genetic Manipulation

In the IGA of this paper, the crossover operator, mutation operator and selection operator constitute the genetic operation of the genetic algorithm, which simulates the process of biological evolution and gradually eliminates the solutions with low fitness function values and increases the solutions with high fitness function values. In this way, individuals with high fitness function values will evolve after iterating for generations. This section designs the genetic manipulation of the improved genetic algorithm.

- Crossover Operator

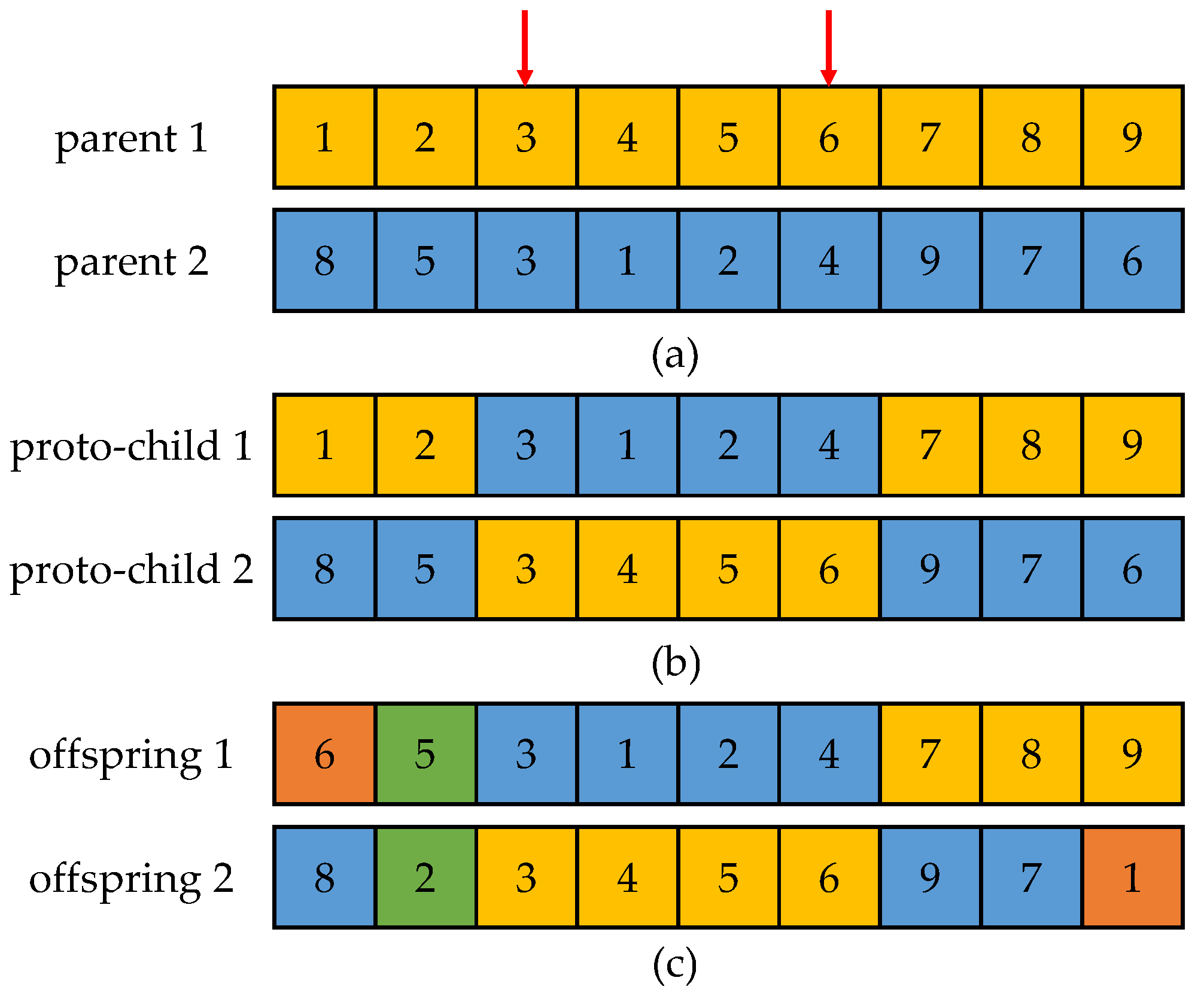

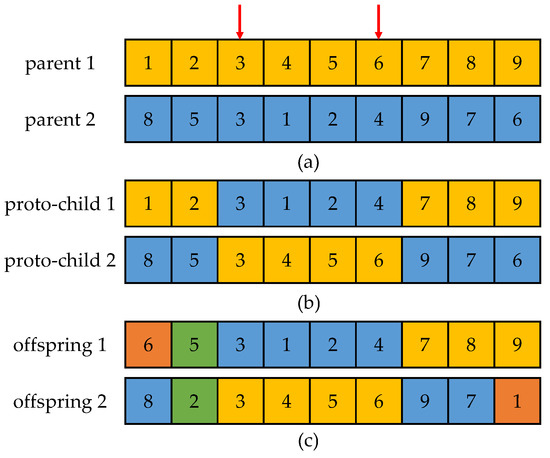

The crossover operator is an important operation of the genetic algorithm, which promotes the evolution of a population by generating a new generation of chromosomes through crossover operation on the population. In this paper, the algorithm uses the partial mapping crossover method (PMX). Through this crossover strategy, no duplicate genes will appear in a chromosome, as shown in Figure 5.

Figure 5.

Chromosome crossover. (a) is a pair of paternal chromosomes; (b) is a pair of crossover-generated proto-child chromosomes; (c) is a pair of offspring chromosomes without gene conflict.

Randomly select a pair of paternal chromosomes with two crossover regions as shown in Figure 5a, where the two chromosomes are selected at the same position, and exchange the genes of the two sets of paternal chromosomes in the crossover region to form the offspring chromosomes as shown in Figure 5b.

At this time, there are identical gene sequences in the formed offspring chromosomes, and the identical genes need to be transformed according to the mapping relationship by conflict detection. Finally, a new pair of offspring chromosomes without gene conflict is formed, as shown in Figure 5c.

- 2.

- Mutation Operator

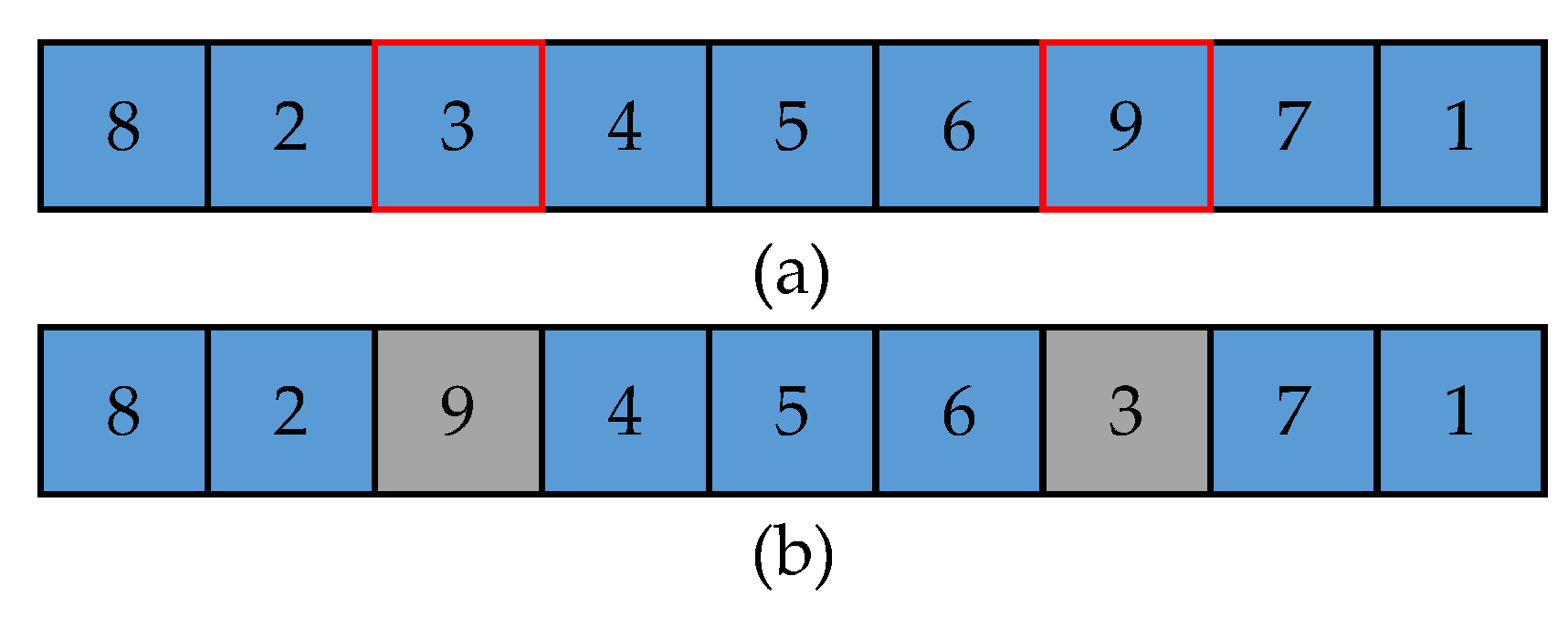

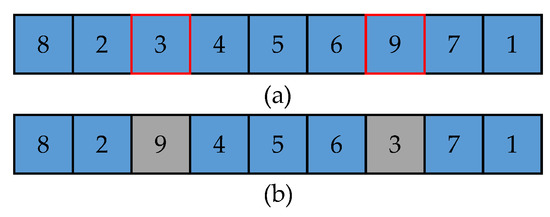

Following the production of offspring chromosomes by the genetic algorithm, anisotropic transformations are performed on certain genes in the chromosomes to form new chromosomes in order to improve the local search ability of the algorithm and maintain population diversity. In this paper, the exchange mutation operator is used, as shown in Figure 6.

Figure 6.

Chromosome mutation. (a) is pre-mutation chromosomes; (b) is post-mutation chromosomes.

Two gene fragments in the chromosome are randomly selected as shown in Figure 6a, and the two genes exchange their values to form a mutant chromosome as shown in Figure 6b. The mutation operation can effectively prevent the GA from falling into a local optimum solution during the optimization process.

- 3.

- Selection Operator

The selection operator simulates the mechanism of meritocracy in nature. Under this mechanism, chromosomes that are more adapted to the scheme model are retained to survive, and chromosomes that are poorly adapted perish. In this paper, chromosomes are selected in the algorithm by using the competition selection method, and two chromosomes are randomly selected from chromosomes based on Equation (9). The chromosome with high adaptation is selected according to the value of the adaptation function, while the contraindication table is updated.

5. Experimental Results and Analysis

In this section, we experimentally verify the feasibility of the IGA by elucidating three key points: (1) building an experimental platform for knitting production; (2) setting up the system validation parameters; and (3) executing the scheduling scheme of the IGA and analyzing the results.

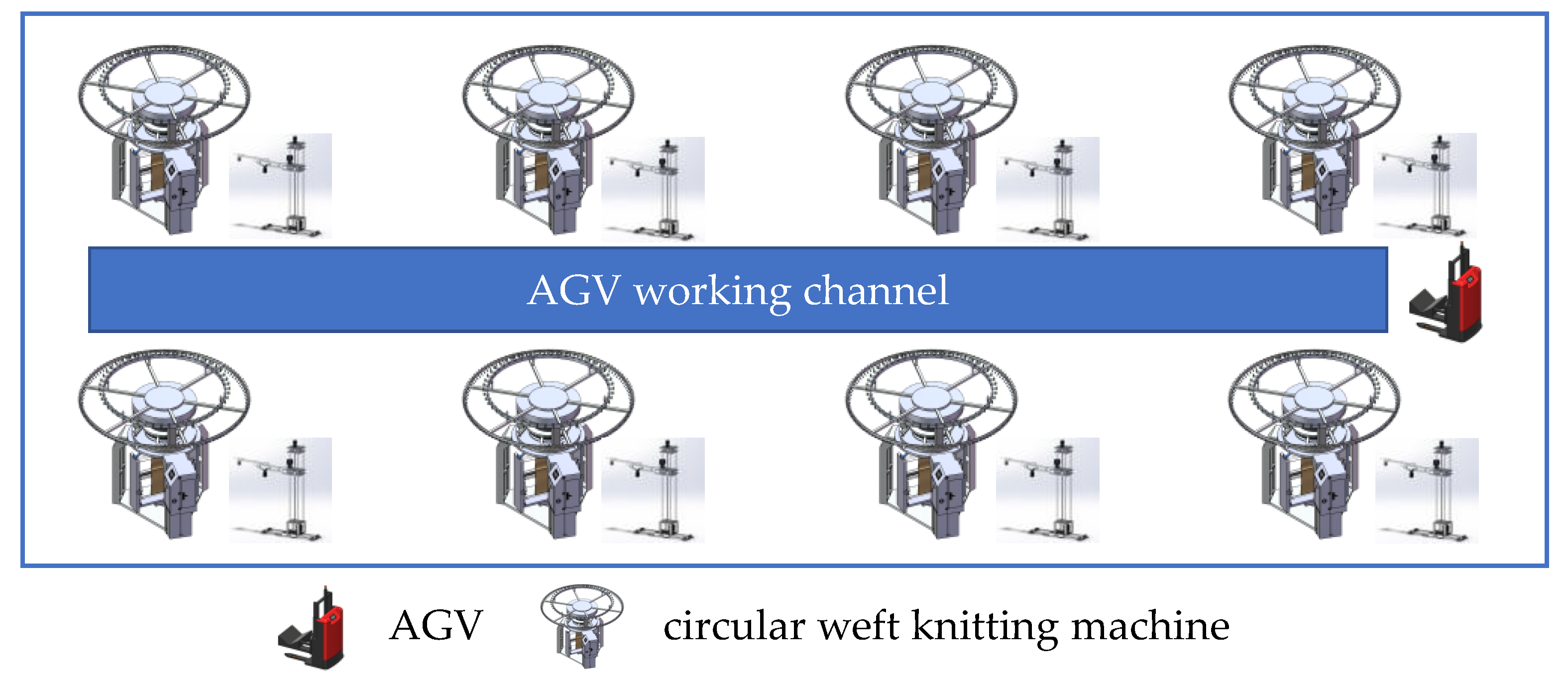

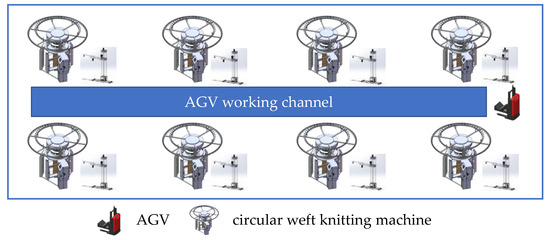

5.1. Knitting Production Experiment Platform

In order to verify the feasibility and effectiveness of the proposed algorithm through experiments, an experimental platform of a knitting workshop production based on industrial Ethernet technology was built, as shown in Figure 7. The experimental platform consisted of eight circular knitting machines (each equipped with a fabric cutting robot) and one fabric transport AGV. After the circular knitting machine completed the production, fabric cutting and dropping processes, the fabric transport AGV completed the full fabric roller feeding and fabric transport process. The finished products were transported to the intermediate warehouse of the fabric, which ensured that the circular knitting machine could accept the production task of the next production order, and realized the continuous production of the knitting workshop.

Figure 7.

Knitting shop production experiment platform.

5.2. System Validation Parameters

The system configuration for the scheduling algorithm programming and verification was as follows: Intel(R) Core i5-10400F processor with 2.9 GHz, 16 GB RAM and Windows 10(64) operating system. The scheduling algorithm was programmed with python 3.9, which mainly used NumPy and Matplotlib and other open-source toolkits. The IGA set the population size to 100, the maximum number of iterations was 50, the crossover rate was 0.65 and the mutation rate was 0.35.

The experimental verification data were exported from Manufacturing Execution System(MES) for 20 production orders. Each production order was divided into three processes: knitting production, fabric cutting and dropping, and fabric roller handling. The knitting production could be processed by any circular knitting machine, the knitting machines and the processing time of each knitting machine had been determined, the fabric roller handling process was completed by the fabric transport AGV and the process time of the fabric transport AGV had also been determined.

The parallel machines were eight circular knitting machines, and the number of machines was eight circular weft machines and one AGV. Process 1 and process 2 were processed by the same circular machine. The production time of each process of the production order is shown in Table 1.

Table 1.

The processing time of machines.

5.3. Scheduling Results and Analysis

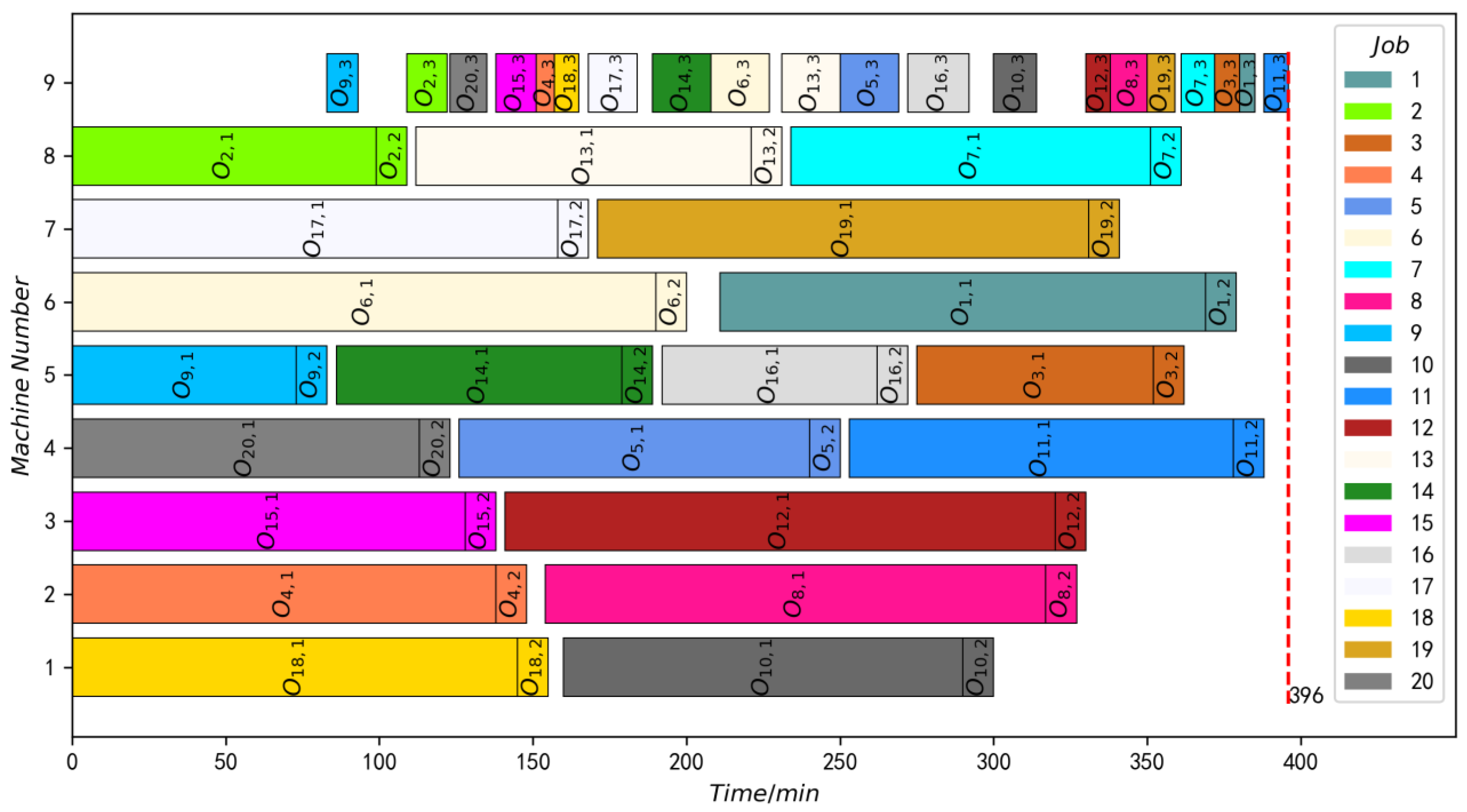

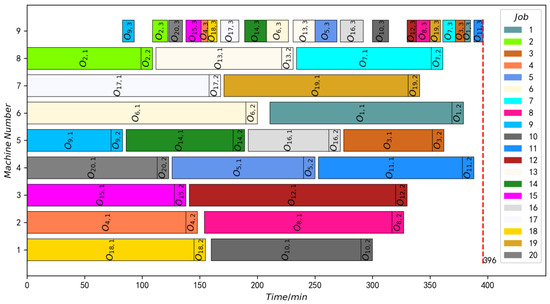

The 20 production order processing data in Table 1 were solved by the IGA, and the resulting Gantt chart is shown in Figure 8.

Figure 8.

The Gantt chart of the improved genetic algorithm validation.

In the production experiment platform of the knitting workshop, after the production orders were finished by the M1 to M8 circular knitting machines, the M9 fabric transport AGV completed the material handling. At this time, the full fabric rollers dropped out and waited for 2 min for the empty fabric rollers to be placed before the circular knitting machines could continue to arrange the knitting production orders. In Figure 8, the M1 circular knitting machine completes process 2 of the 18th production order and then sets aside 2 min before starting to process the 10th production order.

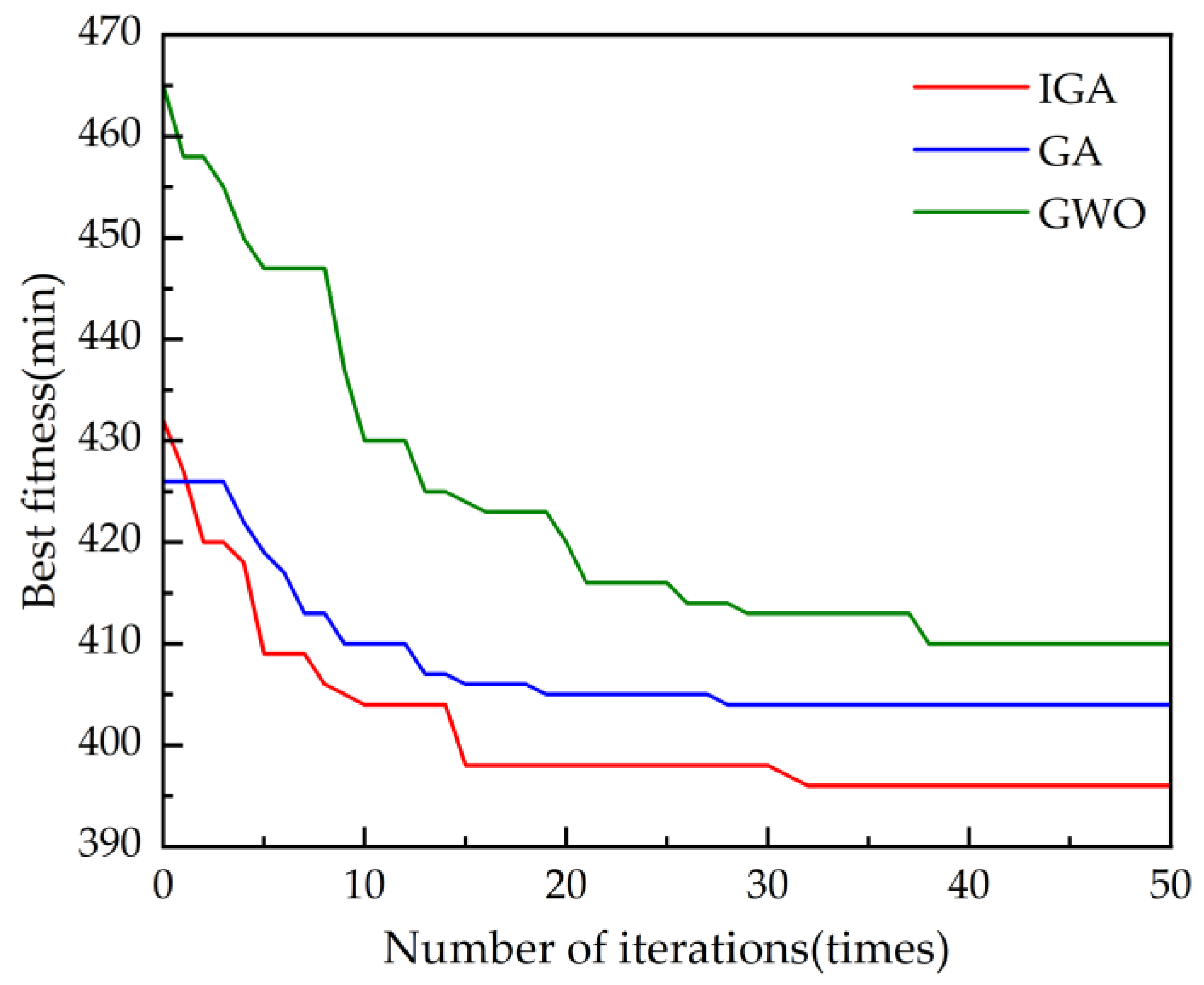

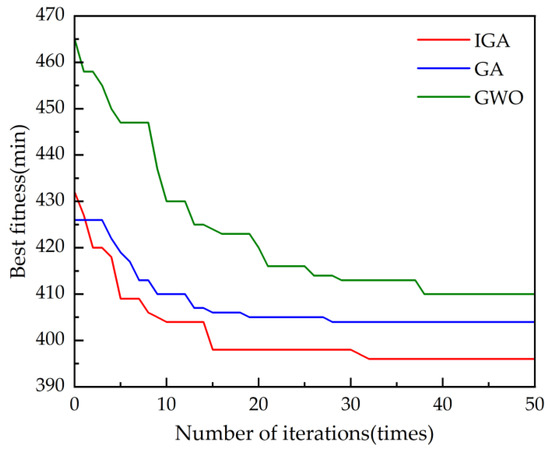

In order to verify the algorithmic characteristics of the proposed IGA based on tabu search for the production scheduling problem in the knitting workshop, the 20 production orders in Table 1 were taken for comparison experiements using the GWO, GA and IGA, and the maximum number of iterations was 50. Then, the value of the fitness function for each iteration was recorded, and the laboratory results are plotted on a line graph as shown in Figure 9.

Figure 9.

The Gantt chart of the improved genetic algorithm validation.

Among these results, the green curve represents the GWO, the blue curve represents the traditional GA and the red curve represents the IGA. Comparing the three genetic algorithms, the GWO has a slow convergence speed, the solution accuracy is poor and it does not perform well in the large-scale order production scheduling in the knitting workshop. Meanwhile, both the GWO and the GA are prone to local optima, while the IGA not only has an excellent performance in the convergence speed of the algorithm, but also the global search ability and local search ability are well improved.

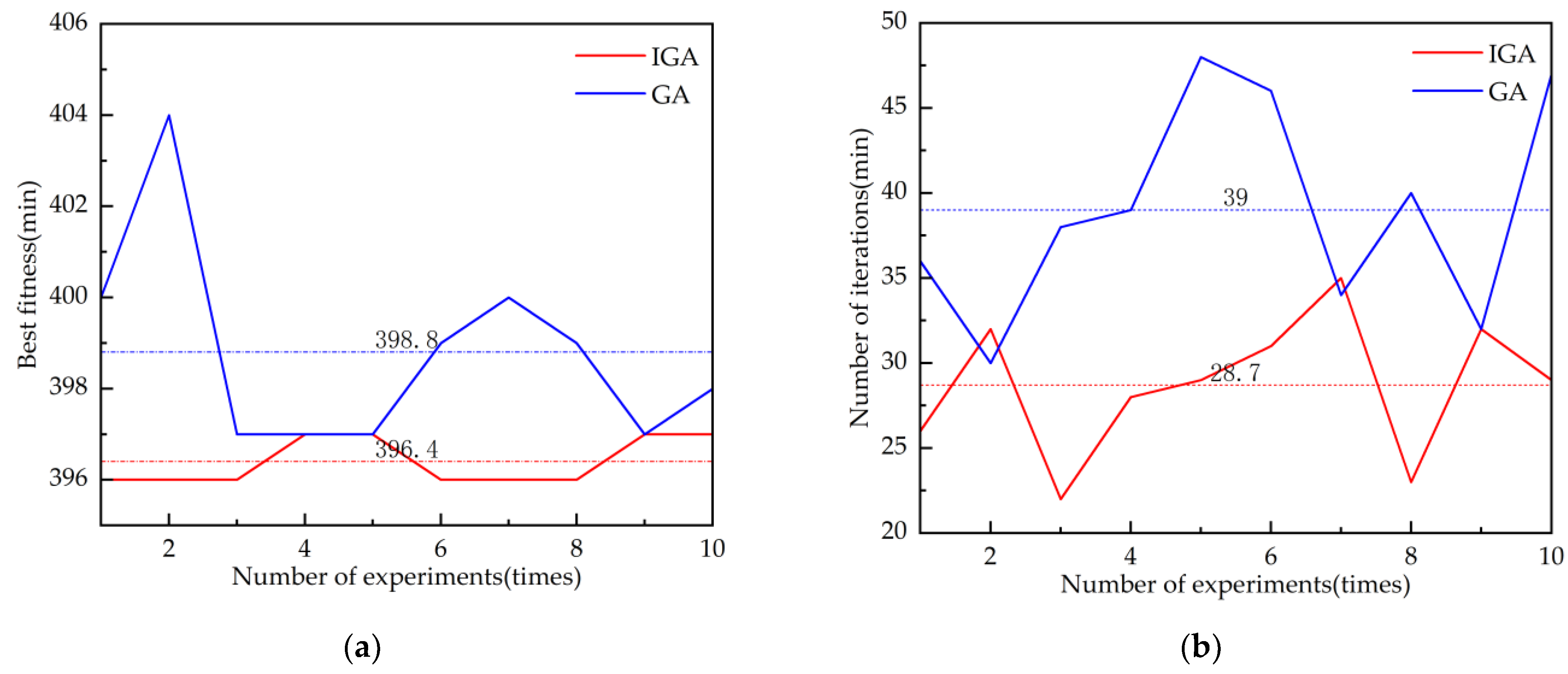

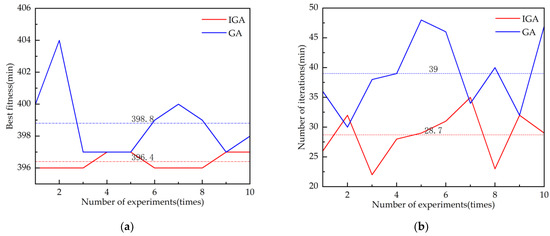

Considering the randomness of the algorithm, the comparison experiment was repeated 10 times for the traditional GA and the IGA. The value of the optimal fitness function and the minimum number of iterations to reach the optimal solution were recorded, and the line graph was plotted as shown in Figure 10, where the red curve represents the IGA and the blue curve represents the traditional GA.

Figure 10.

Comparison experiment of GA and IAG. (a) The value of the optimal fitness function for each group of experiments. (b) The minimum number of iterations to reach the optimal solution for each group of experiments.

Through 10 groups of algorithm comparison experiments, it can be obtained from Figure 10 that the traditional GA reaches the optimal fitness value of 399 after 39 iterations on average, while the IGA based on tabu search can reach the optimal fitness value of 396 after 29 iterations on average, and the convergence speed is improved by about 25%. Compared with the traditional algorithm, the IGA not only performs well in the convergence speed at the beginning of the iteration and the stability of the algorithm solution, but also performs better in the overall convergence speed and the global search ability of the algorithm.

In summary, the IGA based on tabu search algorithm can effectively meet the production scheduling requirements of the knitting workshop and effectively improve the workshop production and processing efficiency.

6. Conclusions

In this paper, we conducted research on the production scheduling problem in the knitting workshop, constructed a workshop production scheduling optimization model and proposed an IGA to achieve sustainable production of the HFSP while ensuring production efficiency. The main contributions of this paper are described as follows:

(1) A knitting workshop production scheduling model was built to achieve sustainable production in the knitting workshop by optimizing the cooperation of circular knitting machine knitting production and fabric transport AGV.

(2) An IGA based on tabu search was proposed. Through simulation experiments, it was shown that the method can effectively, efficiently and stably solve the production scheduling problem of the knitting workshop. The advantages of the IGA in terms of fast convergence, high stability of the algorithm and strong global search capability were verified through comparison experiments with the traditional GA.

The IGA has a number of limitations, such as the fact that the processing process cannot be interrupted and equipment failure was not considered. In future scheduling research, path planning of the AGV, circular knitting machine downtime and other scheduling problems will be considered. There are various uncertainty factors in the actual production at a knitting workshop, such as environmental factors, equipment uncertainty, AGV obstacle avoidance waiting times, etc., which still need to be considered.

Author Contributions

Conceptualization, L.S. and W.S.; methodology, L.S. and J.W.; software, L.S.; validation, L.S., W.S. and J.W.; formal analysis, J.T.; investigation, L.W.; resources, W.S.; data curation, H.M.; writing—original draft preparation, L.S.; writing—review and editing, L.S.; visualization, L.S.; supervision, W.S.; project administration, W.S.; funding acquisition, W.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key Research and Development Program of China, Grant/Award Number: 2017YFB1304000.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors sincerely thank the anonymous reviewers for their critical comments and suggestions for improving the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, J.L.; He, L.; Cheng, L.D. Is China’s Textile Industry Still a Labour-Intensive Industry? Fibres Text. East. Eur. 2021, 29, 13–16. [Google Scholar] [CrossRef]

- Chen, X.J.; Cui, W.Z.; Wei, Y.L. Application of information technology in textile industry. Qing Fang Gong Ye YuJishu 2021, 50, 72–73. [Google Scholar]

- He, B.; Bai, K.-J. Digital twin-based sustainable intelligent manufacturing: A review. Adv. Manuf. 2020, 9, 1–21. [Google Scholar] [CrossRef]

- Hu, X.D.; Shen, C.Y. Intelligent Manufacturing and Practice in Knitting Industry. Knit. Ind. 2019, 367, 1–6. [Google Scholar]

- Wang, S.S.; Peng, L.H.; Hu, X.D. A Testing for Knitting Machine Networking System Based on Analog Terminal. In Proceedings of the 3rd International Conference on Advances in Materials, Machinery, Electronics (AMME), Wuhan, China, 19–20 January 2019; Amer Inst Physics: Wuhan, China, 2019. [Google Scholar]

- Çolak, M.; Keskin, G.A. An extensive and systematic literature review for hybrid flowshop scheduling problems. Int. J. Ind. Eng. Comput. 2022, 13, 185–222. [Google Scholar] [CrossRef]

- Lee, T.-S.; Loong, Y.-T. A review of scheduling problem and resolution methods in flexible flow shop. Int. J. Ind. Eng. Comput. 2019, 10, 67–88. [Google Scholar] [CrossRef]

- Yi, W.C.; Gao, L.; Zhou, Y.Z.; Li, X.Y. Differential Evolution Algorithm with Variable Neighborhood Search for Hybrid Flow Shop Scheduling Problem. In Proceedings of the 20th IEEE International Conference on Computer Supported Cooperative Work in Design (CSCWD), Nanchang, China, 4–6 May 2016; IEEE: Nanchang, China, 2016; pp. 233–238. [Google Scholar]

- Fan, J.; Li, Y.; Xie, J.; Zhang, C.; Shen, W.; Gao, L. A Hybrid Evolutionary Algorithm Using Two Solution Representations for Hybrid Flow-Shop Scheduling Problem. IEEE Trans. Cybern. 2021, 53, 1752–1764. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, C.; Shao, X.; Zhang, B.; Ren, Y.; Lin, W. More MILP models for hybrid flow shop scheduling problem and its extended problems. Int. J. Prod. Res. 2019, 58, 3905–3930. [Google Scholar] [CrossRef]

- Lin, S.-W.; Cheng, C.-Y.; Pourhejazy, P.; Ying, K.-C.; Lee, C.-H. New benchmark algorithm for hybrid flowshop scheduling with identical machines. Expert Syst. Appl. 2021, 183, 115422. [Google Scholar] [CrossRef]

- Brah, S.A.; Hunsucker, J.L. Branch and bound algorithm for the flow shop with multiple processors. Eur. J. Oper. Res. 1991, 51, 88–99. [Google Scholar] [CrossRef]

- Carlier, J.; Néron, E. An Exact Method for Solving the Multi-Processor Flow-Shop. RAIRO—Oper. Res. 2000, 34, 1–25. [Google Scholar] [CrossRef]

- Öztop, H.; Tasgetiren, M.F.; Eliiyi, D.T.; Pan, Q.-K. Metaheuristic algorithms for the hybrid flowshop scheduling problem. Comput. Oper. Res. 2019, 111, 177–196. [Google Scholar] [CrossRef]

- Zhang, X.L.; Zhang, B.A.; Meng, L.L.; Ren, Y.P.; Meng, R.H.; Li, J.Q. An evolutionary algorithm for a hybrid flowshop scheduling problem with consistent sublots. Int. J. Autom. Control 2022, 16, 19–44. [Google Scholar] [CrossRef]

- Li, C.; Zhang, B.; Han, Y.; Wang, Y.; Li, J.; Gao, K. Energy-Efficient Hybrid Flowshop Scheduling with Consistent Sublots Using an Improved Cooperative Coevolutionary Algorithm. Mathematics 2022, 11, 77. [Google Scholar] [CrossRef]

- Li, M.; Wang, G.-G.; Yu, H. Sorting-Based Discrete Artificial Bee Colony Algorithm for Solving Fuzzy Hybrid Flow Shop Green Scheduling Problem. Mathematics 2021, 9, 2250. [Google Scholar] [CrossRef]

- Li, Y.L.; Li, F.; Pan, Q.K.; Gao, L.; Tasgetiren, M.F. An Artificial Bee Colony Algorithm for the Distributed Hybrid Flowshop Scheduling Problem. In Proceedings of the 25th International Conference on Production Research Manufacturing Innovation (ICPR)—Cyber Physical Manufacturing, Chicago, IL, USA, 9–14 August 2019; Elsevier Science Bv: Chicago, IL, USA, 2019; pp. 1158–1166. [Google Scholar]

- Fu, Y.; Li, Z.; Chen, N.; Qu, C. A Discrete Multi-Objective Rider Optimization Algorithm for Hybrid Flowshop Scheduling Problem Considering Makespan, Noise and Dust Pollution. IEEE Access 2020, 8, 88527–88546. [Google Scholar] [CrossRef]

- Lu, C.; Gao, L.; Pan, Q.; Li, X.; Zheng, J. A multi-objective cellular grey wolf optimizer for hybrid flowshop scheduling problem considering noise pollution. Appl. Soft Comput. 2018, 75, 728–749. [Google Scholar] [CrossRef]

- Lu, C.; Liu, Q.; Zhang, B.; Yin, L. A Pareto-based hybrid iterated greedy algorithm for energy-efficient scheduling of distributed hybrid flowshop. Expert Syst. Appl. 2022, 204, 117555. [Google Scholar] [CrossRef]

- Yeh, T.S.; Chiang, T.C. Hybrid Flowshop Scheduling using Leaders and Followers: An Implementation with Iterated Greedy and Genetic Algorithm. In Proceedings of the IEEE Symposium Series on Computational Intelligence (IEEE SSCI), Electr Network, Orlando, FL, USA, 5–7 December 2021. [Google Scholar]

- Zhao, Z.J.; Wang, A.M.; Ge, Y.; Lin, L. An Improved Genetic Algorithms for Multi-objective Hybrid Flow-shop Scheduling Problem. In Proceedings of the 3rd International Conference on Power, Energy and Mechanical Engineering (ICPEME)/8th International Conference on Manufacturing Engineering and Processes (ICMEP), Prague, Czech Republic, 16–19 February 2019; E D P Sciences: Prague, Czech Republic, 2019. [Google Scholar]

- Viana, M.S.; Contreras, R.C.; Junior, O.M. A New Frequency Analysis Operator for Population Improvement in Genetic Algorithms to Solve the Job Shop Scheduling Problem. Sensors 2022, 22, 4561. [Google Scholar] [CrossRef]

- Pang, X.; Xue, H.; Tseng, M.-L.; Lim, M.K.; Liu, K. Hybrid Flow Shop Scheduling Problems Using Improved Fireworks Algorithm for Permutation. Appl. Sci. 2020, 10, 1174. [Google Scholar] [CrossRef]

- Wang, Z. Optimal Scheduling of Flow Shop Based on Genetic Algorithm. J. Adv. Manuf. Syst. 2021, 21, 111–123. [Google Scholar] [CrossRef]

- Ombuki, B.M.; Ventresca, M. Local Search Genetic Algorithms for the Job Shop Scheduling Problem. Appl. Intell. 2004, 21, 99–109. [Google Scholar] [CrossRef]

- Asadzadeh, L. A local search genetic algorithm for the job shop scheduling problem with intelligent agents. Comput. Ind. Eng. 2015, 85, 376–383. [Google Scholar] [CrossRef]

- Kong, L.; Wang, L.; Li, F.; Wang, G.; Fu, Y.; Liu, J. A New Sustainable Scheduling Method for Hybrid Flow-Shop Subject to the Characteristics of Parallel Machines. IEEE Access 2020, 8, 79998–80009. [Google Scholar] [CrossRef]

- Ni, F.; Hao, J.Y.; Lu, J.W.; Tong, X.L.; Yuan, M.X.; Duan, J.H.; Ma, Y.; He, K.; Assoc Comp, M. A Multi-Graph Attributed Reinforcement Learning based Optimization Algorithm for Large-scale Hybrid Flow Shop Scheduling Problem. In Proceedings of the 27th ACM SIGKDD International Conference on Knowledge Discovery and Data Mining (KDD), Electr Network; Assoc Computing Machinery, New York, NY, USA, 14–18 August 2021; pp. 3441–3451. [Google Scholar]

- Li, Y.; Li, X.; Gao, L.; Zhang, B.; Pan, Q.-K.; Tasgetiren, M.F.; Meng, L. A discrete artificial bee colony algorithm for distributed hybrid flowshop scheduling problem with sequence-dependent setup times. Int. J. Prod. Res. 2020, 59, 3880–3899. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, C.; Shao, X.; Ren, Y.; Ren, C. Mathematical modelling and optimisation of energy-conscious hybrid flow shop scheduling problem with unrelated parallel machines. Int. J. Prod. Res. 2018, 57, 1119–1145. [Google Scholar] [CrossRef]

- Li, W.M.; Han, D.; Gao, L.; Li, X.Y.; Li, Y. Integrated Production and Transportation Scheduling Method in Hybrid Flow Shop. Chin. J. Mech. Eng. 2022, 35, 20. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).