Resource Management in FlexSim Modelling: Addressing Drawbacks and Improving Accuracy

Abstract

:1. Introduction

1.1. Function Analysis

1.2. Research Problem

1.3. Significances and Objectives

2. Literature Review

2.1. Resources

2.2. Simulation Modelling

2.3. Technical Contradiction

- Invert the action used to solve the problem (i.e., cooling instead of heating).

- Make a moveable part fixed and a fixed part moveable.

- Turn the object (or process) upside down.

- Extract the disturbing part or property from an object.

- Extract only the necessary part of an object.

- Replace a mechanical system with a sensory one (optical, acoustical, thermal, etc.)

- Use an electric, electromagnetic field to interact with an object.

- Replace a stationary field with a moving field, an unstructured field with a structured one.

- Use fields in conjunction with ferromagnetic particles.

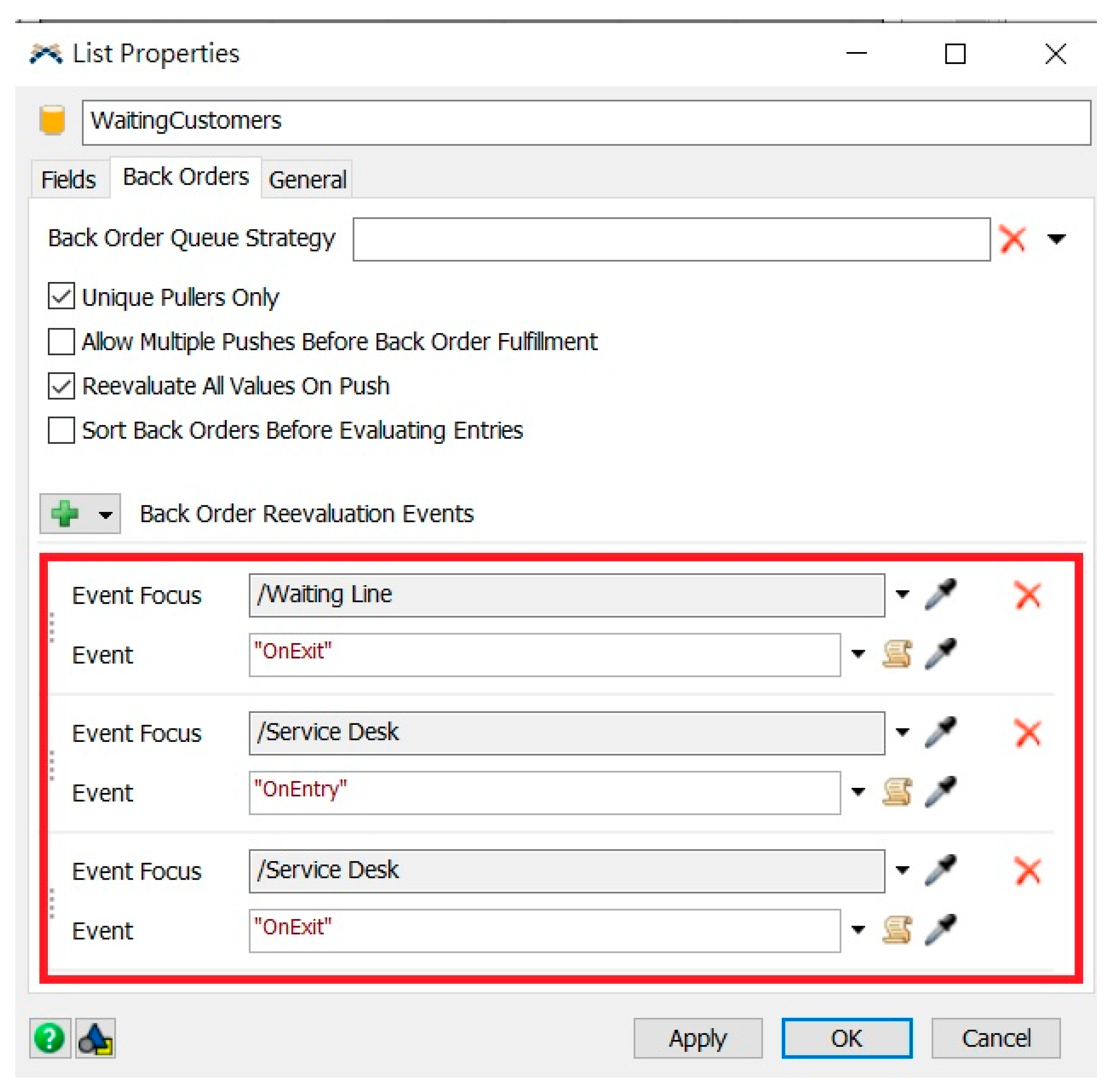

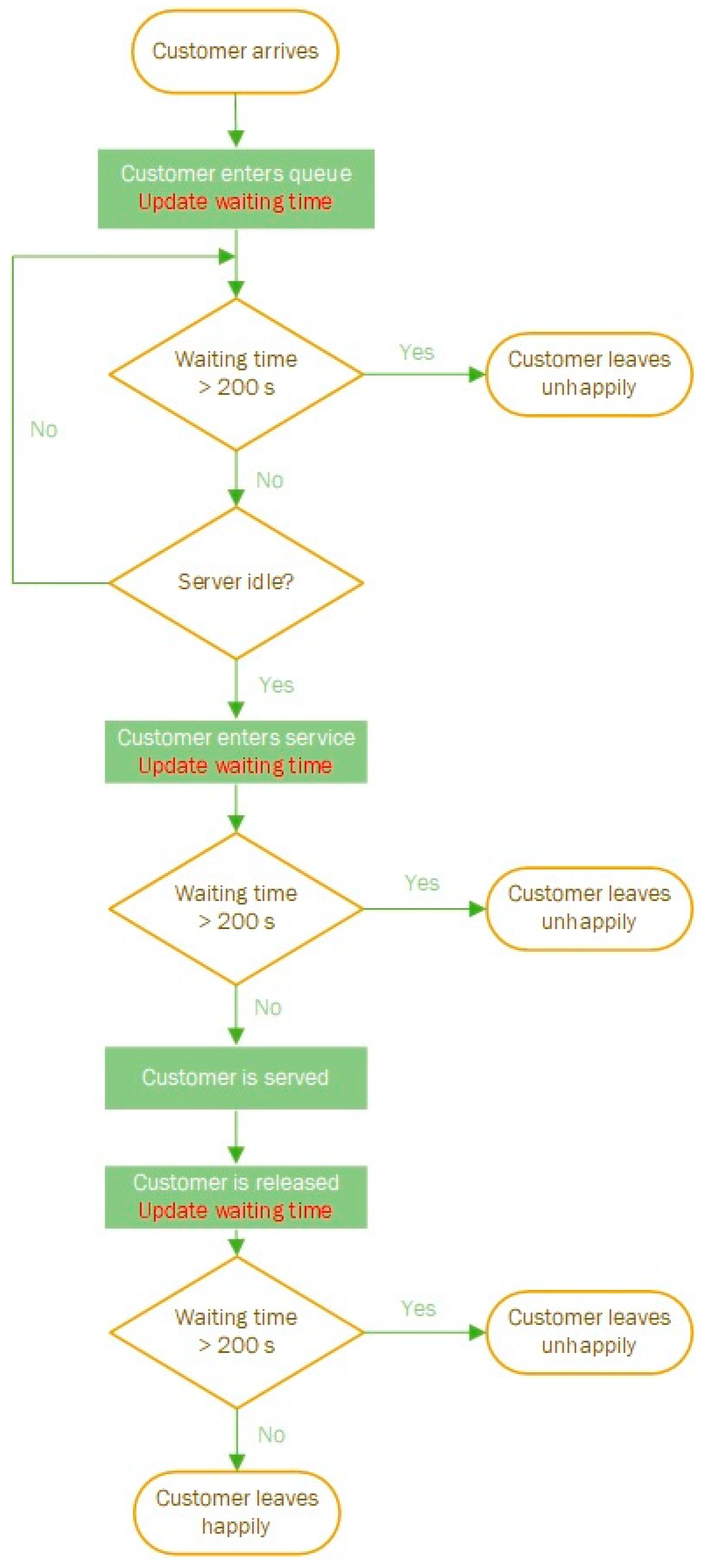

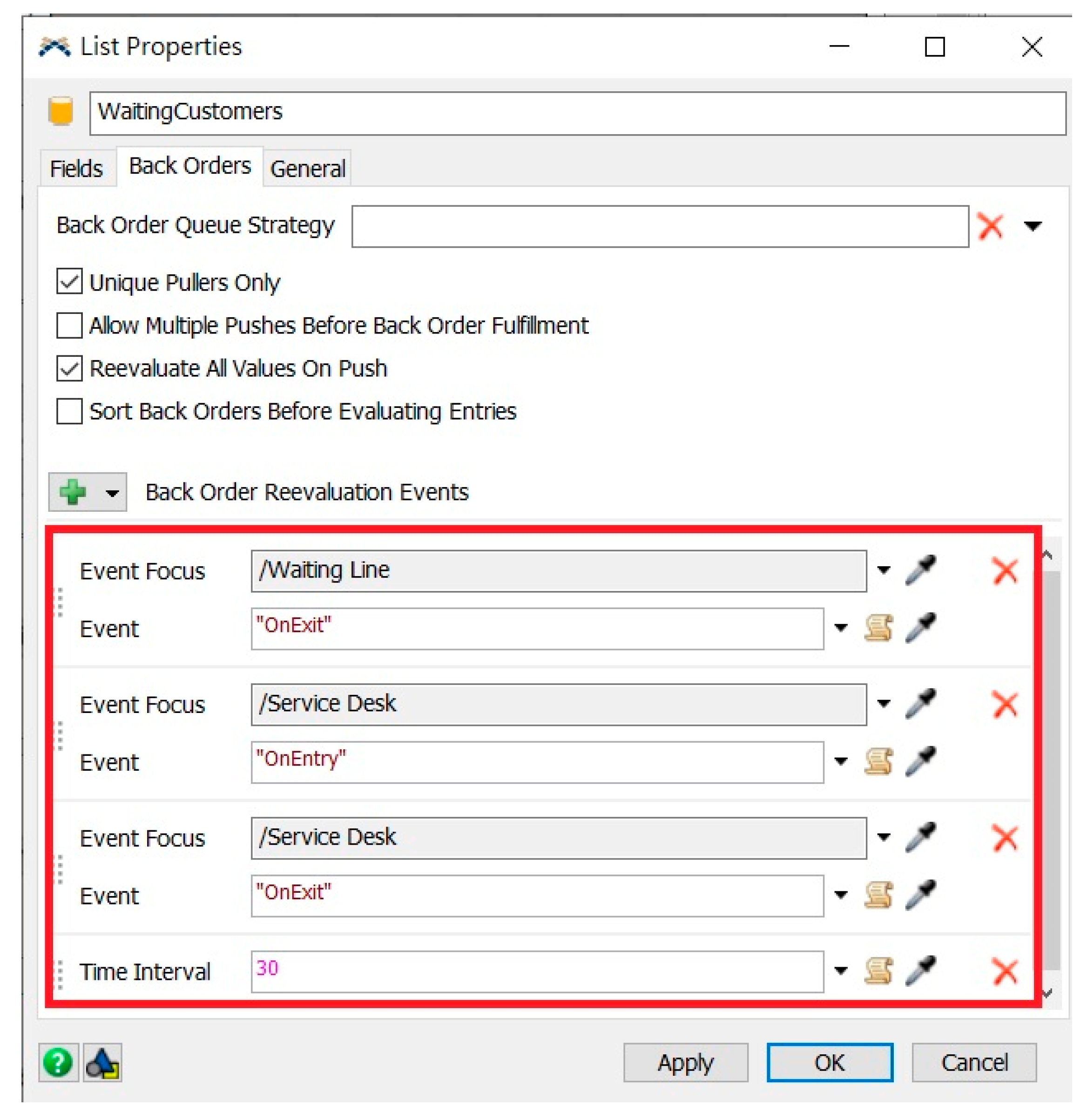

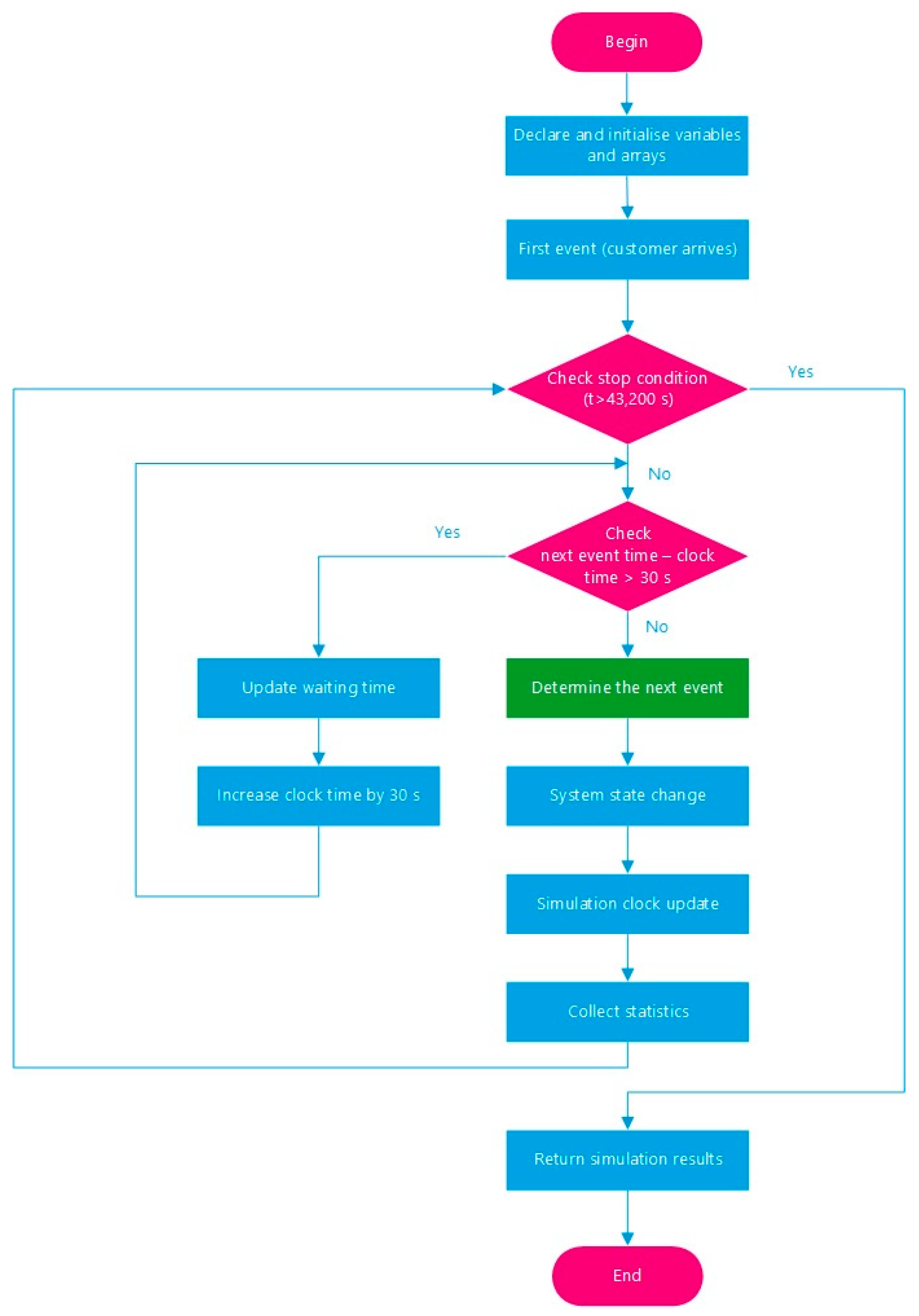

- Use incoming customers to the waiting line to update the time (original alternative provided by the tutorial.) This method is intuitive.

- Use outgoing customers from the waiting line to update the time (this was not thought of in the tutorial.)

- Use incoming customers to the service desk to update the time (this is thinking outside the box.)

- Use outgoing customers from the service desk to update the time (this is thinking outside the box.)

- Use a measurement error limit of 30 s for waiting time and update the waiting time automatically whenever there is no update for more than 30 s (this is thinking outside the box).

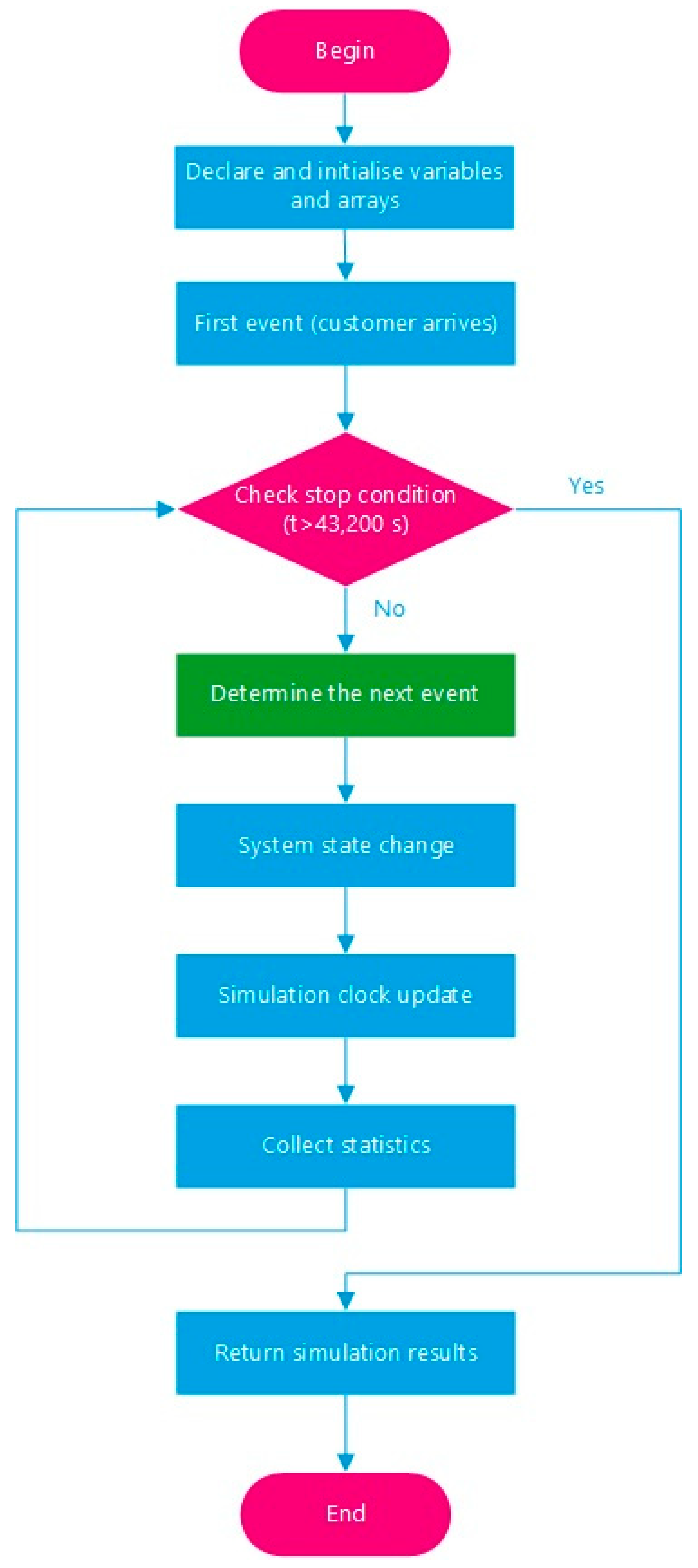

3. Process Flow Model, 3D Model and Experimental Results

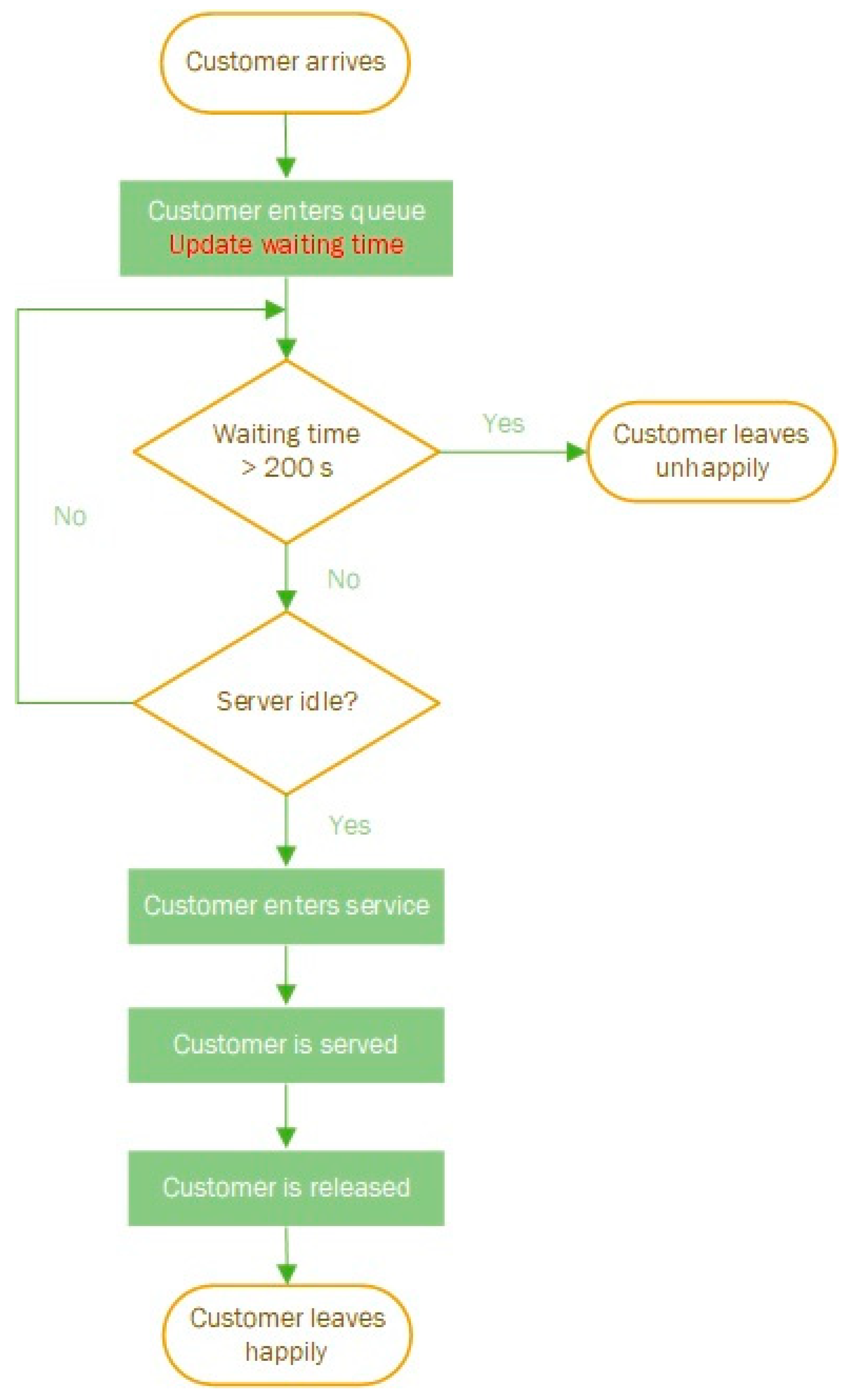

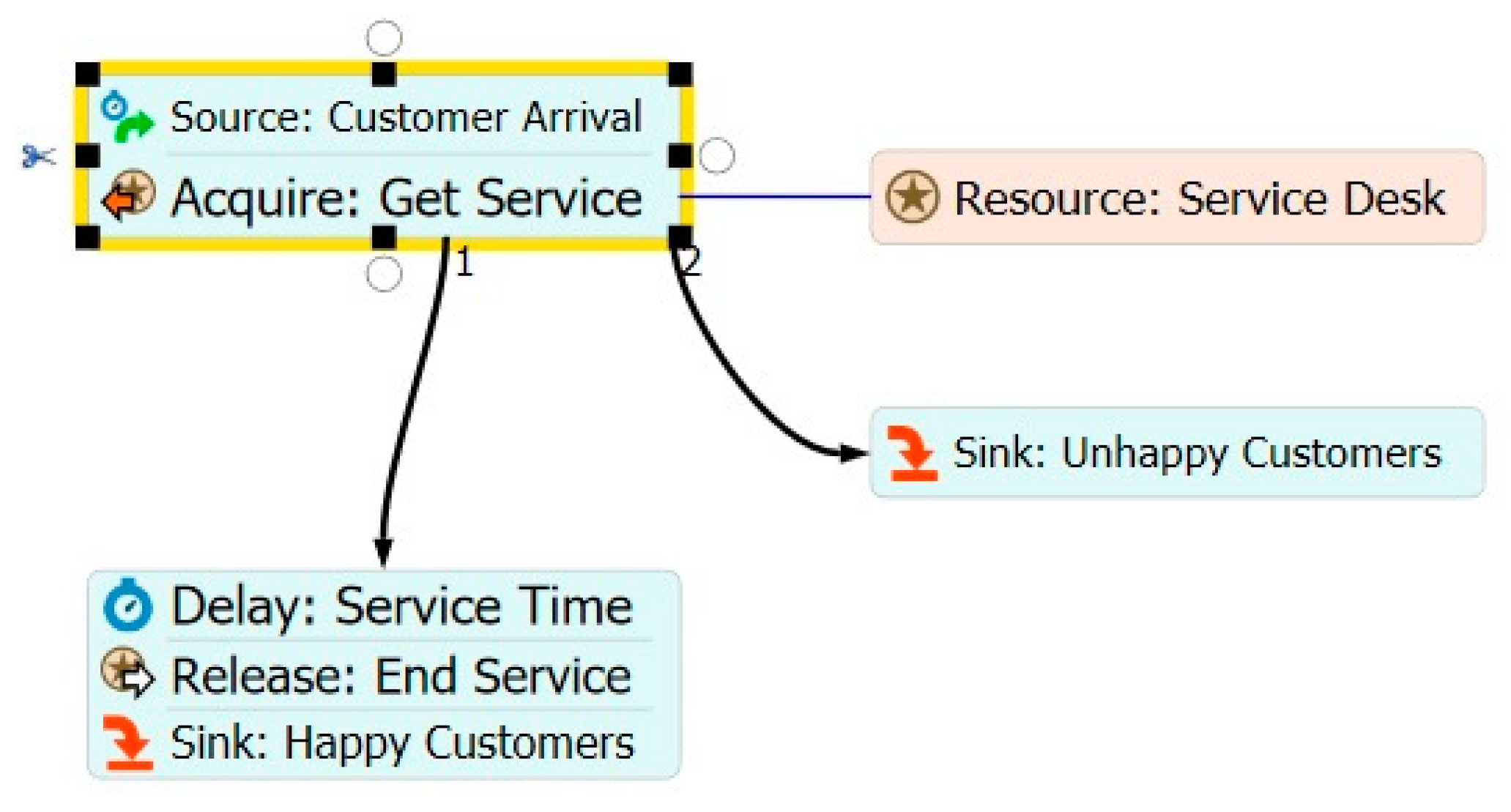

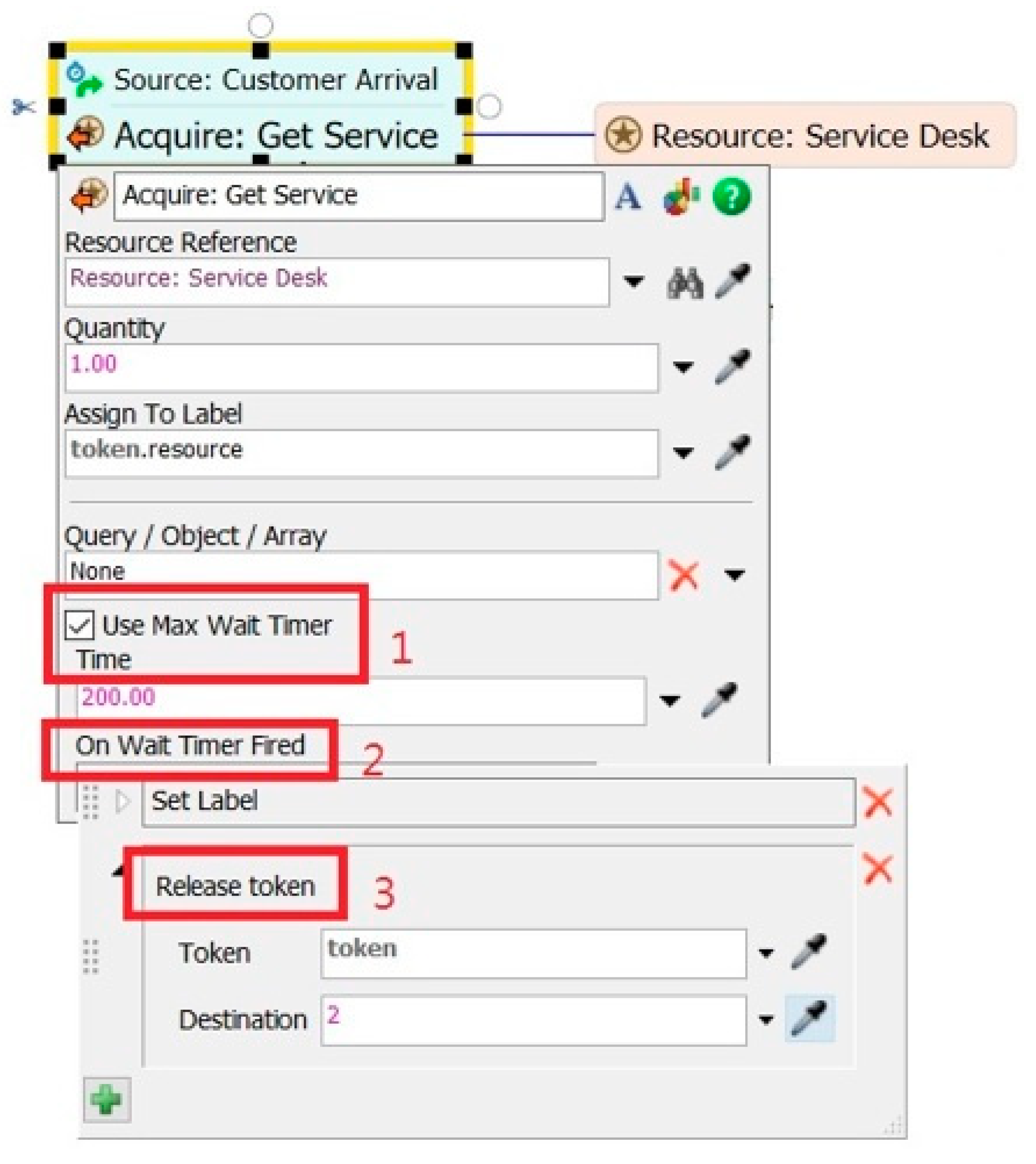

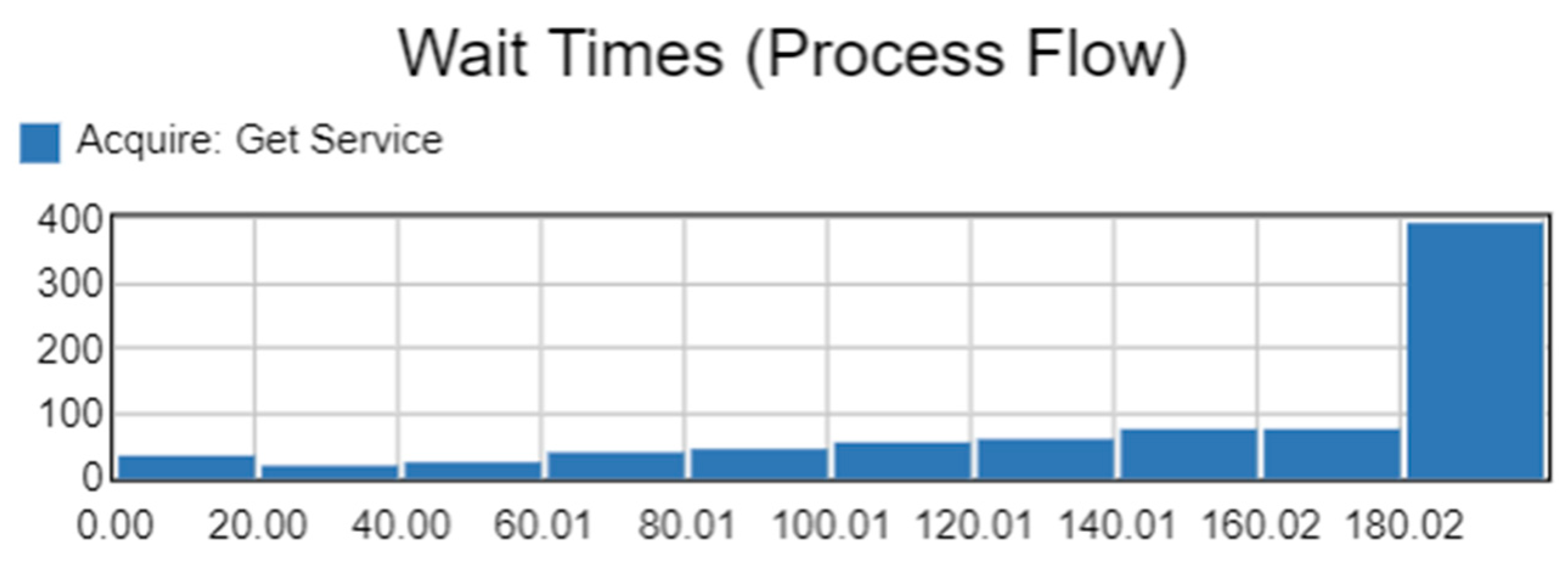

3.1. Process Flow Model

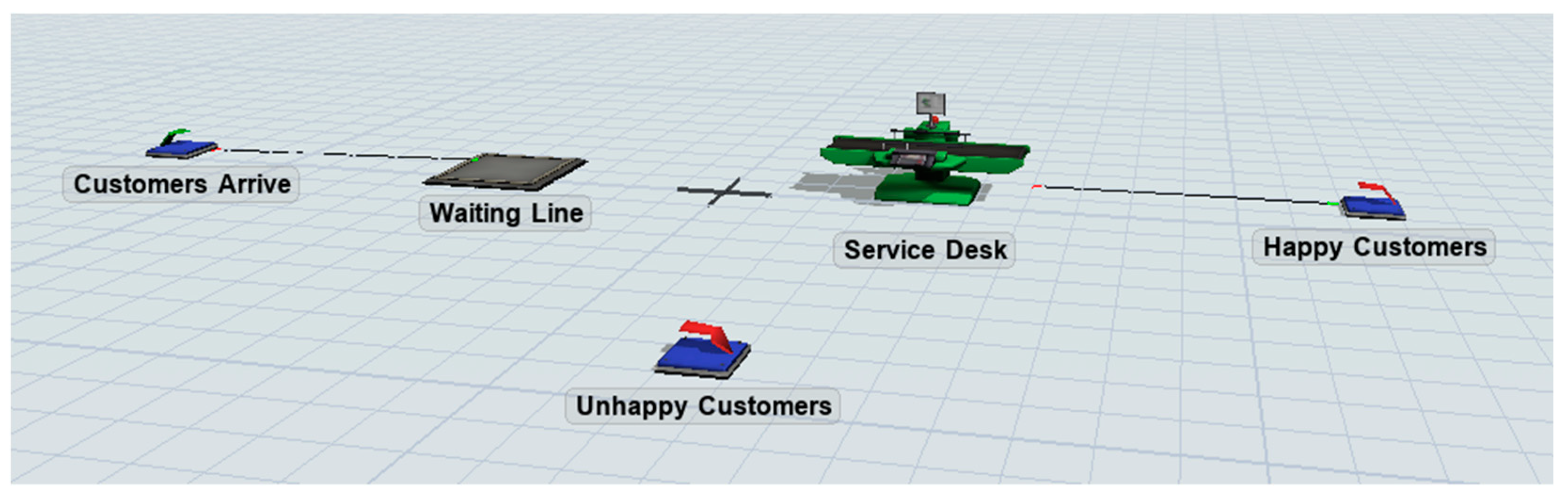

3.2. 3D Model: Default

3.3. Perspective of TRIZ

3.4. Improvement of 3D Model: Default

3.5. Insight of 3D Model: Stage 2

4. Conclusions

4.1. Summarising the Key Findings

4.2. Concise Recommendation

4.3. Highlight the Simulation

4.4. Call to Action

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Altshuller, G. Creativity as an Exact Science: The Theory of the Solution of Inventive Problems; Gordon and Breach: New York, NY, USA, 1984. [Google Scholar]

- Deng, J.; Lin, Y.; Tsai, J.; Lee, J. Resolving the OXO measuring cup problem. In Proceedings of the 9th International Conference on Systematic Innovation, Hsinchu, Taiwan, 18–21 July 2018; p. 20. [Google Scholar]

- FlexSim Tutorial: Task 1.1—Build a 3D Model. 2022. Available online: https://docs.FlexSim.com/en/21.0/Tutorials/FlexSimBasics/1-1Build3DModel/1-1Build3DModel.html (accessed on 1 January 2023).

- Jacobs, P.H.M.; Verbraeck, A. Mastering D-SOL: A Java Based Suite for Simulation; Delft University of Technology, Faculty of Technology, Policy and Management, Systems Engineering Group: Delft, The Netherlands, 2006. [Google Scholar]

- Rykov, V.V.; Kozyrev, D.V. On sensitivity of steady-state probabilities of a cold redundant system to the shapes of life and repair time distributions of its elements. Springer Proc. Math. Stat. 2018, 231, 391–402. [Google Scholar]

- Jiamsanguanwong, A.; Ophaswongse, C.; Chansirinthorn, C.; Kitirattragarn, N.; Kittithreerapronchai, O. Improving patients’ experience concerning insufficient informational flow to patients during COVID-19 pandemic: Case study of a traditional Chinese medicine clinic. Int. J. Healthc. Manag. 2023, 16, 51–60. [Google Scholar] [CrossRef]

- Chang, T.Y.; Horng, S.C. Conceptualizing and measuring experience quality: The customer’s perspective. Serv. Ind. J. 2010, 30, 2401–2419. [Google Scholar] [CrossRef]

- Bin Muhmad Pirus, M.S.; Anis, A. Delays of COVID-19 Swab Tests and COVID-19 Laboratory Reports by Private Healthcare Institutions in Shah Alam, Selangor, Malaysia. Glob. Bus. Manag. Res. 2022, 14, 216–225. [Google Scholar]

- Altshuller, G.; Shulyak, L.; Fedoseev, U. 40 Principles, 2nd ed.; Technical Innovation Center: Worcester, MA, USA, 2001. [Google Scholar]

- Belski, I. Improve Your Thinking: Substance-Field Analysis; TRIZ4U: Melboyrne, Australia, 2007. [Google Scholar]

- Zlotin, B.; Zusman, A. The Concept of Resources in TRIZ: Past, Present and Future; Ideation International: Farmington Hills, MI, USA, 2005. [Google Scholar]

- Kernytskyy, I.; Hlinenko, L.; Yakovenko, Y.; Horbay, O.; Koda, E.; Rusakov, K.; Yankiv, V.; Humenuyk, R.; Polyansky, P.; Berezovetskyi, S.; et al. Problem-Oriented Modelling for Biomedical Engineering Systems. Appl. Sci. 2022, 12, 7466. [Google Scholar] [CrossRef]

- Bogatyrev, N.; Bogatyreva, O. Inventor’s Manual; Salisbury Printing Ltd.: Salisbury, UK, 2011. [Google Scholar]

- Vincent, J.F.V.; Bogatyreva, O.A.; Bogatyrev, N.R.; Bowyer, A.; Pahl, A.-K. Biomimetics: Its practice and theory. J. R. Soc. Interface 2006, 3, 471–482. [Google Scholar] [CrossRef] [PubMed]

- Bogatyreva, O.A.; Shillerov, A.E. Biomimetic Management: Building a Bridge Between People and Nature; BioTRIZ Ltd.: Trowbridge, UK, 2015. [Google Scholar]

- Mann, D.L. Hands-On Systematic Innovation, 2nd ed.; IFR Press: London, UK, 2007. [Google Scholar]

- Mann, D.L. Hands-On Systematic Innovation for Business and Management, 2nd ed.; IFR Press: London, UK, 2007. [Google Scholar]

- Weaver, J.B. Systematic Tools for Innovation: The Trimming Technique; Technical Report; University of Detroit Mercy: Detroit, MI, USA, 2009. [Google Scholar]

- Sheu, D.D.; Hou, C.T. TRIZ-based systematic device trimming: Theory and application. Procedia Eng. 2015, 131, 237–258. [Google Scholar] [CrossRef]

- Mueller, S. The TRIZ resource analysis tool for solving management tasks: Previous classifications and their modification. Creat. Innov. Manag. 2005, 14, 43–58. [Google Scholar] [CrossRef]

- Sheu, D.D.; Yen, M.Z. Systematic analysis and usage of harmful resources. Comput. Ind. Eng. 2020, 145, 106459. [Google Scholar] [CrossRef]

- Sheu, D.D.; Chiu, M.C.; Cayard, D. The 7 pillars of TRIZ philosophies. Comput. Ind. Eng. 2020, 146, 106572. [Google Scholar] [CrossRef]

- Stewart, T.A. Intellectual Capital; Doubleday Business: New York, NY, USA, 1997. [Google Scholar]

- Schumacher, E.F. Small Is Beautiful: A Study of Economics as if People Mattered; Hartley & Marks Publishers: Vancouver, BC, Canada, 1999. [Google Scholar]

- Beaverstock, M.; Greenwood, A.; Nordgren, W. Applied Simulation: Modelling and Analysis Using FlexSim, 5th ed.; FlexSim Software Products, Inc.: Orem, UT, USA, 2017. [Google Scholar]

- Kuzmin, D.; Baginova, V.; Ageikin, A. Discrete event simulation model of the railway station. Transp. Res. Procedia 2022, 63, 929–937. [Google Scholar] [CrossRef]

- Wu, S.; Xu, A.; Song, W.; Li, X. Structural optimization of the production process in steel plant based on FlexSim simulation. Steel Res. Int. 2019, 90, 1900201. [Google Scholar] [CrossRef]

- Wang, Y.R.; Chen, A.N. Production logistics simulation and optimization of industrial enterprise based on FlexSim. Int. J. Simul. Model. 2016, 15, 732–741. [Google Scholar] [CrossRef]

- Wang, J.; Huynh, N.N.; Pena, E. Land side truck traffic modelling at container terminals by a stationary two-class queuing strategy with switching. J. Int. Logist. Trade 2022, 20, 118–134. [Google Scholar] [CrossRef]

- Ohno, T. Toyota Production System: Beyond Large-Scale Production; Productivity Press: New York, NY, USA, 1988. [Google Scholar]

- Maister, D.H. The Psychology of Waiting Lines; Harvard Business School: Boston, MA, USA, 1984; pp. 71–78. [Google Scholar]

- FlexSim Tutorial: Task 1.3—Build a Process Flow Model. 2022. Available online: https://docs.FlexSim.com/en/20.0/Tutorials/FlexSimBasics/1-3BuildProcessFlow/1-3BuildProcessFlow.html (accessed on 1 January 2023).

| Min. | Max. | Average | S.D. | Count | |

|---|---|---|---|---|---|

| Process Flow Model | 0 | 200.00 | 156.37 | 54.69 | 756 |

| 3D Model: default | 0 | 398.83 | 190.97 | 70.25 | 734 |

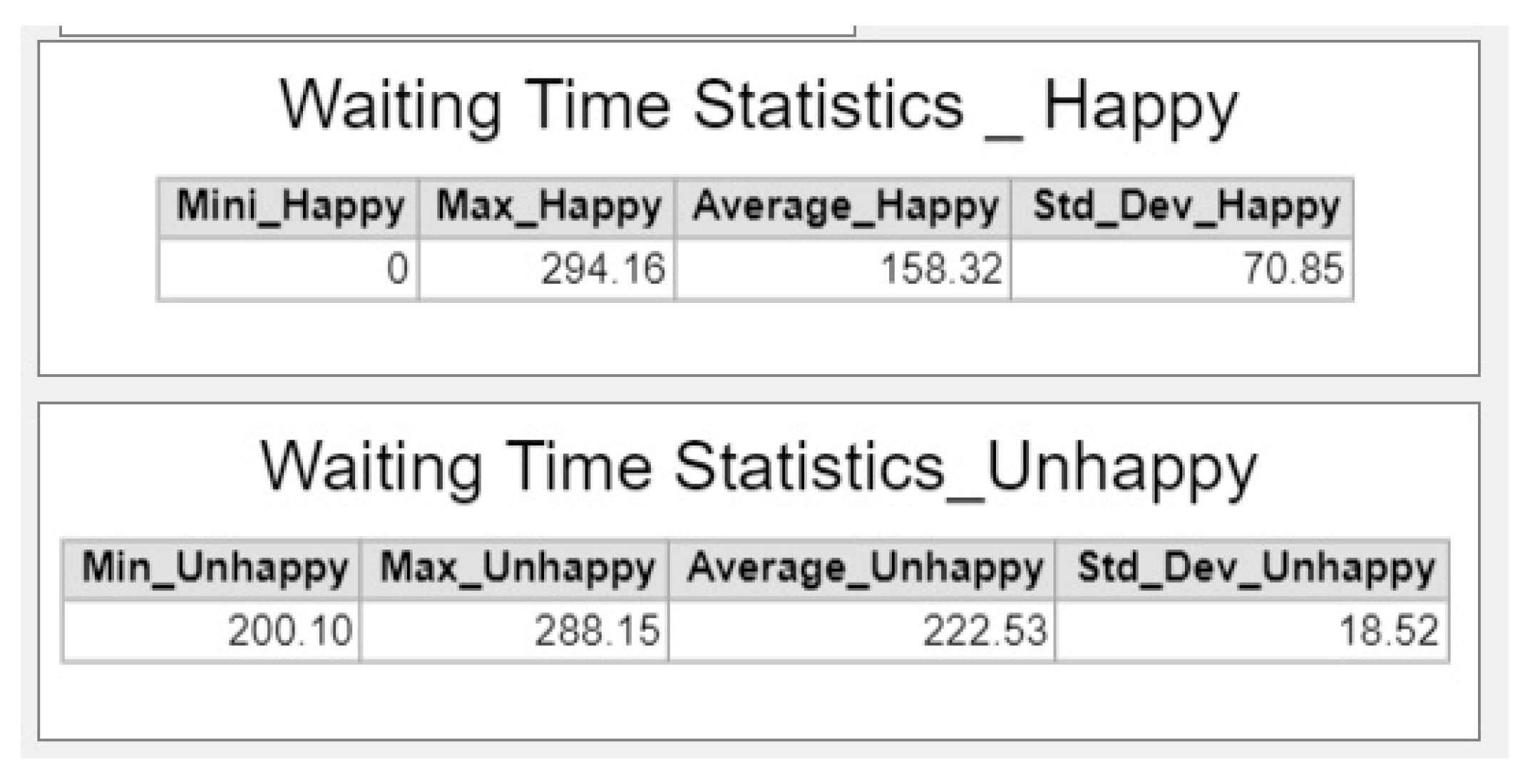

| 3D Model: Stage 1 | 0 | 294.16 | 182.59 | 64.96 | 725 |

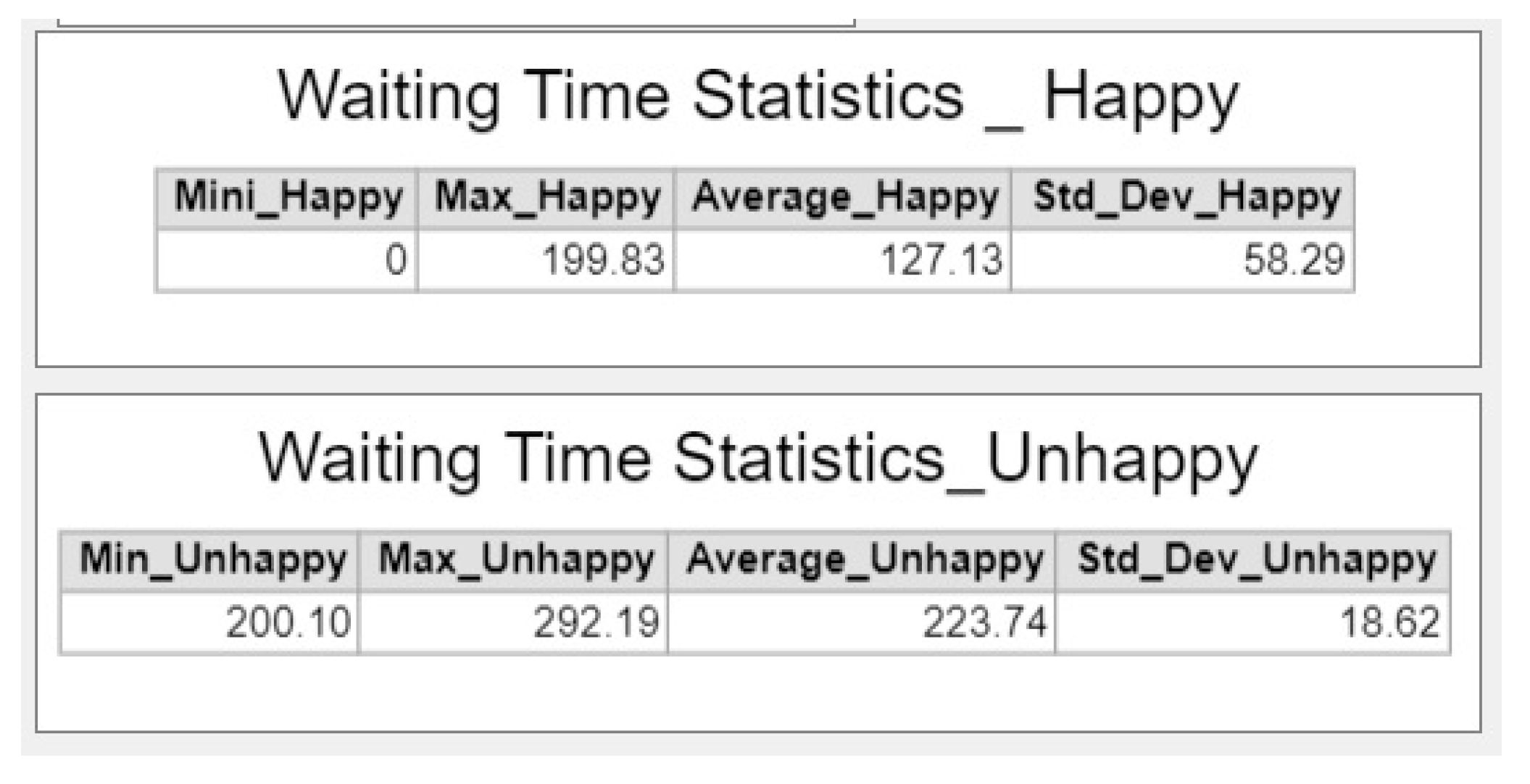

| 3D Model: Stage 2 | 0 | 292.19 | 165.38 | 66.50 | 740 |

| 3D Model: Stage 3 | 0 | 229.77 | 160.08 | 61.11 | 740 |

| Min. | Max. | Average | S.D. | Count | |

|---|---|---|---|---|---|

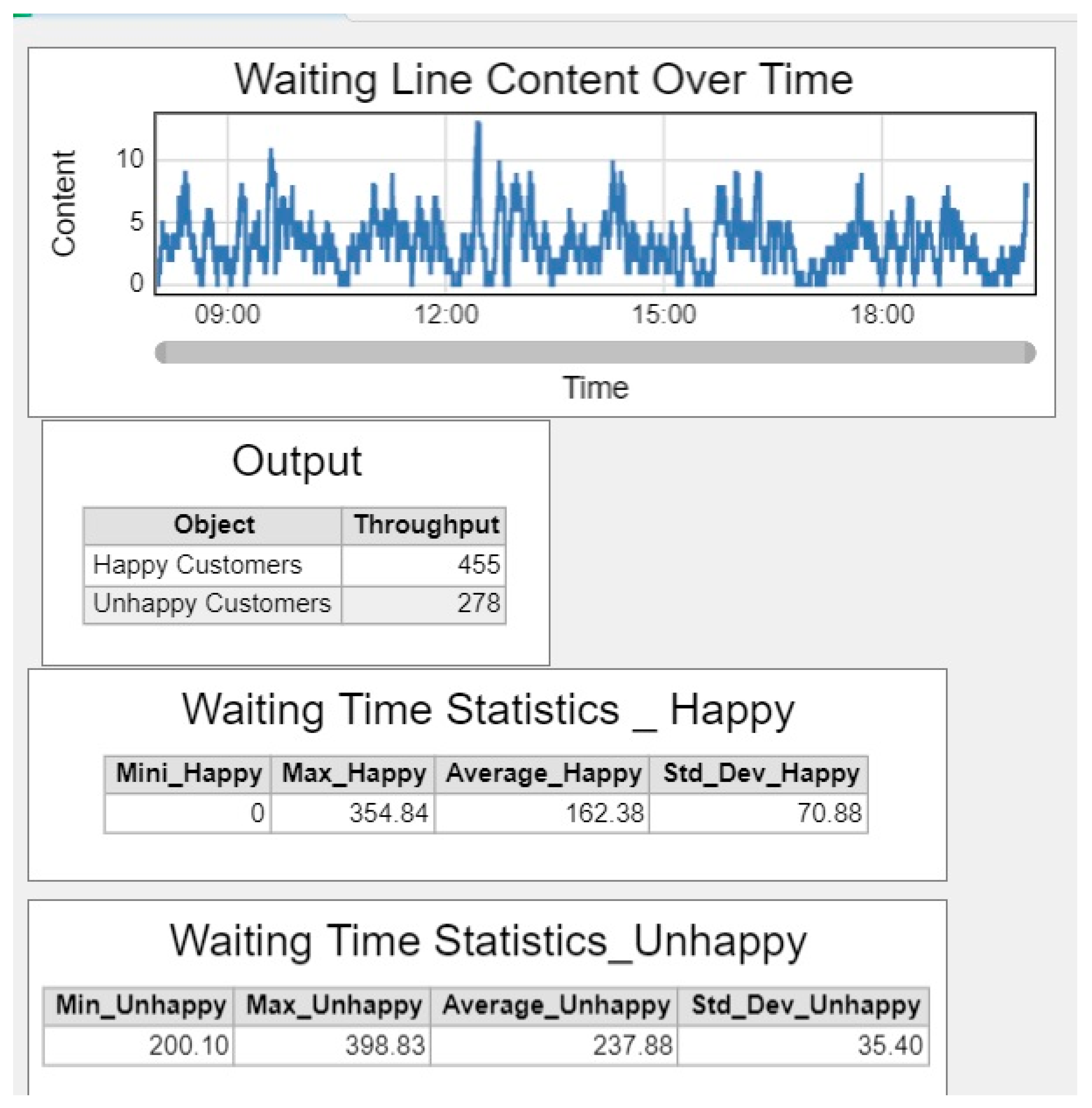

| Process Flow Model | 0 | 199.99 | 127.36 | 53.60 | 454 |

| 3D Model: default | 0 | 354.84 | 162.38 | 70.88 | 456 |

| 3D Model: Stage 1 | 0 | 294.16 | 158.32 | 70.85 | 451 |

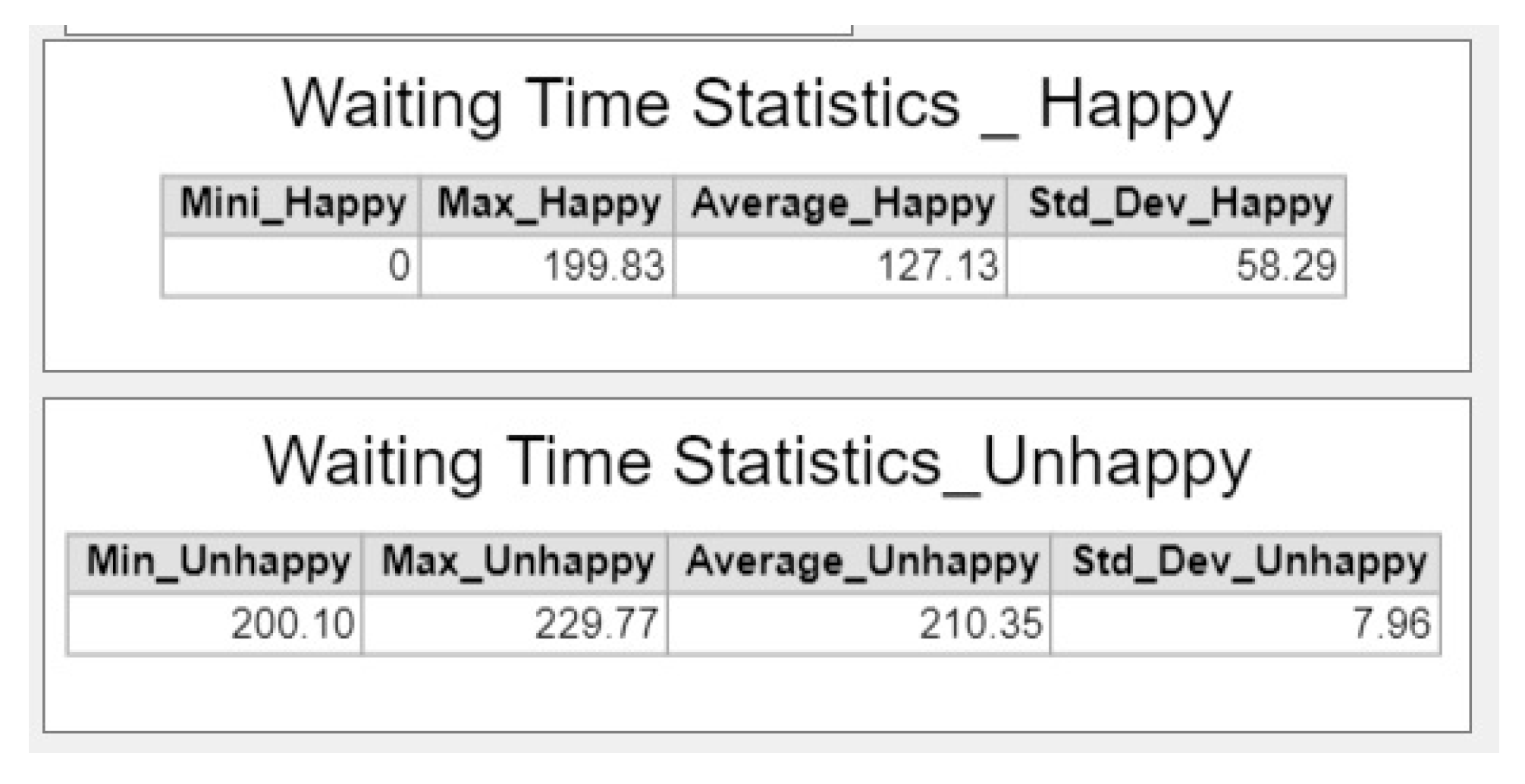

| 3D Model: Stage 2 | 0 | 199.83 | 127.13 | 58.29 | 447 |

| 3D Model: Stage 3 | 0 | 199.83 | 127.13 | 58.29 | 447 |

| Min. | Max. | Average | S.D. | Count | |

|---|---|---|---|---|---|

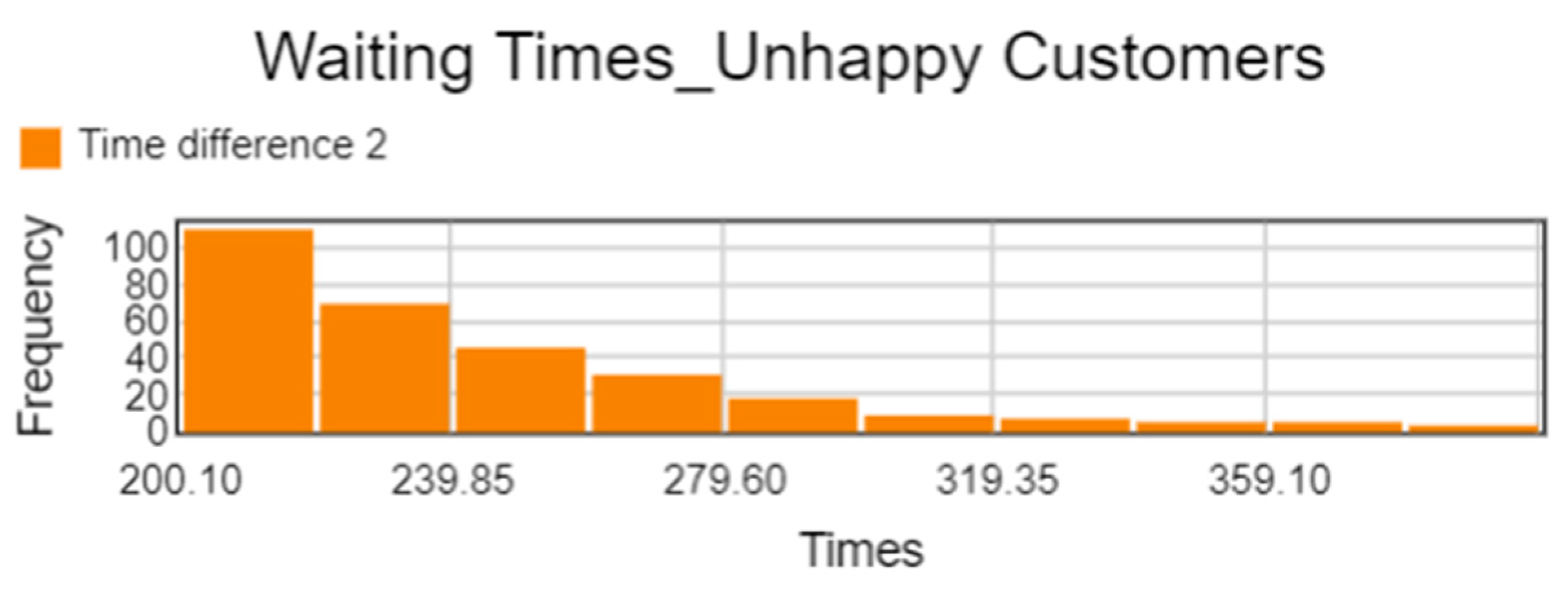

| Process Flow Model | 200.00 | 200.00 | 200.00 | 0 | 302 |

| 3D Model: default | 200.10 | 398.83 | 237.88 | 35.40 | 278 |

| 3D Model: Stage 1 | 200.10 | 288.15 | 222.53 | 18.52 | 274 |

| 3D Model: Stage 2 | 200.10 | 292.19 | 223.74 | 18.62 | 293 |

| 3D Model: Stage 3 | 200.10 | 229.77 | 210.35 | 7.96 | 293 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, J. Resource Management in FlexSim Modelling: Addressing Drawbacks and Improving Accuracy. Appl. Sci. 2023, 13, 5760. https://doi.org/10.3390/app13095760

Deng J. Resource Management in FlexSim Modelling: Addressing Drawbacks and Improving Accuracy. Applied Sciences. 2023; 13(9):5760. https://doi.org/10.3390/app13095760

Chicago/Turabian StyleDeng, Jyhjeng. 2023. "Resource Management in FlexSim Modelling: Addressing Drawbacks and Improving Accuracy" Applied Sciences 13, no. 9: 5760. https://doi.org/10.3390/app13095760

APA StyleDeng, J. (2023). Resource Management in FlexSim Modelling: Addressing Drawbacks and Improving Accuracy. Applied Sciences, 13(9), 5760. https://doi.org/10.3390/app13095760