Towards Lunar In-Situ Resource Utilization Based Subtractive Manufacturing

Abstract

:1. Introduction

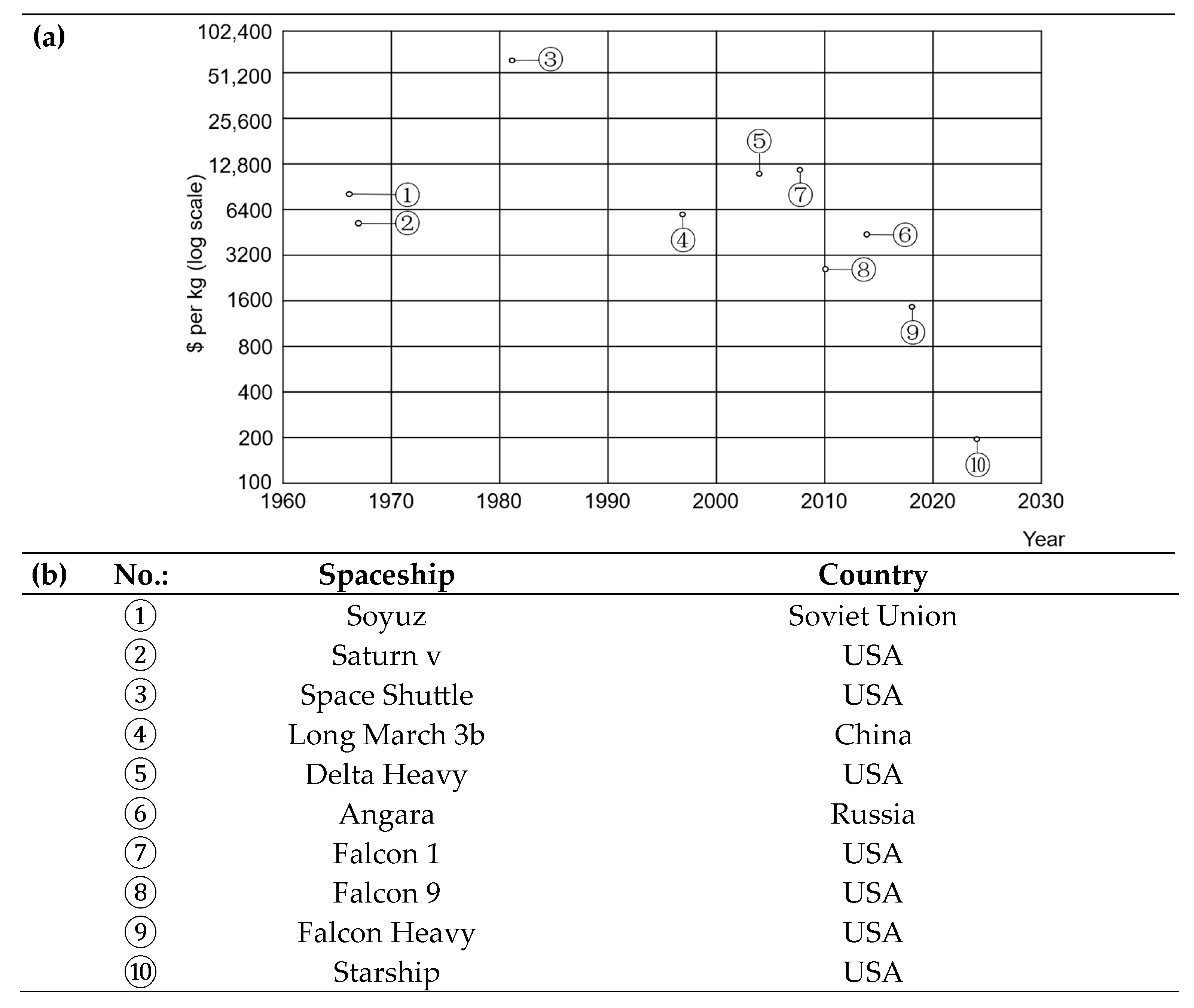

1.1. Manufacturing in Space

1.2. In-Situ Resources Utilisation (ISRU)

- In-Situ Propellant and Consumable Production;

- In-Situ Construction;

- In-Space Manufacturing with, for example, ISRU-Derived Feedstock.

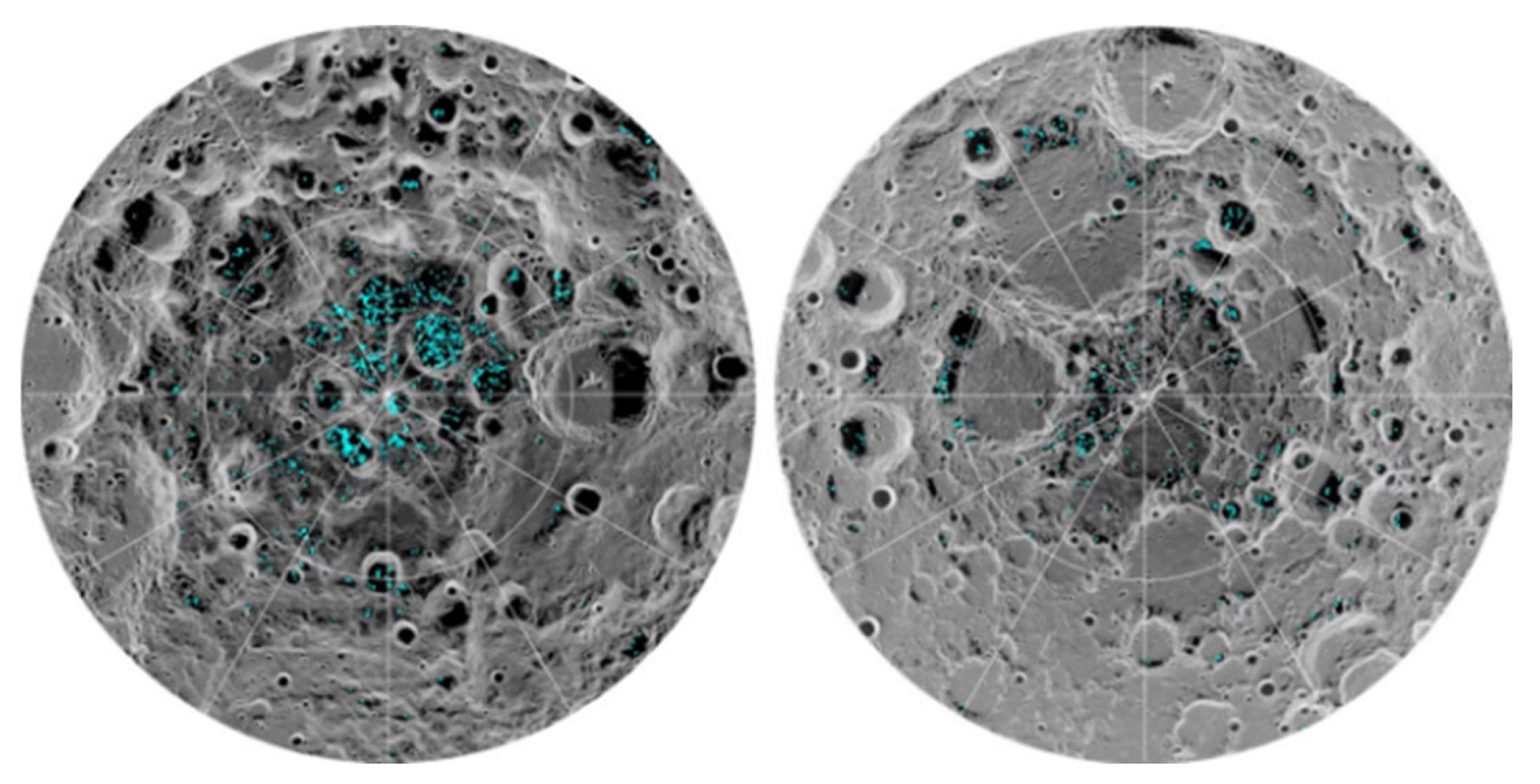

1.3. Natural Lunar Resources

1.4. Discarded Hardware

1.5. Hardware Identified as Relevant to Manufacturing in Space

1.6. In-Space Manufacturing Processes

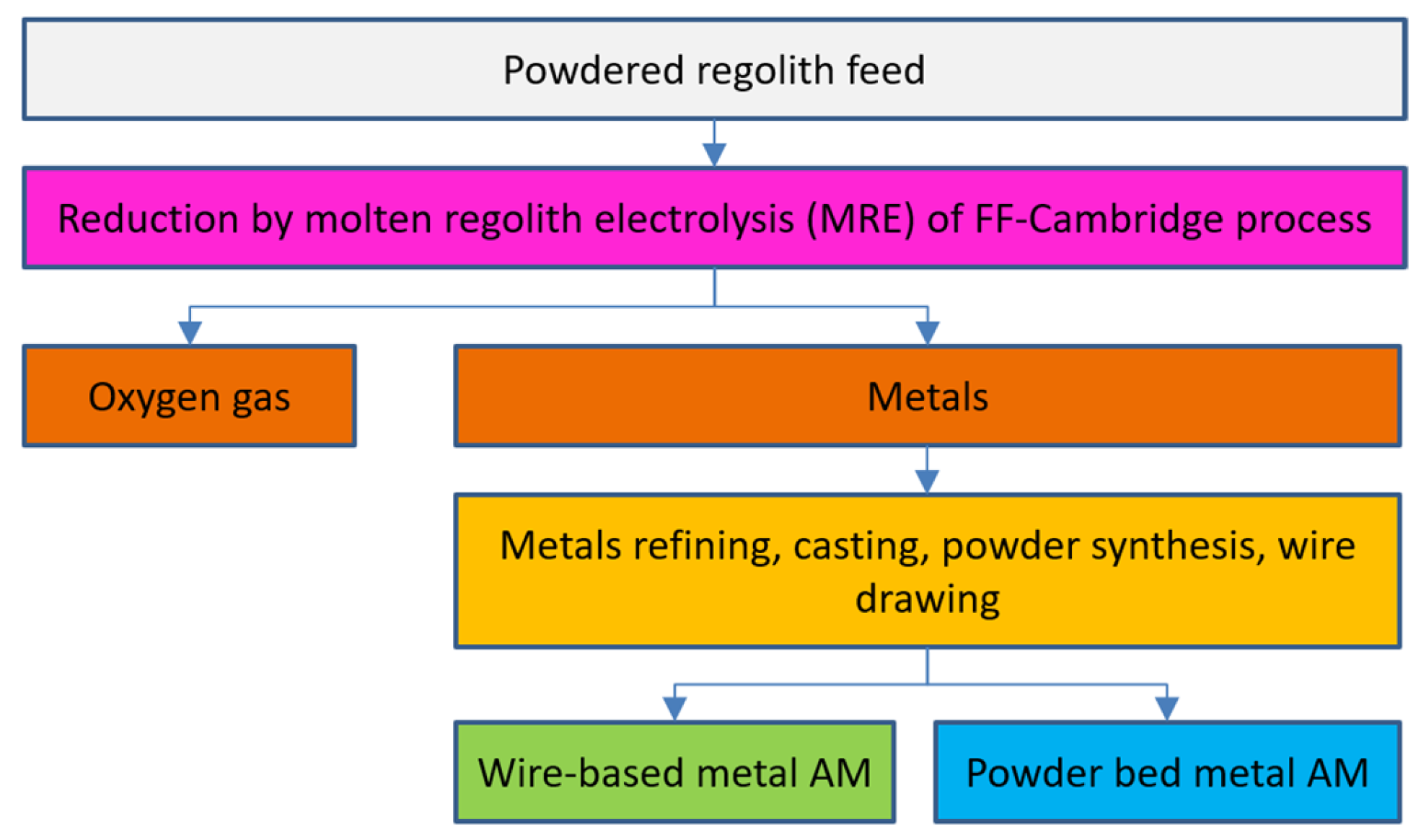

2. Methods and Materials

2.1. Workflow

2.2. Subtractive Machining State of the Art and Trade-Off

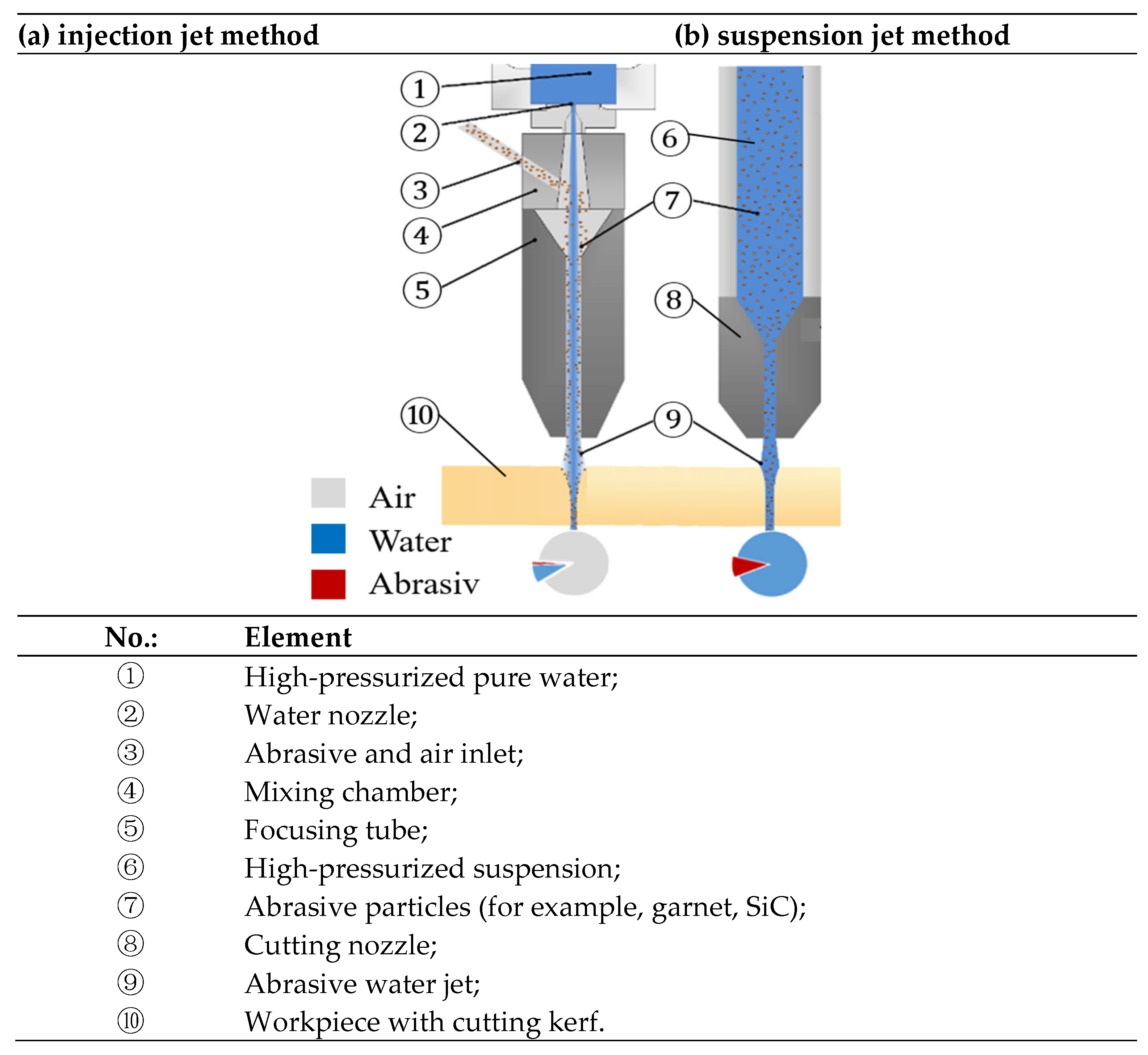

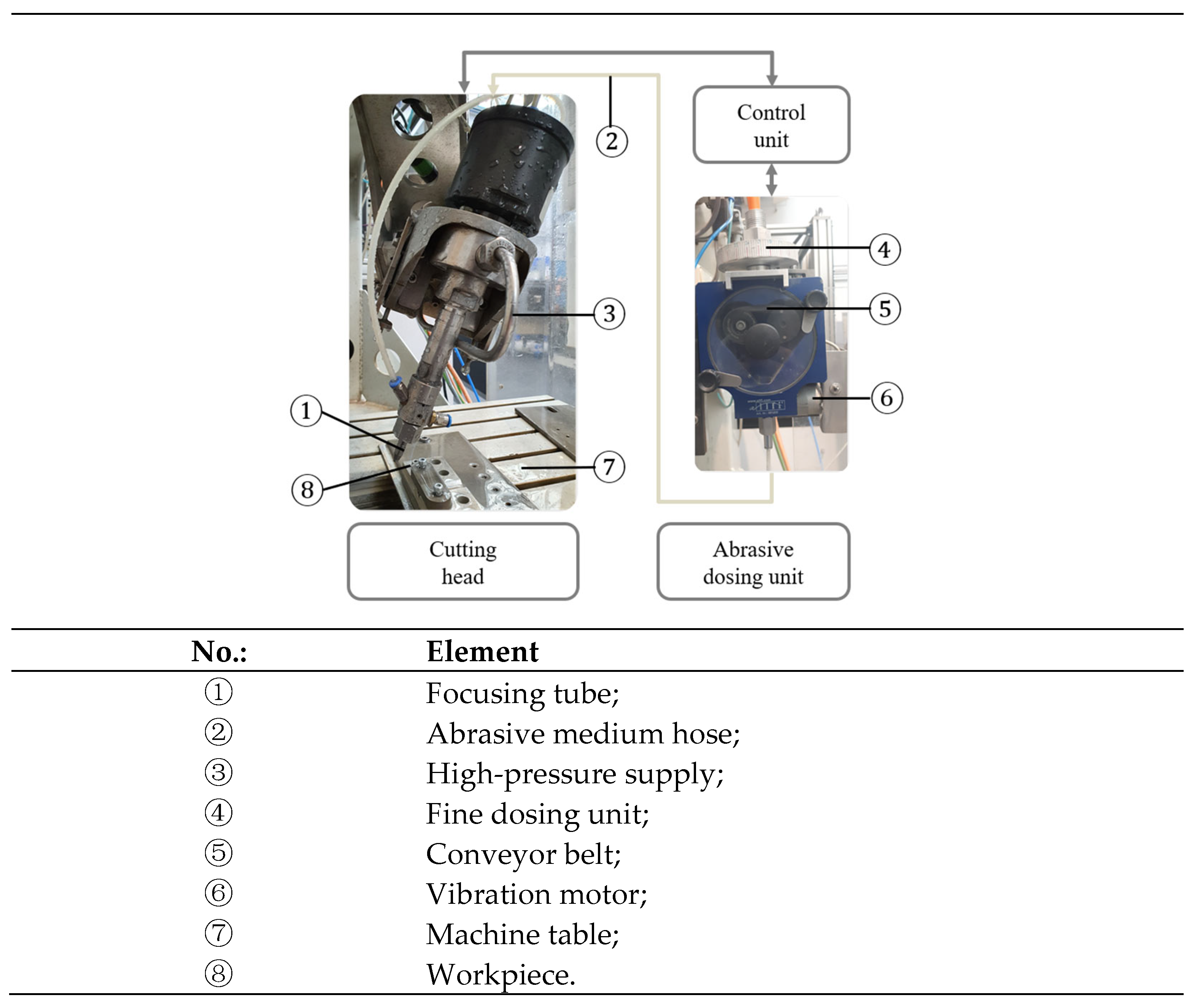

2.3. Abrasive Water Jet Cutting

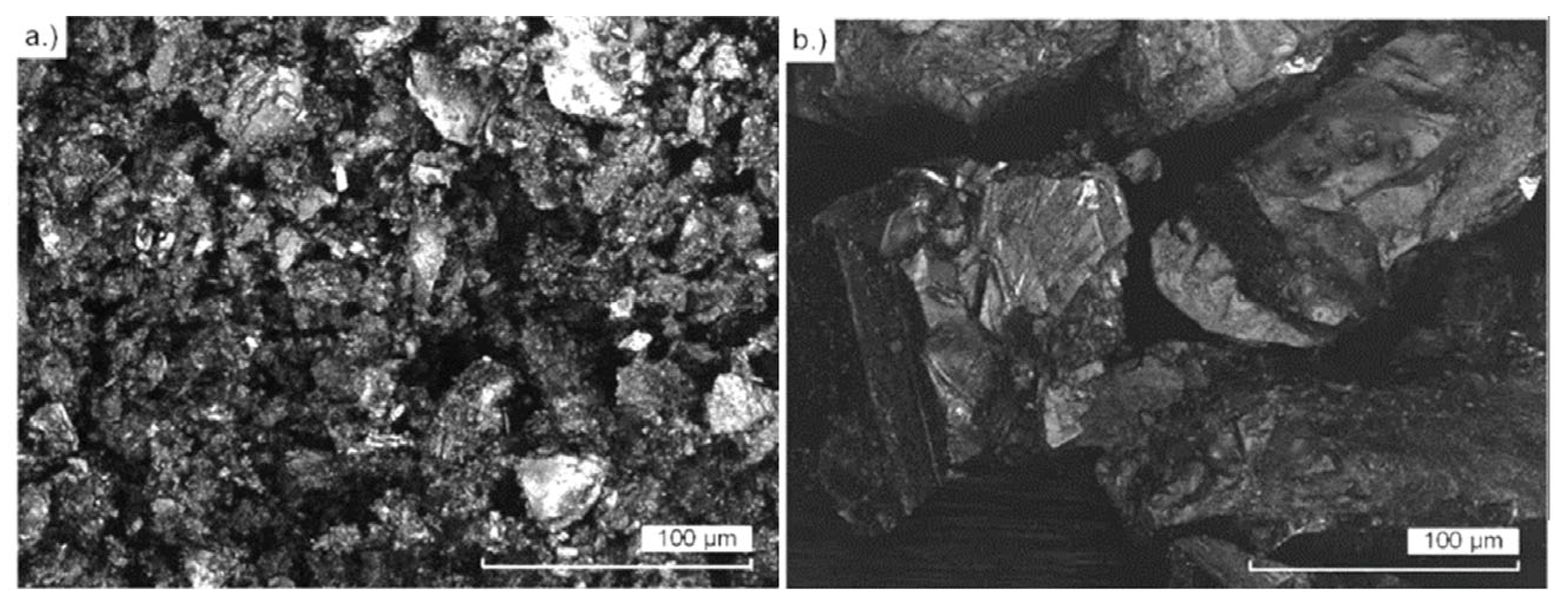

2.4. Regolith Simulate

2.5. Aluminium Alloy

2.6. Lithium Silicate

- Cast of the initial glass from a glass building melt;

- Nucleation;

- Crystal growth of the nuclei.

- Glass, representing other glasses;

- Lithium monosilicate as the main crystal phase, representing rather weak ceramics;

- Lithium disilicate as the main crystal phase, representing high-strength ceramics.

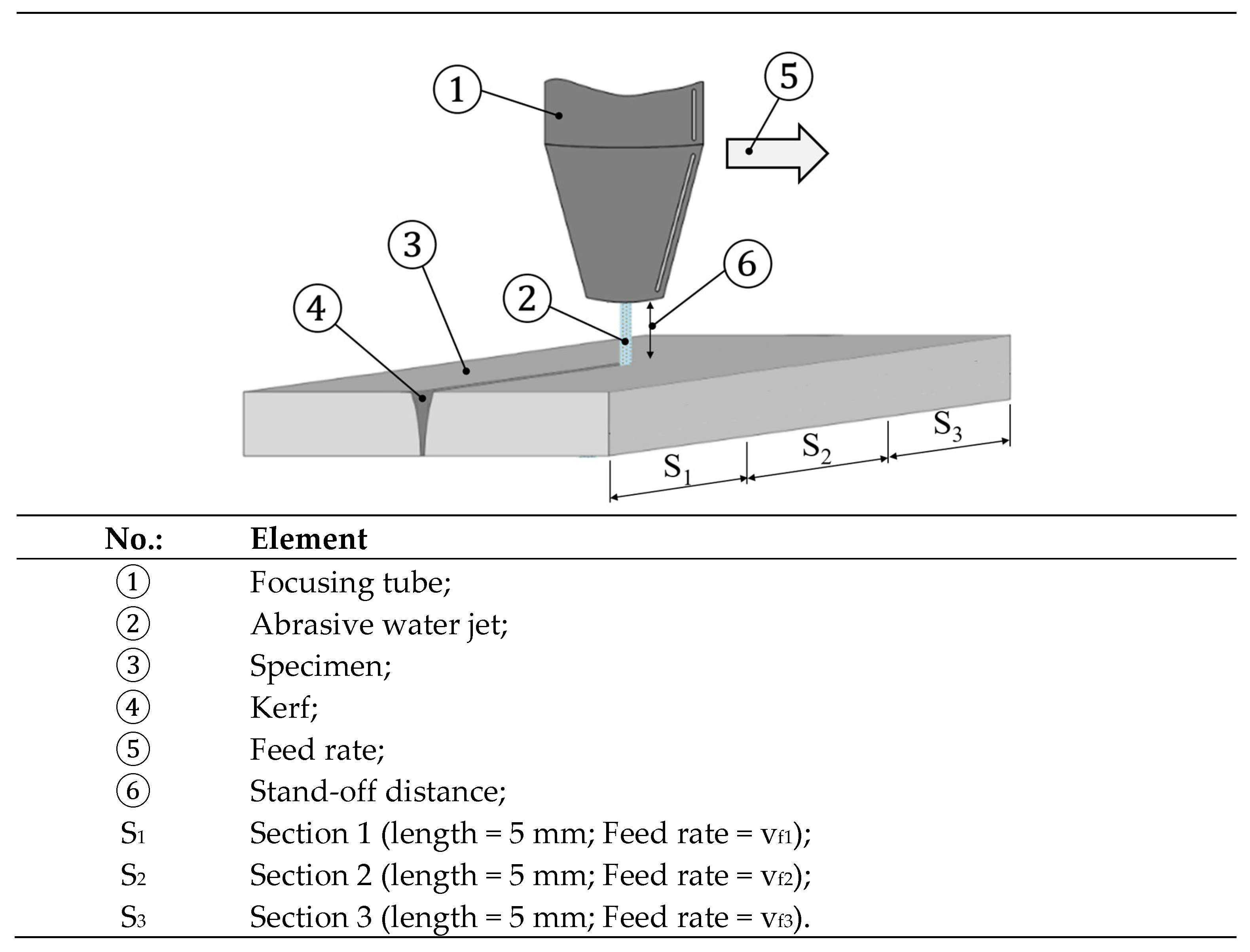

2.7. Experimental Procedure

3. Results

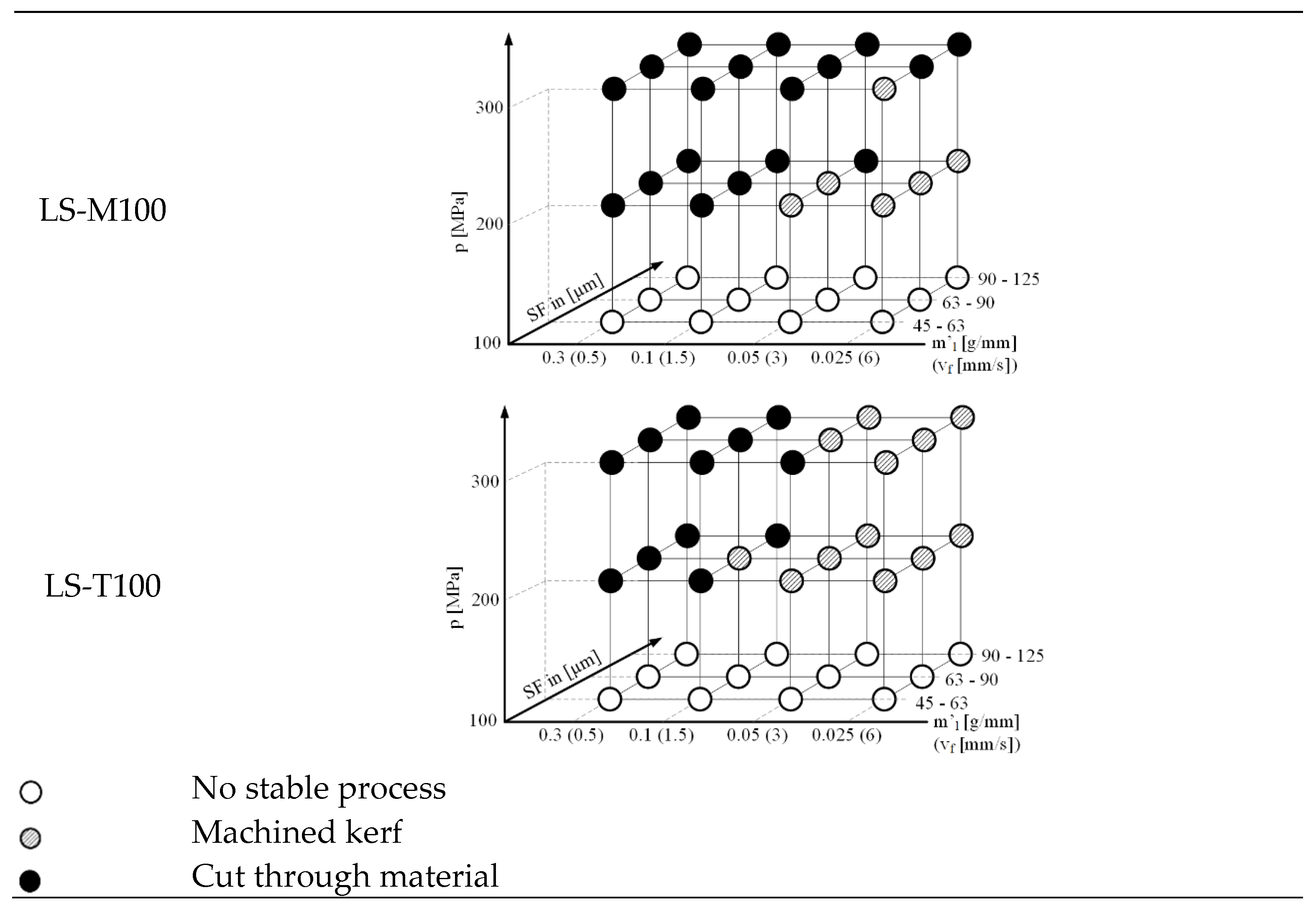

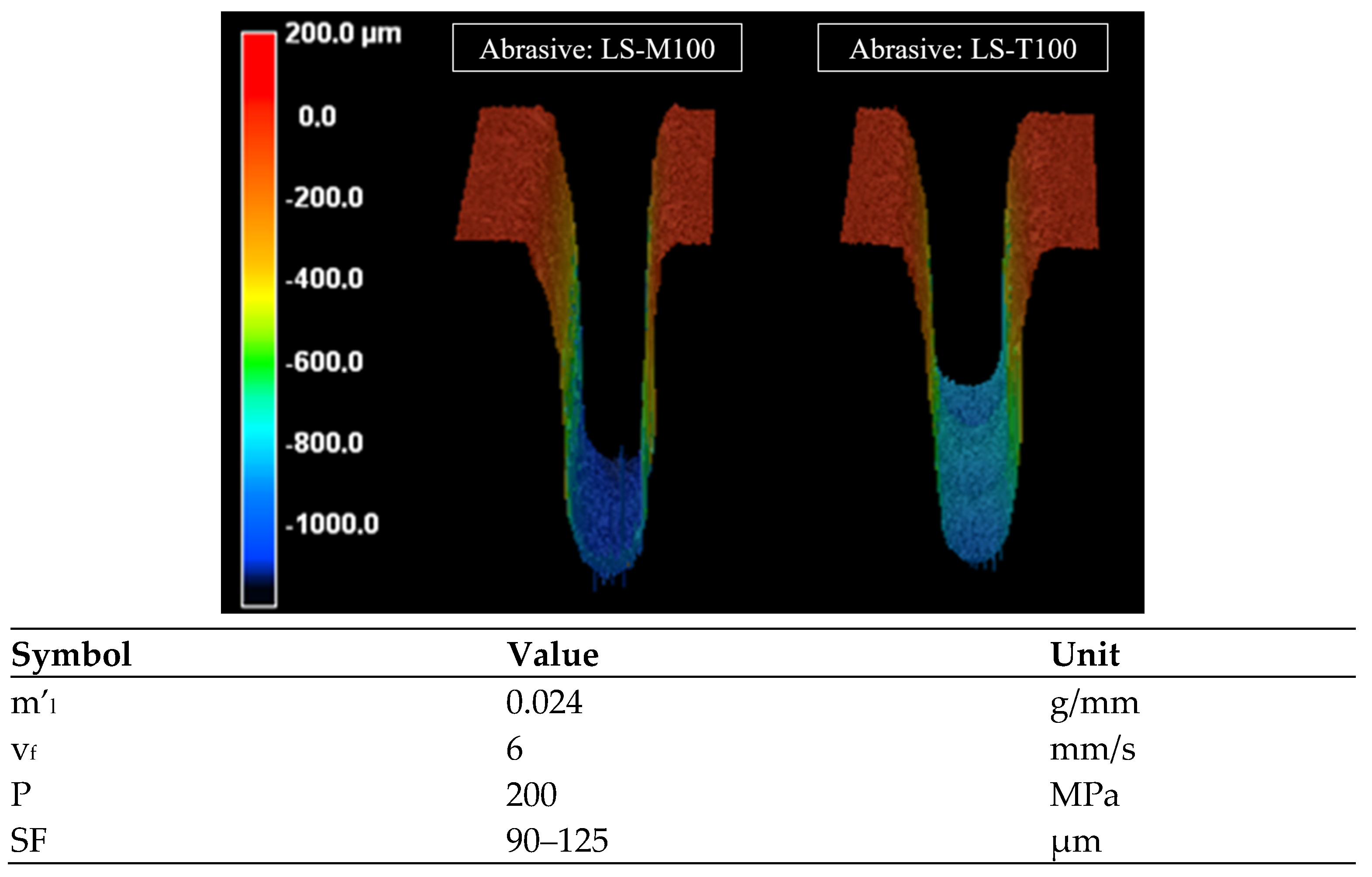

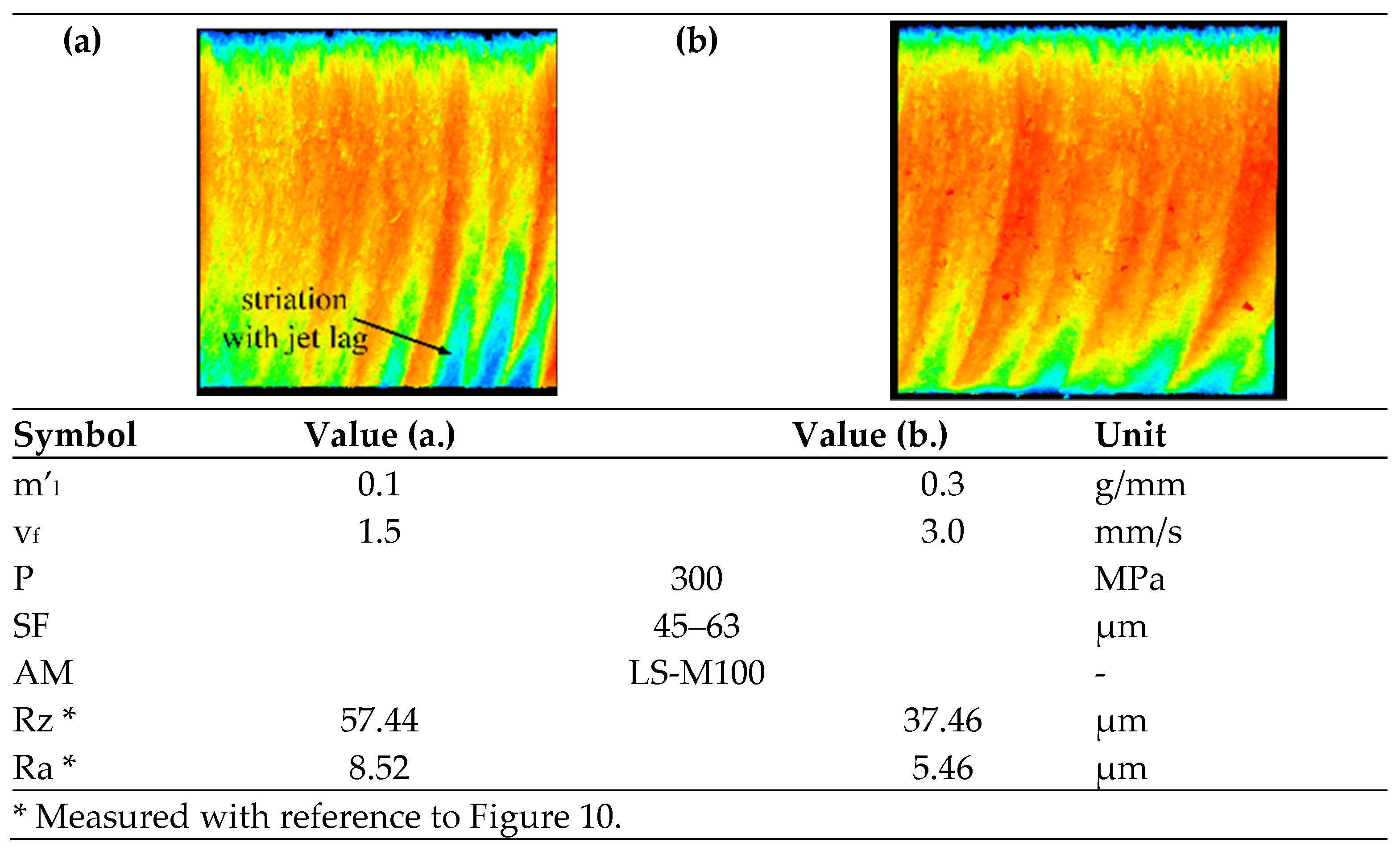

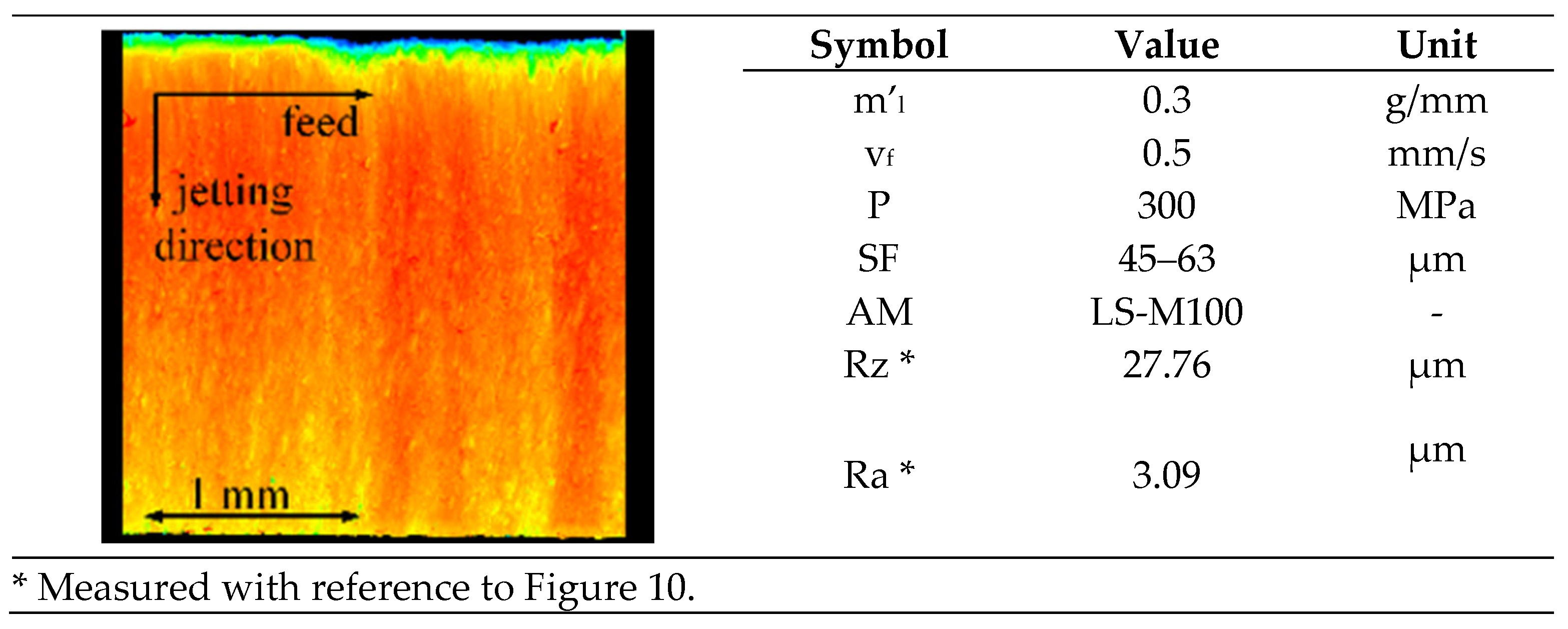

3.1. Water Jet Machining of Al-Alloy

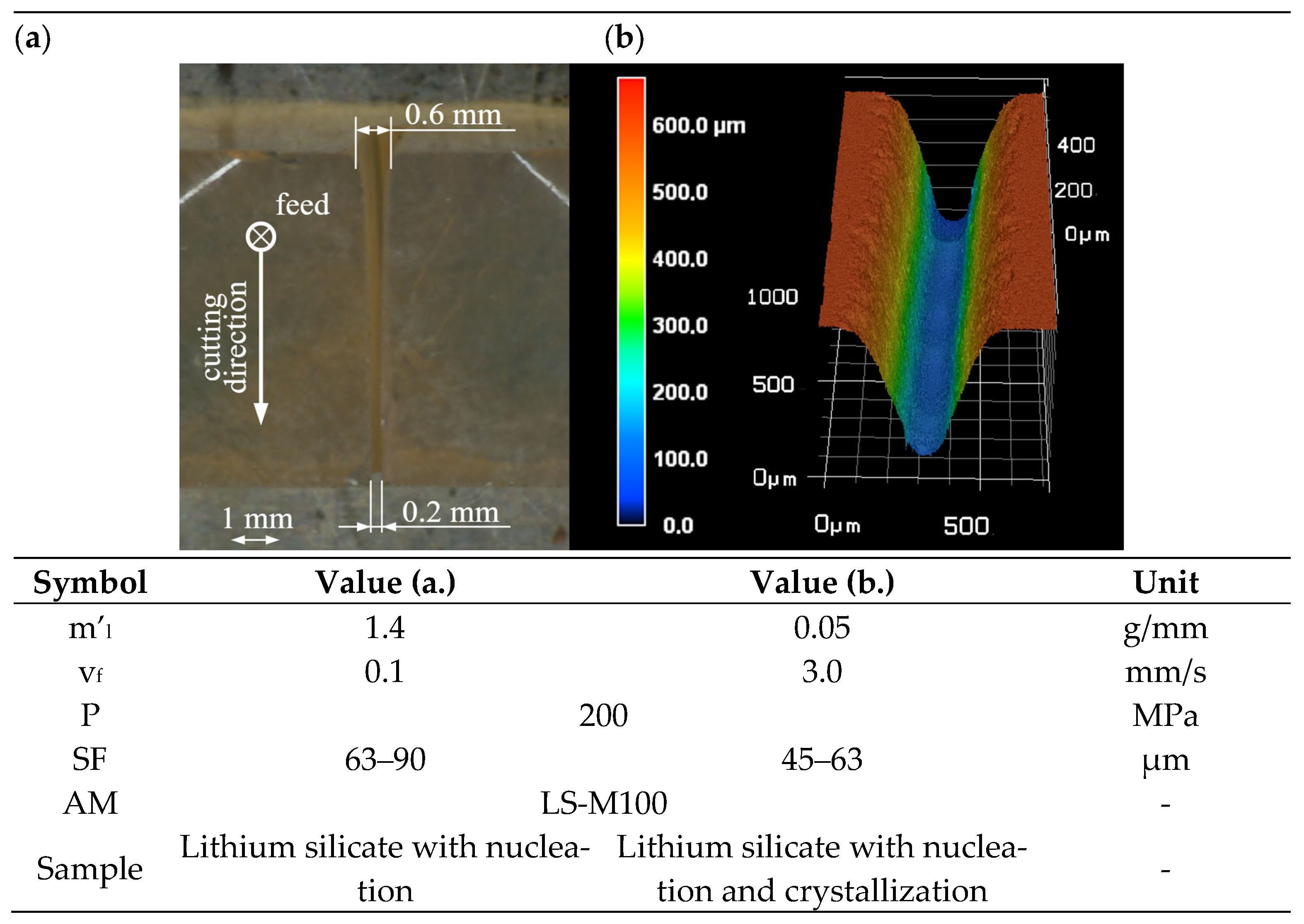

3.2. Water Jet Machining of Lithium Silicate

4. Discussion and Conclusions

- It is possible to perform an abrasive water jet cutting and removal process with regolith simulant on the tested materials;

- LS-M100, the sieved regolith simulant made of basalt representing the material of the mare regions, has a higher suitability as an abrasive due to the higher erosion rates that could be achieved;

- In order to enable the regolith simulant to be conveyed, the abrasive must be sieved, and small particle adhesions must be removed;

- For the regolith particle fractions of 45–63 μm, 63–90 μm and 90–125 μm, the experimentally determined water jet pressure for stable particle transport was between 200 and 300 MPa;

- It is possible to cut and kerf the aluminum material in the investigated test field, whereby the generated geometries are similar to the geometries generated by means of common abrasives with regard to their topography;

- It is possible to machine the investigated lithium materials with the selected test parameters. As with the Al material, typical cutting and kerf geometries are produced for the abrasive water jet technology;

- Uniformly deep kerf can be created with the regolith simulant;

- In the case of lithium silicate materials, due to the brittleness of the materials, the machining strategy must be adapted, for example, via pressure ramps, in order to prevent breakouts.

5. Outlook

- Comprehensive quantification of the results;

- Comparison of test results;

- Analysis of the cut surfaces;

- Determination of erosion rates in surface structuring;

- Check the reusability of abrasives;

- Scale/scalability of hardware in terms of power (maximum power for ISS payload is 2 kw), mass and volume, safety (chip debris capture), limited crew interaction, remote commanding, etc.;

- Operation in reduced gravity (physics of removal);

- Application/operation in an encapsulated environment with circulation of the utilized materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Prater, T.; Werkheiser, M.J.; Ledbetter, F.; Morgan, K. In-Space Manufacturing at NASA Marshall Space Flight Center: A Portfolio of Fabrication and Recycling Technology Development for the International Space Station. In Proceedings of the 2018 AIAA SPACE and Astronautics Forum and Exposition, Orlando, FL, USA, 17–19 September 2018. [Google Scholar]

- Norman, A.; Das, S.; Rohr, T.; Ghidini, T. Advanced manufacturing for space applications. CEAS Space J. 2022, 15, 1–6. [Google Scholar] [CrossRef]

- Owens, A.; de Weck, O. Systems Analysis of In-Space Manufacturing Applications for the International Space Station and the Evolvable Mars Campaign. In Proceedings of the AIAA SPACE 2016, Long Beach, CA, USA, 13–16 September 2016. [Google Scholar]

- Venditti, B.; Parker, S. The Cost of Space Flight before and after SpaceX. Available online: https://www.visualcapitalist.com/the-cost-of-space-flight/ (accessed on 15 December 2023).

- Arianespace Service & Aolutions, Soyuz User’s Manual Issue 2 Revision 0. Available online: https://www.arianespace.com/wp-content/uploads/2015/09/Soyuz-Users-Manual-March-2012.pdf (accessed on 25 April 2023).

- National Aeronautics and Space Administration (NASA). SATURN V FLIGHT MANUAL: SA 507. Available online: https://history.nasa.gov/afj/ap12fj/pdf/a12_sa507-flightmanual.pdf (accessed on 25 April 2023).

- Gatland, K.; Hewish, M.; Wright, P. The Space Shuttle Handbook; The Hamlyn Publishing Group Ltd.: London, UK, 1979. [Google Scholar]

- China Academy of Launch Vehicle Technology. LM-3B USER’S MANUAL. Available online: https://www.mach5lowdown.com/wp-content/uploads/PUG/LM-3B-User-Manual-v1999.pdf (accessed on 25 April 2023).

- United Launch Alliance. DELTA IV HEAVY. Available online: https://www.ulalaunch.com/docs/default-source/rockets/delta-iv-heavy-cutaway.pdf (accessed on 25 April 2023).

- International Launch Services. Angara 1.2 FLIGHT-PROVEN LAUNCH VEHICLE. Available online: https://www.ilslaunch.com/launch-vehicle/angara-1-2/ (accessed on 25 April 2023).

- SpaceX, FALCON USER’S GUIDE. Available online: https://www.spacex.com/media/falcon-users-guide-2021-09.pdf (accessed on 25 April 2023).

- SpaceX, STARSHIP USERS GUIDE: REVISION 1.0 March 2020. Available online: https://www.spacex.com/media/starship_users_guide_v1.pdf (accessed on 25 April 2023).

- Makaya, A.; Pambaguian, L.; Ghidini, T.; Rohr, T.; Lafont, U.; Meurisse, A. Towards out of earth manufacturing: Overview of the ESA materials and processes activities on manufacturing in space. CEAS Space J. 2022, 15, 69–75. [Google Scholar] [CrossRef]

- Del Bianco, M.; Lanciano, O.; Bertacin, R.; Piccirillo, S.; Paillet, A.; Boutte, P.; Tan, E.; Picard, M.; Floyd, M.; On, M.; et al. IN-SITU RESOURCE UTILIZATION GAP ASSESSMENT REPORT. 2021. Available online: https://www.globalspaceexploration.org/wordpress/wp-content/uploads/2021/04/ISECG-ISRU-Technology-Gap-Assessment-Report-Apr-2021.pdf (accessed on 15 December 2023).

- Anand, M.; Crawford, I.A.; Balat-Pichelin, M.; Abanades, S.; Van Westrenen, W.; Péraudeau, G.; Jaumann, R.; Seboldt, W. A brief review of chemical and mineralogical resources on the Moon and likely initial in situ resource utilization (ISRU) applications. Planet. Space Sci. 2012, 74, 42–48. [Google Scholar] [CrossRef]

- Sanders, G. ISRU: An Overview of NASA’s Current Development Activities and Long-Term Goals; NASA: Reno, NV, USA, 2000.

- Nakamura, T.; Smith, B. Solar Thermal Power System for Lunar ISRU Applications: Result of ISRU Analog Test, Mauna Kea, HI. In Proceedings of the AIAA SPACE 2010 Conference & Exposition, Anaheim, CA, USA, 30 August–2 September 2010. [Google Scholar]

- Sanders, G.; Larson, W.; Sacksteder, K.; Mclemore, C. NASA In-Situ Resource Utilization (ISRU) Project: Development and Implementation. In Proceedings of the AIAA SPACE 2008 Conference & Exposition, San Diego, CA, USA, 9–11 September 2008. [Google Scholar]

- Anih, S. Crewed Space Mission Waste-Streams and Impact on Human Exploration of Mars. In Assessing a Mars Agreement Including Human Settlements; Froehlich, A., Ed.; Springer International Publishing: Cham, Switzerland, 2021; pp. 129–146. [Google Scholar]

- Belvin, W.K.; Doggett, W.R.; Watson, J.J.; Dorsey, J.T.; Warren, J.E.; Jones, T.C.; Komendera, E.E.; Mann, T.; Bowman, L.M. In-Space Structural Assembly: Applications and Technology. In Proceedings of the 3rd AIAA Spacecraft Structures Conference, San Diego, CA, USA, 4–8 January 2016. [Google Scholar] [CrossRef]

- Spedding, C.P.; Lim, S.; Nuttall, W.J. ISRU technology deployment at a lunar outpost in 2040: A Delphi survey. Acta Astronaut. 2021, 181, 316–324. [Google Scholar] [CrossRef]

- Sanders, G.; Kleinheinz, J.; Linne, D. NASA Plans for In Situ Resource Utilization (ISRU) Development, Demonstration, and Implementation; NASA: Reno, NV, USA, 2022.

- Bart, G.D.; Nickerson, R.D.; Lawder, M.T.; Melosh, H. Global survey of lunar regolith depths from LROC images. Icarus 2011, 215, 485–490. [Google Scholar] [CrossRef]

- Linke, S.; Voß, A.; Ernst, M.; Taschner, P.A.; Baasch, J.; Stapperfend, S.; Gerdes, N.; Koch, J.; Weßels, P.; Neumann, J.; et al. Two-Dimensional Laser Melting of Lunar Regolith Simulant Using the MOONRISE Payload on a Mobile Manipulator. 3D Print. Addit. Manuf. 2022, 9, 223–231. [Google Scholar] [CrossRef] [PubMed]

- Kalapodis, N.; Kampas, G.; Ktenidou, O.-J. A review towards the design of extraterrestrial structures: From regolith to human outposts. Acta Astronaut. 2020, 175, 540–569. [Google Scholar] [CrossRef]

- Cesaretti, G.; Dini, E.; De Kestelier, X.; Colla, V.; Pambaguian, L. Building components for an outpost on the Lunar soil by means of a novel 3D printing technology. Acta Astronaut. 2014, 93, 430–450. [Google Scholar] [CrossRef]

- Sommariva, A.; Gori, L.; Chizzolini, B.; Pianorsi, M. The economics of moon mining. Acta Astronaut. 2020, 170, 712–718. [Google Scholar] [CrossRef]

- Jolly, S.D.; Happel, J.; Sture, S. Design and Construction of Shielded Lunar Outpost. J. Aerosp. Eng. 1994, 7, 417–434. [Google Scholar] [CrossRef]

- Lomax, B.A.; Conti, M.; Khan, N.; Bennett, N.S.; Ganin, A.Y.; Symes, M.D. Proving the viability of an electrochemical process for the simultaneous extraction of oxygen and production of metal alloys from lunar regolith. Planet. Space Sci. 2020, 180, 104748. [Google Scholar] [CrossRef]

- Jolliff, B.L.; Wieczorek, M.A.; Shearer, C.K.; Neal, C.R. New Views of the Moon; De Gruyter: Berlin, Germany, 2006. [Google Scholar]

- Collinson, D.W. Lunar sourcebook—A user’s guide to the moon. Phys. Earth Planet. Inter. 1992, 72, 132–133. [Google Scholar] [CrossRef]

- Taylor, S.R.; Norman, M.D.; Esat, T. The Lunar Highland Crust: The Origin of the MG Suite. Meteorit. Planet. Sci. 1993, 28, 448. [Google Scholar]

- Sebastian, U. Gesteinskunde: Ein Leitfaden für Einsteiger und Anwender, 3., Überarb. und Aktualisierte Aufl.; Springer Spektrum: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Taylor, S.R. Lunar Science: Scientific Results and Insights from the Lunar Samples; Elsevier Science: Kent, UK, 2016. [Google Scholar]

- Casanova, S.; Espejel, C.; Dempster, A.G.; Anderson, R.C.; Caprarelli, G.; Saydam, S. Lunar polar water resource exploration—Examination of the lunar cold trap reservoir system model and introduction of play-based exploration (PBE) techniques. Planet. Space Sci. 2019, 180, 104742. [Google Scholar] [CrossRef]

- Culler, J. Ice Confirmed at the Moon’s Poles. Available online: https://www.jpl.nasa.gov/news/ice-confirmed-at-the-moons-poles (accessed on 11 May 2023).

- Kornuta, D.; Abbud-Madrid, A.; Atkinson, J.; Barr, J.; Barnhard, G.; Bienhoff, D.; Blair, B.; Clark, V.; Cyrus, J.; DeWitt, B.; et al. Commercial lunar propellant architecture: A collaborative study of lunar propellant production. REACH 2019, 13, 100026. [Google Scholar] [CrossRef]

- Robert, P.M. (Ed.) Lunar Base Construction Planning, Earth and Space; NASA: Reno, NV, USA, 2022.

- Sgambati, A.; Berg, M.; Makaya, A. lUnaR Base Additive maNufacturing (URBAN) Executive Summary Report. 2018. Available online: https://nebula.esa.int/sites/default/files/neb_study/2507/C4000122380ExS.pdf (accessed on 15 December 2023).

- Stenzel, C.; Weiss, L.; Rohr, T. Sustainable challenges on the moon. Curr. Opin. Green Sustain. Chem. 2018, 9, 8–12. [Google Scholar] [CrossRef]

- Uzo-Okoro, E. IN-SPACE SERVICING, ASSEMBLY, AND MANUFACTURING NATIONAL STRATEGY: Product of the IN-SPACE SERVICING, ASSEMBLY, AND MANUFACTURING INTERAGENCY WORKING GROUP of the NATIONAL SCIENCE & TECHNOLOGY COUNCIL. 2022. Available online: https://www.whitehouse.gov/wp-content/uploads/2022/04/04-2022-ISAM-National-Strategy-Final.pdf (accessed on 15 December 2023).

- Willcoxon, R.; Thronson, H.; Varsi, G.; Mueller, R.; Regenie, V.; Inman, T.; Crooke, J.; Coulter, D. NASA Capability Roadmaps Executive Summary; NTRS-NASA Technical Reports Server (Internet): Reno, NV, USA, 2013. [Google Scholar]

- Karl, D.; Cannon, K.M.; Gurlo, A. Review of space resources processing for Mars missions: Martian simulants, regolith bonding concepts and additive manufacturing. Open Ceram. 2022, 9, 100216. [Google Scholar] [CrossRef]

- National Aeronautics and Space Administration (NASA). Space Tools On Demand: 3D Printing in Zero G: NASA Facts. Available online: https://www.nasa.gov/sites/default/files/atoms/files/fs_3dprinting_factsheet_140502.pdf (accessed on 21 April 2023).

- Kramer, H.J. ISS: AMF (Additive Manufacturing Facility). Available online: https://www.eoportal.org/other-space-activities/iss-amf#an-overview-of-ism-in-space-manufacturing (accessed on 25 April 2023).

- Werkheiser, N. The In-Space Refabricator. Available online: https://science.nasa.gov/science-news/news-articles/the-in-space-refabricator (accessed on 25 April 2023).

- European Space Agency. In-Orbit Manufacturing of Very Long Booms. Available online: https://www.esa.int/Enabling_Support/Space_Engineering_Technology/Shaping_the_Future/In-Orbit_Manufacturing_of_Very_Long_Booms (accessed on 25 April 2023).

- Kringer, M.; Schaefer, N.T.; Boehrer, C.; Frey, M.; Schill, F.; Kullmann, M.; Strasser, M.; Pietras, M. Meet the Teams: AIMIS-FYT. Available online: https://www.esa.int/Education/Fly_Your_Thesis/Meet_the_teams_AIMIS-FYT (accessed on 25 April 2023).

- European Space Agency. IMPERIAL: 3D Printing’s New Dimension. Available online: https://www.esa.int/ESA_Multimedia/Videos/2022/03/IMPERIAL_3D_printing_s_new_dimension (accessed on 25 April 2023).

- European Space Agency. Portable On-Board Printer (POP3D Printer). Available online: https://www.esa.int/ESA_Multimedia/Images/2014/11/POP3D_printer (accessed on 25 April 2023).

- European Space Agency. MELT 3D Printer. Available online: https://www.esa.int/ESA_Multimedia/Images/2018/10/MELT_3D_printer (accessed on 25 April 2023).

- Sher, D. China Operates Continuous Composites 3D Printer in Space: The Autonomous System Was Launched with the New Long March 5B Rocket. Available online: https://www.voxelmatters.com/china-operates-autonomous-continuous-composites-3d-printer-in-space/ (accessed on 25 April 2023).

- Zocca, A.; Lüchtenborg, J.; Mühler, T.; Wilbig, J.; Mohr, G.; Villatte, T.; Léonard, F.; Nolze, G.; Sparenberg, M.; Melcher, J.; et al. Enabling the 3D Printing of Metal Components in µ-Gravity. Adv. Mater. Technol. 2019, 4, 1900506. [Google Scholar] [CrossRef]

- Airbus, D.S. In Space Manufacturing and Assembly: Delivering Technological Bricks for Airbus Space Factory. Available online: https://www.airbus.com/en/newsroom/news/2022-05-in-space-manufacturing-and-assembly (accessed on 25 April 2023).

- Peels, J. Space Metal 3D Printer Heads to ISS in 2023. Available online: https://3dprint.com/289836/space-metal-3d-printer-to-head-to-iss-in-2023/ (accessed on 25 April 2023).

- Seidel, A.; Gollee, C.; Schnellhardt, T.; Hammer, M.; Dassing, J.; Vogt, R.; Wiese, T.; Teicher, U.; Hellmich, A.; Ihlenfeldt, S.; et al. Cyber-physical approach toward semiautonomous postprocessing of additive manufactured parts and components. J. Laser Appl. 2021, 33, 012033. [Google Scholar] [CrossRef]

- Horneck, G.; Facius, R.; Reitz, G.; Rettberg, P.; Baumstark-Khan, C.; Gerzer, R. Critical issues in connection with human planetary missions: Protection of and from the environment. Acta Astronaut. 2001, 49, 279–288. [Google Scholar] [CrossRef]

- Witze, A. Success! Mars rover finally collects its first rock core. Nature 2021, 597, 317. [Google Scholar] [CrossRef] [PubMed]

- Bar-Cohen, Y.; Brennan, M.; Briggs, G.; Cooper, G.; Davis, K.; Dolgin, B.; Glaser, D.; Gorevan, S.; Guerrero, J.; Stanley, S.; et al. Drilling Systems for Extraterrestrial Subsurface Exploration. Astrobiology 2008, 8, 665–706. [Google Scholar] [CrossRef]

- Li, H.; Shen, Y.; Wang, Q.; Wang, Y.; Bai, D.; Deng, Z. A Piezoelectric-Driven Rock-Drilling Device for Extraterrestrial Subsurface Exploration. Shock. Vib. 2018, 2018, 1–12. [Google Scholar] [CrossRef]

- Quan, Q.; Bai, D.; Zhao, Z.; Deng, Z.; Li, H.; Wang, Y. Development of a rotary-percussive ultrasonic drill for extraterrestrial rock sampling. In Proceedings of the 2017 IEEE International Ultrasonics Symposium (IUS), Washington, DC, USA, 6–9 September 2017; pp. 1–4. [Google Scholar]

- Bar-Cohen, Y.; Sherrit, S.; Dolgin, B.P.; Bao, X.; Chang, Z.; Pal, D.S.; Krahe, R.; Kroh, J.; Du, S.; Peterson, T. Ultrasonic/sonic drilling/coring (USDC) for planetary applications. In Proceedings of the Smart Structures and Materials 2001: Smart Structures and Integrated Systems, Newport Beach, CA, USA, 5–8 March 2001; pp. 441–448. [Google Scholar]

- Proceedings of the 2008 IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008. Available online: https://researchr.org/publication/icra%3A2008 (accessed on 15 December 2023).

- Badescu, M.; Stroescu, S.; Sherrit, S.; Aldrich, J.; Bao, X.; Bar-Cohen, Y.; Chang, Z.; Hernandez, W.; Ibrahim, A. Rotary hammer ultrasonic/sonic drill system. In Proceedings of the 2008 IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008; pp. 602–607. [Google Scholar]

- Fontes, D.; Mantovani, J.G.; Metzger, P. Numerical estimations of lunar regolith trajectories and damage potential due to rocket plumes. Acta Astronaut. 2022, 195, 169–182. [Google Scholar] [CrossRef]

- Akkurt, A.; Kulekci, M.K.; Seker, U.; Ercan, F. Effect of feed rate on surface roughness in abrasive waterjet cutting applications. J. Am. Acad. Dermatol. 2004, 147, 389–396. [Google Scholar] [CrossRef]

- Van Susante, P.J.; Allen, J.S.; Eisele, T.C.; Medici, E.F.; Foetisch, M.S.; Zacny, K.A.; Fitzgerald, Z. Water Extraction from Rock Gypsum on Mars. In Proceedings of the Earth and Space 2021, Virtual Conference, 19–23 April 2021; pp. 653–659. [Google Scholar]

- Momber, A.W.; Kovacevic, R. Principles of Abrasive Water Jet Machining; Springer: London, UK, 1998. [Google Scholar]

- Miller, D.S. Micromachining with abrasive waterjets. J. Mater. Process. Technol. 2004, 149, 37–42. [Google Scholar] [CrossRef]

- Momber, A.W.; Kovacevic, R. An energy balance of high-speed abrasive water jet erosion. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 1999, 213, 463–472. [Google Scholar] [CrossRef]

- Kartal, F. An Analysis of the Abrasive Water Jet Machining of Polyethylene Using L9 Orthogonal Array; WaterJet Technology Association: New Orleans, LA, USA, 2017. [Google Scholar]

- Hashish, M. A Modeling Study of Metal Cutting with Abrasive Waterjets. J. Eng. Mater. Technol. 1984, 106, 88–100. [Google Scholar] [CrossRef]

- Matsumura, T.; Muramatsu, T.; Fueki, S. Abrasive water jet machining of glass with stagnation effect. CIRP Ann. 2011, 60, 355–358. [Google Scholar] [CrossRef]

- Putz, M.; Dix, M.; Morczinek, F.; Dittrich, M. Suspension Technology for Abrasive Waterjet (AWJ) Cutting of Ceramics. Procedia CIRP 2018, 77, 367–370. [Google Scholar] [CrossRef]

- Putz, M.; Rennau, A.; Dix, M. High Precision Machining of Hybrid Layer Composites by Abrasive Waterjet Cutting. Procedia Manuf. 2018, 21, 583–590. [Google Scholar] [CrossRef]

- Baasch, J.; Windisch, L.; Koch, F.; Linke, S.; Stoll, E.; Schilde, C. Regolith as substitute mold material for aluminum casting on the Moon. Acta Astronaut. 2021, 182, 1–12. [Google Scholar] [CrossRef]

- Gamwell, W.; Tracie, P. Heritage Materials for Launch Vehicles and Spacecraft; NASA Marshall Space Flight Center: Huntsville, AL, USA, 2019.

- Murty, S.V.S.N.; Sharma, S.C. Materials for Indian Space Program: An Overview. J. Indian Inst. Sci. 2022, 102, 513–559. [Google Scholar] [CrossRef]

- Weiland, H.; Rollett, A.D.; Cassada, W.A. (Eds.) ICAA13 Pittsburgh; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Willenshofer, P.D.; Tunes, M.A.; Vo, H.T.; Stemper, L.; Renk, O.; Greaves, G.; Uggowitzer, P.J.; Pogatscher, S. Radiation-resistant aluminium alloy for space missions in the extreme environment of the solar system. arXiv 2022, arXiv:2210.03397. [Google Scholar]

- Rioja, R.J.; Denzer, D.K.; Mooy, D.; Venema, G. Lighter and Stiffer Materials for Use in Space Vehicles. In ICAA13 Pittsburgh; Weiland, H., Rollett, A.D., Cassada, W.A., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 593–598. [Google Scholar]

- Ramkumar, K.R.; Sivasankaran, S.; Al-Mufadi, F.A.; Siddharth, S.; Raghu, R. Investigations on microstructure, mechanical, and tribological behaviour of AA 7075–xwt.% TiC composites for aerospace applications. Arch. Civ. Mech. Eng. 2019, 19, 428–438. [Google Scholar] [CrossRef]

- El-Hameed, A.M.A.; Abdel-Aziz, Y.A. Aluminium Alloys in Space Applications: A Short Report. ARASET 2021, 22, 1–7. [Google Scholar] [CrossRef]

- Newswander, T.; Crowther, B.; Gubbels, G.; Senden, R. Aluminum alloy AA-6061 and RSA-6061 heat treatment for large mirror applications. In Proceedings of the Material Technologies and Applications to Optics, Structures, Components, and Sub-Systems, San Diego, CA, USA, 26–28 August 2013; p. 883704. [Google Scholar]

- Gradl, P.; (Marshall Space Flight Center Redstone Arsenal, Huntsville, AL, USA). Principles of Directed Energy Deposition for Aerospace Applications. Unpublished. 2021. [Google Scholar]

- DIN EN 573-3:2019-10; Aluminium und Aluminiumlegierungen-Chemische Zusammensetzung und Form von Halbzeug-Teil 3: Chemische Zusammensetzung und Erzeugnisformen. Deutsche Fassung EN-573-3:2019; Beuth Verlag GmbH: Berlin, Germany, 2019. [CrossRef]

- DIN EN 10204:2005-01; Metallische Erzeugnisse-Arten von Prüfbescheinigungen. Deutsche Fassung EN-10204:2004; Beuth Verlag GmbH: Berlin, Germany, 2005. [CrossRef]

- Schleppi, J.; Gibbons, J.; Groetsch, A.; Buckman, J.; Cowley, A.; Bennett, N. Manufacture of glass and mirrors from lunar regolith simulant. J. Mater. Sci. 2018, 54, 3726–3747. [Google Scholar] [CrossRef]

- Ulubeyli, S. Lunar shelter construction issues: The state-of-the-art towards 3D printing technologies. Acta Astronaut. 2022, 195, 318–343. [Google Scholar] [CrossRef]

- Linke, S. Mechanische Werkstoffeigenschaften von Lasergeschmolzenem Lunaren Regolith. Doctoral Dissertation, Technische Universität Carolo-Wilhelmina zu Braunschweig, Braunschweig, Germany, 2022. [Google Scholar]

- Morczinek, F.; Putz, M.; Dix, M. Comparison of abrasive water jet technologies in terms of performance and kerf geometry accuracy for cutting ceramics. IJSM 2020, 4, 201. [Google Scholar] [CrossRef]

| Term | Description | Source |

|---|---|---|

| In-space manufacturing (ISM) | Manufacturing in an intravehicular (crew) environment and takes place inside a pressurized habitat structure (e.g., International Space Station) and is primarily focused on logistics reduction and on-demand manufacturing of spares. | [1] |

| Out-of-Earth Manufacturing (OoEM) | Aims to foster and support the development of manufacturing and assembly technologies adequate for implementation in space. | [2] |

| Oxide | Maria [wgt%] | Terrae [wgt%] |

|---|---|---|

| SiO2 | 45.4 | 45.5 |

| TiO2 | 3.9 | 0.6 |

| Al2O3 | 14.9 | 24.0 |

| FeO | 14.1 | 5.9 |

| MgO | 9.2 | 7.5 |

| CaO | 11.8 | 15.9 |

| Na2O | 0.6 | 0.6 |

| Material Nature | Mass | Selection Arguments 1 |

|---|---|---|

| Al-alloys | 44% | -Medium strength at low density; -Cryogenic capability; -Weldability; -Corrosion resistance. |

| Ti-alloys | 15% | -High strength-temperature resistance; -Corrosion resistance-reduced density. |

| Steel | 5% | -High strength. |

| Super-alloys | 2% | -Highest strength. |

| Cu-alloys | 1% | -Special applications. |

| Polyurethane | 1% | |

| Silicone | 5% | |

| Epoxy | 4% | |

| CFRP | 15% | -Highest strength achievable; -Low density; -Corrosion resistance. |

| GFRP | 2% | -Special applications. |

| Polyimide | 1% | |

| Linear Polyesters | ||

| Ceramics | ||

| Others |

| Material Nature | Mass | Specific Improvements for Spacecraft |

|---|---|---|

| Al-alloys | 60% | -Improvement of material characteristics; -Harmonization, for example, reduction of number of alloys; |

| Ti-alloys | 10% | -Minimize cost (material price); -Reduce manufacturing effort; |

| Steel incl. Super-alloys | 2% | -Minimize cost (material price); -Reduce manufacturing effort; |

| CFRP | 25% | -Minimize mass (density); |

| Others | 3% | -Improve manufacturing effort and capabilities; -Minimize mass; -Improve reusability. |

| Group | Hardware Survey Objective | [%] |

|---|---|---|

| 1 | Permanent Infrastructure and maintenance | 21 |

| 2 | Permanent machinery and maintenance | 16 |

| 3 | Long-lasting items and commodities | 20 |

| 4 | Temporary and made-on-demand items | 46 |

| Main Material Distribution | [%] |

|---|---|

| Plastic | 39 |

| Steel | 19 |

| Aluminum | 15 |

| Glass | 12 |

| Rubber | 6 |

| Ceramic | 4 |

| Textile | 3 |

| Copper etc. | 2 |

| PA YoD | Process | Material | PoD | Source |

|---|---|---|---|---|

| 3DP 12/2014 | Polymer manufacturing /recycling | ABS | [44] | |

| AMF 02/2016 | ABS, PEI-PC | Orbit | [45] | |

| REFAB 11/2018 | PEI/PC (Ultem 9085) | [46] | ||

| IOM 05/2017 | Composite and Polymer Manufacturing unlimited size | Epoxy–carbon fabric | Ground demo | [47] |

| AIMIS 11/2019 | Photo-reactive resin | Parabolic flight | [48] | |

| IMPERIAL 01/2019 | Engineering polymers | Ground demo | [49] | |

| POP3D 03/2016 | Composite and Polymer Manufacturing limited size | PLA | Flight demo | [50] |

| MELT 03/2018 | PEEK | Ground demo | [51] | |

05/2020 | Carbon fiber-reinforced thermoplastics | Flight demo | [52] |

| Part | ACTIONS (Events) |

|---|---|

| Introduction |

|

| Methodology |

|

| Results |

|

| Discussion and Conclusions |

|

| Outlook |

|

| Parameter | Terrestrial Relevance | Extraterrestrial Relevance |

|---|---|---|

| Modularity and Plug and Play | o | + |

| Intelligent production plants/machines | + | o |

| Autonomous or semiautonomous processing (low interaction with humans) | - | + |

| Energy efficiency | o | + |

| Weight and space optimized | - | ++ |

| Oxide | LX-M100 [wt. %] | LX-T100 [wt. %] |

|---|---|---|

| SiO2 | 48.3 | 49.5 |

| TiO2 | 2.5 | 0.1 |

| Al2O3 | 13.1 | 31.2 |

| FeO | 10.2 | 0.9 |

| MgO | 8.8 | 0.2 |

| CaO | 8.5 | 15.4 |

| Na2O | 3.6 | 2.4 |

| K2O | 1.7 | 0.1 |

| Alloy | AA-Code | Application | Source |

|---|---|---|---|

| AlCu(Li) | 2xxx | Pressurized Tanks | [78] |

| AlCuMg | 2xxx | Intertanks, Skirts, Adapters | [79] |

| AlSiMg(Cu) | 6xxx | Structural materials | [80] |

| AlZnMg | 7xxx | Structural materials | [81] |

| ALZnMgCu | 7xxx | Unpressurized structures | [82] |

| Alloy Element | Min Amount [wt. %] | Max Amount [wt. %] |

|---|---|---|

| Al | Rem. | |

| Si | 0.4–0.8 | 0.8 |

| Fe | - | 0.7 |

| Cu | 0.15 | 0.4 |

| Mn | - | 0.15 |

| Mg | 0.8 | 1.2 |

| Cr | 0.04 | 0.35 |

| Zn | - | 0.25 |

| Ti | - | 0.15 |

| Other each | - | 0.05 |

| Component | Amount in wt-% |

|---|---|

| SiO2 | 59.4 |

| Li2O | 18.8 |

| P2O5 | 5.9 |

| K2O | 2.0 |

| Al2O3 | 2.0 |

| ZrO2 | 9.9 |

| CeO2 | 2.0 |

| Main Crystal Phase | Temperature Program |

|---|---|

| Lithium metasilicate | 620 °C/60 min |

| Lithium disilicate | 620 °C/60 min + 850 °C/10 min |

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Nozzle diameter | dd | 0.1 | mm |

| Focusing tube diameter | DF | 0.3 | mm |

| Stand-off distance | s | 2 | mm |

| Abrasive mass flow rate | ṁp | 8.5 | g/min |

| Al material thickness | hAl | 2.286 | mm |

| Lithium silicate material thickness (all conditions) | hLi | 7 | mm |

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Water jet pressure | p | 200, 300 | MPa |

| Particle size fraction | SF | 45–63 63–90 90–125 | µm |

| Mass flow per 1 mm of machined workpiece | m’l1-3 | 0.3, 0.1, 0.05 | g/mm |

| Feed rate | vf1-3 | 0.5, 1.5, 3 | mm/s |

| Abrasive material | - | LS-M100; LS-T100 | - |

| Symbol | Value | Unit |

|---|---|---|

| p | 200 | MPa |

| SF | 45–63; 63–90 | µm |

| m’l | 1.4; 0.7; 0.35 | g/mm |

| vf | 0.1; 0.2; 0.4 | mm/s |

| Specimen material | Lithium silicate without crystallization Lithium silicate with nucleation Lithium silicate with nucleation and crystallization | - |

| Abrasive Material | LS-M100 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seidel, A.; Teicher, U.; Ihlenfeldt, S.; Sauer, K.; Morczinek, F.; Dix, M.; Niebergall, R.; Durschang, B.; Linke, S. Towards Lunar In-Situ Resource Utilization Based Subtractive Manufacturing. Appl. Sci. 2024, 14, 18. https://doi.org/10.3390/app14010018

Seidel A, Teicher U, Ihlenfeldt S, Sauer K, Morczinek F, Dix M, Niebergall R, Durschang B, Linke S. Towards Lunar In-Situ Resource Utilization Based Subtractive Manufacturing. Applied Sciences. 2024; 14(1):18. https://doi.org/10.3390/app14010018

Chicago/Turabian StyleSeidel, André, Uwe Teicher, Steffen Ihlenfeldt, Konstantin Sauer, Florian Morczinek, Martin Dix, Rick Niebergall, Bernhard Durschang, and Stefan Linke. 2024. "Towards Lunar In-Situ Resource Utilization Based Subtractive Manufacturing" Applied Sciences 14, no. 1: 18. https://doi.org/10.3390/app14010018

APA StyleSeidel, A., Teicher, U., Ihlenfeldt, S., Sauer, K., Morczinek, F., Dix, M., Niebergall, R., Durschang, B., & Linke, S. (2024). Towards Lunar In-Situ Resource Utilization Based Subtractive Manufacturing. Applied Sciences, 14(1), 18. https://doi.org/10.3390/app14010018