Thermomechanical Properties of a Concrete Composed of Cherry Tree Resin and Expanded Clay (Exclay) Aggregate

Abstract

:1. Introduction

1.1. Effects of Exclay in the Concrete

1.2. Effects of Resin in the Concrete

2. Materials and Methods

2.1. Materials

2.1.1. Expanded Clay

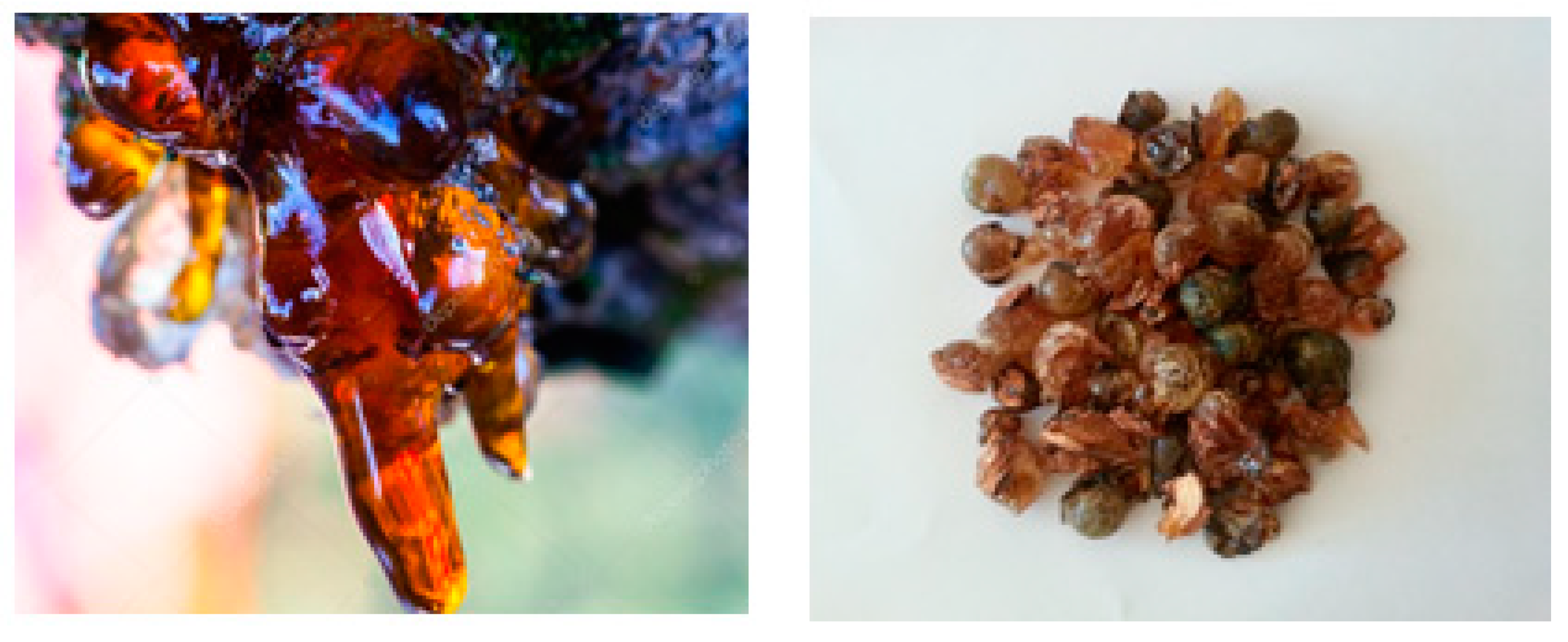

2.1.2. Cherry Tree Resin

2.1.3. Portland Cement

2.2. Methods

2.2.1. Preparation of Samples

2.2.2. Determining the Density

2.2.3. Thermal Conductivity Tests

2.2.4. Compressive Strength Tests

2.2.5. Water Absorption Tests

2.3. Uncertainty Analysis

3. Results and Discussions

3.1. Density and Porosity Variations

3.2. Thermal Conductivity Variations

3.3. Compressive Strength Variations

3.4. Water Absorption Variations

3.5. Comparison to the Literature

3.6. Usability of the Concretes

4. Conclusions

- ✓

- Concretes, including exclay–cement–cherry tree resin, can be utilized as low-density concrete platen walls, apron concretes, briquettes and brick walls. The damages of earthquakes can be minimized with the usage of lightweight concretes.

- ✓

- In the cherry tree resin and exclay-added samples, the density decreases and the total porosity increases due to the artificial micropores generated by the resin. Therefore, the thermal conductivity of the samples decreases. The thermal conductivity value is the lowest around 0.3 W/mK, which indicates that even if there is a low thermal conductivity value, it is not low enough to be an insulating material. Hence, the insulation property of the material should be improved to achieve energy savings. If an insulation material is desired to be produced by exclay and cherry tree resin, new mixing ratios of resin and exclay should be tried.

- ✓

- According to the tests, the samples produced are in good condition in terms of water permeability. Water absorption ratios of the samples with cherry tree resin and exclay are lower than the critical value of 30%, meaning the use of such construction materials is recommended in places that have direct contact with water. However, it is also possible to use them as interior plastering materials, internal filling materials, roof-sheathing plastering materials or applied in sandwich walls.

- ✓

- Compressive strength values show that the materials have low strength. In view of these results, the use of concretes with exclay and cherry tree resin in columns and building beams is not recommended. Regardless of this, these low-density concretes are accepted as panel walls, brick, concrete briquettes, inner and outer plaster and concrete partition elements.

- ✓

- Various usability tests performed on the samples determined that they were appropriate for drilling, nailing and grooving processes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Subasi, S. The effects of using fly ash on high strength lightweight concrete produced with expanded clay aggregate. Sci. Res. Essays 2009, 4, 275–288. [Google Scholar]

- Arioz, O.; Kilinc, K.; Karasu, B.; Kaya, G.; Arslan, G.; Tuncan, M.; Tuncan, A.; Korkut, M.; Kıvrak, S. A preliminary on the properties of lightweight expanded clay aggregate. J. Aust. Ceram. Soc. 2008, 44, 23–30. [Google Scholar]

- Subasi, S. Production of structural lightweight concrete with expanded clay aggregate. J. Fac. Arch. Gazi Univ. 2009, 24, 559–567. [Google Scholar]

- Bartolini, R.; Filippozzi, S.; Princi, E.; Schenone, C.; Vinici, S. Acoustic and mechanical properties of expanded clay granulates consolidated by epoxy resin. Appl. Clay Sci. 2010, 48, 460–465. [Google Scholar] [CrossRef]

- Othman, M.L.B.; Alsarayreh, A.I.M.; Abdullah, R.B.; Sarbini, N.N.B.; Yassin, M.S.B.; Ahmad, H.B. Experimental study on lightweight concrete using lightweight expanded clay aggregate (LECA) and expanded perlıte aggregate (EPA). J. Eng. Sci. Technol. 2020, 15, 1186–1201. [Google Scholar]

- Nahhab, A.; Ketab, A.K. Influence of content and maximum size of light expanded clay aggregate on the fresh, strength, and durability properties of self-compacting lightweight concrete reinforced with micro steel fibers. Constr. Build. Mater. 2020, 233, 117922. [Google Scholar] [CrossRef]

- Fakhfakh, E.; Hajjaji, W.; Medhioub, M.; Rocha, F.; Lopez-Galindo, A.; Settim, M. Effects of sand addition on production of lightweight aggregates from Tunisian smectitr-rich clayey rocks. Appl. Clay Sci. 2007, 35, 228–237. [Google Scholar] [CrossRef]

- Rossignolo, J.A.; Marcos, V.C.; Jerusa, A. Properties of high-performance LWAC for precast structures with Brazilian lightweight aggregates. Cem. Concr. Compos. 2003, 25, 77–82. [Google Scholar] [CrossRef]

- Vasina, M.; Hughes, D.C.; Horoshenkov, K.V.; Lapcik, L. The acoustical properties of consolidated expanded clay granulates. Appl. Acoust. 2006, 67, 787–796. [Google Scholar] [CrossRef]

- Wetzel, A.; Herwegh, M.; Zurbriggen, R.; Winnefeld, F. Influence of Shrinkage and Water Transport Mechanisms on Microstructure and Crack Formation of Tile Adhesive Mortars. Cem. Concr. Res. 2012, 42, 39–50. [Google Scholar] [CrossRef]

- Lee, S.; Kim, G.; Son, M.; Choe, G.; Lee, J.; Nam, J. Effect of Injecting Epoxy Resin Adhesive into Cement Mortar on Tile Adhesion Performance. Appl. Sci. 2020, 10, 8527. [Google Scholar] [CrossRef]

- Ohama, Y.; Demura, K.; Endo, T. Properties of Polymer-Modified Mortars Using Epoxy Resin without Hardener. ASTM Int. 1993, 1176, 90–103. [Google Scholar]

- Devecioglu, A.G.; Bicer, Y. The effects of tragacanth addition on the thermal and mechanical properties of light weight concretes mixed with expanded clay. Period. Polytech. Civil Eng. 2016, 60, 45–50. [Google Scholar] [CrossRef]

- Kaya, A.; Kar, F. Properties of concrete containing waste expanded polystyrene and natural resin. Constr. Build. Mater. 2016, 105, 572–578. [Google Scholar] [CrossRef]

- Bicer, A. Influence of tragacanth resin on the thermal and mechanical properties of fly ash-cement composites. J. Adhes. Sci. Technol. 2019, 33, 1019–1103. [Google Scholar] [CrossRef]

- Hassan, A.M. Thermal and Mechanical Analysis of Concrete Samples Including Pine Cone and Pine Tree Resin. Master’s Thesis, Firat University, Elazığ, Turkey, 2022. [Google Scholar]

- Bicer, A.; Celik, N. Influence of pine resin on thermo-mechanical properties of pumice-cement composites. Cem. Concr. Compos. 2020, 112, 103668. [Google Scholar] [CrossRef]

- Bicer, A.; Kar, F. The effects of apricot resin addition to the light weight concrete with expanded polystyrene. J. Adhes. Sci. Technol. 2017, 31, 2335–2348. [Google Scholar] [CrossRef]

- Akpinar, E.K.; Kocyigit, F. Thermal and mechanical properties of lightweight concretes produced with pumice and tragacanth. J. Adhes. Sci. Technol. 2016, 30, 534–553. [Google Scholar] [CrossRef]

- Frihart, C.R. Wood adhesion and adhesives. In Handbook of Wood Chemistry and Wood Composites; CRC Press: Boca Raton, FL, USA, 2005; pp. 214–278. [Google Scholar]

- Kline, J.; McClintock, F.A. Describing uncertainties in single-sample experiments. Mech. Eng. 1953, 75, 3–8. [Google Scholar]

- Rim, K.A.; Ledhem, A.; Douzane, O.; Dheilly, R.M.; Queneudec, M. Influence of the proportion of wood on the thermal and mechanical performances of clay-cement-wood composites. Cem. Concr. Compos. 1999, 21, 269–276. [Google Scholar] [CrossRef]

| Chemical Characteristics | Exclay | Cement |

|---|---|---|

| SiO2 | 54.83 | 17.08 |

| Al2O3 | 17.71 | 7.25 |

| Fe2O3 | 7.14 | 4.15 |

| CaO | 3.46 | 56.61 |

| MgO | 4.10 | 2.44 |

| SO3 | -- | 2.91 |

| Na2O | 0.73 | -- |

| K2O | 3.58 | 0.7 |

| TiO2 | 0.55 | -- |

| LOI | 7.94 | 3.73 |

| Not available | -- | 5.15 |

| Total | 100.04 | 100.02 |

| Sample | d (mm) | Volumetric Ratio (%) | Mass (g) | Total Mass (g) | Resin Mass (g) | Resin Ratio (%) | ||

|---|---|---|---|---|---|---|---|---|

| Exclay | Cement | Exclay | Cement | Exclay + Cement | ||||

| S1 | 2–4 | 0 | 100 | 0 | 2250 | 2250 | 0 | 0 |

| S2 | 2–4 | 10 | 90 | 41 | 2025 | 2066 | 0 | 0 |

| S3 | 2–4 | 20 | 80 | 82 | 1800 | 1882 | 0 | 0 |

| S4 | 2–4 | 30 | 70 | 123 | 1575 | 1698 | 0 | 0 |

| S5 | 2–4 | 40 | 60 | 164 | 1350 | 1514 | 0 | 0 |

| S6 | 2–4 | 50 | 50 | 205 | 1125 | 1330 | 0 | 0 |

| S7 | 4–6 | 0 | 100 | 0 | 2250 | 2250 | 0 | 0 |

| S8 | 4–6 | 10 | 90 | 37 | 2025 | 2062 | 0 | 0 |

| S9 | 4–6 | 20 | 80 | 74 | 1800 | 1874 | 0 | 0 |

| S10 | 4–6 | 30 | 70 | 222 | 1575 | 1797 | 0 | 0 |

| S11 | 4–6 | 40 | 60 | 148 | 1350 | 1498 | 0 | 0 |

| S12 | 4–6 | 50 | 50 | 185 | 1125 | 1310 | 0 | 0 |

| S13 | 2–4 | 0 | 100 | 0 | 2250 | 2250 | 22.5 | 1 |

| S14 | 2–4 | 10 | 90 | 41 | 2025 | 2066 | 20.7 | 1 |

| S15 | 2–4 | 20 | 80 | 82 | 1800 | 1882 | 18.9 | 1 |

| S16 | 2–4 | 30 | 70 | 123 | 1575 | 1698 | 17.0 | 1 |

| S17 | 2–4 | 40 | 60 | 164 | 1350 | 1514 | 15.1 | 1 |

| S18 | 2–4 | 50 | 50 | 205 | 1125 | 1330 | 13.3 | 1 |

| S19 | 4–6 | 0 | 100 | 0 | 2250 | 2250 | 22.5 | 1 |

| S20 | 4–6 | 10 | 90 | 37 | 2025 | 20.62 | 20.6 | 1 |

| S21 | 4–6 | 20 | 80 | 74 | 1800 | 1874 | 18.7 | 1 |

| S22 | 4–6 | 30 | 70 | 222 | 1575 | 1797 | 18.0 | 1 |

| S23 | 4–6 | 40 | 60 | 148 | 1350 | 1498 | 15.0 | 1 |

| S24 | 4–6 | 50 | 50 | 185 | 1125 | 1310 | 13.1 | 1 |

| S25 | 2–4 | 0 | 100 | 0 | 2250 | 2250 | 33.8 | 1.5 |

| S26 | 2–4 | 10 | 90 | 41 | 2025 | 2066 | 30.1 | 1.5 |

| S27 | 2–4 | 20 | 80 | 82 | 1800 | 1882 | 28.2 | 1.5 |

| S28 | 2–4 | 30 | 70 | 123 | 1575 | 1698 | 25.5 | 1.5 |

| S29 | 2–4 | 40 | 60 | 164 | 1350 | 1514 | 22.7 | 1.5 |

| S30 | 2–4 | 50 | 50 | 205 | 1125 | 1330 | 13.5 | 1.5 |

| S31 | 4–6 | 0 | 100 | 0 | 2250 | 2250 | 33.8 | 1.5 |

| S32 | 4–6 | 10 | 90 | 37 | 2025 | 20.62 | 30.9 | 1.5 |

| S33 | 4–6 | 20 | 80 | 74 | 1800 | 1874 | 28.1 | 1.5 |

| S34 | 4–6 | 30 | 70 | 222 | 1575 | 1797 | 27.0 | 1.5 |

| S35 | 4–6 | 40 | 60 | 148 | 1350 | 1498 | 22.5 | 1.5 |

| S36 | 4–6 | 50 | 50 | 185 | 1125 | 1310 | 19.6 | 1.5 |

| Code | d (mm) | x (%) | ρ (g/cm3) | Փ (%) | k (W/mK) | fcs (MPa) | WAR (%) |

|---|---|---|---|---|---|---|---|

| 1 | 2–4 | 0 | 1.608 | 3.42 | 0.452 | 25.82 | 22.5 |

| 2 | 2–4 | 10 | 1.395 | 10.56 | 0.381 | 23.54 | 23.0 |

| 3 | 2–4 | 20 | 1.175 | 14.82 | 0.319 | 21.77 | 23.8 |

| 4 | 2–4 | 30 | 0.958 | 18.66 | 0.275 | 19.45 | 24.3 |

| 5 | 2–4 | 40 | 0.820 | 22.45 | 0,241 | 17.17 | 25.1 |

| 6 | 2–4 | 50 | 0.731 | 26.14 | 0.220 | 15.64 | 25.6 |

| 7 | 4–6 | 0 | 1.608 | 3.42 | 0.452 | 25.82 | 24.4 |

| 8 | 4–6 | 10 | 1.319 | 11.38 | 0.364 | 22.68 | 25.0 |

| 9 | 4–6 | 20 | 1.124 | 16.62 | 0.305 | 19.46 | 25.6 |

| 10 | 4–6 | 30 | 0.892 | 21.13 | 0.258 | 17.74 | 26.3 |

| 11 | 4–6 | 40 | 0.757 | 24.88 | 0.230 | 15.61 | 27.1 |

| 12 | 4–6 | 50 | 0.685 | 28.10 | 0.207 | 14.55 | 27.5 |

| 13 | 2–4 | 0 | 1.509 | 5.28 | 0.441 | 24.22 | 23.3 |

| 14 | 2–4 | 10 | 1.278 | 12.38 | 0.362 | 21.81 | 24.2 |

| 15 | 2–4 | 20 | 1.038 | 16.86 | 0.298 | 19.23 | 24.8 |

| 16 | 2–4 | 30 | 0.848 | 21.41 | 0.252 | 17.01 | 25.5 |

| 17 | 2–4 | 40 | 0.729 | 24.72 | 0.218 | 14.74 | 26.4 |

| 18 | 2–4 | 50 | 0.627 | 28.38 | 0.198 | 13.13 | 27.6 |

| 19 | 4–6 | 0 | 1.463 | 5.88 | 0.435 | 23.95 | 26.3 |

| 20 | 4–6 | 10 | 1.224 | 12.81 | 0.338 | 20.43 | 26.8 |

| 21 | 4–6 | 20 | 1.012 | 18.28 | 0.279 | 17.86 | 27.5 |

| 22 | 4–6 | 30 | 0.813 | 22.86 | 0.235 | 15.89 | 28.0 |

| 23 | 4–6 | 40 | 0.652 | 26.53 | 0.208 | 14.15 | 28.4 |

| 24 | 4–6 | 50 | 0.583 | 30.10 | 0.187 | 13.06 | 28.7 |

| 25 | 2–4 | 0 | 1.410 | 6.56 | 0.434 | 22.61 | 25.8 |

| 26 | 2–4 | 10 | 1.133 | 14.04 | 0.343 | 20.12 | 26.2 |

| 27 | 2–4 | 20 | 0.910 | 19.03 | 0.281 | 17.84 | 26.6 |

| 28 | 2–4 | 30 | 0.742 | 23.48 | 0.238 | 15.33 | 26.9. |

| 29 | 2–4 | 40 | 0.604 | 27.01 | 0.204 | 13.42 | 27.2 |

| 30 | 2–4 | 50 | 0.532 | 30.15 | 0.181 | 12.83 | 27.8 |

| 31 | 4–6 | 0 | 1.374 | 6.56 | 0.414 | 22.45 | 27.8 |

| 32 | 4–6 | 10 | 1.093 | 14.22 | 0.319 | 19.12 | 28.2 |

| 33 | 4–6 | 20 | 0.893 | 20.16 | 0.261 | 16.75 | 28.6 |

| 34 | 4–6 | 30 | 0.711 | 24.41 | 0.220 | 14.65 | 29.0 |

| 35 | 4–6 | 40 | 0.582 | 28.18 | 0.193 | 13.13 | 29.3 |

| 36 | 4–6 | 50 | 0.545 | 32.21 | 0.171 | 11.82 | 29.9 |

| Materials | ρ (g/cm3) | k (W/mK) | fcs (MPa) | Literature |

|---|---|---|---|---|

| Cement (450 kg/m3)—exclay (22%) + sand (20%) | 1710 | -- | 41.27 | [3] |

| Cement (440 kg/m3)—exclay + sand + silica fume | 1.460 | -- | 39.5 | [8] |

| Cement + exclay (10%) + tragacanth(1%) | 1.056 | 0.263 | 3.97 | [13] |

| Cement (80%) + EPS (20%) + tragacanth (1%) | 1.230 | 0.220 | 10.85 | [14] |

| Cement + fly ash (20%) + tragacanth (1%) | 1.151 | 0.315 | 20.4 | [15] |

| Cement (80%) + pumice (20%) + tragacanth (1%) | 1.306 | 0.306 | - | [18] |

| Cement (80%) + EPS (20%) + apricot resin (1%) | 1.291 | 0.322 | 13.05 | [19] |

| Cement + clay + wood pellet (20%) | 0.870 | 0.160 | 2.35 | [22] |

| Cement + exclay (10%) + cherry resin (1%) | 1.278 | 0.351 | 22.31 | Present study |

| Cement + exclay (20%) + cherry resin (1%) | 1.081 | 0.291 | 20.13 | |

| Cement + exclay (30%) + cherry resin (1%) | 0.848 | 0.251 | 18.22 | |

| Cement + exclay (40%) + cherry resin (1%) | 0.789 | 0.228 | 15.14 | |

| Cement + exclay (50%) + cherry resin (1%) | 0.603 | 0.208 | 13.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bicer, A.; Celik, N.; Ozgen, F.; Kistak, C.; Taskiran, A. Thermomechanical Properties of a Concrete Composed of Cherry Tree Resin and Expanded Clay (Exclay) Aggregate. Appl. Sci. 2024, 14, 336. https://doi.org/10.3390/app14010336

Bicer A, Celik N, Ozgen F, Kistak C, Taskiran A. Thermomechanical Properties of a Concrete Composed of Cherry Tree Resin and Expanded Clay (Exclay) Aggregate. Applied Sciences. 2024; 14(1):336. https://doi.org/10.3390/app14010336

Chicago/Turabian StyleBicer, Ayse, Nevin Celik, Filiz Ozgen, Celal Kistak, and Ali Taskiran. 2024. "Thermomechanical Properties of a Concrete Composed of Cherry Tree Resin and Expanded Clay (Exclay) Aggregate" Applied Sciences 14, no. 1: 336. https://doi.org/10.3390/app14010336

APA StyleBicer, A., Celik, N., Ozgen, F., Kistak, C., & Taskiran, A. (2024). Thermomechanical Properties of a Concrete Composed of Cherry Tree Resin and Expanded Clay (Exclay) Aggregate. Applied Sciences, 14(1), 336. https://doi.org/10.3390/app14010336