Design and Control of an Ultra-Low-Cost Logistic Delivery Fixed-Wing UAV

Abstract

:1. Introduction

1.1. Background

1.2. Major Innovations

- This study reduces the cost of a fixed-wing UAV composed of composite materials while ensuring that the mission requirements are met;

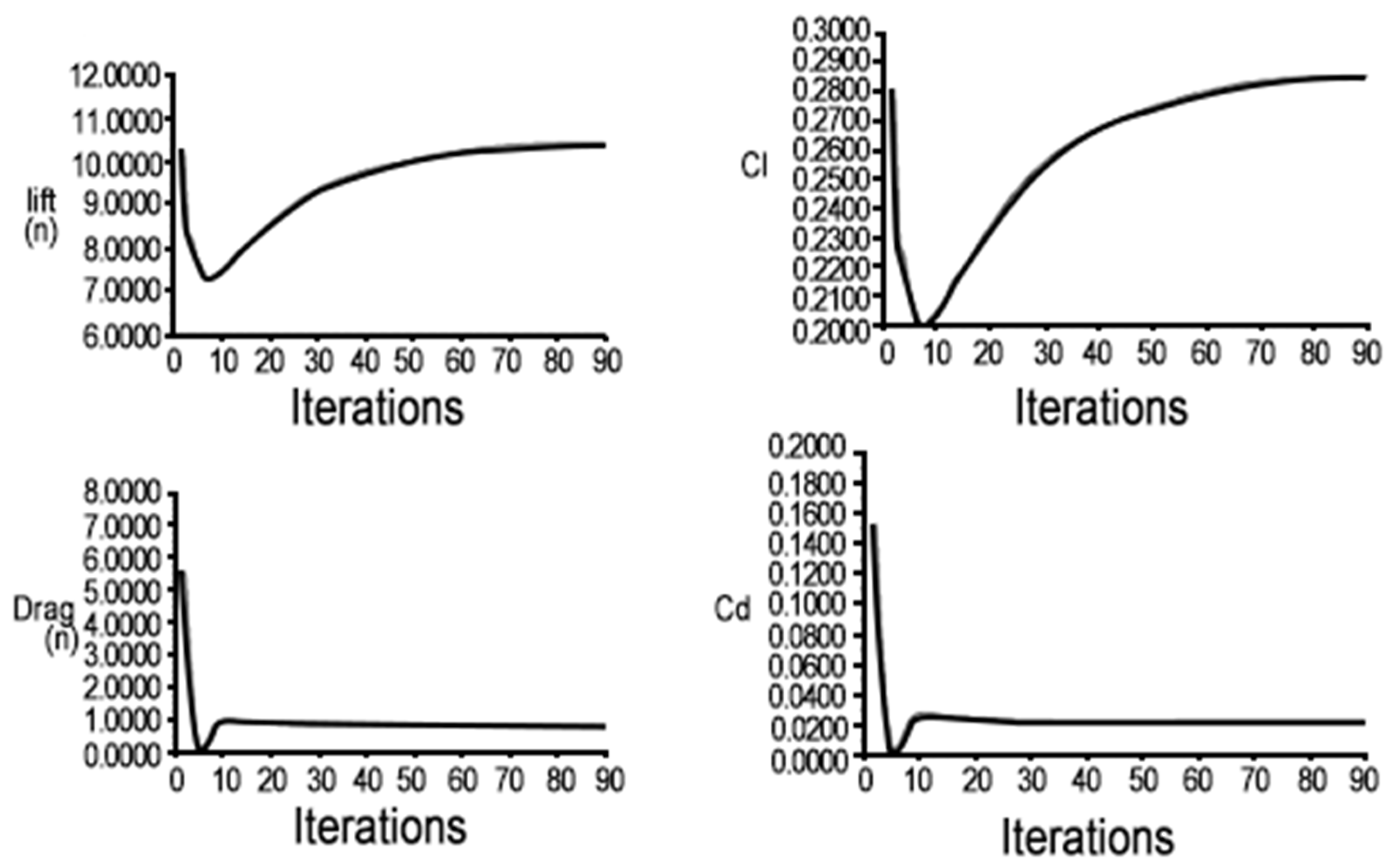

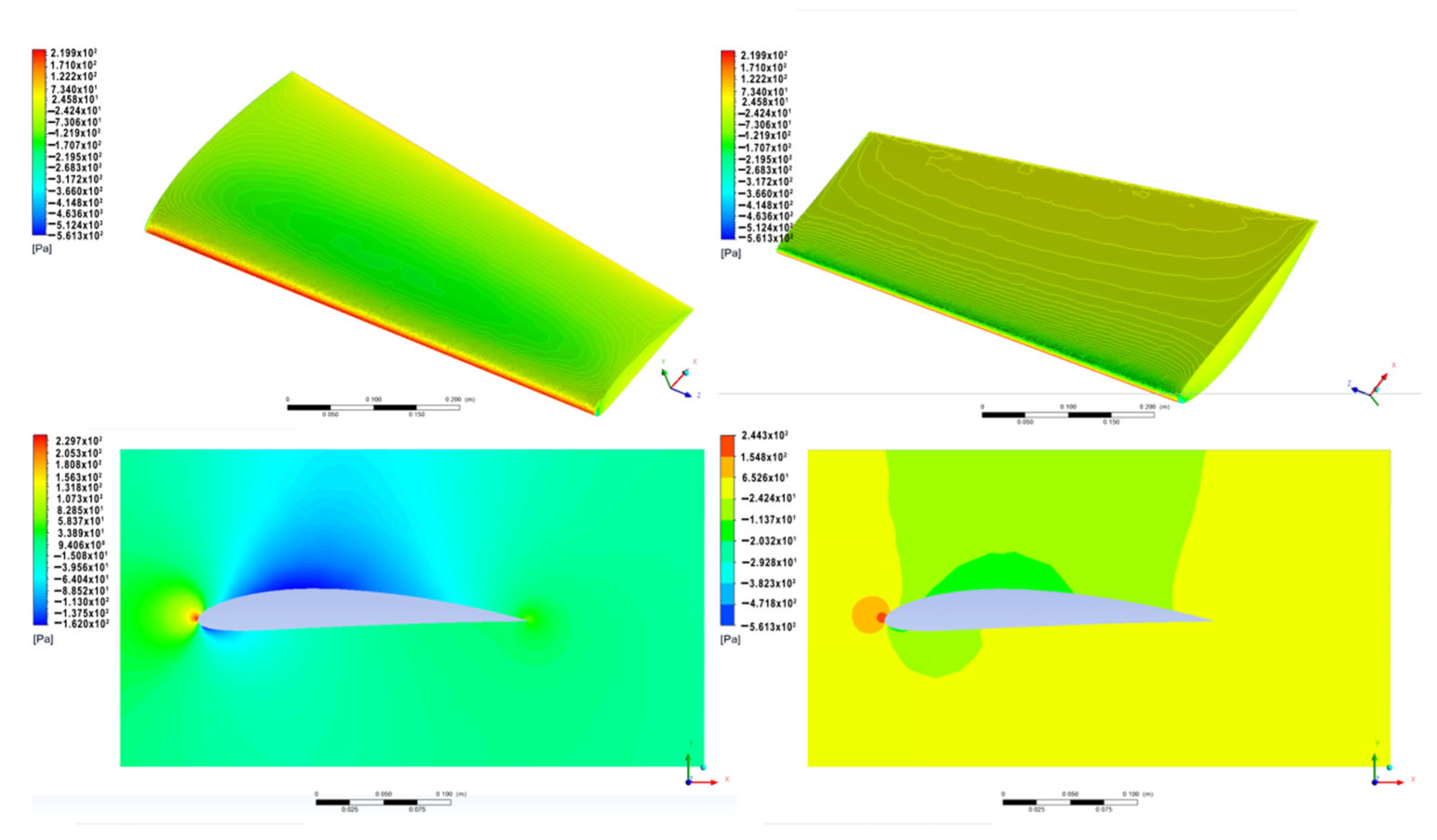

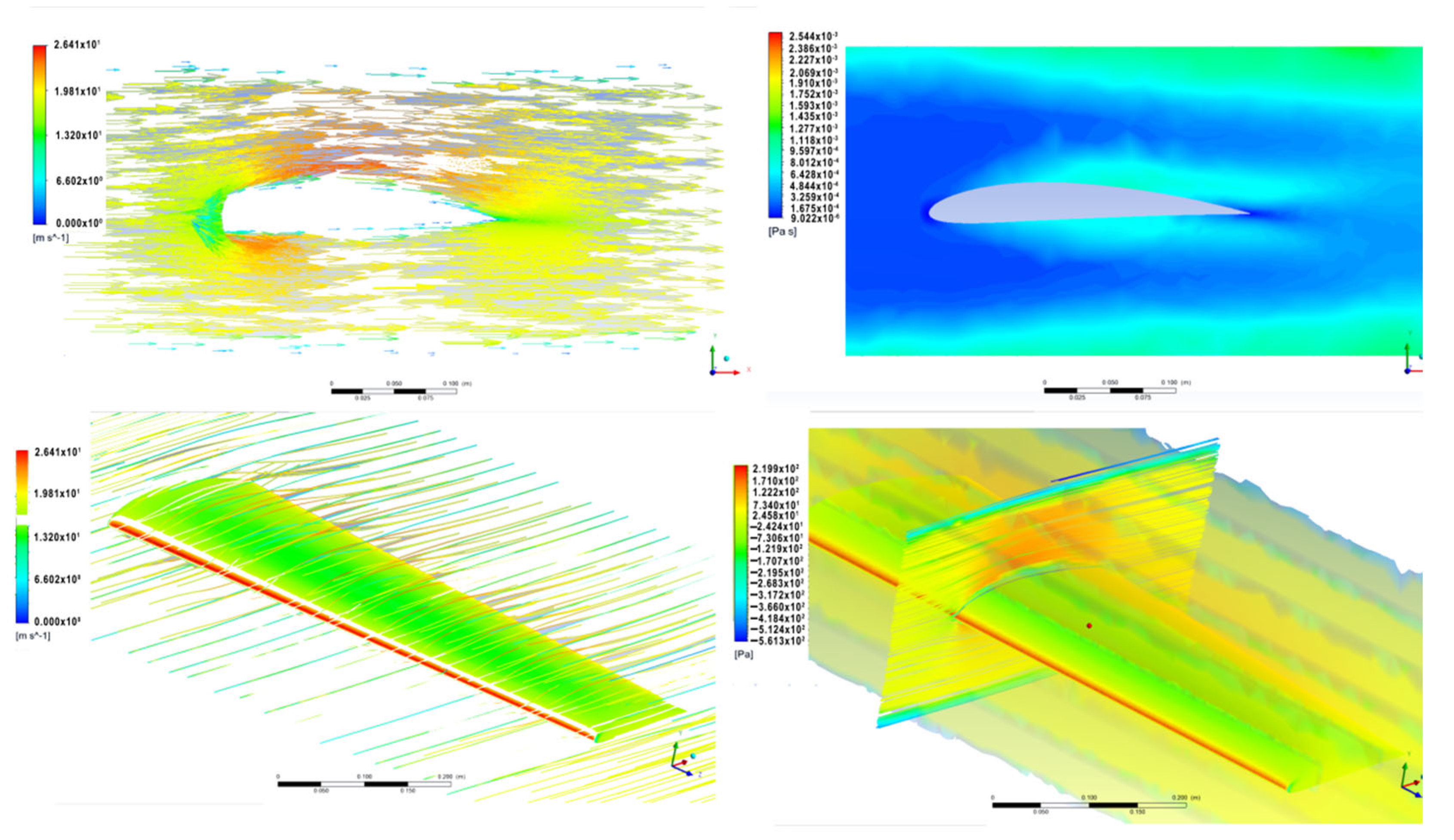

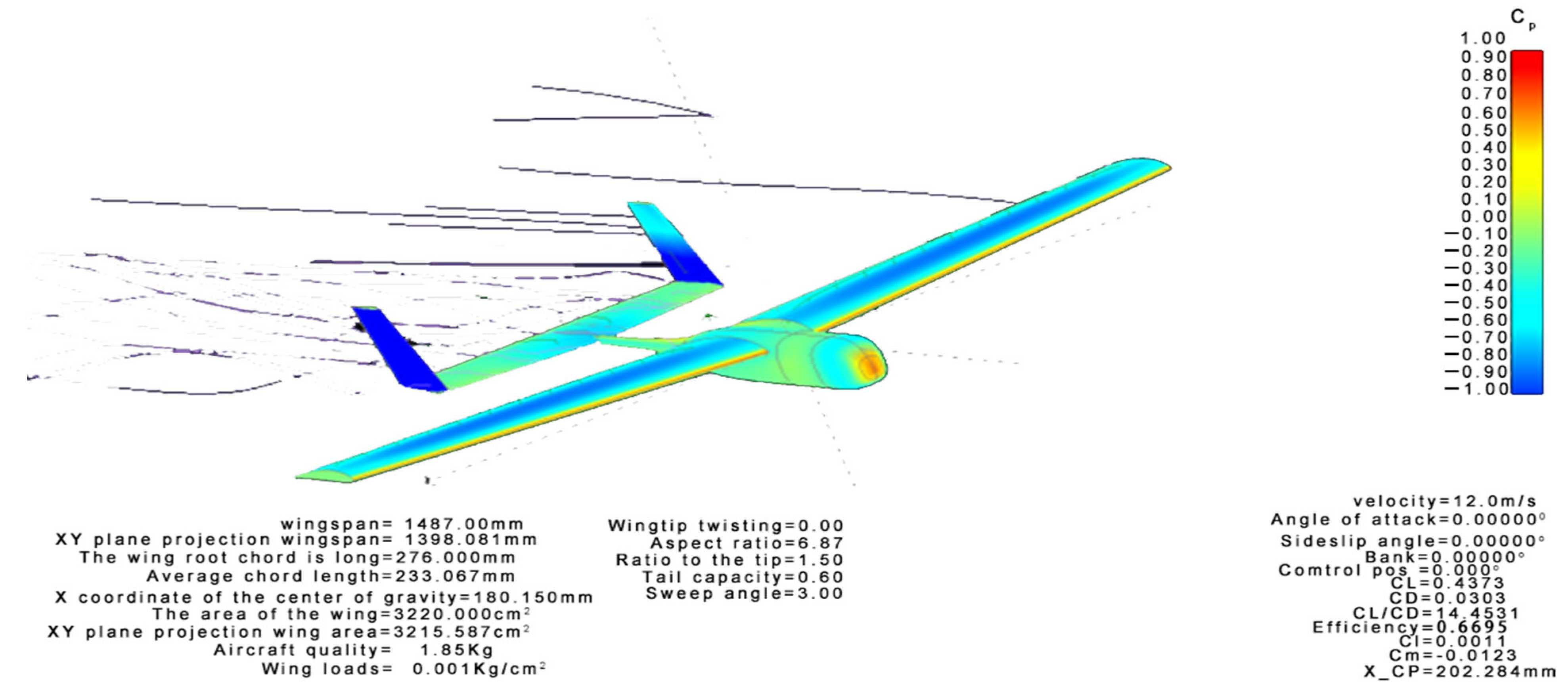

- We designed a streamlined wing and dual vertical h-tail based on accurate aerodynamic analysis; our wing model parameters were satisfied, and the results converged. The displacement reduces the fuselage vibration, and the volume factor is reduced by 10% to 20%, which shows that the aircraft has a more optimized performance compared to the same type of commercially available aircrafts;

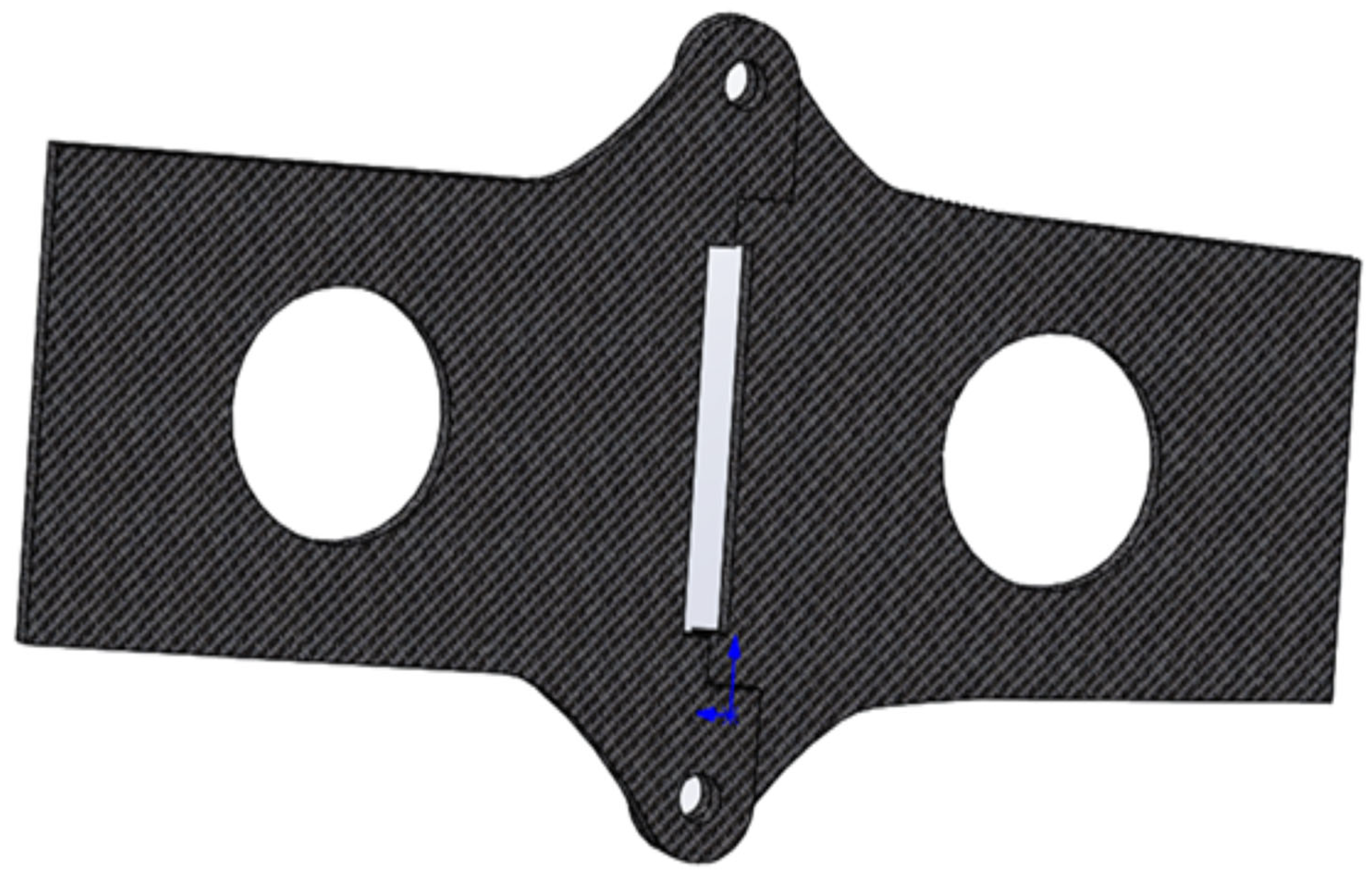

- We designed an autonomous projectile mechanism and spring hinges that are more flexible than commercially available UAVs and protect the dropped package.

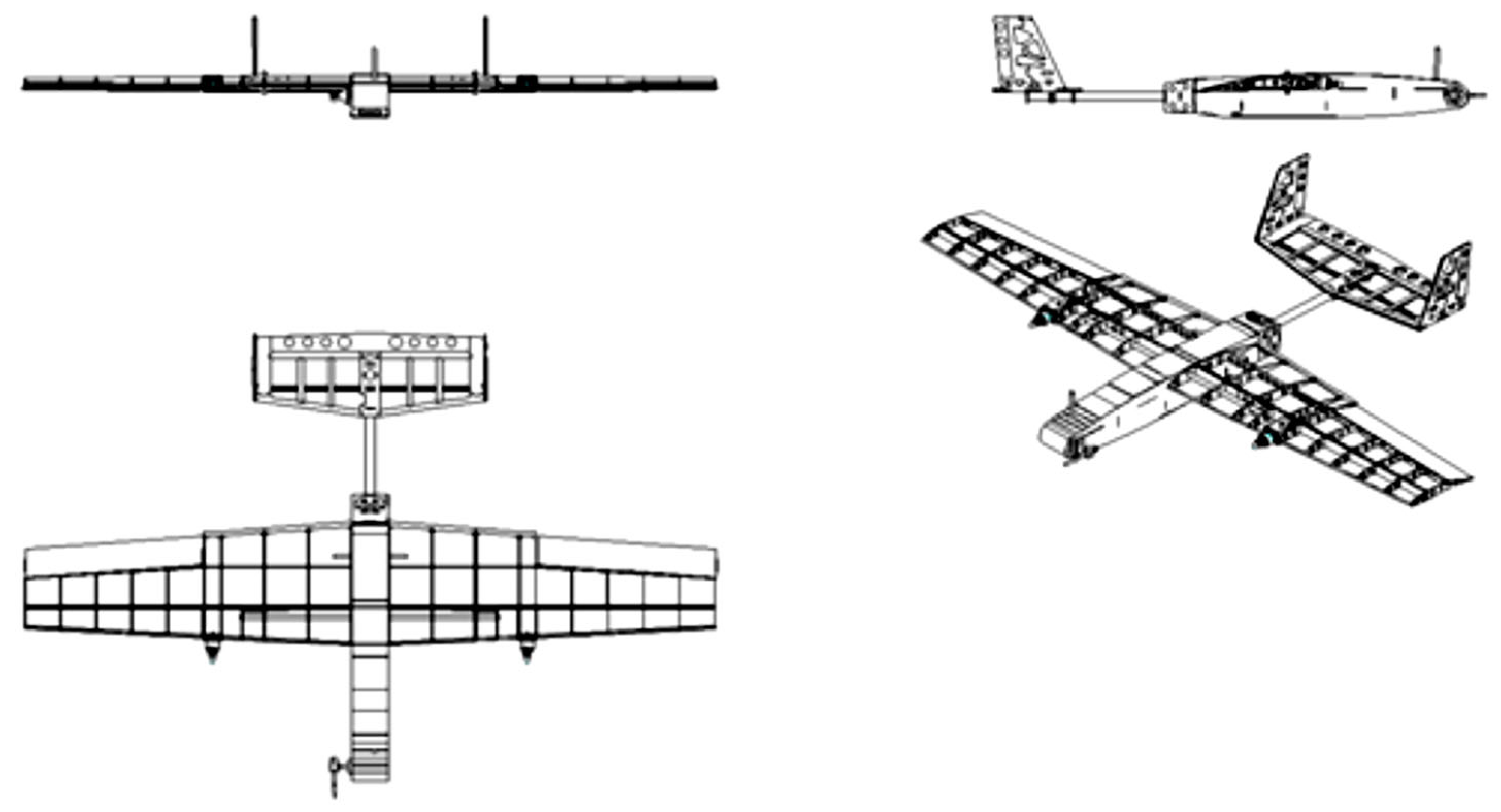

2. Overall UAV Design

2.1. Design Philosophy and Principles

2.2. Aircraft Production Cost

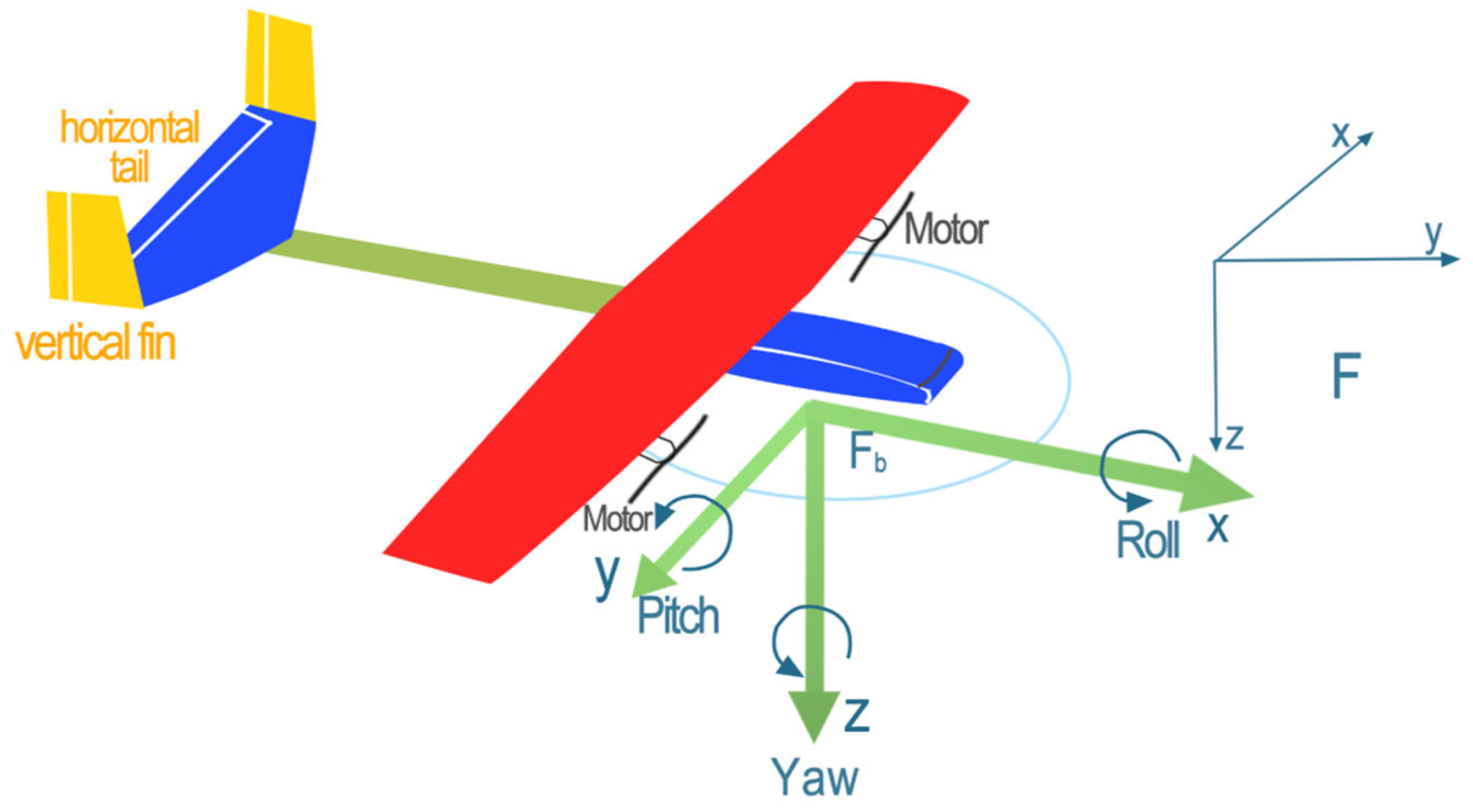

2.3. Fixed-Wing UAV Dynamic Modeling

2.4. Wing Design

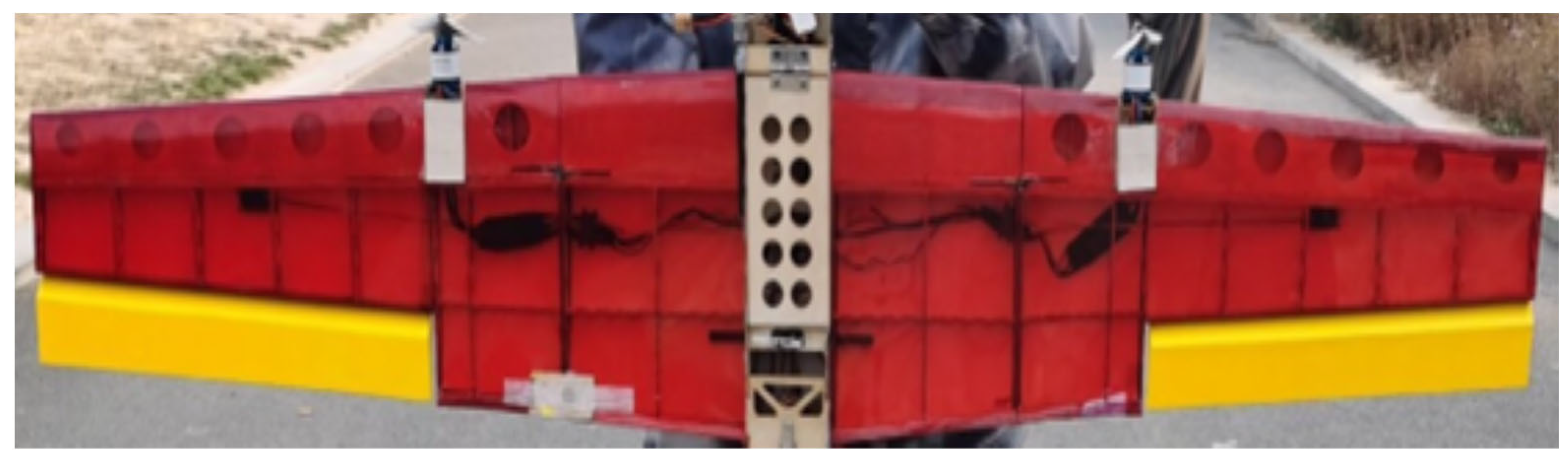

2.4.1. Wing Shape and Function

- A trapezoidal planar wing is used; this shape is simple and practical, suitable for low- and medium-speed flights, and easy to manufacture and install;

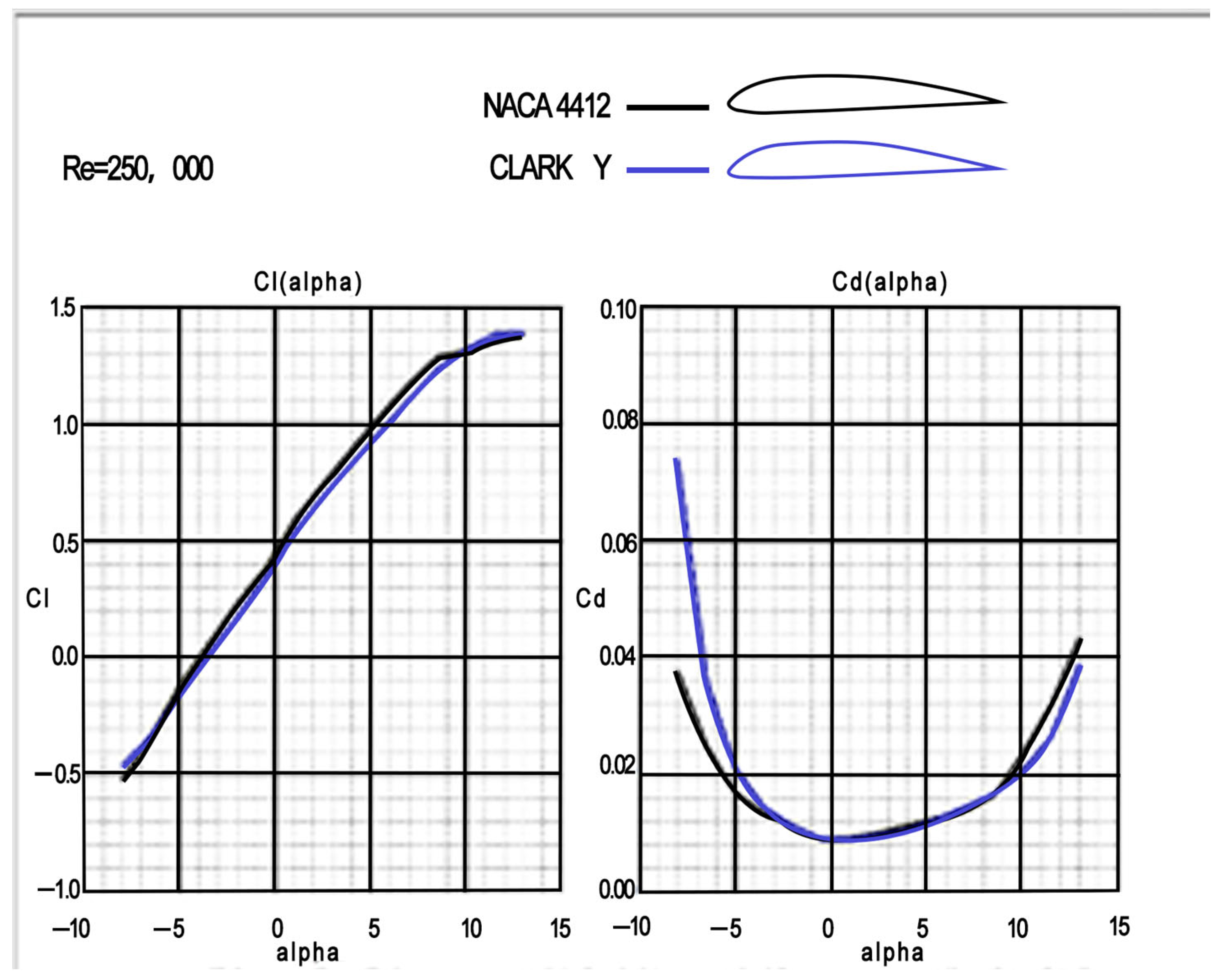

- NACA 4412 is chosen as the wing model, which has a high lift coefficient and low drag coefficient and is suitable for low- and medium-speed flights, as well as under takeoff and landing and stall conditions;

- The wing sweep angle is designed as 3°; this camber can reduce the induced drag of the wing and improve the lateral stability and maneuverability of the aircraft.

2.4.2. Relationship between Wing Parameters and Performance

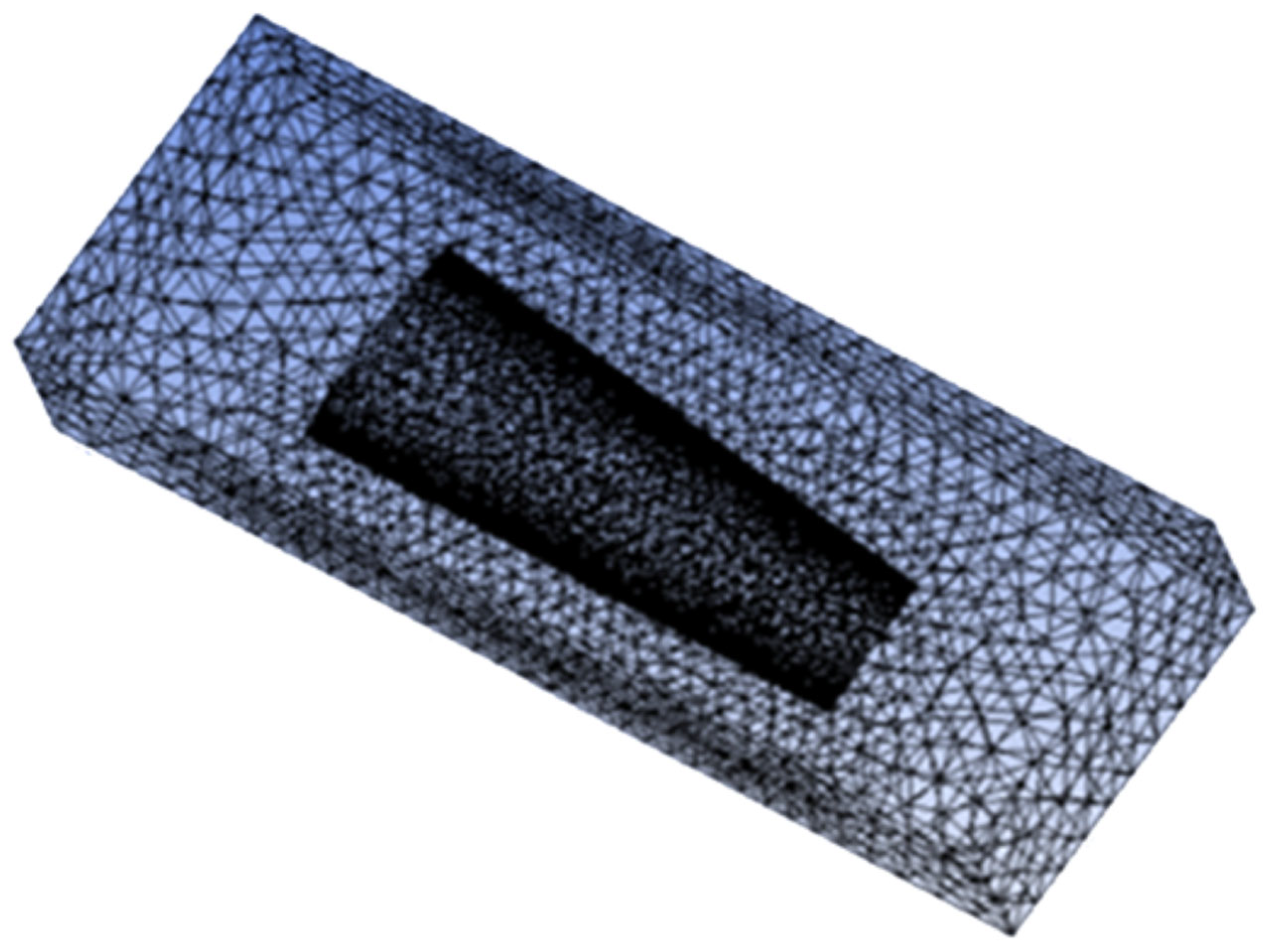

2.4.3. Analysis of Wing Aerodynamics

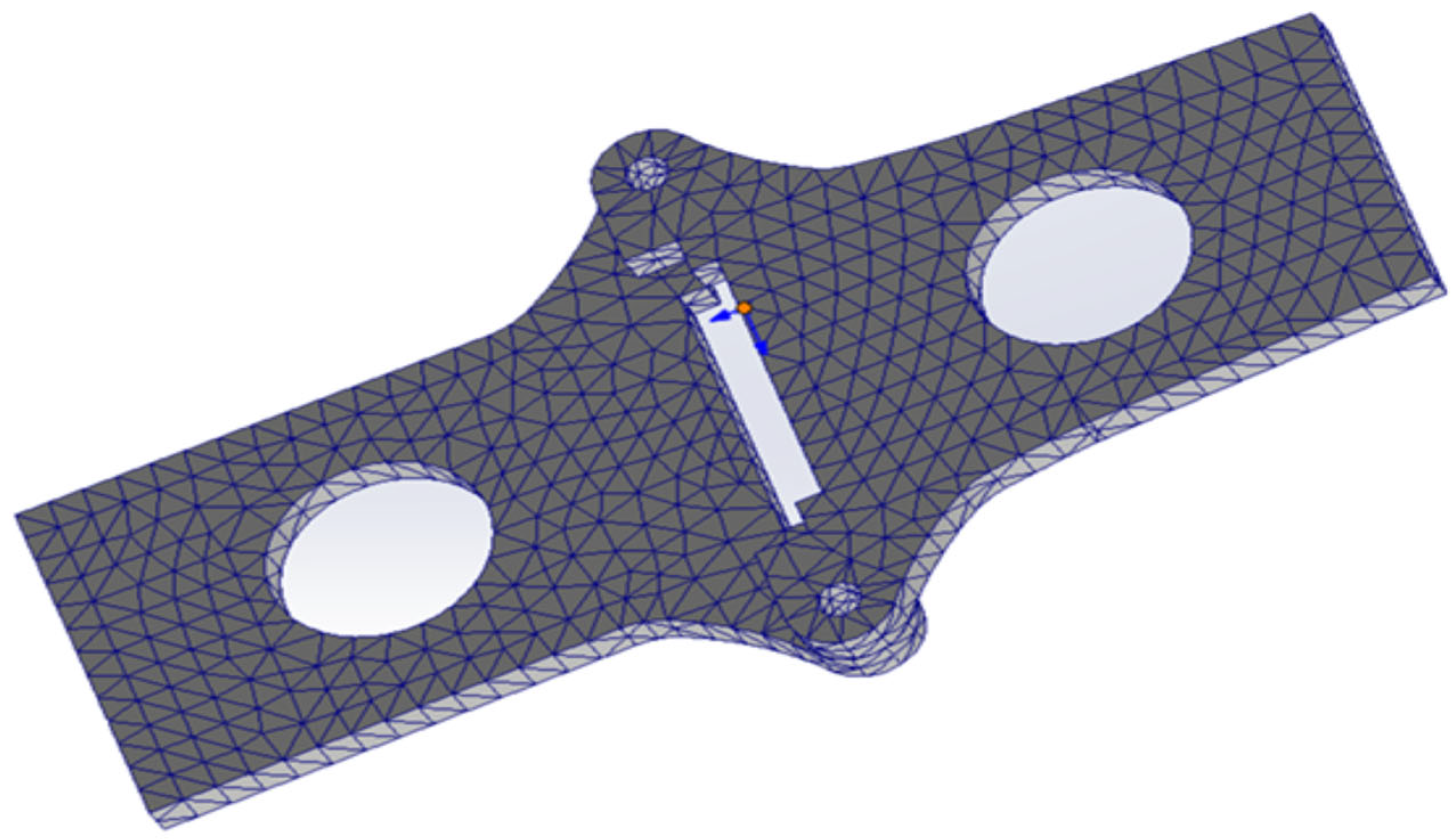

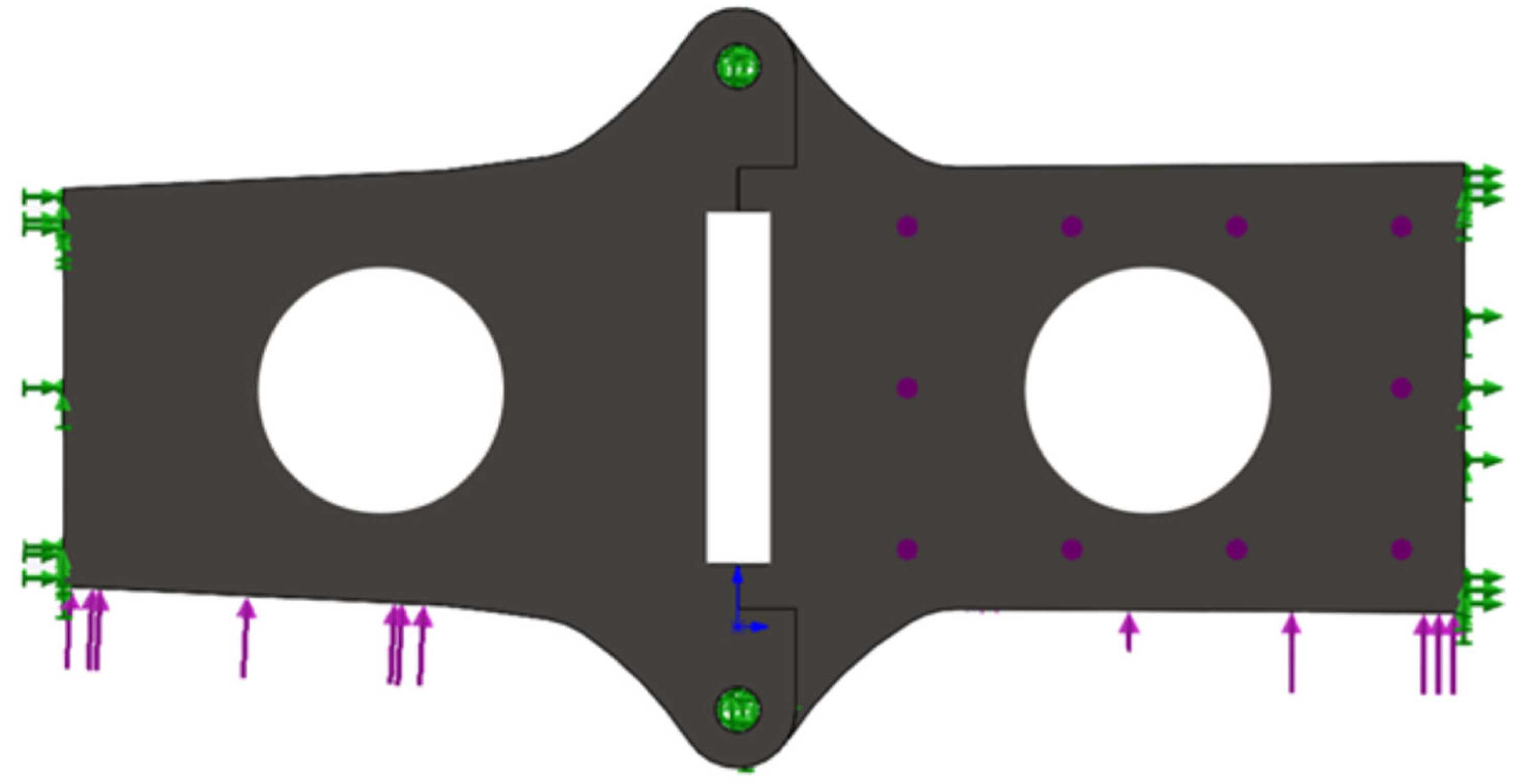

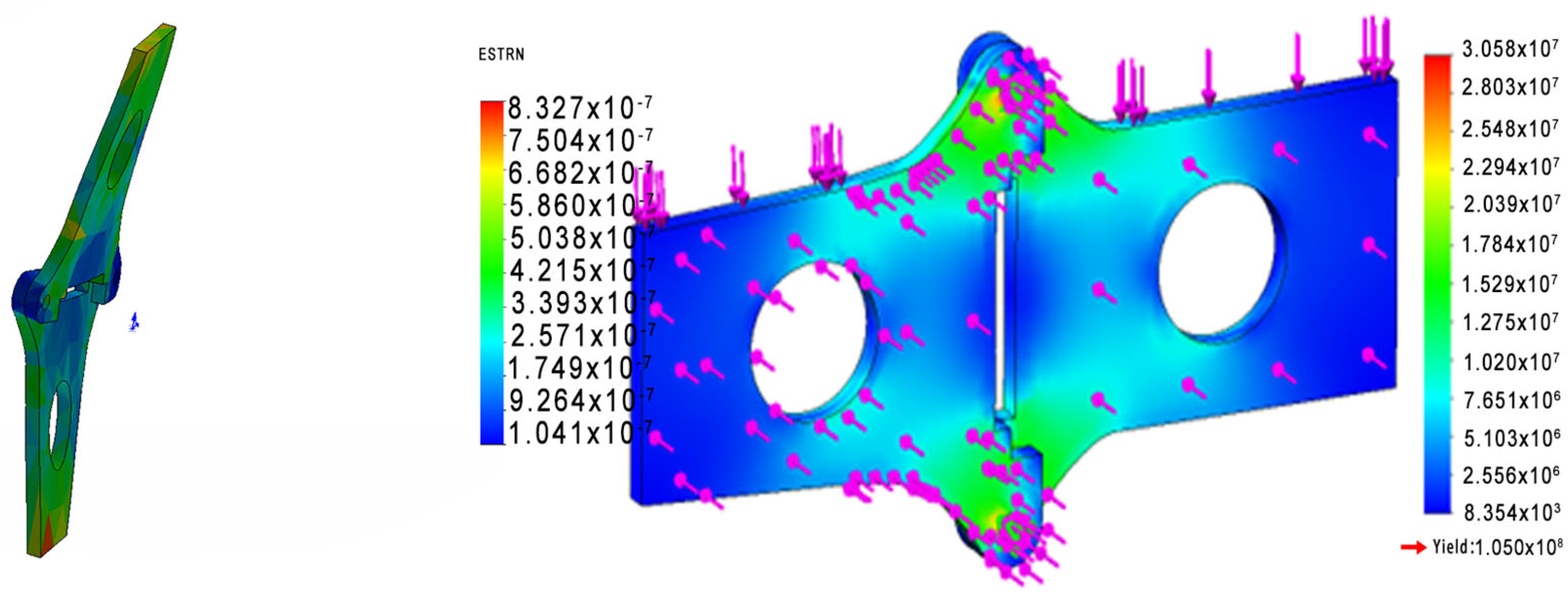

2.4.4. Finite Element Analysis of Outer Wing and Middle Wing Connector

2.5. Design of the Tail and Fuselage [48]

2.5.1. Determination of the Role and Parameters of the Tail Wing

2.5.2. Fuselage Design

2.6. Design of Main Parameters

- 1.

- Lift–drag ratio

- (1)

- Lift and lift coefficient

- (2)

- Drag and drag coefficient

- 2.

- Service ceiling (Hmax)

2.7. Establishment Process of Aircraft Modeling

2.8. Optional Configuration of UAV Bomb-Dropping Mechanism and Power Unit

2.8.1. Power Device Selection

2.8.2. The Drone’s Throwing Mechanism

3. Overview of Image Recognition Technology

3.1. Basic Composition of Image Recognition System

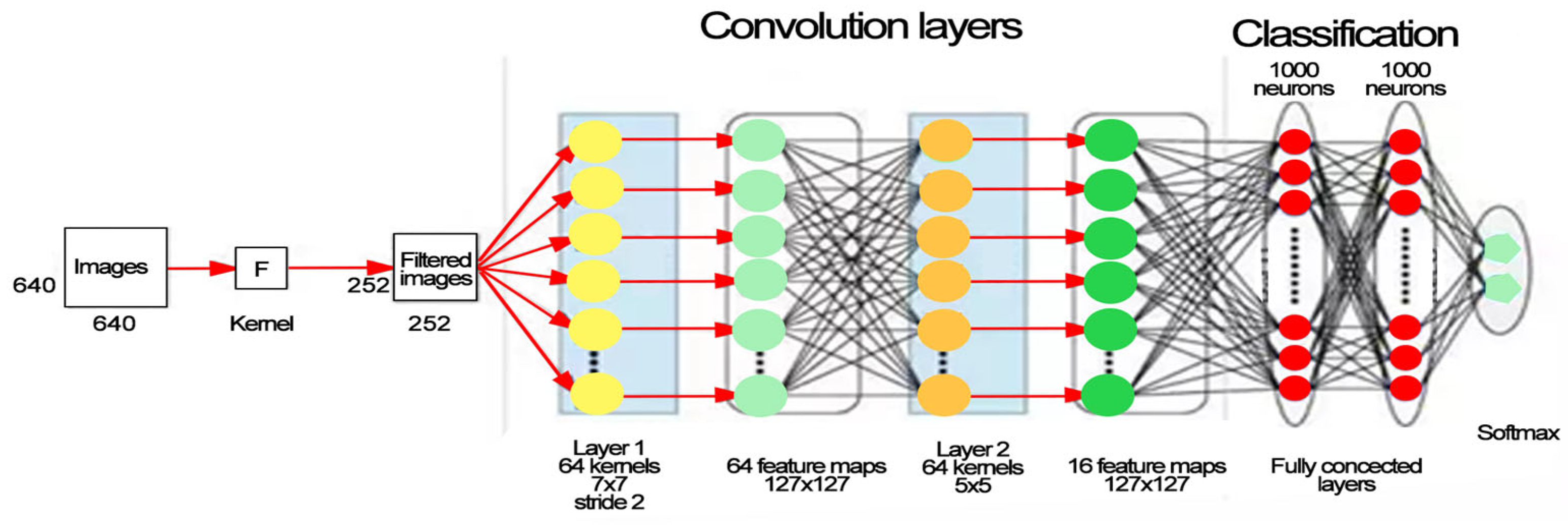

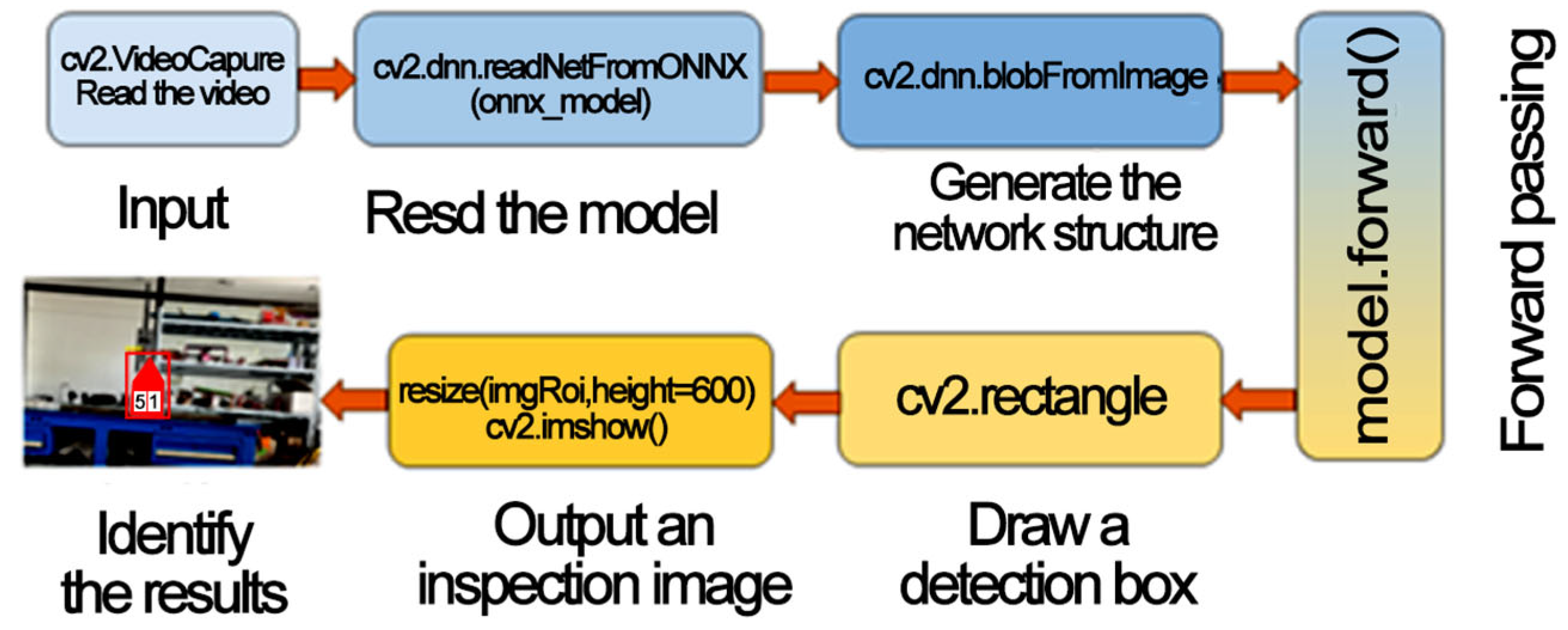

3.2. Image Recognition Algorithm and Implementation

Feature Extraction Algorithm

3.3. Target Identification Applications

3.3.1. The Challenge and Demand of Target Identification

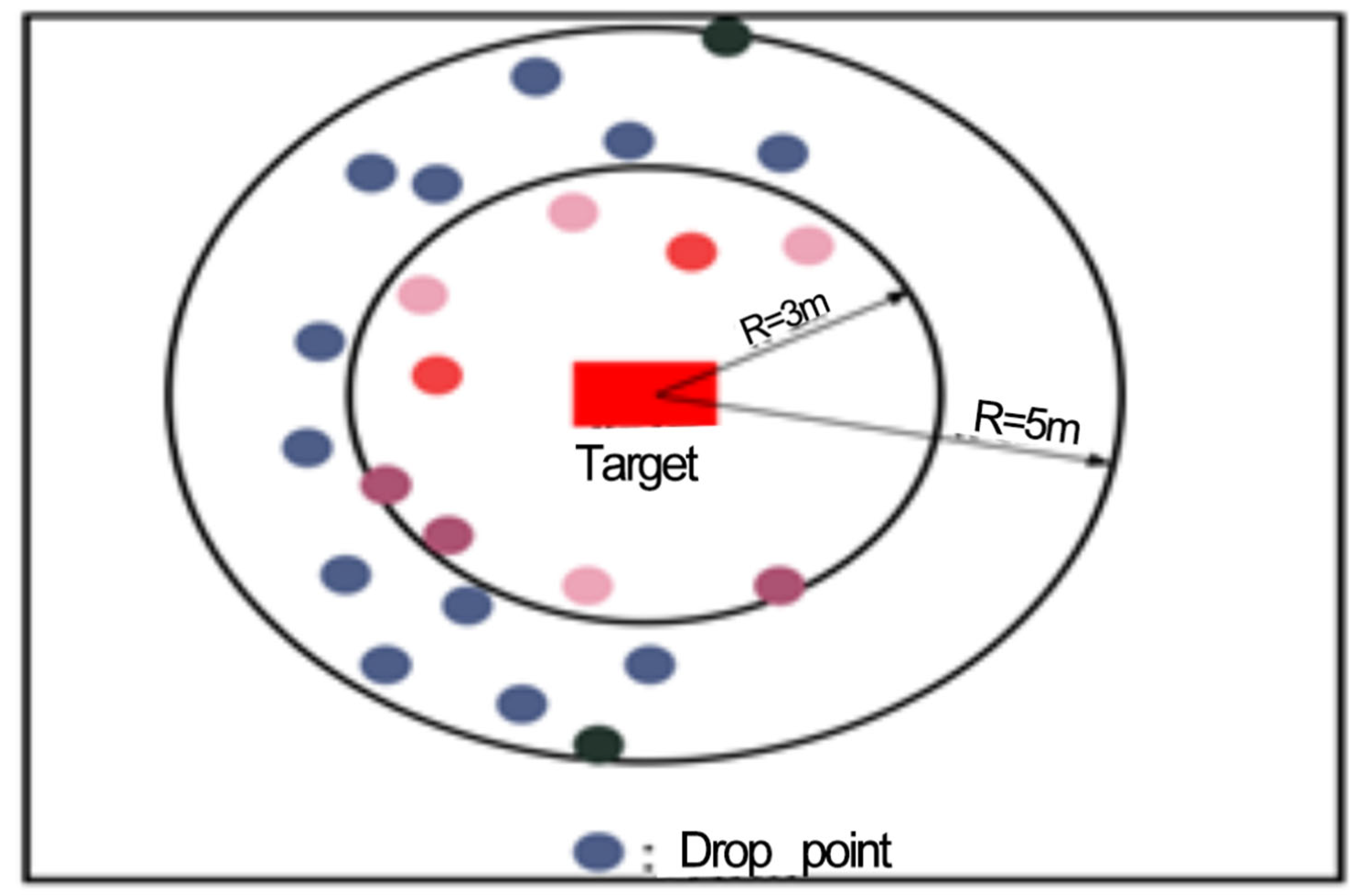

3.3.2. Target Recognition Scheme for UAV Dropping

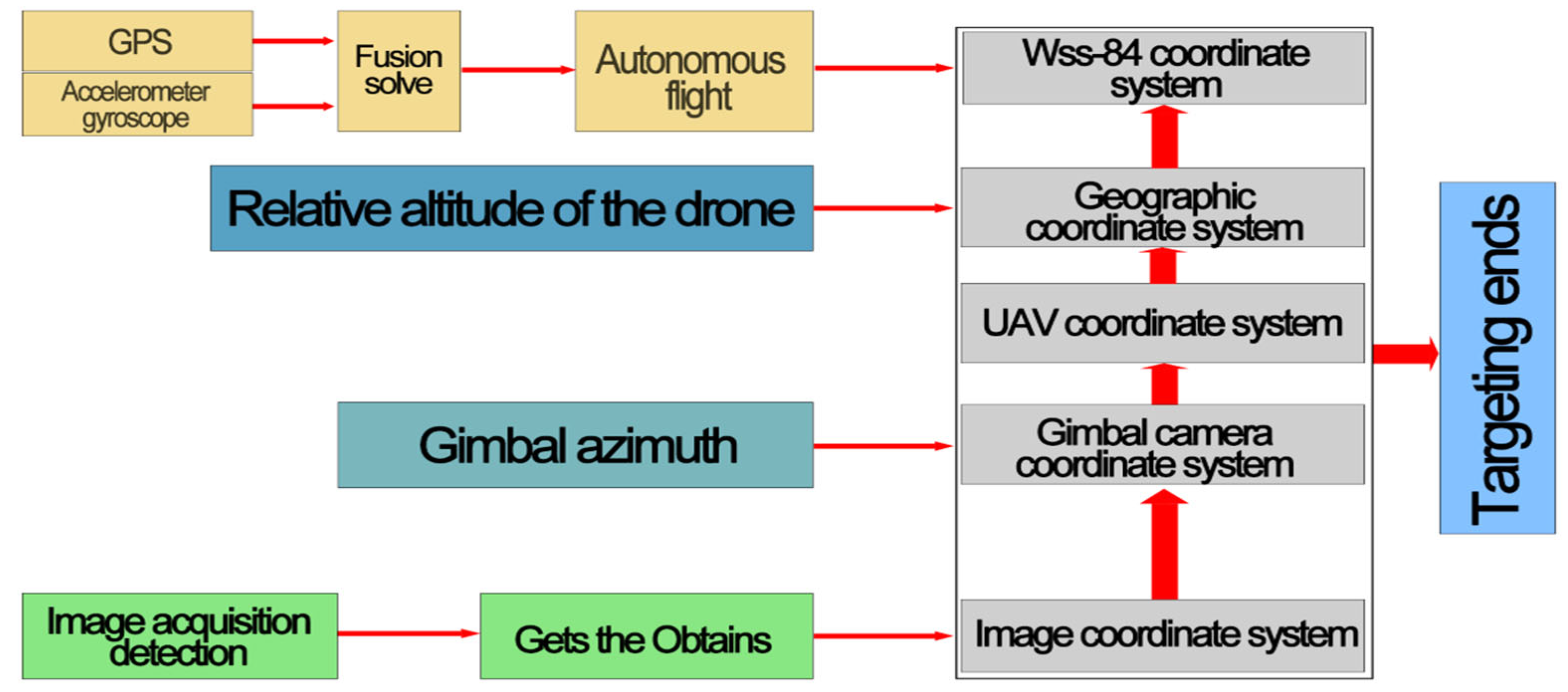

3.3.3. Target Coordinate Information Solution

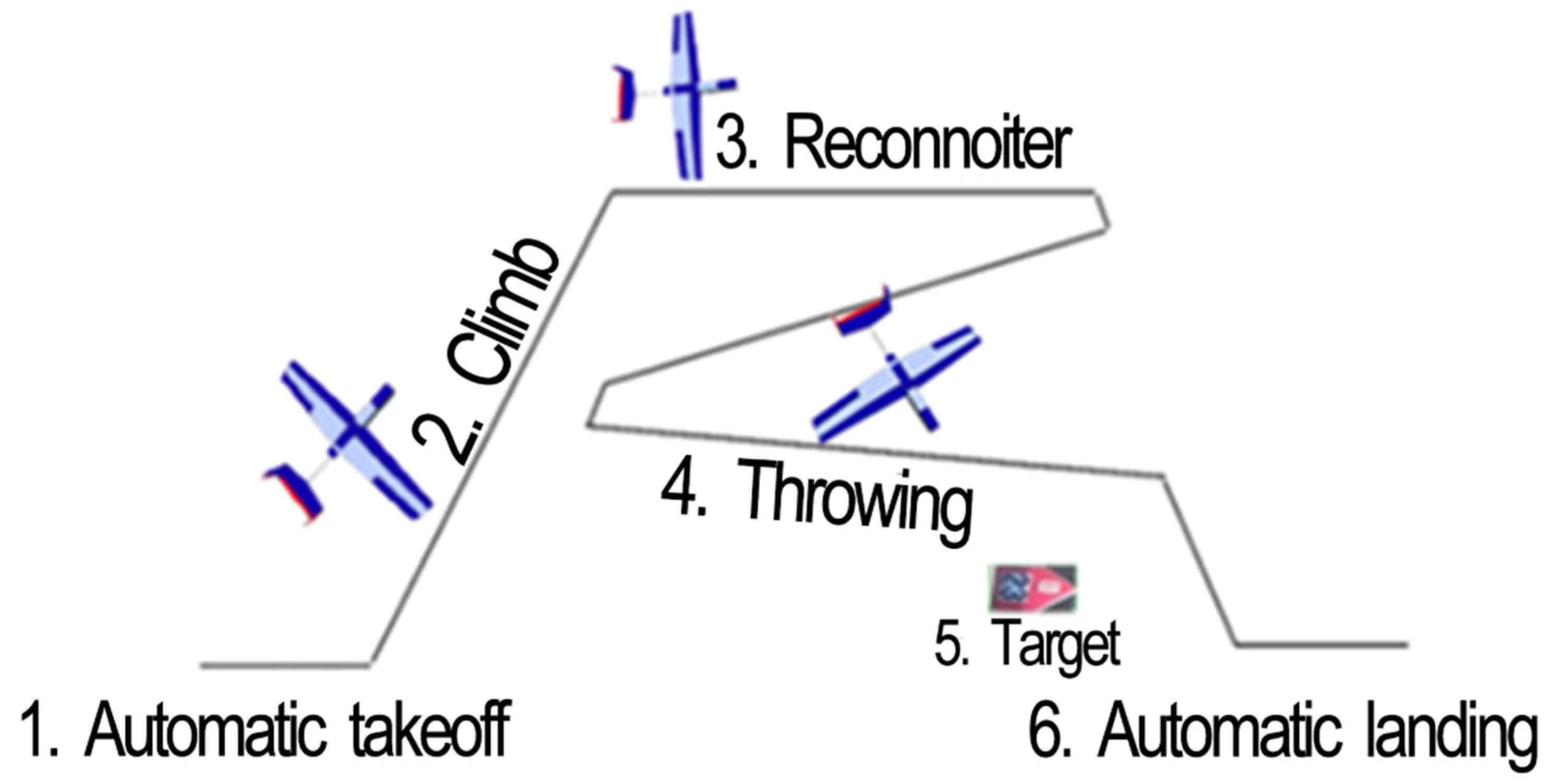

3.3.4. Target’s Throwing Test

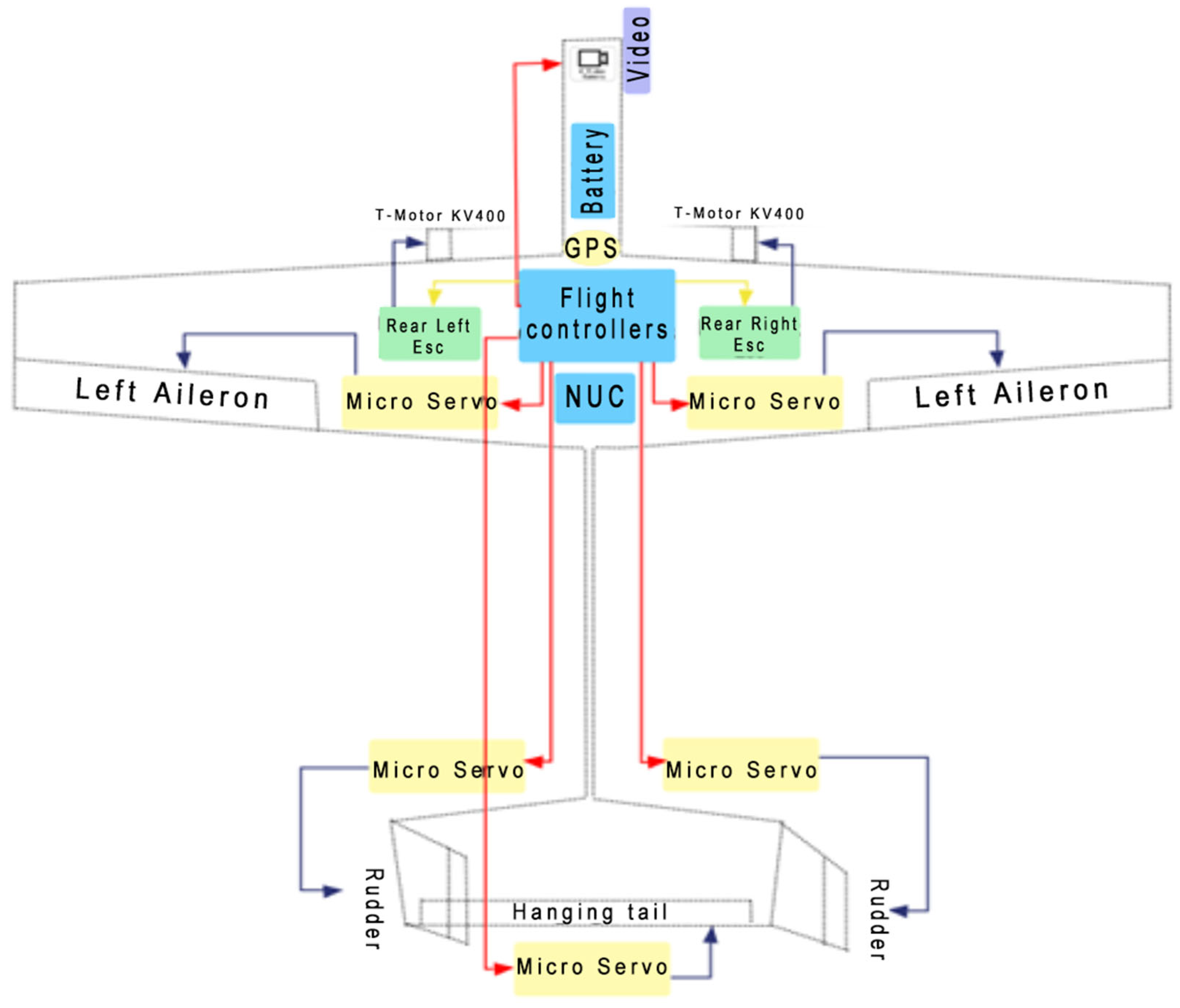

4. Flight Control System

4.1. Flight Control System Overview

4.2. Fundamentals of Control Law Design and Optimization

4.3. Implementation and Verification of the Control Algorithm

5. Test Process and Result Analysis

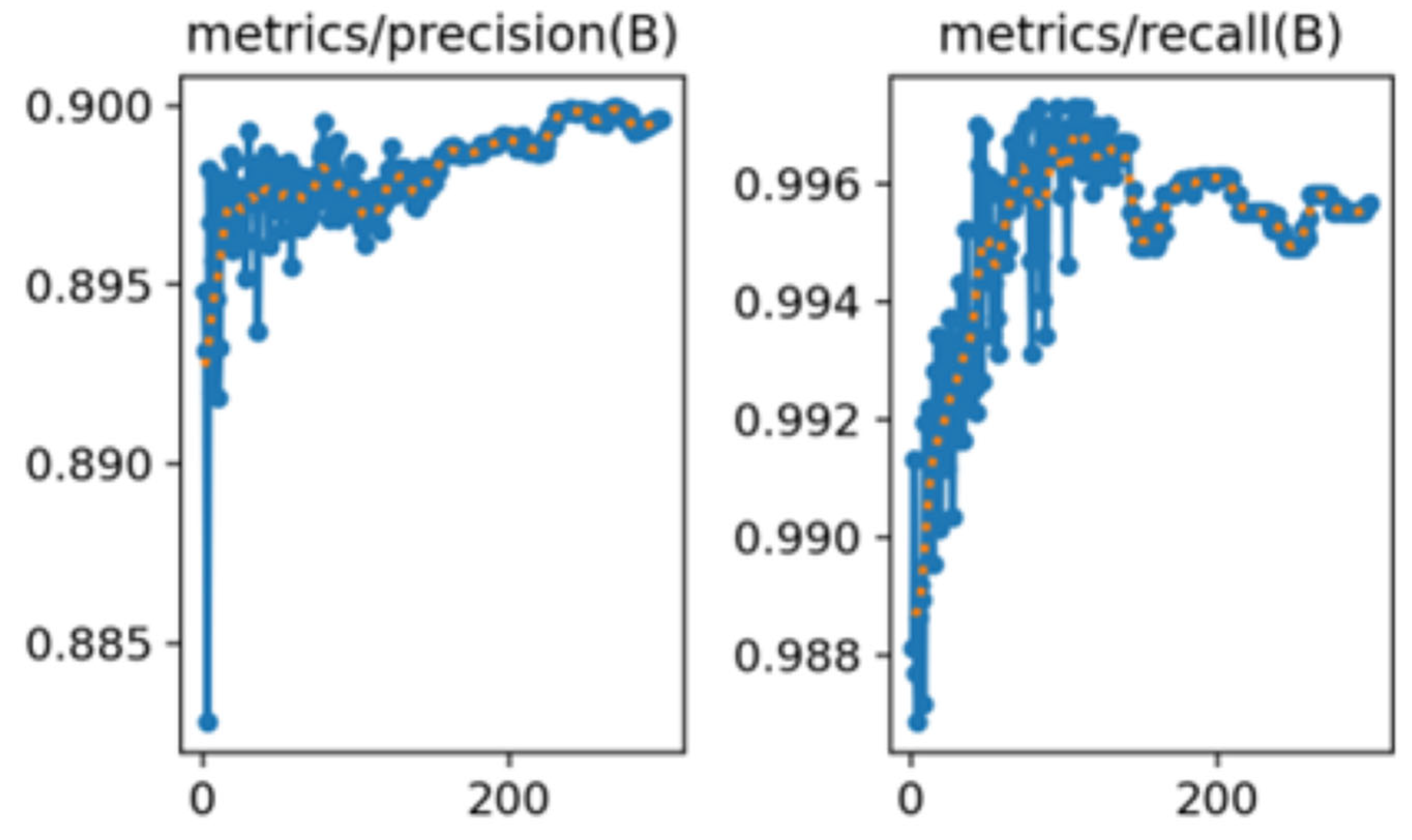

5.1. Image Recognition Effect Test

5.2. Field Experiments Compared to Those of Other Ultra-Low-Cost Drones

5.2.1. Test Environment and Conditions

- Information on the takeoff point, waypoint, landing point, and target point of the unmanned aerial vehicle, as well as flight parameters and control parameters, appear on the flight control panel. It is prohibited to use any equipment for the real-time control and autonomous flight of the model;

- The drone carried a simulated package consisting of an unopened 500 mL bottle of water;

- The drone’s mission simulated the precise delivery of a courier package by a low-cost drone, with the model aircraft in the autonomous flight mode, while completing parcel organizer identification and parcel-dropping tasks;

- The flight process and results of the UAV were recorded and displayed on a computer at the ground station, including data on the UAV’s position, speed, attitude, control inputs, and image information, as well as images of the UAV’s flight trajectory, the location of the parcel organizer, and the point at which the parcel was released.

5.2.2. Presentation and Analysis of Test Results

6. Conclusions and Prospects

- The total production cost of the UAV described in this paper is 101 USD, while the generation cost of the same type of UAV on the market is 280 USD, which greatly reduces the production cost and usage cost;

- We designed a streamlined wing and dual vertical h-shaped tail, based on an accurate aerodynamic analysis, which has higher lift, strength, and stiffness and lower drag and lateral drag than the same type of aircrafts, in which our wing model parameterization meets the requirements and the results converge. The displacement reduces the fuselage oscillations, and the volume factor is reduced by 10% to 20%, which shows that the aircraft has a more optimized performance compared to the same type of commercially available aircrafts;

- We designed an autonomous projectile mechanism and spring hinges, which are more flexible and protect the projected package compared to marketed UAVs;

- After several test experiments, we found that the UAV optimized in this study has less deviation from the desired values and meets specific performance metrics and constraints. This demonstrates the superior control performance and structural design of the proposed UAV, highlighting the effectiveness and superiority of the autonomous flight algorithms and the implemented control laws. In addition, the UAV successfully performed target search and localization, demonstrating the accuracy and reliability of the image recognition system. Based on the precise target strike and smooth return to the base, the comprehensiveness and practicality of the UAV’s design and control schemes proposed in this study are further verified.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Goran, P.; Sasa, S.; Marina, I.-K. Application of Ray Cast Method for Person Geolocalization and Distance Determination Using UAV Images in Real-World Land Search and Rescue Scenarios. Expert Syst. Appl. 2024, 237, 121495. [Google Scholar]

- Yi, Z.; Hongda, Y. Application of Hybrid Swarming Algorithm on a UAV Regional Logistics Distribution. Biomimetics 2023, 8, 96. [Google Scholar] [CrossRef] [PubMed]

- Peck, M. Close encounters of the drone kind. Aerosp. America 2015, 53, 18–23. [Google Scholar]

- Cui, L.; Zhou, Q.; Huang, D.; Yang, H. Fixed-Time Disturbance Observer-Based Fixed-Time Path Following Control for Small Fixed-Wing UAVs under Wind Disturbances. Int. J. Adapt. Control Signal Process. 2023, 38, 23–38. [Google Scholar] [CrossRef]

- Popova, I.; Abdullina, E.; Danilov, I.; Marusin, A.; Marusin, A.; Ruchkina, I.; Shemyakin, A. Application of the RFID technology in logistics. Transp. Res. Procedia 2021, 57, 452–462. [Google Scholar] [CrossRef]

- Deng, M.; Yang, Q.; Peng, Y. A Real-Time Path Planning Method for Urban Low-Altitude Logistics UAVs. Sensors 2023, 23, 7472. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Jia, W.; Ma, Y.; Yan, X.; Liu, Y.; Song, G.; Yang, X. A Password-Sending-And-Receiving Device for Unmanned Aerial Vehicle for Logistics Delivery and Distribution. U.S. Patent Application No. 16/300,563, 30 May 2019. [Google Scholar]

- Ko, Y.D. The airfare pricing and seat allocation problem in full-service carriers and subsidiary low-cost carriers. J. Air Transp. Manag. 2019, 75, 92–105. [Google Scholar] [CrossRef]

- Inghels, M.; Mee, P.; Diallo, O.H.; Cissé, M.; Nelson, D.; Tanser, F.; Asghar, Z.; Koita, Y.; Laborde-Balen, G.; Breton, G. Improving Early Infant Diagnosis for HIV-Exposed Infants Using Unmanned Aerial Vehicles for Blood Sample Transportation in Conakry, Guinea: A Comparative Cost-Effectiveness Analysis. BMJ Glob. Health 2023, 8, e012522. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Shi, Z.; Zhong, Y. Robust Adaptive Three-Dimensional Trajectory Tracking Control Scheme Design for Small Fixed-Wing UAVs. ISA Trans. 2023, 141, 377–391. [Google Scholar] [CrossRef]

- Santos, N.P.; Lobo, V.; Bernardino, A. Fixed-Wing Unmanned Aerial Vehicle 3D-Model-Based Tracking for Autonomous Landing. Drones 2023, 7, 243. [Google Scholar] [CrossRef]

- Alwaseela, A.; Wheeler, T.A.; Dever, J.; Lin, Z.; Arce, J.; Guo, W. Assessing Fusarium Oxysporum Disease Severity in Cotton Using Unmanned Aerial System Images and a Hybrid Domain Adaptation Deep Learning Time Series. Model. Biosyst. Eng. 2024, 237, 220–231. [Google Scholar]

- Cheonghwa, L.; Hwanhee, K.; Baeksuk, C. Airdrop Operation and Autonomous Flight-Back Experiment of Dual Unmanned Aircraft. J. Inst. Control Robot. Syst. 2019, 25, 519–525. [Google Scholar]

- Tong, Z.; Guo, J.; Wu, Q.; Xu, C. An Unmanned Aerial Vehicle Identification and Tracking System Based on Weakly Supervised Semantic Segmentation Technology. Phys. Commun. 2022, 54, 101758. [Google Scholar]

- Fanghao, H.; Chen, X.; Xu, Y.; Yang, X.; Chen, Z. Immersive Virtual Simulation System Design for the Guidance, Navigation, and Control of Unmanned Surface Vehicles. Ocean Eng. 2023, 281, 114884. [Google Scholar]

- Shakhatreh, H.; Sawalmeh, A.; Alenezi, A.H.; Abdel-Razeq, S. Mobile-IRS Assisted Next Generation UAV Communication Networks. Comput. Commun. 2024, 215, 51–61. [Google Scholar] [CrossRef]

- Bokhtier, G.M.; Crawford, S.W.; Shahroudi, K.E. Integrated Systems Architectural Modeling with Architectural Trade Study of a UAV Surface-less Flight Control Systems for Wildfire Detection and Communication Utilizing MBSAP. INCOSE Int. Symp. 2023, 33, 229–250. [Google Scholar] [CrossRef]

- Kuhara, S. Method of Displaying Flight Route of Unmanned Aerial Vehicle That Flies Autonomously, Terminal, and Non-Transitory Computer-Readable Recording Medium Storing Program. U.S. Patent 10,685,573, 16 June 2020. [Google Scholar]

- Shalyhin, A.; Nerubatsky, V.; Denysova, S. The UAV Flight Route Optimization by Taking into Consideration the Wind Influence. Наука і Техніка Пoвітряних Сил Збрoйних Сил України 2018, 3, 20–24. [Google Scholar] [CrossRef]

- Anosri, S.; Panagant, N.; Champasak, P.; Bureerat, S.; Thipyopas, C.; Kumar, S.; Pholdee, N.; Yıldız, B.S.; Yildiz, A.R. A Comparative Study of State-of-the-Art Metaheuristics for Solving Many-Objective Optimization Problems of Fixed Wing Unmanned Aerial Vehicle Conceptual Design. Arch. Comput. Methods Eng. 2023, 30, 3657–3671. [Google Scholar] [CrossRef]

- Nikolas, H.; Christoph, B.; Michael, A. Performance Evaluation of Image-based Location Recognition Approaches Based on Large-scale UAV Imagery. In Proceedings of the Electro-Optical Remote Sensing, Photonic Technologies, and Applications VIII; and Military Applications in Hyperspectral Imaging and High Spatial Resolution Sensing II, Amsterdam, The Netherlands, 22–25 September 2014; Volume 9250, pp. 154–159. [Google Scholar]

- Hassan, S.A. Effective Range of Unmanned Aerial Vehicle (UAV) in the Malaysian Army Tactical Operations. Appl. Mech. Mater. 2014, 3446, 399–403. [Google Scholar] [CrossRef]

- Muzzi, F.A.G.; de Mello Cardoso, P.R.; Pigatto, D.F.; Branco, K.R.L.J.C. Using Botnets to Provide Security for Safety-Critical Embedded Systems—A Case Study Focused on UAVs. J. Phys. Conf. Ser. 2015, 633, 012053. [Google Scholar] [CrossRef]

- Thomas, P.; Delbecq, S.; Pommier-Budinger, V.; Bénard, E. Modeling and Design Optimization of an Electric Environmental Control System for Commercial Passenger Aircraft. Aerospace 2023, 10, 260. [Google Scholar] [CrossRef]

- Li, W.; Yang, Z.; Liu, K.; Wang, W. MIMO Multi-Frequency Active Vibration Control for Aircraft Panel Structure Using Piezoelectric Actuators. Int. J. Struct. Stab. Dyn. 2023, 23, 2350157. [Google Scholar] [CrossRef]

- Lim, Y.X. Cognitive Human-Machine Interfaces and Interactions for Avionics Systems. Ph.D. Thesis, RMIT University, Melbourne, VIC, Australia, 2020. Available online: https://researchrepository.rmit.edu.au/esploro/outputs/doctoral/Cognitive-human-machine-interfaces-and-interactions-for-avionics-systems/9921957511601341 (accessed on 30 March 2024).

- Pavithran, R.; Lalith, V.; Naveen, C.; Sabari, S.P.; Kumar, M.A.; Hariprasad, V. A Prototype of Fixed Wing UAV for Delivery of Medical Supplies. IOP Conf. Ser. Mater. Sci. Eng. 2020, 995, 012015. [Google Scholar] [CrossRef]

- Sabri, F.; Elzaabalawy, A.; Meguid, S.A. Aeroelastic Behavior of a Flexible Morphing Wing Design for Unmanned Aerial Vehicle. Acta Mech. 2022, 233, 851–867. [Google Scholar] [CrossRef]

- Liu, W.; Li, X.; Shen, Z.; Ma, C. A Digital Twin Method for Civil Aircraft Power Distribution System Based on Unity3D and Simulink. J. Phys. Conf. Ser. 2023, 2615, 012017. [Google Scholar] [CrossRef]

- Zhou, Q.; Wei, Y.; Zhu, L. Research on Reliability Modeling of Unmanned Aircraft System Avionics Systems Based on 5G. Int. J. Distrib. Sens. Netw. 2019, 15, 1550147719860381. [Google Scholar] [CrossRef]

- Sikorsky Aircraft Corporation. Aircraft Route Systems” in Patent Application Approval Process. Def. Aerosp. Week 2019, 103. [Google Scholar]

- Madika, B.; Syahrial, A.Z. Study of Aluminum/Kevlar Fiber Composite Laminate with and without TiC Nanoparticle Impregnation and Aluminum/Carbon Fiber Composite Laminate for Anti-Ballistic Materials. Int. J. Light. Mater. Manuf. 2024, 7, 62–71. [Google Scholar] [CrossRef]

- Guo, W.; Bu, W.; Mao, Y.; Wang, E.; Yang, Y.; Liu, C.; Guo, F.; Mai, H.; You, H.; Long, Y. Magnesium Hydroxide as a Versatile Nanofiller for 3D-Printed PLA Bone Scaffolds. Polymers 2024, 16, 198. [Google Scholar] [CrossRef]

- Sam, C.; Filip, S.; Clara, U. An Experimental Investigation of the Mechanical Performance of EPS Foam Core Sandwich Composites Used in Surfboard Design. Polymers 2023, 15, 2703. [Google Scholar] [CrossRef]

- Watson, M.; Gonzalez, F. Design and Implementation of a Ultra-low Cost Folding-Wing UAV for Model Rocket Deployment. In Proceedings of the 2023 IEEE Aerospace Conference, Big Sky, MT, USA, 4–11 March 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–10. [Google Scholar]

- Papadopoulos, C.; Vlachos, S.; Yakinthos, K. Conceptual Design of a Fixed Wing Hybrid UAV UUV Platform. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1226, 012028. [Google Scholar] [CrossRef]

- Okulski, M.; Ławryńczuk, M. A Small UAV Optimized for Efficient Long-Range and VTOL Missions: An Experimental Tandem-Wing Quadplane Drone. Appl. Sci. 2022, 12, 7059. [Google Scholar] [CrossRef]

- Ranasinghe, N.D.; Gunawardana, W.A.D.L. Development of Gasoline-Electric Hybrid Propulsion Surveillance and Reconnaissance VTOL UAV. In Proceedings of the 2021 IEEE International Conference on Robotics, Automation and Artificial Intelligence (RAAI), Hong Kong, China, 21–23 April 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 63–68. [Google Scholar]

- Chung, P.-H.; Ma, D.-M.; Shiau, J.-K. Design, Manufacturing, and Flight Testing of an Experimental Flying Wing UAV. Appl. Sci. 2019, 9, 3043. [Google Scholar] [CrossRef]

- Demircali, A.A.; Uvet, H. Mini Glider Design and Implementation with Wing-Folding Mechanism. Appl. Sci. 2018, 8, 1541. [Google Scholar] [CrossRef]

- Mesquita, G.P.; Rodríguez-Teijeiro, J.D.; de Oliveira, R.R.; Mulero-Pázmány, M. Steps to Build a DIY Ultra-Low Cost Fixed-Wing Drone for Biodiversity Conservation. PLoS ONE 2021, 16, e0255559. [Google Scholar] [CrossRef] [PubMed]

- Gerdes, J.W.; Cellon, K.C.; Bruck, H.A.; Gupta, S.K. Characterization of the Mechanics of Compliant Wing Designs for Flapping-Wing Miniature Air Vehicles. Exp. Mech. 2013, 53, 1561–1571. [Google Scholar] [CrossRef]

- Panigrahi, S.; Krishna, Y.S.S.; Thondiyath, A. Design, Analysis, and Testing of a Hybrid VTOL Tilt-Rotor UAV for Increased Endurance. Sensors 2021, 21, 5987. [Google Scholar] [CrossRef] [PubMed]

- Mansor, Y.; Sahwee, Z.; Asri, M.H.M. Development of Multiple Configuration Flying Wing UAV. In Proceedings of the 2019 International Conference on Computer and Drone Applications (IConDA), Kuching, Malaysia, 19–21 December 2019. [Google Scholar]

- Anonymous. Micro AeroDynamics’ VG Kits Raise the Service Ceiling. Plane Pilot 2015, 51, 13. [Google Scholar]

- Ramanan, G.; Krishnan, P.R.; Ranjan, H.M. An Aerodynamic Performance Study and Analysis of SD7037 Fixed-Wing UAV Airfoil. Mater. Today Proc. 2021, 47, 2547–2552. [Google Scholar] [CrossRef]

- Hyun, P.S.; Joon, K.O.; Sang, L. Aerodynamic Analysis of High-Speed Compound Unmanned Rotorcraft Using an Unstructured Flow Solver. Int. J. Aeronaut. Space Sci. 2023, 24, 1077–1085. [Google Scholar]

- Lawson, N.J.; Davies, S.G.; Khanal, B.; Hoff, R.I. Wake-Tailplane Interaction of a Slingsby Firefly Aircraft. Aerospace 2022, 9, 787. [Google Scholar] [CrossRef]

- Li, Y. A Novel Design for Reinforcing the Aircraft Tail Leading Edge Structure against Bird Strike. Int. J. Impact Eng. 2016, 105, 89–101. [Google Scholar] [CrossRef]

- Sanchez-Carmona, A.; Cuerno-Rejado, C. Vee-tail Conceptual Design Criteria for Commercial Transport Airplanes. Chin. J. Aeronaut. 2019, 32, 595–610. [Google Scholar] [CrossRef]

- Wang, J.; Wang, D.; Wang, C.; Deng, F. Robust Formation Control for Unmanned Helicopters with Collision Avoidance. J. Frankl. Inst. 2020, 357, 11997–12018. [Google Scholar] [CrossRef]

- Yue, T.; Wang, L.; Ai, J. Gain Self-Scheduled H∞ Control for Morphing Aircraft in the Wing Transition Process Based on an LPV Model. Chin. J. Aeronaut. 2013, 26, 909–917. [Google Scholar] [CrossRef]

- Yur’evich, M.A.; Ribhatovich, Z.A.; Mihailovich, D.M. Experimental and Theoretical Researches on Influence of Parametric Excitation on the Flutter Critical Speed of Aircraft Model of Wing. Visual. Mech. Process. 2013, 3. [Google Scholar] [CrossRef]

- Bayrak, Z.U.; Kaya, U.; Oksuztepe, E. Investigation of PEMFC Performance for Cruising Hybrid Powered Fixed-Wing Electric UAV in Different Temperatures. Int. J. Hydrogen Energy 2020, 45, 7036–7045. [Google Scholar] [CrossRef]

- Senthilkumar, R.; Balamurugan, R. Adaptive Fuzzy-Based SMC for Controlling Torque Ripples in Brushless DC Motor Drive Applications. Cybern. Syst. 2023, 54, 1132–1153. [Google Scholar] [CrossRef]

- Yu, B.; Liu, W.; Yue, Y. Improved Calibration of Eye-in-Hand Robotic Vision System Based on Binocular Sensor. Sensors 2023, 23, 8604. [Google Scholar] [CrossRef]

- Wei, T.; Liu, H.; Tian, H.; Wang, X. A Visual Positioning Method for Wedge Support Robot Based on Pruned-Ghost-YOLOv3. Proc. Inst. Mech. Eng. 2023, 237, 3931–3944. [Google Scholar] [CrossRef]

- Chen, N.; Li, Y.; Yang, Z.; Lu, Z.; Wang, S.; Wang, J. LODNU: Lightweight Object Detection Network in UAV Vision. J. Supercomput. 2023, 79, 10117–10138. [Google Scholar] [CrossRef]

- Magana-Salgado, U.; Namburi, P.; Feigin-Almon, M.; Pallares-Lopez, R.; Anthony, B. A Comparison of Point-Tracking Algorithms in Ultrasound Videos from the Upper Limb. Biomed. Eng. Online 2023, 22, 52. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.; Zhang, T.; Chen, C. Method and Device for Effectively Utilizing OpenCV to Detect PCB Board Size. J. Eng. Mech. Mach. 2023, 8, 44–50. [Google Scholar]

- Varçin, H.; Üneş, F.; Gemici, E.; Zelenakova, M. Development of a Three-Dimensional CFD Model and OpenCV Code by Comparing with Experimental Data for Spillway Model Studies. Water 2023, 15, 756. [Google Scholar] [CrossRef]

- Yu, Z.; Ning, Z.; Yang, H. OpenCV-Based SF6 Density Controller Dial Pointer Angle Recognition. J. Phys. Conf. Ser. 2023, 2450, 012024. [Google Scholar] [CrossRef]

- Long, L.; Bing, L.; Yong, Y. Moving Scene Object Tracking Method Based on Deep Convolutional Neural Network. Alex. Eng. J. 2024, 86, 592–602. [Google Scholar]

- Liu, W.; Zhou, G.; Mao, X.; Bao, S.; Li, H.; Shi, J.; Chen, H.; Shen, J.; Huang, Y. Global Disentangled Graph Convolutional Neural Network Based on a Graph Topological Metric. Knowl.-Based Syst. 2024, 284, 111283. [Google Scholar] [CrossRef]

- Wu, Y.; Han, Q.; Jin, Q.; Li, J.; Zhang, Y. LCA-YOLOv8-Seg: An Improved Lightweight YOLOv8-Seg for Real-Time Pixel-Level Crack Detection of Dams and Bridges. Appl. Sci. 2023, 13, 10583. [Google Scholar] [CrossRef]

- Wang, X.; Gao, H.; Jia, Z.; Li, Z. BL-YOLOv8: An Improved Road Defect Detection Model Based on YOLOv8. Sensors 2023, 23, 8361. [Google Scholar] [CrossRef]

- Chen, H.; Zhou, G.; Jiang, H. Student Behavior Detection in the Classroom Based on Improved YOLOv8. Sensors 2023, 23, 8385. [Google Scholar] [CrossRef]

- Karakuş, S.; Kaya, M.; Tuncer, S.A. Real-Time Detection and Identification of Suspects in Forensic Imagery Using Advanced YOLOv8 Object Recognition Models. Trait. Signal 2023, 40, 2029. [Google Scholar] [CrossRef]

- Matsubara, S.; Zennouji, T.; Jiang, H.; Hamamoto, K. Rapid Automatic Waveguide Recognition Using YOLO and OpenCV for 3D Waveguide Fabrication. Jpn. J. Appl. Phys. 2022, 61, SK1023. [Google Scholar] [CrossRef]

- Junqiong, C.; Ting, L. An Autonomous Positioning Method of Tube-to-Tubesheet Welding Robot Based on Coordinate Trans formation and Template Matching. IEEE Robot. Autom. Lett. 2021, 6, 787–794. [Google Scholar]

- Yinhu, Z.H.; Shaojie, C.H.; Zhang, C.; Ruopu, W.A. Rigorous and Integrated Self-Calibration Model for a Large-Field-of-View Camera Using a Star Image. Chin. J. Aeronaut. 2023, 36, 375–389. [Google Scholar]

- Lee, J.; Kim, S.H.; Lee, H.; Kim, Y. Self-Scheduled LPV Control of Asymmetric Variable-Span Morphing UAV. Sensors 2023, 23, 3075. [Google Scholar] [CrossRef] [PubMed]

- Hangyue, Z.; Yanchu, Y.; Rong, C. Dynamics Simulation of Folding Wing UAVs Launched from a High-Altitude Balloon Platform. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2023, 237, 3072–3091. [Google Scholar]

- Ravin, K.; Kumar, A.A. Drone GPS Data Analysis for Flight Path Reconstruction: A Study on DJI, Parrot & Yuneec Make Drones. Forensic Sci. Int. Digital Investig. 2021, 38, 301182. [Google Scholar]

- Zhou, Z.; Wang, Y.; Chen, M.; Wu, Q. Integrated Fire/Flight Control Coupler Design for Armed Helicopters Based on Improved Non-monotone Adaptive Trust Region Algorithm with Distributionally Robust Optimization. Proc. Inst. Mech. Eng. 2023, 237, 3304–3320. [Google Scholar] [CrossRef]

| Parameter | Numerical Value |

|---|---|

| Wingspan | 1.5 m |

| Maximum takeoff weight | 2 kg |

| Cruising speed | 30 m/s |

| Battery life | 0.2 h |

| Start Year | Project | Demonstration Place | Material |

|---|---|---|---|

| 2023 | [35] | Queensland University of Technology | 3D-printed polylactic acid (PLA) |

| 2022 | [36] | Aristotle University of Thessaloniki | Carbon fiber |

| 2022 | [37] | Warsaw University of Technology | Carbon fiber |

| 2021 | [38] | Kempten University of Applied Sciences | Carbon fiber |

| 2019 | [39] | University of Putra Malaysia (UPM) | Expanded polystyrene (EPS) |

| 2018 | [40] | Yildiz Mah University | Carbon fiber |

| 2012 | [41] | Autonomous University of Barcelona | Polypropylene foam |

| 2012 | [42] | University of Maryland, College Park | Carbon fiber |

| L/mm | b0/mm | b1/mm | MAC/mm | λ | av | Sweep Angle/° |

|---|---|---|---|---|---|---|

| 1487 | 276 | 184 | 233 | 6.87 | 1.5 | 3 |

| Tail Arm/mm | Tail Capacity | Area/mm2 | Sweep Angle/° | |

|---|---|---|---|---|

| Horizontal tail | 550 | 0.67 | 85,000 | 6 |

| Vertical tail | 0.05 | 22,000 × 2 | 25 |

| Overall Length/mm | Maximum Height/mm | Width/mm | Magazine Length/mm |

|---|---|---|---|

| 655 | 97 | 80 | 182 |

| Wingspan/m | 1.50 | Maximum Takeoff Weight/kg | 2.0 |

| Ratio to the tip | 1.50 | Minimum takeoff speed m/s | 10 |

| Fuselage length/m | 0.655 | Maximum level-flight speed m/s | 30 |

| String span ratio | 6.87 | Battery life/h | 0.2 |

| Wing loads g/dm3 | 65 | Practical ceiling/m | 100 |

| Thrust-to-weight ratio | 1.5 | Payload/kg | 0.5 |

| Type | Paddle | Throttle Point | Voltage (V) | Current (A) | Power (W) | Torque (N·m) | Tension (g) | Force Effect (G/W) |

|---|---|---|---|---|---|---|---|---|

| AS2317 KV1400 | APC 9 × 6 | 60% | 11.64 | 15.7 | 183.56 | 0.143 | 810 | 4.41 |

| 100% | 11.16 | 37.13 | 414.33 | 0.259 | 1416 | 3.42 |

| Model | Precision | Recall | [email protected] | S (m) |

|---|---|---|---|---|

| YOLOv5s | 0.823 | 0.672 | 0.726 | 5.5 |

| YOLOv5n | 0.823 | 0.606 | 0.687 | 3.6 |

| YOLOv7n | 0.876 | 0.721 | 0.785 | 3.5 |

| YOLOv8s | 0.896 | 0.856 | 0.854 | 3.4 |

| YOLOv8n | 0.910 | 0.925 | 0.869 | 2.8 |

| YOLOv8x | 0.904 | 0.910 | 0.814 | 3.4 |

| YOLOv8l | 0.890 | 0.897 | 0.809 | 3.8 |

| Frequency | Height | Speeds | Drop Distances | Landing Errors |

|---|---|---|---|---|

| 1 | 8 m | 11 m/s; 12 m/s | 13.91 m; 15.18 m | 4.12 m; 4.32 m |

| 2 | 8.5 m | 11 m/s; 12 m/s | 14.34 m; 15.65 m | 4.13 m; 4.42 m |

| 3 | 9 m | 11 m/s; 12 m/s | 14.76 m; 16.10 m | 4.03 m; 4.11 m |

| 4 | 9.5 m | 11 m/s; 12 m/s | 15.16 m; 16.54 m | 3.98 m; 3.60 m |

| 5 | 10 m | 11 m/s; 12 m/s | 15.55 m; 16.67 m | 2.86 m; 2.66 m |

| 6 | 10.5 m | 11 m/s; 12 m/s | 15.94 m; 17.39 m | 2.86 m; 2.65 m |

| 7 | 11 m | 11 m/s; 12 m/s | 16.31 m; 17.80 m | 2.99 m; 3.01 m |

| 8 | 11.5 m | 11 m/s; 12 m/s | 16.68 m; 18.02 m | 2.86 m; 3.05 m |

| 9 | 12 m | 11 m/s; 12 m/s | 17.04 m; 18.15 m | 3.08 m; 3.12 m |

| 10 | 12 m | 11 m/s; 12 m/s | 13.5 m; 12 8 m | 4.95 m; 5.18 m |

| Command | Value | New Value |

|---|---|---|

| INS_GYR1_CAL | 39.49276 | 17.75362 |

| INS_GYR2_CAL | 22.48535 | 12.24728 |

| INS_GYR20FFS_X | 0.02180705 | −0.002505591 |

| INS_GYR20FFS_Y | −0.007266462 | −0.008429104 |

| INS_GYR20FFS_Z | 0.007931517 | 0.006754024 |

| INS_GYR3_CAL | 37.83039 | 25.74678 |

| INS_GYR30FFS_X | 0.007584155 | −0.003129626 |

| INS_GYR30FFS_Y | −0.03437863 | −0.02893007 |

| INS_GYR30FFS_Z | 0.01442171 | 0.01368616 |

| INS_GYR0FFS_X | 0.002235635 | 0.006046154 |

| INS_GYR0FFS_Y | 0.005703443 | 0.01224557 |

| INS_GYR0FFS_Z | −0.01396238 | −0.01341222 |

| STAT_BOOTCNT | 163 | 161 |

| STAT_RUNTIME | 67,684 | 62,540 |

| TECS_PITCH_MAX | 20 | 15 |

| TKOFF_THR_DELAY | 2 | 0 |

| TKOFF_THR_MT | 15 | 0 |

| TKOFF_THR_MT | 1 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhao, Q.; Mao, P.; Bai, Q.; Li, F.; Pavlova, S. Design and Control of an Ultra-Low-Cost Logistic Delivery Fixed-Wing UAV. Appl. Sci. 2024, 14, 4358. https://doi.org/10.3390/app14114358

Zhang Y, Zhao Q, Mao P, Bai Q, Li F, Pavlova S. Design and Control of an Ultra-Low-Cost Logistic Delivery Fixed-Wing UAV. Applied Sciences. 2024; 14(11):4358. https://doi.org/10.3390/app14114358

Chicago/Turabian StyleZhang, Yixuan, Qinyang Zhao, Peifu Mao, Qiaofeng Bai, Fuzhong Li, and Svitlana Pavlova. 2024. "Design and Control of an Ultra-Low-Cost Logistic Delivery Fixed-Wing UAV" Applied Sciences 14, no. 11: 4358. https://doi.org/10.3390/app14114358